Feasibility of Production of Multimaterial Metal Objects by Laser-Directed Energy Deposition

Abstract

1. Introduction

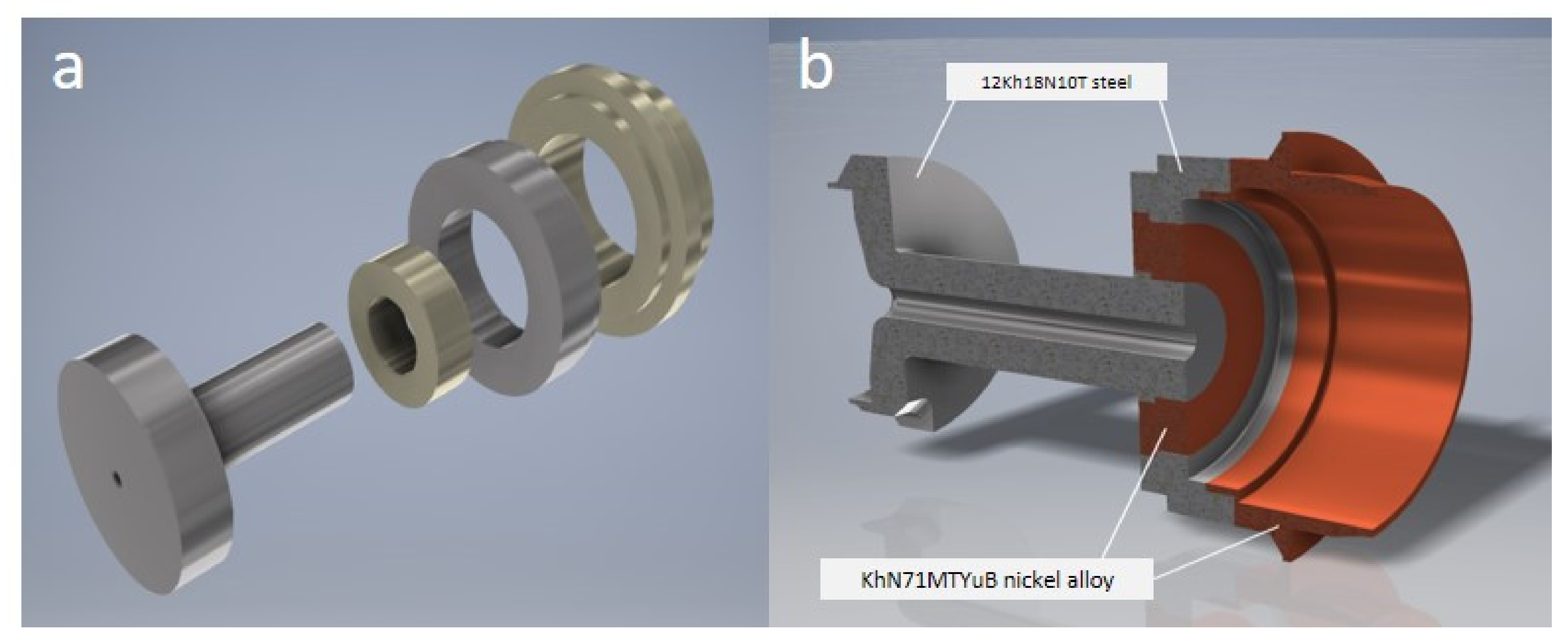

2. Materials and Methods

2.1. Raw Materials

2.2. LDED Equipment

2.3. Microstructure Analysis and Properties Evaluation

3. Results and Discussion

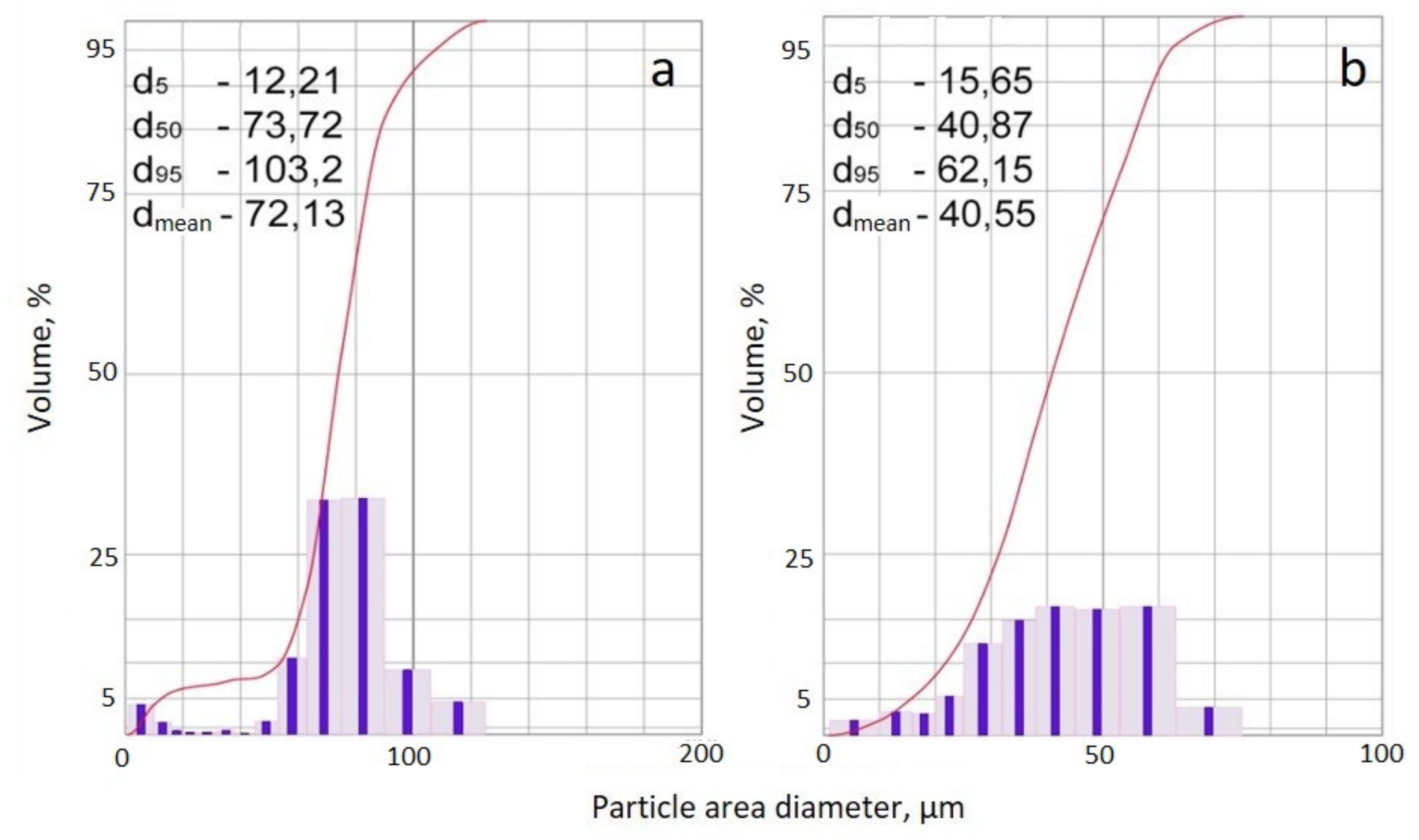

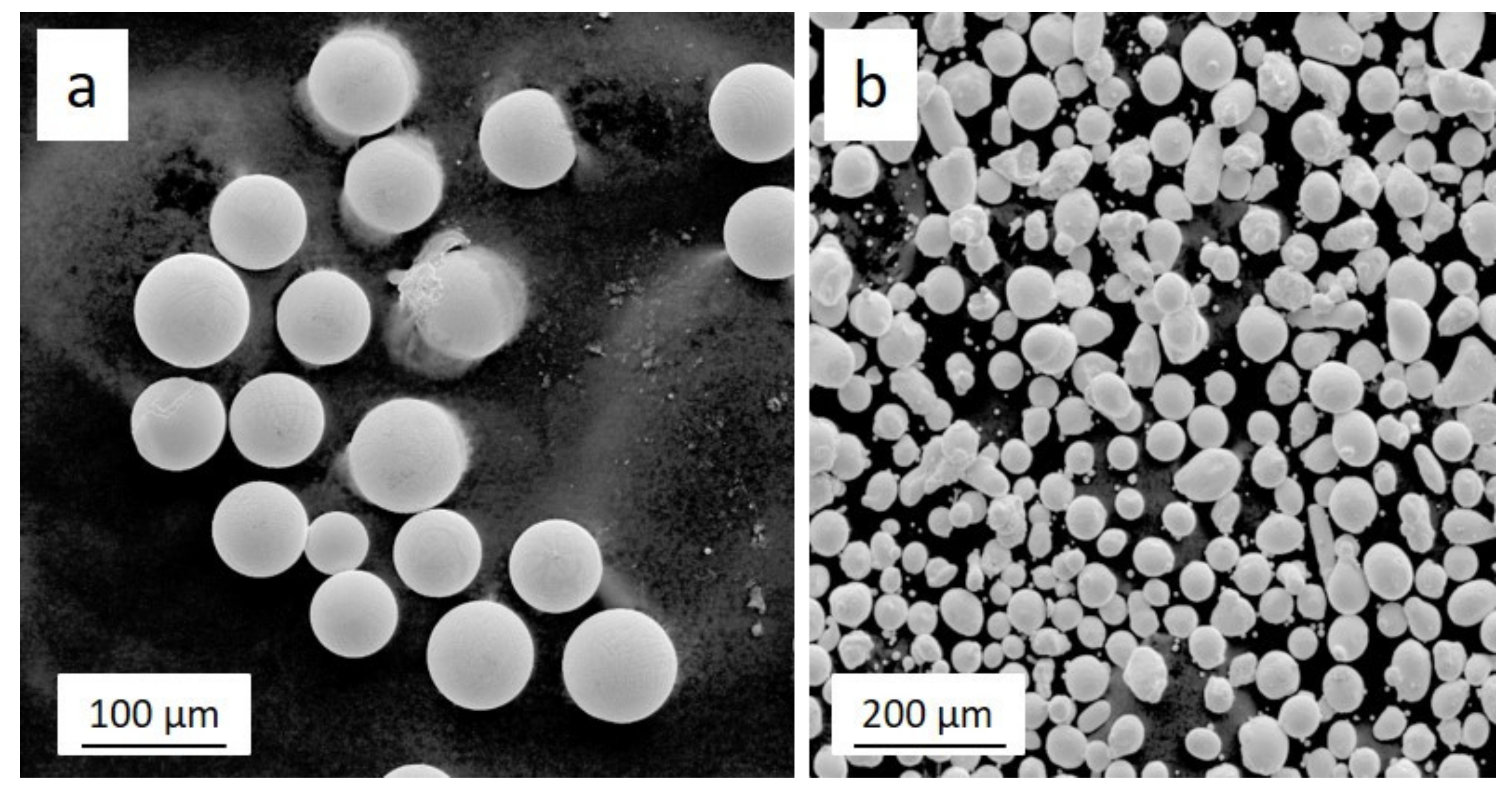

3.1. Granulometric and Morphological Analysis of the Raw Materials

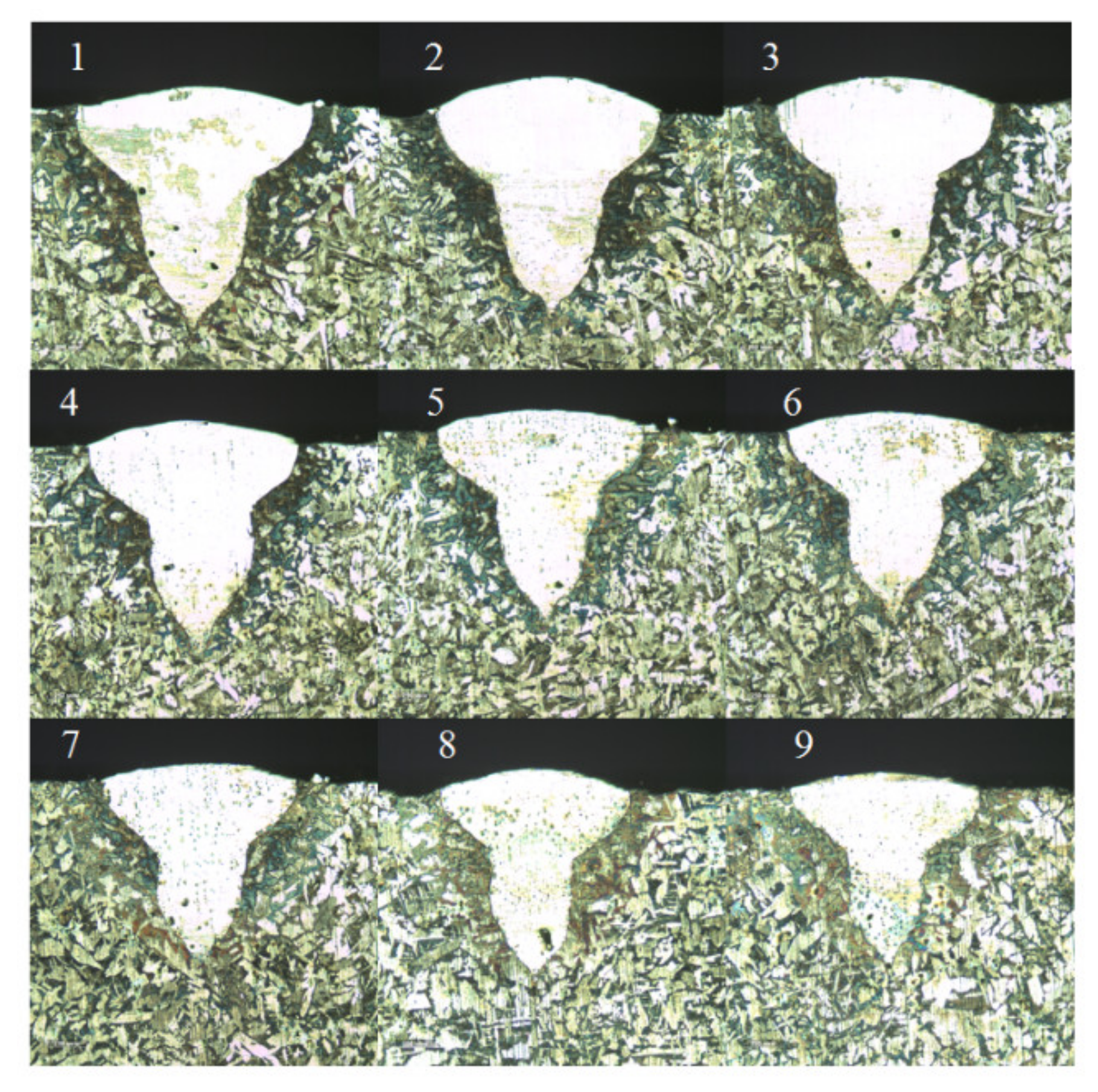

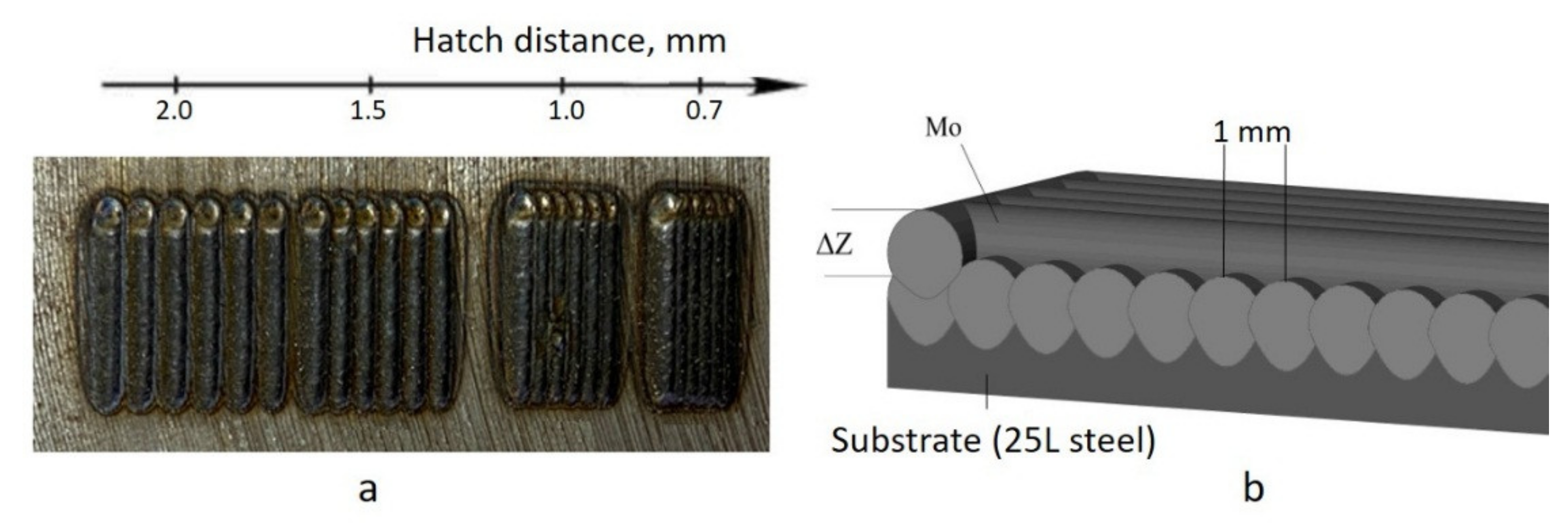

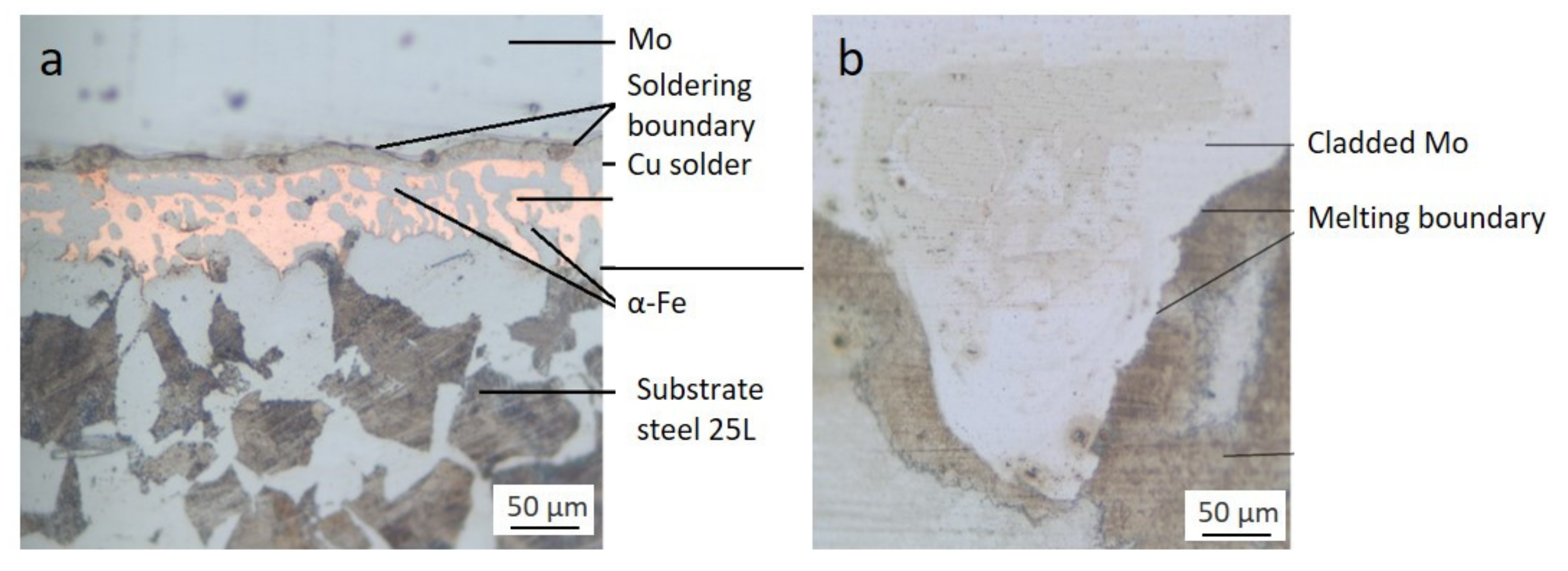

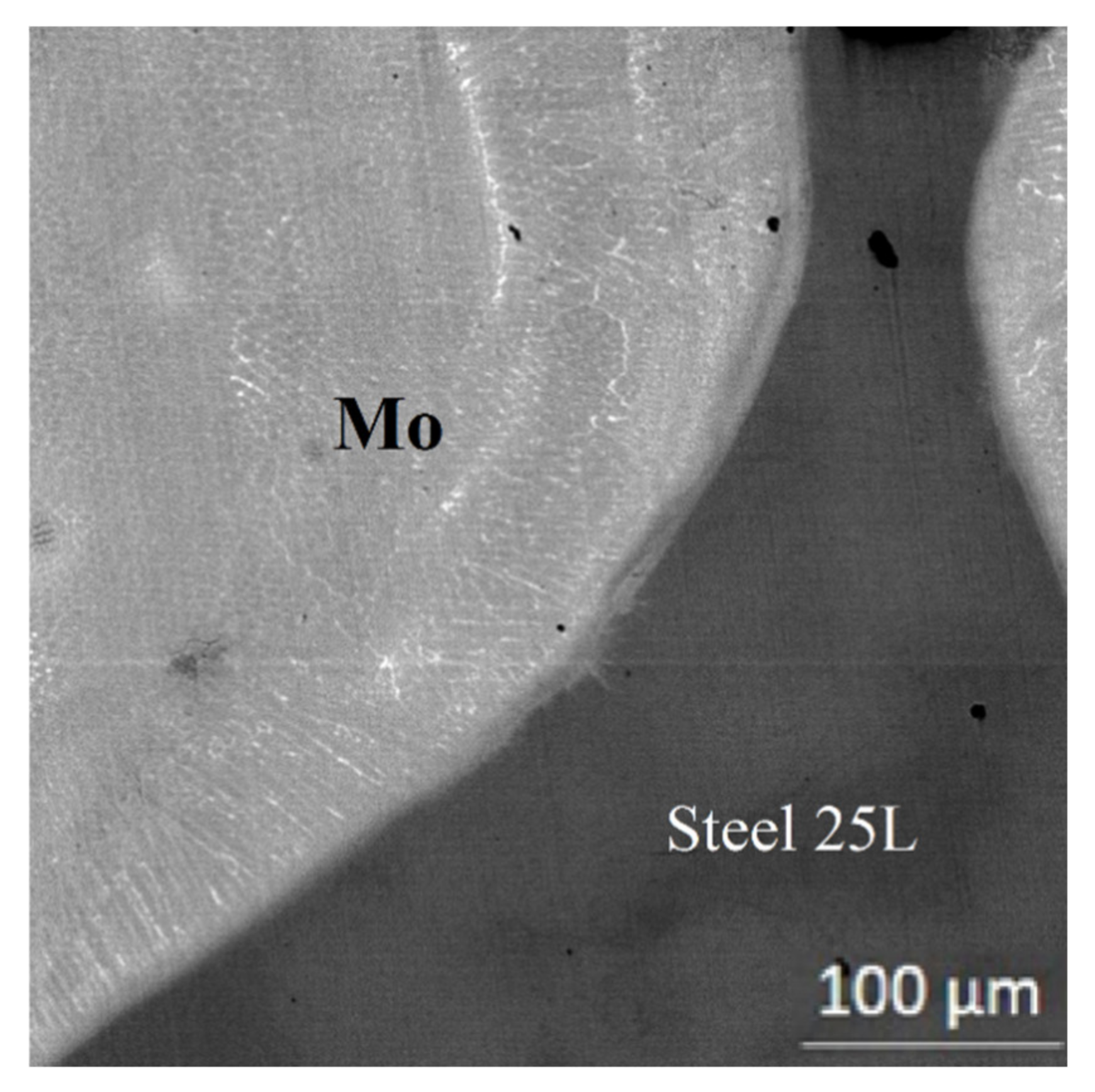

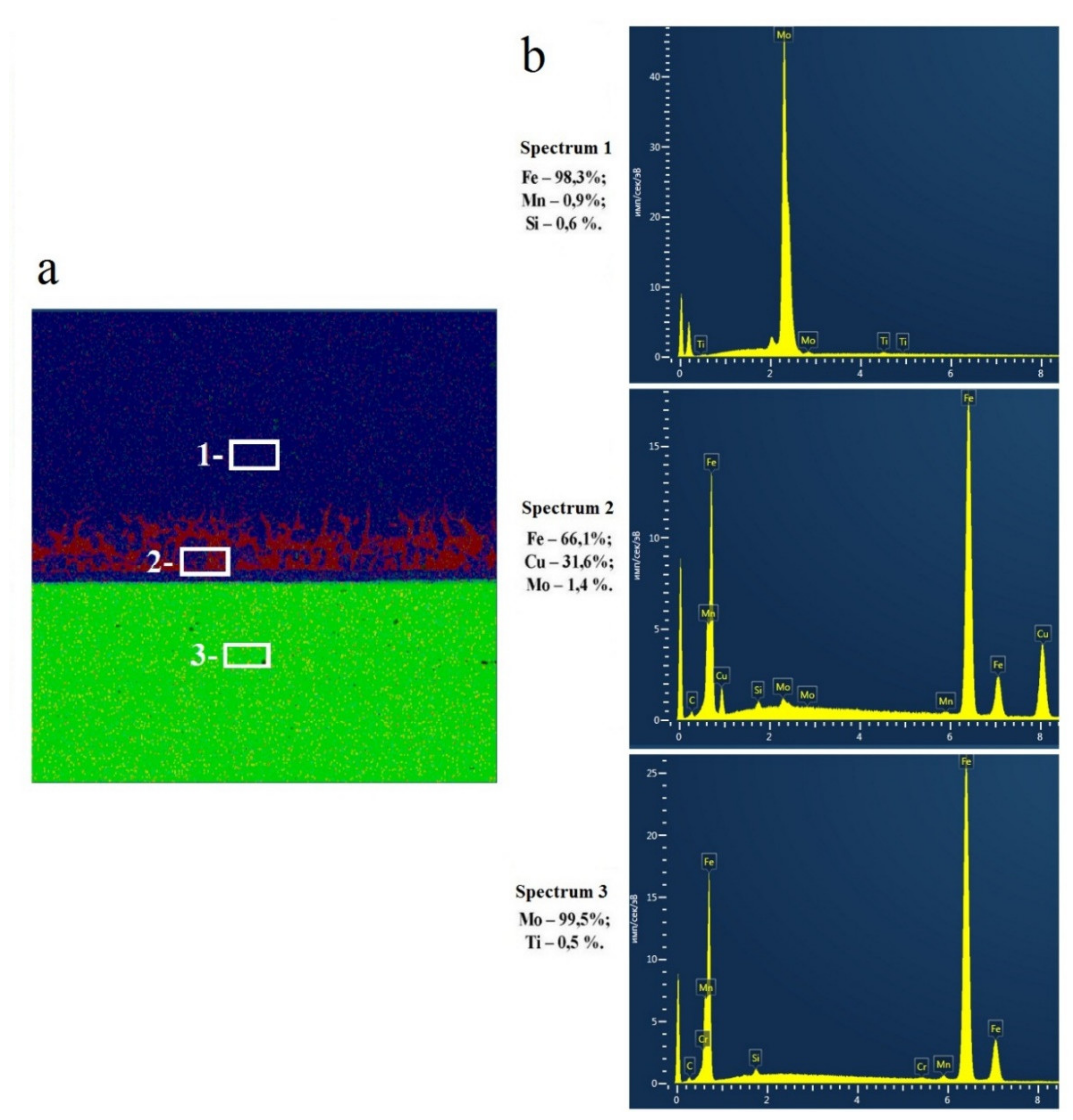

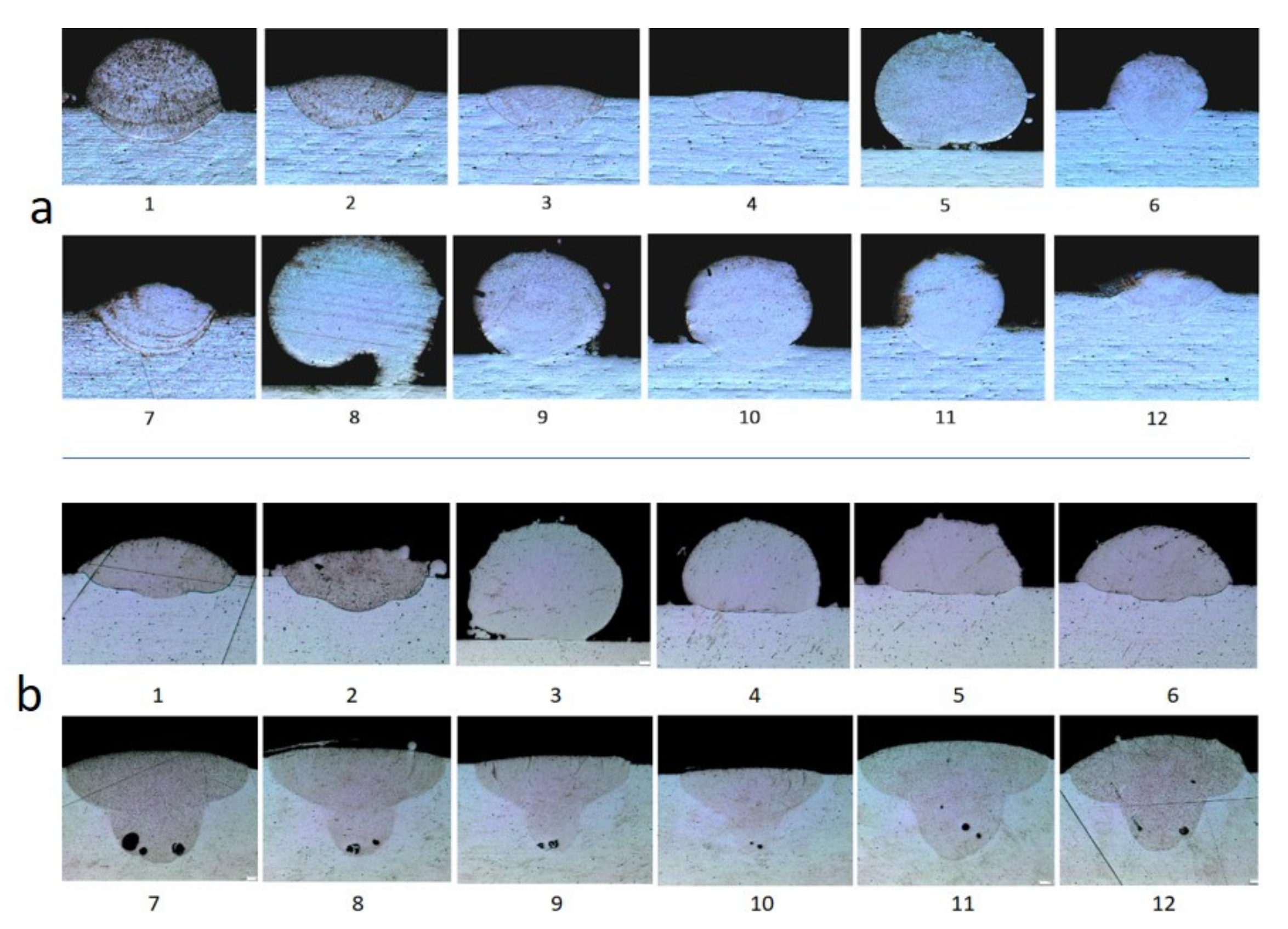

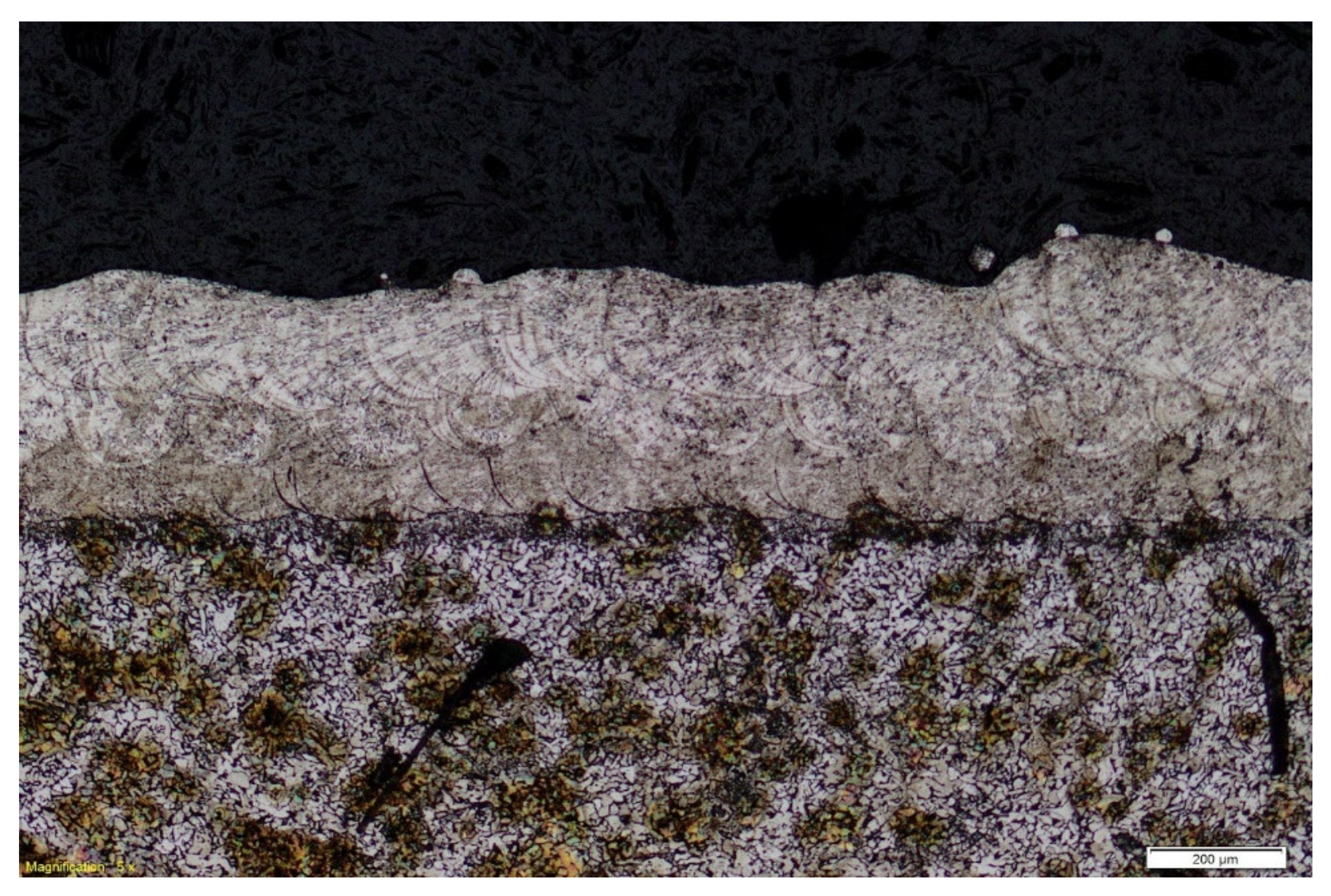

3.2. Study of the LDED Processing of the ‘Body’ Part from Molybdenum Powder on a Steel Substrate

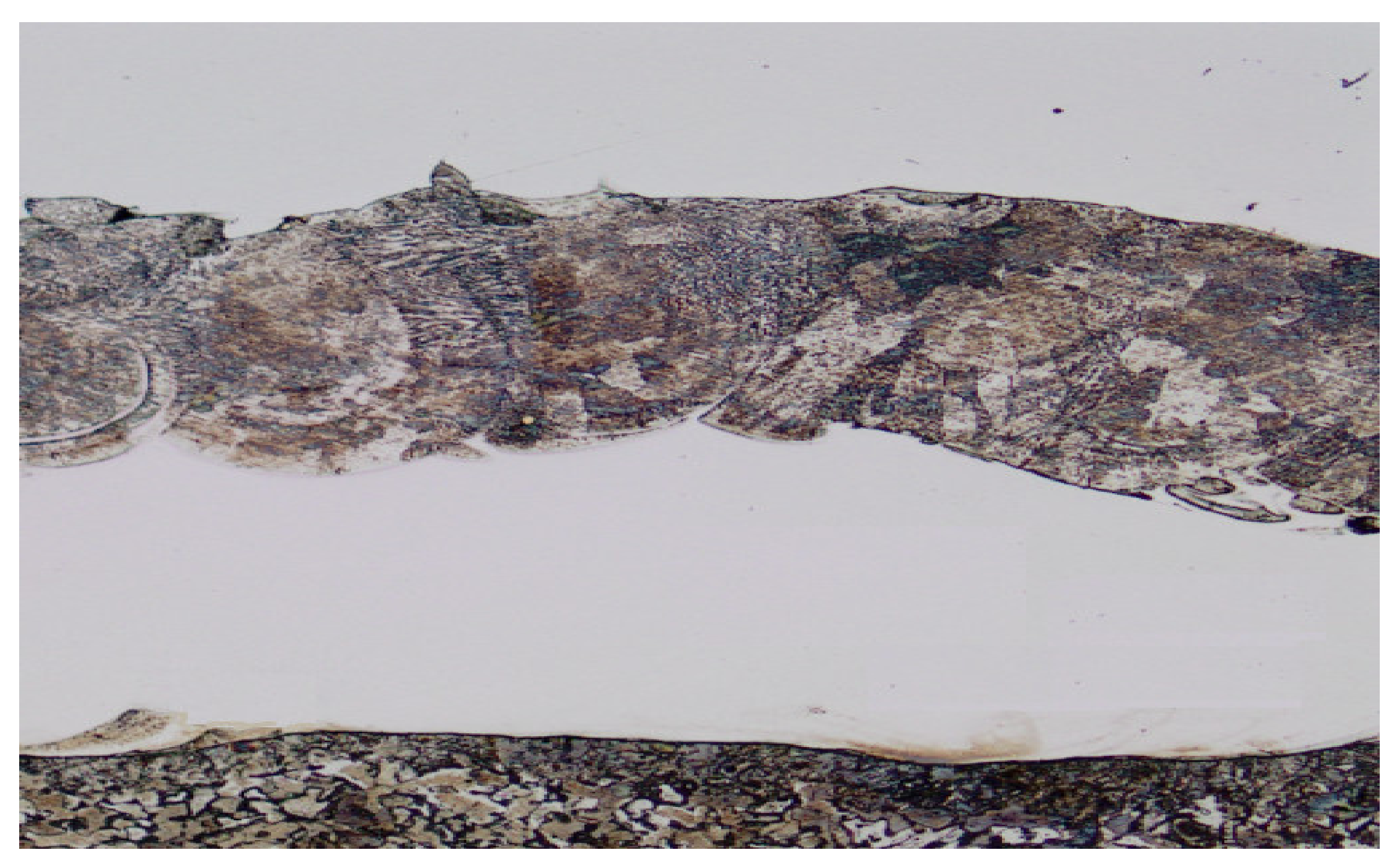

3.3. Study of the LDED Process of Manufacturing the ‘Electromagnet Case’ from Steel 12H18N10T and Alloy HN71MTYuB Powders

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- ASTMF2792-12a; Standard Terminology for Additive Manufacturing Technologies. ASTM International: West Conshohocken, PA, USA, 2012.

- ISO/ASTM 52900:2015. Additive Manufacturing—General Principles—Terminology. ISO/ASTM International: Geneva, Switzerland, 2015; p. 19. Available online: https://www.sis.se/api/document/preview/919975/ (accessed on 15 August 2015).

- Grigoriev, S.N.; Tarasova, T.V.; Gvozdeva, G.O. Optimization of parameters of laser surfacing of Al-Si system alloys. Met. Sci. Heat. Treat. 2015, 10, 15–20. [Google Scholar] [CrossRef]

- Tarasova, T. Additive Manufacturing, 1st ed.; INFRA-M: Moscow, Russia, 2019; p. 196. [Google Scholar]

- Grigoriev, S.N.; Tarasova, T.V. Possibilities of the technology of additive production for making complex-shape parts and depositing functional coatings from metallic powders. Met. Sci. Heat Treat. 2016, 57, 579–584. [Google Scholar] [CrossRef]

- Doubenskaia, M.; Pavlov, M.; Grigoriev, S.N.; Smurov, I. Definition of brightness temperature and restoration of true temperature in laser cladding using infrared camera. Surf. Coat. Technol. 2013, 220, 244–247. [Google Scholar] [CrossRef]

- Smurov, I.; Doubenskaia, M.; Grigoriev, S.N.; Nazarov, A. Optical Monitoring in Laser Cladding of Ti6Al4V. J. Therm. Spray Tech. 2012, 21, 1257–1362. [Google Scholar] [CrossRef]

- Pinkerton, A.J.; Lin, L. A Verified Model of the Behaviour of the Axial Powder Stream Concentration from a Coaxial Laser Cladding Nozzle. In Proceedings of the International Congress «ICALEO’2002», Scottsdale, AZ, USA, 14–17 October 2002. [Google Scholar]

- Yao, J.; Kovalenko, V.S.; Zhang, Q.; Anyakin, N.I.; Hu, X.; Wang, W. Modeling of Laser Cladding with Diode Laser Robotized System. Surf. Eng. Appl. Elect. 2010, 46, 82–86. [Google Scholar] [CrossRef]

- Zhang, Q.; Yao, J.; Kovalenko, V.S.; Hu, X.; Anyakin, N.I.; Kondrashev, P.V.; Zhuk, P.O.; Stepura, A.N. Productivity and quality of surfacing with coaxial supply of laser radiation and gas-powder mixture (jet). Surf. Eng. Appl. Elect. 2015, 51, 34–41. [Google Scholar] [CrossRef]

- Doubenskaia, M.; Pavlov, M.; Grigoriev, S.N.; Tikhonova, E.; Smurov, I. Comprehensive Optical Monitoring of Selective Laser Melting. J. Laser Micro Nanoen. 2012, 7, 236–243. [Google Scholar] [CrossRef]

- Khmyrov, R.S.; Grigoriev, S.N.; Okunkova, A.A.; Gusarov, A.V. On the possibility of selective laser melting of quartz glass. Phys. Procedia 2014, 56, 345–356. [Google Scholar] [CrossRef]

- Khmyrov, R.S.; Protasov, C.E.; Grigoriev, S.N.; Gusarov, A.V. Crack-free selective laser melting of silica glass: Single beads and monolayers on the substrate of the same material. Int. J. Adv. Manuf. Technol. 2016, 85, 1461–1469. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Bertrand, P.; Antonenkova, G.; Grigoriev, S.N.; Smurov, I. Use of track/layer morphology to develop functional parts by selective laser melting. J. Laser Appl. 2013, 25, 052003. [Google Scholar] [CrossRef]

- Gusarov, A.V.; Grigoriev, S.N.; Volosova, M.A.; Melnik, Y.A.; Laskin, A.; Kotoban, D.V.; Okunkova, A.A. On productivity of laser additive manufacturing. J. Mater. Process. Tech. 2018, 261, 213–232. [Google Scholar] [CrossRef]

- Liu, Z.H.; Zhang, D.K.; Sing, S.L.; Chua, S.K. Interfacial behavior of SLM parts in multi-material processing: Metallurgical diffusion between stainless steel 316L and C18400 copper alloy. Mater. Charact. 2014, 94, 116–125. [Google Scholar] [CrossRef]

- Yakovlev, A.; Trunova, E.; Grevy, D.; Pilloz, M.; Smurov, I. Direct production of 3D objects with functional gradation using a laser. J. Mater. Sci. 2005, 190, 15–24. [Google Scholar] [CrossRef]

- Sova, A.; Grigoriev, S.; Okunkova, A.; Smurov, I. Potential of cold gas dynamic spray as additive manufacturing technology. Int. J. Adv. Manuf. Technol. 2013, 69, 2269–2278. [Google Scholar] [CrossRef]

- Kotoban, D.; Grigoriev, S.; Okunkova, A.; Sova, A. Influence of a shape of single track on deposition efficiency of 316L stainless steel powder in cold spray. Surf. Coat. Technol. 2017, 309, 951–958. [Google Scholar] [CrossRef]

- Sova, A.; Okunkova, A.; Grigoriev, S.; Smurov, I. Velocity of the particles accelerated by a cold spray micronozzle: Experimental measurements and numerical simulation. J. Therm. Spray Technol. 2013, 22, 75–80. [Google Scholar] [CrossRef]

- Muller, P.; Mognol, P.; Hascoet, J.Y. Simulation and control of the process of direct laser deposition of powder for the manufacture of parts from functionally graded materials (FGM). J. Mat. Process. Techn. 2013, 213, 685–692. [Google Scholar] [CrossRef]

- Tarasova, T.V.; Gvozdeva, G.O.; Nowotny, S.; Ableyeva, R.R.; Dolzhikova, E.Y. Analysis of coaxial laser micro cladding processing conditions. ARPN J. Eng. Appl. Sci. 2018, 3, 1438–1442. [Google Scholar]

- Grigoriev, S.N.; Tarasova, T.V.; Gvozdeva, G.O.; Nowotny, S. Solidification behavior during laser microcladding of Al-Si alloys. Surf. Coat. Technol. 2015, 268, 303–309. [Google Scholar] [CrossRef]

- Gnyusov, S.F.; Orishich, A.M. Structural-phase state and mechanical properties of welded joints in laser welding of titanium and stainless steel. Ed. Tomsk. Polytech. Univ. 2012, 321, 94–99. [Google Scholar]

- Gomez, X.; Echeberria, J. Microstructure and mechanical properties of bimetallic pipes made of A210 carbon steel—Sanicro 28 superalloy. Mater. Sci. Eng. A Struct. Mater. 2003, 348, 180–191. [Google Scholar] [CrossRef]

- Weigl, M.; Schmidt, M. Modulated laser spot welding of dissimilar copper-aluminum joints. In Proceedings of the Conference 4M/ICOMM 2009, Karlsruhe, Germany, 23–25 September 2009. [Google Scholar]

- Vasiltsov, V.V.; Galushkin, M.G.; Ilyichev, I.N.; Misyurov, A.I.; Panchenko, V.Y. Layer-by-layer laser surfacing of metal powders: Analytical theory and experiment. Bull. Mosc. State Tech. Univ. 2012, 6, 69–77. [Google Scholar] [CrossRef][Green Version]

- Wang, W.; Sun, Q.; Wang, D.; Hou, J.; Qi, W.; Li, D.; Xie, L. Microstructure and Mechanical Properties of the ((CoCrFeNi)95Nb5)100−xMox High-Entropy Alloy Coating Fabricated under Different Laser Power. Metals 2021, 11, 1477. [Google Scholar] [CrossRef]

- Jiao, X.; Wang, J.; Wang, C.; Gong, Z.; Pang, X.; Xiong, S.M. Effect of laser scanning speed on microstructure and wear properties of T15M cladding coating fabricated by laser cladding technology. Opt. Lasers Eng. 2018, 110, 163–171. [Google Scholar] [CrossRef]

- Weng, F.; Yu, H.; Chen, C.; Liu, J.; Zhao, L.; Dai, J.; Zhao, Z. Effect of process parameters on the microstructure evolution and wear property of the laser cladding coatings on Ti-6Al-4V alloy. J. Alloys Compd. 2017, 692, 989–996. [Google Scholar] [CrossRef]

- Sun, M.; Pang, M. Defect Formation Mechanism and Performance Study of Laser Cladding Ni/Mo Composite Coating. Coatings 2021, 11, 1460. [Google Scholar] [CrossRef]

- Zheng, C.; Liu, Z.; Liu, Q.; Kong, Y.; Liu, C. Effect of Cr on Corrosion Behavior of Laser Cladding Ni-Cr-Mo Alloy Coatings in Sulfuric Acid Dew Point Corrosion Environment. Coatings 2022, 12, 421. [Google Scholar] [CrossRef]

- Li, W.; Guo, W.; Zhang, H.; Xu, H.; Chen, L.; Zeng, J.; Liu, B.; Ding, Z. Influence of Mo on the Microstructure and Corrosion Behavior of Laser Cladding FeCoCrNi High-Entropy Alloy Coatings. Entropy 2022, 24, 539. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.D.; Wang, H.M. High-temperature sliding wear behaviors of laser clad Mo2Ni3Si/NiSi metal silicide composite coatings. Appl. Surf. Sci. 2003, 214, 190–195. [Google Scholar] [CrossRef]

- Polema. Powders for Additive Manufacturing. Available online: http://www.polema.net (accessed on 25 December 2020).

- Tarasova, T.V.; Filatova, A.A.; Protasov, K.E. Methods for controlling the granulometric composition of powders of corrosion-resistant steels of domestic production. Bull. MSTU «STANKIN» 2016, 1, 53–58. [Google Scholar]

- Grigoriev, S.N.; Teleshevskii, V.I. Measurement problems in technological shaping processes. Meas. Tech. 2011, 54, 744–749. [Google Scholar] [CrossRef]

| Material | Elements Composition, % Mass. | ||

|---|---|---|---|

| Mo | Residual Elements 1, Total | O | |

| Mo powder | >99.9 | 0.1 | 0.025 |

| Material | Elements Composition, % Mass. | |||||

|---|---|---|---|---|---|---|

| Fe | C | Mn | Si | S | P | |

| 25L steel | balance | 0.22–0.30 | 0.45–0.90 | 0.20–0.52 | 0.05 | 0.05 |

| Material | Elements Composition, % Mass. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fe | C | Si | Ni | S | Cr | Ce | Mo | Nb | Ti | Al | B | Pb | |

| HN71MTYuB alloy | ≤2.0 | 0.03–0.07 | ≤0.5 | 71.034–78.46 | ≤0.007 | 13.0–16.0 | ≤0.01 | 2.8–3.2 | 1.9–2.2 | 2.35–2.75 | 1.45–1.8 | 0.011–0.013 | ≤0.001 |

| Material | Elements Composition, % Mass. | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Cr | Fe | Mn | Ni | P | S | Si | Ti | Cu | |

| PR-12H18N9T steel | ≤0.12 | 17.0–19.0 | balance | ≤2.0 | 8.0–9.5 | ≤0.035 | ≤0.02 | ≤0.8 | 1.9–2.2 | ≤0.3 |

| Track Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| Laser-scanning velocity, mm/min | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 |

| Hardness, HV | 430 | 436 | 428 | 421 | 425 | 418 | 423 | 421 | 426 |

| Deposition Technology | Hardness, HV | Density, g/cm3 |

|---|---|---|

| Vacuum brazing (t = 1120 °C, τ = 10 min) | 182–192 | 10.0–10.2 |

| LDED | 412–443 | 10.0–10.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Metel, A.S.; Tarasova, T.; Skorobogatov, A.; Podrabinnik, P.; Melnik, Y.; Grigoriev, S.N. Feasibility of Production of Multimaterial Metal Objects by Laser-Directed Energy Deposition. Metals 2022, 12, 1566. https://doi.org/10.3390/met12101566

Metel AS, Tarasova T, Skorobogatov A, Podrabinnik P, Melnik Y, Grigoriev SN. Feasibility of Production of Multimaterial Metal Objects by Laser-Directed Energy Deposition. Metals. 2022; 12(10):1566. https://doi.org/10.3390/met12101566

Chicago/Turabian StyleMetel, Alexander S., Tatiana Tarasova, Andrey Skorobogatov, Pavel Podrabinnik, Yury Melnik, and Sergey N. Grigoriev. 2022. "Feasibility of Production of Multimaterial Metal Objects by Laser-Directed Energy Deposition" Metals 12, no. 10: 1566. https://doi.org/10.3390/met12101566

APA StyleMetel, A. S., Tarasova, T., Skorobogatov, A., Podrabinnik, P., Melnik, Y., & Grigoriev, S. N. (2022). Feasibility of Production of Multimaterial Metal Objects by Laser-Directed Energy Deposition. Metals, 12(10), 1566. https://doi.org/10.3390/met12101566