Effect of Substituting Hf for Zr on Fe-Co-M-Nb-B (M = Zr, Hf) Amorphous Alloys with High Saturation Magnetization

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

- (a)

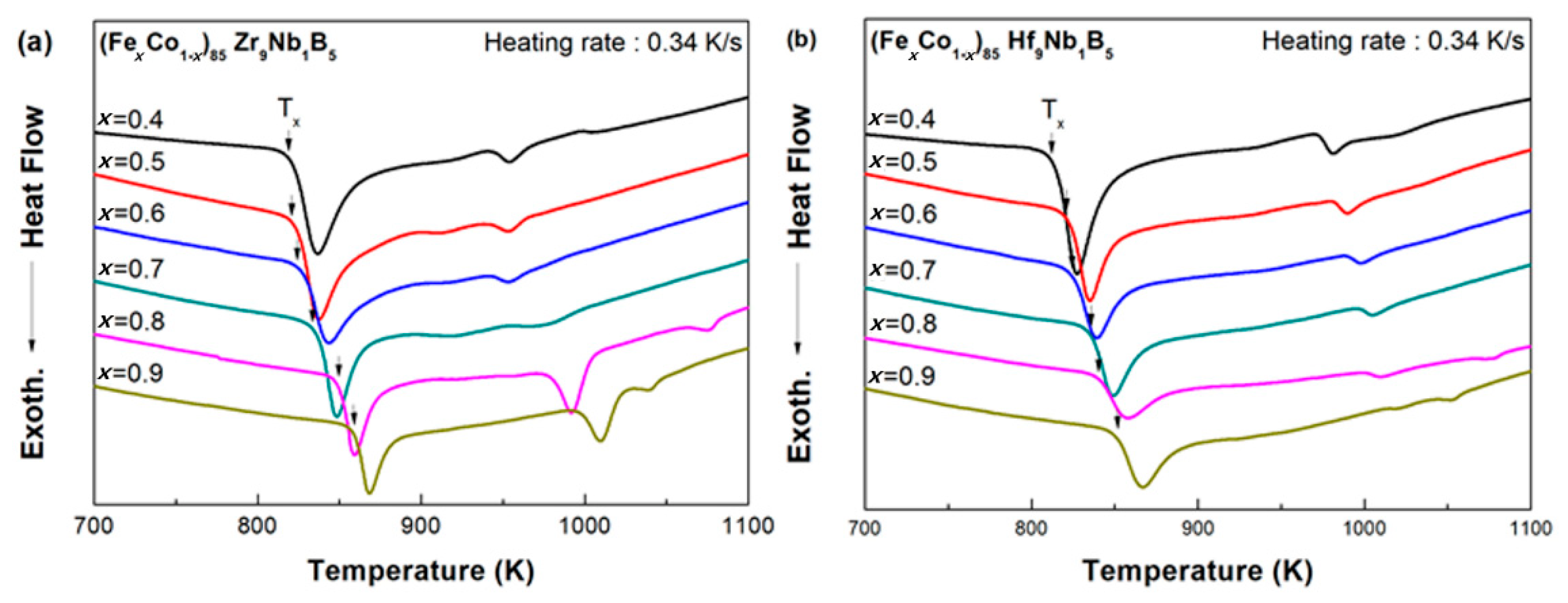

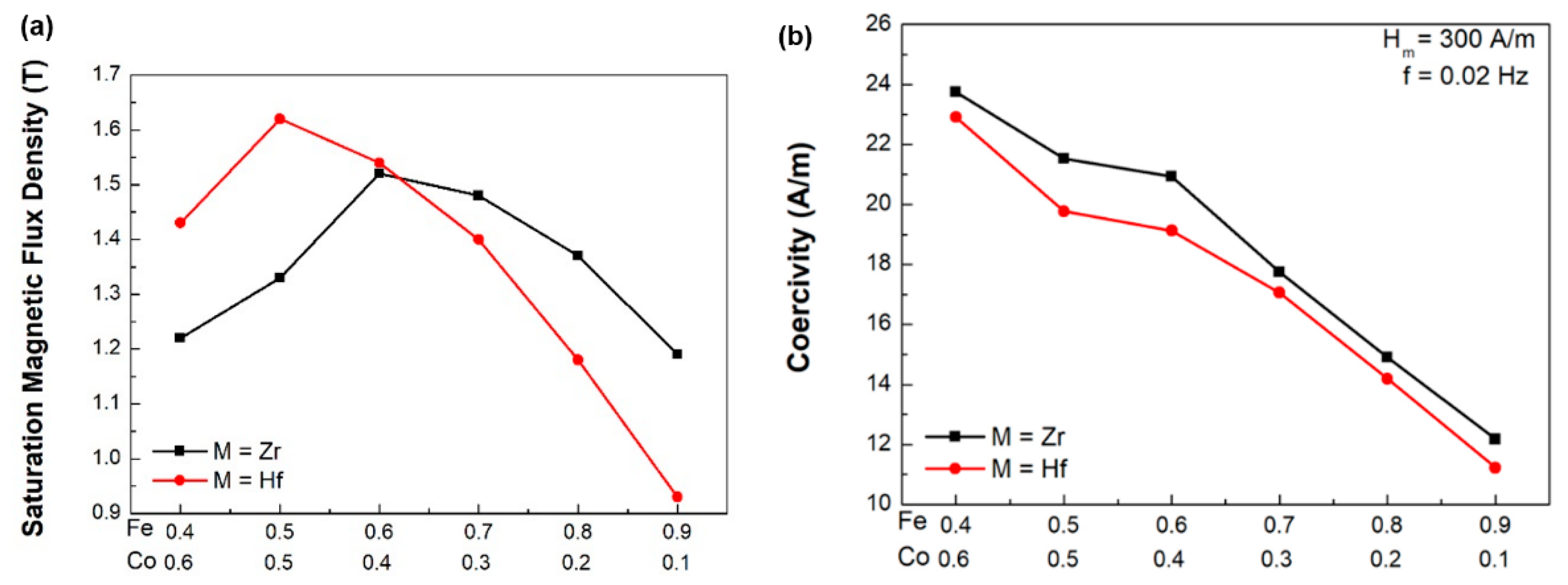

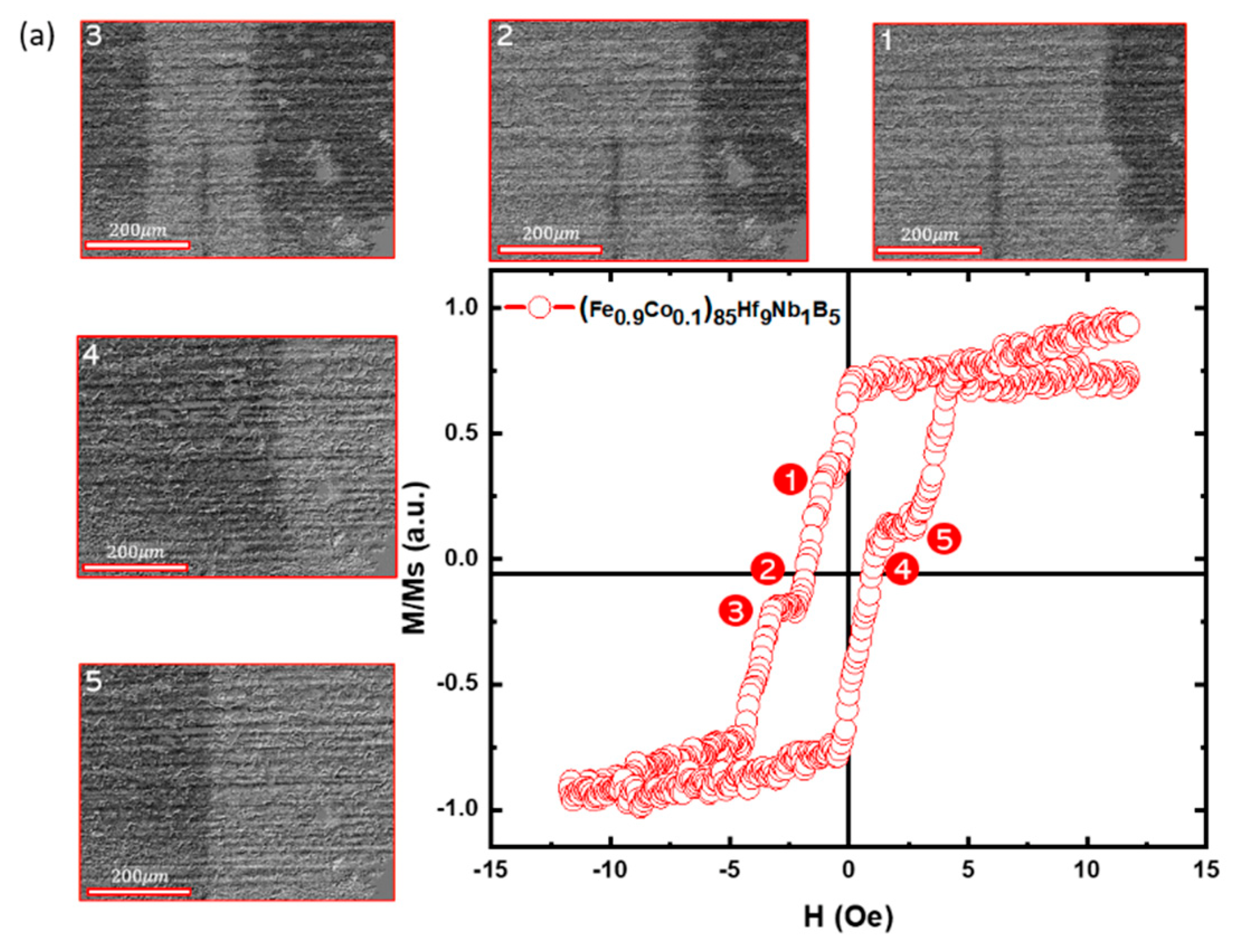

- The effects of substituting Hf for Zr on Tx, Bs, and Hc values are noted as follows. The Tx decreased for every given Fe/Co ratio by incorporating Hf. The variation of Bs is increased by the incorporation of Hf so that both the highest and the lowest Bs values are observed in the Fe-Co-Hf-Nb-B alloys. Particularly, the highest Bs is 1.62 T in Fe47.5Co47.5Hf9Nb1B5 (M = Hf and x = 0.5) amorphous ribbon. Moreover, the Hc decreases by substituting Hf for Zr for every given Fe/Co ratio. The lowest Hc value is 11 A/m in Fe76.5Co8.5Hf9Nb1B5 (M = Hf and x = 0.9) melt-spun ribbon. Therefore, the soft magnetic properties, both Bs and Hc, are enhanced by substituting Hf for Zr.

- (b)

- The effects of varying the Fe/Co ratio from 4/6 to 9/1 on thermal and magnetic properties are noted as follows. The Tx increases gradually from 819 to 858 K and from 808 to 849 K in the Zr- and Hf-added alloys, respectively, with the increase in the ratio of Fe/Co from 4/6 to 9/1, suggesting that the Fe/Co ratio affects the thermal stability of the alloys. The optimum Fe/Co ratios for maximizing Bs are 6/4 for the Fe-Co-Zr-Nb-B alloys and 5/5 for the Fe-Co-Hf-Nb-B alloys. The Hc decreases continuously from 24 to 12 A/m for the Fe-Co-Zr-Nb-B alloys and 23 to 11 A/m for the Fe-Co-Hf-Nb-B alloys with the variation of Fe/Co ratio from 4/6 to 9/1. As a result, it can be concluded that the values of Tx and Hc depend on Fe/Co ratio, and the optimum mixing ratio of Fe/Co achieves the maximum saturation magnetization (Bs).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Duwez, P.; Lin, S.C.H. Amorphous ferromagnetic phase in iron-carbon-phosphorus alloys. J. Appl. Phys. 1967, 38, 4096–4097. [Google Scholar] [CrossRef] [Green Version]

- Mizushima, T.; Makino, A.; Inoue, A. Structure and magnetic properties of Fe-based glassy alloys. Mater. Sci. Eng. A 1997, 226, 721–725. [Google Scholar] [CrossRef]

- Hasegawa, R. Spin-fluctuation resistivity in alloys. Phys. Lett. A 1972, 38, 5–7. [Google Scholar] [CrossRef]

- Masumoto, T.; Waseda, Y.; Kimura, H.; Inoue, A. Structural stability of amorphous metals. Sci. Rep. Res. Inst. Tohoku Univ. Ser. A Phys. Chem. Metall. 1976, 26, 96. [Google Scholar] [CrossRef]

- Inoue, A.; Kobayashi, K.; Nose, M.; Masumoto, T. Mechanical properties of (Fe, Co, Ni)-MB (M = Ti, Zr, Hf, V, Nb, Ta and Mo) amorphous alloys with low boron concentration. J. Phys. Colloq. 1980, 41, C8-831–C8-834. [Google Scholar] [CrossRef]

- Han, B.; Kim, Y.K.; Choi-Yim, H. Effect of compositional variation on the soft magnetic properties of Fe(87−x−y) CoxTi7 Zr6By amorphous ribbons. Curr. Appl. Phys. 2014, 14, 685–687. [Google Scholar] [CrossRef]

- Inoue, A.; Wang, X.M.; Zhang, W. Developments and Applications of Bulk Metallic Glasses. Rev. Adv. Mater. Sci. 2008, 18, 1–9. [Google Scholar]

- Chang, H.W.; Huang, Y.C.; Chang, C.W.; Hsieh, C.C.; Chang, W.C. Soft magnetic properties and glass formability of Y–Fe–B–M bulk metals (M = Al, Hf, Nb, Ta, and Ti). J. Alloys Compd. 2009, 472, 166–170. [Google Scholar] [CrossRef]

- Inoue, A.; Shen, B.L.; Chang, C.T. Super-high strength of over 4000 MPa for Fe-based bulk glassy alloys in [(Fe1−xCox)0.75B0.2Si0.05]96Nb4 system. Acta Mater. 2004, 52, 4093–4099. [Google Scholar] [CrossRef]

- Shen, B.; Inoue, A.; Chang, C. Superhigh strength and good soft-magnetic properties of (Fe, Co)–B–Si–Nb bulk glassy alloys with high glass-forming ability. Appl. Phys. Lett. 2004, 85, 4911–4913. [Google Scholar] [CrossRef]

- Shen, B.; Chang, C.; Kubota, T.; Inoue, A. Superhigh strength and excellent soft-magnetic properties of [(Co1−xFex)0.75B0.2Si0.05]96 Nb4 bulk glassy alloys. J. Appl. Phys. 2006, 100, 013515. [Google Scholar] [CrossRef]

- Matsubara, E.; Tamura, T.; Waseda, Y.; Inoue, A.; Zhang, T.; Masumoto, T. Structural study of Zr60Al15Ni25 amorphous alloys with a wide supercooled liquid region by the anomalous X-ray scattering (AXS) method. Mater. Trans. JIM 1992, 33, 873–878. [Google Scholar] [CrossRef] [Green Version]

- Inoue, A.; Takeuchi, A.; Zhang, T.; Murakami, A.; Makino, A. Soft magnetic properties of bulk Fe-based amorphous alloys prepared by copper mold casting. IEEE Trans. Magn. 1996, 32, 4866–4871. [Google Scholar] [CrossRef]

- Hiroyoshi, H.; Fukamichi, K. Ferromagnetic-spin glass transition in Fe-Zr amorphous alloy system. J. Appl. Phys. 1982, 53, 2226–2228. [Google Scholar] [CrossRef]

- Ennas, G.; Magini, M.; Padella, F.; Susini, P.; Boffitto, G.; Licheri, G. Preparation of amorphous Fe-Zr alloys by mechanical alloying and melt spinning methods. J. Mater. Sci. 1989, 24, 3053–3058. [Google Scholar] [CrossRef]

- Ohnuma, S.; Masateru, N.; Kiwamu, S. Magnetic properties of amorphous Fe-Zr-B alloys. Sci. Rep. Res. Inst. Tohoku Univ. Ser. A Phys. Chem. Metall. 1980, 29, 254–264. [Google Scholar]

- Masumoto, T.; Ohnuma, S.; Shirakawa, K.; Nose, M.; Kobayashi, K. Magnetic properties of metal-metal amorphous alloys. J. Phys. Colloq. 1980, 41, C8-686–C8-689. [Google Scholar] [CrossRef]

- Suzuki, K.; Makino, A.; Inoue, A.; Masumoto, T. Soft magnetic properties of nanocrystalline bcc Fe-Zr-B and Fe-M-B-Cu (M = transition metal) alloys with high saturation magnetization. J. Appl. Phys. 1991, 70, 6232–6237. [Google Scholar] [CrossRef]

- Makino, A.; Suzuki, K.; Inoue, A.; Hirotsu, Y.; Masumoto, T. Magnetic properties and microstructure of nanocrystalline bcc Fe-MB (M = Zr, Hf, Nb) alloys. J. Magn. Magn. Mater. 1994, 133, 329–333. [Google Scholar] [CrossRef]

- Ma, L.; Wang, L.; Zhang, T.; Inoue, A. Effect of Nb addition on glass-forming ability, strength, and hardness of Fe–B–Zr amorphous alloys. Mater. Res. Bull. 1999, 34, 915–920. [Google Scholar] [CrossRef]

- Inoue, A.; Shen, B. New Fe-based bulk glassy alloys with high saturated magnetic flux density of 1.4–1.5 T. Mater. Sci. Eng. A 2004, 375, 302–306. [Google Scholar] [CrossRef]

- Makino, A.; Bitoh, T.; Kojima, A.; Inoue, A.; Masumoto, T. Magnetic properties of zero-magnetostrictive nanocrystalline Fe–Zr–Nb–B soft magnetic alloys with high magnetic induction. J. Magn. Magn. Mater. 2000, 215, 288–292. [Google Scholar] [CrossRef]

- Makino, A.; Hatanai, T.; Naitoh, Y.; Bitoh, T.; Inoue, A.; Masumoto, T. Applications of nanocrystalline soft magnetic Fe-MB (M= Zr, Nb) alloys “NANOPERM (R)”. IEEE Trans. Magn. 1997, 33, 3793–3798. [Google Scholar] [CrossRef]

- Inoue, A. Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 2000, 48, 279–306. [Google Scholar] [CrossRef]

- Itoi, T.; Inoue, A. Thermal stability and soft magnetic properties of Co–Fe–M–B (M = Nb, Zr) amorphous alloys with large supercooled liquid region. Mater. Trans. JIM 2000, 41, 1256–1262. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Wang, Z.; Jia, Y.Y.; Shi, R.M.; Wen, Z.P. High temperature soft magnetic properties of (FexCo1−x) 73.5 Cu1Mo3Si13. 5B9 (x = 0.5, 1) alloys. J. Magn. Magn. Mater. 2013, 328, 62–65. [Google Scholar] [CrossRef]

- Wang, F.; Inoue, A.; Han, Y.; Kong, F.L.; Zhu, S.L.; Shalaan, E.; Al-Marzouki, F.; Obaid, A. Excellent soft magnetic Fe-Co-B-based amorphous alloys with extremely high saturation magnetization above 1.85 T and low coercivity below 3 A/m. J. Alloys Compd. 2017, 711, 132–142. [Google Scholar] [CrossRef]

- Shi, Z.; Li, R.; Zhang, T. Tunable magnetic properties and heat-treatable bending ductility of Fe-Co-BPC amorphous alloys with a high saturated magnetization up to 1.79 T. J. Alloys Compd. 2019, 778, 302–308. [Google Scholar] [CrossRef]

- Kim, D.H.; Choe, S.B.; Shin, S.C. Direct observation of Barkhausen avalanche in Co thin films. Phys. Rev. Lett. 2003, 90, 087203. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mamaev, G.; Bolotin, I.; Ctcherbakov, A.; Mamaev, S.; Poutchkov, S.; Tenyakov, I. Technology for production of amorphous alloys large scale cores. In Proceedings of the 1997 Particle Accelerator Conference (Cat. No. 97CH36167), Vancouver, BC, Canada, 16 May 1997; pp. 1313–1315. [Google Scholar]

- Horvat, J.; Babi, E.; Marohni, Ž.; Liebermann, H.H. Domain wall stabilization in Co74Fe6B20 amorphous alloys. Philos. Mag. B 1991, 63, 1235–1245. [Google Scholar] [CrossRef]

- Horvat, J.; Babić, E. The variation of the domain wall pinning strength with the depth within the Co74Fe6B20 amorphous alloy. J. Magn. Magn. Mater. 1991, 96, L13–L16. [Google Scholar] [CrossRef]

| Alloys | Thermal Properties | Magnetic Properties | ||||||

|---|---|---|---|---|---|---|---|---|

| Fe/Co Ratio | Alloy Composition | Tx | Hc | Bs | ||||

| (K) | (A/m) | (T) | ||||||

| 4:6 | Fe34 | Co51 | Zr9 | Nb1 | B5 | 819 | 24 | 1.22 |

| 5:5 | Fe47.5 | Co47.5 | Zr9 | Nb1 | B5 | 822 | 22 | 1.33 |

| 6:4 | Fe51 | Co34 | Zr9 | Nb1 | B5 | 827 | 21 | 1.52 |

| 7:3 | Fe59.5 | Co25.5 | Zr9 | Nb1 | B5 | 837 | 18 | 1.48 |

| 8:2 | Fe68 | Co17 | Zr9 | Nb1 | B5 | 850 | 15 | 1.38 |

| 9:1 | Fe76.5 | Co8.5 | Zr9 | Nb1 | B5 | 858 | 12 | 1.19 |

| 4:6 | Fe34 | Co51 | Hf9 | Nb1 | B5 | 808 | 23 | 1.43 |

| 5:5 | Fe47.5 | Co47.5 | Hf9 | Nb1 | B5 | 817 | 20 | 1.62 |

| 6:4 | Fe51 | Co34 | Hf9 | Nb1 | B5 | 823 | 19 | 1.54 |

| 7:3 | Fe59.5 | Co25.5 | Hf9 | Nb1 | B5 | 832 | 17 | 1.40 |

| 8:2 | Fe68 | Co17 | Hf9 | Nb1 | B5 | 839 | 14 | 1.18 |

| 9:1 | Fe76.5 | Co8.5 | Hf9 | Nb1 | B5 | 849 | 11 | 0.93 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Son, H.; Yoo, G.; Mustaghfiroh, Q.; Kim, D.-H.; Choi-Yim, H. Effect of Substituting Hf for Zr on Fe-Co-M-Nb-B (M = Zr, Hf) Amorphous Alloys with High Saturation Magnetization. Metals 2022, 12, 12. https://doi.org/10.3390/met12010012

Son H, Yoo G, Mustaghfiroh Q, Kim D-H, Choi-Yim H. Effect of Substituting Hf for Zr on Fe-Co-M-Nb-B (M = Zr, Hf) Amorphous Alloys with High Saturation Magnetization. Metals. 2022; 12(1):12. https://doi.org/10.3390/met12010012

Chicago/Turabian StyleSon, Hyunsol, Garam Yoo, Qoimatul Mustaghfiroh, Dong-Hyun Kim, and Haein Choi-Yim. 2022. "Effect of Substituting Hf for Zr on Fe-Co-M-Nb-B (M = Zr, Hf) Amorphous Alloys with High Saturation Magnetization" Metals 12, no. 1: 12. https://doi.org/10.3390/met12010012

APA StyleSon, H., Yoo, G., Mustaghfiroh, Q., Kim, D.-H., & Choi-Yim, H. (2022). Effect of Substituting Hf for Zr on Fe-Co-M-Nb-B (M = Zr, Hf) Amorphous Alloys with High Saturation Magnetization. Metals, 12(1), 12. https://doi.org/10.3390/met12010012