The powder bed fusion (PBF) additive manufacturing process uses an electron or laser beam to fuse metallic powders over a build platform to print one layer of the build dictated by a computer-aided design (CAD) software. The machine takes design instruction from the CAD software and creates the part by adding layers. After the first layer is created, another layer of metal powder is distributed over the build plate using a powder hopper. This layer is then melted and solidified based on the CAD design. The process continues until the final product is built. Additive processes have the ability to produce lightweight materials with a complicated design, as well as to reduce the tooling cost, which gives them an edge over conventional manufacturing processes, such as machining in aerospace and medical industries [

1,

2]. The laser powder bed fusion process has been the subject of extensive research lately [

3,

4,

5,

6]. Melt pool physics is one of the most crucial and complicated phenomena during the process. Many factors impact the final quality of the melt, including the energy balance, thermo-physical properties of materials and the types of heat source used for the process. Researchers showed that melt pool and bead features, such as contact angle, porosity, voids and melt pool size, can change depending on the intensity of input energy that is supplied to the powder bed [

7,

8,

9,

10,

11]. The energy input in turn depends on the process variables, such as laser power, scanning speed, and thickness of the layers, etc. Due to the variability of these parameters, the molten region possesses distinguished features. These features, such as lower value of contact angle, are desirable as they ensure proper adhesion with previous layers [

12], and some features, such as high amount of porosity that results in distortion of the part, are not very desirable.

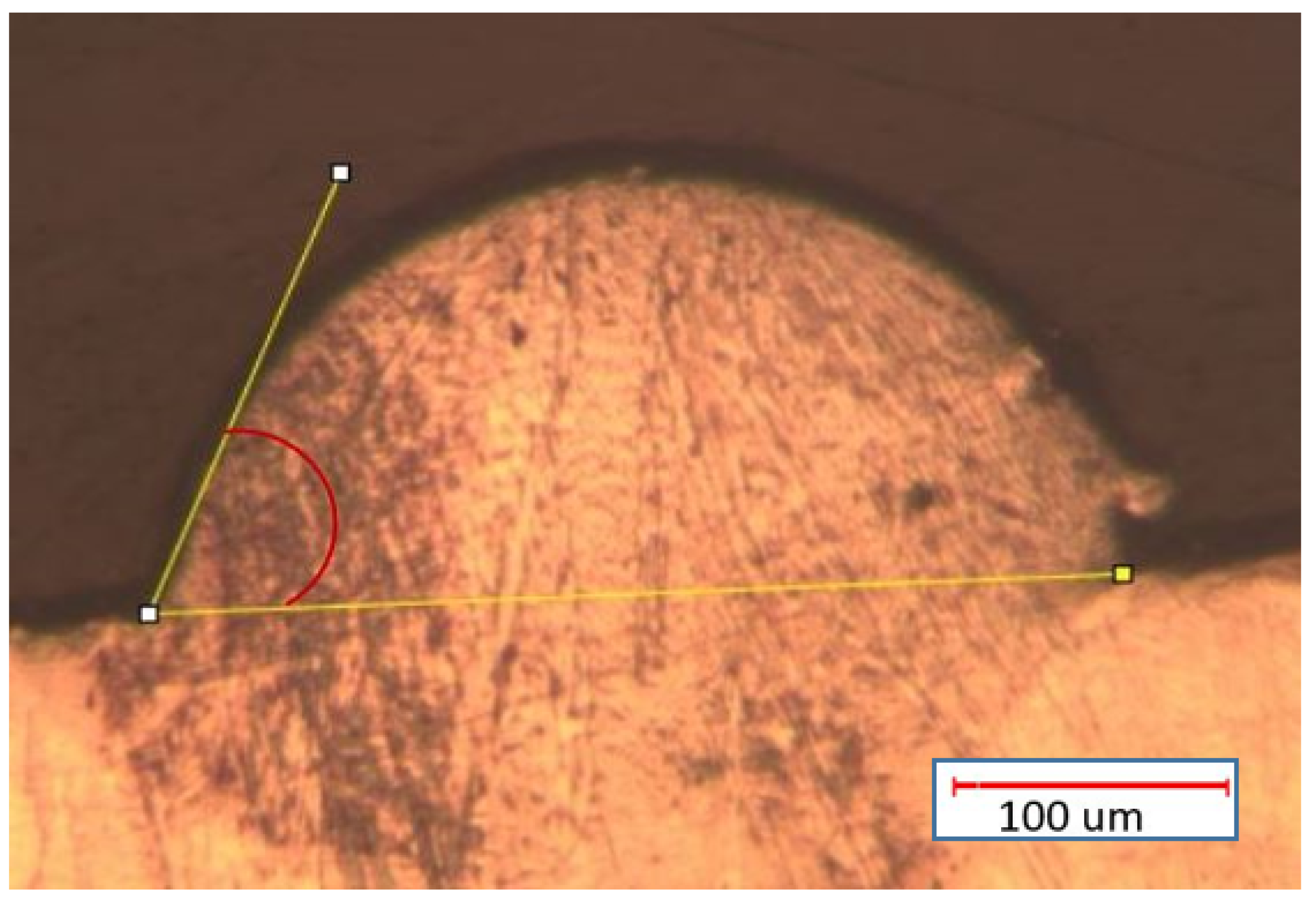

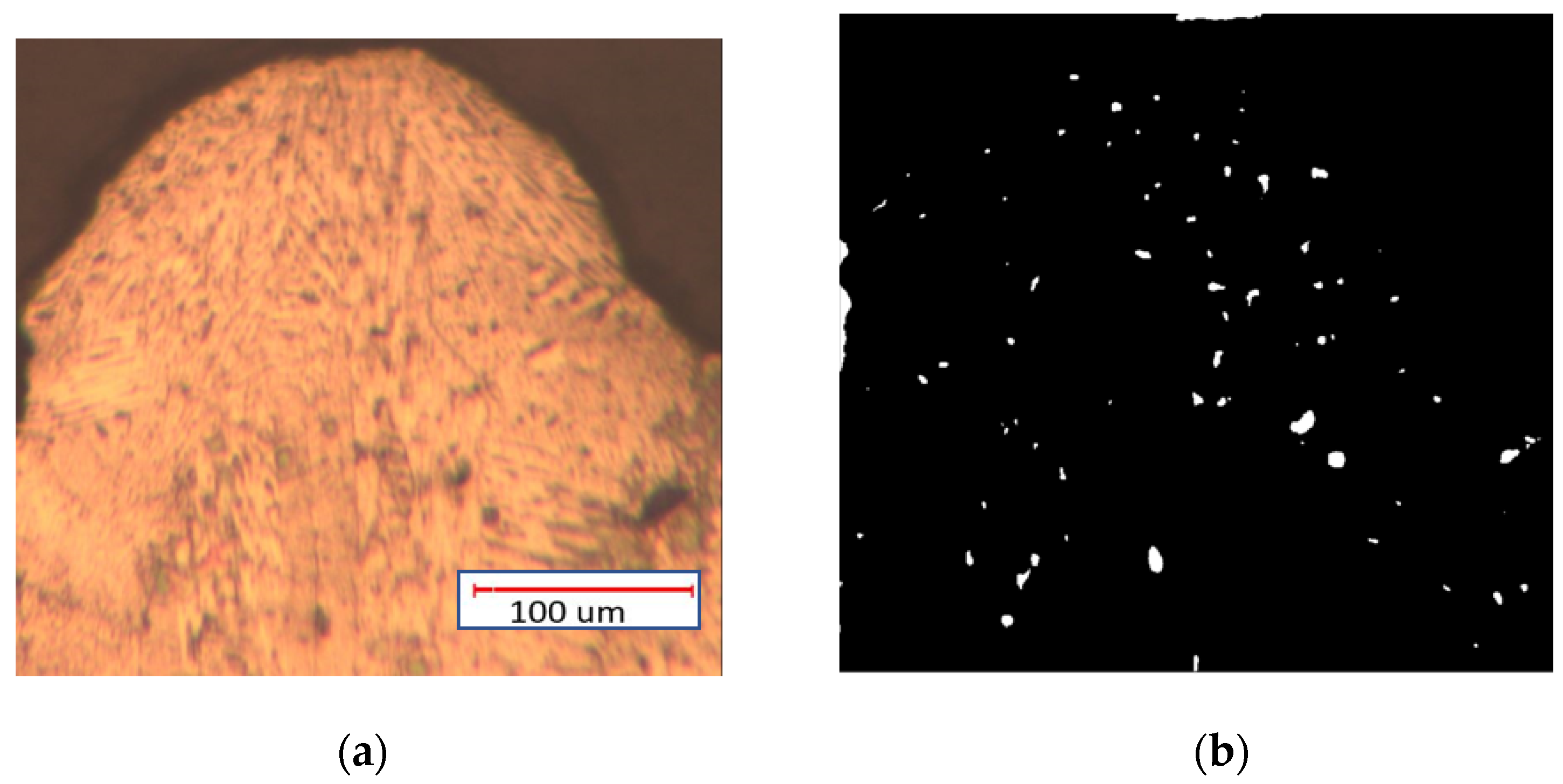

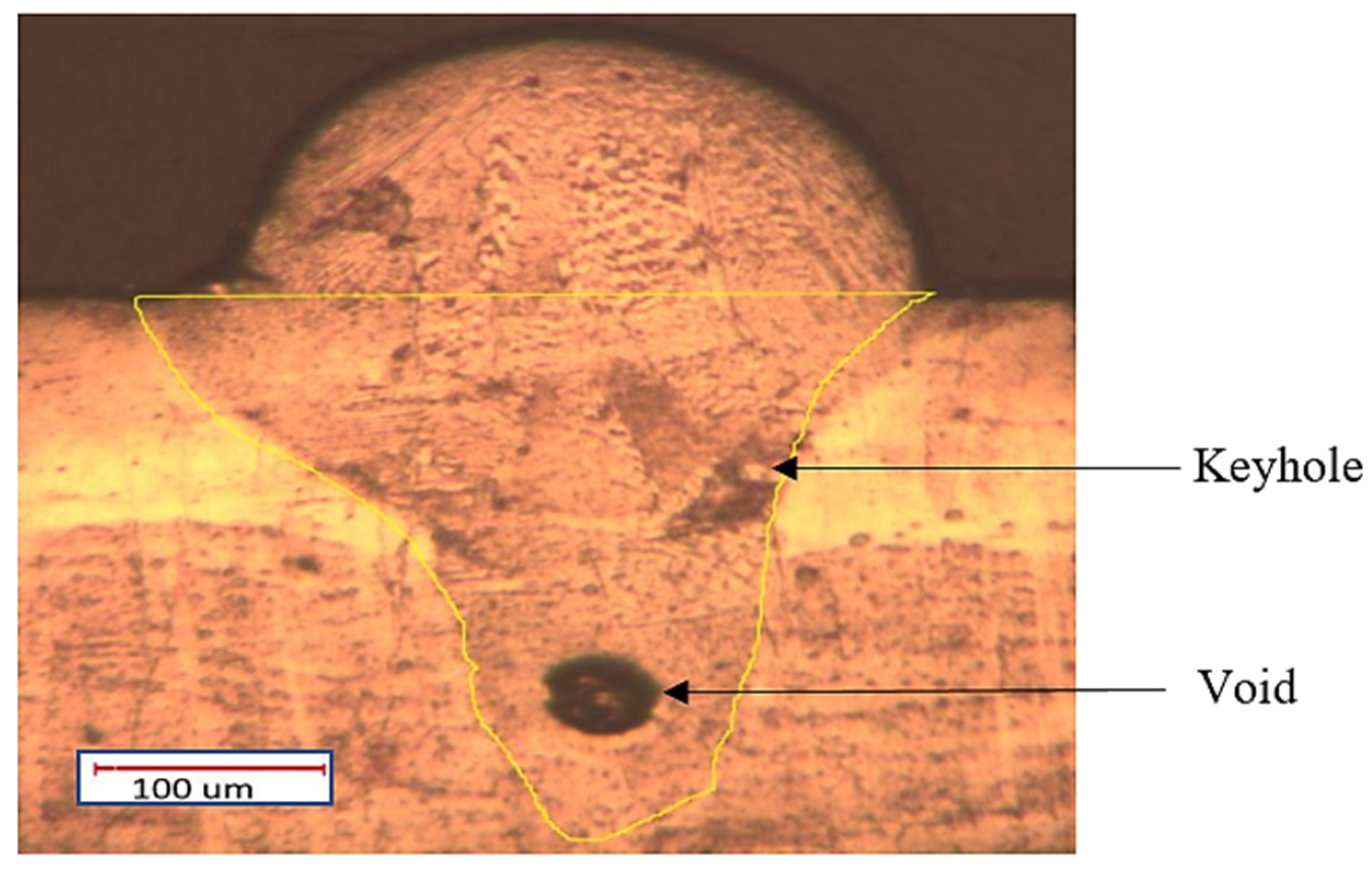

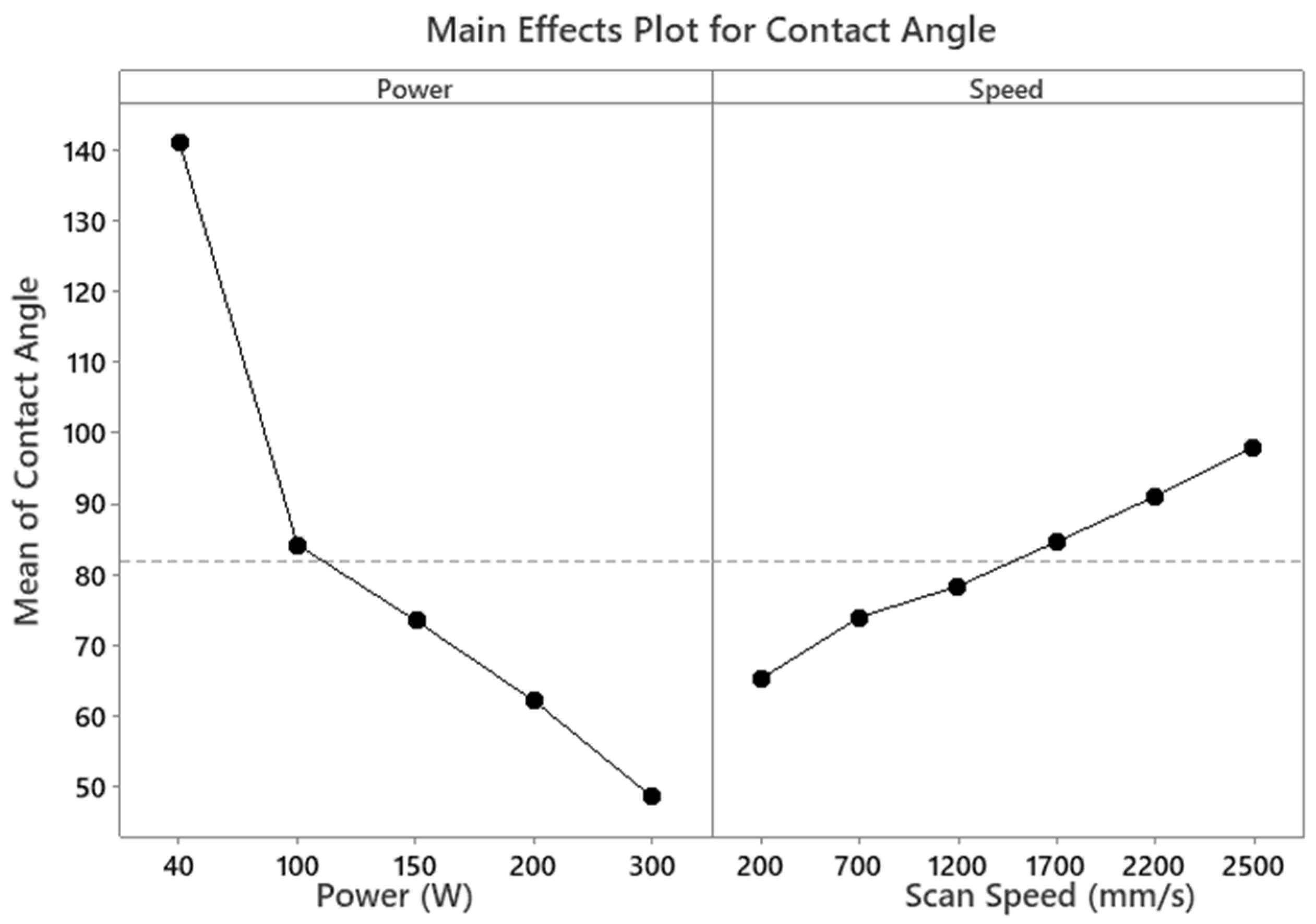

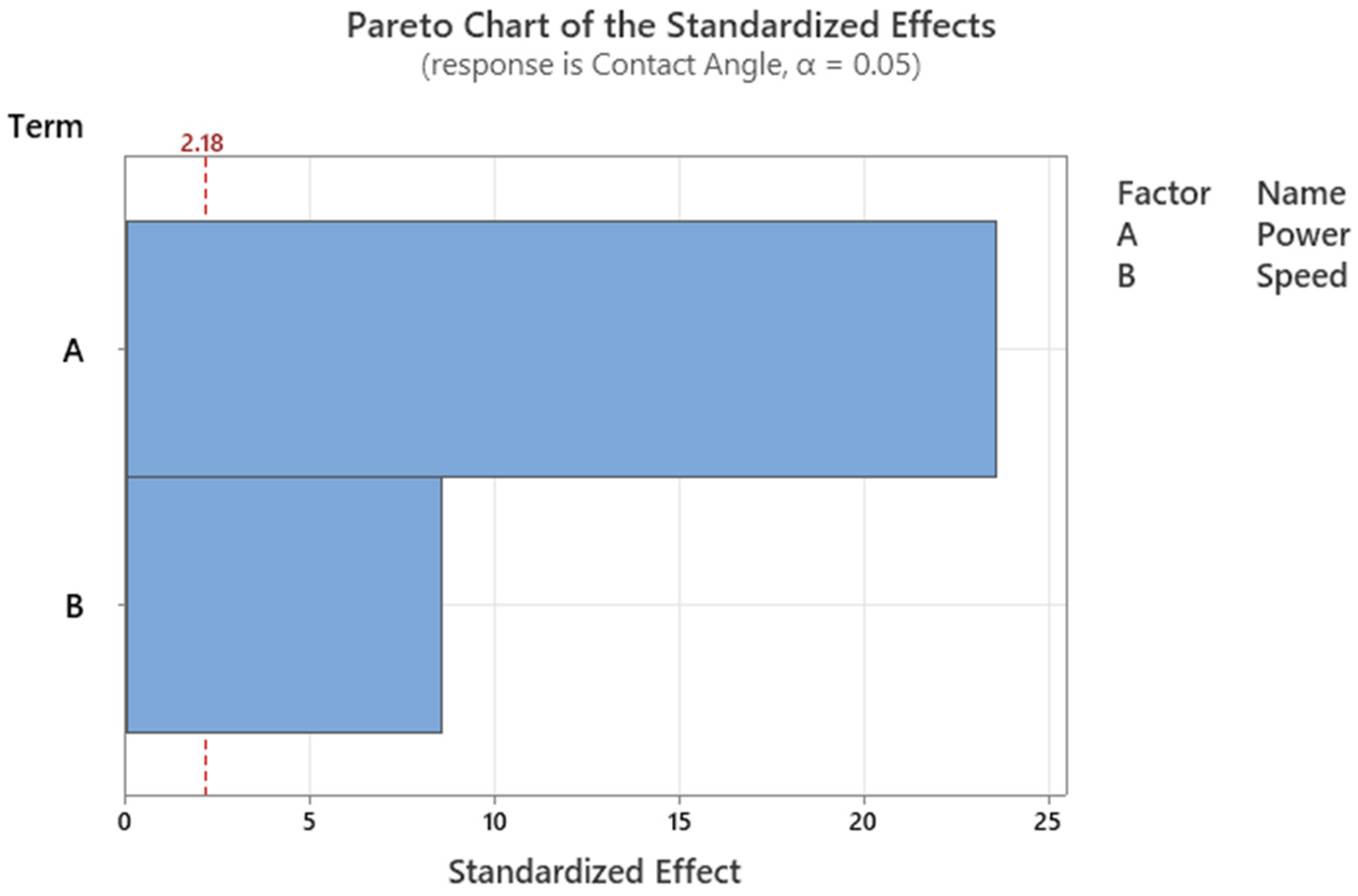

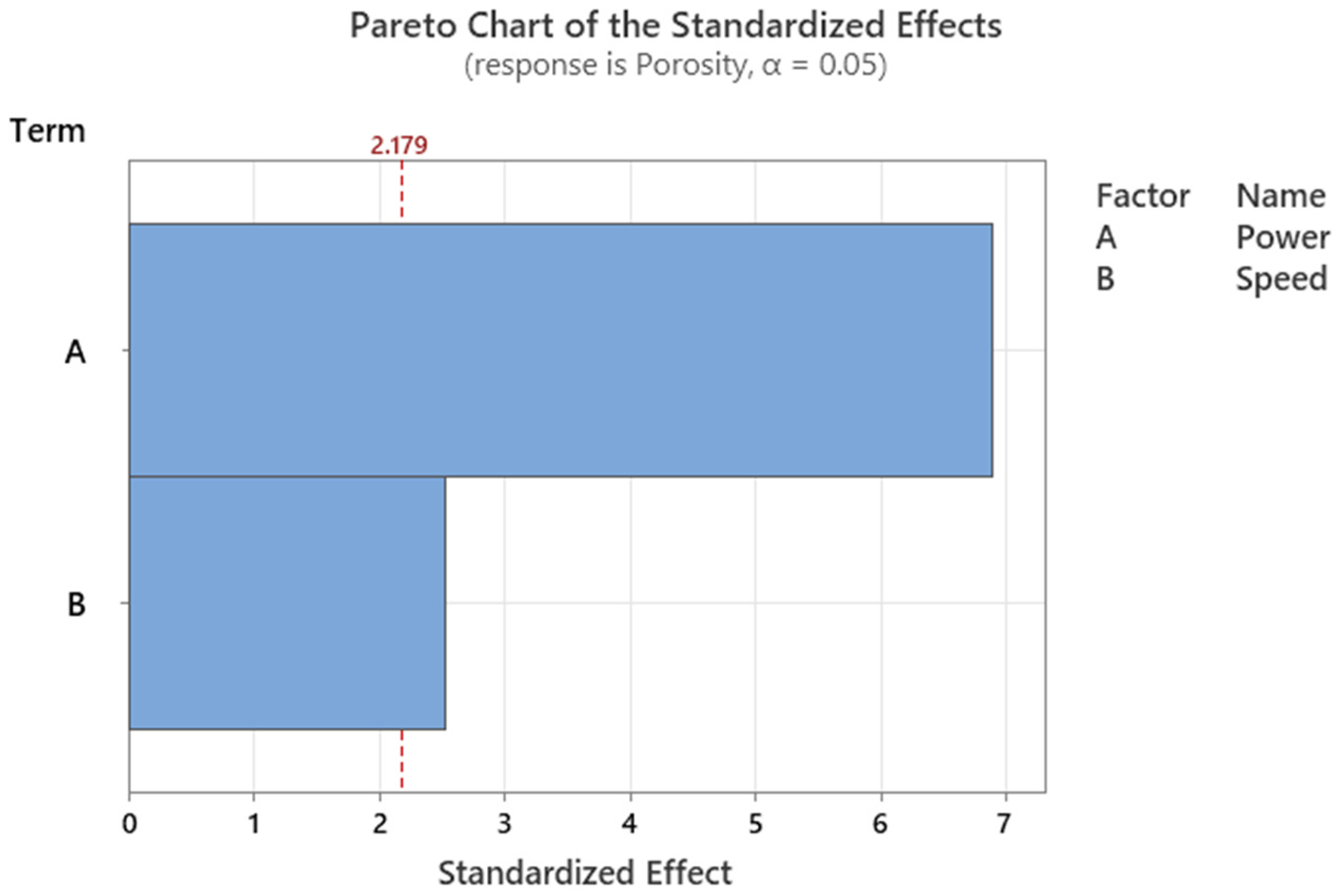

Researchers have tried to analyze the characteristics of different aspects of the build to optimize the parameters that can influence the process. Geometrical features such as contact angle between the present and the preceding layers, which dictates the wetting behavior of the melt pool, have been studied by several scientists. Fateri et al. [

12] investigated the effect of temperature and viscosity towards the evolution of contact angle using hot stage microscopy. The study showed that contact angle decreases as the powders start to sinter at higher temperature points. Haley et al. [

13] used a computational fluid dynamics (CFD) simulation technique to observe the influence of particle size, melt pool shape and surface tension on wetting dynamics. They found out that powder particle residence time, which is termed as the time between the interaction of the powder and heat source, and complete melting are dependent on particle size and surface tension, and contact angle varies inversely with residence time. Triantafyllidis et al. [

14] experimentally established a relationship between power and contact angle during a laser surface treatment of Al2O3-based refractory ceramics and deduced that contact angle increases with reduced power. Hu et al. [

15] used a computational model to show that contact angle decreases with increasing number of tracks and decreasing scan speed during selective laser melting. Process defect in melt pool is another important feature that has been a major concern in additive manufacturing (AM) processes. It will not be feasible to move towards large-scale production without addressing these defects. Extensive research has been dedicated towards the physics behind the formation of these defects. Brennan et al. [

16] discussed different defects, such as porosity, voids, lack of fusion defects and how they can be reduced using a hot isostatic process (HIP). Other papers [

17,

18] have also tried to investigate defects from a different perspective. These papers mainly focused on the formation of defects, such as the lack of fusion, porosity, surface roughness, etc., on the build direction. An analysis of these defects along the bead cross section based on process parameters such as laser power and scan speed is largely missing from the literature.

The specific features of the beads discussed above can be utilized to optimize the process parameters in the powder bed process. Traditionally, process parameter optimizations are implemented using experimental and computational methods [

8,

19,

20]. Although computational modeling can reveal important information about melt pool, microstructure, temperature history, etc., that change with the input variables, due to the complications in the process, these models possess a lot of simplified assumptions, which result in a deviation from actual experimental results [

21,

22,

23,

24]. To solve the issue, many researchers have recently opted to use machine learning algorithm techniques to optimize the process parameters. Kwon et al. [

25] used a convolutional neural network (CNN) to forecast laser power from images of the molten pool taken during the experiment and built a model with 96% accuracy. Caiazzo et al. [

26] built a three-layer cascade forward propagation artificial neural network (ANN) to predict the process parameters needed to print the optimum part dimension. They produced a result with 2% error for laser power and 5.8% for scan speed. Although machine learning models have become increasingly popular as they can predict data with high accuracy, these techniques are still not good enough to predict process parameters with smaller datasets [

27]. These techniques require a large number of experimental data set to train [

25,

28], which is both time-consuming and expensive. Statistical analysis techniques have also been employed to identify patterns in additive manufacturing. Sanaei et al. [

29] analyzed the defects in an AM part based on specific locations, such as the narrow section and at the perimeter of the dog-bone samples. They used a K–S statistical test to show that the distribution of defects are different in the neck and perimeter region. Casalino et al. [

30] investigated the impact of laser power and scan speed on mechanical properties, such as hardness and tensile strength of the final build. They found out that increasing energy density decreases surface roughness and increases hardness. Whip et al. [

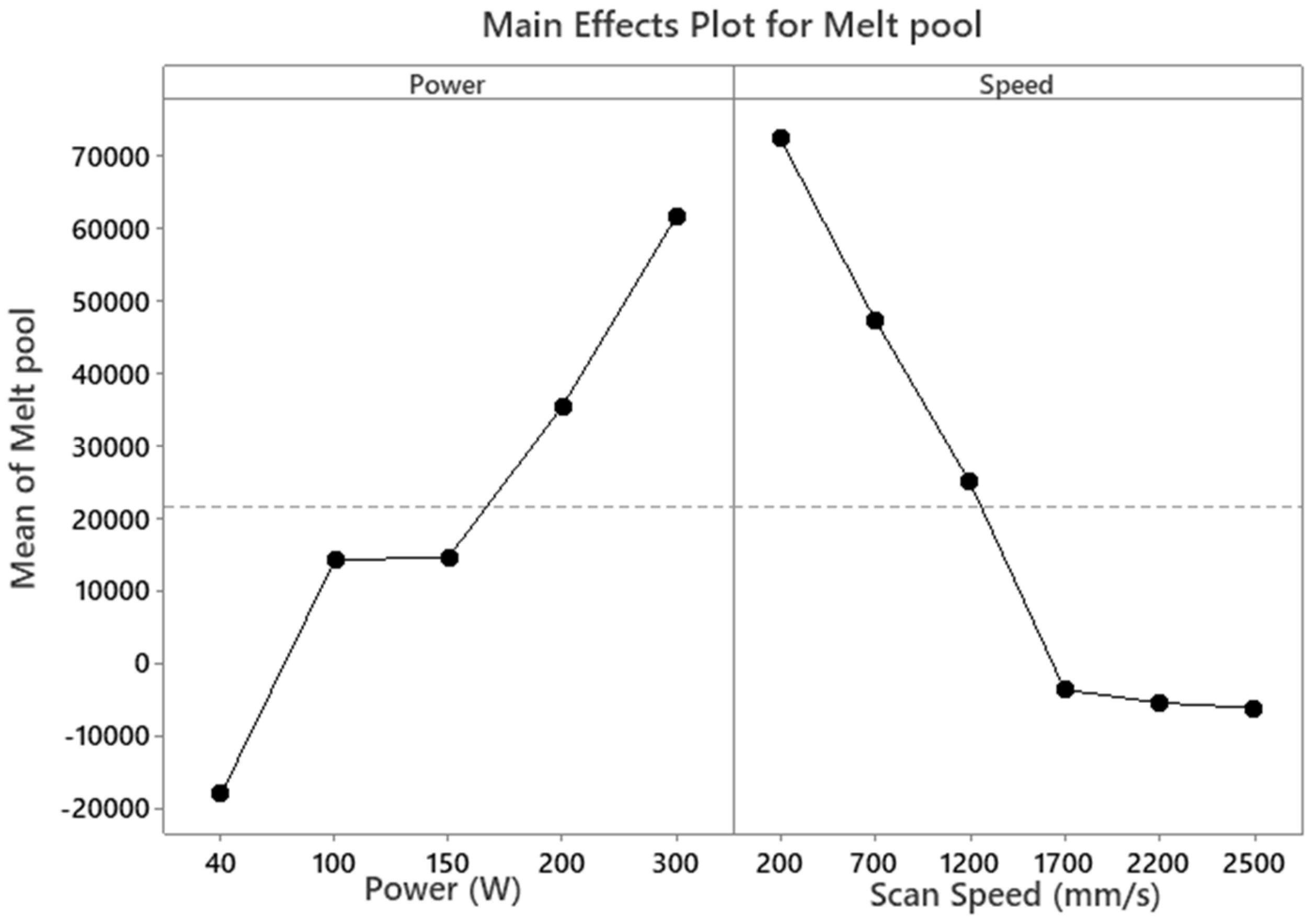

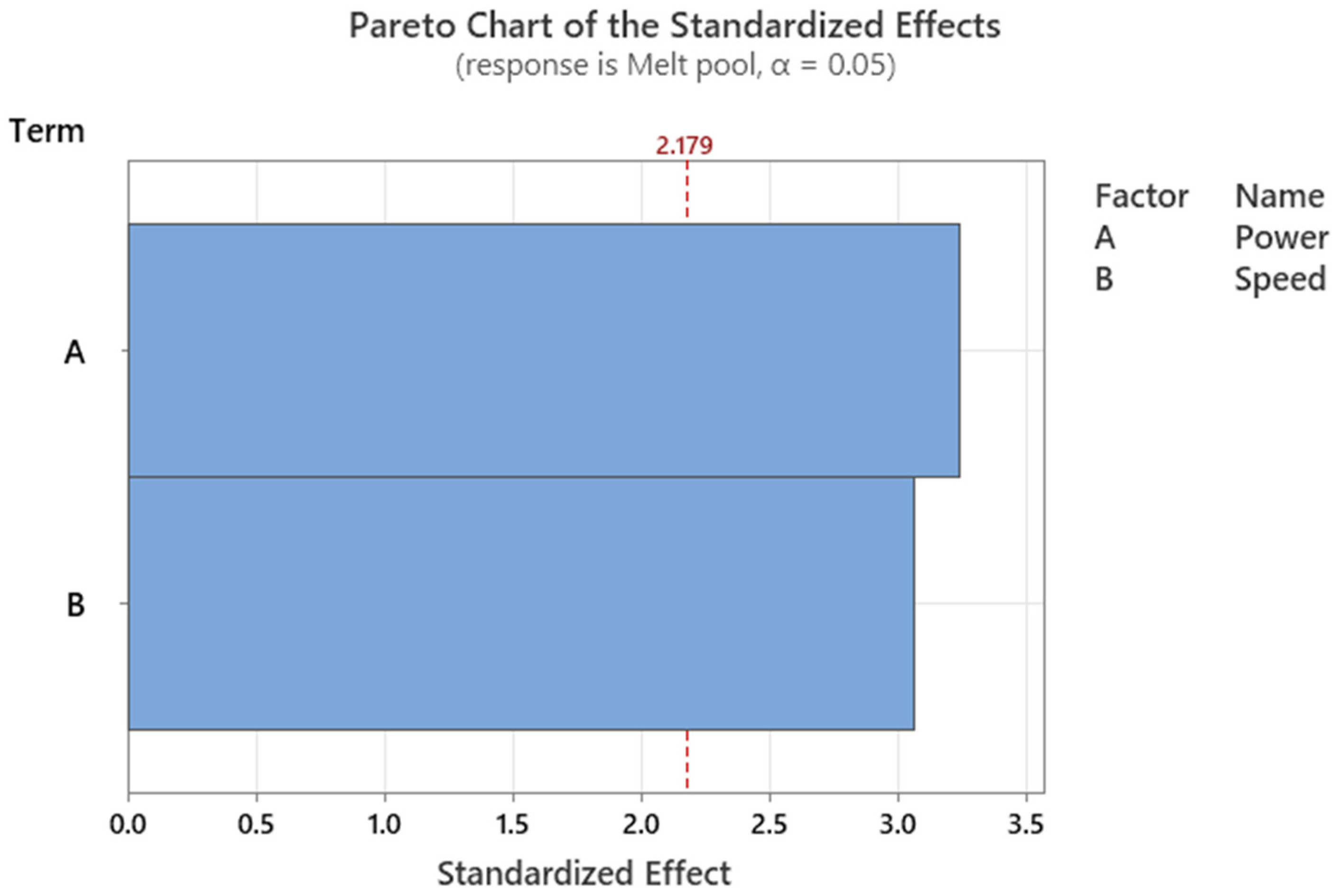

31] used an analysis of variance method to observe the effect of process parameters in melt pool and surface roughness. They found out that increasing laser power increases the melt pool size, which facilitates in a smoother surface due to proper wettability. The effect of process parameters on the evaluation of bead formation has been discussed in several works [

32,

33,

34].

Although there is a handful of research discussions about the defects of AM parts, a comprehensive analysis of different features of the bead cross section is missing. Moreover, most of this research focuses on an analysis of defects on the surface and beneath. This work attempts to provide a detailed analysis of different features of the bead cross section for a nickel-based Inconel 718 sample, which has a high strength over a wide range of temperatures. Contact angle, porosity, void, melt pool area and keyhole formation are quantified. Individual significance of each parameter is analyzed using a full factorial design of experiment and analysis of variance (ANOVA). Process parameter optimization in terms of multiple response parameters is largely missing from the literature as well. A multi-response analysis is conducted in this work, including all the features as a part of process parameter optimization.