Duplex Aging and Gas Nitriding Process as a Method of Surface Modification of Titanium Alloys for Aircraft Applications

Abstract

:1. Introduction

2. Titanium Nitriding Methods: Drawbacks and Benefits

2.1. Plasma Nitriding

2.2. Laser-Assisted Nitriding

2.3. Gas-Blow Induction Heating Nitriding Method

2.4. Electron-Beam Vacuum Nitriding

2.5. Gas Nitriding

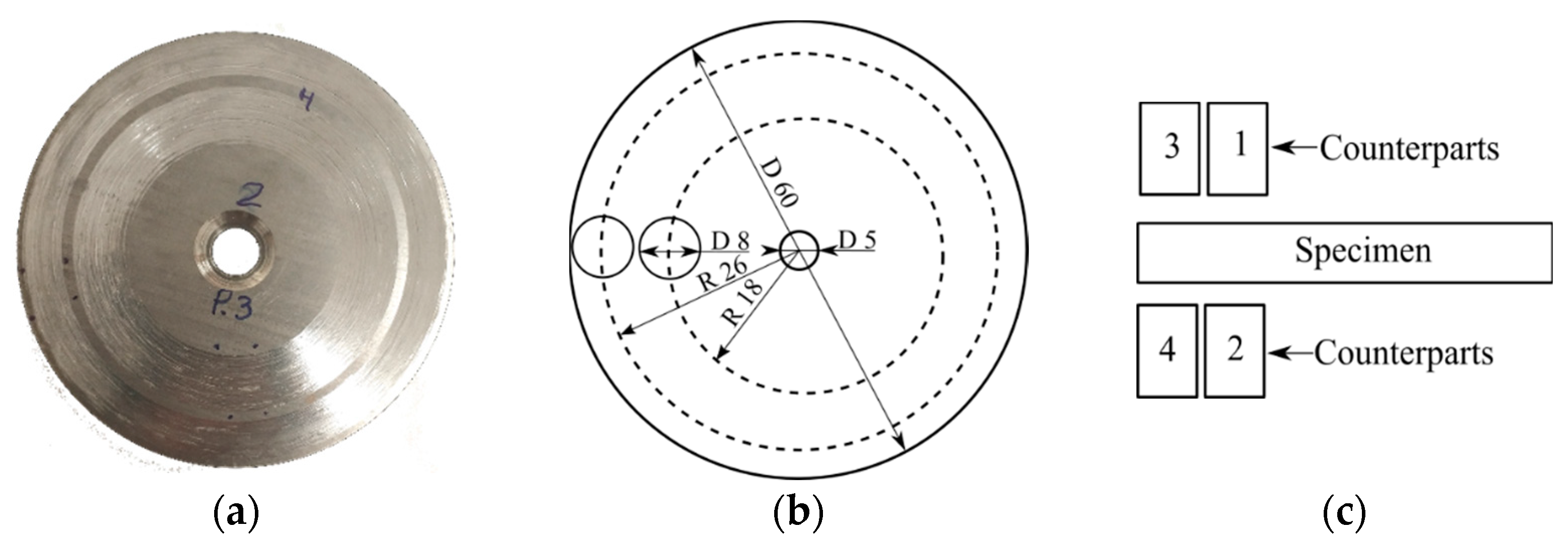

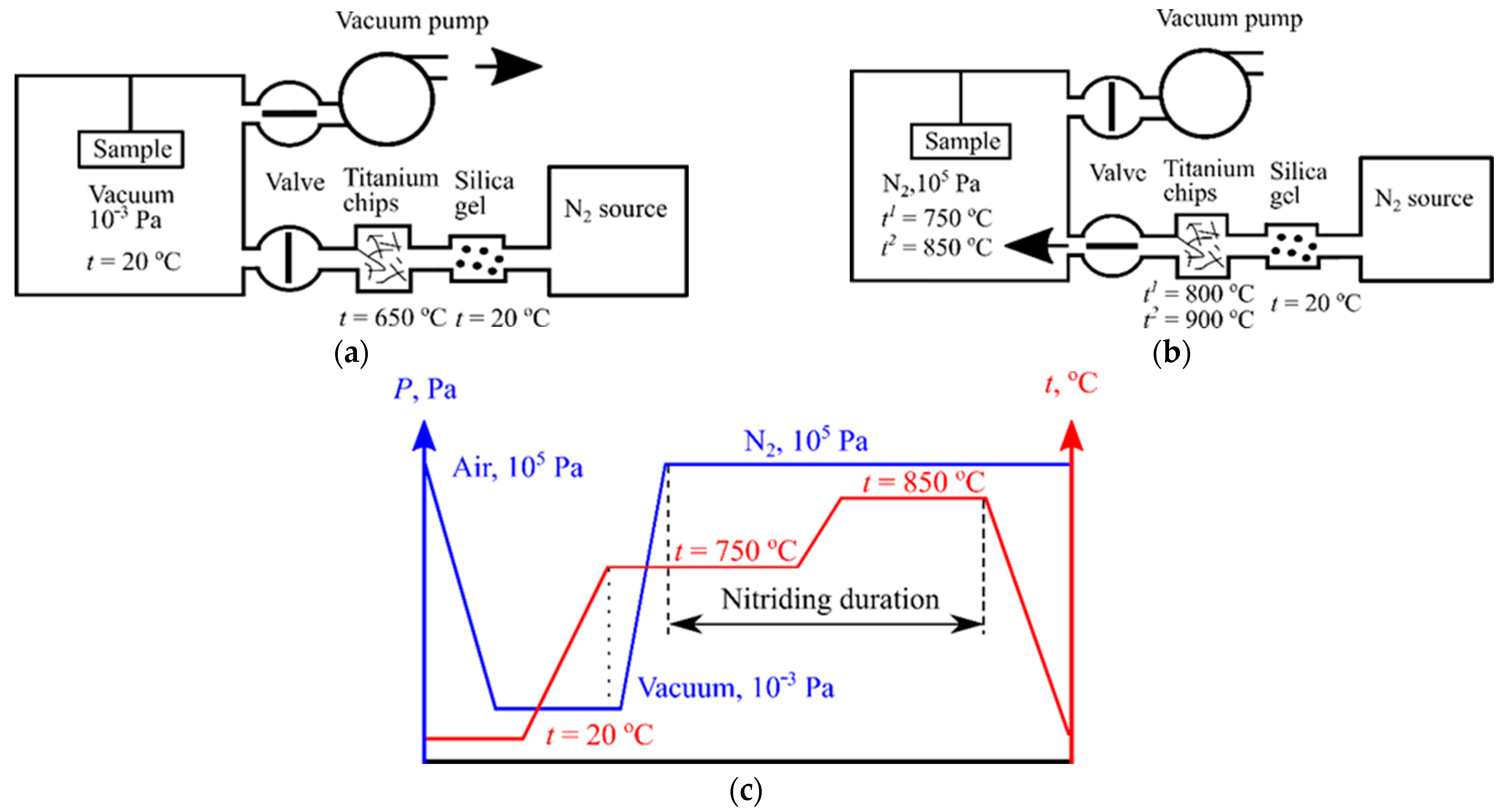

3. Materials and Methods

4. Results

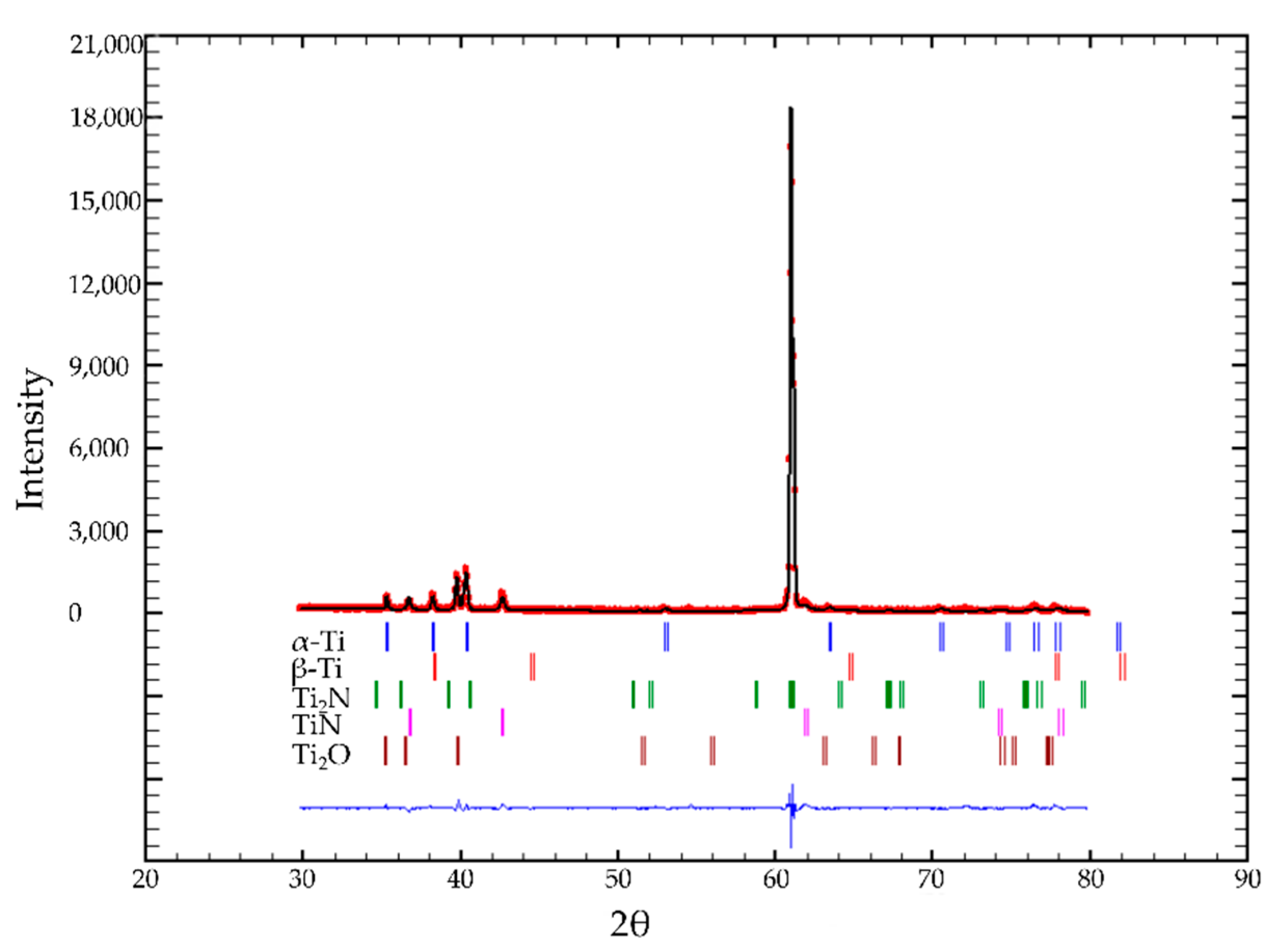

4.1. Microstructure and Phase Analyses

4.2. Hardness

4.3. Wear Resistance Test

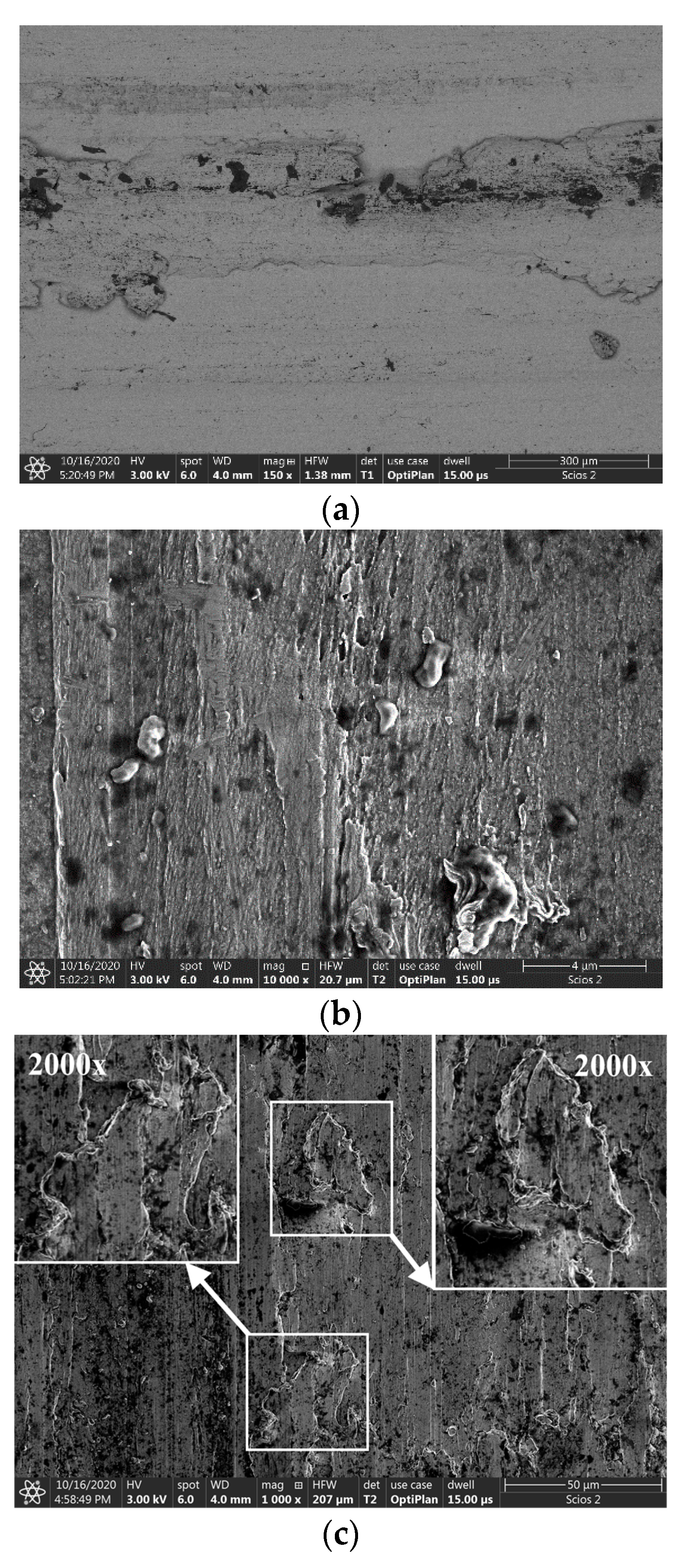

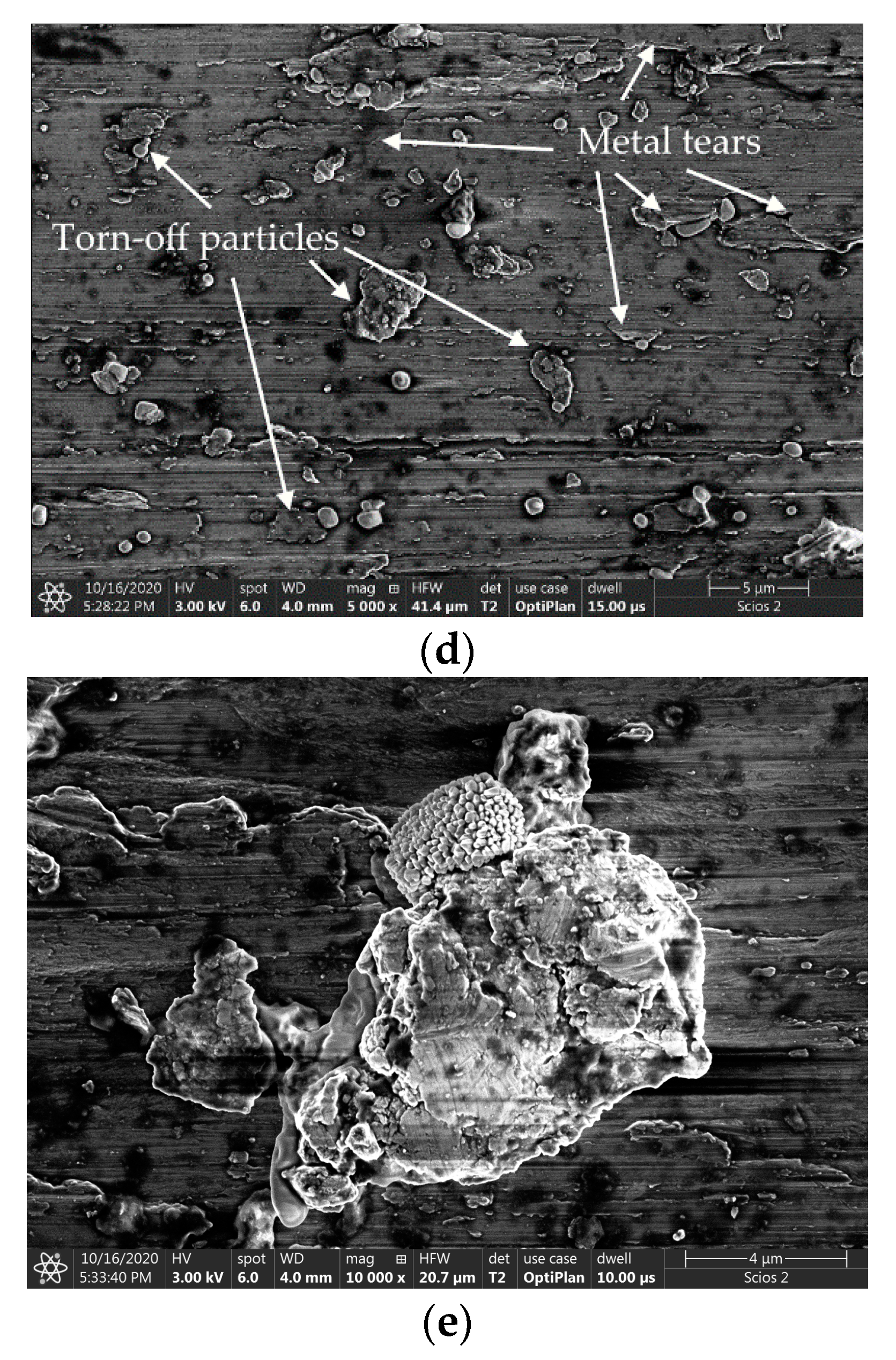

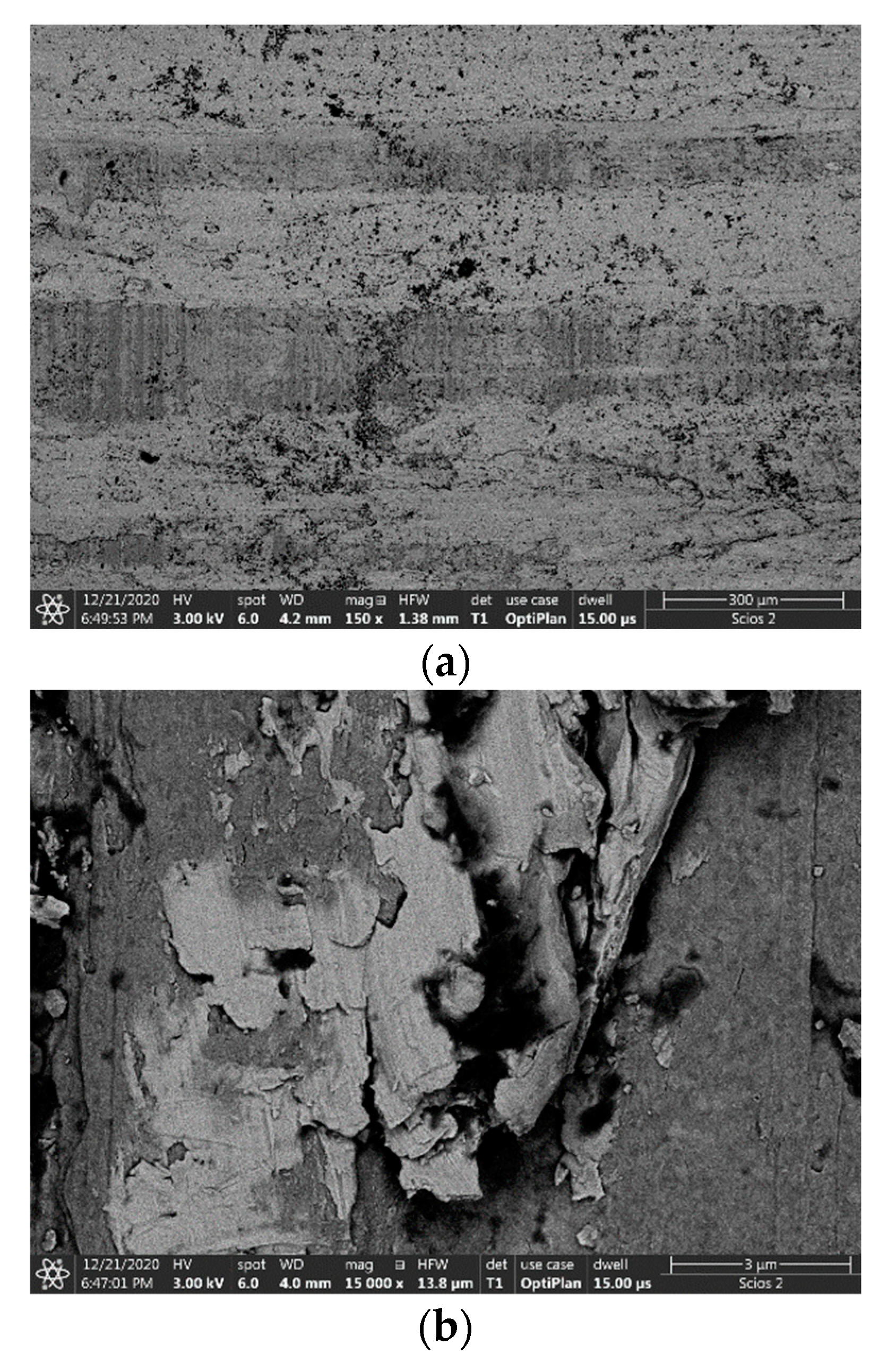

4.4. The Wear Tracks’ Topography

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, C.; Li, H.; van der Zwaag, S. Unravelling the abrasion resistance of two novel meta-stable titanium alloys on the basis of multi-pass-dual-indenter tests. Wear 2019, 440–441, 203094. [Google Scholar] [CrossRef]

- Sandomierski, M.; Buchwald, T.; Patalas, A.; Voelkel, A. Improving the abrasion resistance of Ti6Al4V alloy by modifying its surface with a diazonium salt and attaching of polyurethane. Sci. Rep. 2020, 10, 19289. [Google Scholar] [CrossRef]

- Dong, H. Tribological properties of titanium-based alloys. In Woodhead Publishing Series in Metals and Surface Engineering, Surface Engineering of Light Alloys; Woodhead Publishing: Cambridge, UK, 2010; pp. 58–80. [Google Scholar] [CrossRef]

- Grigoriev, O.N.; Mazur, P.V.; Neshpor, I.P.; Mosina, T.V.; Bega, M.D.; Varchenko, V.T.; Vedel, D.V.; Konoval, V.P.; Dukhota, A.I.; Kharchenko, V.V.; et al. Wear-Resistant TiCN-Based Ceramic Materials for High-Load Friction Units. Powder Metall. Met. Ceram. 2021, 59, 528–536. [Google Scholar] [CrossRef]

- Yang, Q.; Zhou, W.; Zheng, X.; Niu, Z.; Li, Z.; Zou, B.; Fu, X. Investigation of shot peening combined with plasma-sprayed CuNiIn coating on the fretting fatigue behavior of Ti-6Al-4V dovetail joint specimens. Surf. Coat. Technol. 2019, 358, 833–842. [Google Scholar] [CrossRef]

- AMS4911R. Titanium Alloy, Sheet, Strip, and Plate 6Al—4V Annealed; SAE International: Warrendale, PA, USA, 2019. [Google Scholar]

- AMSH81200D. Heat Treatment of Titanium and Titanium Alloys; SAE International: Warrendale, PA, USA, 2014. [Google Scholar]

- AMS2801B. Heat Treatment of Titanium Alloy Parts; SAE International: Warrendale, PA, USA, 2014. [Google Scholar]

- AMS2488E. Anodic Treatment—Titanium and Titanium Alloys Solution pH 13 or Higher; SAE International: Warrendale, PA, USA, 2019. [Google Scholar]

- AMS2487B. Anodic Treatment of Titanium and Titanium Alloys Solution pH 12.4 Maximum; SAE International: Warrendale, PA, USA, 2018. [Google Scholar]

- Anoshkin, N.F. Titanium Alloys. Metallography of Titanium Alloys; Metallurgy: Moscow, USSR, 1980; 464p. [Google Scholar]

- Khorev, A.I. Alloying and Heat treatment of high-strength structural titanium β alloys. Russ. Eng. Res. 2010, 30, 781–788. [Google Scholar] [CrossRef]

- Weiss, I.; Semiatin, S.L. Thermomechanical processing of beta titanium alloys—An overview. Mater. Sci. Eng. A 1998, 243, 46–65. [Google Scholar] [CrossRef]

- Shekhar, S.; Sarkar, R.; Kar, S.K.; Bhattacharjee, A. Effect of Solid solution treatment and aging on microstructure and tensile properties of high strength β titanium alloy, Ti-5Al-5V-5Mo-3Cr. Mater. Des. 2015, 66, 596–610. [Google Scholar] [CrossRef]

- Glazunov, S.; Moiseev, V. Titanium Alloys. Structural Titanium Alloys; Metallurgy: Moscow, USSR, 1974; 368p. [Google Scholar]

- Yan, D.P.; Hilditch, T.; Kishawy, H.A.; Littlefair, G. On Quantifying the Strain Rate During Chip Formation When Machining Aerospace Alloy Ti-5553. Procedia CIRP 2013, 8, 123–128. [Google Scholar] [CrossRef] [Green Version]

- Parida, A.K.; Maity, K. Analysis of some critical aspects in hot machining of Ti-5553 superalloy: Experimental and FE analysis. Def. Technol. 2019, 15, 344–352. [Google Scholar] [CrossRef]

- Wagner, V.; Baili, M.; Dessein, G. The relationship between the cutting speed, tool wear, and chip formation during Ti-5553 dry cutting. Int. J. Adv. Manuf. Technol. 2015, 76, 893–912. [Google Scholar] [CrossRef]

- Opini, V.C.; Salvador, C.A.F.; Campo, K.N.; Lopes, E.S.N.; Chaves, R.R.; Caram, R. α phase precipitation and mechanical properties of Nb-modified Ti-5553 alloy. Mater. Sci. Eng. A 2016, 670, 112–121. [Google Scholar] [CrossRef]

- Ghosh, A.; Sivaprasad, S.; Bhattacharjee, A.; Kar, S.K. Microstructure–fracture toughness correlation in an aircraft structural component alloy Ti–5Al–5V–5Mo–3Cr. Mater. Sci. Eng. A 2013, 568, 61–67. [Google Scholar] [CrossRef]

- Huang, C.; Zhao, Y.; Xin, S.; Zhou, W.; Li, Q.; Zeng, W. Effect of microstructure on tensile properties of Ti-5Al-5Mo-5V-3Cr-1Zr alloy. J. Alloys Compd. 2017, 693, 582–591. [Google Scholar] [CrossRef]

- Li, P.; Sun, Q.; Xiao, L.; Sun, J. Tuning the morphology of Ti–5Al–5Mo–5V–3Cr–1Zr alloy: From brittle to ductile fracture. Mater. Sci. Eng. A 2020, 769, 138487. [Google Scholar] [CrossRef]

- Qin, D.; Lu, Y.; Guo, D.; Zheng, L.; Liu, Q.; Zhou, L. Tensile deformation and fracture of Ti-5Al-5V-5Mo-3Cr-1.5Zr-0.5Fe alloy at room temperature. Mater. Sci. Eng. A 2013, 587, 100–109. [Google Scholar] [CrossRef]

- Wu, C.; Zhao, Y.; Huang, S.; Lei, L.; Zhao, Q.; Sun, Q.; Zhou, L. Microstructure tailoring and impact toughness of a newly developed high strength Ti-5Al-3Mo-3V-2Cr-2Zr-1Nb-1Fe alloy. Mater. Charact. 2021, 175, 111103. [Google Scholar] [CrossRef]

- Wang, H.; Xin, S.W.; Zhao, Y.Q.; Zhou, W.; Zeng, W.-D. Forging-microstructure-tensile properties correlation in a new near β high-strength titanium alloy. Rare Met. 2020, 40, 2109–2117. [Google Scholar] [CrossRef]

- Wang, Z.-Y.; Liu, L.-B.; Wu, D.; Zhang, L.-G.; Wang, W.-L.; Zhou, K.-C. α″ phase-assisted nucleation to obtain ultrafine α precipitates for designing high-strength near-β titanium alloys. Trans. Nonferrous Met. Soc. China 2020, 30, 2681–2696. [Google Scholar] [CrossRef]

- Ivasishin, O.M.; Markovsky, P.E.; Semiatin, S.L.; Ward, C.H. Aging response of coarse- and fine-grained β titanium alloys. Mater. Sci. Eng. A 2005, 405, 296–305. [Google Scholar] [CrossRef]

- Zherebtsov, S.V.; Murzinova, M.A.; Klimova, M.V.; Salishchev, G.A.; Popov, A.A.; Semiatin, S.L. Microstructure evolution during warm working of Ti–5Al–5Mo–5V–1Cr–1Fe at 600 and 800 °C. Mater. Sci. Eng. A 2013, 563, 168–176. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Shao, H.; Shan, D.; Wang, K.; Cai, L.; Yin, E.; Wang, Y.; Zhuo, L. Influence of strain rates on high temperature deformation behaviors and mechanisms of Ti-5Al-5Mo-5V-3Cr-1Zr alloy. Mater. Charact. 2021, 171, 110794. [Google Scholar] [CrossRef]

- Łępicka, M.; Grądzka-Dahlke, M.; Pieniak, D.; Pasierbiewicz, K.; Kryńska, K.; Niewczas, A. Tribological performance of titanium nitride coatings: A comparative study on TiN-coated stainless steel and titanium alloy. Wear 2019, 422–423, 68–80. [Google Scholar] [CrossRef]

- Łȩpicka, M.; Gradzka-Dahlke, M. Surface modification of Ti6Al4V titanium alloy for biomedical applications and its effect on tribological performance—A review. Rev. Adv. Mater. Sci. 2016, 46, 86–103. [Google Scholar]

- Fedirko, V.M.; Pohrelyuk, I.M.; Luk’yanenko, O.H.; Lavrys’, S.M.; Kindrachuk, M.V.; Dukhota, O.I.; Tisov, O.V.; Zahrebel’nyi, V.V. Thermodiffusion saturation of the surface of VT22 titanium alloy from a controlled oxygen–nitrogen-containing atmosphere in the stage of aging. Mater. Sci. 2018, 53, 691–701. [Google Scholar] [CrossRef]

- Pohrelyuk, I.M.; Kindrachuk, M.V.; Lavrys’, S.M. Wear resistance of VT22 titanium alloy after nitriding combined with heat treatment. Mater. Sci. 2016, 52, 56–61. [Google Scholar] [CrossRef]

- Szymkiewicz, K.; Morgiel, J.; Maj, Ł.; Pomorska, M.; Tarnowski, M.; Tkachuk, O.; Wierzchoń, T. Effect of nitriding conditions of Ti6Al7Nb on microstructure of TiN surface layer. J. Alloys Compd. 2020, 845, 156320. [Google Scholar] [CrossRef]

- Taktak, S.; Akbulut, H. Dry wear and friction behaviour of plasma nitrided Ti–6AL–4V alloy after explosive shock treatment. Tribol. Int. 2020, 40, 423–432. [Google Scholar] [CrossRef]

- El-Hossary, F.M.; Negm, N.Z.; Abd El-Rahman, A.M.; Raaif, M.; Seleem, A.A.; Abd El-Moula, A.A. Tribo-mechanical and electrochemical properties of plasma nitriding titanium. Surf. Coat. Technol. 2015, 276, 658–667. [Google Scholar] [CrossRef]

- Borisyuk, Y.V.; Oreshnikova, N.M.; Berdnikova, M.A.; Tumarkin, A.V.; Khodachenko, G.V.; Pisarev, A.A. Plasma nitriding of titanium alloy Ti5Al4V2Mo. Phys. Procedia 2015, 71, 105–109. [Google Scholar] [CrossRef] [Green Version]

- Shen, H.; Wang, L. Formation, tribological and corrosion properties of thicker Ti-N layer produced by plasma nitriding of titanium in a N2-NH3 mixture gas. Surf. Coat. Technol. 2020, 393, 125846. [Google Scholar] [CrossRef]

- She, D.; Yue, W.; Fu, Z.; Wang, C.; Yang, X.; Liu, J. Effects of nitriding temperature on microstructures and vacuum tribological properties of plasma-nitrided titanium. Surf. Coat. Technol. 2015, 264, 32–40. [Google Scholar] [CrossRef]

- Shen, H.; Wang, L. Corrosion resistance and electrical conductivity of plasma nitrided titanium. Int. J. Hydrogen Energy 2021, 46, 11084–11091. [Google Scholar] [CrossRef]

- Escalona, M.; Bhuyan, H.; Ibacache, S.; Retamal, M.J.; Saikia, P.; Borgohain, C.; Valenzuela, J.C.; Veloso, F.; Favre, M.; Wyndham, E. Study of titanium nitride film growth by plasma enhanced pulsed laser deposition at different experimental conditions. Surf. Coat. Technol. 2021, 405, 126492. [Google Scholar] [CrossRef]

- Abboud, J.H. Effect of processing parameters on titanium nitrided surface layers produced by laser gas nitriding. Surf. Coat. Technol. 2013, 214, 19–29. [Google Scholar] [CrossRef]

- Marchuk, V.; Kindrachuk, M.; Tisov, O.; Kornienko, A.; Radko, O.; Kharchenko, V. Stress-strained state of textured surfaces with selectively indented regions. Funct. Mater. 2019, 26, 773–778. [Google Scholar] [CrossRef]

- Kindrachuk, M.; Shevchenko, A.; Kryzhanovskyi, A. Improvement of the quality of TiC-Co system plasma coating by laser treatment. Aviation 2016, 20, 155–159. [Google Scholar] [CrossRef]

- Katahira, K.; Tanida, Y.; Takesue, S.; Komotori, J. Rapid surface nitriding of titanium alloy by a nanosecond fiber laser under atmospheric conditions. CIRP Ann. 2018, 67, 563–566. [Google Scholar] [CrossRef]

- Senthilselvan, J.; Monisha, K.; Gunaseelan, M.; Yamini, S.; Arun Kumar, S.; Kanimozhi, K.; Manonmani, J.; Shariff, S.M.; Padmanabham, G. High power diode laser nitriding of titanium in nitrogen gas filled simple acrylic box container: Microstructure, phase formation, hardness, dendrite and martensite solidification analyses. Mater. Charact. 2020, 160, 110118. [Google Scholar] [CrossRef]

- Takesue, S.; Kikuchi, S.; Akebono, H.; Morita, T.; Komotori, J. Characterization of surface layer formed by gas blow induction heating nitriding at different temperatures and its effect on the fatigue properties of titanium alloy. Results Mater. 2020, 5, 100071. [Google Scholar] [CrossRef]

- Takesue, S.; Kikuchi, S.; Akebono, H.; Misaka, Y.; Komotori, J. Effect of pre-treatment with fine particle peening on surface properties and wear resistance of gas blow induction heating nitrided titanium alloy. Surf. Coat. Technol. 2019, 359, 476–484. [Google Scholar] [CrossRef]

- Takesue, S.; Kikuchi, S.; Misaka, Y.; Morita, T.; Komotori, J. Rapid nitriding mechanism of titanium alloy by gas blow induction heating. Surf. Coat. Technol. 2020, 399, 126160. [Google Scholar] [CrossRef]

- Takesue, S.; Kikuchi, S.; Akebono, H.; Komotori, J.; Fukazawa, K.; Misaka, Y. Effects of gas blow velocity on the surface properties of Ti-6Al-4V alloy treated by gas blow IH nitriding. Mater. Trans. 2017, 58, 1155–1160. [Google Scholar] [CrossRef] [Green Version]

- Burdovitsin, V.A.; Golosov, D.A.; Oks, E.M.; Tyunkov, A.V.; Yushkov, Y.G.; Zolotukhin, D.B.; Zavadsky, S.M. Electron beam nitriding of titanium in medium vacuum. Surf. Coat. Technol. 2019, 358, 726–731. [Google Scholar] [CrossRef]

- Tyunkov, A.V.; Golosov, D.A.; Zolotukhin, D.B.; Nikonenko, A.V.; Oks, E.M.; Yushkov, Y.G.; Yakovlev, E.V. Nitriding of titanium in electron beam excited plasma in medium vacuum. Surf. Coat. Technol. 2020, 383, 125241. [Google Scholar] [CrossRef]

- Liang, S.X.; Yin, L.X.; Liu, X.Y.; Wu, X.X.; Ma, M.Z.; Liu, R.P. Kinetics of thermodiffusion of TZ20 titanium alloy gas-nitride within temperature of 500 °C–650 °C. J. Alloys Compd. 2018, 734, 172–178. [Google Scholar] [CrossRef]

- Yang, C.; Liu, J. Intermittent vacuum gas nitriding of TB8 titanium alloy. Vacuum 2019, 163, 52–58. [Google Scholar] [CrossRef]

- Zhecheva, A.; Malinov, S.; Sha, W. Titanium alloys after surface gas nitriding. Surf. Coat. Technol. 2006, 201, 2467–2474. [Google Scholar] [CrossRef]

- Toboła, D.; Morgiel, J.; Maj, Ł. TEM analysis of surface layer of Ti-6Al-4V ELI alloy after slide burnishing and low-temperature gas nitriding. Appl. Surf. Sci. 2020, 515, 145942. [Google Scholar] [CrossRef]

- Jeong, H.-G.; Lee, Y.; Lee, D.-G. Effects of preheat conditions on diffusion hardening of pure titanium by vacuum rapid nitriding. Surf. Coat. Technol. 2017, 326, 395–401. [Google Scholar] [CrossRef]

- Ajikumar, P.K.; Kamruddin, M.; Shankar, P.; Gouda, R.; Balamurugan, A.K.; Nithya, R.; Raj, B. Internal nitride formation during gas-phase thermal nitridation of titanium. Scr. Mater. 2009, 61, 403–406. [Google Scholar] [CrossRef] [Green Version]

- Łępicka, M.; Grądzka-Dahlke, M. The initial evaluation of performance of hard anti-wear coatings deposited on metallic substrates: Thickness, mechanical properties and adhesion measurements—A brief review. Rev. Adv. Mater. 2019, 58, 50–65. [Google Scholar] [CrossRef]

- Dong, H. Surface Engineering of Light Alloys. Aluminium, Magnesium and Titanium Alloys, 1st ed.; Woodhead Publishing: Cambridge, UK, 2010; 680p. [Google Scholar]

- Dong, H.; Bell, T. Enhanced wear resistance of titanium surfaces by a new thermal oxidation treatment. Wear 2000, 238, 131–137. [Google Scholar] [CrossRef]

- Cherepova, T.; Dmitrieva, G.; Tisov, O.; Dukhota, O.; Kindrachuk, M. Research on the properties of Co-TiC and Ni-TiC HIP-sintered alloys. Acta Mech. Autom. 2019, 13, 57–67. [Google Scholar] [CrossRef] [Green Version]

- Pohrelyuk, I.M.; Padgurskas, J.; Lavrys, S.M.; Luk’yanenko, A.G.; Trush, V.S.; Kreivaitis, R. Topography, hardness, elastic modulus and wear resistance of nitride coatings on titanium. In Proceedings of the 9th International Conference BALTTRIB’ 2017, Kaunas, Lithuania, 16–17 November 2017. [Google Scholar] [CrossRef] [Green Version]

- Çelik, A.; Acar, M.T.; Yetim, T.; Kovacı, H.; Yetim, A.F. Improving structural, tribological and electrochemical properties of Ti6Al4V alloy with B-doped TiO2 thin films. Tribol. Int. 2020, 146, 106210. [Google Scholar] [CrossRef]

- Alam, M.O.; Haseeb, A.S.M.A. Response of Ti–6Al–4V and Ti–24Al–11Nb alloys to dry sliding wear against hardened steel. Tribol. Int. 2002, 35, 357–362. [Google Scholar] [CrossRef]

- Qian, J. Ion Nitriding of Ti-10V-2Fe-3Al Alloy for Aerospace Applications. Master’s Thesis, University of Windsor, Ottawa, CA, USA, 2013; 254p. [Google Scholar]

| Alloy | Al | V | Mo | Cr | Fe | Zr | Nb | Properties |

|---|---|---|---|---|---|---|---|---|

| BT6 | 6 | 4 | - | - | <0.3 | <0.3 | - | UTS 850–1100 MPa, 4–13% elongation |

| Ti-64 | 6 | 4 | - | - | <0.4 | - | - | High strength, cryogenic to 427 °C temperature range, UTS 1100 MPa, 10% elongation |

| BT22 | 5.2 | 4.8 | 4.8 | 1.2 | 1 | <0.3 | - | UTS 1100–1400 MPa, good machinability and weldability, elongation 10% |

| Ti-5553 | 5 | 5 | 5 | 3 | - | UTS 1260 MPa, 5–12% elongation, high fracture toughness | ||

| Ti-55531 | 5 | 5 | 5 | 3 | 0.5 | 1.5 | - | UTS 1250 MPa |

| Ti-1023 | 3 | 10 | - | - | 2 | - | - | UTS 1100–1300 MPa, 5–12% elongation |

| Ti-5321 | 5 | 3 | 3 | 2 | 2 | 2 | 1 | UTS 1147–1439 MPa, 3–26% elongation |

| Phase | Lattice Parameter | Space Group | % | ||

|---|---|---|---|---|---|

| a | b | c | |||

| α-Ti | 2.9334 (1) | 2.9334 (1) | 4.7120 (9) | P63/mmc | 12.39 |

| β-Ti | 4.0703 (9) | 4.0703 (9) | 4.0703 (9) | Fm-3m | 1.34 |

| Ti2N | 4.9697 (4) | 4.9697 (4) | 3.0356 (9) | P42/mnm | 68.06 |

| TiN | 4.2392 (8) | 4.2392 (8) | 4.2392 (8) | Fm-3m | 9.29 |

| Ti2O | 2.9458 (1) | 2.9458 (1) | 4.9311 (8) | P-3m1 | 8.92 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tisov, O.; Łępicka, M.; Tsybrii, Y.; Yurchuk, A.; Kindrachuk, M.; Dukhota, O. Duplex Aging and Gas Nitriding Process as a Method of Surface Modification of Titanium Alloys for Aircraft Applications. Metals 2022, 12, 100. https://doi.org/10.3390/met12010100

Tisov O, Łępicka M, Tsybrii Y, Yurchuk A, Kindrachuk M, Dukhota O. Duplex Aging and Gas Nitriding Process as a Method of Surface Modification of Titanium Alloys for Aircraft Applications. Metals. 2022; 12(1):100. https://doi.org/10.3390/met12010100

Chicago/Turabian StyleTisov, Oleksandr, Magdalena Łępicka, Yurii Tsybrii, Alina Yurchuk, Myroslav Kindrachuk, and Oleksandr Dukhota. 2022. "Duplex Aging and Gas Nitriding Process as a Method of Surface Modification of Titanium Alloys for Aircraft Applications" Metals 12, no. 1: 100. https://doi.org/10.3390/met12010100

APA StyleTisov, O., Łępicka, M., Tsybrii, Y., Yurchuk, A., Kindrachuk, M., & Dukhota, O. (2022). Duplex Aging and Gas Nitriding Process as a Method of Surface Modification of Titanium Alloys for Aircraft Applications. Metals, 12(1), 100. https://doi.org/10.3390/met12010100