Abstract

In situ atomic-scale bending tests of twin-structured Ni nanowires were realised using a homemade deformation device. The results showed that the plastic deformation mechanism in twin-structured Ni nanowires depended on the deformation stage. At the early stages of bending deformation, the plasticity of twin-structured Ni nanowires was controlled by dislocations interacting with the twin boundaries or parallel to them. With increasing bending strain, both dislocation and face-centred cubic–body-centred tetragonal phase transition occurred. At very high bending strain, grain boundaries resulting from the lattice distortion/collapse were formed. This study details the deformation mechanisms of the twin-structured Ni nanowires under bending deformation, which advances the basic understanding of the plasticity mechanisms in metals.

1. Introduction

The mechanical properties of nanomaterials, including strength, hardness, and ductility, are directly related to their atomic-scale plastic deformation mechanisms [1,2]. Therefore, revealing the atomic-scale plastic deformation mechanism of nanoscale metals can guide the design of nanomaterials with desired mechanical properties [1,2,3,4,5]. Twin-structured nanomaterials have recently attracted considerable attention because of their ultrahigh strength [3,4,5,6]. Particularly, a large number of studies have shown that twin-structured metallic nanowires (NWs) can approach the ideal strength [7,8,9,10,11,12,13] because the twin boundary (TB) can prevent the dislocation motion and nucleation, thereby causing a significant strengthening effect [7,8,9,10,11,12,13]. In the past decades, many studies have been conducted on the mechanical properties of twin-structured metallic NWs because of the importance of their deformation mechanism; however, most of these studies are based on conventional tensile or compressive experiments [5,7,8,9,10,11,12,13,14,15]. At the same time, the mechanism of accommodation of the bending strain in twin-structured NWs has rarely been investigated experimentally because direct atomic-scale experimental techniques are usually difficult to apply [16,17,18,19,20,21,22]. For this reason, our current understanding of the atomic-scale deformation mechanisms of twin-structured metallic NWs under bending strain heavily relies on molecular dynamics (MD) simulations [7,8,9,11,12,13,15]. However, the deformation mechanisms proposed by MD simulations must ultimately be validated experimentally, which has not yet been done. Therefore, it is important to obtain direct atomic-scale data on the mechanism of accommodation of the bending strain in the twin-structured metallic NWs.

To address this issue, in this study, the twin-structured Ni NWs were subjected to bending strains from 1.9 to 36.5% using our previously developed experimental method [23]. Our in situ atomic-scale observations show that the dislocation interaction with TBs, face-centred cubic (fcc)–body-centred tetragonal (bct) phase transitions, and grain boundary (GB) generation via lattice collapse may all occur during bending deformation. Notably, we reveal that these plastic behaviours appear in the above order at different deformation stages.

2. Experimental Section

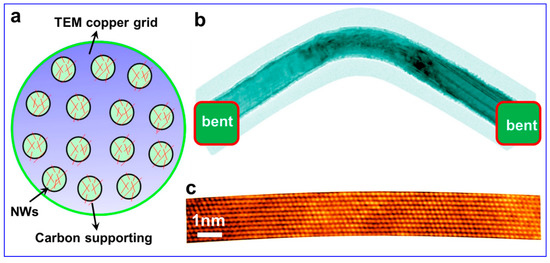

The atomic-scale in situ bending tests of the metallic NWs were realised using a homemade in situ deformation device [23]. As illustrated in Figure 1a, the NWs were randomly spread to bridge on a prebroken colloidal thin film on a transmission electron microscopy (TEM) specimen grid. The scattered NWs were then bent or stretched controllably through expansion or contraction of the colloidal thin film under electron beam irradiation. Figure 1b shows typical TEM images of the bending of Ni NWs with diameters of ~40 nm at the effective average strain rate of ~10−4 s−1. We monitored the continuous bending deformation of the Ni NWs by observing their bending angle. Using our specially designed device, the sample could be tilted in two orthogonal directions at angles of ±20°, which allowed us to deform NWs without the need for other sample holder or mechanical tensile attachment. The NWs could also be rotated to a low-index crystallographic direction, allowing in situ recording of the atomic-scale bending or tensile deformation of individual metallic NWs. With this in situ deformation device, the bending process of the Ni NWs was recorded at the atomic scale, as shown in Figure 1c. The experiments were performed at strain rates of ~10−4–10−3 s−1, and observations were made using transmission electron microscope (TEM) JEOL-2010F (JEOL, Tokyo, Japan) with a point resolution of 0.12 nm.

Figure 1.

(a) Schematic showing the twin-structured Ni NWs scattered on the previously broken TEM grid, which was covered by colloidal thin films. (b) An example showing that a single NW could be bent using the colloidal thin films. (c) HTEM image showing the highly bent, arc-shaped {111} lattices.

3. Results

3.1. TEM Characterisation of the Twin-Structured Ni NWs

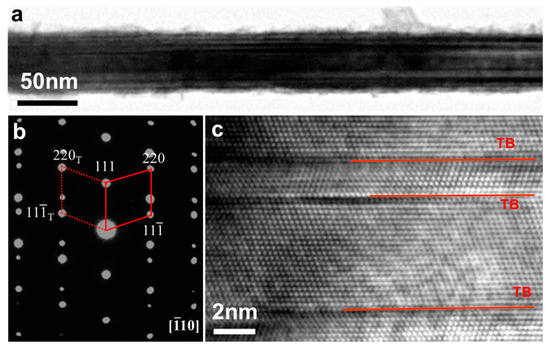

Ni NWs for the in situ bending tests were ~50 μm in length and ~40 nm in diameter. Figure 2a shows a typical TEM image of twin-structured Ni NWs consisting of parallel {111} twins. Figure 2b provides the corresponding selected area electron diffraction patterns captured along the axis of NWs. This is a typical twin-structured diffraction pattern, showing that the NWs grew along the [112] direction (as shown in Figure 2c) and have nanoscale growth twins. The growth of twins with thicknesses of 1–14 nm was observed in many high-resolution TEM (HTEM) images. In particular, Figure 2c presents a typical HTEM image revealing the atomic-scale structure of TB: the NWs are well crystalline with no pre-existing dislocations on TBs.

Figure 2.

(a) TEM image showing the microstructure of twin-structured Ni NWs. (b) The corresponding selected area electron diffraction patterns captured along the direction, indicating the presence of (111) twins in the NWs. (c) HTEM image revealing the growth of several twins in the Ni NWs.

3.2. In Situ TEM Observation of the Bending of Twin-Structured Ni NWs

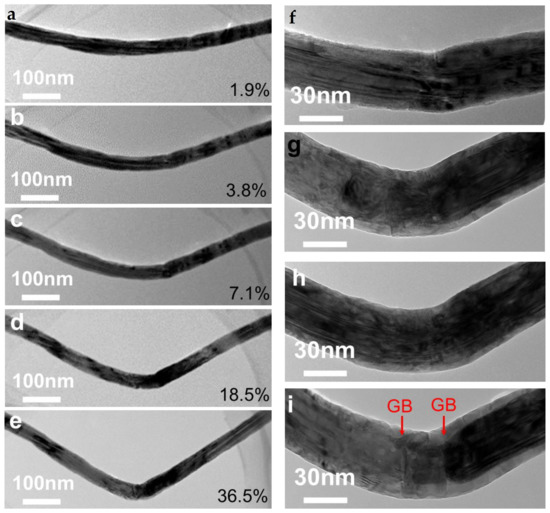

Figure 3a–e present low-magnification TEM images. These images outline the nano-scale structure evolution of a Ni NW with growth twins. According to a previously reported theoretical formula εbent=r/(r+R)% [24], where εbent is the bending strain, R is the bending curvature, and r is the NW diameter, the maximum bending strain in the Ni NWs increases from 1.9 (Figure 3a) to ~36.5% (Figure 3e). During bending deformation, the atomic and nanoscale structural evolution and the plastic behaviours of the bent Ni NWs were recorded in situ. Figure 3f–i display several high-magnification TEM images showing arc-shaped TBs. Two GBs (indicated with the red arrows in Figure 3i) formed during the severe bending deformation of the twin-structured Ni NWs. This is direct evidence that the deformation of twin-structured Ni NWs under high bending strain involves GB generation.

Figure 3.

(a–e) Low-magnification bright field TEM images showing the evolution of the nanoscale structure of a Ni NW with growth twins under the bending strain of 1.9–36.5%. (f–i) Enlarged TEM images show two GBs generated in severely bent Ni NWs.

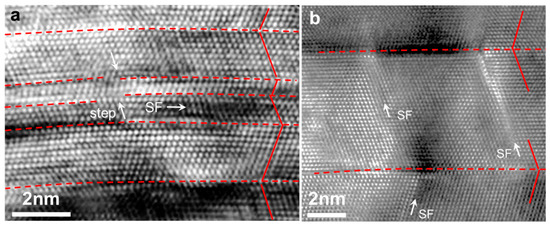

3.3. Dislocation Governs Plasticity at the Low Strain Stage

To demonstrate how the twin-structured Ni NWs accommodated the plasticity under bending deformation, their atomic-scale deformation mechanisms at different straining stages were investigated. At very low strain values, partial dislocation activities frequently occurred. In twins with a thickness of ~2.4 nm, partial dislocation glide on the {111} plane, which was parallel to the TBs, was the dominant plastic activity. Figure 4a shows the HTEM image captured along the zone axis during bending deformation. In Figure 4a, many steps on the original flat TBs in the thinner twins are observed. These steps resulted from the nucleation and gliding of the partial dislocations on the TBs, which was the dominant plastic deformation event in twins with thicknesses below ~6 nm. In the thicker twins, partial dislocations resulting in stacking faults (SFs) were frequently observed. These partial dislocations intersected with the TBs during the bending of the NWs. Figure 4b shows a typical HTEM image captured after the occurrence of plastic deformation. As shown in Figure 4b, most of the partial dislocations intersect with the TBs. These dislocation activities were frequently observed in twins with thicknesses greater than ~6 nm, indicating a considerable effect of twin thickness on the deformation mechanism of the metallic NWs. Similar observations have been reported for twin-structured nanocrystalline Cu [3,4,25,26,27,28,29,30,31,32,33,34,35].

Figure 4.

(a) Partial dislocations on the TBs leading to the formation of several steps (marked by arrows) on the TBs for twins with thicknesses of 0.6–2.4 nm. (b) Partial dislocations resulting in SFs intersect with the TBs in thicker twins (marked with SF).

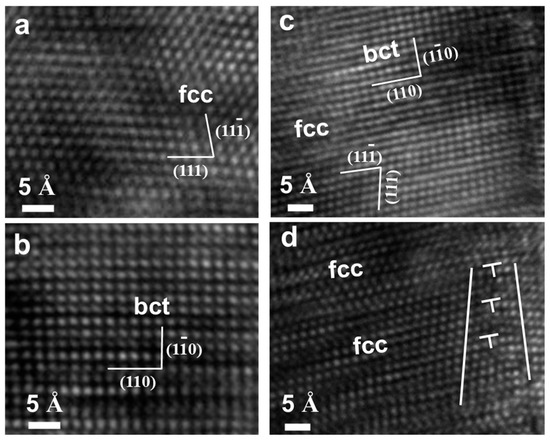

3.4. In Situ Atomic-Scale Observation of Reversible fcc–bct Phase Transition

At relatively large bending strains, the complex stress distribution in the bent NWs enabled the direct observation of the transition of the original fcc structure into the bct structure occurring with increasing bending strain. In particular, Figure 5 shows the in situ atomic-scale observation of bending inducing an fcc–bct phase transition in a severely bent Ni NW with growth twins. This phase transition was frequently detected when the maximum bending strain was increased to approximately 10.3%. Figure 5 shows that the lattice angle of the two {111} planes increased from 70.5° (projected along the direction) to ~90°. As shown in the HRTEM image captured along the zone axis (Figure 5a), the lattices exhibit a parallelogram shape at relatively low strain values. Figure 5b shows that with increasing bending strain, the original parallelogram-shaped lattices transformed into square-shaped lattices.

Figure 5.

(a,b) In situ atomic-scale results show the fcc–bct structure transition. (c,d) In situ atomic-scale results show the reversible fcc–bct transition.

Interestingly, the square-shaped lattices were also reversed by localised strain relaxation, such as dislocation nucleation in the bct-structured region. Figure 5c,d show a complete reversal of the fcc–bct transition after the bct lattice region is interrupted by dislocation nucleation. As shown in Figure 5c, the lattices are square-shaped, corresponding to the bct lattice. Based on the values reported in previous studies, the measured lattice distances are very close to those of the bct-structured Ni viewed along the [001] zone axis [36,37,38,39,40]. This result directly confirms the occurrence of a phase transformation in the Ni NWs under bending strain and the dependence of the deformation mechanism on the deformation stage. With increasing bending strain, as shown in Figure 5d, three full dislocation nucleations made the square lattices revert to the parallelogram shape and caused the lattice angle of the two {111} planes to return to ~70.5°, indicating a reversible fcc–bct phase transformation.

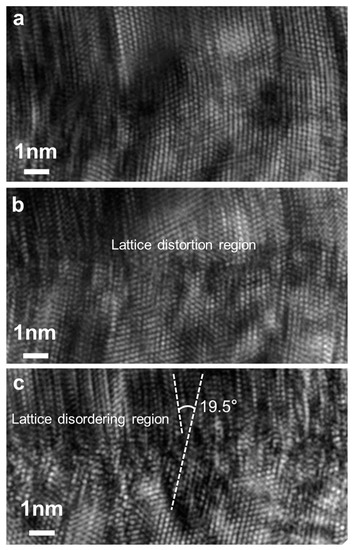

3.5. Direct Atomic-Scale Evidence of the Grain Boundary Formation through Lattice Bending

As the bending strain increases to a very high level (greater than ~18.5%), the formation of GBs was activated. Figure 6 shows three zone-axis HTEM images (captured at different deformation stages) detailing the GB formation mechanism. Figure 6a presents the HTEM image before the GB generation in the Ni NW under bending train. At this high-bending-strain stage, the lattices are highly curved, and the lattice strain is nonuniform in this local region. As shown in Figure 6b, with increasing bending strain, the original parallelogram-shaped lattice becomes highly distorted. With a further increase in the bending strain, the lattice in the local region becomes disordered, and a tilted GB with an angle of ~19.5° is induced, as shown in Figure 6c. This disordered lattice spreads in the entire GB region, and no disclination or well-arranged dislocations are observed. These results, in contrast to those of previous studies, indicate that GB generation can also occur through lattice collapse [41,42,43,44].

Figure 6.

(a) HTEM image showing the {111} lattices are arc-shaped under bending. (b) the lattices became disordered under large bent strain. (c) Direct observation of the bending deformation leading to the generation of a tilted GB.

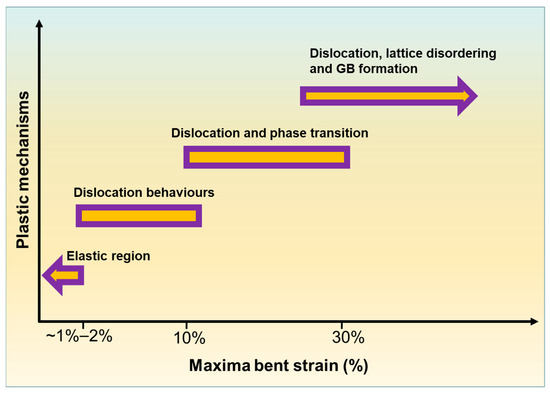

3.6. Effect of Strain Magnitude on the Deformation Mechanism of the Twin-Structural Ni NWs

More than 10 twin-structured Ni NWs were used to clarify the effect of bending strain on the plastic deformation mechanism. Our results revealed that a transition in the deformation modes occurred with increasing bending strain. Figure 7 shows the plastic deformation picture of the twin-structured Ni NWs at different strain stages. According to this picture, their plastic deformation can be fitted into three regions. The first plasticity region corresponds to the bending strain of ~2–10%. At this stage, the twin-structured NWs accommodate bending strain via the dislocation activities, consistent with most previous studies on twin-structured materials [1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22]. The second region (~10–18.5%) is the plasticity governed by both phase transitions and dislocation activities. As the bending strain increases over ~18.5%, the deformation is in the third deformation region, in which GBs are observed. This effect of the magnitude of strain on the plastic deformation model of metallic NWs has rarely been studied in previous research.

Figure 7.

The NWs are first in the elastic strain region at the strain below ~1%. At the maximum bending strain below ~10%, plastic deformation is controlled by dislocation slips. At the bending strain of ~10–18.5%, phase transition occurs. At the bending strain above 18.5%, a GB is formed.

4. Discussion

In the past few decades, there has been a dramatic increase in the number of studies on the nanomechanical testing of nanosized metals [2,8,10,20,21,22,35,44,45,46,47,48,49]. However, most of these studies were based on conventional tensile or compressive tests, which showed that the deformation of metals was governed by partial dislocation. In contrast, the present study demonstrated that the plastic deformation of the twin-structured Ni NWs under bending was governed by dislocation, reversible fcc–bct phase transition, and GB formation. The observed deformation mechanism depended on the deformation stage, which has rarely been reported [5,36,47,48,49,50]. The GB generation and phase transformation occurred at high strain and always after the dislocation, making them difficult to detect at not sufficiently large plastic strain [51,52,53,54].

5. Conclusions

The bending twin-structured Ni NWs were captured in situ at the atomic scale. The HTEM results revealed that the deformation model changed with increasing bending strain, which has rarely been previously reported. These findings provide valuable insights into plastic deformation mechanisms in metallic NWs and show a general picture of the deformation mechanism; some of the deformation modes are different from previous studies.

Author Contributions

C.N. and L.W. designed the project and guided the research; Z.Z. and L.W. prepared the manuscript; Z.Z., C.Y. and Y.G. performed the experiment; C.Y., Y.G. and L.W. analysed the data and prepared the figures; X.L., D.K., Y.L., C.N. and L.W. reviewed the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Key R&D Program of China (2021YFA1200201), Beijing Outstanding Young Scientists Projects (BJJWZYJH01201910005018), Beijing Natural Science Foundation (Z180014) and the Natural Science Foundation of China (12174014).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhu, Y.T.; Liao, X.Z.; Wu, X.L. Deformation twinning in nanocrystalline materials. Prog. Mater. Sci. 2012, 57, 1–62. [Google Scholar] [CrossRef]

- Zhu, T.; Li, J. Ultra-strength materials. Prog. Mater. Sci. 2010, 55, 710–757. [Google Scholar] [CrossRef]

- Li, X.Y.; Wei, Y.J.; Lu, L.; Lu, K.; Gao, H.J. Dislocation nucleation governed softening and maximum strength in nano-twinned metals. Nature 2010, 464, 877–880. [Google Scholar] [CrossRef] [PubMed]

- Lu, L.; Shen, Y.F.; Chen, X.H.; Qian, L.H.; Lu, K. Ultrahigh strength and high electrical conductivity in copper. Science 2004, 304, 422–426. [Google Scholar] [CrossRef]

- Long, J.Z.; Pan, Q.S.; Tao, N.R.; Lu, L. Residual stress induced tension-compression asymmetry of gradient nanograined copper. Mater. Res. Lett. 2018, 6, 456–461. [Google Scholar] [CrossRef]

- Pan, Q.S.; Zhou, H.F.; Lu, Q.H.; Gao, H.J.; Lu, L. History-independent cyclic response of nanotwinned metals. Nature 2017, 551, 214–217. [Google Scholar] [CrossRef]

- Cao, A.J.; Wei, Y.G.; Mao, S.X. Deformation mechanisms of face-centered-cubic metal nanowires with twin boundaries. Appl. Phys. Lett. 2007, 90, 151909. [Google Scholar] [CrossRef]

- Jang, D.C.; Li, X.Y.; Gao, H.J.; Greer, J.R. Deformation mechanisms in nanotwinned metal nanopillars. Nat. Nanotechnol. 2012, 7, 594–601. [Google Scholar] [CrossRef]

- Zhu, T.; Li, J.; Samanta, A.; Kim, H.G.; Suresh, S. Interfacial plasticity governs strain rate sensitivity and ductility in nanostructured metals. Proc. Natl. Acad. Sci. USA 2007, 104, 3031–3036. [Google Scholar] [CrossRef]

- Wang, L.H.; Liu, P.; Guan, P.F.; Yang, M.J.; Sun, J.L.; Cheng, Y.Q.; Hirata, A.; Zhang, Z.; Ma, E.; Chen, M.; et al. In situ atomic-scale observation of continuous and reversible lattice deformation beyond the elastic limit. Nat. Commun. 2013, 4, 2413. [Google Scholar] [CrossRef]

- Afanasyev, K.A.; Sansoz, F. Strengthening in gold nanopillars with nanoscale twins. Nano Lett. 2007, 7, 2056–2062. [Google Scholar] [CrossRef]

- Deng, C.; Sansoz, F. Near-ideal strength in gold nanowires achieved through microstructural design. ACS Nano 2009, 3, 3001–3008. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.W.; Sansoz, F.; Huang, J.Y.; Liu, Y.; Sun, S.H.; Zhang, Z.; Mao, S.X. Near-ideal theoretical strength in gold nanowires containing angstrom scale twins. Nat. Commun. 2013, 4, 1742. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.Z.; Wang, Z.X.; Zhang, B.; Teng, J.; Zeng, W.J.; Zhao, Y.F.; Fu, L.B.; Li, D.W.; Ma, Y.; Song, W.X.; et al. Twin thickness and dislocation interactions affect the incoherent-twin boundary phase in face-centered cubic metals. Cell Rep. Phys. Sci. 2022, 3, 100736. [Google Scholar] [CrossRef]

- Deng, C.; Sansoz, F. Fundamental differences in the plasticity of periodically twinned nanowires in Au, Ag, Al, Cu, Pb and Ni. Acta Mater. 2009, 57, 6090–6101. [Google Scholar] [CrossRef]

- Zhu, Y.; Espinosa, H.D. An electromechanical material testing system for in situ electron microscopy and applications. Proc. Natl. Acad. Sci. USA 2005, 102, 14503–14508. [Google Scholar] [CrossRef]

- Wang, L.; Guan, P.; Teng, J.; Liu, P.; Han, X.D. New twinning route in face-centered cubic nanocrystalline metals. Nat. Commun. 2017, 8, 2142. [Google Scholar] [CrossRef]

- Kong, D.L.; Xin, T.J.; Sun, S.D.; Lu, Y.; Shu, X.Y.; Long, H.B.; Chen, Y.H.; Teng, J.; Zhang, Z.; Wang, L.H.; et al. Surface energy driven liquid-drop-like pseudoelastic behaviors and in situ atomistic mechanisms of small-sized face-centered cubic metals. Nano Lett. 2019, 19, 292. [Google Scholar] [CrossRef]

- Li, J.; Zhang, J.Y.; Liu, G.; Sun, J. Using the room temperature creep to strengthen nanotwinned Ni: The scaling behavior between the twin thickness and the grain size, Mater. Today Nano 2020, 11, 100086. [Google Scholar] [CrossRef]

- Sun, S.D.; Li, D.W.; Yang, C.P.; Fu, L.B.; Kong, D.L.; Lu, Y.; Guo, Y.Z.; Liu, D.M.; Guan, P.F.; Zhang, Z.; et al. Direct Atomic-Scale Observation of Ultrasmall Ag Nanowires that Exhibit fcc, bcc, and hcp Structures under Bending. Phys. Rev. Lett. 2022, 128, 015701. [Google Scholar] [CrossRef]

- Seo, J.H.; Yoo, Y.D.; Park, N.Y.; Yoon, S.W.; Lee, H.; Han, S.; Lee, S.W.; Seong, T.Y.; Lee, S.C.; Lee, K.B.; et al. Superplastic deformation of defect-free Au nanowires via coherent twin propagation. Nano Lett. 2011, 11, 3499–3502. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Song, J.; Huang, J.Y.; Lou, J. Fracture of sub-20nm ultrathin gold nanowires. Adv. Funct. Mater. 2011, 21, 3982–3989. [Google Scholar] [CrossRef]

- Han, X.D.; Zheng, K.; Zhang, Y.F.; Zhang, X.N.; Zhang, Z.; Wang, Z.L. Low-temperature in situ large-strain plasticity of silicon nanowires. Adv. Mater. 2007, 19, 2112–2118. [Google Scholar] [CrossRef]

- Landau, L.D.; Lifshitz, E.M. Theory of Elasticity; Pergamon Press: New York, NY, USA, 1986. [Google Scholar]

- Li, X.Y.; Dao, M.; Eberl, C.; Hodge, A.M.; Gao, H.J. Fracture, fatigue, and creep of nanotwinned metals. MRS Bull. 2016, 41, 298–304. [Google Scholar] [CrossRef]

- Li, X.Y.; Yin, S.; Oh, S.H.; Gao, H.J. Hardening and toughening mechanisms in nanotwinned ceramics. Scr. Mater. 2017, 133, 105–112. [Google Scholar] [CrossRef]

- Shin, Y.A.; Yin, S.; Li, X.; Lee, S.; Moon, S.; Jeong, J.; Kwon, M.; Yoo, S.J.; Kim, Y.M.; Zhang, T.; et al. Nanotwin-governed toughening mechanism in hierarchically structured biological materials. Nat. Commun. 2016, 7, 10772. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.H.; Du, K.; Yang, C.P.; Teng, J.; Fu, L.B.; Guo, Y.Z.; Zhang, Z.; Han, X.D. In situ atomic-scale observation of grain size and twin thickness effect limit in twin-structural nanocrystalline platinum. Nat. Commun. 2020, 11, 1167. [Google Scholar] [CrossRef] [PubMed]

- Peng, C.; Ganesan, Y.; Lu, Y.; Lou, J. Size dependent mechanical properties of single crystalline nickel nanowires. J. Appl. Phys. 2012, 111, 063524. [Google Scholar] [CrossRef]

- Chen, Z.M.; Jin, Z.H.; Gao, H.J. Repulsive force between screw dislocation and coherent twin boundary in aluminum and copper. Phys. Rev. B 2007, 75, 212104. [Google Scholar] [CrossRef]

- Warner, D.H.; Curtin, W.A.; Qu, S. Rate dependence of crack-tip processes predicts twinning trends in fcc metals. Nat. Mater. 2007, 6, 876–881. [Google Scholar] [CrossRef]

- Liao, X.Z.; Zhou, F.; Lavernia, E.J.; He, D.W.; Zhu, Y.T. Deformation twins in nanocrystalline Al. Appl. Phy. Lett. 2003, 83, 5062–5064. [Google Scholar] [CrossRef]

- Chen, M.W.; Ma, E.; Hemker, K.J.; Sheng, H.W.; Wang, Y.M.; Cheng, X.M. Deformation twinning in nanocrystalline aluminum. Science 2003, 300, 1275–1277. [Google Scholar] [CrossRef] [PubMed]

- Yue, Y.H.; Liu, P.; Zhang, Z.; Han, X.D.; Ma, E. Approaching the theoretical elasticstrainlimit in copper nanowires. Nano Lett. 2011, 11, 3151–3155. [Google Scholar] [CrossRef] [PubMed]

- Yue, Y.H.; Liu, P.; Deng, Q.S.; Ma, E.; Zhang, Z.; Han, X.D. Quantitative evidence of crossover toward partial dislocation mediated plasticity in copper single crystalline nanowires. Nano Lett. 2012, 12, 4045–4049. [Google Scholar] [CrossRef] [PubMed]

- Bain, E.C.; Dunkirk, N.Y. The nature of martensite. Trans. Am. Inst. Min. Metall. Eng. 1924, 70, 25. [Google Scholar]

- Bowles, J.S.; Wayman, C.M. The Bain strain, lattice correspondences, and deformations related to martensitic transformations. Metall. Mater. Trans. B 1972, 3, 1113–1121. [Google Scholar] [CrossRef]

- Olson, G.B.; Cohen, M. Interphase-boundary dislocations and the concept of coherency. Acta Metall. 1979, 27, 1907–1918. [Google Scholar] [CrossRef]

- Kajiwara, S.; Ogawa, K.; Kikuchi, T. High-resolution electron microscopy observations of transient lattices from fcc to bcc at the austenite martensite interface. Phil. Mag. Lett. 1996, 74, 405–414. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Wu, X.L.; Liu, Q.; Zuo, R.L.; Zhu, A.W.; Jiang, P.; Wei, Q.M. Phase transformation accommodated plasticity in nanocrystalline nickel. Appl. Phys. Lett. 2008, 93, 031901. [Google Scholar] [CrossRef]

- Murayama, M.; Howe, J.M.; Hidaka, H.; Takaki, S. Atomic-level observation of disclination dipoles in mechanically milled, nanocrystalline Fe. Science 2002, 295, 2433–2435. [Google Scholar] [CrossRef]

- Ovid’ko, I.A. Deformation of nanostructures. Science 2002, 295, 2386. [Google Scholar] [CrossRef] [PubMed]

- Komanduri, R.; Chandrasekaran, N.; Raff, L.M. Molecular dynamics (MD) simulation of uniaxial tension of some single-crystal cubic metals at nanolevel. Int. J. Mech. Sci. 2001, 43, 2237–2260. [Google Scholar] [CrossRef]

- Fu, L.B.; Yang, C.P.; Wei, R.J.; Pei, X.F.; Teng, J.; Kong, D.L.; Lu, Y.; Guo, Y.Z.; Liu, T.F.; Hu, Y.L.; et al. In situ atomic-scale observation of AuCu alloy nanowire with superplasticity and high strength at room temperature. Mater. Today Nano 2021, 15, 100123. [Google Scholar] [CrossRef]

- Fu, L.B.; Kong, D.L.; Yang, C.P.; Teng, J.; Lu, Y.; Guo, Y.Z.; Yang, G.; Yan, X.; Liu, P.; Chen, M.W.; et al. Ultra-high strength yet superplasticity in a hetero-grain-sized nanocrystalline Au nanowire. J. Mater. Sci. Technol. 2022, 101, 95–106. [Google Scholar] [CrossRef]

- Greer, J.R.; Nix, W.D. Nanoscale gold pillars strengthened through dislocation starvation. Phys. Rev. B 2006, 73, 245410. [Google Scholar] [CrossRef]

- Fu, L.B.; Yang, C.P.; Lu, Y.; Teng, J.; Kong, D.L.; Guo, Y.Z.; Zhang, Z.; Wang, L.H.; Han, X.D. In situ atomistic mechanisms of detwinning in nanocrystalline AuAg alloy. Sci. China Mater. 2022, 65, 820–826. [Google Scholar] [CrossRef]

- Seo, J.H.; Park, H.S.; Yoo, Y.; Seong, T.Y.; Li, J.; Ahn, J.P.; Kim, B.; Choi, I.S. Origin of Size Dependency in Coherent-Twin-Propagation-Mediated Tensile Deformation of Noble Metal Nanowires. Nano Lett. 2013, 13, 5112–5116. [Google Scholar] [CrossRef]

- Wang, Q.N.; Wang, J.W.; Li, J.X.; Zhang, Z.; Mao, S.X. Consecutive crystallographic reorientations and superplasticity in body-centered cubic niobium nanowires. Sci. Adv. 2018, 4, eaas8850. [Google Scholar] [CrossRef]

- Sun, S.D.; Kong, D.L.; Li, D.H.; Liao, X.Z.; Liu, D.M.; Mao, S.C.; Zhang, Z.; Wang, L.H.; Han, X.D. Atomistic mechanism of stress-induced combined slip and diffusion in sub-5 nanometer-sized Ag nanowires. ACS Nano 2019, 13, 8708–8716. [Google Scholar] [CrossRef]

- Lu, Q.H.; You, Z.S.; Huang, X.X.; Hansen, N.; Lu, L. Dependence of dislocation structure on orientation and slip systems in highly oriented nanotwinned Cu. Acta Mater. 2017, 127, 85–97. [Google Scholar] [CrossRef]

- Wang, L.H.; Zhang, Y.; Zeng, Z.; Zhou, H.; He, J.; Liu, P.; Chen, M.W.; Han, J.; Srolovitz, D.J.; Teng, J.; et al. Tracking the sliding of grain boundaries at the atomic scale. Science 2022, 375, 1261–1265. [Google Scholar] [CrossRef] [PubMed]

- Evans, A.G.; Hutchinson, J.W. A critical assessment of theories of strain gradient plasticity. Acta Mater. 2009, 57, 1675–1688. [Google Scholar] [CrossRef]

- Wang, L.H.; Teng, J.; Sha, X.C.; Zou, J.; Zhang, Z.; Han, X.D. Plastic deformation through dislocation saturation in ultrasmall Pt nanocrystals and Its in situ atomistic mechanisms. Nano Lett. 2017, 17, 4733–4739. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).