Effect of Process Parameters on the Surface Microgeometry of a Ti6Al4V Alloy Manufactured by Laser Powder Bed Fusion: 3D vs. 2D Characterization

Abstract

:1. Introduction

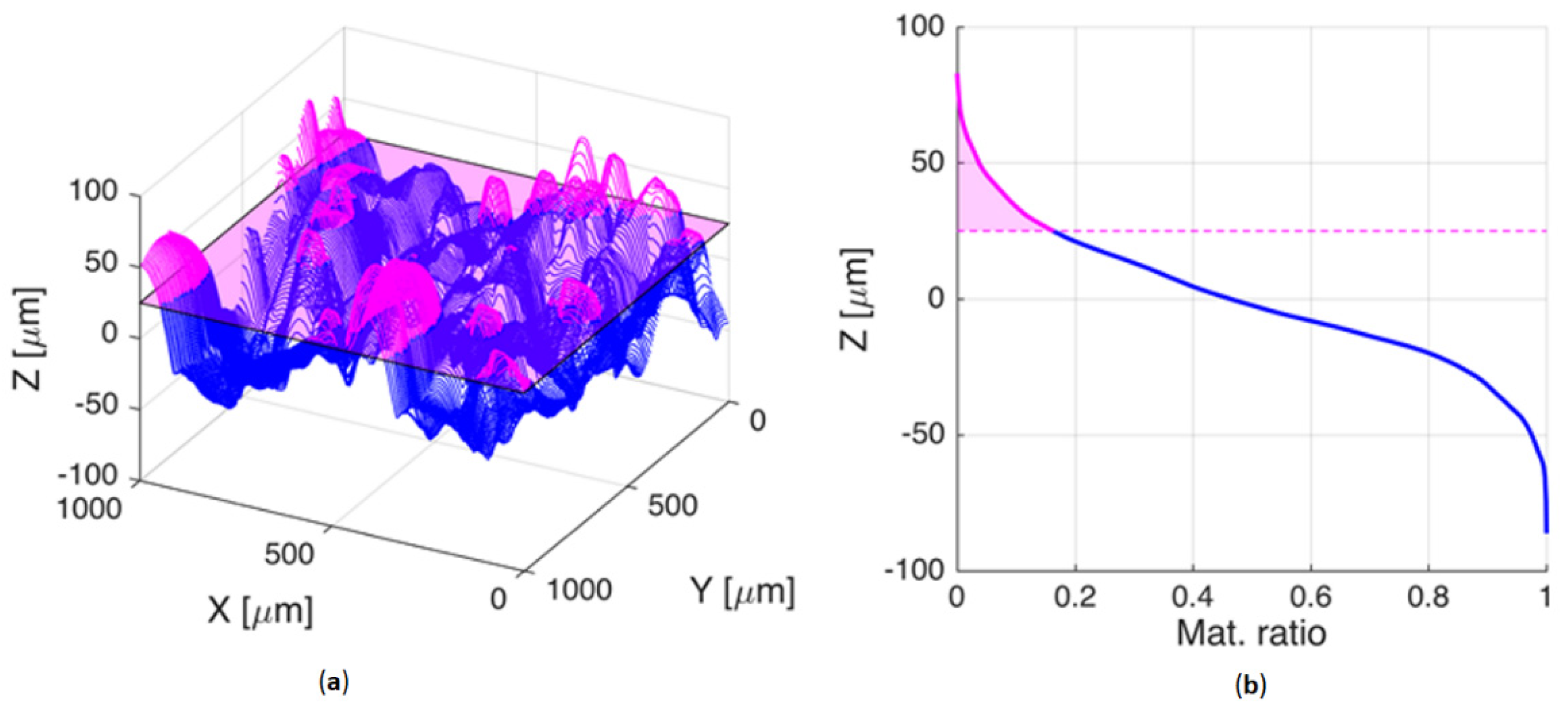

- (a)

- to compare the suitability of the 3D and of the 2D approaches to describe the surface microgeometry;

- (b)

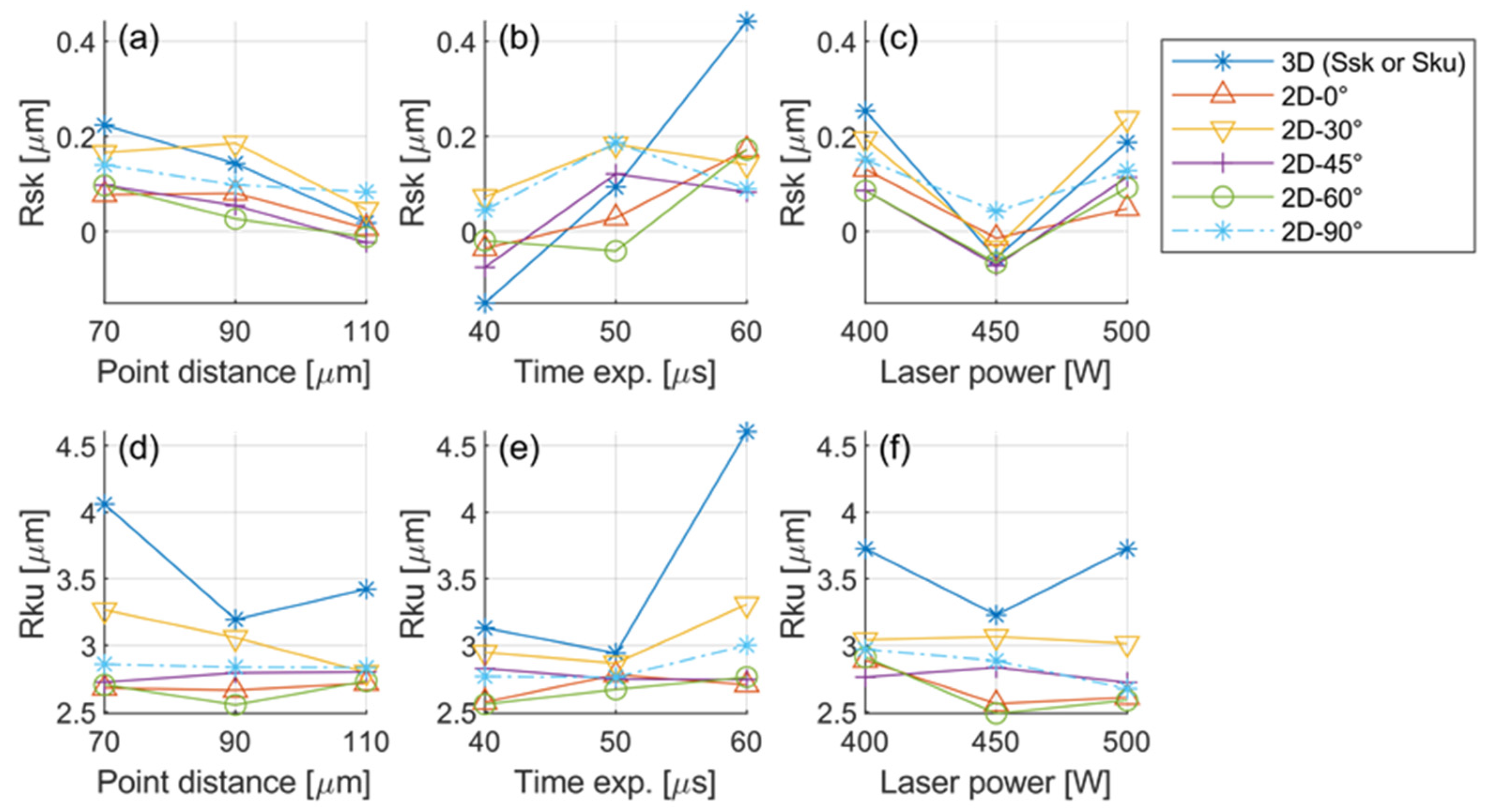

- to investigate the influence of the processing parameters on the surface microgeometry and in particular the effect of point distance and time exposure that have an opposite effect on scan speed and, in turn, on energy density;

- (c)

- to identify which of the aforementioned parameters are more sensitive to the variations of laser power, time exposure and point distance and are, therefore, more suitable to characterize the surface microgeometry.

2. Materials and Methods

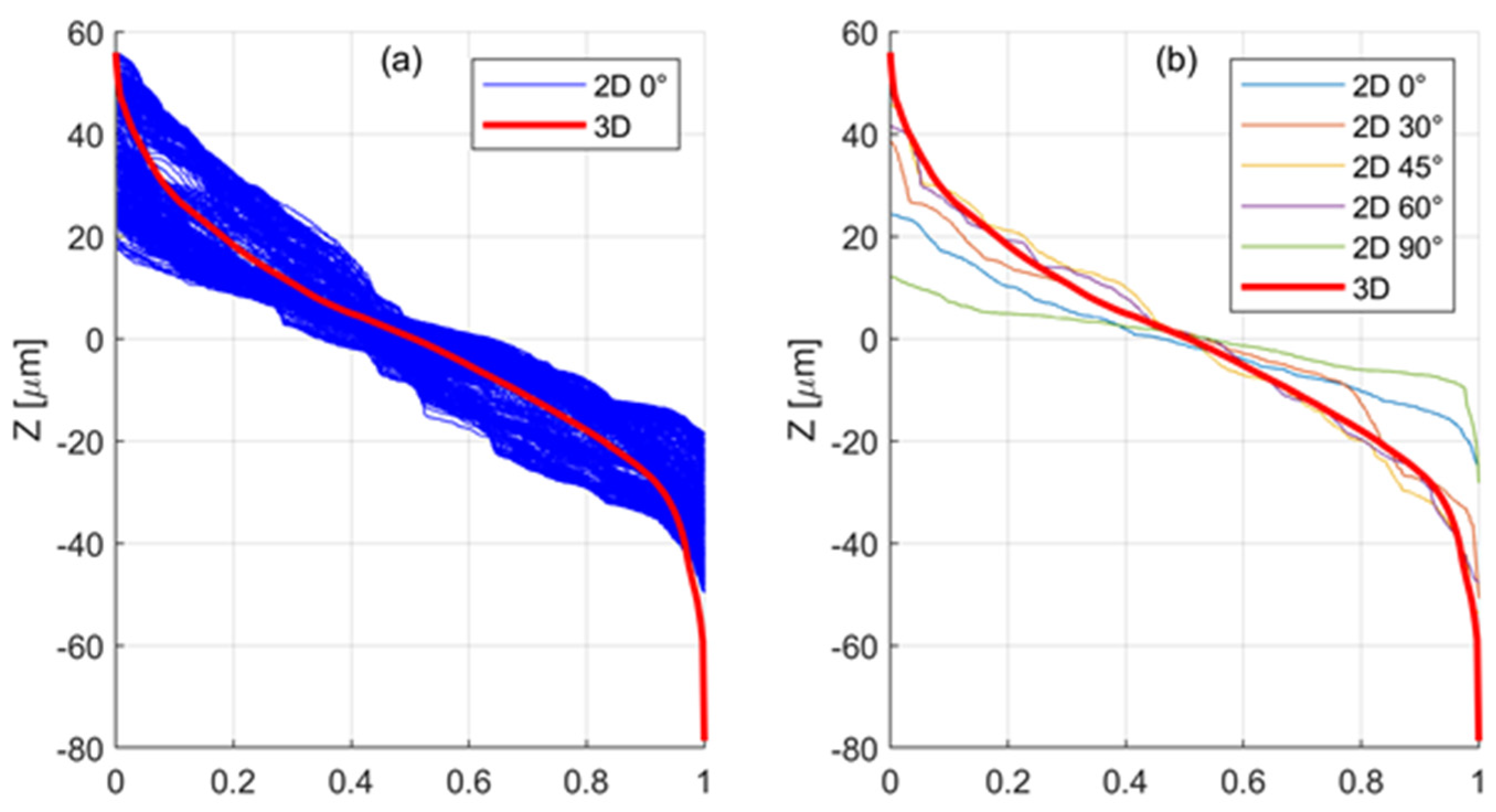

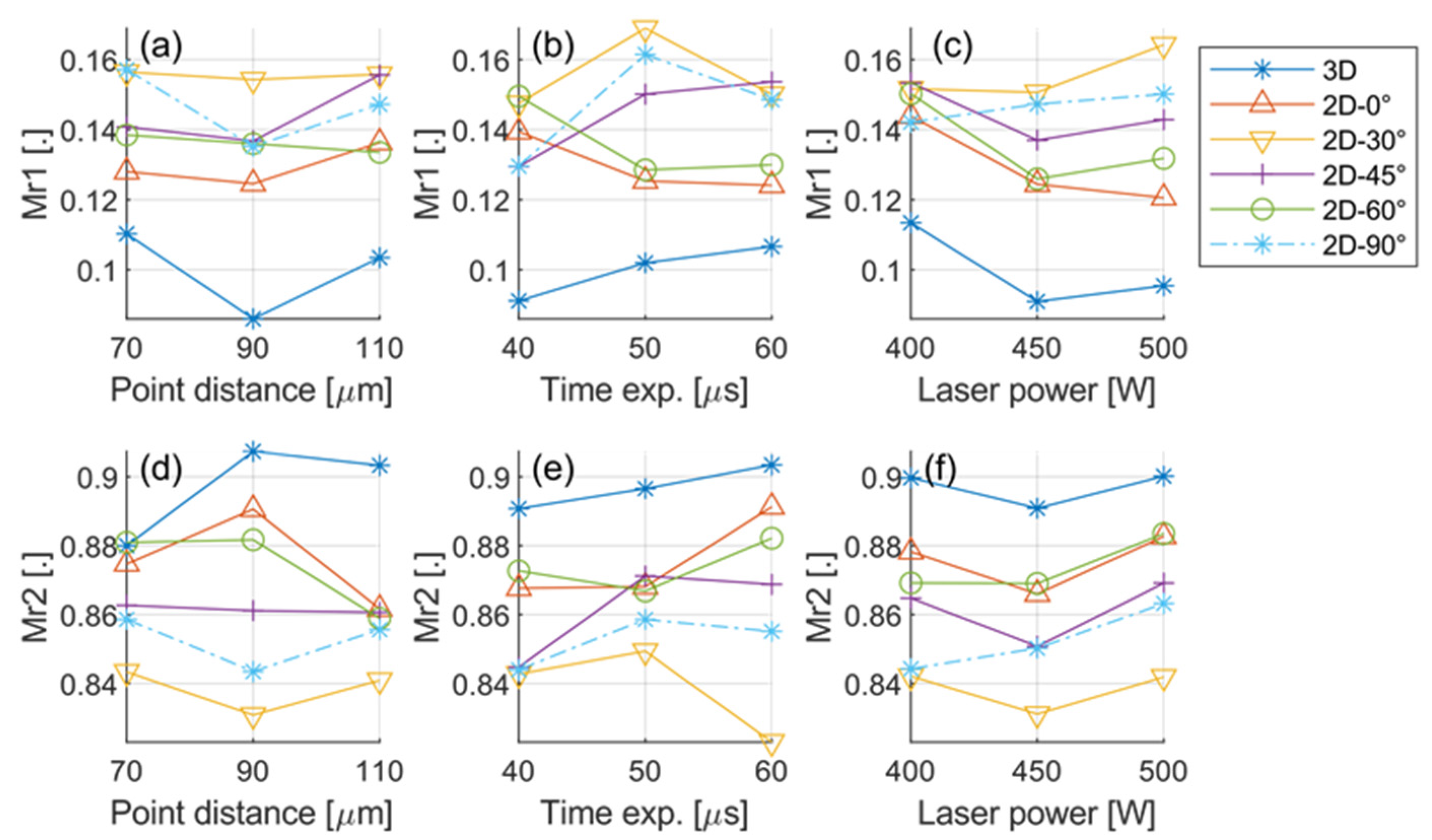

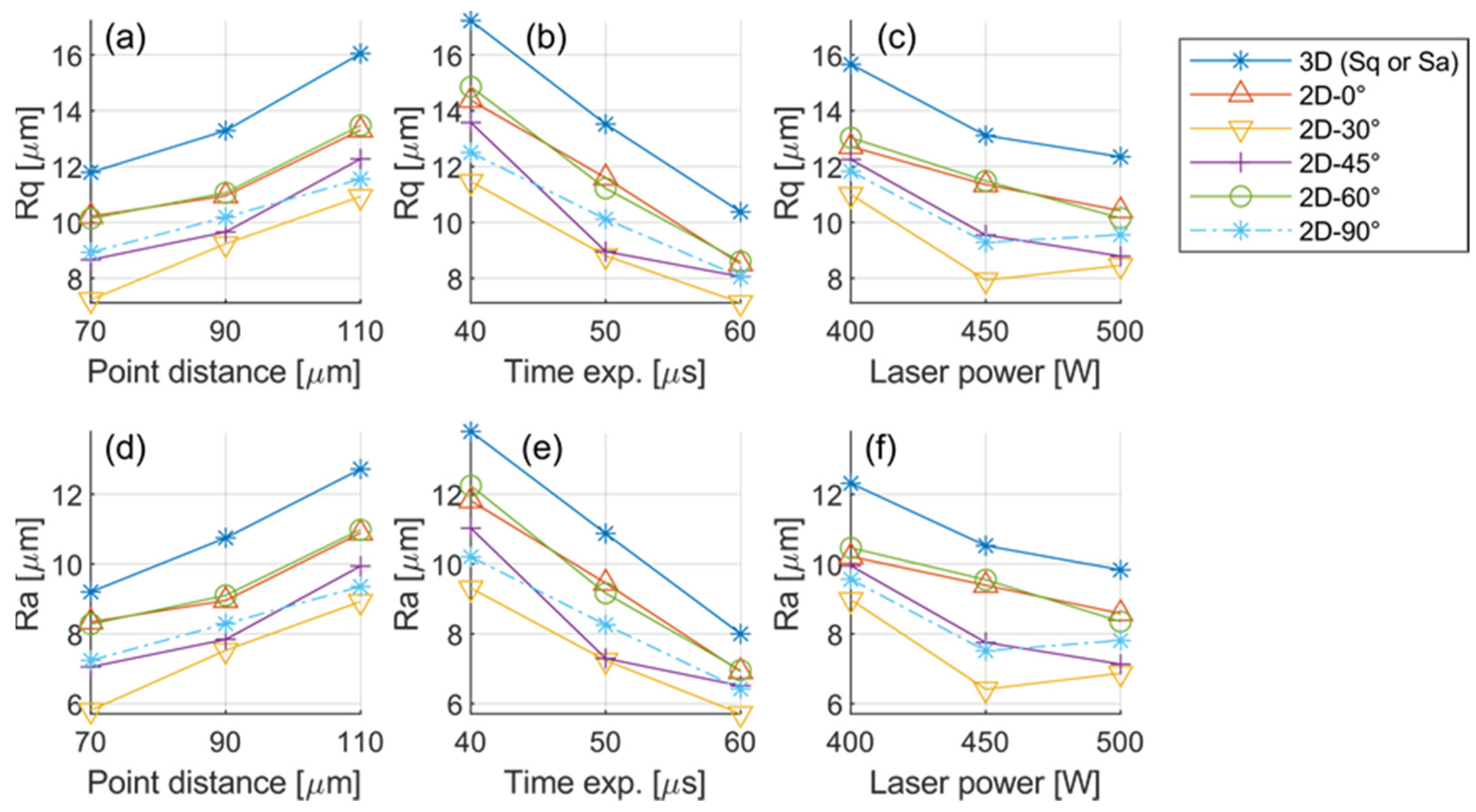

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Alvarez, A.G.; Evans, P.L.; Dovgalski, L.; Goldsmith, I. Design, additive manufacture and clinical application of a patient-specific titanium implant to anatomically reconstruct a large chest wall defect. Rapid Prototyp. J. 2021, 27, 304–310. [Google Scholar] [CrossRef]

- Abele, E.; Kniepkamp, M. Analysis and optimisation of vertical surface roughness in micro selective laser melting. Surf. Topogr. Metrol. Prop. 2015, 3, 034007. [Google Scholar] [CrossRef]

- Wang, D.; Wu, S.; Fu, F.; Mai, S.; Yang, Y.; Liu, Y.; Song, C. Mechanisms and characteristics of spatter generation in SLM processing and its effect on the properties. Mater. Des. 2017, 117, 121–130. [Google Scholar] [CrossRef]

- Wycisk, E.; Emmelmann, C.; Siddique, S.; Walther, F. High Cycle Fatigue (HCF) Performance of Ti-6Al-4V Alloy Processed by Selective Laser Melting. Adv. Mater. Res. 2013, 816–817, 134–139. [Google Scholar] [CrossRef]

- Chastand, V.; Tezenas, A.; Cadoret, Y.; Quaegebeur, P.; Maia, W.; Charkaluk, E. Fatigue characterization of Titanium Ti-6Al-4V samples produced by Additive Manufacturing. Procedia Struct. Integr. 2016, 2, 3168–3176. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.; Cao, S.; Wu, X.; Davies, C.H.J. Surface roughness and fatigue properties of selective laser melted Ti–6Al–4V alloy. In Additive Manufacturing for the Aerospace Industry; Froes, F., Boyer, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 283–299. [Google Scholar]

- Carlotto, A.; Loggi, A.; Zito, D.; Sborniccchia, P.; Maggian, D.; Fockele, M.; Unterberg, P.; Molinari, A.; Cristofolini, I. Optimization of the main Selective Laser melting technology parameters in the production of gold jewelry. Int. J. Powder Metall. 2015, 51, 43–55. [Google Scholar]

- Cabanettes, F.; Joubert, A.; Chardon, G.; Dumas, V.; Rech, J.; Grosjean, C.; Dimkovski, Z. Topography of as built surfaces generated in metal additive manufacturing: A multi scale analysis from form to roughness. Precis. Eng. 2018, 52, 249–265. [Google Scholar] [CrossRef]

- Townsend, A.; Senin, N.; Blunt, L.; Leach, R.; Taylor, J. Surface texture metrology for metal additive manufacturing: A review. Precis. Eng. 2016, 46, 34–47. [Google Scholar] [CrossRef] [Green Version]

- ISO 4287; Geometrical Product Specifications (GPS), Surface Texture: Profile Method—Terms, Definitions and Surface Texture Parameters. ISO: Geneva, Switzerland, 1997.

- Jamshidinia, M.; Kovacevic, R. The influence of heat accumulation on the surface roughness in powder-bed additive manufacturing. Surf. Topogr. Metrol Prop. 2015, 3, 014003. [Google Scholar] [CrossRef]

- ISO 25178–2; Geometrical product specifications (GPS), Surface texture: Areal—Part 2: Terms, definitions and surface texture parameters, TC 213—Dimensional and geometrical product specifications and verification. ISO: Geneva, Switzerland, 2012.

- Senin, N.; Thompson, A.; Leach, R. Feature-based characterisation of signature topography in laser powder bed fusion of metals. Meas. Sci. Technol. 2017, 29, 045009. [Google Scholar] [CrossRef]

- Yang, T.; Liu, T.; Liao, W.; MacDonald, E.; Wei, H.; Chen, X.; Jiang, L. The influence of process parameters on vertical surface roughness of the AlSi10Mg parts fabricated by selective laser melting. J. Mater. Process. Technol. 2018, 266, 26–36. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Bertrand, P.; Smurov, I. Parametric analysis of the selective laser melting process. Appl. Surf. Sci. 2007, 253, 8064–8069. [Google Scholar] [CrossRef]

- Gu, D.; Shen, Y. Balling phenomena in direct laser sintering of stainless steel powder: Metallurgical mechanisms and control methods. Mater. Des. 2009, 30, 2903–2910. [Google Scholar] [CrossRef]

- Wang, L.-Z.; Wang, S.; Wu, J.-J. Experimental investigation on densification behavior and surface roughness of AlSi10Mg powders produced by selective laser melting. Opt. Laser Technol. 2017, 96, 88–96. [Google Scholar] [CrossRef]

- Józwik, J.; Ostrowski, D.; Milczarczyk, R.; Krolczyk, G.M. Analysis of relation between the 3D printer laser beam power and the surface morphology properties in Ti-6Al-4V titanium alloy parts. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 215. [Google Scholar] [CrossRef] [Green Version]

- Hitzler, L.; Hirsch, J.; Merkel, M.; Hall, W.; Öchsner, A. Position dependent surface quality in selective laser melting. Mater. und Werkst. 2017, 48, 327–334. [Google Scholar] [CrossRef] [Green Version]

- Weißmann, V.; Drescher, P.; Seitz, H.; Hansmann, H.; Bader, R.; Seyfarth, A.; Klinder, A.; Jonitz-Heincke, A. Effects of Build Orientation on Surface Morphology and Bone Cell Activity of Additively Manufactured Ti6Al4V Specimens. Materials 2018, 11, 915. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Leary, M. Surface roughness optimisation for selective laser melting (SLM): Accommodating relevant and irrelevant surfaces. In Laser Additive Manufacturing: Materials, Design, Technologies, and Applications; Brandt, M., Ed.; Woodhead Publishing: Duxford, UK, 2016; pp. 99–118. [Google Scholar]

- Spierings, A.; Herres, N.; Levy, G.J. Influence of the particle size distribution on surface quality and mechanical properties in AM steel parts. Rapid Prototyp. J. 2011, 17, 195–202. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Chen, Q.; Guillemot, G.; Gandin, C.-A.; Bellet, M. Numerical modelling of fluid and solid thermomechanics in additive manufacturing by powder-bed fusion: Continuum and level set formulation applied to track- and part-scale simulations. C. R. Méc. 2018, 346, 1055–1071. [Google Scholar] [CrossRef]

- Matthews, M.J.; Guss, G.; Khairallah, S.A.; Rubenchik, A.M.; DePond, P.; King, W.E. Denudation of metal powder layers in laser powder bed fusion processes. Acta Mater. 2016, 114, 33–42. [Google Scholar] [CrossRef] [Green Version]

- DePond, P.J.; Guss, G.; Ly, S.; Calta, N.; Deane, D.; Khairallah, S.; Matthews, M.J. In situ measurements of layer roughness during laser powder bed fusion additive manufacturing using low coherence scanning interferometry. Mater. Des. 2018, 154, 347–359. [Google Scholar] [CrossRef]

- Kaji, F.; Barari, A. Evaluation of the Surface Roughness of Additive Manufacturing Parts Based on the Modelling of Cusp Geometry. IFAC-PapersOnLine 2015, 48, 658–663. [Google Scholar] [CrossRef]

- Boschetto, A.; Bottini, L.; Veniali, F. Roughness modeling of AlSi10Mg parts fabricated by selective laser melting. J. Mater. Process. Technol. 2017, 241, 154–163. [Google Scholar] [CrossRef]

- Ancellotti, S.; Fontanari, V.; Molinari, A.; Iacob, E.; Bellutti, P.; Luchin, V.; Zappini, G.; Benedetti, M. Numerical/experimental strategies to infer enhanced liquid thermal conductivity and roughness in laser powder-bed fusion processes. Addit. Manuf. 2019, 27, 552–564. [Google Scholar] [CrossRef]

- Lutter-Günther, M.; Bröker, M.; Mayer, T.; Lizak, S.; Seidel, C.; Reinhart, G. Spatter formation during laser beam melting of AlSi10Mg and effects on powder quality. Procedia CIRP 2018, 74, 33–38. [Google Scholar] [CrossRef]

- ISO 4288; Geometrical product specification (GPS), Surface texture: Profile method—rules and procedures for the assessment of surface texture. ISO: Geneva, Switzerland, 1998.

| Combination | Point Distance (μm) | Time of Exposure (μs) | Laser Power (W) | Scan Speed (mm/s) | Energy Density (J/mm3) |

|---|---|---|---|---|---|

| 1 | 70 | 40 | 400 | 1750 | 38.1 |

| 2 | 70 | 40 | 450 | 1750 | 42.9 |

| 3 | 70 | 40 | 500 | 1750 | 47.6 |

| 4 | 70 | 50 | 400 | 1400 | 47.6 |

| 5 | 70 | 50 | 450 | 1400 | 53.6 |

| 6 | 70 | 50 | 500 | 1400 | 59.5 |

| 7 | 70 | 60 | 400 | 1167 | 57.1 |

| 8 | 70 | 60 | 450 | 1167 | 64.3 |

| 9 | 70 | 60 | 500 | 1167 | 71.4 |

| 10 | 90 | 40 | 400 | 2250 | 29.6 |

| 11 | 90 | 40 | 450 | 2250 | 33.3 |

| 12 | 90 | 40 | 500 | 2250 | 37.0 |

| 13 | 90 | 50 | 400 | 1800 | 37.0 |

| 14 | 90 | 50 | 450 | 1800 | 41.7 |

| 15 | 90 | 50 | 500 | 1800 | 46.3 |

| 16 | 90 | 60 | 400 | 1500 | 44.4 |

| 17 | 90 | 60 | 450 | 1500 | 50.0 |

| 18 | 90 | 60 | 500 | 1500 | 55.6 |

| 19 | 110 | 40 | 400 | 2750 | 24.2 |

| 20 | 110 | 40 | 450 | 2750 | 27.3 |

| 21 | 110 | 40 | 500 | 2750 | 30.3 |

| 22 | 110 | 50 | 400 | 2200 | 30.3 |

| 23 | 110 | 50 | 450 | 2200 | 34.1 |

| 24 | 110 | 50 | 500 | 2200 | 37.9 |

| 25 | 110 | 60 | 400 | 1833 | 36.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Molinari, A.; Ancellotti, S.; Fontanari, V.; Iacob, E.; Luchin, V.; Zappini, G.; Benedetti, M. Effect of Process Parameters on the Surface Microgeometry of a Ti6Al4V Alloy Manufactured by Laser Powder Bed Fusion: 3D vs. 2D Characterization. Metals 2022, 12, 106. https://doi.org/10.3390/met12010106

Molinari A, Ancellotti S, Fontanari V, Iacob E, Luchin V, Zappini G, Benedetti M. Effect of Process Parameters on the Surface Microgeometry of a Ti6Al4V Alloy Manufactured by Laser Powder Bed Fusion: 3D vs. 2D Characterization. Metals. 2022; 12(1):106. https://doi.org/10.3390/met12010106

Chicago/Turabian StyleMolinari, Alberto, Simone Ancellotti, Vigilio Fontanari, Erica Iacob, Valerio Luchin, Gianluca Zappini, and Matteo Benedetti. 2022. "Effect of Process Parameters on the Surface Microgeometry of a Ti6Al4V Alloy Manufactured by Laser Powder Bed Fusion: 3D vs. 2D Characterization" Metals 12, no. 1: 106. https://doi.org/10.3390/met12010106

APA StyleMolinari, A., Ancellotti, S., Fontanari, V., Iacob, E., Luchin, V., Zappini, G., & Benedetti, M. (2022). Effect of Process Parameters on the Surface Microgeometry of a Ti6Al4V Alloy Manufactured by Laser Powder Bed Fusion: 3D vs. 2D Characterization. Metals, 12(1), 106. https://doi.org/10.3390/met12010106