Microstructure Comparison for AlSn20Cu Antifriction Alloys Prepared by Semi-Continuous Casting, Semi-Solid Die Casting, and Spray Forming

Abstract

1. Introduction

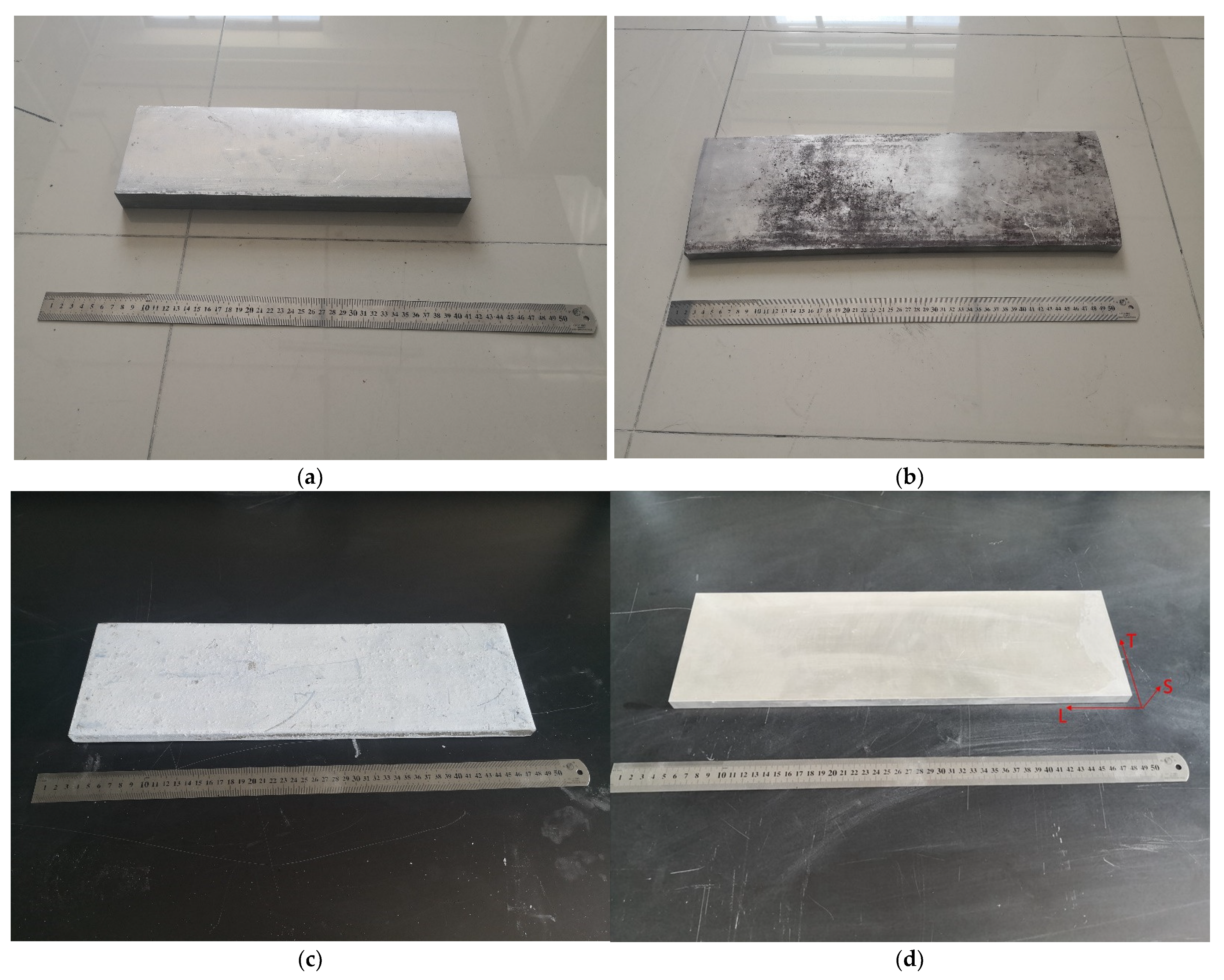

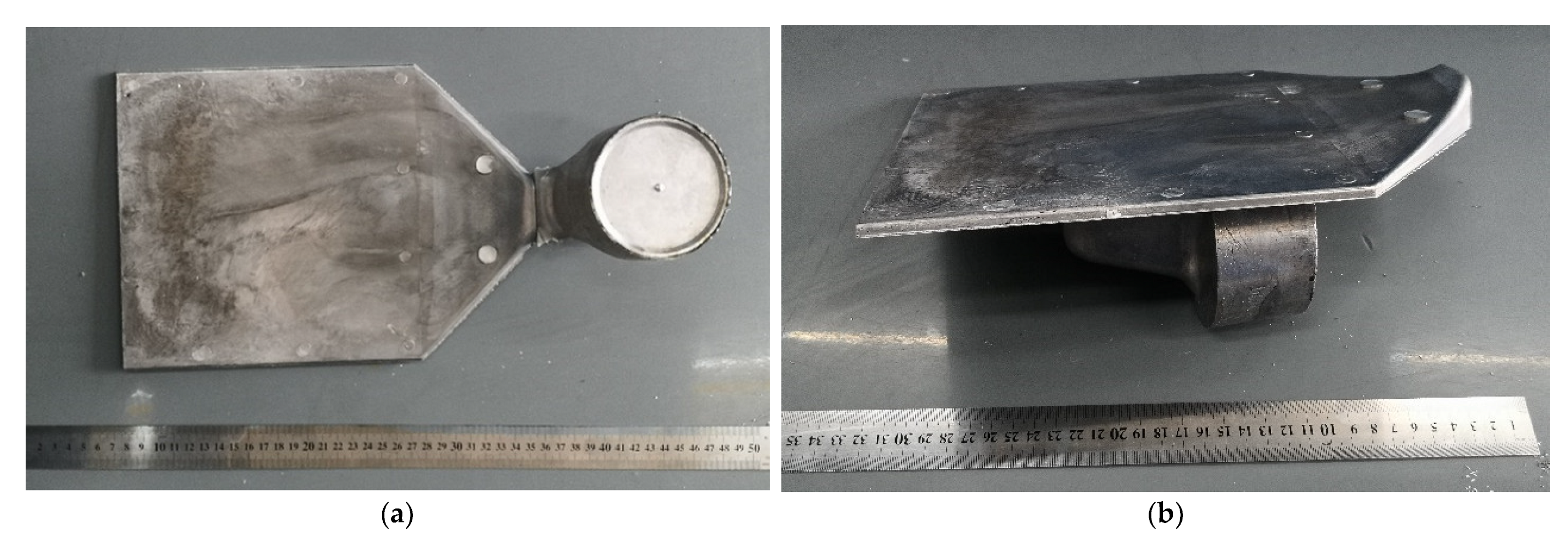

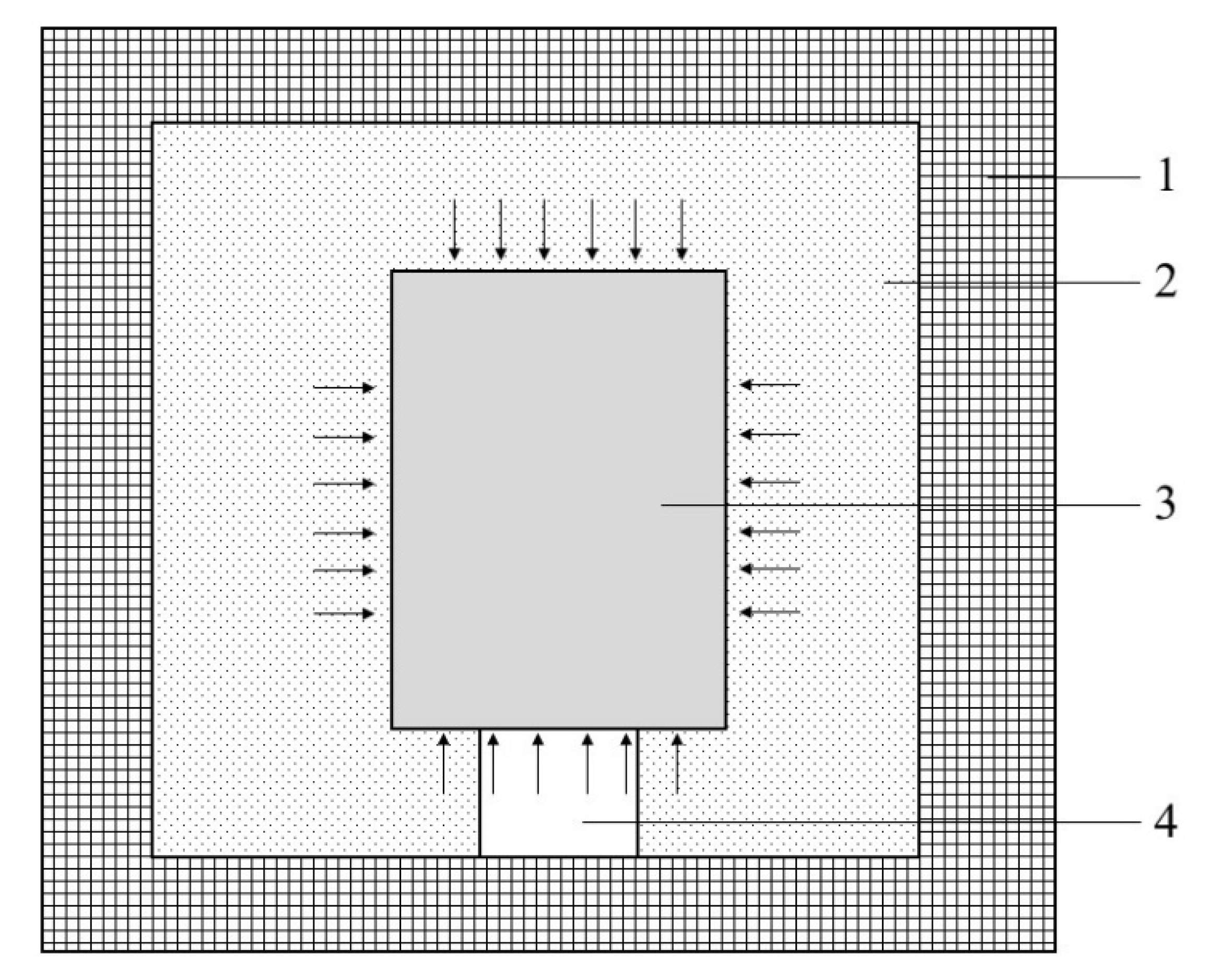

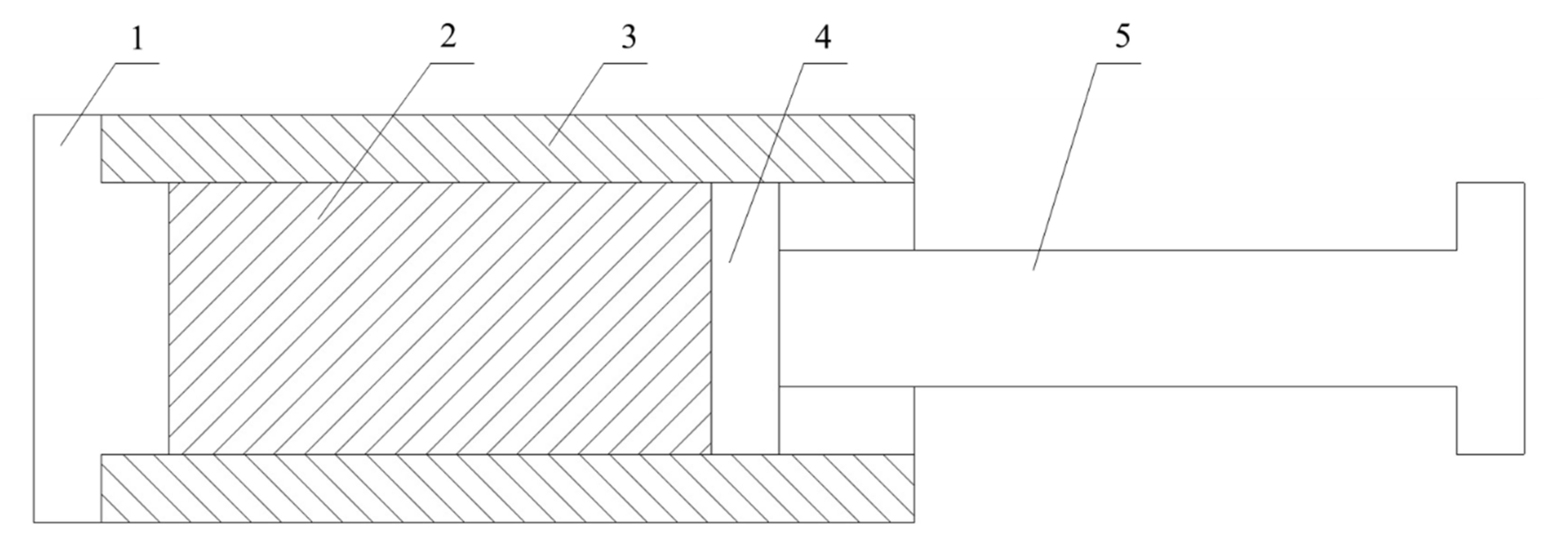

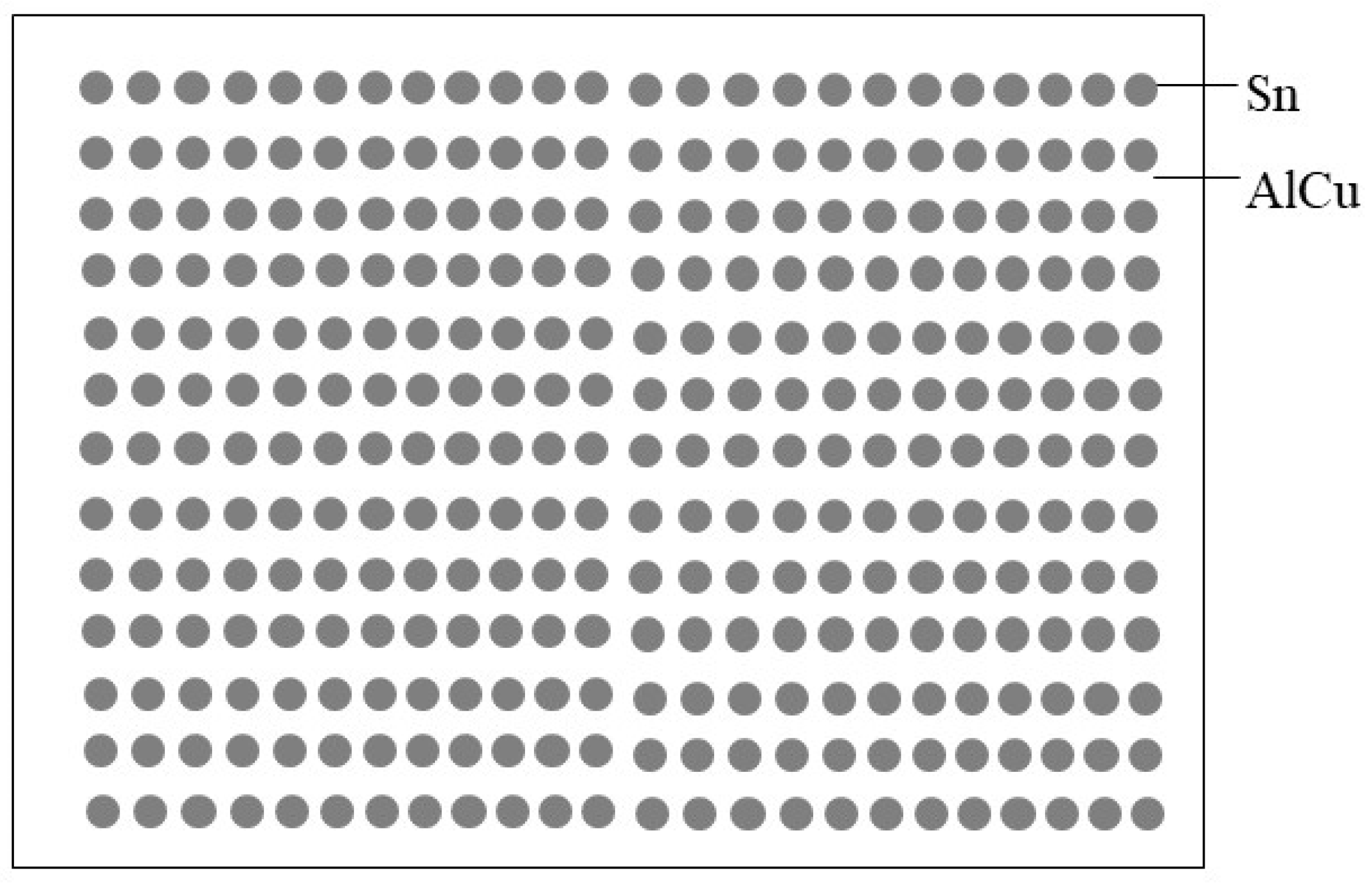

2. Materials and Methods

3. Results

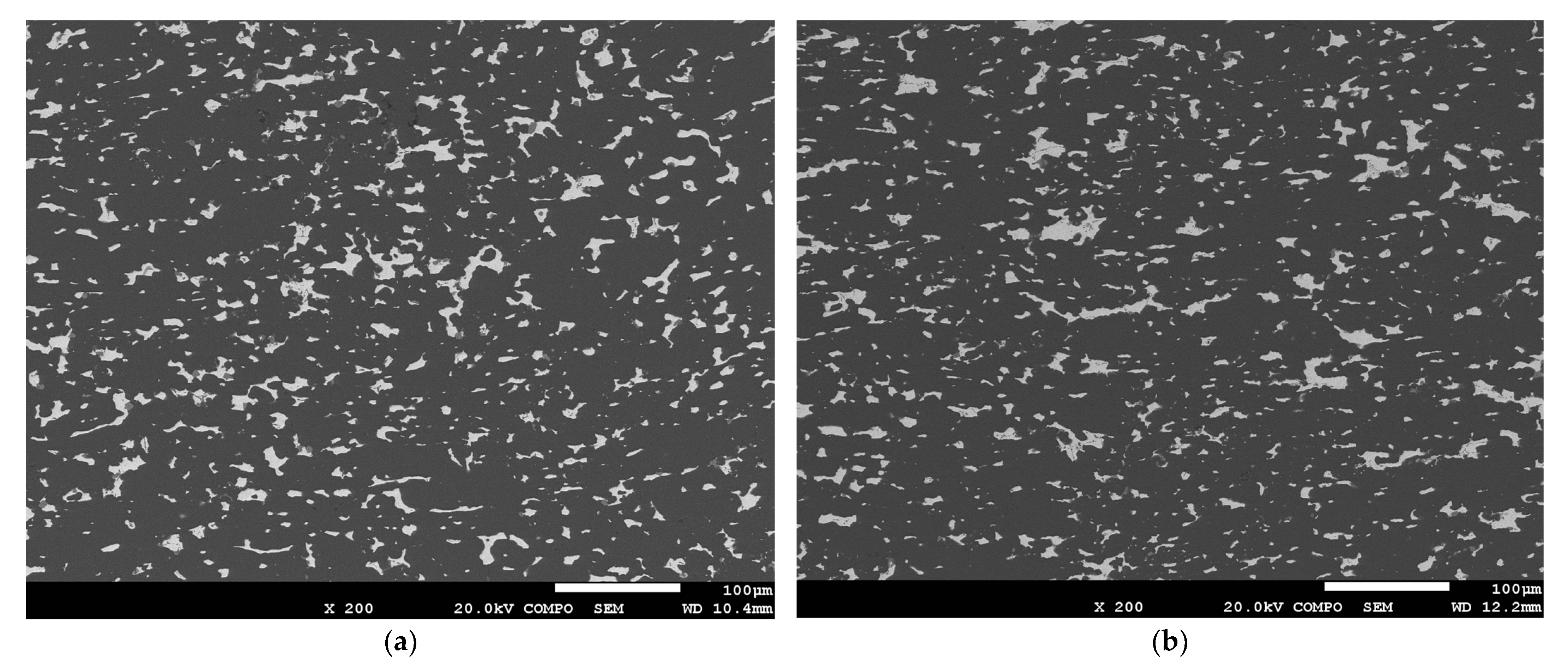

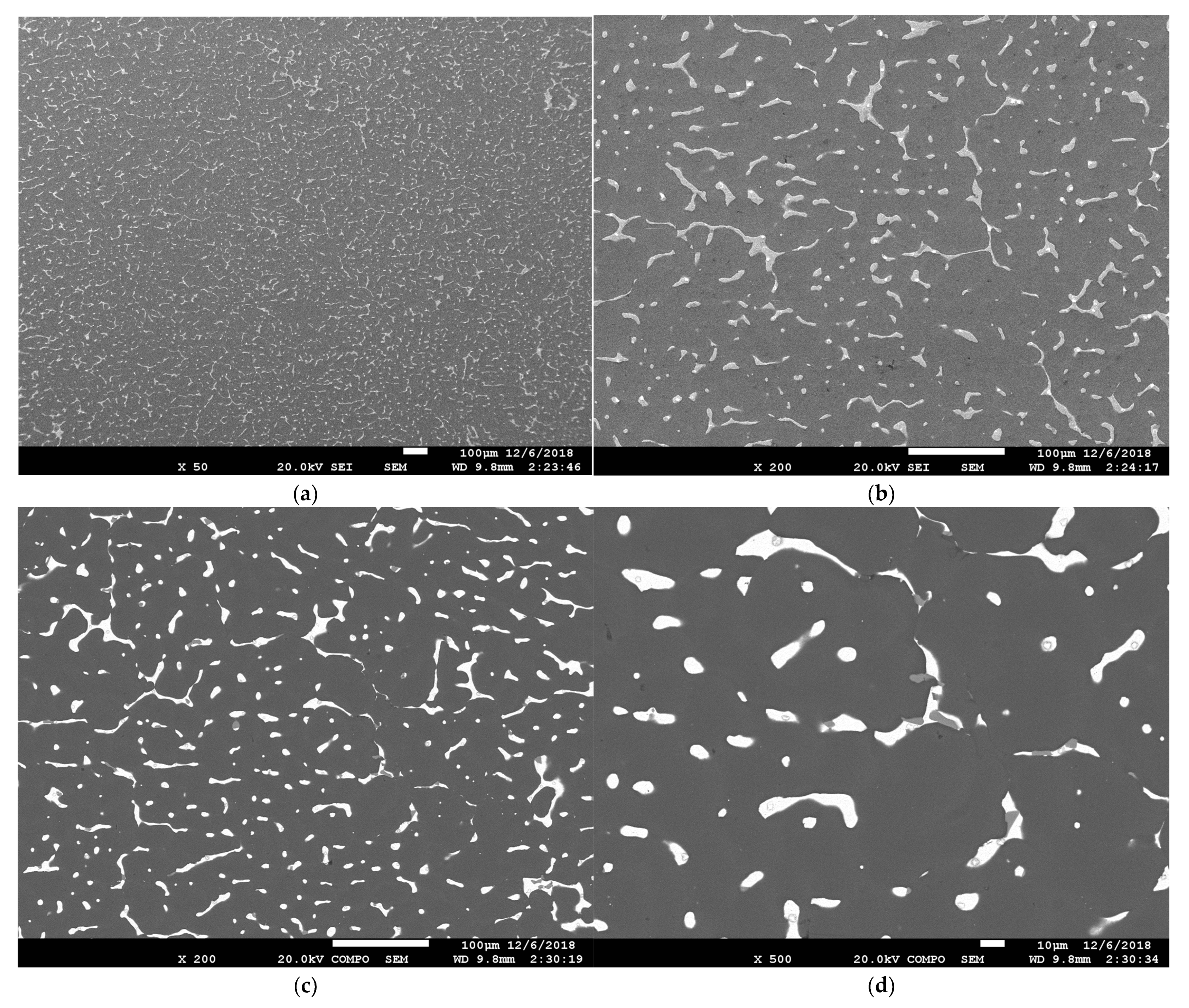

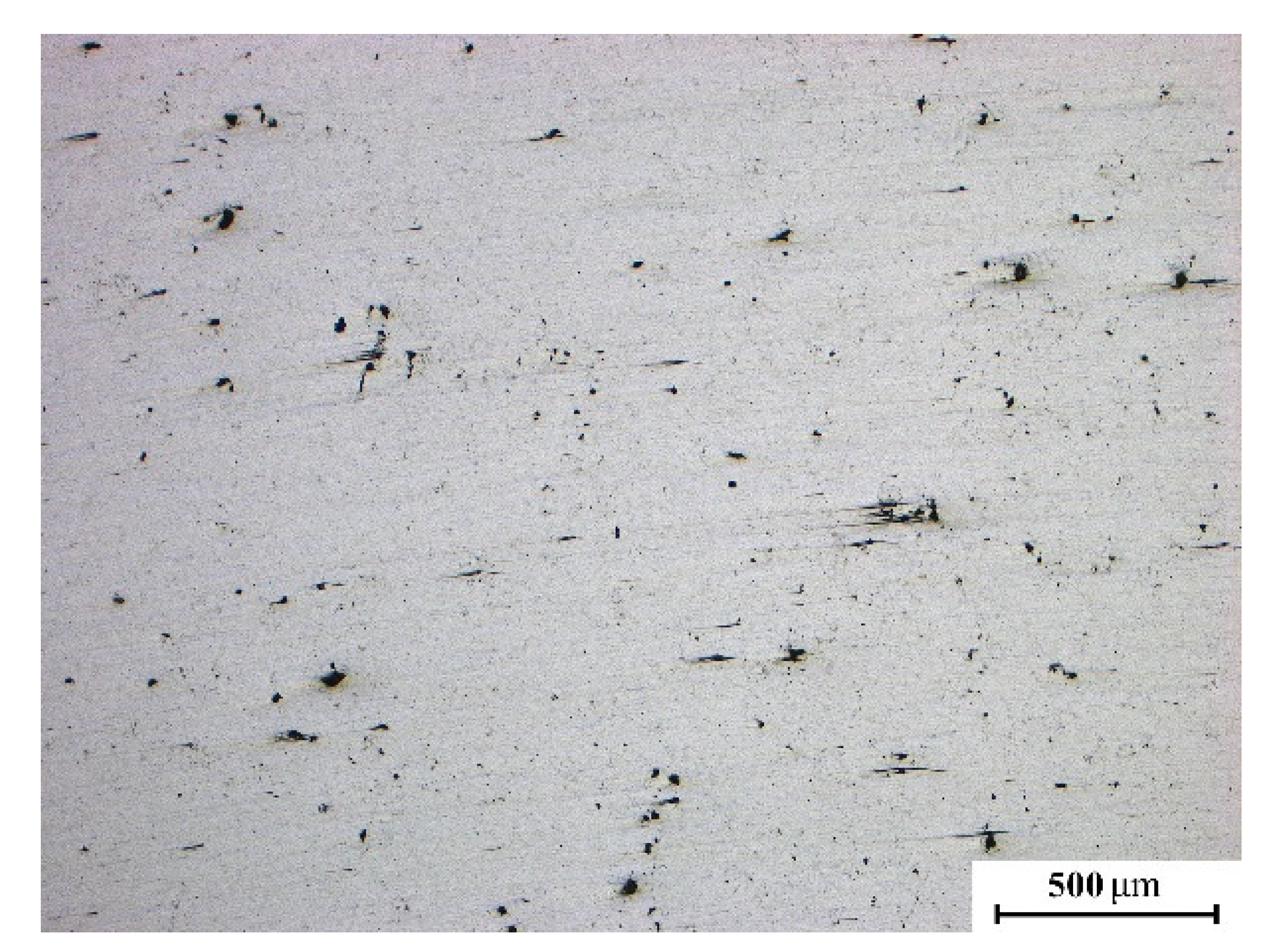

3.1. Semi-Continuous Casting

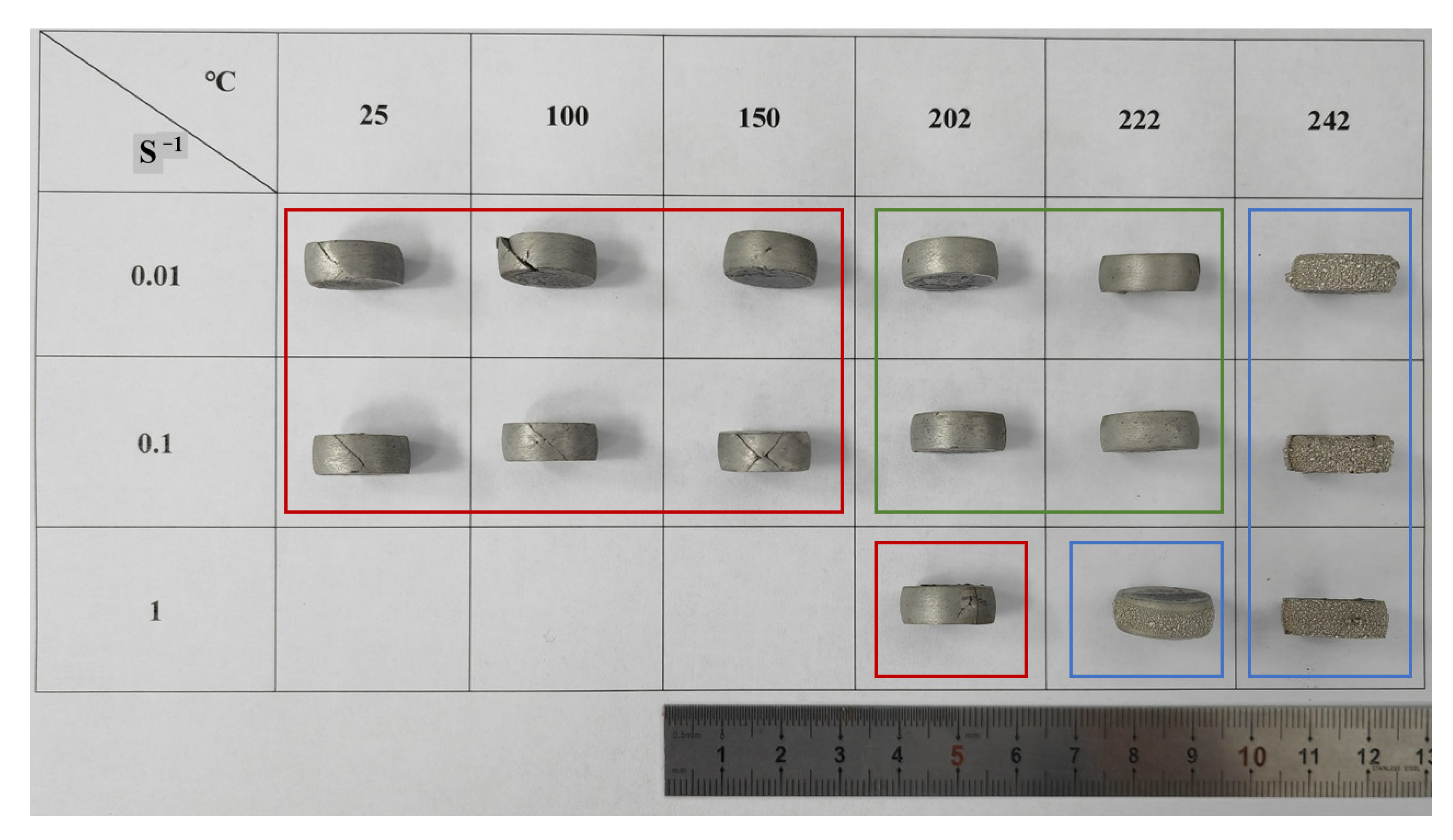

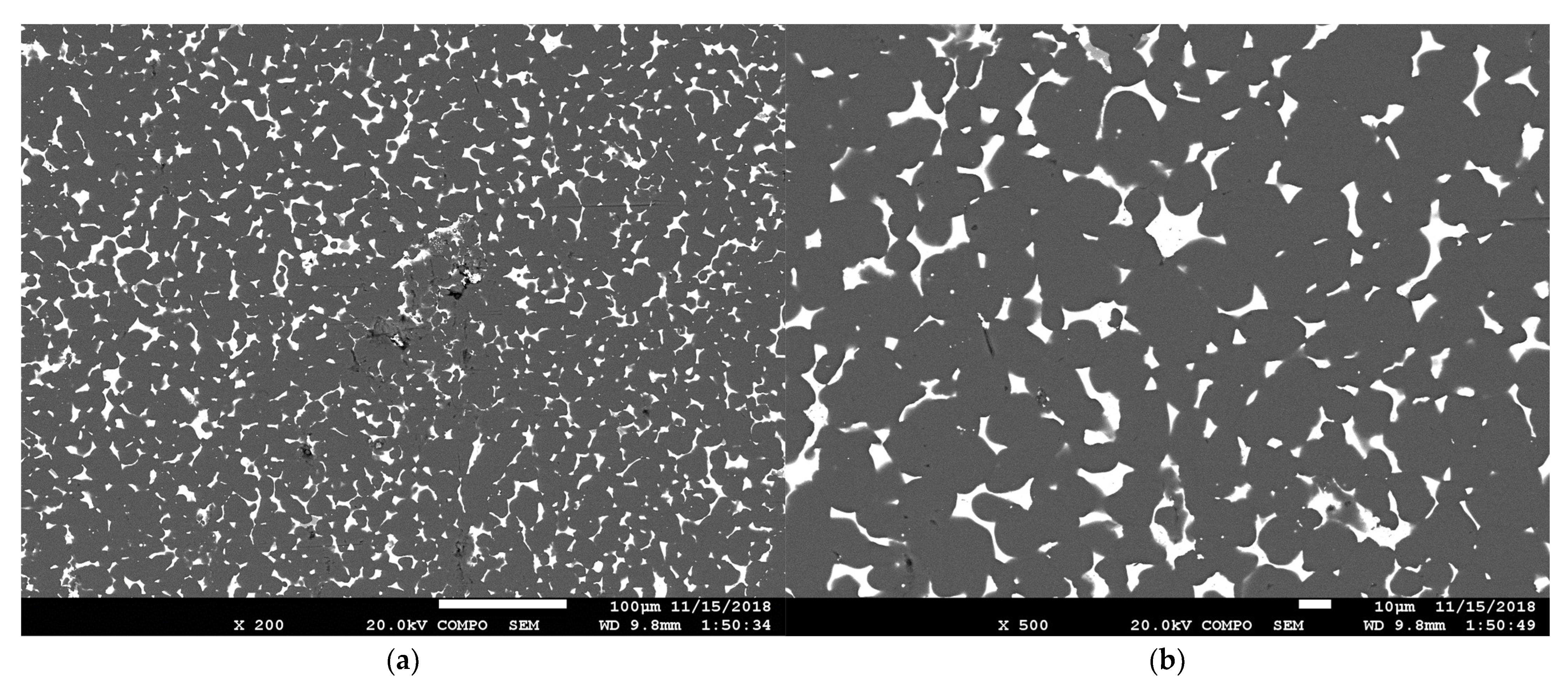

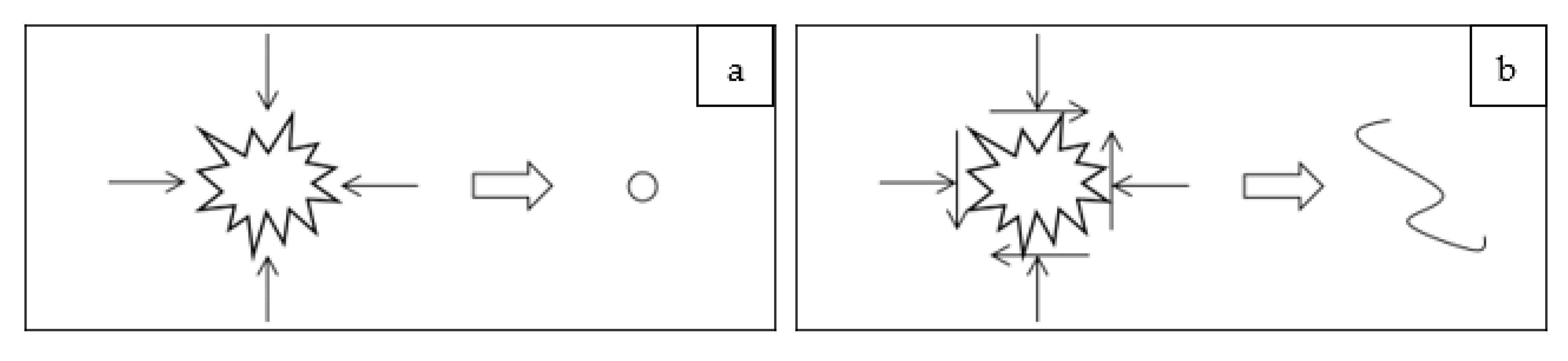

3.2. Semi-Solid Die Casting

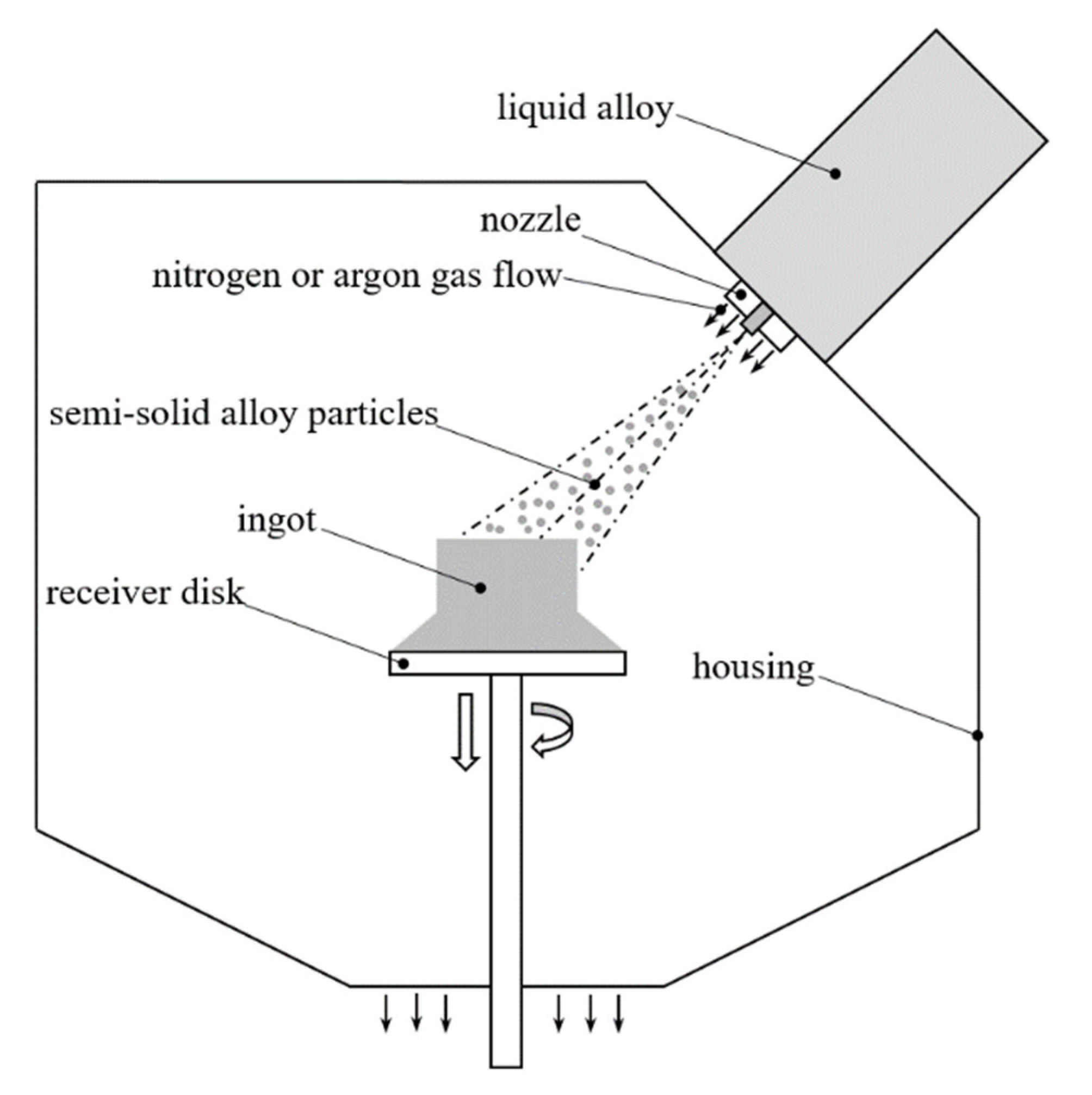

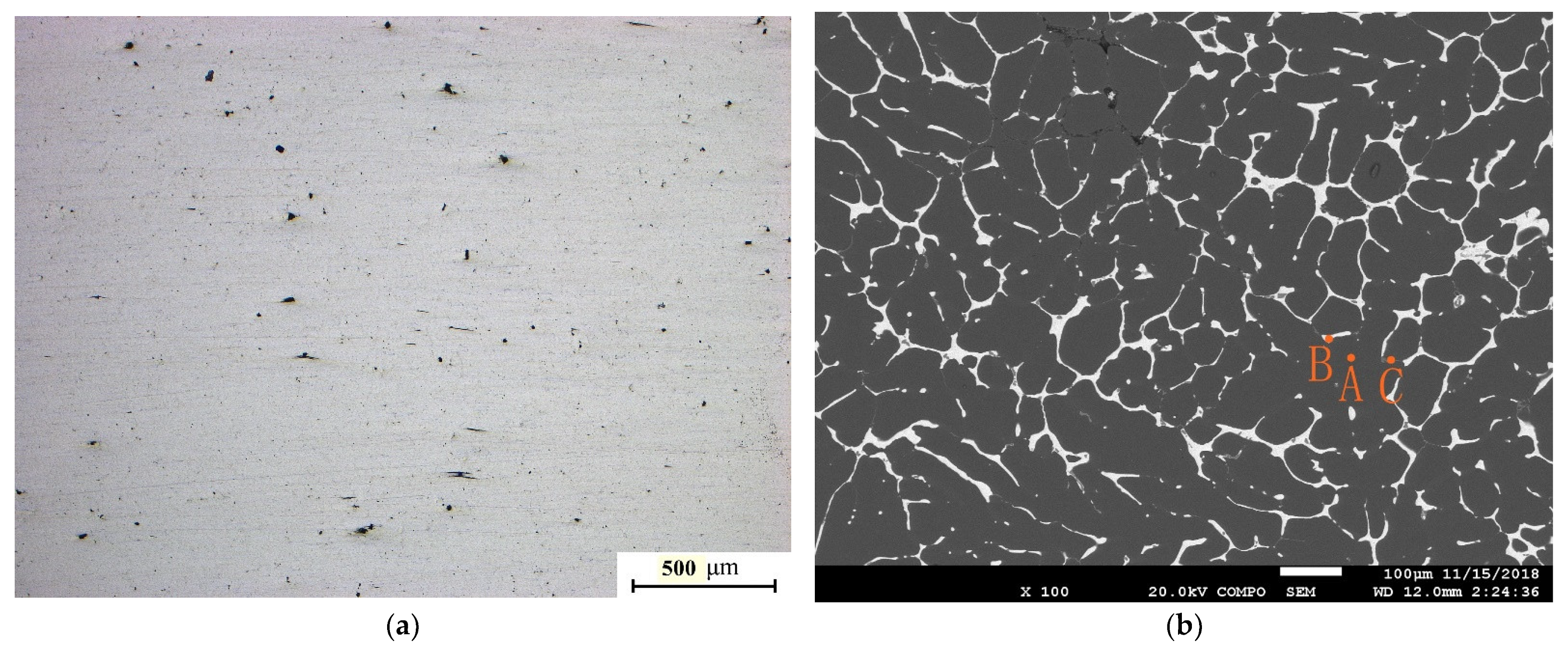

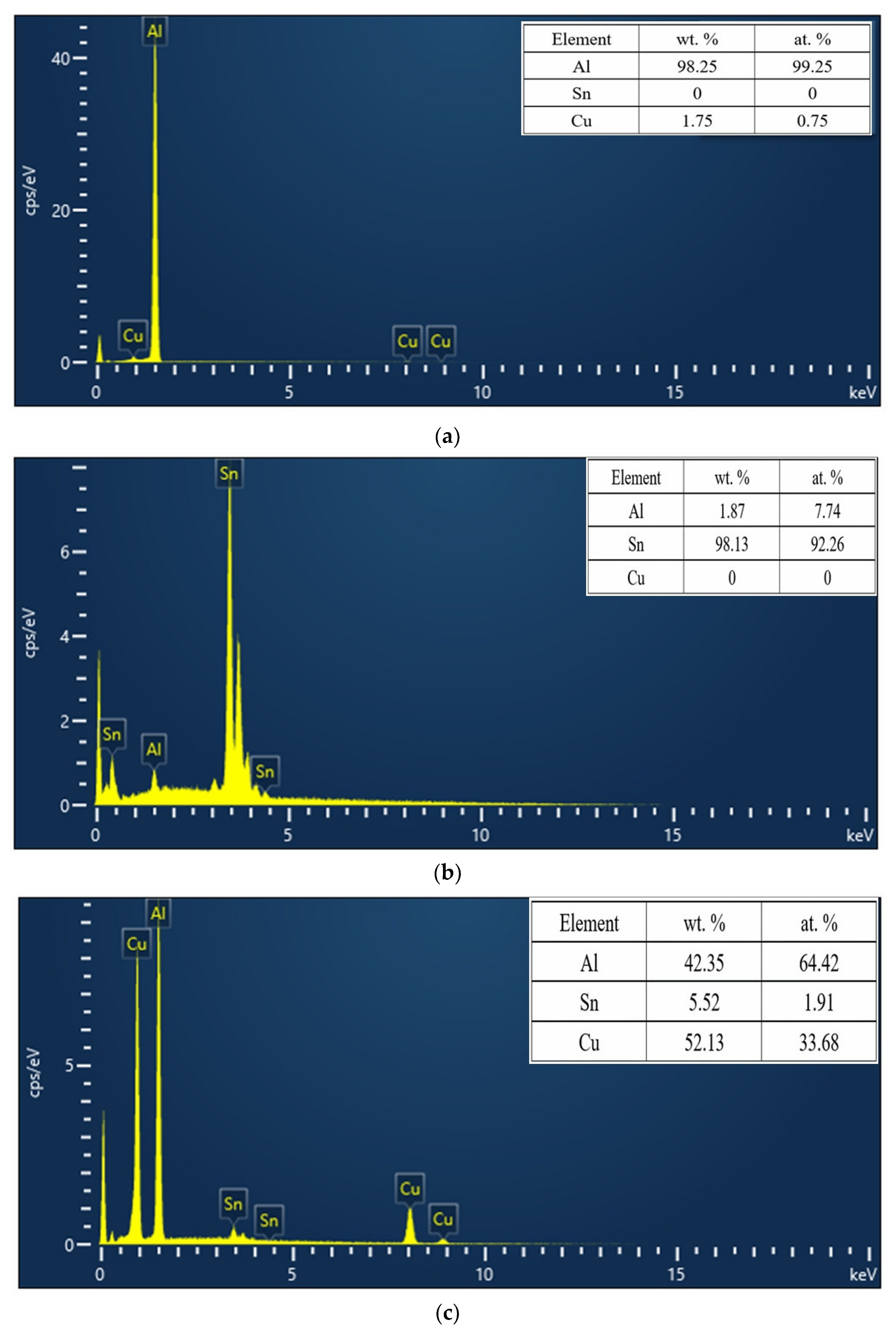

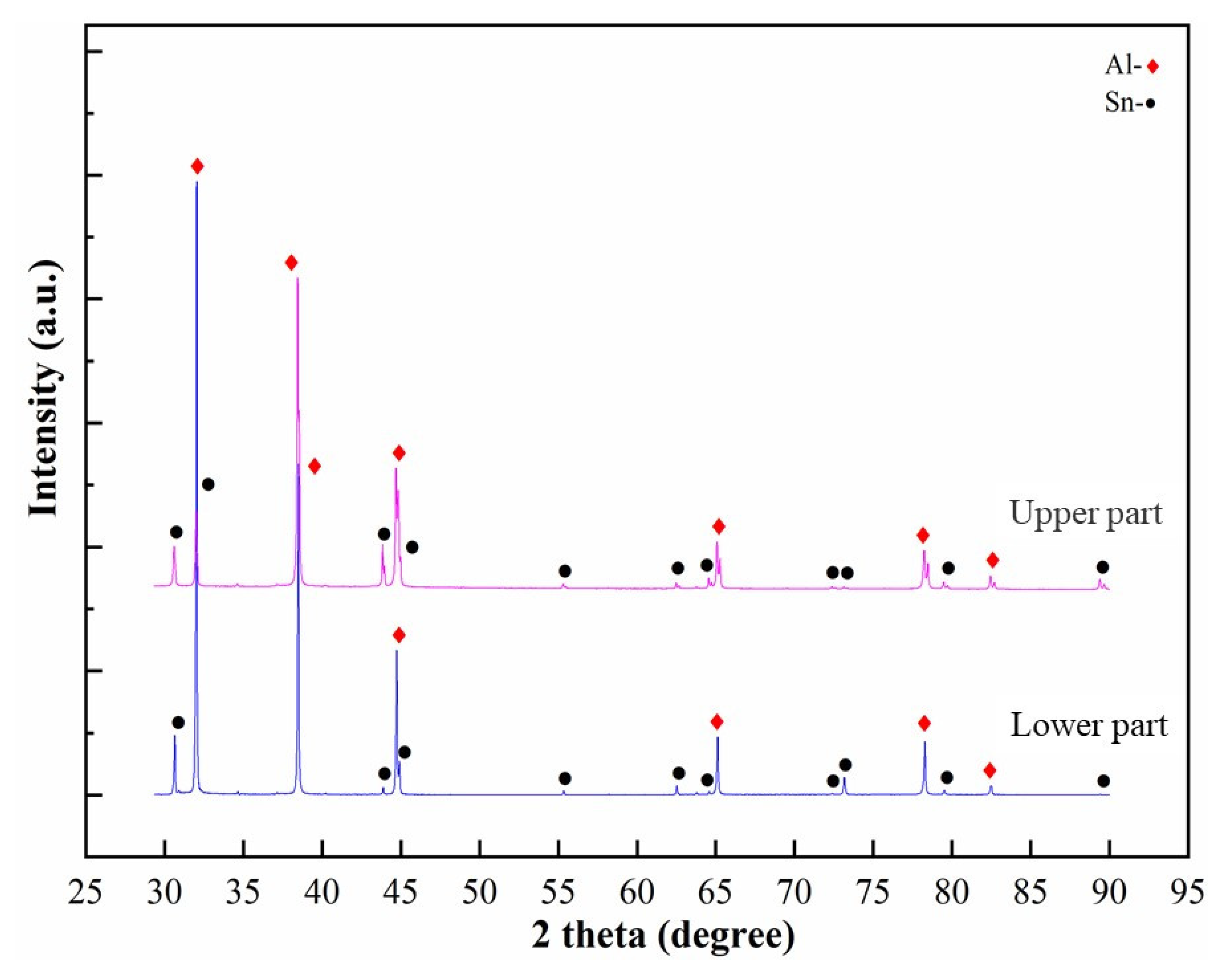

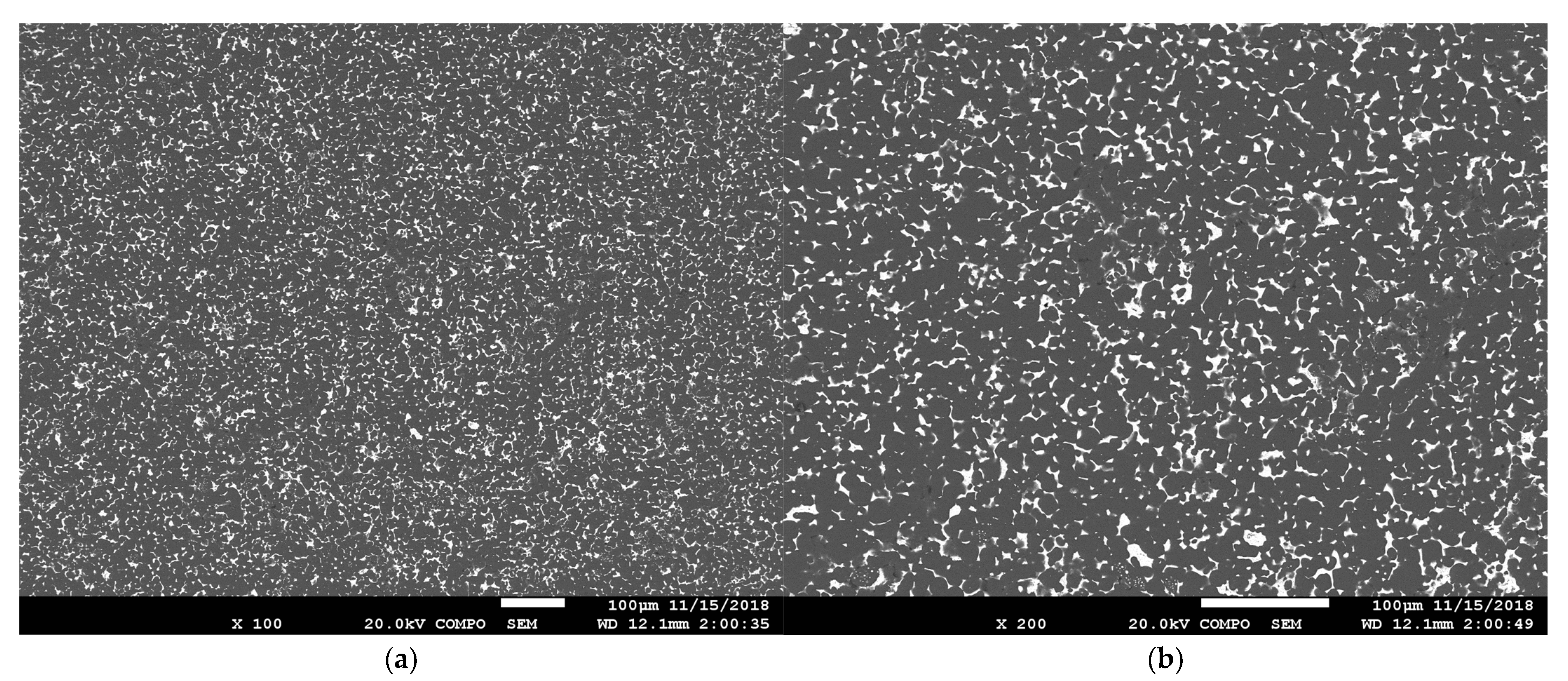

3.3. Spray Forming

4. Discussion

5. Conclusions

- (1)

- For the AlSn20Cu alloy prepared by semi-continuous casting, the majority of the tin phase is distributed in a network along the grain boundaries of the aluminum matrix. After deformation and annealing treatment, the tin-phase morphology changes from that of a network to prolate particles. The average particle diameter and total area ratio of the tin phase are 12.6 µm and 8.2%, respectively. Although the annealing process results in a granular tin phase, it also leads to a situation in which the tin phase overflows from the aluminum matrix.

- (2)

- The tin phase of AlSn20Cu alloy products prepared by semi-solid die casting forms two shapes: nearly spherical and strips. The average particle diameter and total area ratio of the tin phase are 9.6 µm and 9.2%, respectively. The cooling rate of the semi-solid die casting process used in this study is not sufficient to prevent serious macro-segregation of the tin.

- (3)

- In the AlSn20Cu alloy prepared by spray forming, the tin phase is mostly equilateral, although there are some defects in the matrix. After hot extrusion at 215 °C, the defects are completely eliminated, and the tin-phase morphology remains almost unchanged. The average particle diameter and total area ratio of the tin phase are 6.2 µm and 13.8%, respectively.

- (4)

- The initial shape of the Sn phase is determined by both thermal and mechanical factors during preparation. A finer and more uniform tin-phase structure may be obtained by using the spray-forming process. Preparing an AlSn20Cu alloy by semi-solid die casting requires the shortest time of the three studied methods, and this method therefore presents a promising possibility for further optimization.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Stuczynski, T. Metallurgical problems associated with the production of aluminium-tin alloys. Mater. Des. 1997, 18, 369–372. [Google Scholar] [CrossRef]

- Lu, Z.C.; Gao, Y.; Zeng, M.Q.; Zhu, M. Improving wear performance of dual-scale Al-Sn alloys: The role of Mg addition in enhancing Sn distribution and tribolayer stability. Wear 2014, 309, 216–225. [Google Scholar] [CrossRef]

- Bertelli, F.; Brito, C.; Ferreira, I.L.; Reinhart, G.; Nguyen-Thi, H.; Mangelinck-Noël, N.; Cheung, N.; Garcia, A. Cooling thermal parameters, microstructure, segregation and hardness in directionally solidified Al-Sn-(Si;Cu) alloys. Mater. Des. 2015, 72, 31–42. [Google Scholar] [CrossRef]

- Belova, N.A.; Akopyan, T.K.; Gershman, I.S.; Stolyarova, O.O.; Yakovleva, A.O. Effect of Si and Cu additions on the phase composition, microstructure and properties of Al-Sn alloys. J. Alloys Compd. 2017, 695, 2730–2739. [Google Scholar] [CrossRef]

- Bertelli, F.; Freitas, E.S.; Cheung, N.; Arenas, M.A.; Conde, A.; Damborenea, J.; Garcia, A. Microstructure, tensile properties and wear resistance correlations on directionally solidified Al-Sn-(Cu; Si) alloys. J. Alloys Compd. 2017, 695, 3621–3631. [Google Scholar] [CrossRef]

- Xu, K.; Russell, A.M. Texture strength relationships in a deformation processed Al-Sn metal-metal composite. Mater. Sci. Eng. A 2004, 373, 99–106. [Google Scholar] [CrossRef]

- Mirkovic, D.; Grobner, J.; Schmid-Fetzer, R. Liquid demixing and microstructure formation in ternary Al–Sn–Cu alloys. Mater. Sci. Eng. A 2008, 487, 456–467. [Google Scholar] [CrossRef]

- Schouwenaars, R.; Ramírez, E.I.; Romero, J.; Jacobo, V.H.; Ortiz, A. Fracture of thin cast slabs of Al-Sn alloys during cold rolling. Eng. Fail. Anal. 2012, 25, 175–181. [Google Scholar] [CrossRef]

- Hernández, O.; Gonzalez, G. Microstructural and mechanical behavior of highly deformed Al–Sn alloys. Mater. Charact. 2008, 59, 534–541. [Google Scholar] [CrossRef]

- Mahdavian, M.M.; Khatami-Hamedani, H.; Abedi, H.R. Macrostructure evolution and mechanical properties of accumulative roll bonded Al/Cu/Sn multilayer composite. J. Alloys Compd. 2017, 703, 605–613. [Google Scholar] [CrossRef]

- Liu, X.; Zeng, M.Q.; Ma, Y.; Zhu, M. Promoting the high load-carrying capability of Al-20 wt%Sn bearing alloys through creating nanocomposite structure by mechanical alloying. Wear 2012, 294–295, 387–394. [Google Scholar] [CrossRef]

- Xu, K.; Russell, A.M.; Chumbley, L.S.; Laabs, F.C. A deformation processed Al-20%Sn in-situ composite. Scr. Mater. 2001, 44, 935–940. [Google Scholar] [CrossRef]

- Patel, J.; Morsi, K. Effect of mechanical alloying on the microstructure and properties of Al–Sn–Mg alloy. J. Alloys Compd. 2012, 540, 100–106. [Google Scholar] [CrossRef]

- Lu, Z.C.; Zeng, M.Q.; Gao, Y.; Zhu, M. Significant improvement of wear properties by creating micro/nano dual-scale structure in Al-Sn alloys. Wear 2012, 296, 469–478. [Google Scholar] [CrossRef]

- Liu, X.; Zeng, M.Q.; Ma, Y.; Zhu, M. Wear behavior of Al-Sn alloys with different distribution of Sn dispersoids manipulated by mechanical alloying and sintering. Wear 2008, 265, 1857–1863. [Google Scholar] [CrossRef]

- Lavernia, E.J.; Ayers, J.D.; Srivatsan, T.S. Rapid solidification processing with specific application to aluminium alloys. Int. Mater. Rev. 1992, 37, 1–44. [Google Scholar] [CrossRef]

- Lavernia, E.J.; Gutierrez, E.M.; Szekely, J. Spray deposition of metals. Mater. Sci. Eng. A 1988, 98, 381–394. [Google Scholar] [CrossRef]

- Lucchetta, M.C.; Saporiti, F.; Audebert, F. Improvement of surface properties of an Al-Sn-Cu plain bearing alloy produced by rapid solidi cation. J. Alloys Compd. 2019, 805, 709–717. [Google Scholar] [CrossRef]

- Li, H.; Jiang, X.; Wang, X. Effects of Target Microstructure on Al-Cu Alloy Sputtering and Depositing Performance. Rare Met. 2009, 33, 442–445. [Google Scholar]

- Zhu, Q. Semi-solid moulding: Competition to cast and machine from forging in making automotive complex components. Trans. Nonferrous Met. Soc. 2010, 20 (Suppl. S3), sl042–sl047. [Google Scholar] [CrossRef]

- Atkinson, H.V.; Liu, D. Microstructural coarsening of semi-solid aluminium alloys. Mater. Sci. Eng. A 2008, 496, 439–446. [Google Scholar] [CrossRef]

- Tebib, M.; Morin, J.B.; Jersch, F.A. Semi-solid processing of hypereutectic A390 alloys using novel rheoforming process. Trans. Nonferrous Met. Soc. 2010, 20, 1743–1748. [Google Scholar] [CrossRef]

| Morphological Parameters of Tin Phase | Original State | Final State | ||||

|---|---|---|---|---|---|---|

| Semi-Continuous Casting | Semi-Solid Die Casting | Spray Forming | Semi-Continuous Casting | Semi-Solid Die Casting | Spray Forming | |

| Total area ratio (%) | 11.4 | 9.2 | 13.6 | 8.2 | 9.2 | 13.8 |

| Quantity density [number/(100µm)2] | 8.4 | 12.6 | 39.3 | 6.5 | 12.6 | 40.2 |

| Average particle area (µm2) | 135.8 | 72.6 | 32.8 | 125.7 | 72.6 | 30.5 |

| Average particle diameter (µm) | 13.1 | 9.6 | 6.5 | 12.6 | 9.6 | 6.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, S.; Zhu, B.; Zhang, Y.; Liu, H.; Wu, S.; Xie, H. Microstructure Comparison for AlSn20Cu Antifriction Alloys Prepared by Semi-Continuous Casting, Semi-Solid Die Casting, and Spray Forming. Metals 2022, 12, 1552. https://doi.org/10.3390/met12101552

Huang S, Zhu B, Zhang Y, Liu H, Wu S, Xie H. Microstructure Comparison for AlSn20Cu Antifriction Alloys Prepared by Semi-Continuous Casting, Semi-Solid Die Casting, and Spray Forming. Metals. 2022; 12(10):1552. https://doi.org/10.3390/met12101552

Chicago/Turabian StyleHuang, Shuhui, Baohong Zhu, Yongan Zhang, Hongwei Liu, Shuaishuai Wu, and Haofeng Xie. 2022. "Microstructure Comparison for AlSn20Cu Antifriction Alloys Prepared by Semi-Continuous Casting, Semi-Solid Die Casting, and Spray Forming" Metals 12, no. 10: 1552. https://doi.org/10.3390/met12101552

APA StyleHuang, S., Zhu, B., Zhang, Y., Liu, H., Wu, S., & Xie, H. (2022). Microstructure Comparison for AlSn20Cu Antifriction Alloys Prepared by Semi-Continuous Casting, Semi-Solid Die Casting, and Spray Forming. Metals, 12(10), 1552. https://doi.org/10.3390/met12101552