Friction Stir Welded AA5052-H32 under Dissimilar Pin Profile and Preheat Temperature: Microstructural Observations and Mechanical Properties

Abstract

:1. Introduction

2. Research Configuration and Scheme

2.1. Fundamental Research Concept

2.2. Tested Materials

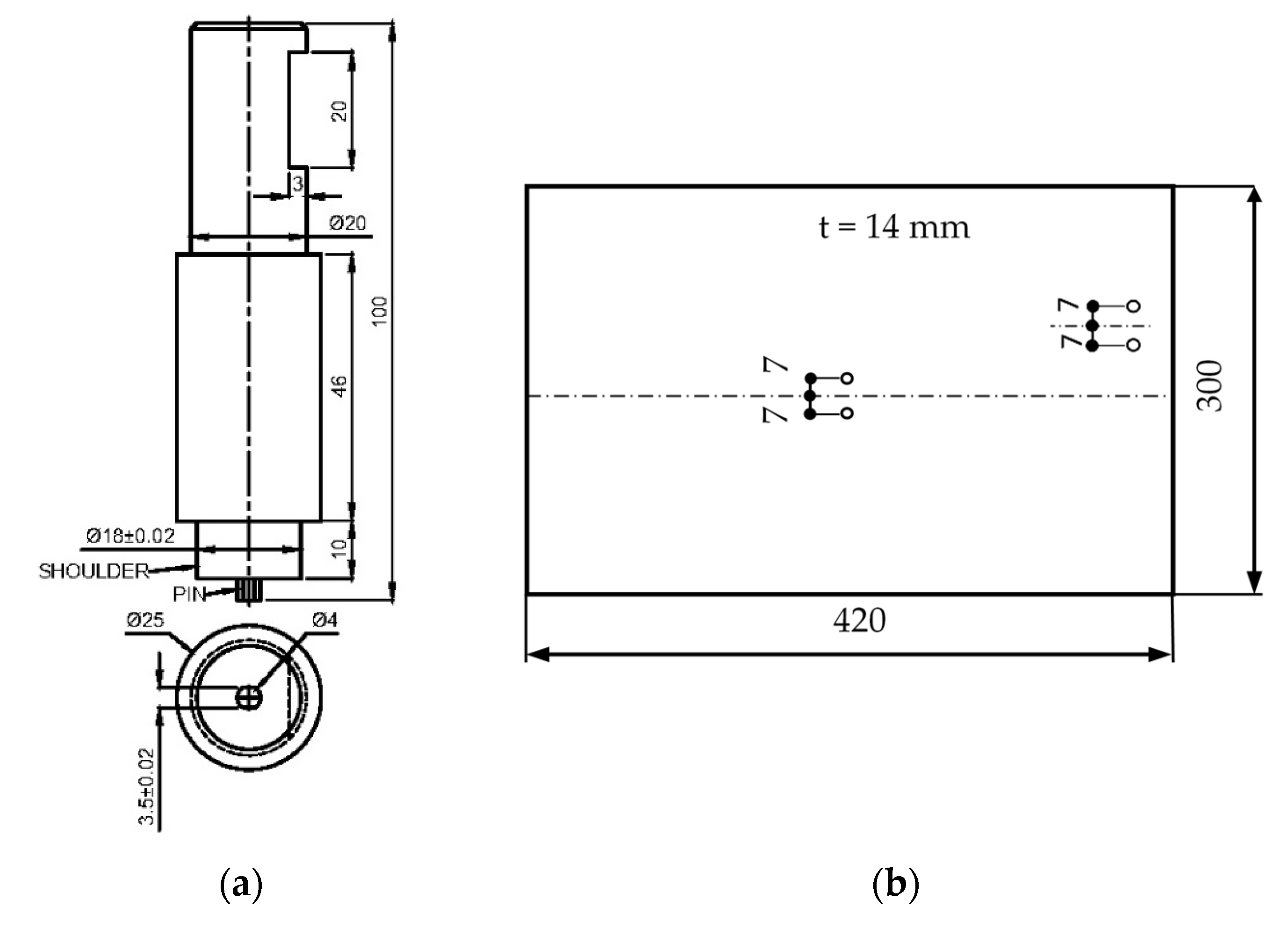

2.3. Research Instrument

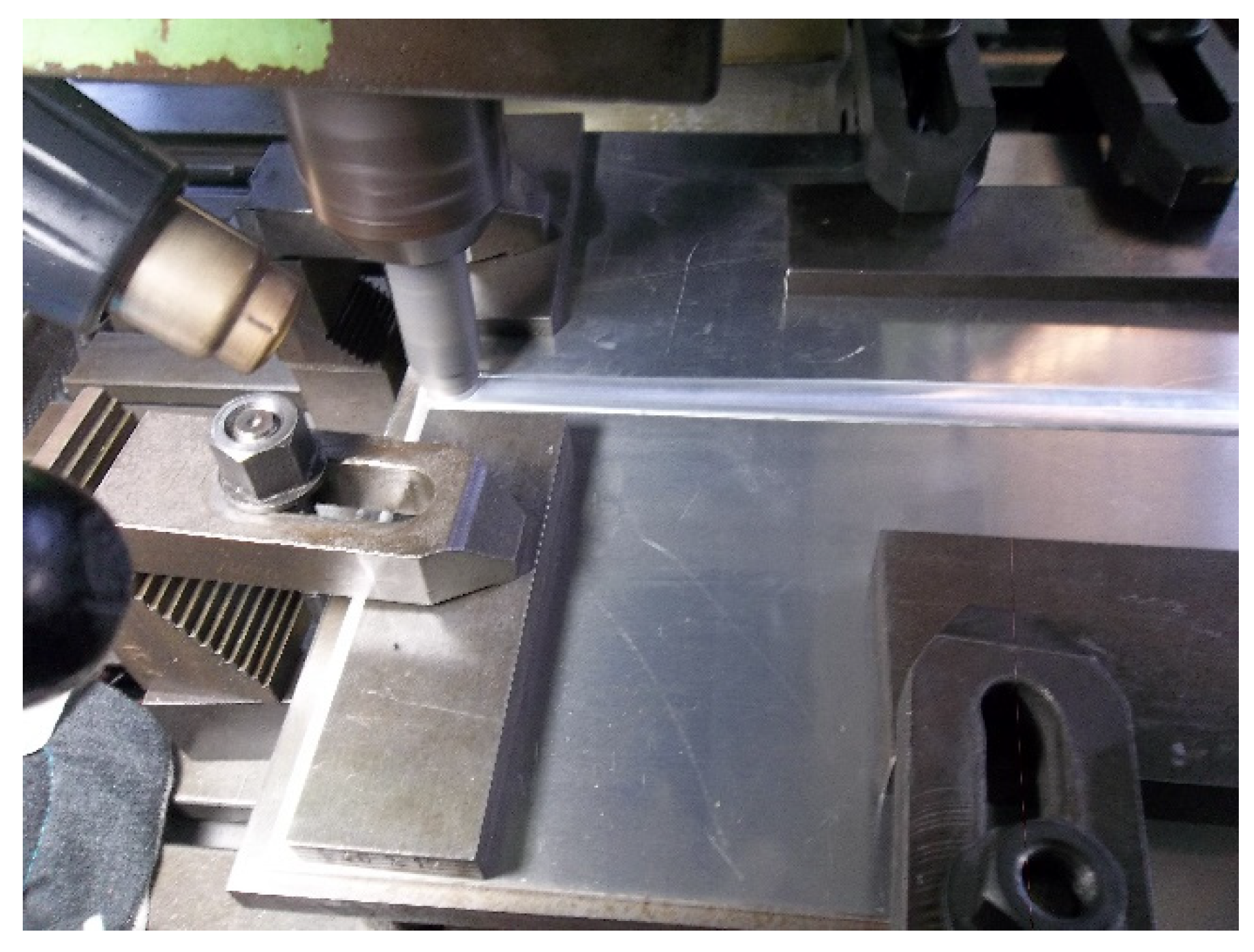

2.4. Welding Preparation and Process

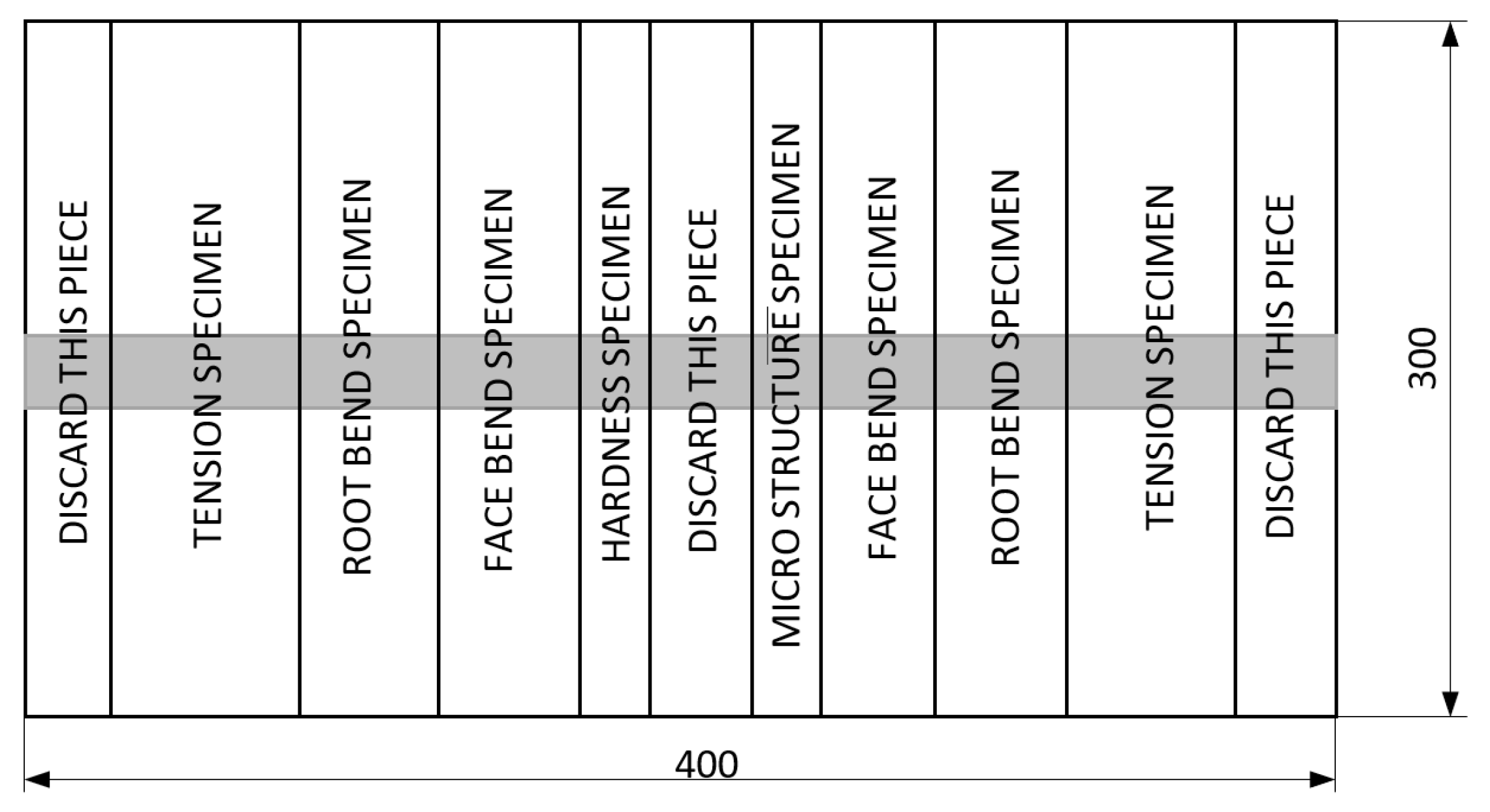

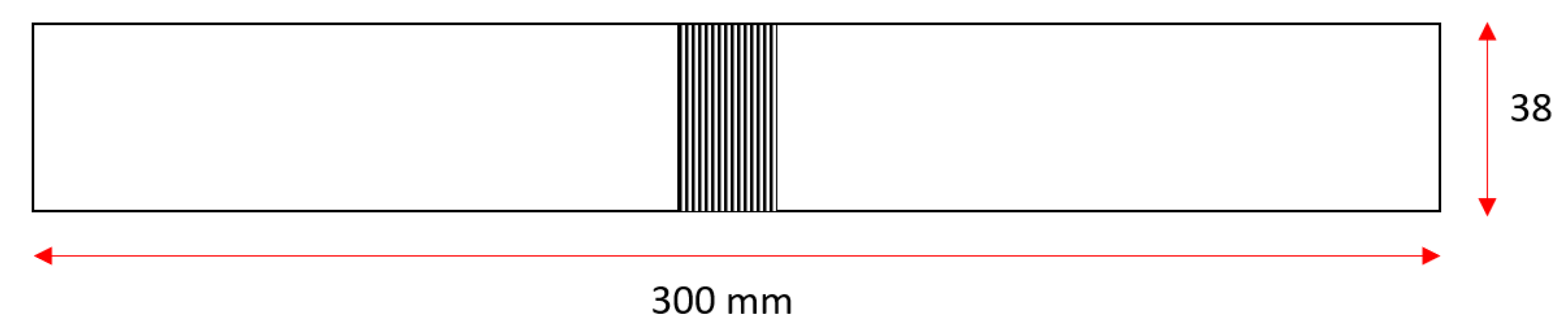

2.5. Welding Specimen Testing

2.6. Macrostructure and Microstructure Observations

3. Welding Data Properties

3.1. Properties of Base Material

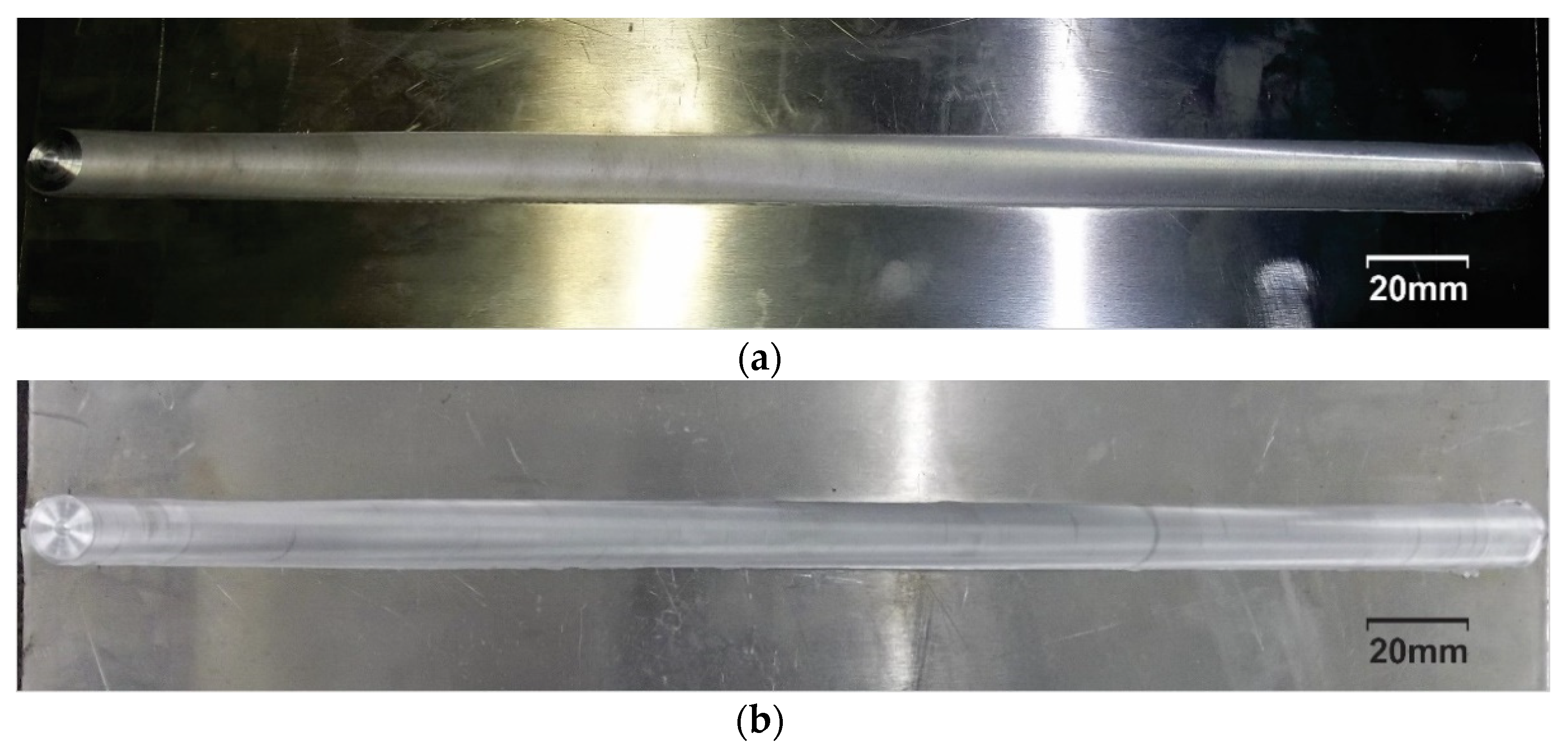

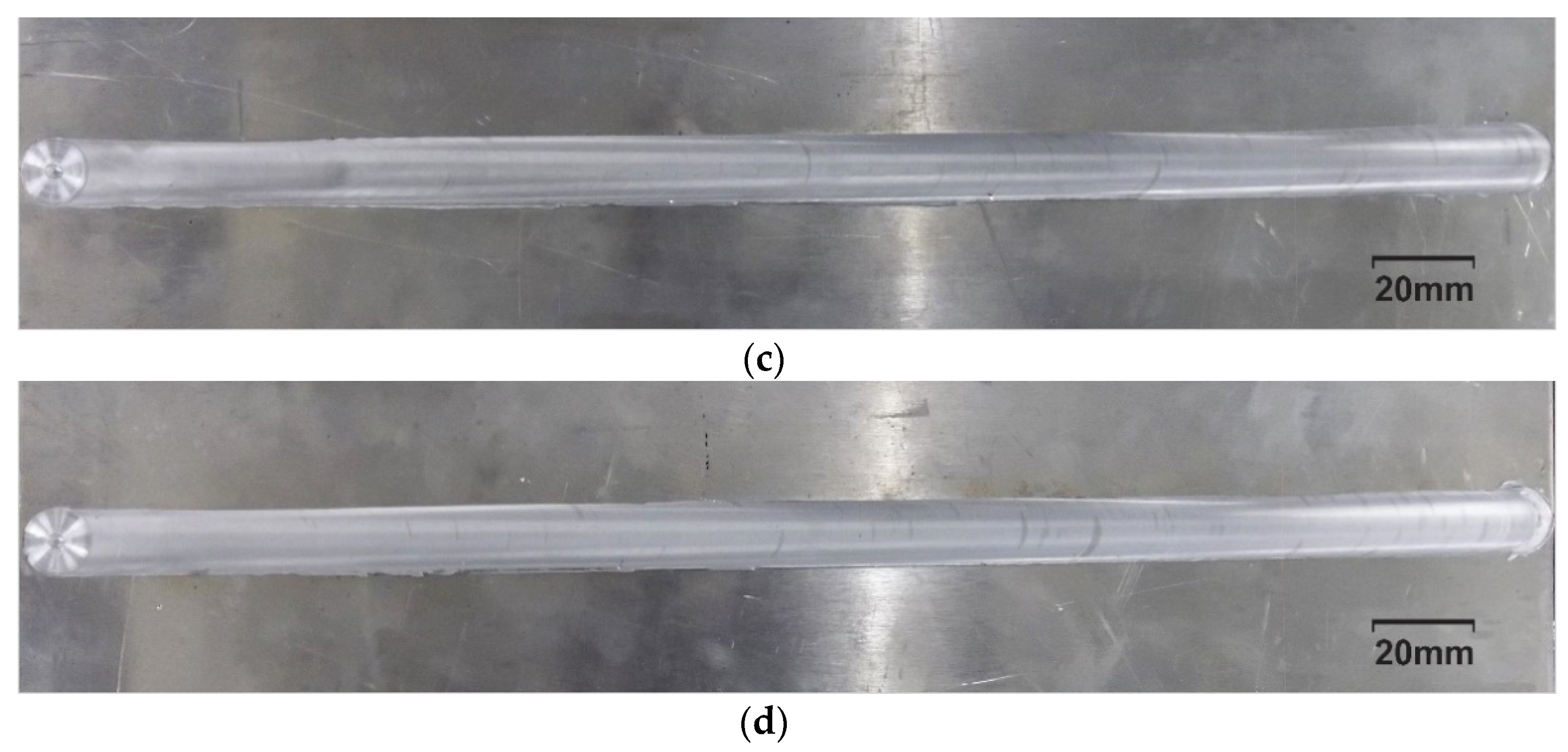

3.2. Experimental Data of Pin Profiles without Preheating

3.3. Experimental Data of Cylindrical Pin Profiles with Different Preheat Temperature

3.4. Experimental Data of Two Flat Sides Pin Profile with Different Preheat Temperature

3.5. Experimental Data of Three-Flat-Sided Pin Profile at Different Preheat Temperatures

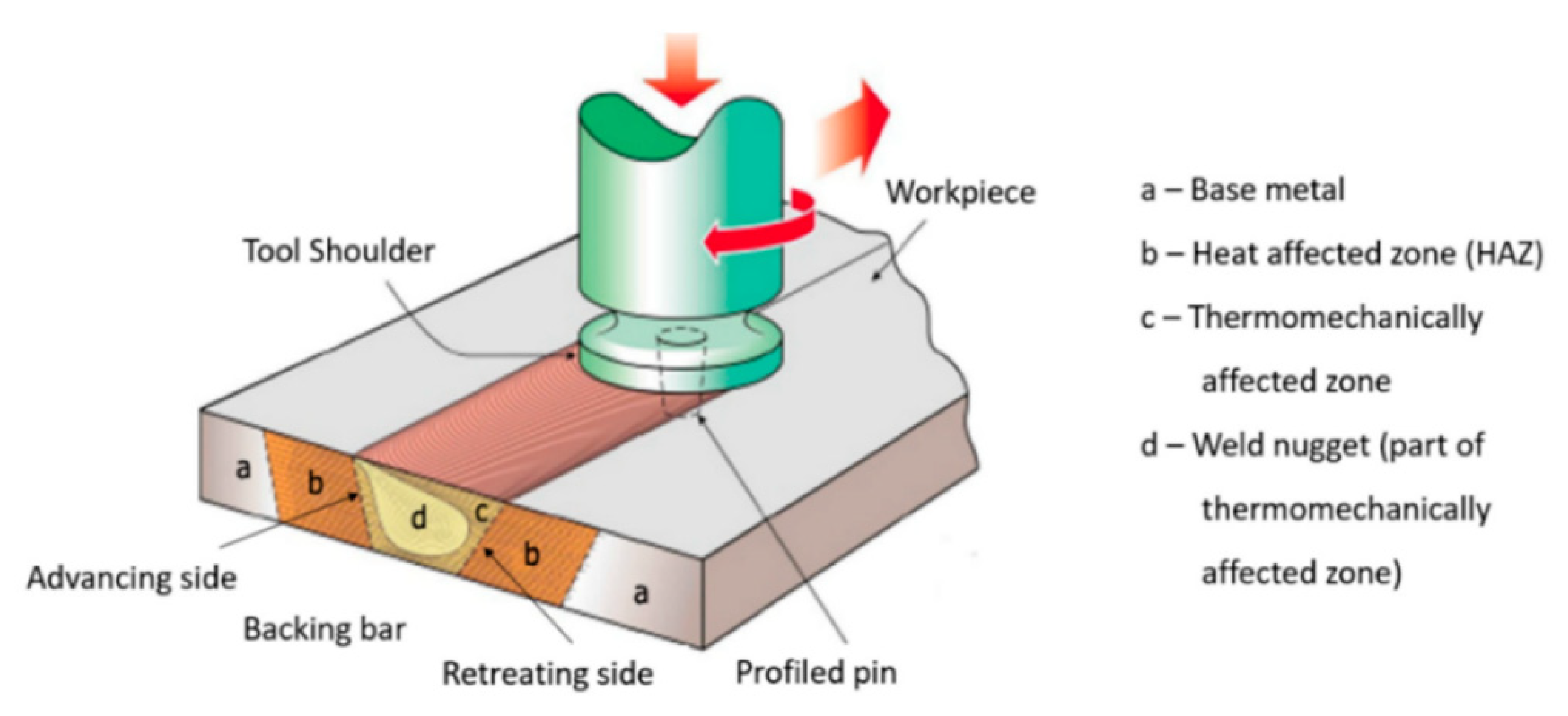

4. Results of Microstructure Observation and Mechanical Properties

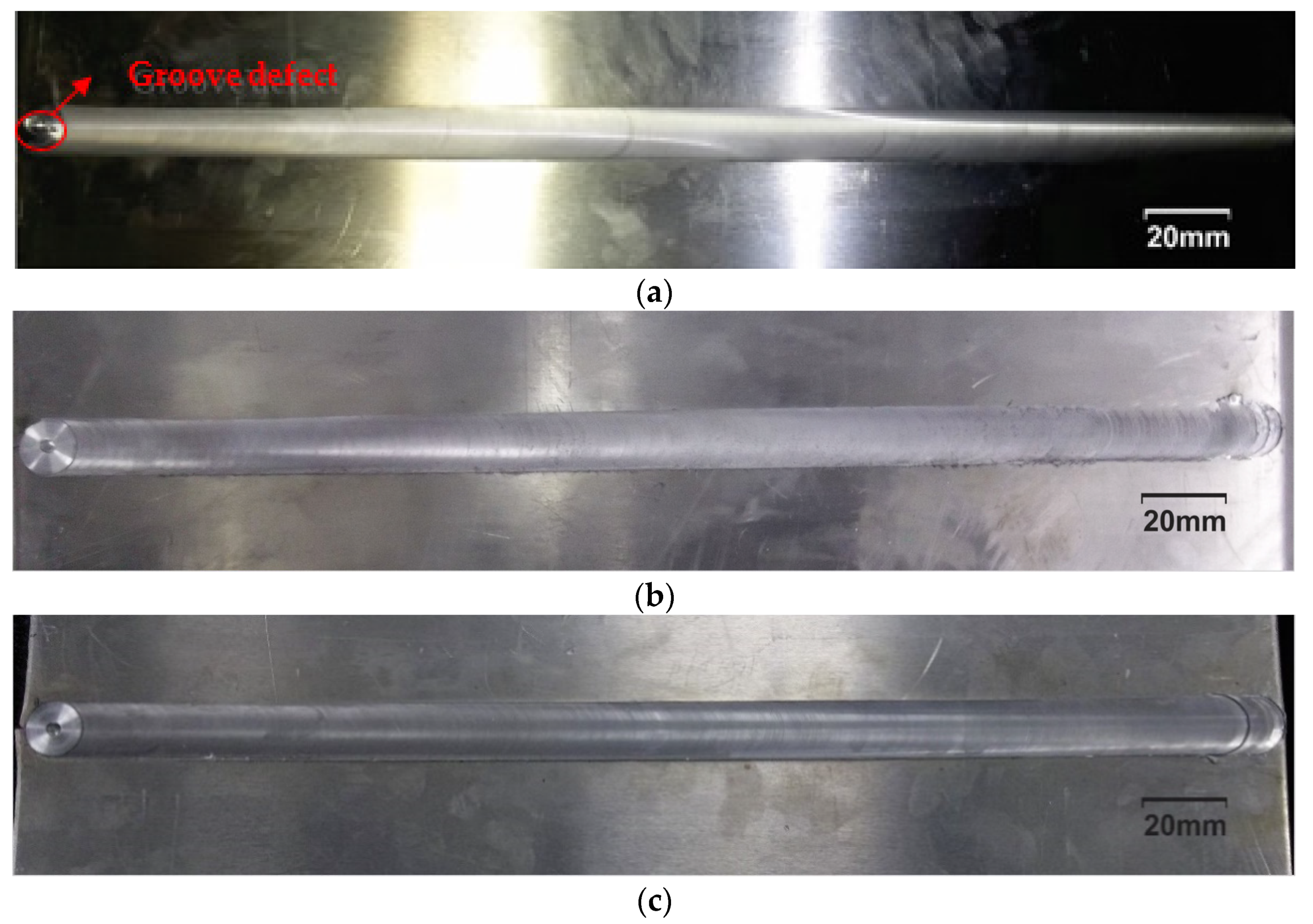

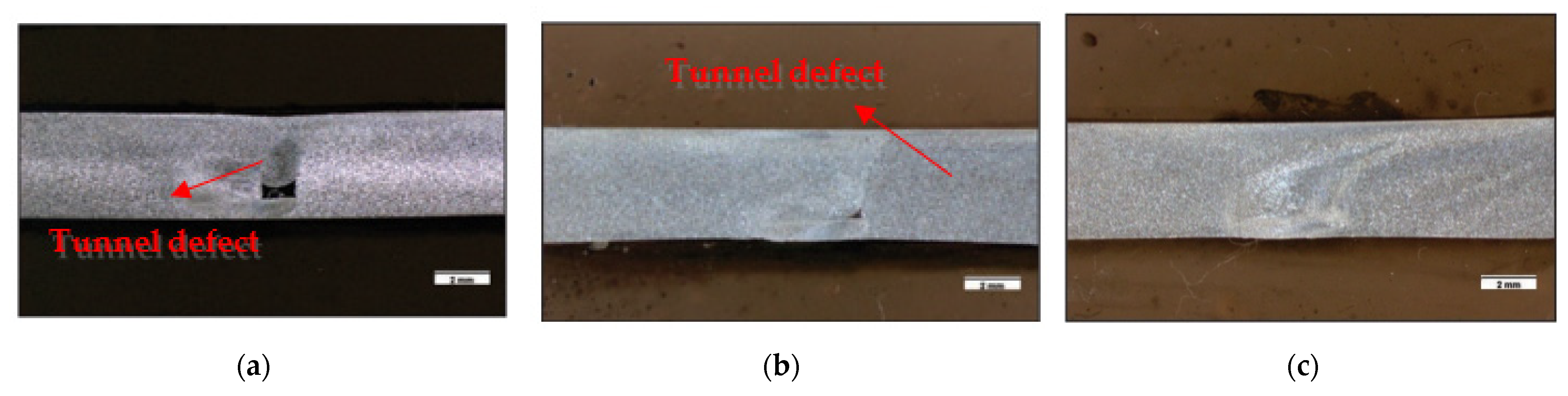

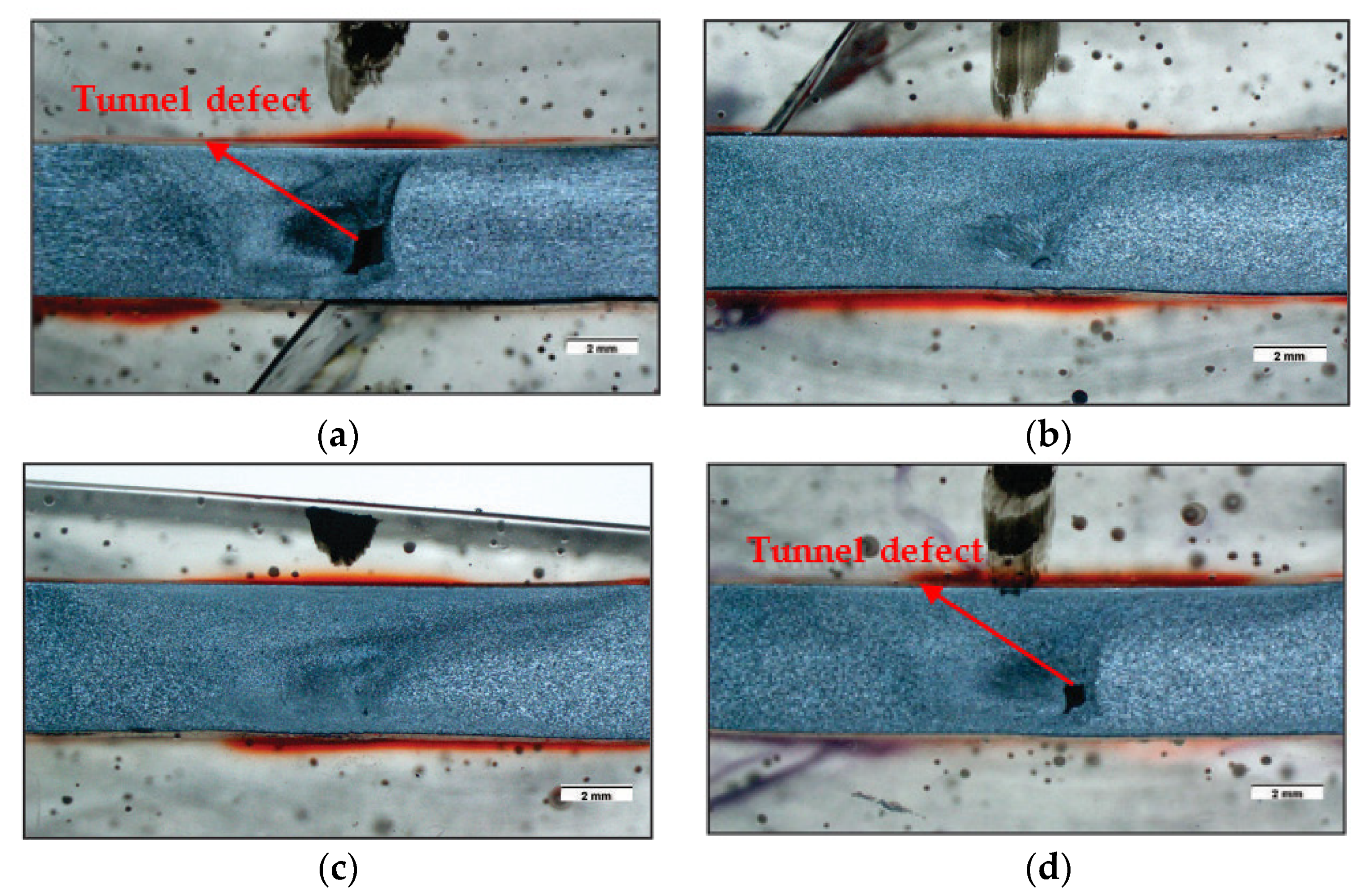

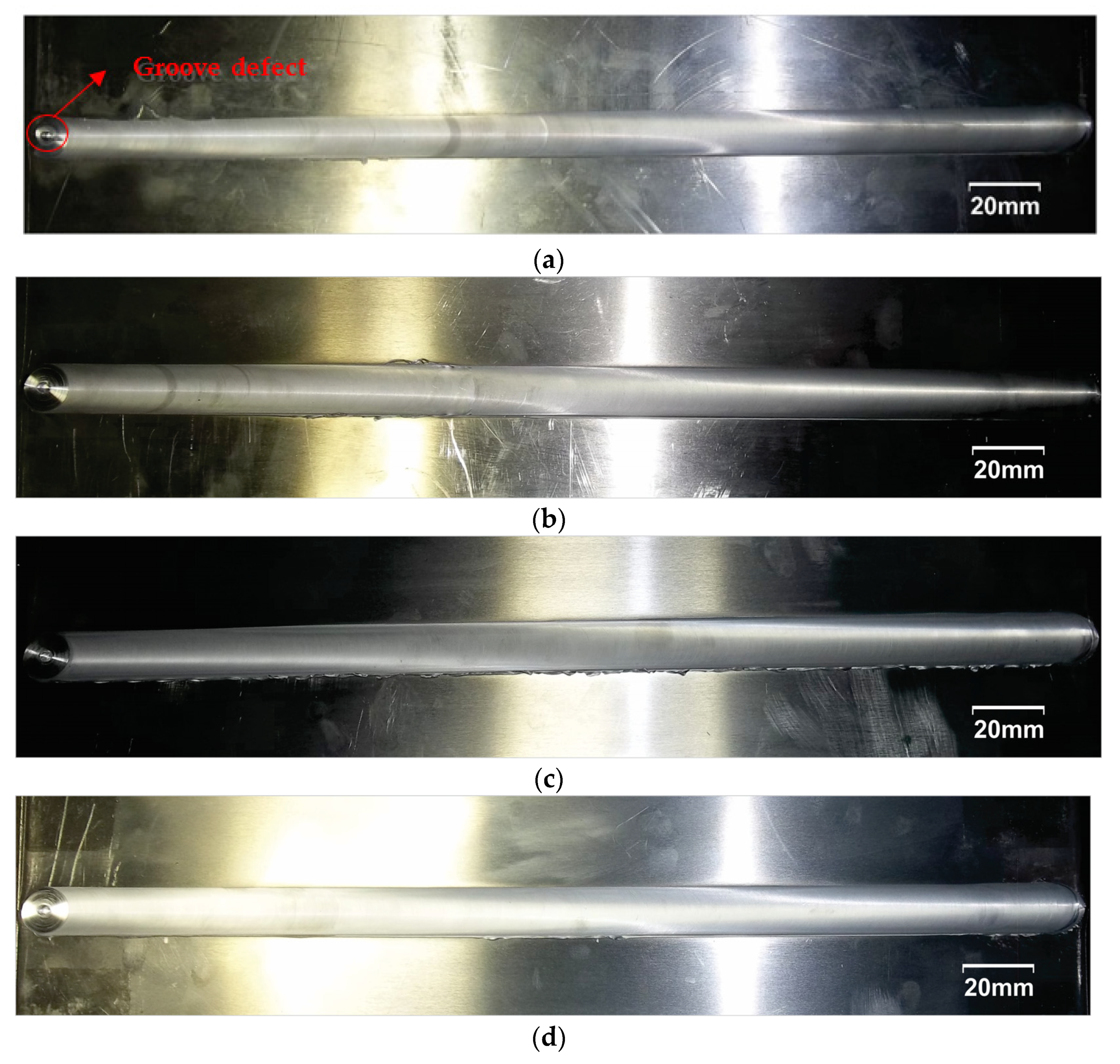

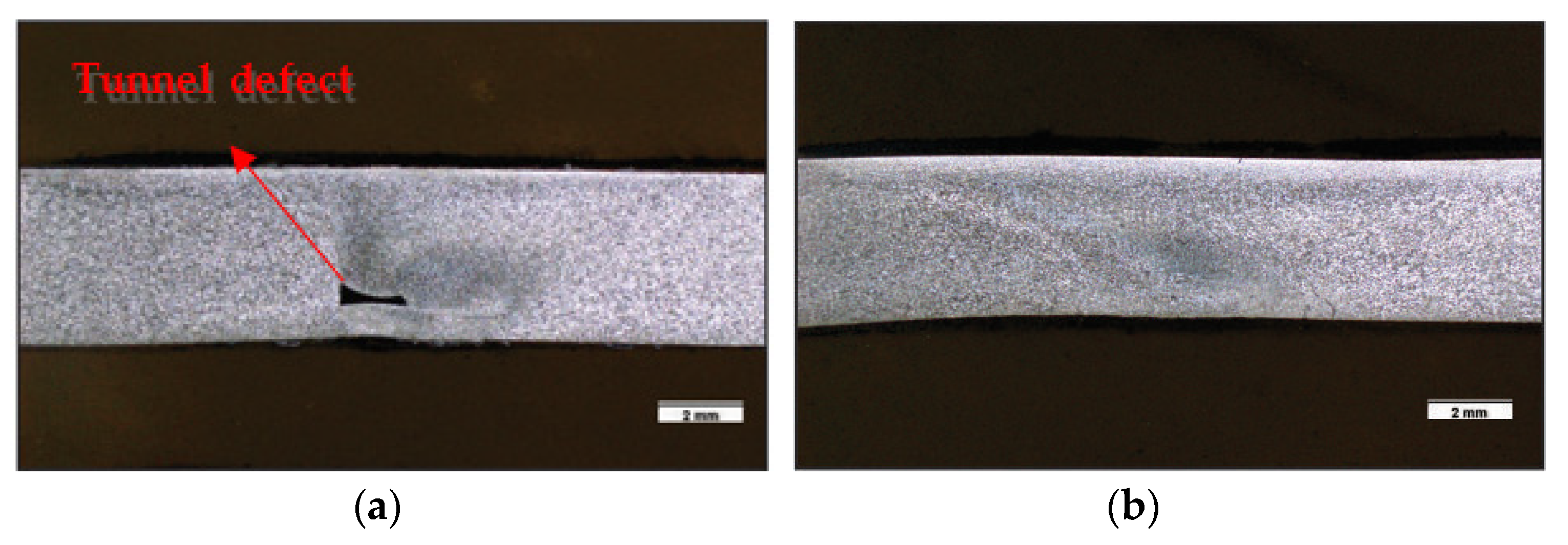

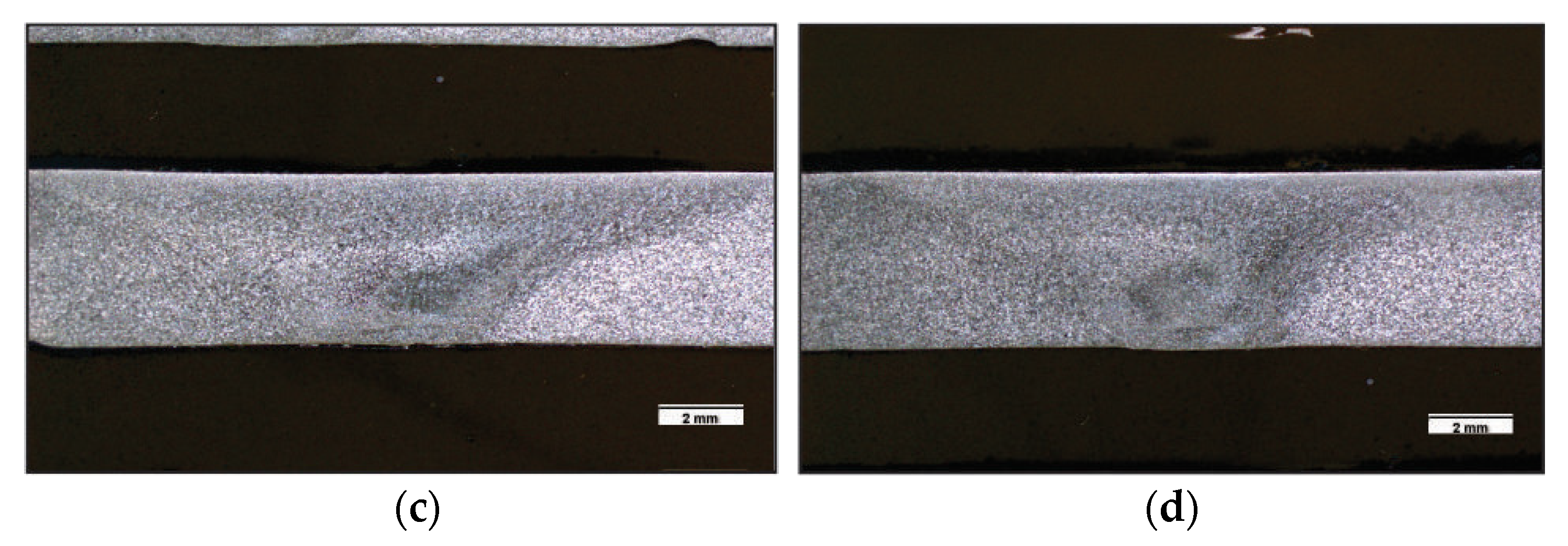

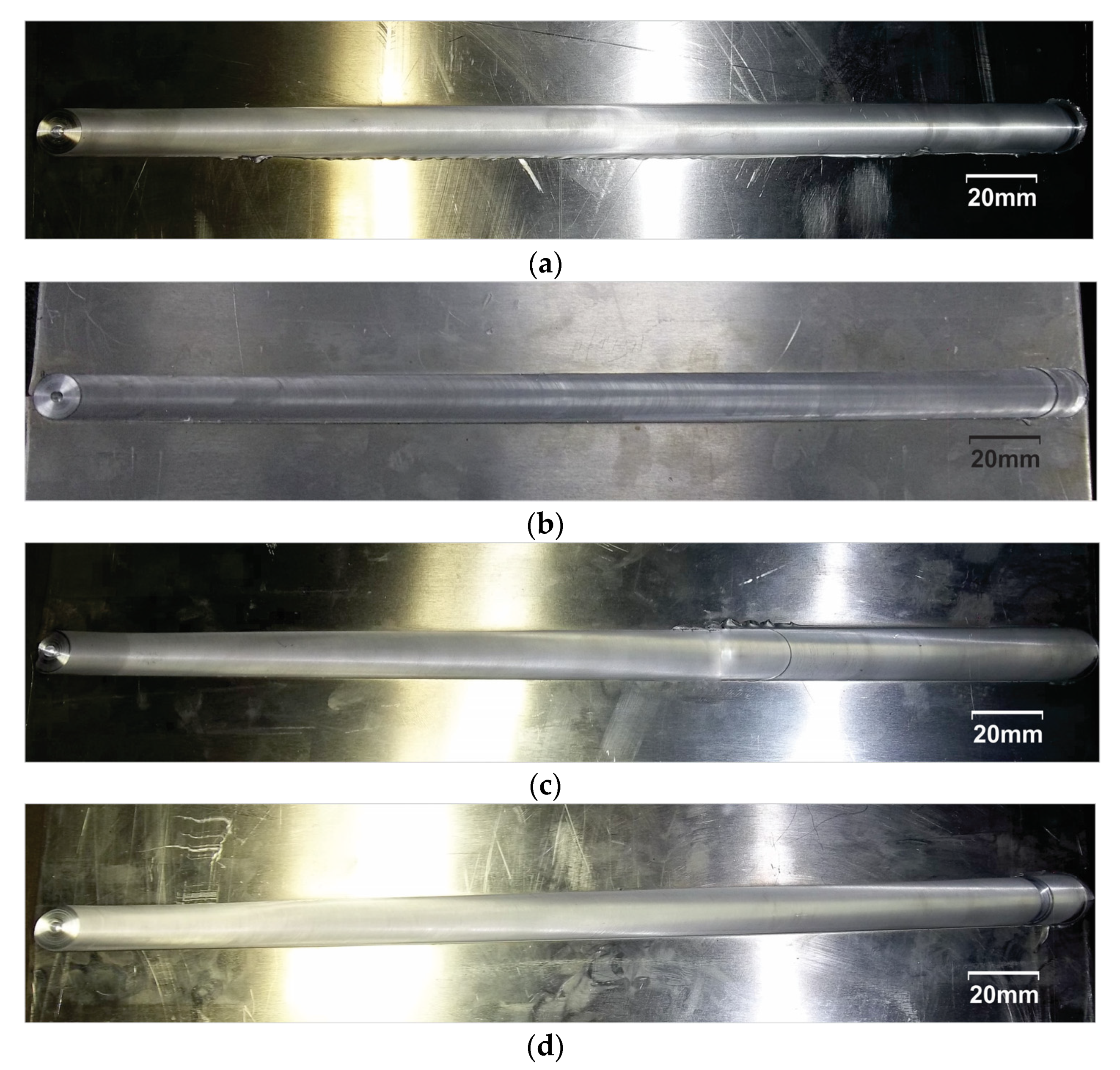

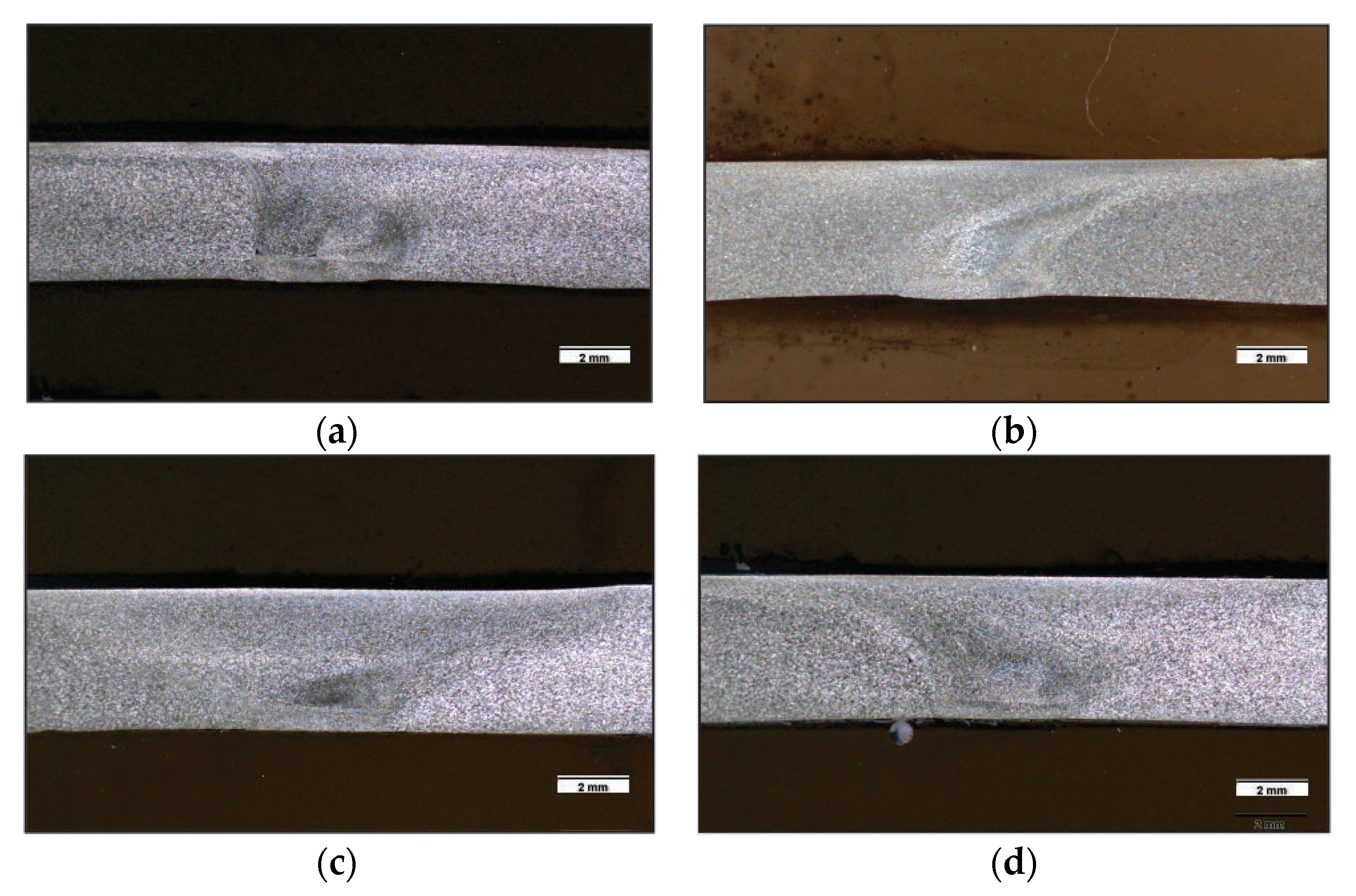

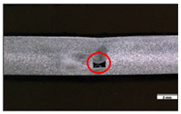

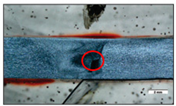

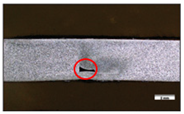

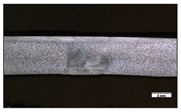

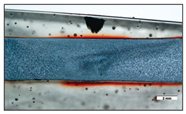

4.1. Macrostructure Analysis

4.2. Microstructure Observation

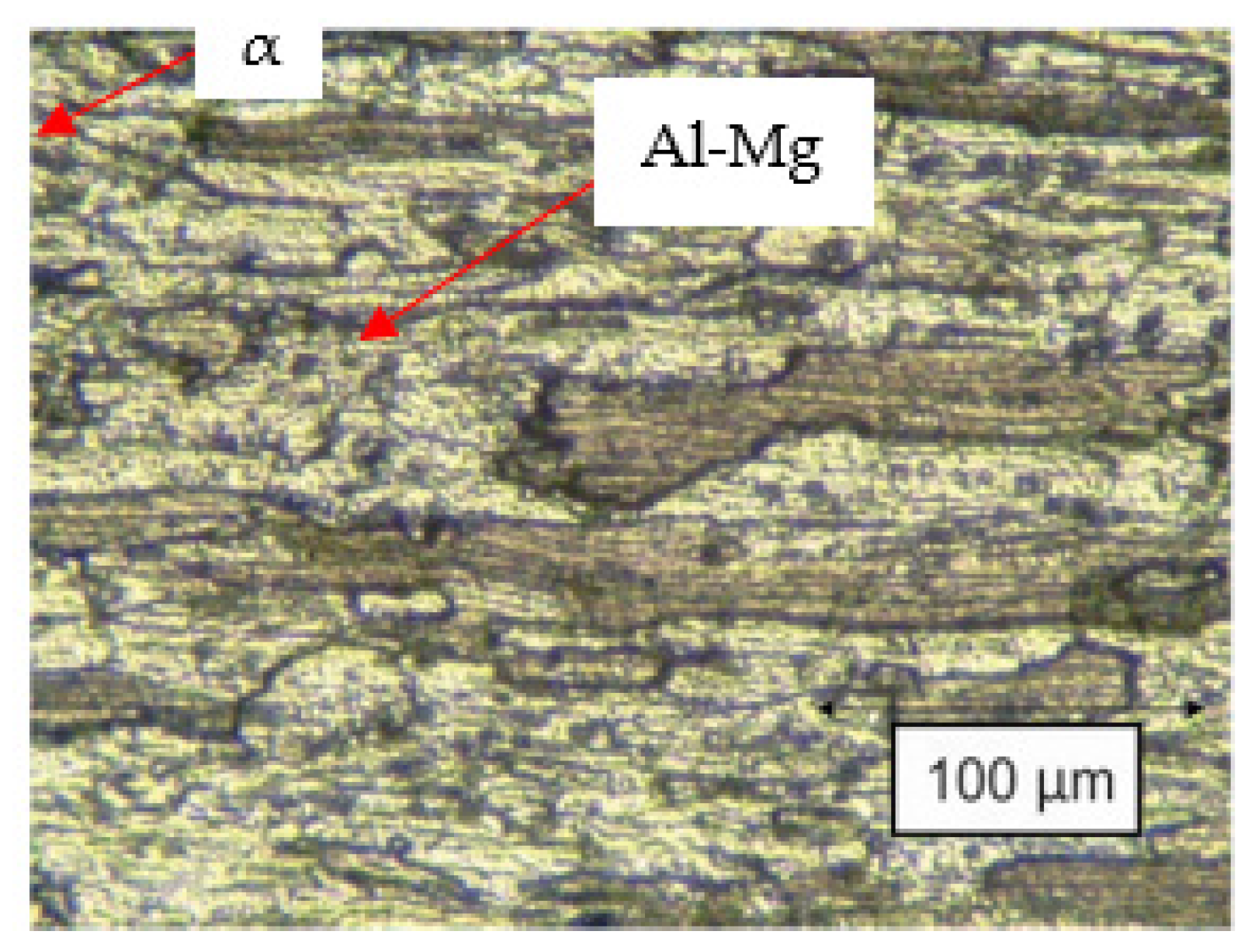

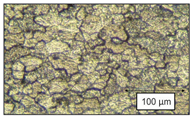

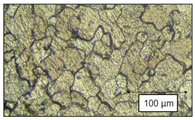

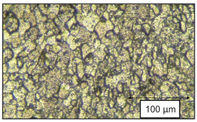

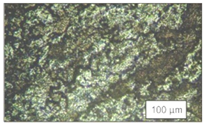

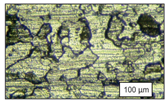

4.2.1. Microstructure of Base Metal AA 5052-H32

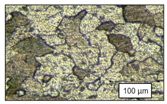

4.2.2. Influence of Pin Profiles and Preheat Temperature at HAZ

4.2.3. Influence of Pin Profiles and Preheat Temperature at TMAZ

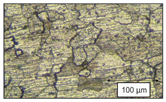

4.2.4. Influence of Pin Profiles and Preheat Temperature at Weld Nugget

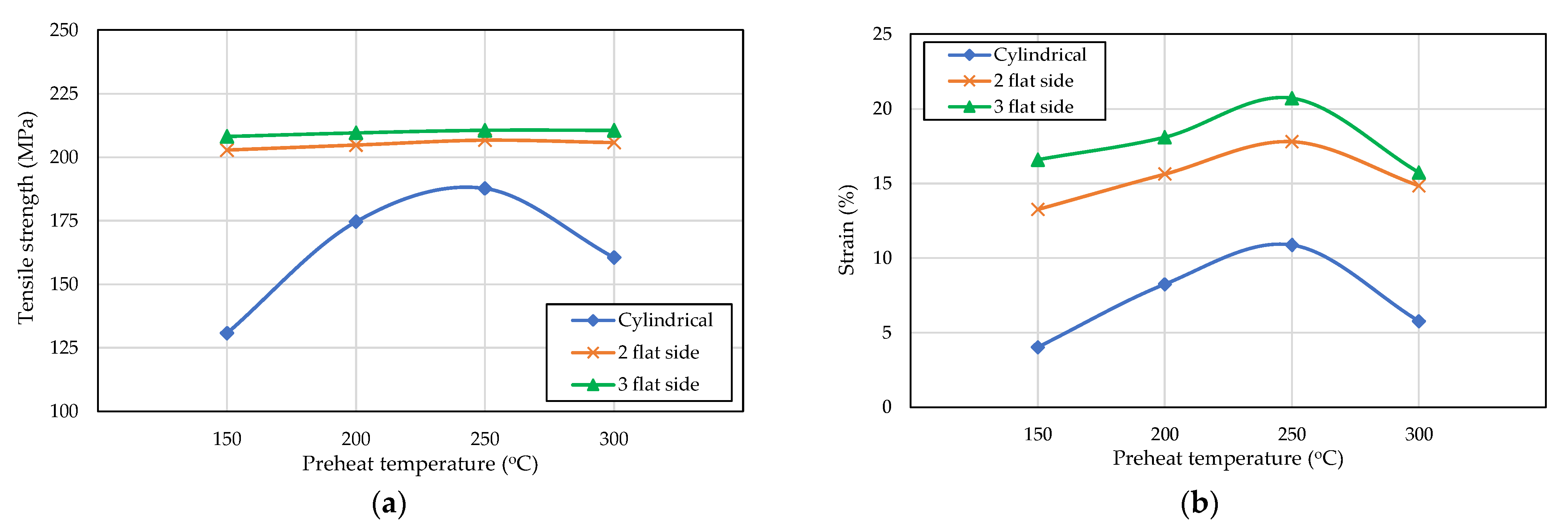

4.3. Tensile Strength Result

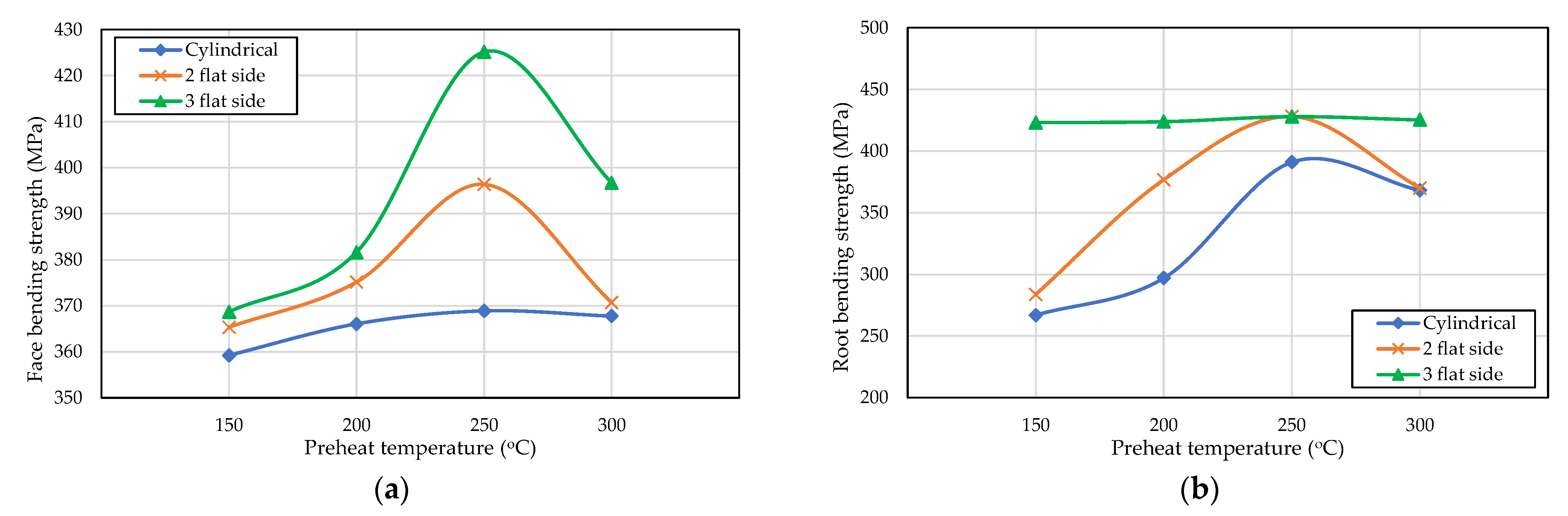

4.4. Bending Strength Result

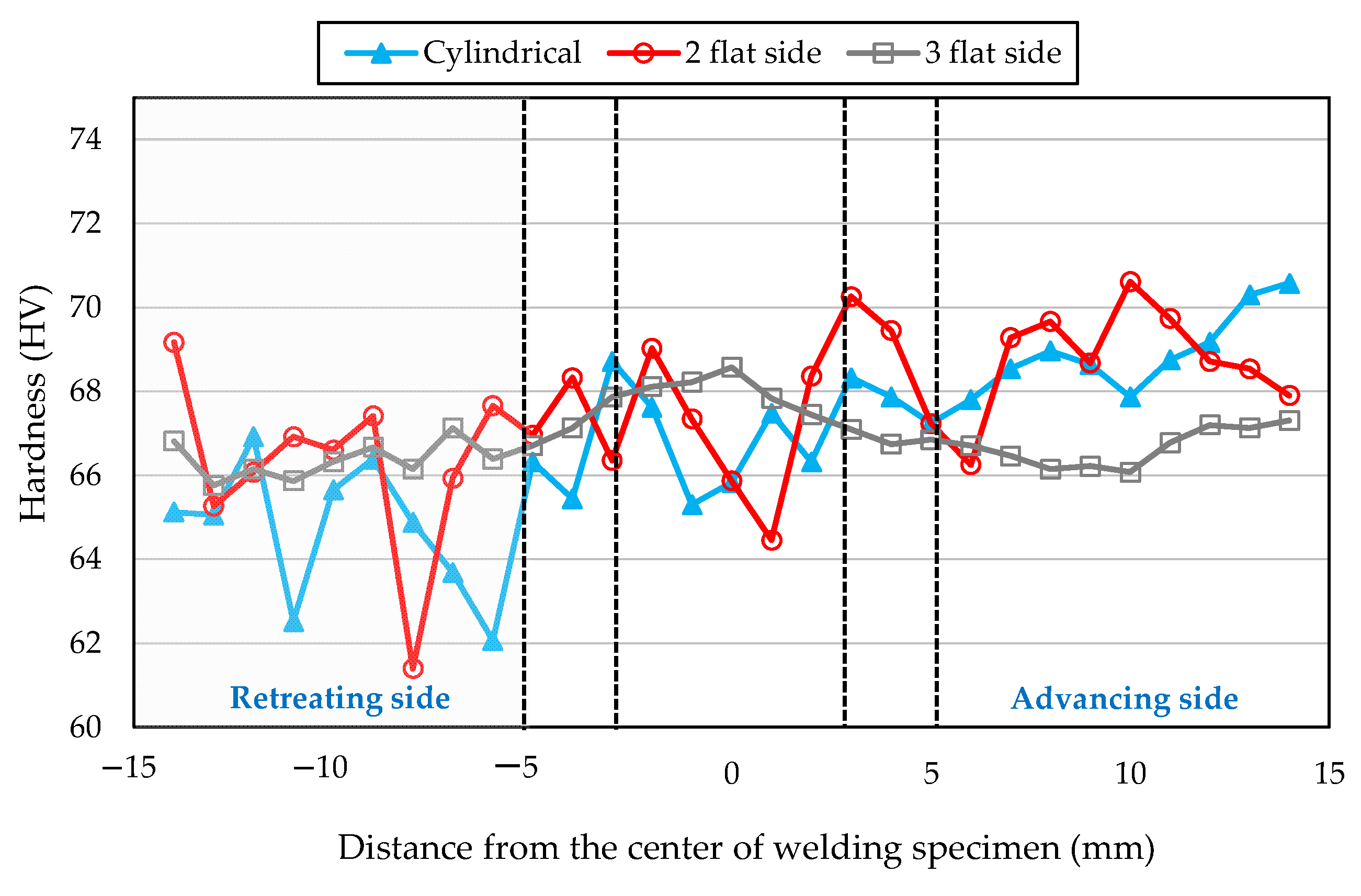

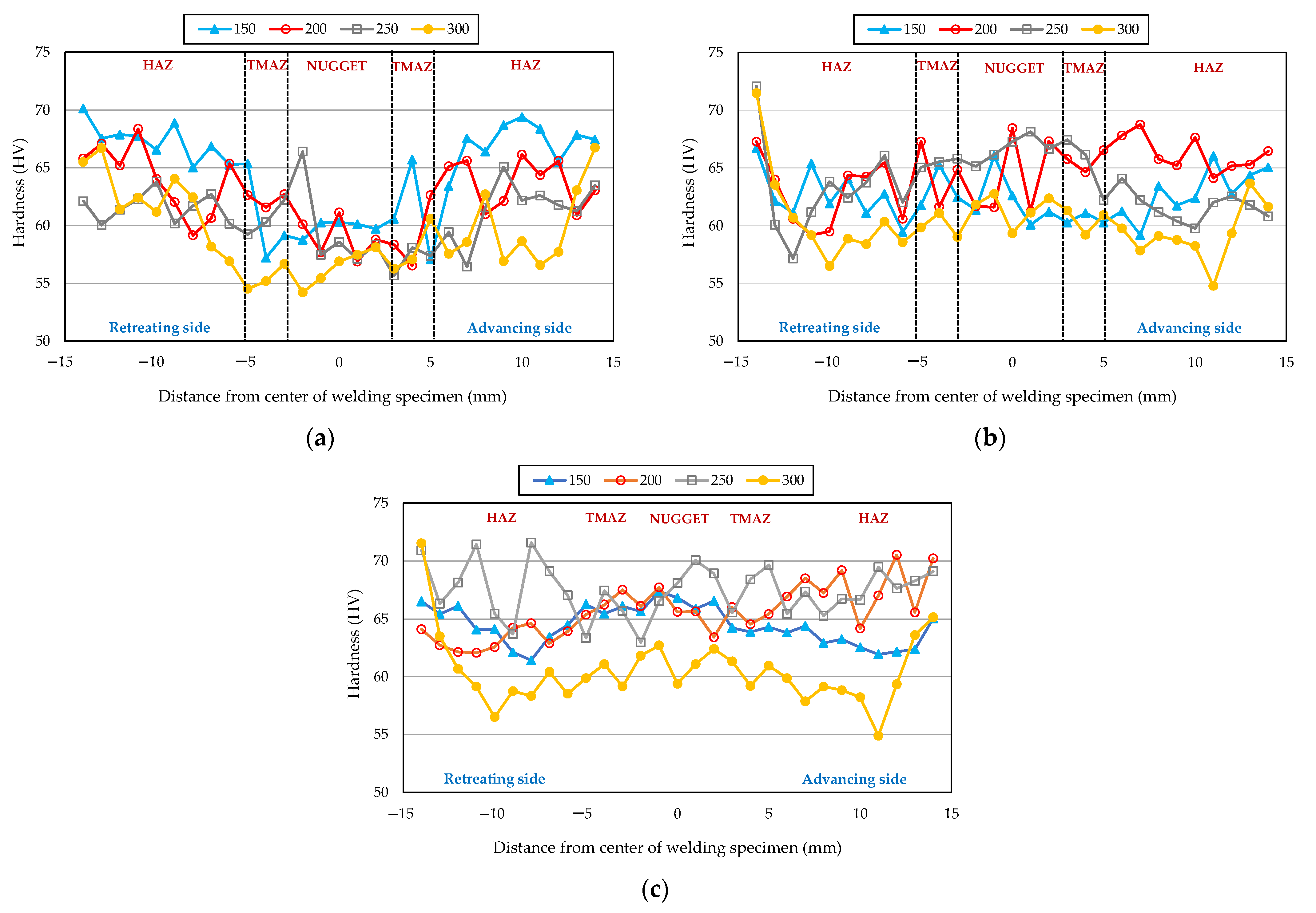

4.5. Hardness Test Result

5. Conclusions

- Tunnel defects are found in the macrostructure of the cylindrical pin profile design without preheating and at the 150 °C and 300 °C preheating temperatures as well as in the flat two-sided pin profile without preheating and at the 150 °C preheating temperature. However, none of the preheating temperatures resulted in any visible defects in the three-flat-sided pin profile designs. The defects which occur in the cylindrical and two-flat-sided pin profiles are due to the improper pin profile design. The specimens received insufficient heat input to soften the material in the sample without preheating and with aheating at 150 °C, causing the observed tunnel defect.

- The microstructural observations show that the weld nugget area was plastically deformed by stirring from the FSW tool, and the grain had grain refinement as a result of dynamic recrystallization. The grain size became finer than in the HAZ and TMAZ regions. Preheating softens the materials and increases the flow of the materials in the stir zone, but at a high preheating temperature (300 °C), it leads grain size growth due to a slow cooling rate.

- The tool pin profile design affects the joint strength and performance of the FSW. The three-flat-sided pin profile has better mechanical properties in terms of hardness, tensile strength, and bending strength than the two other designs. The mechanical properties of the three-flat-sided pin profile demonstrate an increase in the tensile strength of 12.2%, increases of 15.3% and 9.4% for the face and root bending strength, and an 11.2% increase in hardness compared to the cylindrical pin profile at the 250 °C preheating temperature.

- The optimal preheating temperature appears to be 250 °C, because it is best able to increase the mechanical properties of the joint. The increased preheat temperature produces a coarser grain size. It influences the small decrease that is seen in the mechanical properties at the preheat temperature of 300 °C.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chalmers, D.W. The Properties and Uses of Marine Structural Materials. Mar. Struct. 1988, 1, 47–70. [Google Scholar] [CrossRef]

- Purslow, M.A. Reducing the ecological impact of arc welding: Practical strategies are offered for reducing energy consumption when using various arc welding processes. Weld. J. 2012, 91, 24–27. [Google Scholar]

- Muhayat, N.; Zubaydi, A.; Sulistijono; Yuliadi, M.Z. Effect of Tool Tilt Angle and Tool Plunge Depth on Mechanical Properties of Friction Stir Welded AA 5083 Joints. Appl. Mech. Mater. 2014, 493, 709–714. [Google Scholar] [CrossRef]

- Suryanarayanan, R.; Sridhar, V.G. Influence of welding parameters on the weld properties in friction stir spot welding of aluminium alloys of varying thicknesses. Mater. Today Proc. 2021, 46, 8525–8531. [Google Scholar] [CrossRef]

- Praveen, P.; Yarlagadda, P.K.D.V.; Kang, M.J. Advancements in pulse gas metal arc welding. J. Mater. Process. Technol. 2005, 164–165, 1113–1119. [Google Scholar] [CrossRef]

- Soysal, T.; Kou, S. Effect of filler metals on solidification cracking susceptibility of Al alloys 2024 and 6061. J. Mater. Process. Technol. 2019, 66, 421–428. [Google Scholar] [CrossRef]

- Mahoney, M.W.; Rhodes, C.G.; Flintoff, J.G.; Bingel, W.H.; Spurling, R.A. Properties of friction-stir-welded 7075 T651 aluminum. Metall. Mater. Trans. A 1998, 29, 1955–1964. [Google Scholar] [CrossRef]

- Kah, P.; Rajan, R.; Martikainen, J.; Suoranta, R. Investigation of weld defects in friction-stir welding and fusion welding of aluminium alloys. Int. J. Mech. Mater. Eng. 2015, 10, 26. [Google Scholar] [CrossRef] [Green Version]

- Salih, O.S.; Ou, H.; Sun, W.; McCartney, D.G. A review of friction stir welding of aluminum matrix composites. Mater. Des. 2015, 86, 61–71. [Google Scholar] [CrossRef]

- Staron, P.; Kocak, M.; Williams, S.; Wescott, A. Residual stress in friction stir-welded Al sheets. Phys. B Condens. Matter 2004, 350, 491–493. [Google Scholar] [CrossRef]

- Somasekaran, A.C.; Murr, L.E. Microstructures in friction stir welded dissimilar magnesium alloys and magnesium alloys to 6061-T6 aluminum alloy. Mater. Charact. 2004, 52, 49–64. [Google Scholar] [CrossRef]

- Piccinia, J.M.; Svoboda, H.G. Effect of pin length on friction stir spot welding (FSSW) of dissimilar aluminum-steel joints. Procedia Mater. Sci. 2015, 9, 504–513. [Google Scholar] [CrossRef] [Green Version]

- Hirasawa, S.; Badarinarayan, H.; Okamoto, K.; Tomimura, T.; Kawanami, T. Analysis of effect of tool geometry on plastic flow during friction stir spot welding using particle method. J. Mater. Process. Technol. 2010, 210, 1455–1463. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Chen, Y.; Feng, J. Effect of zigzag line on the mechanical properties of friction stir welded joints of an Al−Cu alloy. Scr. Mater. 2006, 55, 231–234. [Google Scholar] [CrossRef]

- Elangovan, K.; Balasubramanian, V. Influences of tool pin profile and welding speed on the formation of friction stir processing zone in AA2219 aluminium alloy. J. Mater. Process. Technol. 2008, 200, 163–175. [Google Scholar] [CrossRef]

- Gopi, S.; Manonmani, K. Influence of Shoulder Profile and Shoulder Penetration on Joint Strength of Friction Stir Welded AA6082 in Conventional Milling Machine. Eur. J. Sci. Res. 2012, 73, 20–32. [Google Scholar]

- Janeczek, A.; Tomków, J.; Fydrych, D. The Influence of Tool Shape and Process Parameters on the Mechanical Properties of AW-3004 Aluminium Alloy Friction Stir Welded Joints. Materials 2021, 14, 3244. [Google Scholar] [CrossRef] [PubMed]

- Dawood, H.I.; Mohammed, K.S.; Rahmat, A.; Uday, M.B. Effect of Small Tool Pin Profiles on Microstructures and Mechanical Properties of 6061 Aluminum Alloy by Friction Stir Welding. Trans. Nonferr. Met. Soc. China 2015, 25, 2856–2865. [Google Scholar] [CrossRef]

- Trueba, L.; Heredia, G.; Rybicki, D.; Johannes, L.B. Effect of Tool Shoulder Features on Defects and Tensile Properties of Friction Stir Welded Aluminum 6061-T6. J. Mater. Process. Technol. 2015, 219, 271–277. [Google Scholar] [CrossRef]

- Emamian, S.; Awang, M.; Hussai, P.; Meyghani, B.; Zafar, A. Influences of Tool Pin Profile on The Friction Stir Welding of AA6061. ARPN J. Eng. Appl. Sci. 2016, 11, 12258–12261. [Google Scholar]

- Marzbanrad, J.; Akbari, M.; Asadi, P.; Safaee, S. Characterization of the Influence of Tool Pin Profile on Microstructural and Mechanical Properties of Friction Stir Welding. Metall. Mater. Trans. B 2014, 45, 1887–1894. [Google Scholar] [CrossRef]

- Verma, S.; Gupta, M.; Misra, J.P. Effect of pin-profiles on thermal cycle, mechanical and metallurgical properties of friction stir–welded aviation-grade aluminum alloy. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2019, 233, 2183–2195. [Google Scholar] [CrossRef]

- Aldanondo, E.; Vivas, J.; Álvarez, P.; Hurtado, I. Effect of Tool Geometry and Welding Parameters on Friction Stir Welded Lap Joint Formation with AA2099-T83 and AA2060-T8E30 Aluminium Alloys. Metals 2020, 10, 872. [Google Scholar] [CrossRef]

- Muhayat, N.; Priatmana Putra, B.; Triyono. Mechanical Properties and Microstructure of Friction Stir Spot Welded 6082-T6 Aluminium Alloy Joint. MATEC Web Conf. 2019, 269, 01005. [Google Scholar] [CrossRef] [Green Version]

- Chupradit, S.; Bokov, D.O.; Suksatan, W.; Landowski, M.; Fydrych, D.; Abdullah, M.E.; Derazkola, H.A. Pin Angle Thermal Effects on Friction Stir Welding of AA5058 Aluminum Alloy: CFD Simulation and Experimental Validation. Materials 2021, 14, 7565. [Google Scholar] [CrossRef]

- Muhayat, N.; Triyono; Rahmanto, R.D.; Zubaydi, A. Effect of Tool Plunge Depth and Pin Profile on Mechanical Properties of Friction Stir Spot Welded AA5052 Joints. J. Mech. Eng. 2018, 5, 181–191. [Google Scholar]

- Heidarzadeh, A.; Javidani, M.; Mofarrehi, M.; Farzaneh, A.; Chen, X.-G. Submerged Dissimilar Friction Stir Welding of AA6061 and AA7075 Aluminum Alloys: Microstructure Characterization and Mechanical Property. Metals 2021, 11, 1592. [Google Scholar] [CrossRef]

- Sinclair, P.C.; Longhurst, W.R.; Cox, C.D.; Lammlein, D.H.; Strauss, A.M.; Cook, G.E. Heated Friction Stir Welding: An Experimental and Theoretical Investigation into How Preheating Influences Process Forces. Mater. Manuf. Process. 2010, 25, 4–37. [Google Scholar] [CrossRef]

- Verma, S.; Misra, J.P. Study on Temperature Distribution During Friction Stir Welding of 6082 Aluminum Alloy. Mater. Today Proc. 2017, 4, 1350–1356. [Google Scholar] [CrossRef]

- Yaduwanshi, D.K.; Bag, S.; Pal, S. Effect of Preheating on Mechanical Properties of Hybrid Friction Stir Welded Dissimilar Joint. In Proceedings of the 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR), Assam, India, 12–14 December 2014. [Google Scholar]

- Muhayat, N.; Triyono; Kusharjanta, B.; Handika, R.T. Effect of Preheat Temperature on Friction Stir Welded Aluminum Alloy 5052 Joints. Appl. Mech. Mater. 2014, 597, 253–256. [Google Scholar]

- Jia, Y.; Lin, S.; Liu, J.; Qin, Y.; Wang, K. The Influence of Pre- and Post-Heat Treatment on Mechanical Properties and Microstructures in Friction Stir Welding of Dissimilar Age-Hardenable Aluminum Alloys. Metals 2019, 9, 1162. [Google Scholar] [CrossRef] [Green Version]

- Verma, S.; Gupta, M.; Misra, J.P. Effect of preheating and water cooling on the performance of friction-stir-welded aviation-grade aluminum alloy joints. J. Mater. Eng. Perform. 2019, 28, 4209–4220. [Google Scholar] [CrossRef]

- Rai, R.; De, A.; Bhadeshia, H.K.; DebRoy, T. Review: Friction stir welding tools. Sci. Technol. Weld. Join. 2011, 16, 325–342. [Google Scholar] [CrossRef]

- Fujii, H.; Cui, L.; Maeda, M.; Nogi, K. Effect of tool shape on mechanical properties and microstructure of friction stir welded aluminum alloys. Mater. Sci. Eng. A 2006, 419, 25–31. [Google Scholar] [CrossRef]

- Kumar, A.; Raju, L.S. Influence of tool pin-profiles on friction stir welding of copper. Mater. Manuf. Process. 2012, 27, 1414–1418. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Rao, D.; Huber, K.; Heerens, J.; Dos Santos, J.F.; Huber, N. Asymmetric mechanical properties and tensile behaviour prediction of aluminium alloy 5083 friction stir welding joints. Mater. Sci. Eng. A 2013, 565, 44–50. [Google Scholar] [CrossRef] [Green Version]

- Vimalraj, C.; Kah, P. Experimental Review on Friction Stir Welding of Aluminium Alloys with Nanoparticles. Metals 2021, 11, 390. [Google Scholar] [CrossRef]

- Kwon, Y.J.; Shim, S.B.; Park, D.W. Friction stir welding of 5052 aluminum alloy plates. Trans. Nonferr. Met. Soc. China 2009, 19, 23–27. [Google Scholar] [CrossRef]

- Prabowo, A.R.; Tuswan, T.; Ridwan, R. Advanced development of sensors’ roles in maritime-based industry and research: From field monitoring to high-risk phenomenon measurement. Appl. Sci. 2021, 11, 3954. [Google Scholar] [CrossRef]

- Paik, J.K. Recent Advances and Future Trends on Plasticity and Impact Mechanics of Ships and Offshore Structures. Proc. Eng. 2017, 173, 17–24. [Google Scholar] [CrossRef]

- Prabowo, A.R.; Tuswan, T.; Prabowoputra, D.M.; Ridwan, R. Deformation of designed steel plates: An optimisation of the side hull structure using the finite element approach. Open Eng. 2021, 11, 1034–1047. [Google Scholar] [CrossRef]

- Ridwan, R.; Prabowo, A.R.; Muhayat, N.; Putranto, T.; Sohn, J.M. Tensile analysis and assessment of carbon and alloy steels using fe approach as an idealization of material fractures under collision and grounding. Curved Layer Struct. 2020, 7, 188–198. [Google Scholar] [CrossRef]

- Smaradhana, D.F.; Prabowo, A.R.; Ganda, A.N.F. Exploring the potential of graphene materials in marine and shipping industries—A technical review for prospective application on ship operation and material-structure aspects. J. Ocean Eng. Sci. 2021, 6, 299–316. [Google Scholar] [CrossRef]

- Rigueiro, C.; Ribeiro, J.; Santiago, A. Numerical assessment of the behaviour of a fixed offshore platform subjected to ship collision. Proc. Eng. 2017, 199, 2494–2499. [Google Scholar] [CrossRef]

- Prabowo, A.R.; Do, Q.T.; Cao, B.; Bae, D.M. Land and marine-based structures subjected to explosion loading: A review on critical transportation and infrastructure. Proc. Struct. Integ. 2020, 27, 77–84. [Google Scholar] [CrossRef]

- Akbar, M.S.; Prabowo, A.R.; Tjahjana, D.D.D.P.; Tuswan, T. Analysis of plated-hull structure strength against hydrostatic and hydrodynamic loads: A case study of 600 TEU container ships. J. Mech. Behav. Mater. 2021, 30, 237–248. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Rotational speed (n) | 1125 rpm |

| Tool tilt angle (θ) | 2° |

| Heater tilt angle (β) | 45° |

| Welding speed (v) | 60 mm/min |

| Depth plunge (h) | 3.95 mm |

| Distance between heater and tool (l) | 60 mm |

| Heater height (h) | 20 mm |

| Preheat temperature | 150 °C, 200 °C, 250 °C, 300 °C |

| Tensile Strength (MPa) | Face Bending Strength (MPa) | Root Bending Strength (MPa) | Hardness (HV) |

|---|---|---|---|

| 229.35 | 437.66 | 437.66 | 68 |

| No | Micro Photo | Tools | ||

|---|---|---|---|---|

| Cylindrical | Two Flat Sides | Three Flat Sides | ||

| 1 | HAZ RS |  |  |  |

| 2 | TMAZ RS |  |  |  |

| 3 | NUGGET |  |  |  |

| 4 | TMAZ AS |  |  |  |

| 5 | HAZ AS |  |  |  |

| Code | Tool | Tensile Strength (MPa) | Face Bending Strength (MPa) | Root Bending Strength (MPa) | Hardness (HV) |

|---|---|---|---|---|---|

| FT0-TP | Cylindrical | 128.27 | 383.84 | 194.12 | 66.87 |

| FT2-TP | 2 flat sides | 193.17 | 391.78 | 382.95 | 67.53 |

| FT3-TP | 3 flat sides | 196.31 | 424.43 | 397.95 | 66.91 |

| Micro Photo | Preheat Temperature | |||

|---|---|---|---|---|

| 150 °C | 200 °C | 250 °C | 300 °C | |

| HAZ RS |  |  |  |  |

| TMAZ RS |  |  |  |  |

| NUGGET |  |  |  |  |

| TMAZ AS |  |  |  |  |

| HAZ AS |  |  |  |  |

| Code | Tool | Yield Strength (MPa) | Face Bending Strength (MPa) | Root Bending Strength (MPa) | Hardness (HV) |

|---|---|---|---|---|---|

| FT0-150 | Cylindrical | 131.83 | 359.13 | 268.24 | 64.70 |

| FT0-200 | Cylindrical | 174.39 | 366.19 | 298.25 | 62.52 |

| FT0-250 | Cylindrical | 188.05 | 368.84 | 390.90 | 60.69 |

| FT0-300 | Cylindrical | 161.00 | 367.95 | 368.84 | 59.32 |

| Micro Photo | Preheat Temperature | |||

|---|---|---|---|---|

| 150 °C | 200 °C | 250 °C | 300 °C | |

| HAZ RS |  |  |  |  |

| TMAZ RS |  |  |  |  |

| NUGGET |  |  |  |  |

| TMAZ AS |  |  |  |  |

| HAZ AS |  |  |  |  |

| Code | Tool | Tensile Strength (MPa) | Face Bending Strength (MPa) | Root Bending Strength (MPa) | Hardness (HV) |

|---|---|---|---|---|---|

| FT2-150 | 2 flat side | 203.61 | 365.31 | 284.13 | 62.54 |

| FT2-200 | 2 flat side | 205.13 | 375.01 | 376.78 | 64.58 |

| FT2-250 | 2 flat side | 207.60 | 396.19 | 429.72 | 63.82 |

| FT2-300 | 2 flat side | 206.71 | 370.60 | 368.84 | 60.33 |

| Micro Photo | Preheat Temperature | |||

|---|---|---|---|---|

| 150 °C | 200 °C | 250 °C | 300 °C | |

| HAZ RS |  |  |  |  |

| TMAZ RS |  |  |  |  |

| NUGGET |  |  |  |  |

| TMAZ AS |  |  |  |  |

| HAZ AS |  |  |  |  |

| Code | Tool | Tensile Strength (MPa) | Face Bending Strength (MPa) | Root Bending Strength (MPa) | Hardness (HV) |

|---|---|---|---|---|---|

| FT3-150 | 3 flat side | 208.90 | 368.84 | 425.31 | 64.42 |

| FT3-200 | 3 flat side | 210.13 | 382.07 | 426.19 | 65.54 |

| FT3-250 | 3 flat side | 211.22 | 425.31 | 430.60 | 67.52 |

| FT3-300 | 3 flat side | 210.76 | 397.07 | 427.07 | 60.45 |

| Pin Profiles | |||

|---|---|---|---|

| Preheat Temperature | Cylindrical | Two Flat Sides | Three Flat Sides |

| Without preheat |  |  |  |

| 150 °C |  |  |  |

| 200 °C |  |  |  |

| 250 °C |  |  |  |

| 300 °C |  |  |  |

| Pin Profiles | ||||

|---|---|---|---|---|

| Preheat temperature | Cylindrical | Two Flat Sides | Three Flat Sides | |

| 150 °C |  |  |  | |

| 200 °C |  |  |  | |

| 250 °C |  |  |  | |

| 300 °C |  |  |  | |

| Pin Profiles | ||||

|---|---|---|---|---|

| Preheat temperature | Cylindrical | Two Flat Sides | Three Flat Sides | |

| 150 °C |  |  |  | |

| 200 °C |  |  |  | |

| 250 °C |  |  |  | |

| 300 °C |  |  |  | |

| Pin Profiles | ||||

|---|---|---|---|---|

| Preheat temperature | Cylindrical | Two Flat Sides | Three Flat Sides | |

| 150 °C |  |  |  | |

| 200 °C |  |  |  | |

| 250 °C |  |  |  | |

| 300 °C |  |  |  | |

| Pin Profiles | ||||

|---|---|---|---|---|

| Preheat temperature | Cylindrical | Two Flat Sides | Three Flat Sides | |

| 150 °C |  |  |  | |

| 200 °C |  |  |  | |

| 250 °C |  |  |  | |

| 300 °C |  |  |  | |

| Pin Profiles | ||||

|---|---|---|---|---|

| Preheat temperature | Cylindrical | Two Flat Sides | Three Flat Sides | |

| 150 °C |  |  |  | |

| 200 °C |  |  |  | |

| 250 °C |  |  |  | |

| 300 °C |  |  |  | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muhayat, N.; Harjono, M.S.; Depari, Y.P.D.S.; Prabowo, A.R.; Triyono, T.; Putri, E.D.W.S.; Tuswan, T. Friction Stir Welded AA5052-H32 under Dissimilar Pin Profile and Preheat Temperature: Microstructural Observations and Mechanical Properties. Metals 2022, 12, 4. https://doi.org/10.3390/met12010004

Muhayat N, Harjono MS, Depari YPDS, Prabowo AR, Triyono T, Putri EDWS, Tuswan T. Friction Stir Welded AA5052-H32 under Dissimilar Pin Profile and Preheat Temperature: Microstructural Observations and Mechanical Properties. Metals. 2022; 12(1):4. https://doi.org/10.3390/met12010004

Chicago/Turabian StyleMuhayat, Nurul, Mulyadi Sinung Harjono, Yohanes Pringeten Dilianto Sembiring Depari, Aditya Rio Prabowo, Triyono Triyono, Ericha Dwi Wahyu Syah Putri, and Tuswan Tuswan. 2022. "Friction Stir Welded AA5052-H32 under Dissimilar Pin Profile and Preheat Temperature: Microstructural Observations and Mechanical Properties" Metals 12, no. 1: 4. https://doi.org/10.3390/met12010004

APA StyleMuhayat, N., Harjono, M. S., Depari, Y. P. D. S., Prabowo, A. R., Triyono, T., Putri, E. D. W. S., & Tuswan, T. (2022). Friction Stir Welded AA5052-H32 under Dissimilar Pin Profile and Preheat Temperature: Microstructural Observations and Mechanical Properties. Metals, 12(1), 4. https://doi.org/10.3390/met12010004