The Effect of Long-Term Ageing at 475 °C on Microstructure and Properties of a Precipitation Hardening MartensiticStainless Steel

Abstract

:1. Introduction

2. Experimental Material and Procedures

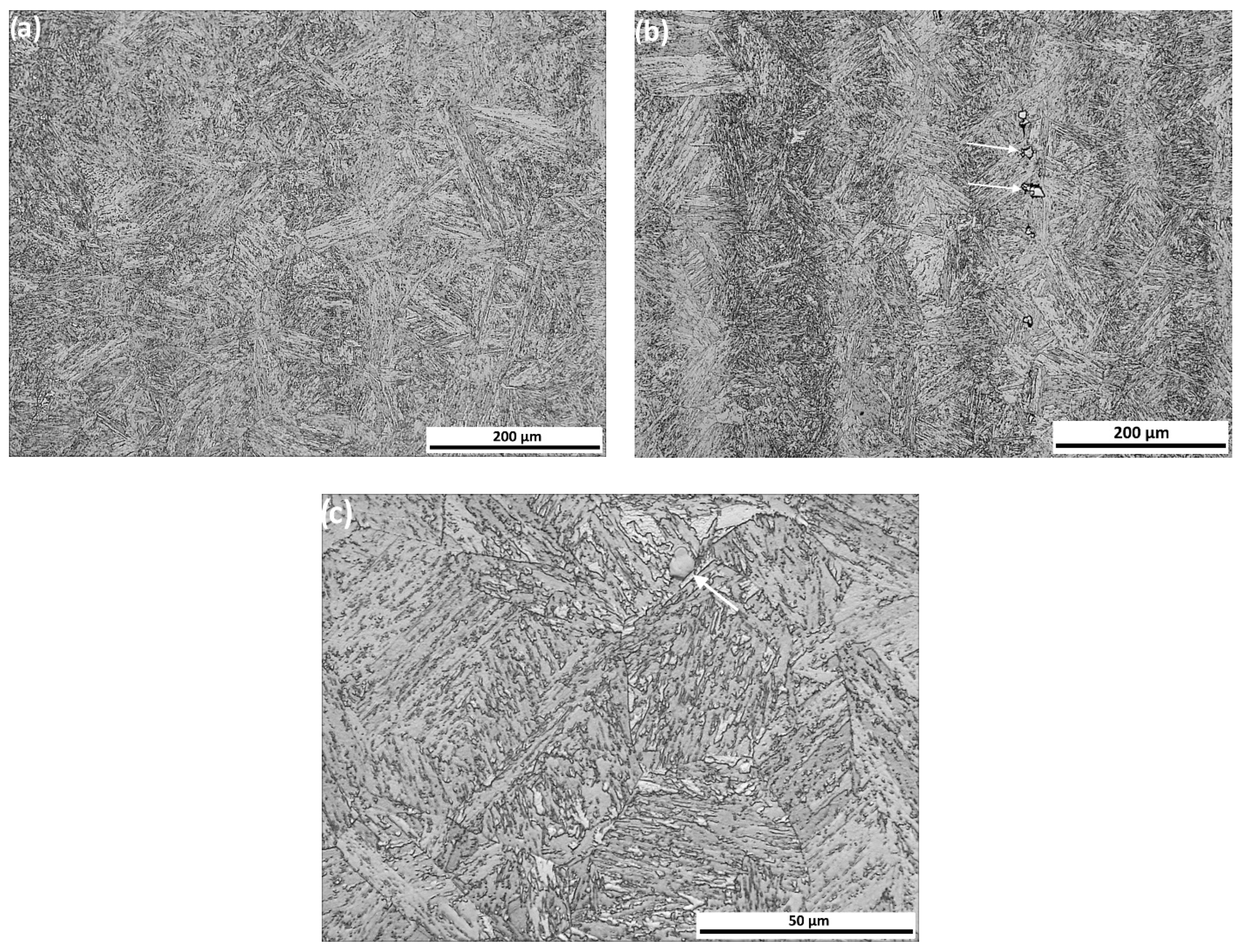

3. Results and Discussion

- −

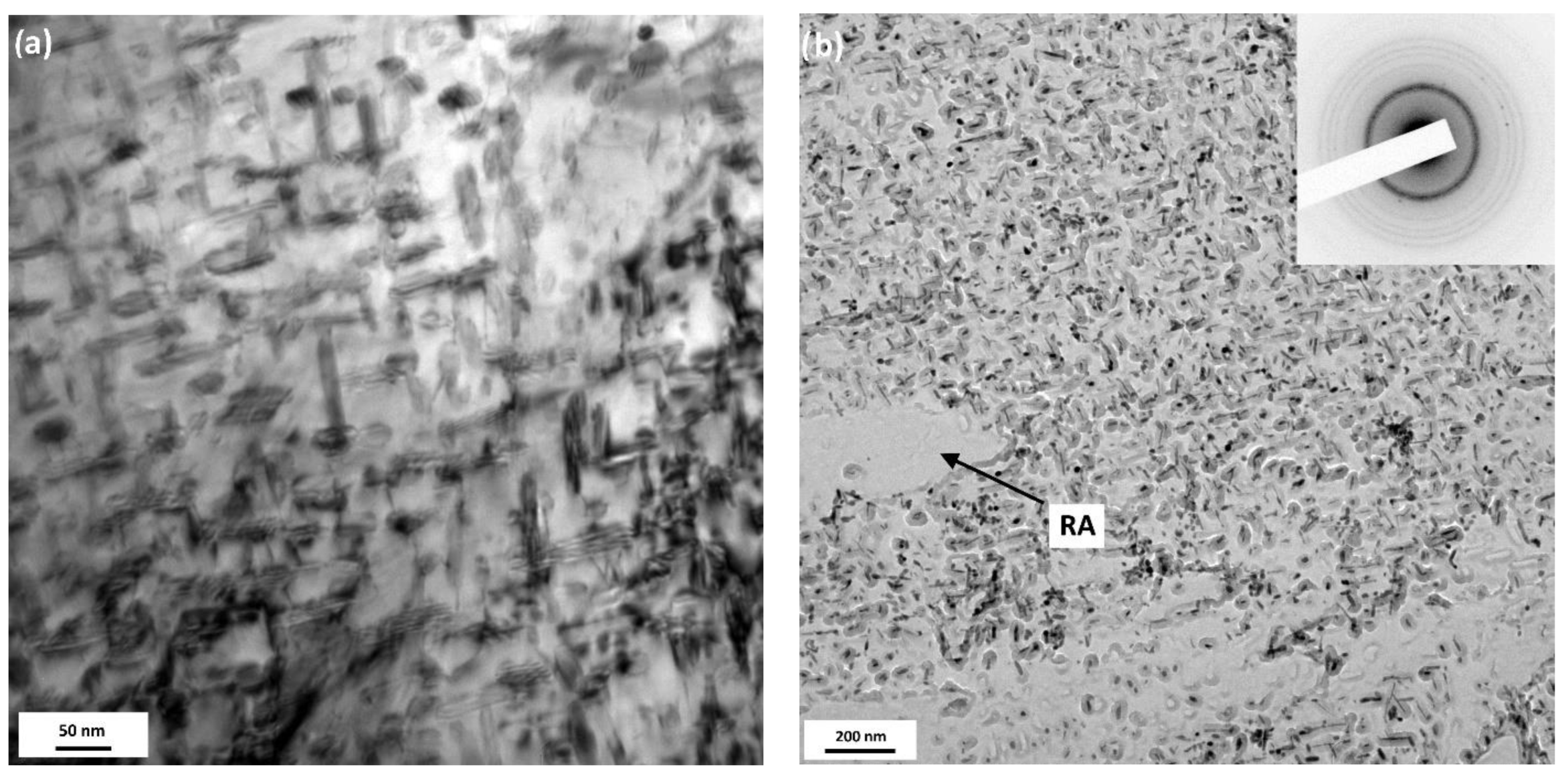

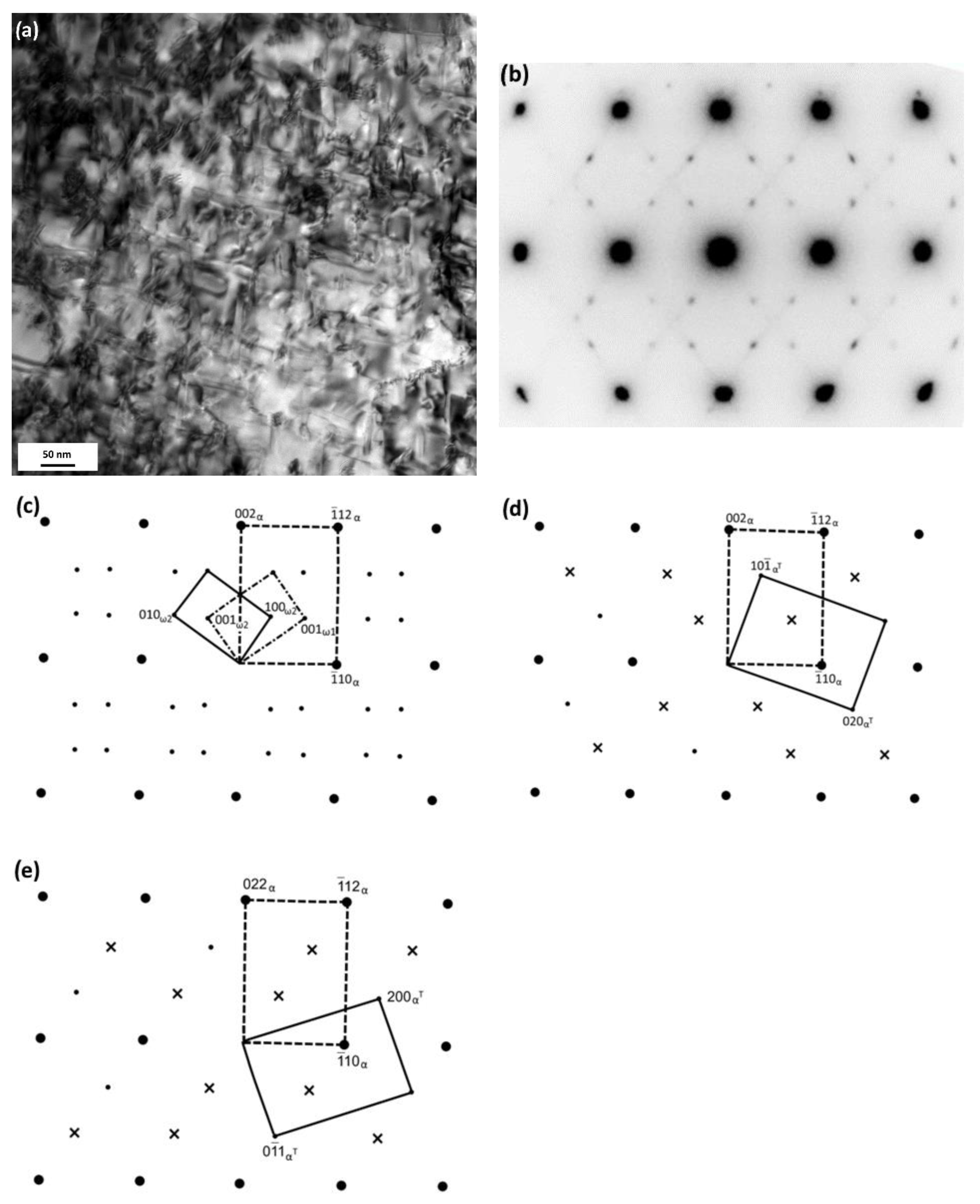

- Extensive TEM studies of precipitation reactions in lath martensite using carbon extraction replicas revealed only precipitation of η-Ni3Ti and Cr-rich α’ phases. No Mo-enriched particles of metastable ω phase [12] were detected.

- −

4. Conclusions

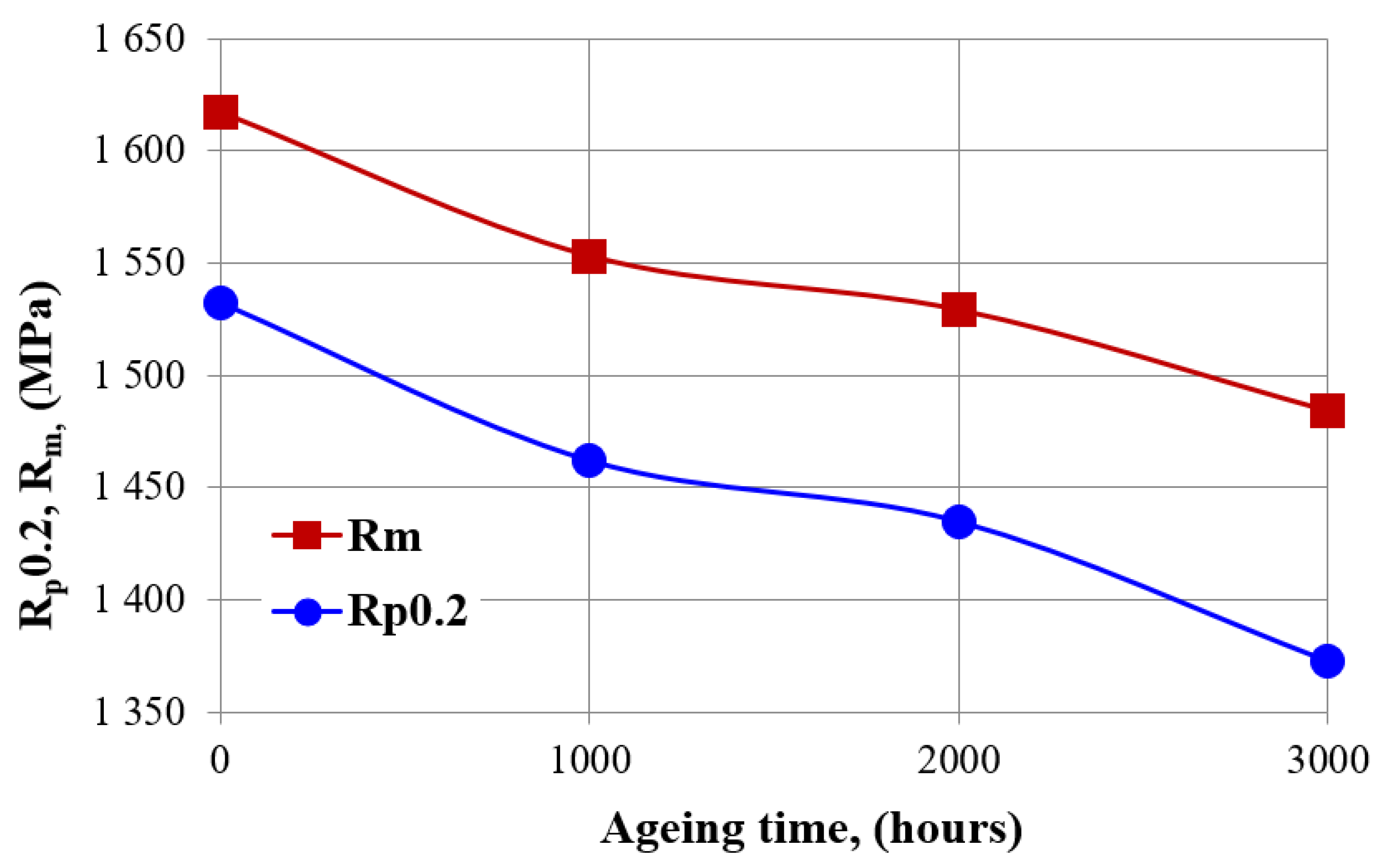

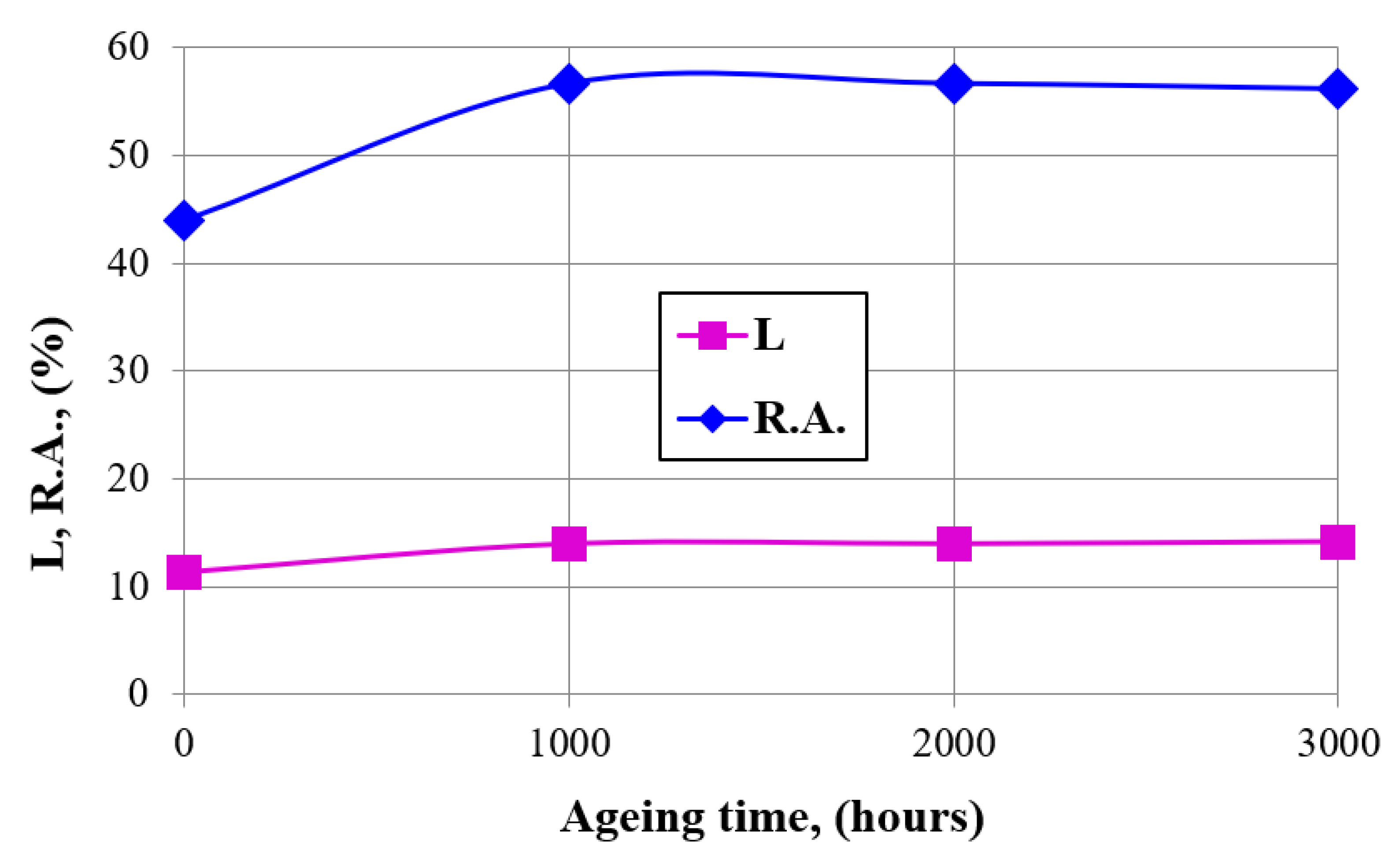

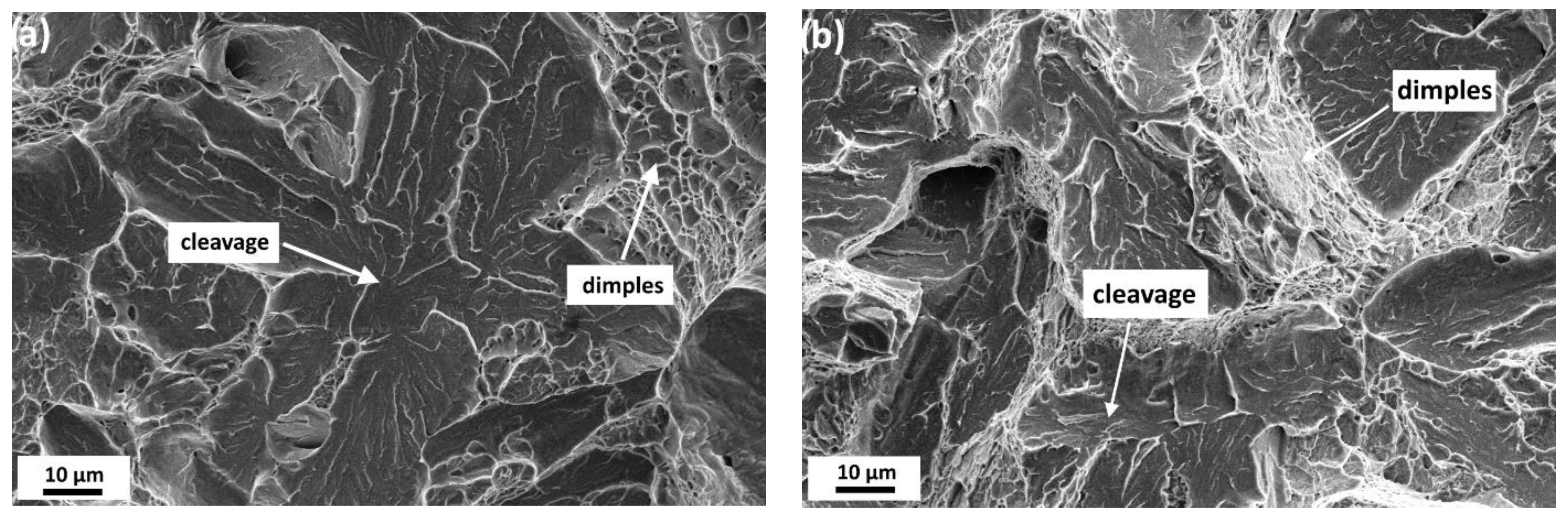

- Ageing of the steel at 475 °C for 1000, 2000, and 3000 h was accompanied by a gradual slight decline in strength. The longest exposure led to a drop in yield strength of only 8% and 10% in the case of ultimate tensile strength. On the other hand, ductility and toughness values remained almost unchanged.

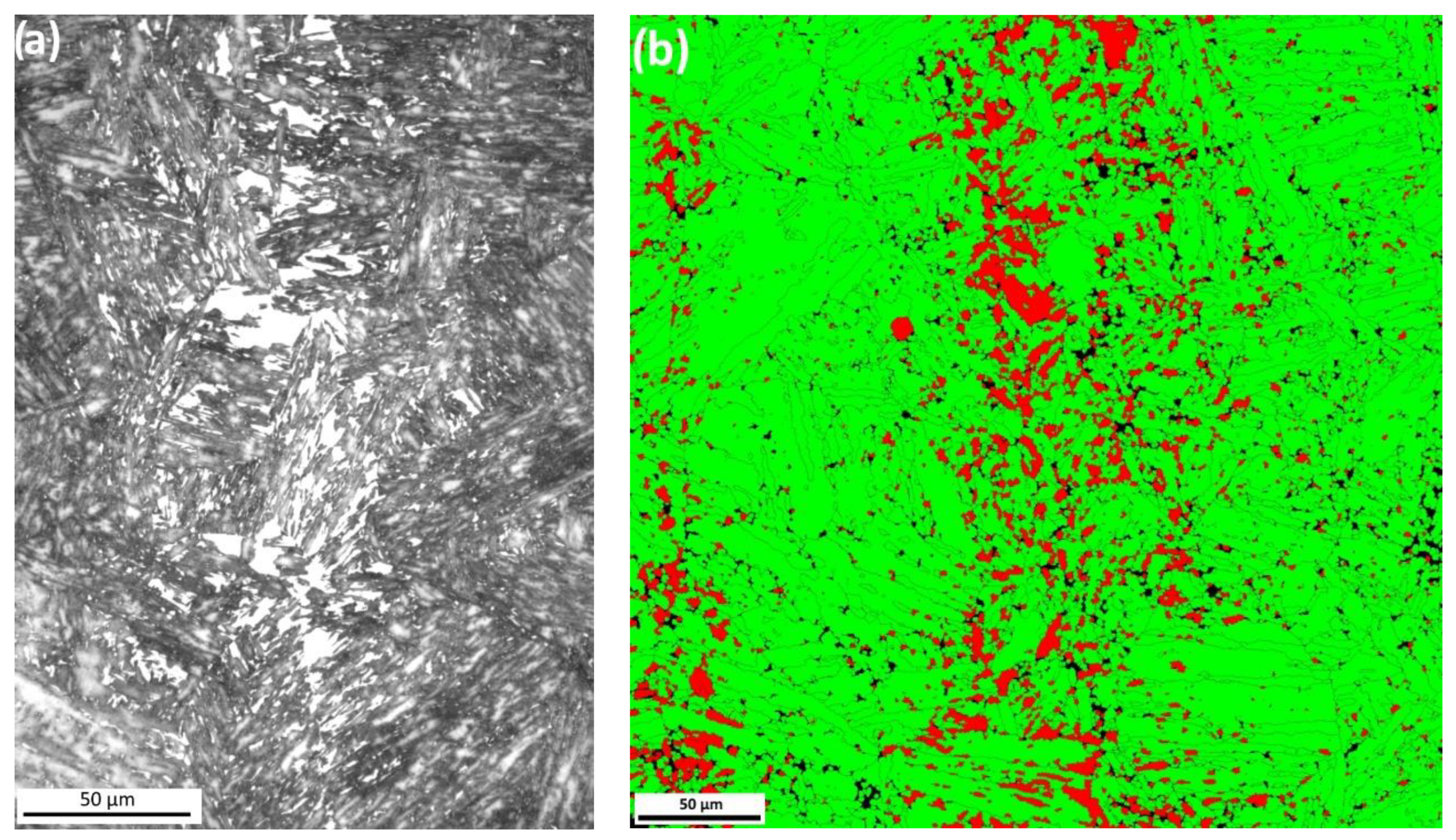

- During ageing at 475 °C, additional precipitation of nanometric η-Ni3Ti particles in lath martensite took place. This is the most important minor phase in the alloy investigated. Furthermore, ageing at 475 °C resulted in decomposition of the BCC solid solution (α), which was accompanied by the formation of Cr-rich particles of α’ phase. The formation of this phase partly compensated the decline of strength due to slow growth of η-Ni3Ti particles and the formation of reverted austenite.

- Diffraction studies revealed the existence of {112} <111> twinning in lath martensite. Two variants of thin twins were found in a single martensitic lath. It is likely that these thin twins did not form during martensitic transformation but only during subsequent ageing.

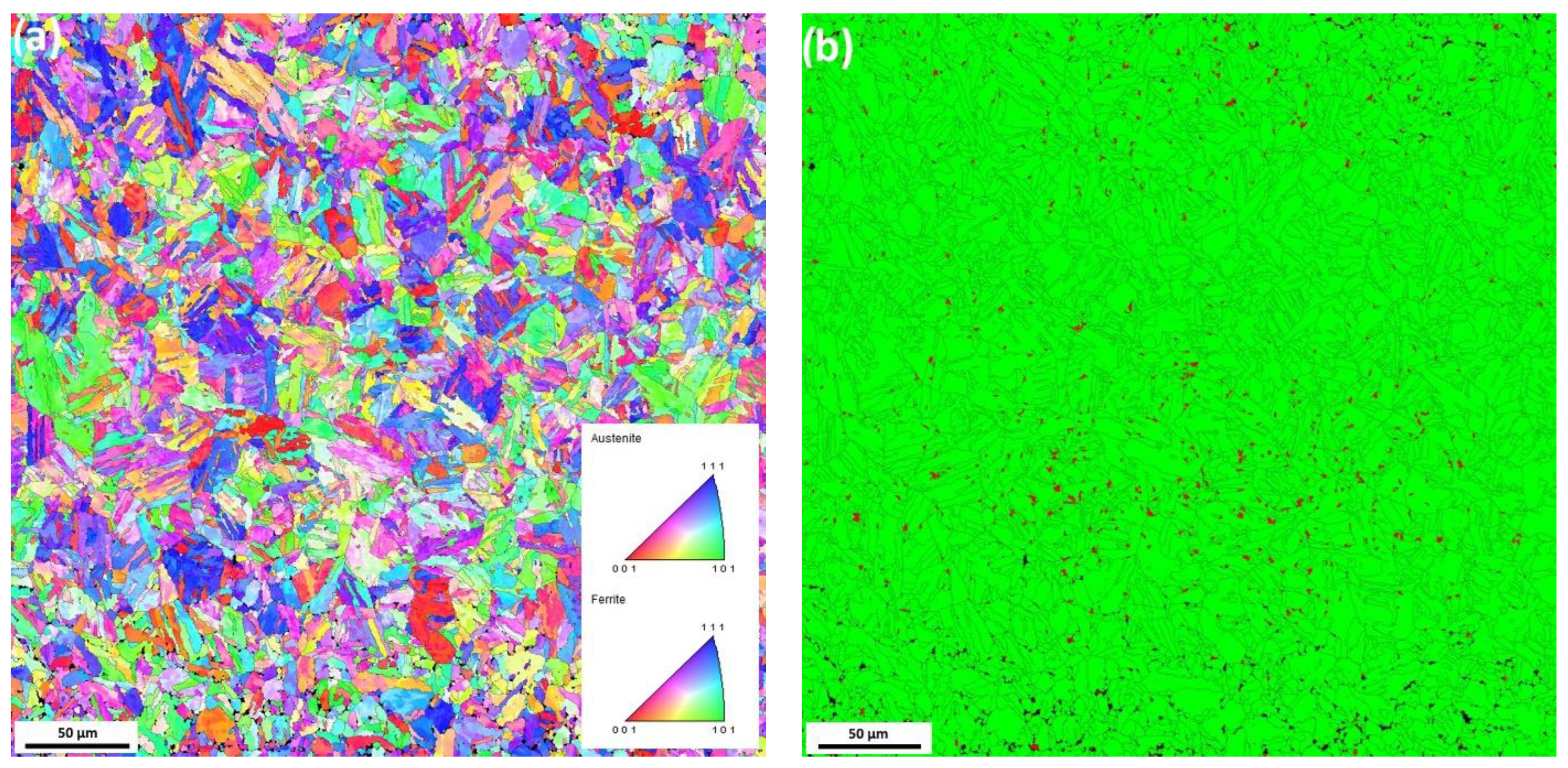

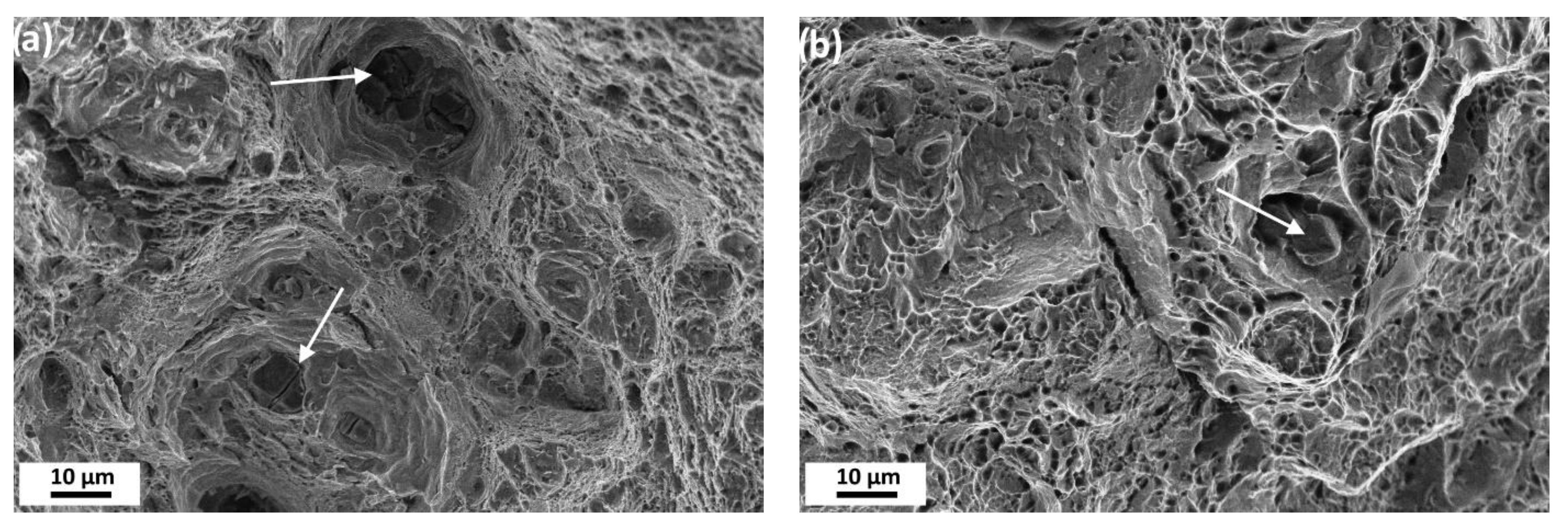

- The fraction of reverted austenite after ageing for 3000 h was approximately double compared to that in the state after quality heat treatment. Reverted austenite formed blocks, interlath films, and small intralath particles. Particles of reverted austenite were free of precipitates.

- Slow kinetics of martensite recovery and growth of η-Ni3Ti rods, and additional precipitation of η-Ni3Ti and Cr-rich particles of α’ phase minimized the decrease of martensite strength during the long-term ageing at 475 °C. At the same time, the formation of reverted austenite contributed to softening of martensite, but also had a positive effect on ductility and toughness of the alloy investigated. No susceptibility to 475 °C embrittlement was proved.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Morris, J.W. Maraging steels: Making steel strong and cheap. Nat. Mater. 2017, 16, 787–789. [Google Scholar] [CrossRef] [PubMed]

- Sha, W.; Guo, Z. Maraging Steels: Modelling of Microstructure, Properties and Applications; Woodhead Publishing Limited: Cambridge, UK, 2009; pp. 10–14. [Google Scholar]

- Pereloma, E.; Edmonds, D.V. Phase Transformations in Steels: Diffusionless Transformations, High Strength Steels, Modelling and Advanced Analytical Techniques, 1st ed.; Woodhead Publishing: Cambridge, UK, 2012; ISBN 978-0-85709-611-1. [Google Scholar]

- ALLOY Data. CUSTOM 465® Stainless. Carpenter. 2011. Available online: https://www.cartech.com/globalassets/literature-files/car-tech-custom-465_fact-sheet (accessed on 11 August 2022).

- Ifergane, S.; Pinkas, M.; Barkay, Z.; Ezersky, V.; Brosh, E.; Eliaz, N.; Beeri, O. The relation between aging temperature, microstructure evolution and hardening of Custom 465® stainless steel. Mater. Charact. 2017, 127, 129–136. [Google Scholar] [CrossRef]

- Vasudevan, V.K.; Kim, S.J.; Wayman, C.M. Precipitation reactions and strengthening behaviour in 18 wt pct nickel maraging steels. Metall. Trans. A 1990, 21A, 2655–2668. [Google Scholar] [CrossRef]

- Xu, W.; Rivra-Diáz-del Castillo, P.E.J.; Wang, W.; Yang, K.; Bliznuk, V.; Kestens, L.A.I.; van der Zwaag, S. Genetic design and characterization of novel ultra-high-strength stainless steels strengthened by Ni3Ti intermetallic nanoprecipitates. Acta Mater. 2010, 58, 3582–3593. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H.; Honeycombe, R. Steels: Microstructure and Properties, 4th ed.; Butterworth-Heinemann: Oxford, UK, 2017. [Google Scholar]

- Chen, C.-Y.; Chiu, P.-H.; Liu, W.-S.; Chen, Z.-W.; Lin, Y.-H.; Kang, Y.-C. Interaction between η-Ni3Ti and reversed austenite within Custom 465 stainless steel: Experimental evidence and related patents investigation. Mater. Sci. Eng. A 2022, 839, 142852. [Google Scholar] [CrossRef]

- Thuvander, M.; Andersson, M.; Stiller, K. Atom probe tomography investigations of lath boundary segregation and precipitation in a maraging stainless steel. Ultramicroscopy 2013, 132, 265–270. [Google Scholar] [CrossRef] [PubMed]

- Thuvander, M.; Andersson, M.; Stiller, K. Multiple influences of molybdenum on the precipitation process in a martensitic PH stainless steel. Metals 2019, 9, 1118. [Google Scholar] [CrossRef]

- Niu, M.C.; Zin, L.C.; Yang, K.; Luan, J.H.; Wang, W.; Jiao, Z.B. Synergetic alloying effects of nanoscale precipitation and mechanical properties of ultra-high strength steel strengthened by Ni3Ti, Mo-enriched, and Cr-rich co-precipitates. Acta Mater. 2021, 209, 116788. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, C.; Zhang, S.L.; Ding, Y.L.; Ge, Q.I.; Su, J. Effect of aging temperature on the precipitation behavior and mechanical properties of Fe-Cr-Ni maraging stainless steel. Mater. Sci. Eng. A 2021, 806, 140763. [Google Scholar] [CrossRef]

- Kim, S.J.; Wayman, C.M. Crystallographic orientation relationships among η-Ni3Ti precipitate, reverted austenite, and martensitic matrix in Fe-10Cr-10Ni-2W maraging alloy. Scr. Metall. Mater. 1990, 24, 1851–1856. [Google Scholar] [CrossRef]

- Suk, J.I.; Hong, S.H.; Nam, S.W. Crystallographic Orientation relationships among η-Ni3Ti precipitate, reverted austenite and martensitic matrix in Fe-10Cr-10Ni-2W maraging alloy. Metall. Trans. A 1993, 24A, 2643–2652. [Google Scholar] [CrossRef]

- Vanderwalker, D.M. The precipitation sequence of Ni3Ti in Co-free maraging steel. Metall. Trans. A 1987, 18, 1191–1194. [Google Scholar] [CrossRef]

- Niu, M.C.; Zhou, G.; Wang, W.; Shahzad, W.B.; Yang, K. Precipitate evolution and strengthening behaviour during aging process in a 2,5GPa grade maraging steel. Acta Mater. 2019, 179, 296–307. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, M.; Ma, D.; Xu, B.; Wang, T.; Li, D.; Li, Y. Effect of aging temperature on the heterogeneous microstructure and mechanical properties of a 12Cr-10Ni-Mo-Ti maraging steel for cryogenic applications. J. Mater. Sci. 2021, 56, 11469–11484. [Google Scholar] [CrossRef]

- Leitner, H.; Schober, M.; Schnitzer, R. Splitting phenomenon in the precipitation evolution in an Fe-Ni-Al-Ti-Cr stainless steel. Acta Mater. 2010, 58, 1261–1269. [Google Scholar] [CrossRef]

- Shmulevitsch, M.; Ifergane, S.; Eliaz, N.; Shneck, R.Z. The effect of the elastic energy on the shape and orientation relations of η-Ni3Ti precipitates in lath martensite. J. Alloys Compd. 2022, 921, 165935. [Google Scholar] [CrossRef]

- Song, P.; Liu, W.; Zhang, C.; Liu, L.; Yang, Z. Reversed austenite growth behaviour of a 13%Cr-5%Ni stainless steel during intercritical annealing. ISIJ Int. 2016, 56, 148–153. [Google Scholar] [CrossRef]

- Cao, H.; Luo, X.; Zhan, G.; Liu, S. Effect of intercritical quenching on the microstructure and cryogenic mechanical properties of a 7 pct Ni steel. Metall. Mater. Trans. 2017, 48, 4403–4410. [Google Scholar] [CrossRef]

- Schnitzer, R.; Radis, R.; Nöhrer, M.; Schober, M.; Hochfellner, R.; Zinner, S.; Povoden-Karadeniz, E.; Kozeschnik, E.; Leitner, H. Reverted austenite in PH 13-8 Mo maraging steels. Mater. Chem. Phys. 2010, 122, 138–145. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, C.; Wang, A.; Zheng, C.; Liu, Z.; Liang, J.; Su, J.; Ge, Q. Effect of aging on transformation behavior of reverted austenite and toughness in Co-free maraging stainless steel. J. Mater. Eng. Perform. 2022, 31, 1–14. [Google Scholar] [CrossRef]

- Raabe, D.; Sandlőbes, S.; Millán, J. Segregation engineering enables nanoscale martensite to austenite phase transformation at grain boundaries: A pathway to ductile martensite. Acta Mater. 2013, 61, 6132–6152. [Google Scholar] [CrossRef]

- Suleimani, M.; Mirzadeh, H.; Kalhor, A. Transformation induced plasticity (TRIP) in advanced steels: A review. Mater. Sci. Eng. A 2020, 795, 140023. [Google Scholar] [CrossRef]

- Lian, Y.; Huang, J.; Zhao, C.; Gao, W.; Zhang, Z.; Ma, M. Effects of cold rolling on the microstructure and properties of Fe-Cr-Ni-Mo-Ti maraging steel. Mater. Sci. Eng. 2018, 712, 663–670. [Google Scholar] [CrossRef]

- Yedneral, A.F.; Perkas, M.D. Formation of metastable ordered omega-phase on aging of martensite iron-nickel-cobalt-molybdenum alloys. Fiz. Met. Metalloved. 1972, 33, 315–325. [Google Scholar]

- Ping, D.H.; Geng, W.T. A popular metastable omega phase in body centered cubic steels. Mater. Chem. Phys. 2013, 139, 830–835. [Google Scholar] [CrossRef]

- Zhang, P.; Chen, Y.; Xiao, W.; Ping, D.; Zhao, X. Twin structure of the lath martensite in low carbon steel. Prog. Nat. Sci.: Met. Mater. Int. 2016, 26, 169–172. [Google Scholar] [CrossRef]

- Casillas, G.; Song, W.; Gazder, A.A. Twins or the omega phase: Which is it in high carbon steel? Scr. Mater. 2020, 186, 293–297. [Google Scholar] [CrossRef]

- Shibata, A.; Morito, S.; Furuhara, T.; Maki, T. Substructures of lenticular martensites with different martensite start temperatures in ferrous alloys. Acta Mater. 2009, 57, 483–492. [Google Scholar] [CrossRef]

- Patterson, R.L.; Wayman, G.M. The crystallography and growth of partially twinned martensite plates in Fe-Ni alloys. Acta Metall. 1965, 14, 347–369. [Google Scholar] [CrossRef]

- Wang, Z.M.; Li, H.; Shen, Q.; Liu, W.Q.; Wang, Z.Y. Nano precipitates evolution and their effects on mechanical properties of 17-4 precipitation-hardening stainless steel. Acta Mater. 2018, 156, 158–171. [Google Scholar] [CrossRef]

- Othen, P.J.; Jenkins, M.I.; Smith, G.D.W. High resolution electron microscopy studies of the structure of Cu precipitates in α-Fe. Philos. Mag. A 1994, 70, 1–24. [Google Scholar] [CrossRef]

- Heo, Y.U.; Kim, Y.K.; Kim, J.S.; Kim, J.K. Phase transformation of Cu precipitates from bcc to fcc in Fe-3Si-2Cu alloy. Acta Mater. 2013, 61, 519–528. [Google Scholar] [CrossRef]

- Davis, J. Alloy Digest Sourcebook: Stainless Steels; ASM International: Materials Park, OH, USA, 2000. [Google Scholar]

- Alhegagi, F.A. 475 °C embrittlement in stainless steels. Int. J. Sci. Eng. Res. 2015, 6, 145–154. [Google Scholar]

- Zhou, J.; Odqvist, J.; Thuvander, M.; Hedstrom, P. Quantitative evaluation of spinodal decomposition in Fe-Cr by atom probe tomography and radial distribution function analysis. Microsc. Microanal. 2013, 19, 665–675. [Google Scholar] [CrossRef]

- Porter, D.A.; Easterling, K.E.; Sherif, M.Y. Phase Transformations in Metals and Alloys, 4th ed.; Taylor and Francis Inc.: Abingdon, UK, 2021. [Google Scholar]

- Miller, M.K.; Anderson, I.M.; Bentley, J.; Russel, K.F. Phase separation in the Fe-Cr-Ni system. Appl. Surf. Sci. 1996, 94–95, 391–397. [Google Scholar] [CrossRef]

- Pandey, C.; Saini, N.; Mahapatra, M.M.; Kumar, P. Study of the fracture surface morphology of impact and tensile tested cast and forged (C&F) Grade 91 steel at room temperature for different heat treatment regimes. Eng. Fail. Anal. 2017, 71, 131–147. [Google Scholar]

| C | S | P | Mn | Si | Ni | Cr | Mo | Ti | Al | V | W | Cu |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.01 | 0.001 | 0.006 | 0.01 | 0.048 | 10.82 | 11.07 | 0.93 | 1.55 | 0.054 | <0.003 | 0.006 | 0.57 |

| Ac1 (°C) | Ac3 (°C) | Ms (°C) |

|---|---|---|

| 589 | 738 | 131 |

| Rp0.2 (MPa) | Rm (MPa) | L (%) | R.A. (%) | HV 30 | KV (J) |

|---|---|---|---|---|---|

| 1531 | 1617 | 11.3 | 44.0 | 500 | 18 |

| Sample | Dwell (hours) | Rp0.2 | Rm | Rp0.2/Rm | L | R.A. | HV 30 |

|---|---|---|---|---|---|---|---|

| (MPa) | (%) | ||||||

| C 1/1 | 1000 | 1461 | 1550 | 0.942 | 14.0 | 56.7 | - |

| C 1/2 | 1463 | 1555 | 0.941 | 14.0 | 56.7 | 494 | |

| C 2/1 | 2000 | 1435 | 1528 | 0.939 | 14.0 | 56.7 | - |

| C 2/2 | 1435 | 1530 | 0.938 | 14.0 | 56.7 | 472 | |

| C 3/1 | 3000 | 1376 | 1488 | 0.924 | 13.3 | 54.4 | - |

| C 3/2 | 1369 | 1480 | 0.925 | 15.0 | 57.9 | 460 | |

| Sample | Dwell (hours) | KV (J) |

|---|---|---|

| C 1/1 | 1000 | 16 |

| C 1/2 | 15 | |

| C 2/1 | 2000 | 16 |

| C 2/2 | 17 | |

| C 3/1 | 3000 | 18 |

| C 3/2 | 18 |

| No. | Mo | Ti | Cr | Fe | Ni |

|---|---|---|---|---|---|

| 1 | 6.4 | 24.7 | 5.1 | 1.3 | 62.6 |

| 2 | 5.7 | 23.4 | 4.2 | 1.4 | 65.3 |

| 3 | 6.2 | 23.6 | 2.2 | 1.1 | 66.8 |

| Average | 6.1 | 23.9 | 3.8 | 1.3 | 64.9 |

| No. | Cr | Fe | Mo |

|---|---|---|---|

| 1 | 72.2 | 12.2 | 15.6 |

| 2 | 69 | 16.2 | 14.8 |

| 3 | 72.3 | 11.6 | 17.1 |

| Average | 70.8 | 13.3 | 15.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vodárek, V.; Rožnovská, G.; Kuboň, Z.; Volodarskaja, A.; Palupčíková, R. The Effect of Long-Term Ageing at 475 °C on Microstructure and Properties of a Precipitation Hardening MartensiticStainless Steel. Metals 2022, 12, 1643. https://doi.org/10.3390/met12101643

Vodárek V, Rožnovská G, Kuboň Z, Volodarskaja A, Palupčíková R. The Effect of Long-Term Ageing at 475 °C on Microstructure and Properties of a Precipitation Hardening MartensiticStainless Steel. Metals. 2022; 12(10):1643. https://doi.org/10.3390/met12101643

Chicago/Turabian StyleVodárek, Vlastimil, Gabriela Rožnovská, Zdeněk Kuboň, Anastasia Volodarskaja, and Renáta Palupčíková. 2022. "The Effect of Long-Term Ageing at 475 °C on Microstructure and Properties of a Precipitation Hardening MartensiticStainless Steel" Metals 12, no. 10: 1643. https://doi.org/10.3390/met12101643

APA StyleVodárek, V., Rožnovská, G., Kuboň, Z., Volodarskaja, A., & Palupčíková, R. (2022). The Effect of Long-Term Ageing at 475 °C on Microstructure and Properties of a Precipitation Hardening MartensiticStainless Steel. Metals, 12(10), 1643. https://doi.org/10.3390/met12101643