Austenite-Based Fe-Mn-Al-C Lightweight Steels: Research and Prospective

Abstract

1. Introduction

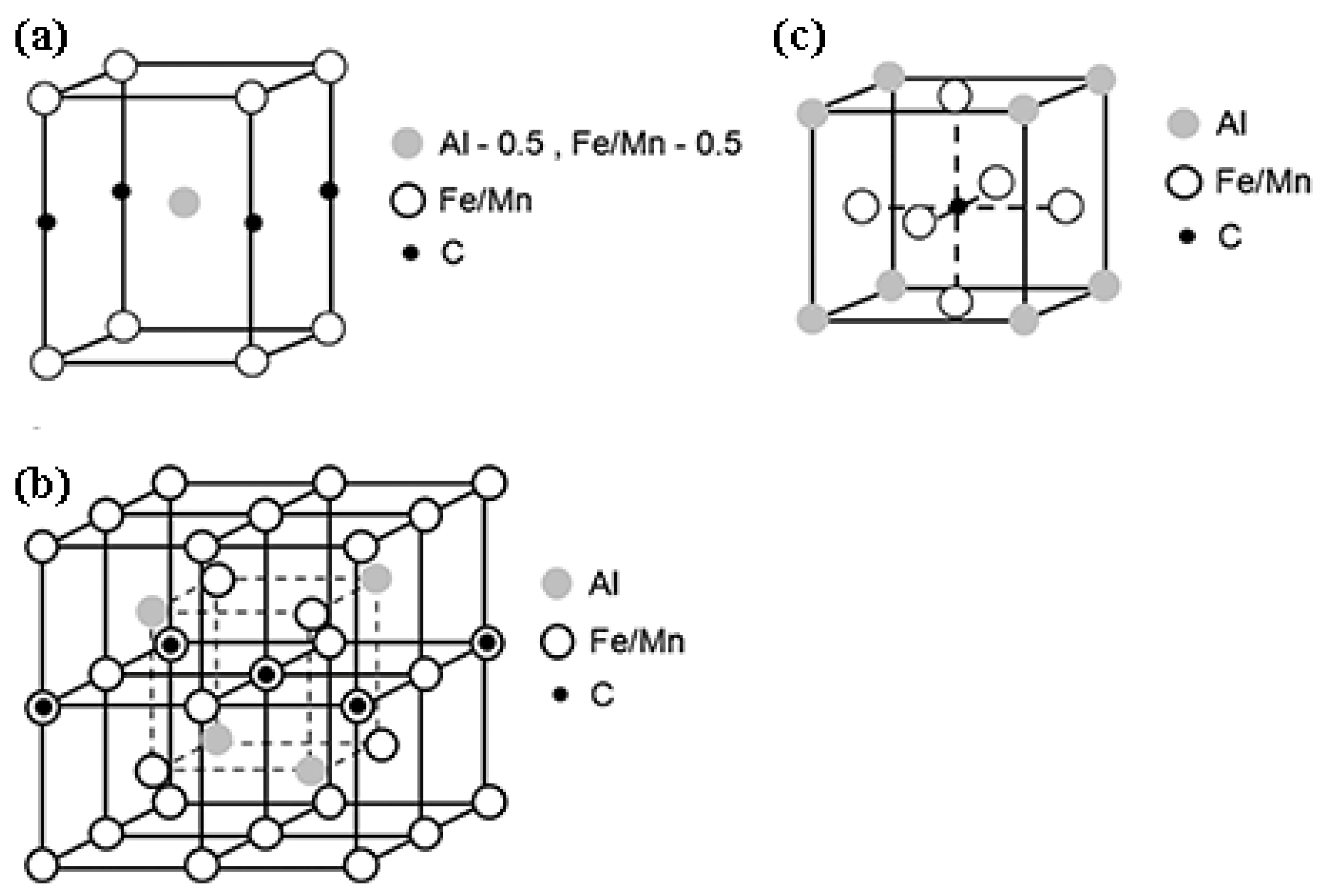

2. Phase Constituents in the Austenite-Based Fe-Mn-Al-C Lightweight Steels

3. Mechanical Properties

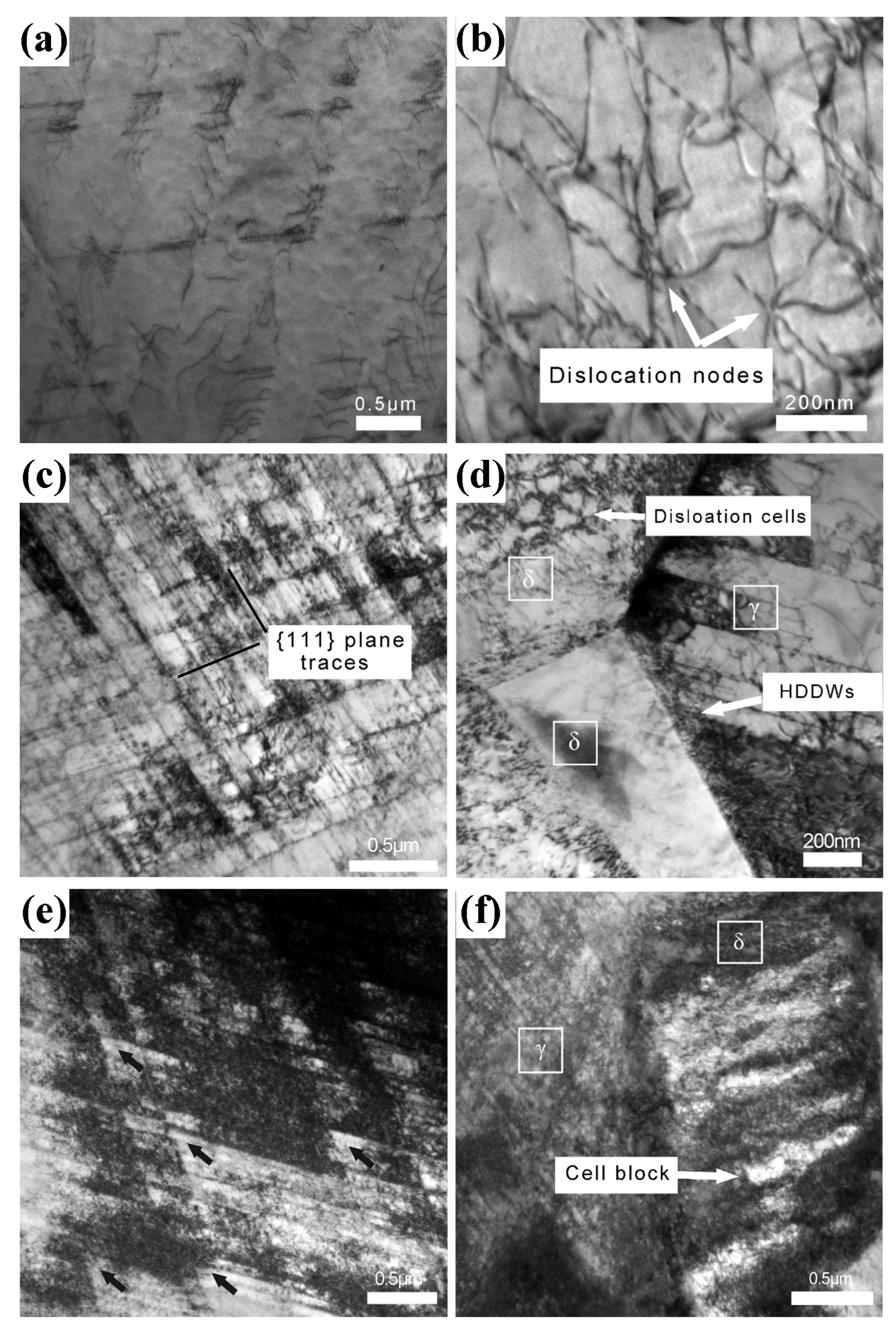

4. Strengthening Mechanisms

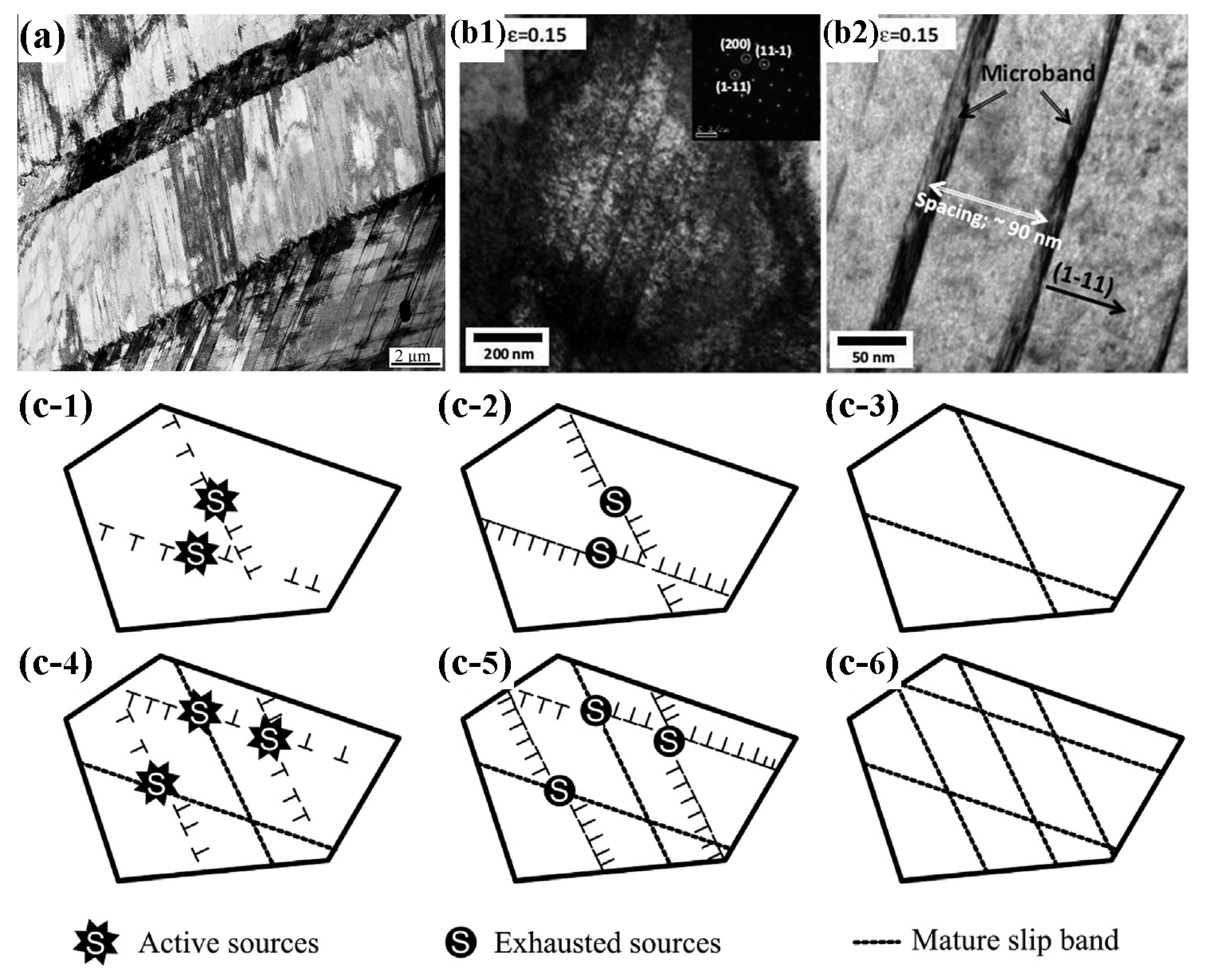

5. Strain Hardening Behaviors and Deformation Mechanisms

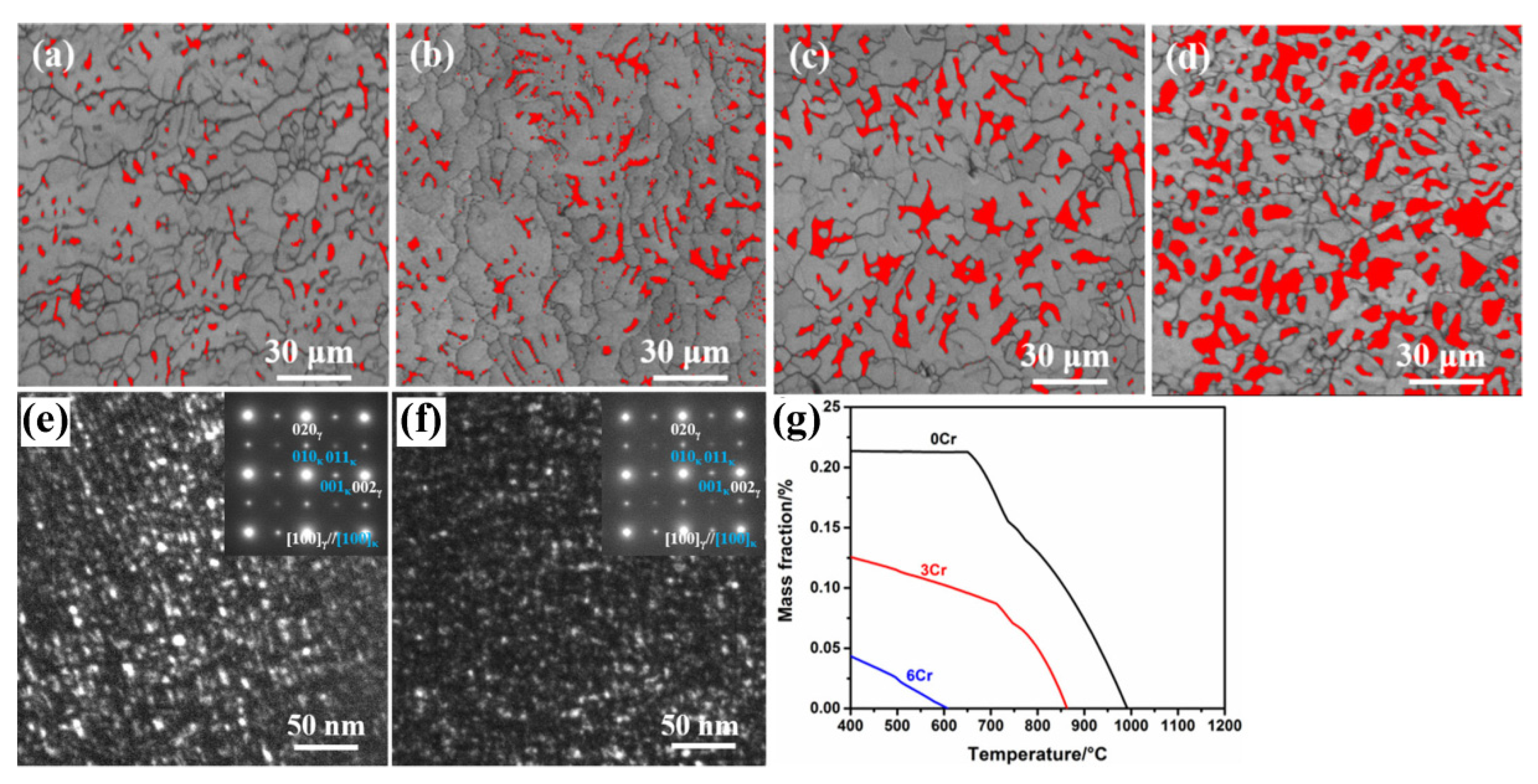

6. Effect of Trace Alloying Elements

7. Fabrication of Fe-Mn-Al-C Lightweight Steels

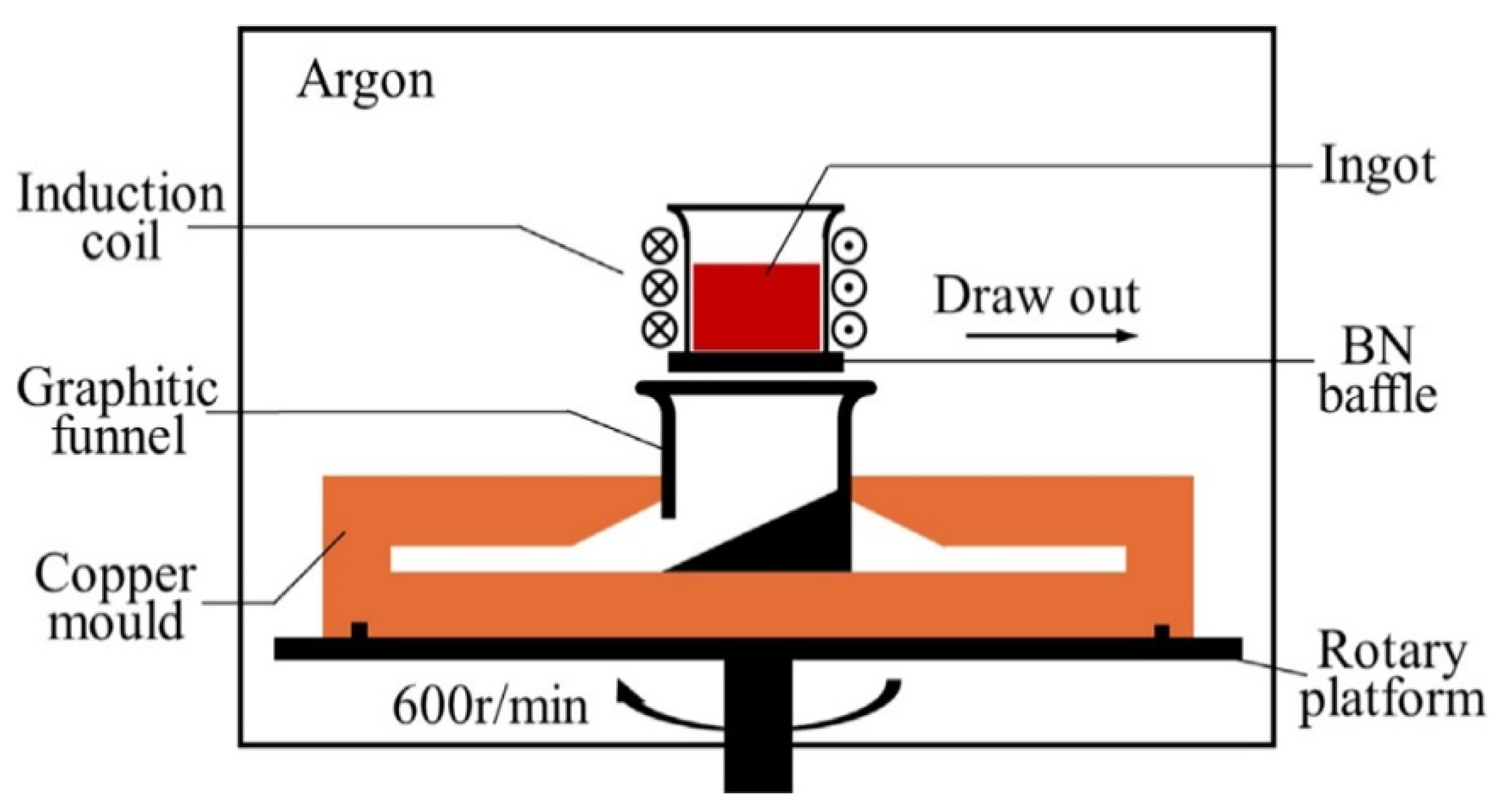

7.1. Fabrication Methods

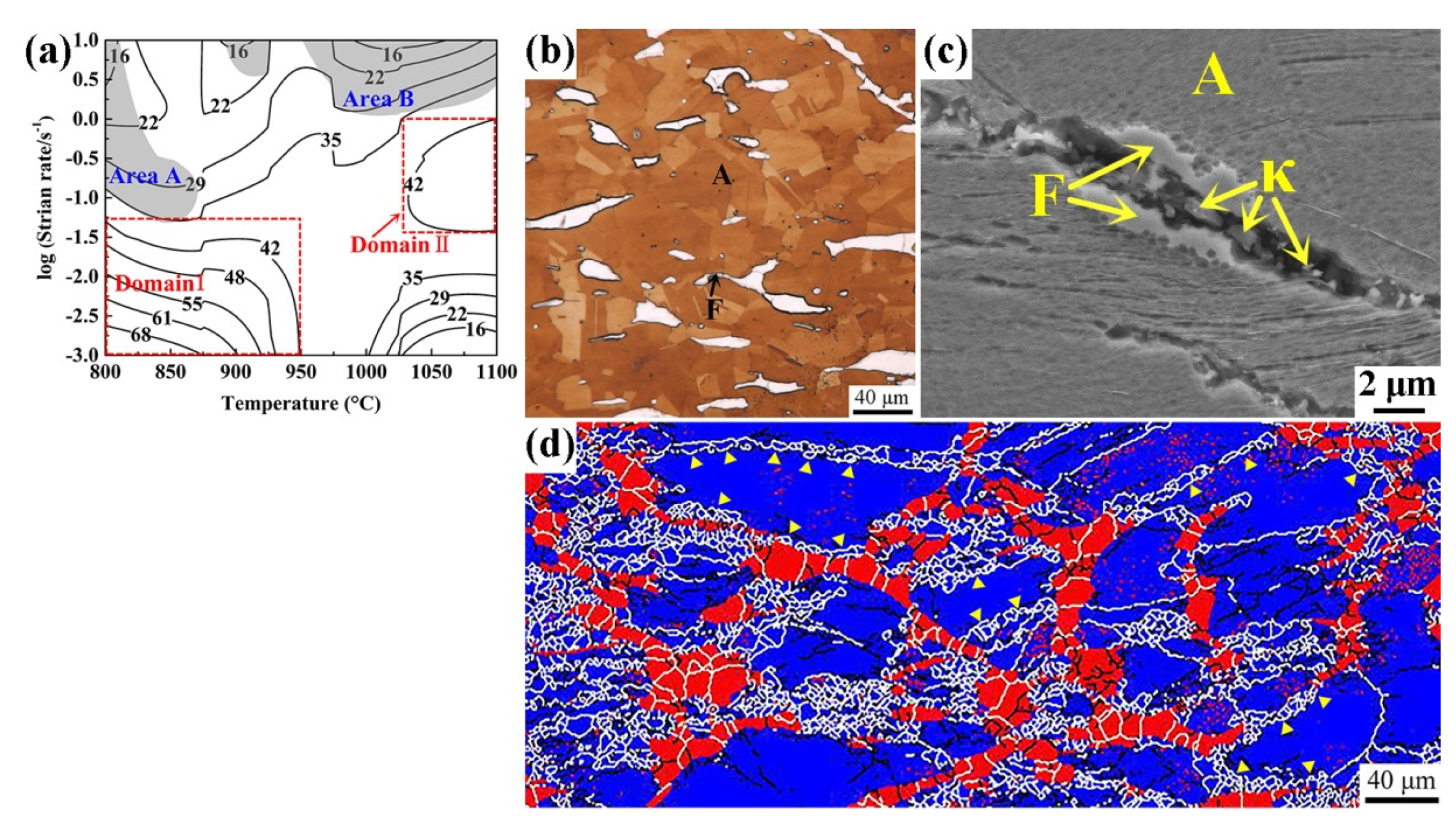

7.2. Hot Deformation Behavior

8. Future Research Aspects

8.1. Alloy Design

8.2. Microstructure Design

8.3. Comprehensive Properties

8.4. Fabrication Method Development

9. Summary

- (1)

- In austenitic Fe-Mn-Al-C steels, the microstructure in solution treated condition is a single γ phase or the one with nano-sized κ‘-carbide, depending on the compositions and heat treatment schedules. Solid solution hardening, grain size refinement, and precipitation hardening are the basic strengthening mechanisms. Measures to effectively utilize nano-sized precipitates should be explored to increase the strengths and strain hardening rates of the steels.

- (2)

- Austenite-based duplex Fe-Mn-Al-C steels generally possess high strength with moderate ductility. The strain partitioning between the dual phases should be investigated to guarantee the accommodation of deformation in two phases with different properties so as to achieve higher performance.

- (3)

- Mn and Al, the major alloying elements of the present alloy, play the opposite role on the phase stabilization of alloys as the austenite stabilizer and ferrite stabilizer, respectively. It is essential to examine the phase constituents of the steels treated with different schedules and their effects on the mechanical properties. The effects of trace elements on the mechanical properties still need to be investigated to modify the microstructures and tailor properties of the materials.

- (4)

- Mechanical behaviors of the Fe-Mn-Al-C steels at different temperatures and strain rates need to be investigated to meet the requirements for actual applications. Other properties such as fatigue, formability, weldability, and coatability need to be evaluated further to fulfill the requirements in the different practical uses.

- (5)

- The fabrications of the lightweight Fe-Mn-Al-C steels need to be explored in the conventional production line. New methods to fabricate the Fe-Mn-Al-C steels with relatively high Al concentrations need to be developed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, S.P.; Rana, R.; Haldar, A.; Ray, R.K. Current state of Fe-Mn-Al-C low density steels. Prog. Mater. Sci. 2017, 89, 345–391. [Google Scholar] [CrossRef]

- Ho, N.J.; Wu, L.T.; Tjong, S.C. Cyclic deformation of duplex Fe-30Mn-10Al-0.4C alloy at room temperature. Mater. Sci. Eng. 1988, 102, 49–55. [Google Scholar] [CrossRef]

- He, L.; Jian-ping, Z.; Zhan-yu, W.; Li, D. Effect of heat treatment on cyclic deformation properties of Fe-26Mn-10Al-C steel. J. Iron Steel Res. Int. 2019, 26, 200–210. [Google Scholar]

- Kalashnikov, I.S.; Acselrad, O.; Pereira, L.C.; Kalichak, T.; Khadyyev, M.S. Behavior of Fe-Mn-Al-C steels during cyclic tests. J. Mater. Eng. Perform. 2000, 9, 334–337. [Google Scholar] [CrossRef]

- Ho, N.J.; Tjong, S.C. Cyclic stress-strain behaviour of austenitic Fe-29.7Mn-8.7A1-1.04C alloy at room temperature. Mater. Sci. Eng. 1987, 94, 195–202. [Google Scholar] [CrossRef]

- Chang, S.C.; Hsisu, Y.H.; Jahn, M.T. Tensile and fatigue properties of Fe-Mn-Al-C alloys. J. Mater. Sci. 1989, 24, 1117–1120. [Google Scholar] [CrossRef]

- Sie, C.T. Dislocation microstructures in fatigued Fe-30Mn-10Al-0.4C alloy. Phys. Status Solidi 1990, 121, 119–127. [Google Scholar]

- Yang, W.S.; Wan, C.M. High temperature studies of Fe-Mn-Al-C alloys with different manganese concentrations in air and nitrogen. J. Mater. Sci. 1989, 24, 3497–3503. [Google Scholar] [CrossRef]

- Peng, W.; Wang, J.J.; Zhang, H.W.; Hong, X.Y.; Wu, Z.Y.; Xu, Y.L.; Li, J.; Xiao, X.S. Insights into the role of grain refinement on high-temperature initial oxidation phase transformation and oxides evolution in high aluminium Fe-Mn-Al-C duplex lightweight steel. Corros. Sci. 2017, 126, 3497–3503. [Google Scholar] [CrossRef]

- Huang, Z.Y.; Jiang, Y.S.; Hou, A.L.; Wang, P.; Shi, Q.; Hou, Q.Y.; Liu, X.H. Rietveld refinement, microstructure and high-temperature oxidation characteristics of low-density high manganese steels. J. Mater. Sci. Technol. 2017, 33, 1531–1539. [Google Scholar] [CrossRef]

- Wang, C.J.; Chang, Y.C. Formation and growth morphology of nodules in the high-temperature oxidation of Fe-Mn-Al-C alloy. Mater. Chem. Phys. 2003, 77, 738–743. [Google Scholar] [CrossRef]

- Balaško, T.; Šetina, B.B.; Medved, J.; Burja, J. High-Temperature Oxidation Behaviour of Duplex Fe-Mn-Al-Ni-C Lightweight Steel. Crystals 2022, 12, 957. [Google Scholar] [CrossRef]

- Rana, R.; Liu, C.; Ray, R.K. Low-density low-carbon Fe-Al ferritic steels. Scr. Mater. 2013, 68, 354–359. [Google Scholar] [CrossRef]

- Janda, D.; Ghassemi-Armaki, H.; Bruder, E.; Hockauf, M.; Heilmaier, M.; Kumar, K.S. Effect of strain-rate on the deformation response of D03-ordered Fe3Al. Acta Mater. 2016, 103, 909–918. [Google Scholar] [CrossRef]

- Herrmann, J.; Inden, G.; Sauthoff, G. Deformation behaviour of iron-rich iron-aluminum alloys at low temperatures. Acta Mater. 2003, 51, 2847–2857. [Google Scholar] [CrossRef]

- Zargaran, A.; Kim, H.S.; Kwak, J.H.; Kim, N.J. Effects of Nb and C additions on the microstructure and tensile properties of lightweight ferritic Fe-8Al-5Mn alloy. Scr. Mater. 2014, 89, 37–40. [Google Scholar] [CrossRef]

- Castan, C.; Montheillet, F.; Perlade, A. Dynamic recrystallization mechanisms of an Fe-8% Al low density steel under hot rolling conditions. Scr. Mater. 2013, 68, 360–364. [Google Scholar] [CrossRef]

- Min, C.H.; Koo, J.-M.; Lee, J.-K.; Si, W.H.; Park, K.-T. Tensile deformation of a low density Fe-27Mn-12Al-0.8C duplex steel in association with ordered phases at ambient temperature. Mater. Sci. Eng. 2013, 586, 276–283. [Google Scholar]

- Łyszkowski, R.; Bystrzycki, J. Hot deformation and processing maps of a Fe-Al intermetallic alloy. Mater. Charact. 2014, 96, 196–205. [Google Scholar] [CrossRef]

- Łyszkowski, R.; Czujko, T.; Varin, R.A. Multi-axial forging of Fe3Al-base intermetallic alloy and its mechanical properties. J. Mater. Sci. 2017, 52, 2902–2914. [Google Scholar] [CrossRef]

- Rana, R.; Liu, C.; Ray, R.K. Evolution of microstructure and mechanical properties during thermomechanical processing of a low-density multiphase steel for automotive application. Acta Mater. 2014, 75, 227–245. [Google Scholar] [CrossRef]

- Seol, J.-B.; Raabe, D.; Choi, P.; Park, H.-S.; Kwak, J.-H.; Park, C.-G. Direct evidence for the formation of ordered carbides in a ferrite-based low-density Fe-Mn-Al-C alloy studied by transmission electron microscopy and atom probe tomography. Scr. Mater. 2013, 68, 348–353. [Google Scholar] [CrossRef]

- Han, S.Y.; Shin, S.Y.; Lee, S.; Kim, N.J.; Kwak, J.-H.; Chin, K.-G. Effect of Carbon Content on Cracking Phenomenon Occurring during Cold Rolling of Three Light-Weight Steel Plates. Metall. Mater. Trans. 2011, 42, 138–146. [Google Scholar] [CrossRef]

- Sohn, S.S.; Lee, B.-J.; Lee, S.; Kwak, J.-H. Effect of Mn Addition on Microstructural Modification and Cracking Behavior of Ferritic Light-Weight Steels. Metall. Mater. Trans. 2014, 45, 5469–5485. [Google Scholar] [CrossRef]

- Sohn, S.S.; Lee, B.-J.; Lee, S.; Kwak, J.-H. Effects of aluminum content on cracking phenomenon occurring during cold rolling of three ferrite-based lightweight steel. Acta Mater. 2013, 61, 5626–5635. [Google Scholar] [CrossRef]

- Shin, S.Y.; Lee, H.; Han, S.Y.; Seo, C.-H.; Choi, K.; Lee, S.; Kim, N.J.; Kwak, J.-H.; Chin, K.-G. Correlation of Microstructure and Cracking Phenomenon Occurring during Hot Rolling of Lightweight Steel Plates. Metall. Mater. Trans. 2010, 41, 138. [Google Scholar] [CrossRef]

- Sohn, S.S.; Lee, B.-H.; Lee, S.; Kim, N.J.; Kwak, J.-H. Effect of annealing temperature on microstructural modification and tensile properties in 0.35C-3.5Mn-5.8Al lightweight steel. Acta Mater. 2013, 61, 5050–5066. [Google Scholar] [CrossRef]

- Seo, C.-H.; Kwon, K.H.; Choi, K.; Kim, K.-H.; Kwak, J.-H.; Lee, S.; Kim, N.J. Deformation behavior of ferrite-austenite duplex lightweight Fe-Mn-Al-C steel. Scr. Mater. 2012, 66, 519–522. [Google Scholar] [CrossRef]

- Sohn, S.S.; Choi, K.; Kwak, J.-H.; Kim, N.J.; Lee, S. Novel ferrite–austenite duplex lightweight steel with 77% ductility by transformation induced plasticity and twinning induced plasticity mechanisms. Acta Mater. 2014, 78, 181–189. [Google Scholar] [CrossRef]

- Park, S.J.; Hwang, B.; Lee, K.H.; Lee, T.H.; Suh, D.W.; Han, H.N. Microstructure and tensile behavior of duplex low-density steel containing 5mass% aluminum. Scr. Mater. 2013, 68, 365–369. [Google Scholar] [CrossRef]

- Jeong, J.; Lee, C.-Y.; Park, I.-J.; Lee, Y.-K. Isothermal precipitation behavior of κ-carbide in the Fe-9Mn-6Al-0.15C lightweight steel with a multiphase microstructure. J. Alloy Compd. 2013, 574, 299–304. [Google Scholar] [CrossRef]

- Lee, S.; Jeong, J.; Lee, Y.-K. Precipitation and dissolution behavior of κ-carbide during continuous heating in Fe-9.3Mn-5.6Al-0.16C lightweight steel. J. Alloy Compd. 2015, 648, 149–153. [Google Scholar] [CrossRef]

- Rigaud, V.; Daloz, D.; Drillet, J.; Perlade, A.; Maugis, P.; Lesoult, G. Phases Equilibrium Study in Quaternary Iron-rich Fe-Al-Mn-C Alloys. ISIJ Int. 2007, 47, 898–906. [Google Scholar] [CrossRef]

- Sohn, S.S.; Song, H.; Kim, J.G.; Kwak, J.-H.; Kim, H.S.; Lee, S. Effects of Annealing Treatment Prior to Cold Rolling on Delayed Fracture Properties in Ferrite-Austenite Duplex Lightweight Steels. Metall. Mater. Trans. 2016, 47, 706–717. [Google Scholar] [CrossRef]

- Han, S.Y.; Shin, S.Y.; Lee, H.-J.; Lee, B.-J.; Lee, S.; Kim, N.J.; Kwak, J.-H. Effects of Annealing Temperature on Microstructure and Tensile Properties in Ferritic Lightweight Steels. Metall. Mater. Trans. 2012, 43, 843–853. [Google Scholar] [CrossRef]

- Li, X.; Song, R.B.; Zhou, N.P.; Li, J.J. Microstructure and tensile behavior of Fe-8Mn-6Al-0.2C low density steel. Mater. Sci. Eng. 2018, 709, 97–104. [Google Scholar] [CrossRef]

- Jung, H.; Lee, G.; Koo, M.; Song, H.; Ko, W.S.; Sohn, S.S. Effects of Mn Segregations on Intergranular Fracture in a Medium-Mn Low-Density Steel. Steel Res. Int. 2022, 2200240. [Google Scholar] [CrossRef]

- Zhou, N.P.; Song, R.B.; Li, X.; Li, J.J. Dependence of austenite stability and deformation behavior on tempering time in an ultrahigh strength medium Mn TRIP steel. Mater. Sci. Eng. 2018, 738, 153–162. [Google Scholar] [CrossRef]

- Mozumder, Y.H.; Babu, K.A.; Saha, R.; Mandal, S. Flow characteristics and hot workability studies of a Ni-containing Fe-Mn-Al-C lightweight duplex steel. Mater. Charact. 2018, 146, 1–14. [Google Scholar] [CrossRef]

- Zhao, C.; Song, R.B.; Zhang, L.F.; Yang, F.Q.; Kang, T. Effect of annealing temperature on the microstructure and tensile properties of Fe-10Mn-10Al-0.7C low-density steel. Mater. Des. 2016, 91, 348–360. [Google Scholar] [CrossRef]

- Liu, D.G.; Cai, M.H.; Ding, H.; Han, D. Control of inter/intra-granular κ-carbides and its influence on overall mechanical properties of a Fe-11Mn-10Al-1.25C low density steel. Mater. Sci. Eng. 2018, 715, 25–32. [Google Scholar] [CrossRef]

- Liu, D.G.; Ding, H.; Cai, M.H.; Han, D. Mechanical behaviors of a lower-Mn-added Fe-11Mn-10Al-1.25C lightweight steel with distinguished microstructural features. Mater. Lett. 2019, 242, 131–134. [Google Scholar] [CrossRef]

- Lee, Y.; Kim, J.N.; Kim, G.; Lee, T.; Lee, C.S. Improved cold-rollability of duplex lightweight steels utilizing deformationinduced ferritic transformation. Mater. Sci. Eng. 2019, 742, 835–841. [Google Scholar]

- Lee, C.-Y.; Lee, Y.-K. The Solidification Mode of Fe-Mn-Al-C Lightweight Steel. JOM 2014, 66, 1821–1827. [Google Scholar] [CrossRef]

- Liu, D.G.; Ding, H.; Han, D.; Cai, M.H.; Lee, Y.K. Microstructural evolution and tensile properties of Fe-11Mn-10Al-1.2C medium-Mn lightweight steel. Mater. Sci. Eng. 2020, 797, 140256. [Google Scholar] [CrossRef]

- Liu, D.G.; Ding, H.; Han, D.; Cai, M.H. Improvement of the yield strength of Fe-11Mn-xAl-yC medium-Mn lightweight steels by tuning partial recrystallization and intra-granular κ-carbide strengthening. Mater. Sci. Eng. 2022, 833, 142553. [Google Scholar] [CrossRef]

- Sohn, S.S.; Song, H.; Jo, M.C.; Song, T.; Kim, H.S.; Lee, S. Novel 1.5 GPa-strength with 50%-ductility by transformation-induced plasticity of non-recrystallized austenite in duplex steels. Sci. Rep. 2017, 7, 1255. [Google Scholar] [CrossRef]

- Sohn, S.S.; Song, H.; Kwak, J.-H.; Lee, S. Dramatic improvement of strain hardening and ductility to 95% in highly-deformable high-strength duplex lightweight steels. Sci. Rep. 2017, 7, 1927. [Google Scholar] [CrossRef]

- Liu, M.X.; Zhou, J.Y.; Zhang, J.K.; Song, C.J.; Zhai, Q.J. Ultra-high strength medium-Mn lightweight steel by dislocation slip band refinement and suppressed intergranular κ-carbide with Cr addition. Mater. Charact. 2022, 190, 112042. [Google Scholar] [CrossRef]

- He, W.; Wang, B.L.; Yang, Y.; Zhang, Y.H.; Duan, L.; Luo, Z.P.; Song, C.J.; Zhai, Q.J. Microstructure and mechanical behavior of a low-density Fe-12Mn-9Al-1.2C steel prepared using centrifugal casting under near-rapid solidification. J. Iron Steel Res. Int. 2018, 25, 830–838. [Google Scholar]

- Sohn, S.S.; Song, H.; Suh, B.C.; Kwak, J.H.; Lee, B.J.; Kim, N.J.; Lee, S. Novel ultra-high-strength (ferrite plus austenite) duplex lightweight steels achieved by fine dislocation substructures (Taylor lattices), grain refinement, and partial recrystallization. Acta Mater. 2015, 96, 301–310. [Google Scholar] [CrossRef]

- Liu, S.; Ge, Y.L.; Liu, H.Y.; Liu, J.Y.; Feng, Y.L.; Chen, C.; Zhang, F.C. Tensile Properties and Microstructure Evolutions of Low-Density Duplex Fe-12Mn-7Al-0.2C-0.6Si Steel. Materials 2022, 15, 2498. [Google Scholar] [CrossRef]

- Song, H.J.; Yoo, J.; Kim, S.H.; Sohn, S.S.; Koo, M.; Kim, N.J.; Lee, S. Novel ultra-high-strength Cu-containing medium-Mn duplex lightweight steels. Acta Mater. 2017, 135, 215–225. [Google Scholar] [CrossRef]

- Wu, Z.Q.; Ding, H.; Li, H.Y.; Huang, M.L.; Cao, F.R. Microstructural evolution and strain hardening behavior during plastic deformation of Fe-12Mn-8Al-0.8C steel. Mater. Sci. Eng. 2013, 584, 150–155. [Google Scholar] [CrossRef]

- Song, H.; Kwon, Y.; Sohn, S.S.; Koo, M.; Kim, N.J.; Lee, B.J.; Lee, S. Improvement of tensile properties in (austenite + ferrite + κ-carbide) triplex hot-rolled lightweight steels. Mater. Sci. Eng. 2018, 730, 177–186. [Google Scholar]

- Song, H.; Jo, M.; Kim, D.W. Vanadium or copper alloyed duplex lightweight steelwith enhanced hydrogen embrittlement resistance at room temperature. Mater. Sci. Eng. 2021, 817, 141347. [Google Scholar] [CrossRef]

- Han, D.; Ding, H.; Liu, D.G.; Rolfe, B.; Beladi, H. Influence of C content and annealing temperature on the microstructures and tensile properties of Fe-13Mn-8Al-(0.7,1.2)C steels. Mater. Sci. Eng. 2020, 785, 139286. [Google Scholar] [CrossRef]

- Han, D.; Ding, H.; Liu, D.G. The microstructures and tensile properties of aged Fe-xMn-8Al-0.8C low-density steels. Mater. Sci. Technol. 2020, 36, 681–689. [Google Scholar] [CrossRef]

- Chen, W.C.; Wu, C.C.; Chang, W.Y. Effects of Aging Treatment on Microstructure of High-Al-content Fe-15Mn-10Al-1.0C Alloy. Sens. Mater. 2018, 30, 515–523. [Google Scholar]

- Yang, M.X.; Yuan, F.P.; Xie, Q.G.; Wang, Y.D.; Ma, E.; Wu, X.L. Strain hardening in Fe-16Mn-10Al-0.86C-5Ni high specific strength steel. Acta Mater. 2016, 109, 213–222. [Google Scholar] [CrossRef]

- Kumar, N.; Singh, K.; Singh, A. Microstructural evolution after heat treatment of high specific strength steel: Fe-13Al-16Mn-5Ni-0.8C and correlation with tensile properties. Materialia 2022, 22, 101412. [Google Scholar] [CrossRef]

- Cheng, W.-C. Phase Transformations of an Fe-0.85C-17.9Mn-7.1Al Austenitic Steel After Quenching and Annealing. JOM 2014, 66, 1809–1820. [Google Scholar] [CrossRef]

- Ding, H.; Han, D.; Zhang, J.; Cai, Z.H.; Wu, Z.Q.; Cai, M.H. Tensile deformation behavior analysis of low density Fe-18Mn-10Al-xC steels. Mater. Sci. Eng. 2016, 652, 69–76. [Google Scholar] [CrossRef]

- Ding, H.; Han, D.; Cai, Z.H.; Wu, Z.Q. Microstructures and Mechanical Behavior of Fe-18Mn-10Al-(0.8-1.2)C Steels. JOM 2014, 66, 1821–1827. [Google Scholar] [CrossRef]

- Huo, Y.T.; He, Y.L.; Zhu, N.Q.; Ding, M.L.; Liu, R.D.; Zhang, Y. Deformation Mechanism Investigation on Low Density 18Mn Steels under Different Solid Solution Treatments. Metals 2021, 11, 1497. [Google Scholar] [CrossRef]

- Piston, M.; Bartlett, L.; Limmer, K.R.; Field, D.M. Microstructural Influence on Mechanical Properties of a Lightweight Ultrahigh Strength Fe-18Mn-10Al-0.9C-5Ni (wt%) Steel. Metals 2020, 10, 1305. [Google Scholar] [CrossRef]

- Hwang, S.W.; Ji, J.H.; Lee, E.G.; Park, K.T. Tensile deformation of a duplex Fe-20Mn-9Al-0.6C steel having the reduced specific weight. Mater. Sci. Eng. 2011, 528, 5196–5203. [Google Scholar] [CrossRef]

- Ma, B.; Li, C.S.; Zheng, J.J.; Song, Y.L.; Han, Y.H. Strain hardening behavior and deformation substructure of Fe-20/27Mn-4Al-0.3C non-magnetic steels. Mater. Des. 2016, 92, 313–321. [Google Scholar] [CrossRef]

- Sutou, Y.; Kamiya, N.; Umino, R.; Ohnuma, I.; Ishida, K. High-strength Fe-20Mn-Al-C-based Alloys with Low Density. ISIJ Int. 2010, 50, 893–899. [Google Scholar] [CrossRef]

- Liu, L.B.; Li, C.M.; Yang, Y.; Luo, Z.P.; Song, C.J.; Zhai, Q.J. A simple method to produce austenite-based low-density Fe-20Mn-9Al-0.75C steel by a near-rapid solidification process. Mater. Sci. Eng. 2017, 679, 282–291. [Google Scholar] [CrossRef]

- Ma, B.; Li, C.S.; Song, Y.L.; Zheng, J.J. Effect of manganese content on hot deformation behaviour of Fe-(20/27)Mn-4Al-0.3C non-magnetic steels. Mater. Sci. Technol. 2016, 32, 890–897. [Google Scholar] [CrossRef]

- Lee, S.I.; Lee, S.W.; Kim, S.G.; Hwang, B. Correlation of Delta-Ferrite with Tensile and Charpy Impact Properties of Austenitic Fe-23Mn-Al-C Steels. Metall. Mater. Trans. 2021, 52, 4170–4180. [Google Scholar] [CrossRef]

- Feng, Y.F.; Song, R.B.; Pei, Z.Z.; Song, R.F.; Dou, G.Y. Effect of Aging Isothermal Time on the Microstructure and Room-Temperature Impact Toughness of Fe-24.8Mn-7.3Al-1.2C Austenitic Steel with kappa-Carbides Precipitation. Met. Mater. Int. 2018, 24, 1012–1023. [Google Scholar] [CrossRef]

- Ding, H.; Li, H.Y.; Misra, R.D.K.; Wu, Z.Q.; Cai, M.H. Strengthening Mechanisms in Low Density Fe-26Mn-xAl-1C Steels. Steel Res. Int. 2018, 89, 1700381. [Google Scholar] [CrossRef]

- Frommeyer, G.; Brux, U. Microstructures and mechanical properties of high-strength Fe-Mn-Al-C light-weight TRIPLEX steels. Steel Res. Int. 2006, 77, 627–633. [Google Scholar] [CrossRef]

- Yang, F.Q.; Song, R.B.; Li, Y.P.; Sun, T.; Wang, K.K. Tensile deformation of low density duplex Fe-Mn-Al-C steel. Mater. Des. 2015, 76, 32–39. [Google Scholar] [CrossRef]

- Zhang, L.F.; Song, R.B.; Zhao, C.; Yang, F.Q. Work hardening behavior involving the substructural evolution of an austenite-ferrite Fe-Mn-Al-C steel. Mater. Sci. Eng. 2015, 640, 225–234. [Google Scholar] [CrossRef]

- Park, K.T.; Hwang, S.W.; Son, C.Y.; Lee, J.K. Effects of Heat Treatment on Microstructure and Tensile Properties of a Fe-27Mn-12Al-0.8C Low-Density Steel. JOM 2014, 66, 1828–1836. [Google Scholar] [CrossRef]

- Etienne, A.; Massardier-Jourdan, V.; Cazottes, S.; Garat, X.; Soler, M.; Zuazo, I.; Kleber, X. Ferrite Effects in Fe-Mn-Al-C Triplex Steels. Metall. Mater. Trans. 2014, 45A, 324–334. [Google Scholar] [CrossRef]

- Zhang, L.F.; Song, R.B.; Zhao, C.; Yang, F.Q.; Xu, Y.; Peng, S.G. Evolution of the microstructure and mechanical properties of an austenite-ferrite Fe-Mn-Al-C steel. Mater. Sci. Eng. 2015, 643, 183–193. [Google Scholar] [CrossRef]

- Song, H.; Yoo, J.; Sohn, S.S.; Koo, M.; Lee, S. Achievement of high yield strength and strain hardening rate by forming fine ferrite and dislocation substructures in duplex lightweight steel. Mater. Sci. Eng. 2017, 704, 287–291. [Google Scholar] [CrossRef]

- Lee, K.; Park, S.J.; Kang, J.Y.; Park, S.; Han, S.S.; Park, J.Y.; Oh, K.H.; Lee, S.; Rollett, A.D.; Han, H.N. Investigation of the aging behavior and orientation relationships in Fe-31.4Mn-11.4Al-0.89C low-density steel. J. Alloy Compd. 2017, 723, 146–156. [Google Scholar] [CrossRef]

- Xie, Z.Q.; Hui, W.J.; Zhang, Y.J.; Zhao, X.L. Effect of Cu and solid solution temperature on microstructure and mechanical properties of Fe- Mn-Al-C low-density steels. J. Mater. Res. Technol. 2022, 18, 1307–1321. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, J.; Hu, C.; Luo, Z.; Zhang, Y.; Song, C.; Zhai, Q. Structures and properties of Fe-(8–16)Mn-9Al-0.8 C low density steel made by a centrifugal casting in near-rapid solidification. Mater. Sci. Eng. 2019, 748, 74–84. [Google Scholar] [CrossRef]

- Kim, C.; Terner, M.; Hong, H.-U.; Lee, C.-H.; Park, S.-J.; Moon, J. Influence of inter/intra-granular κ-carbides on the deformation mechanism in lightweight Fe-20Mn-11.5Al-1.2C steel. Mater. Charact. 2020, 161, 110142. [Google Scholar] [CrossRef]

- Park, K.-T.; Jin, K.G.; Han, S.H.; Hwang, S.W.; Choi, K.; Lee, C.S. Stacking fault energy and plastic deformation of fully austenitic high manganese steels: Effect of Al addition. Mater. Sci. Eng. 2010, 527, 3651–3661. [Google Scholar] [CrossRef]

- Yoo, J.D.; Park, K.T. Microband-induced plasticity in a high Mn-Al-C light steel. Mater. Sci. Eng. 2008, 496, 417–424. [Google Scholar] [CrossRef]

- Yoo, J.D.; Hwang, S.W.; Park, K.T. Origin of Extended Tensile Ductility of a Fe-28Mn-10Al-1C Steel. Metall. Mater. Trans. 2009, 40A, 1520–1523. [Google Scholar] [CrossRef]

- Park, K.T. Tensile deformation of low-density Fe-Mn-Al-C austenitic steels at ambient temperature. Scr. Mater. 2013, 68, 375–379. [Google Scholar] [CrossRef]

- Choi, K.; See, C.H.; Lee, H.; Kim, S.K.; Kwak, J.H.; Chin, K.G.; Parkd, K.T.; Kim, N.J. Effect of aging on the microstructure and deformation behavior of austenite base lightweight Fe-28Mn-9Al-0.8C steel. Scr. Mater. 2010, 63, 1028–1031. [Google Scholar] [CrossRef]

- Chang, K.M.; Chao, C.G.; Liu, T.F. Excellent combination of strength and ductility in an Fe-9Al-28Mn-1.8C alloy. Scr. Mater. 2010, 63, 162–165. [Google Scholar] [CrossRef]

- Lin, C.L.; Chao, C.G.; Bor, H.Y.; Liu, T.F. Relationship between Microstructures and Tensile Properties of an Fe-30Mn-8.5Al-2.0C Alloy. Mater. Trans. 2010, 51, 1084–1088. [Google Scholar] [CrossRef]

- Lin, C.L.; Chao, C.G.; Juang, J.Y.; Yang, J.M.; Liu, T.F. Deformation mechanisms in ultrahigh-strength and high-ductility nanostructured FeMnAlC alloy. J. Alloy Compd. 2014, 586, 616–620. [Google Scholar] [CrossRef]

- Gutierrez-Urrutia, I.; Raabe, D. Multistage strain hardening through dislocation substructure and twinning in a high strength and ductile weight-reduced Fe-Mn-Al-C steel. Acta Mater. 2012, 60, 5791–5802. [Google Scholar] [CrossRef]

- Gutierrez-Urrutia, I.; Raabe, D. High strength and ductile low density austenitic FeMnAlC steels: Simplex and alloys strengthened by nanoscale ordered carbides. Mater. Sci. Technol. 2014, 30, 1099–1104. [Google Scholar] [CrossRef]

- Springer, H.; Raabe, D. Compositional and thermo-mechanical high throughput bulk combinatorial design of structural materials based on the example of 30Mn-1.2C-xAl triplex steels. Acta Mater. 2012, 60, 4950–4959. [Google Scholar] [CrossRef]

- Welsch, E.; Ponge, D.; Haghighat, S.M.H.; Sandlobes, S.; Choi, P.; Herbig, M.; Zaefferer, S.; Raabe, D. Strain hardening by dynamic slip band refinement in a high-Mn lightweight steel. Acta Mater. 2016, 116, 188–199. [Google Scholar] [CrossRef]

- Lai, H.J.; Wan, C.M. The study of work hardening in Fe-Mn-Al-C alloys. J. Mater. Sci. 1989, 24, 3407–3412. [Google Scholar] [CrossRef]

- Choo, W.K.; Kim, J.H.; Yoon, J.C. Microstructural change in austenitic Fe-30.0wt%Mn-7.8wt%Al-1.3wt%C initiated by spinodal decomposition and its influence on mechanical properties. Acta Mater. 1997, 45, 4877–4885. [Google Scholar] [CrossRef]

- Wang, F.; Wang, S.T.; Chen, B.H.; Ma, W.; Jing, Q.; Zhang, X.Y.; Ma, M.Z.; Wang, Q.F.; Liu, R.P. Effect of Ti addition on the mechanical properties and microstructure of novel Al-rich low-density multi-principal-element alloys. J. Alloy Compd. 2022, 891, 162028. [Google Scholar] [CrossRef]

- Wan, P.; Kang, T.; Li, F.; Gao, P.F.; Zhang, L.; Zhao, Z.Z. Dynamic recrystallization behavior and microstructure evolution of low-density high-strength Fe-Mn-Al-C steel. J. Mater. Res. Technol. 2021, 15, 1059–1068. [Google Scholar] [CrossRef]

- Wang, H.; Gao, Z.Y.; Shi, Z.Y.; Xu, H.F.; Zhang, L.; Wu, G.L.; Wang, C.; Wang, C.Y.; Weng, Y.Q.; Cao, W.Q. High Temperature Deformation Behavior and Microstructure Evolution of Low-Density Steel Fe30Mn11Al1C Micro-Alloyed with Nb and V. Materials 2021, 14, 6555. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.X.; Wu, H.B.; He, J.S.; Yang, S.W.; Ding, C. Effect of κ-carbides on the mechanical properties and superparamagnetism of Fe-28Mn-11Al-1.5/1.7C-5Cr lightweight steels. Mater. Sci. Eng. 2022, 849, 143462. [Google Scholar] [CrossRef]

- Xing, J.; Hou, L.F.; Du, H.Y.; Liu, B.S.; Wei, Y.H. A New Explanation for the Effect of Dynamic Strain Aging on Negative Strain Rate Sensitivity in Fe-30Mn-9Al-1C Steel. Materials 2019, 12, 3426. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Tan, Y.; Malik, A.; Wang, Y.W.; Naqvi, S.Z.H.; Cheng, H.W.; Tian, J.B.; Meng, X.M. Dynamic Compressive Mechanical Behavior and Microstructure Evolution of Rolled Fe-28Mn-10Al-1.2C Low-Density Steel. Material 2022, 15, 3550. [Google Scholar] [CrossRef]

- Feng, Y.F.; Song, R.B.; Wang, Y.J.; Liu, M.; Li, H.; Liu, X.G. Aging hardening and precipitation behavior of Fe-31.6Mn-8.8Al-1.38C austenitic cast steel. Vacuum 2020, 181, 109662. [Google Scholar] [CrossRef]

- Wu, Z.Q.; Ding, H.; An, X.H.; Han, D.; Liao, X.Z. Influence of Al content on the strain-hardening behavior of aged low density Fe-Mn-Al-C steels with high Al content. Mater. Sci. Eng. 2015, 639, 187–191. [Google Scholar] [CrossRef]

- Wang, F.; An, Z.L.; Wang, S.T.; Ji, P.F.; Li, B.; Jing, Q.; Zhang, X.Y.; Ma, M.Z.; Wang, Q.F.; Liu, R.P. Effect of Different Hot Deformation Temperatures on the Microstructure and Mechanical Properties of High Al/Mn Lightweight Steel. J. Mater. Eng. Perform. 2022, 31, 3799–3810. [Google Scholar] [CrossRef]

- Ma, L.; Tang, Z.Y.; You, Z.Y.; Guan, G.F.; Ding, H.; Misra, D. Microstructure, Mechanical Properties and Deformation Behavior of Fe-28.7Mn-10.2Al-1.06C High Specific Strength Steel. Metals 2022, 12, 602. [Google Scholar] [CrossRef]

- Ren, P.; Chen, X.P.; Mei, L.; Nie, Y.Y.; Cao, W.Q.; Liu, Q. Intragranular brittle precipitates improve strain hardening capability of Fe-30Mn-11Al-1.2C low-density steel. Mater. Sci. Eng. 2020, 775, 138984. [Google Scholar] [CrossRef]

- Zhang, J.L.; Raabe, D.; Tasan, C.C. Designing duplex, ultrafine-grained Fe-Mn-Al-C steels by tuning phase transformation and recrystallization kinetics. Acta Mater. 2017, 141, 374–387. [Google Scholar] [CrossRef]

- Chen, X.P.; Xu, Y.P.; Ren, P.; Li, W.J.; Cao, W.Q.; Liu, Q. Aging hardening response and β-Mn transformation behavior of high carbon high manganese austenitic low-density Fe-30Mn-10Al-2C steel. Mater. Sci. Eng. 2017, 703, 167–172. [Google Scholar] [CrossRef]

- Kang, L.; Yuan, H.; Li, H.Y.; Ji, Y.F.; Liu, H.T.; Liu, G.M. Enhanced Mechanical Properties of Fe-Mn-Al-C Low Density Steel via Aging Treatment. Front. Mater. 2021, 8, 680776. [Google Scholar] [CrossRef]

- Zhang, J.L.; Jiang, Y.S.; Zheng, W.S.; Liu, Y.X.; Addad, A.; Ji, G.; Song, C.J.; Zhai, Q.J. Revisiting the formation mechanism of intragranular κ-carbide in austenite of a Fe-Mn-Al-Cr-C low-density steel. Scr. Mater. 2021, 199, 113836. [Google Scholar] [CrossRef]

- Ren, P.; Chen, X.P.; Wang, C.Y.; Zhou, Y.X.; Cao, W.Q.; Liu, Q. Evolution of microstructure, texture and mechanical properties of Fe-30Mn-11Al-1.2C low-density steel during cold rolling. Mater. Charact. 2021, 174, 111013. [Google Scholar] [CrossRef]

- Yao, M.J.; Welsch, E.; Ponge, D.; Haghighat, S.M.H.; Sandlobes, S.; Choi, P.; Herbig, M.; Bleskov, I.; Hickel, T.; Lipinska-Chwalek, M.; et al. Strengthening and strain hardening mechanisms in a precipitation-hardened high-Mn lightweight steel. Acta Mater. 2017, 140, 258–273. [Google Scholar] [CrossRef]

- Pang, J.Y.; Zhou, Z.M.; Zhao, Z.Z.; Tang, D.; Liang, J.H.; He, Q. Tensile Behavior and Deformation Mechanism of Fe-Mn-Al-C Low Density Steel with High Strength and High Plasticity. Metals 2019, 9, 897. [Google Scholar] [CrossRef]

- Kim, B.; Jeong, S.; Park, S.-J.; Moon, J.; Lee, C. Roles of (Fe, Mn)3Al Precipitates and MBIP on the Hot Ductility Behavior of Fe-30Mn-9Al-0.9C Lightweight Steels. Met. Mater. Int. 2019, 25, 1019–1026. [Google Scholar] [CrossRef]

- Wang, C.S.; Hwang, C.N.; Chao, C.G.; Liu, T.F. Phase transitions in an Fe-9Al-30Mn-2.0C alloy. Scr. Mater. 2007, 57, 809–812. [Google Scholar] [CrossRef]

- Kim, C.W.; Terner, M.; Lee, J.H.; Hong, H.U.; Moon, J.; Park, S.J.; Jang, J.H.; Lee, C.H.; Lee, B.H.; Lee, Y.J. Partitioning of C into κ-carbides by Si addition and its effect on the initial deformation mechanism of Fe-Mn-Al-C lightweight steels. J. Alloy Compd. 2019, 775, 554–564. [Google Scholar] [CrossRef]

- Yoo, J.D.; Hwang, S.W.; Park, K.T. Factors influencing the tensile behavior of a Fe-28Mn-9Al-0.8C steel. Mater. Sci. Eng. 2009, 508, 234–240. [Google Scholar] [CrossRef]

- Christian, H.; Christoffer, Z.; Tobias, I.; André, B.; Florian, T.; Bengt, H.; Weiping, H.; Wolfgang, B.; Dmitri, A.M. On the deformation behavior of κ-carbide-free and κ-carbide-containing high-Mn light-weight steel. Acta Mater. 2017, 122, 332–343. [Google Scholar]

- Park, S.W.; Park, J.Y.; Cho, K.M.; Jang, J.H.; Park, S.J.; Moon, J.; Lee, T.H.; Shin, J.H. Effect of Mn and C on Age Hardening of Fe-Mn-Al-C Lightweight Steels. Met. Mater. Int. 2019, 25, 683–696. [Google Scholar] [CrossRef]

- Ba, Q.N.; Song, R.B.; Zhou, N.P.; Pei, Z.Z.; Feng, Y.F.; Song, R.F. Revealing working hardening behavior and substructure evolutions of ultrahigh strength and enhanced wear resistance Fe-25Mn-7Al-1C steel treated by explosion processing. J. Mater. Sci. 2020, 55, 1256–1268. [Google Scholar] [CrossRef]

- Lee, J.; Park, S.; Kim, H.; Park, S.-J.; Lee, K.; Kim, M.-Y.; Madakashira, P.P.; Han, H.N. Simulation of κ-Carbide Precipitation Kinetics in Aged Low-Density Fe-Mn-Al-C Steels and Its Effects on Strengthening. Met. Mater. Int. 2018, 24, 702–710. [Google Scholar] [CrossRef]

- Feng, Y.F.; Song, R.B.; Peng, S.G.; Pei, Z.Z.; Song, R.F. Microstructures and Impact Wear Behavior of Al-Alloyed High-Mn Austenitic Cast Steel after Aging Treatment. J. Mater. Eng. Perform. 2019, 28, 4845–4855. [Google Scholar] [CrossRef]

- Feng, Y.F.; Song, R.B.; Liu, S.; Tan, Z.D.; Peng, S.G.; Dou, G.Y. Compression Deformation Behavior of a Fe-26Mn-7Al-1.3C Austenitic Steel after Precipitation-Hardened Treatment. Steel Res. Int. 2019, 90, 1800571. [Google Scholar] [CrossRef]

- Ren, P.; Chen, X.P.; Cao, Z.X.; Mei, L.; Li, W.J.; Cao, W.Q.; Liu, Q. Synergistic strengthening effect induced ultrahigh yield strength in lightweight Fe 30Mn 11Al-1.2C steel. Mater. Sci. Eng. 2019, 752, 160–166. [Google Scholar] [CrossRef]

- Chao, C.Y.; Liu, C.H. Effects of Mn contents on the microstructure and mechanical properties of the Fe-10Al-xMn-1.0C alloy. Mater. Trans. 2002, 43, 2635–2642. [Google Scholar] [CrossRef]

- Hwang, S.W.; Ji, J.N.; Park, K.T. Effects of Al addition on high strain rate deformation of fully austenitic high Mn steels. Mater. Sci. Eng. 2011, 528, 7267–7275. [Google Scholar] [CrossRef]

- Kim, S.H.; Kim, H.; Kim, N.J. Brittle intermetallic compound makes ultrastrong low-density steel with large ductility. Nature 2015, 518, 77–79. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.J.; Man, T.H.; Zhang, M.; Wang, Y.; Dong, H. δ-ferrite dynamic recrystallization behavior during thermal deformation in Fe-32Mn-11Al-0.9C low density steel. J. Mater. Res. Technol. 2022, 18, 1345–1357. [Google Scholar] [CrossRef]

- Xu, L.X.; Wu, H.B. Microstructural evolution and mechanical property optimization under solution treatment of an ultra-low carbon Fe-Mn-Al duplex steel. Mater. Sci. Eng. 2018, 738, 163–173. [Google Scholar] [CrossRef]

- Xu, L.X.; Wu, H.B.; Xie, B.S. An improved constitutive model for high-temperature flow behaviour of the Fe-Mn-Al duplex steel. Mater. Sci. Technol. 2018, 34, 229–241. [Google Scholar] [CrossRef]

- Yao, M. κ-Carbide in a High-Mn Light-Weight Steel: Precipitation, off-Stoichiometry and Deformation. Ph.D. Dissertation, Universitätsbibliothek der RWTH Aachen, Aachen, Germany, 2017. [Google Scholar]

- Yao, M.J.; Dey, P.; Seol, J.B.; Choi, P.; Raabe, D. Combined atom probe tomography and density functional theory investigation of the Al off-stoichiometry of κ-carbides in an austenitic Fe-Mn-Al-C low density steel. Acta Mater. 2016, 106, 229–238. [Google Scholar] [CrossRef]

- Sato, K.; Tagawa, K.; Inoue, Y. Spinodal decomposition and mechanical properties of an austenitic Fe-30wt.%Mn-9wt.%Al-0.9wt.%C alloy. Mater. Sci. Eng. 1989, 111, 45–50. [Google Scholar] [CrossRef]

- Cheng, W.-C.; Cheng, C.-Y.; Hsu, C.-W.; Laughlin, D.E. Phase transformation of the L12 phase to kappa-carbide after spinodal decomposition and ordering in an Fe-C-Mn-Al austenitic steel. Mater. Sci. Eng. 2015, 642, 128–135. [Google Scholar] [CrossRef]

- Han, K.H.; Yoon, J.C.; Choo, W.K. TEM evidence of modulated structure in Fe-Mn-Al-C austenitic alloys. Scr. Metall. 1986, 20, 33–36. [Google Scholar] [CrossRef]

- Sato, K.; Tagawa, K.; Inoue, Y. Age hardening of an Fe-30Mn-9Al-0.9C alloy by spinodal decomposition. Scr. Metall. 1988, 22, 899–902. [Google Scholar] [CrossRef]

- Wang, Z.W.; Lu, W.J.; Zhao, H.; He, J.Y.; Wang, K.; Zhou, B.C.; Ponge, D.; Raabe, D.; Li, Z.M. Formation mechanism of κ-carbides and deformation behavior in Si-alloyed FeMnAlC lightweight steels. Acta Mater. 2020, 198, 258–270. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Y.C.; Cheng, X.W.; Li, Z.Y.; Du, J.K.; Li, S.K. The effect of Ti-Mo-Nb on the microstructures and tensile properties of a Fe-Mn-Al-C austenitic steel. Mater. Sci. Eng. 2020, 780, 139220. [Google Scholar] [CrossRef]

- Zhang, J.L.; Hu, C.H.; Liu, Y.X.; Yang, Y.; Ji, G.; Song, C.J.; Zhai, Q.J. Precipitation strengthening of nano-scale TiC in a duplex low-density steel under near-rapid solidification. J. Iron Steel Res. Int. 2021, 28, 1141–1148. [Google Scholar] [CrossRef]

- Park, B.H.; Kim, C.W.; Lee, K.W.; Park, J.U.; Park, S.J.; Hong, H.U. Role of Nb Addition on Microstructural Stability and Deformation Behaviors of FeMnAlC Lightweight Steels at 400 degrees C. Metall. Mater. Trans. 2021, 52, 4191–4205. [Google Scholar] [CrossRef]

- Han, K.H. The microstructures and mechanical properties of an austenitic Nb-bearing Fe-Mn-Al-C alloy processed by controlled rolling. Mater. Sci. Eng. 2000, 279, 1–9. [Google Scholar] [CrossRef]

- Ma, T.; Gao, J.X.; Li, H.R.; Li, C.Q.; Zhang, H.C.; Li, Y.G. Microband-Induced Plasticity in a Nb Content Fe-28Mn-10Al-C Low Density Steel. Metals 2021, 11, 345. [Google Scholar] [CrossRef]

- Gao, S.; Yoshimura, T.; Mao, W.Q.; Bai, Y.; Gong, W.; Park, M.H.; Shibata, A.; Adachi, H.; Sato, M.; Tsuji, N. Tensile Deformation of Ultrafine-Grained Fe-Mn-Al-Ni-C Alloy Studied by in situ Synchrotron Radiation X-ray Diffraction. Crystals 2020, 10, 1115. [Google Scholar] [CrossRef]

- Kim, C.; Hong, H.-U.; Jang, J.H.; Lee, B.H.; Park, S.-J.; Moon, J.; Lee, C.-H. Reverse partitioning of Al from κ-carbide to the γ-matrix upon Ni addition and its strengthening effect in Fe-Mn-Al-C lightweight steel. Mater. Sci. Eng. 2021, 820, 141563. [Google Scholar] [CrossRef]

- Zargaran, A.; Trang, T.T.T.; Park, G.; Kim, N.J. κ-Carbide assisted nucleation of B2: A novel pathway to develop high specific strength steels. Acta Mater. 2021, 220, 117349. [Google Scholar] [CrossRef]

- Liu, Y.X.; Liu, M.X.; Zhang, J.L.; He, W.; Luo, Z.P.; Song, C.J.; Zhai, Q.J. Microstructure and mechanical properties of a Fe-28Mn-9Al-1.2C-(0,3,6,9)Cr austenitic low-density steel. Mater. Sci. Eng. 2021, 821, 141583. [Google Scholar] [CrossRef]

- Yoo, J.; Jo, M.C.; Kim, D.W.; Song, H.; Koo, M.; Sohn, S.S.; Lee, S. Effects of Cu addition on resistance to hydrogen embrittlement in 1 GPa-grade duplex lightweight steels. Acta Mater. 2020, 196, 370–383. [Google Scholar] [CrossRef]

- Liu, M.X.; Li, X.; Zhang, Y.H.; Song, C.J.; Zhai, Q.J. Multiphase precipitation and its strengthening mechanism in a V-containing austenite-based low density steel. Intermetallics 2021, 134, 107179. [Google Scholar] [CrossRef]

- Moon, J.; Ha, H.Y.; Park, S.J.; Lee, T.H.; Jang, J.H.; Lee, C.H.; Han, H.N.; Hong, H.U. Effect of Mo and Cr additions on the microstructure, mechanical properties and pitting corrosion resistance of austenitic Fe-30Mn-10.5Al-1.1C lightweight steels. J. Alloy Compd. 2019, 775, 1136–1146. [Google Scholar] [CrossRef]

- Zhang, G.F.; Ma, W.; Tang, Y.H.; Wang, F.; Zhang, X.Y.; Wang, Q.F.; Liu, R.P. Investigation on the microstructural evolution and mechanical properties of partially recrystallized Fe-27Mn-10Al-1.4C steel. Mater. Sci. Eng. 2022, 833, 142545. [Google Scholar] [CrossRef]

- Kwok, T.W.J.; Rahman, K.M.; Vorontsov, V.A.; Dye, D. Strengthening κ-carbide steels using residual dislocation content. Scr. Mater. 2022, 213, 114626. [Google Scholar] [CrossRef]

- Liu, M.X.; Li, X.; Zhang, Y.H.; Song, C.J.; Zhai, Q.J. Precipitation of κ-Carbide in a V-Containing Austenite-Based Lightweight Steel. Metall. Mater. Trans. 2022, 53, 1231–1243. [Google Scholar] [CrossRef]

- Saha, M.; Ponnuchamy, M.B.; Sadhasivam, M.; Mahata, C.; Vijayaragavan, G.; Gururaj, K.; Suresh, K.; Chandrasekaran, N.; Prabhu, D.; Kumbhar, K.; et al. Revealing the Localization of NiAl-Type Nano-Scale B2 Precipitates Within the BCC Phase of Ni Alloyed Low-Density FeMnAlC Steel. JOM 2022, 74, 3181–3190. [Google Scholar] [CrossRef]

- Peng, S.G.; Song, R.B.; Sun, T.; Pei, Z.Z.; Cai, C.H.; Feng, Y.F.; Tan, Z.D. Wear Behavior and Hardening Mechanism of Novel Lightweight Fe-25.1Mn-6.6Al-1.3C Steel Under Impact Abrasion Conditions. Tribol. Lett. 2016, 64, 13. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Y.C.; Cheng, X.W.; Li, Z.Y.; Gao, C.; Li, S.K. The effect of rolling and subsequent aging on microstructures and tensile properties of a Fe-Mn-Al-C austenitic steel. Mater. Sci. Eng. 2021, 822, 141683. [Google Scholar] [CrossRef]

- Lee, S.; Kang, S.H.; Nam, J.H.; Lee, S.M.; Seol, J.B.; Lee, Y.K. Effect of Tempering on the Microstructure and Tensile Properties of a Martensitic Medium-Mn Lightweight Steel. Metall. Mater. Trans. 2019, 50A, 2655–2664. [Google Scholar] [CrossRef]

- Byun, T.S. On the stress dependence of partial dislocation separation and deformation microstructure in austenitic stainless steels. Acta Mater. 2003, 51, 3063–3071. [Google Scholar] [CrossRef]

- Moon, J.; Park, S.-J.; Jang, J.H.; Lee, T.-H.; Lee, C.-H.; Hong, H.-U.; Suh, D.-W.; Kim, S.H.; Han, H.N.; Lee, B.H. Atomistic investigations of κ-carbide precipitation in austenitic Fe-Mn-Al-C lightweight steels and the effect of Mo addition. Scr. Mater. 2017, 127, 97–101. [Google Scholar] [CrossRef]

- Kim, K.W.; Park, S.J.; Moon, J.; Jang, J.H.; Ha, H.Y.; Lee, T.H.; Hong, H.U.; Lee, B.H.; Han, H.N.; Lee, Y.J.; et al. Characterization of microstructural evolution in austenitic Fe-Mn-Al-C lightweight steels with Cr content. Mater. Charact. 2020, 170, 110717. [Google Scholar] [CrossRef]

- Zhang, J.L.; Liu, Y.X.; Hu, C.H.; Jiang, Y.S.; Addad, A.; Ji, G.; Song, C.J.; Zhai, Q.J. The effect of Cr content on intragranular κ-carbide precipitation in Fe-Mn-Al-(Cr)-C low-density steels: A multiscale investigation. Mater. Charact. 2022, 186, 111801. [Google Scholar] [CrossRef]

- Yang, L.; Li, Z.M.; Li, X.; Zhang, Y.H.; Han, K.; Song, C.J.; Zhai, Q.J. An Enhanced Fe-28Mn-9Al-0.8C Lightweight Steel by Coprecipitation of Nanoscale Cu-Rich and κ-Carbide Particles. Steel Res. Int. 2020, 91, 1900665. [Google Scholar] [CrossRef]

- Rahnama, A.; Kotadia, H.; Sridhar, S. Effect of Ni alloying on the microstructural evolution and mechanical properties of two duplex light-weight steels during different annealing temperatures: Experiment and phase-field simulation. Acta Mater. 2017, 132, 627–643. [Google Scholar] [CrossRef]

- Kaar, S.; Krizan, D.; Schwabe, J.; Hofmann, H.; Hebesberger, T.; Commenda, C.; Samek, L. Influence of the Al and Mn content on the structure-property relationship in density reduced TRIP-assisted sheet steels. Mater. Sci. Eng. 2018, 735, 475–486. [Google Scholar] [CrossRef]

- Wang, W.L.; An, Z.J.; Luo, S.; Zhu, M.Y. In-situ observation of peritectic solidification of Fe-Mn-Al-C steel with medium manganese. J. Alloy Compd. 2022, 909, 164750. [Google Scholar] [CrossRef]

- Zhao, J.X.; Zhu, H.Y.; Wang, L.Q.; Song, M.M.; Li, J.L.; Xue, Z.L. Effect of CaO/Al2O3 ratio on desulphurization and non-metallic inclusions in low-density steel. Ironmak. Steelmak. 2022, 49, 302–310. [Google Scholar] [CrossRef]

- Ji, C.X.; Cui, Y.; Zeng, Z.; Tian, Z.H.; Zhao, C.L.; Zhu, G.S. Continuous Casting of High-Al Steel in Shougang Jingtang Steel Works. J. Iron Steel Res. Int. 2015, 22, 53–56. [Google Scholar] [CrossRef]

- Li, K.W.; Zhuang, C.L.; Liu, J.H.; Shen, S.B.; Ji, Y.L.; Han, Z.B. Smelting and Casting Technologies of Fe-25Mn-3Al-3Si Twinning Induced Plasticity Steel for Automobiles. J. Iron Steel Res. Int. 2015, 22, 75–79. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, M.X.; Zhang, J.K.; Yang, L.; Zhang, Y.H.; Song, C.J.; Zhai, Q.J. Effect of annealing treatment on microstructures and properties of austenite-based Fe-28Mn-9Al-0.8C lightweight steel with addition of Cu. China Foundry 2021, 18, 207–216. [Google Scholar] [CrossRef]

- Zhang, J.L.; Hu, C.H.; Zhang, Y.H.; Li, J.H.; Song, C.J.; Zhai, Q.J. Microstructures, mechanical properties and deformation of near-rapidly solidified low-density Fe-20Mn-9Al-1.2C-xCr steels. Mater. Des. 2020, 186, 108307. [Google Scholar] [CrossRef]

- Leonhardt, M.; Loser, W.; Lindenkreuz, H.G. Solidification kinetics and phase formation of undercooled eutectic Ni-Nb melts. Acta Mater. 1999, 47, 2961–2968. [Google Scholar] [CrossRef]

- Li, Y.P.; Song, R.B.; Wen, E.D.; Yang, F.Q. Hot Deformation and Dynamic Recrystallization Behavior of Austenite-Based Low-Density Fe-Mn-Al-C Steel. Acta Metall. Sin.-Engl. Lett. 2016, 29, 441–449. [Google Scholar] [CrossRef]

- Mohamadizadeh, A.; Zarei-Hanzaki, A.; Abedi, H.R.; Mehtonen, S.; Porter, D. Hot deformation characterization of duplex low-density steel through 3D processing map development. Mater. Charact. 2015, 107, 293–301. [Google Scholar] [CrossRef]

- Abedi, H.R.; Hanzaki, A.Z.; Liu, Z.; Xin, R.; Haghdadi, N.; Hodgson, P.D. Continuous dynamic recrystallization in low density steel. Mater. Des. 2017, 114, 55–64. [Google Scholar] [CrossRef]

- Wu, Z.Q.; Tang, Y.B.; Chen, W.; Lu, L.W.; Li, E.; Li, Z.C.; Ding, H. Exploring the influence of Al content on the hot deformation behavior of FeMn-Al-C steels through 3D processing map. Vacuum 2019, 159, 447–455. [Google Scholar] [CrossRef]

- Pierce, D.T.; Field, D.M.; Limmer, K.R.; Muth, T.; Sebeck, K.M. Hot deformation behavior of an industrially cast large grained low density austenitic steel. Mater. Sci. Eng. 2021, 825, 141785. [Google Scholar] [CrossRef]

- Zambrano, O.A.; Valdes, J.; Aguilar, Y.; Coronado, J.J.; Rodriguez, S.A.; Loge, R.E. Hot deformation of a Fe-Mn-Al-C steel susceptible of kappa-carbide precipitation. Mater. Sci. Eng. 2017, 689, 269–285. [Google Scholar] [CrossRef]

- Liu, D.G.; Ding, H.; Hu, X.; Han, D.; Cai, M.H. Dynamic recrystallization and precipitation behaviors during hot deformation of a κ-carbide-bearing multiphase Fe-11Mn-10Al-0.9C lightweight steel. Mater. Sci. Eng. 2020, 772, 138682. [Google Scholar] [CrossRef]

- Liu, D.G.; Ding, H.; Cai, M.H.; Han, D. Hot Deformation Behavior and Processing Map of a Fe-11Mn-10Al-0.9C Duplex Low-Density Steel Susceptible to kappa-Carbides. J. Mater. Eng. Perform. 2019, 28, 5116–5126. [Google Scholar] [CrossRef]

- Mozumder, Y.H.; Babu, K.A.; Saha, R.; Sarma, V.S.; Mandal, S. Dynamic microstructural evolution and recrystallization mechanism during hot deformation of intermetallic-hardened duplex lightweight steel. Mater. Sci. Eng. 2020, 788, 139613. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, H.; Liu, D.; Cai, M.; Zhang, Y. Austenite-Based Fe-Mn-Al-C Lightweight Steels: Research and Prospective. Metals 2022, 12, 1572. https://doi.org/10.3390/met12101572

Ding H, Liu D, Cai M, Zhang Y. Austenite-Based Fe-Mn-Al-C Lightweight Steels: Research and Prospective. Metals. 2022; 12(10):1572. https://doi.org/10.3390/met12101572

Chicago/Turabian StyleDing, Hua, Degang Liu, Minghui Cai, and Yu Zhang. 2022. "Austenite-Based Fe-Mn-Al-C Lightweight Steels: Research and Prospective" Metals 12, no. 10: 1572. https://doi.org/10.3390/met12101572

APA StyleDing, H., Liu, D., Cai, M., & Zhang, Y. (2022). Austenite-Based Fe-Mn-Al-C Lightweight Steels: Research and Prospective. Metals, 12(10), 1572. https://doi.org/10.3390/met12101572