Fatigue Analysis of Threaded Components with Cd and Zn-Ni Anticorrosive Coatings

Abstract

1. Introduction

2. Materials and Methods

2.1. Material and Coatings

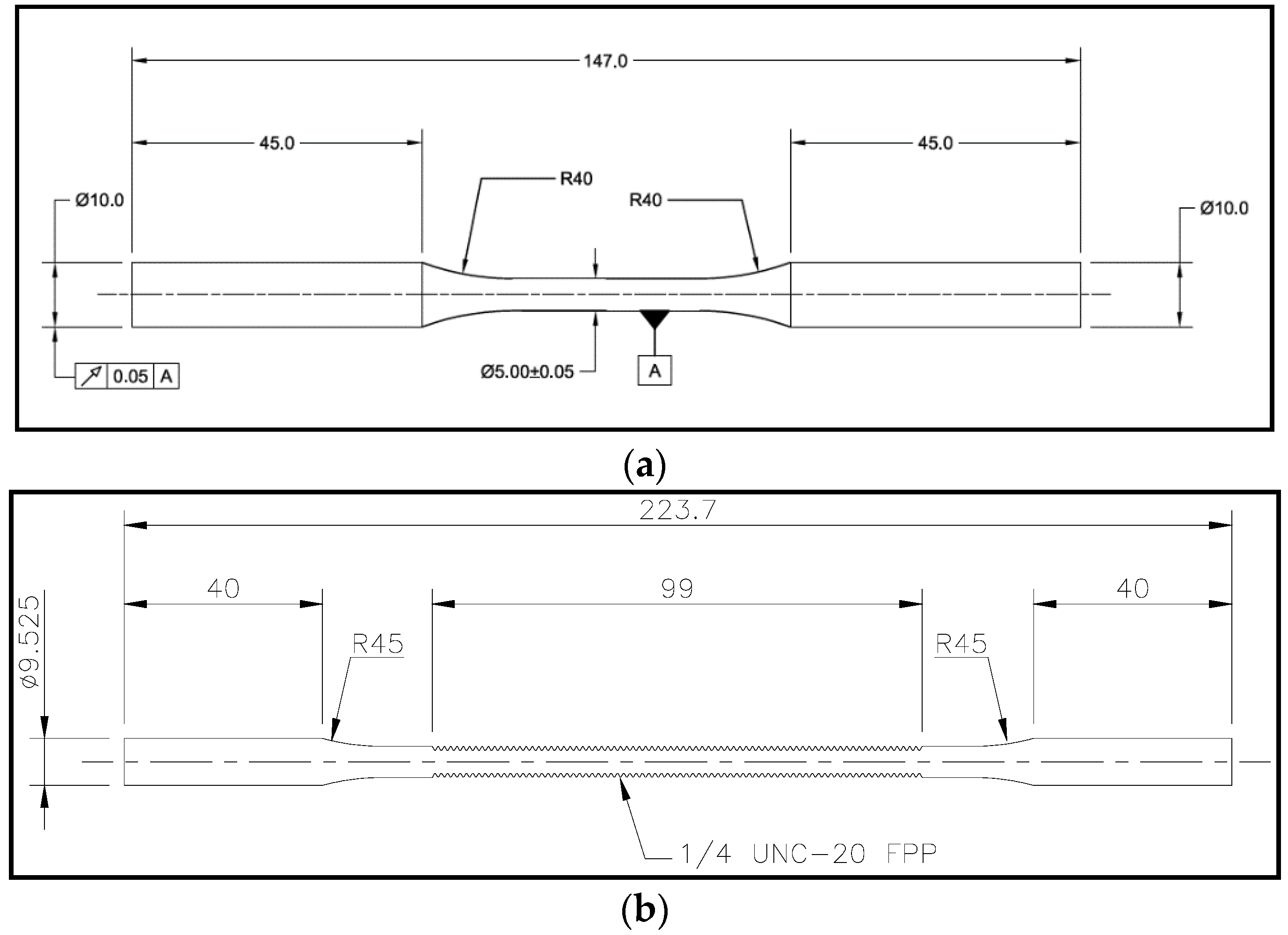

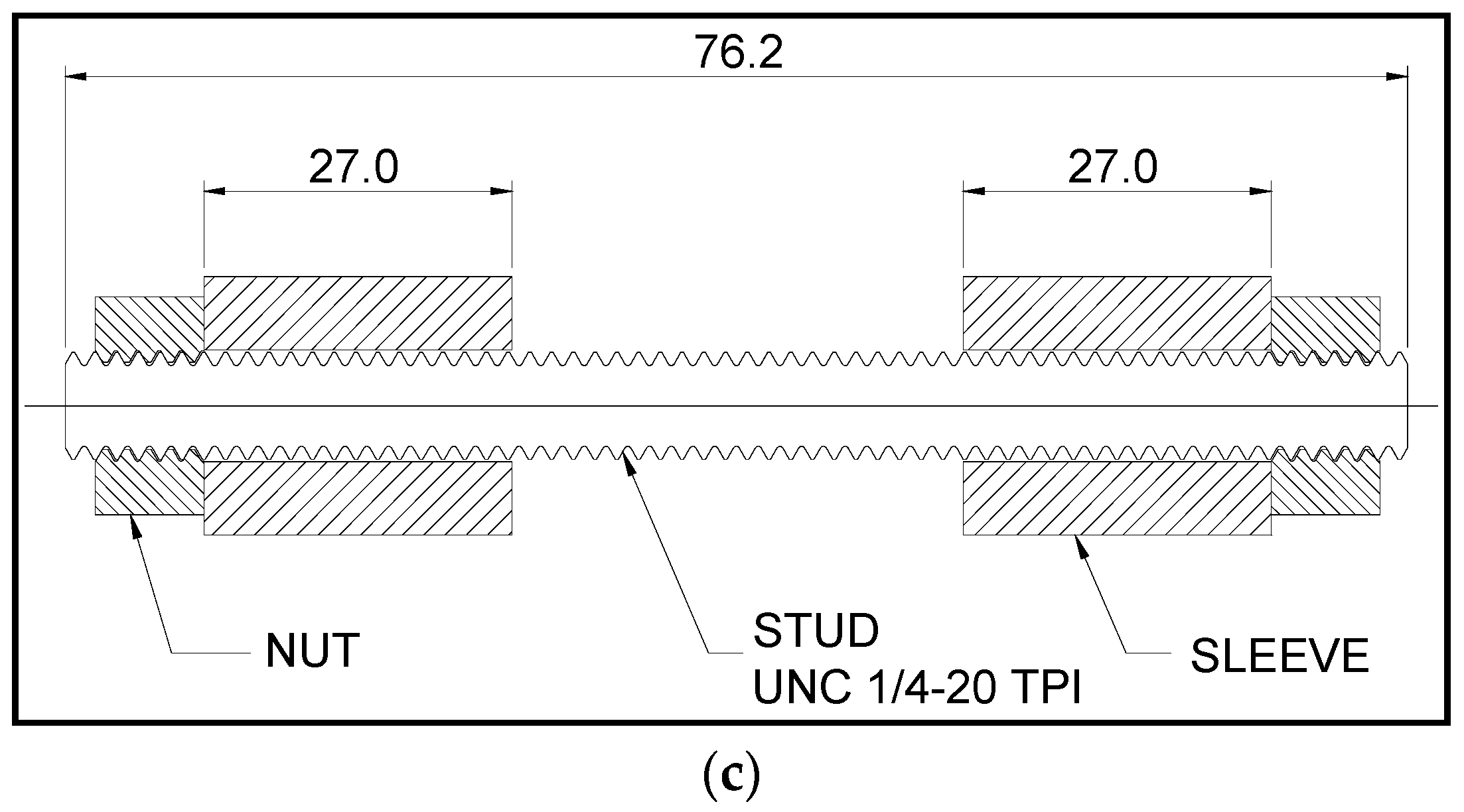

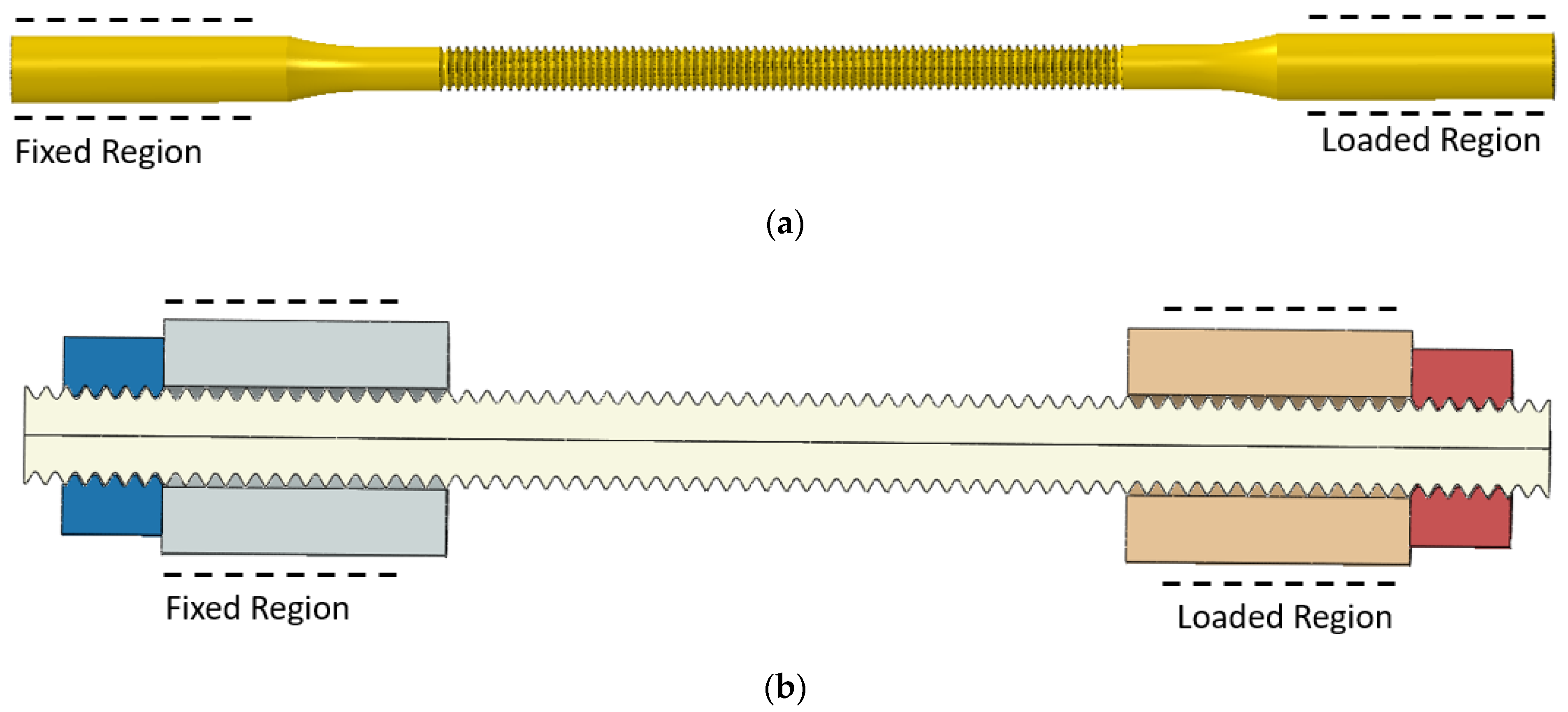

2.2. Experimental Fatigue Tests

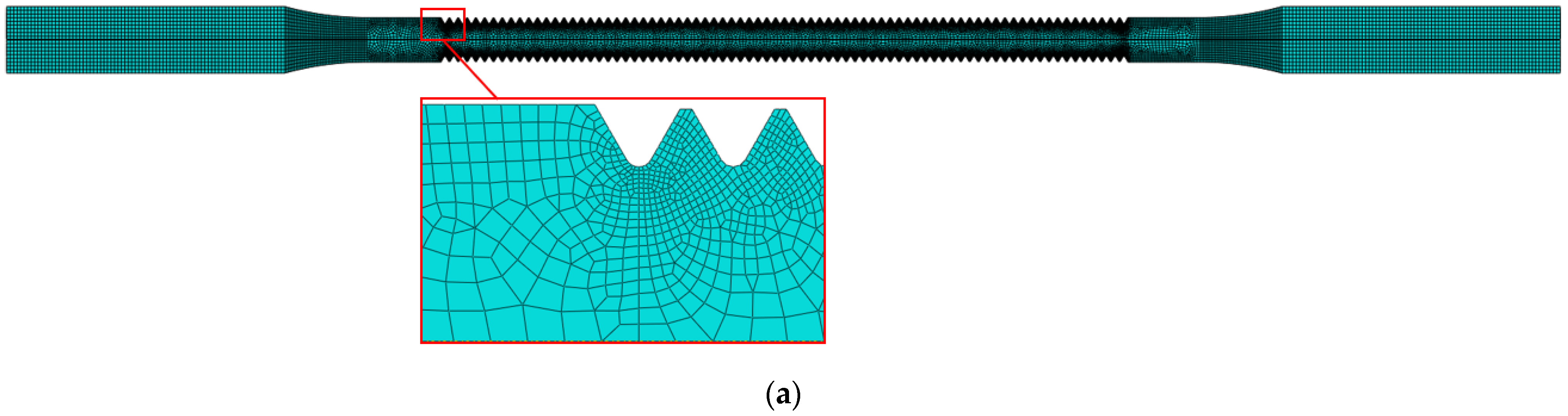

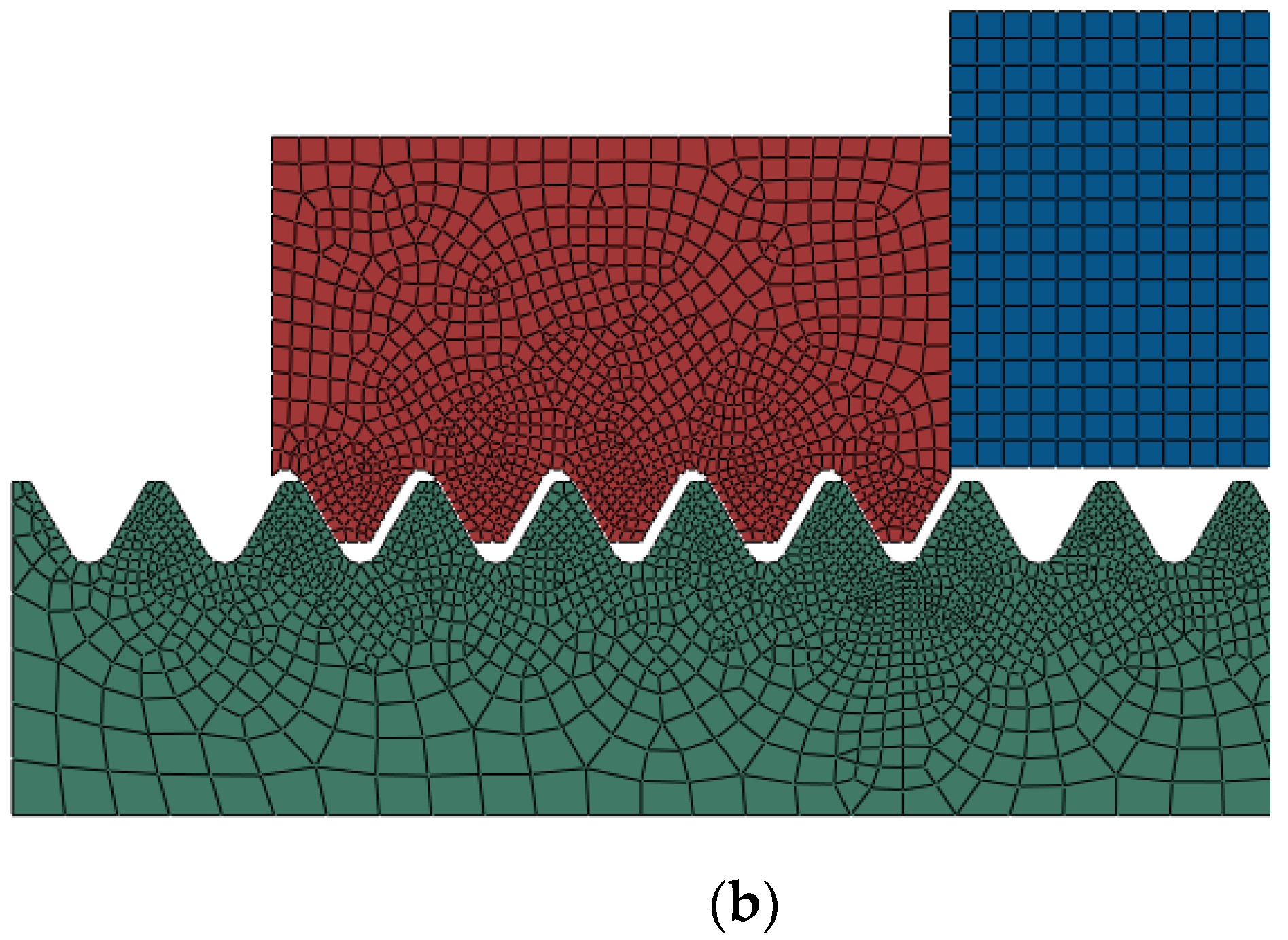

2.3. Finite Element Analysis

3. Results and Discussion

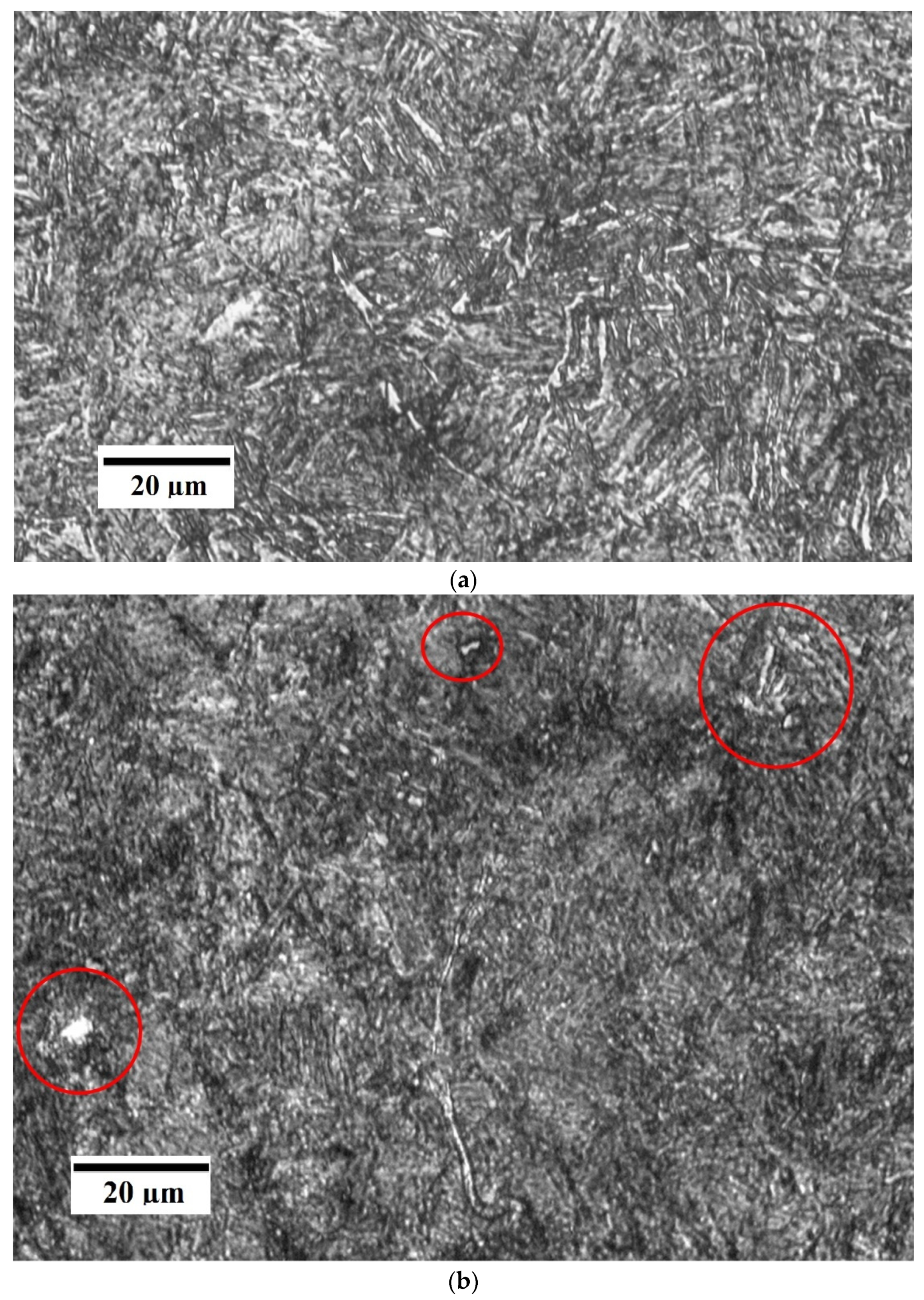

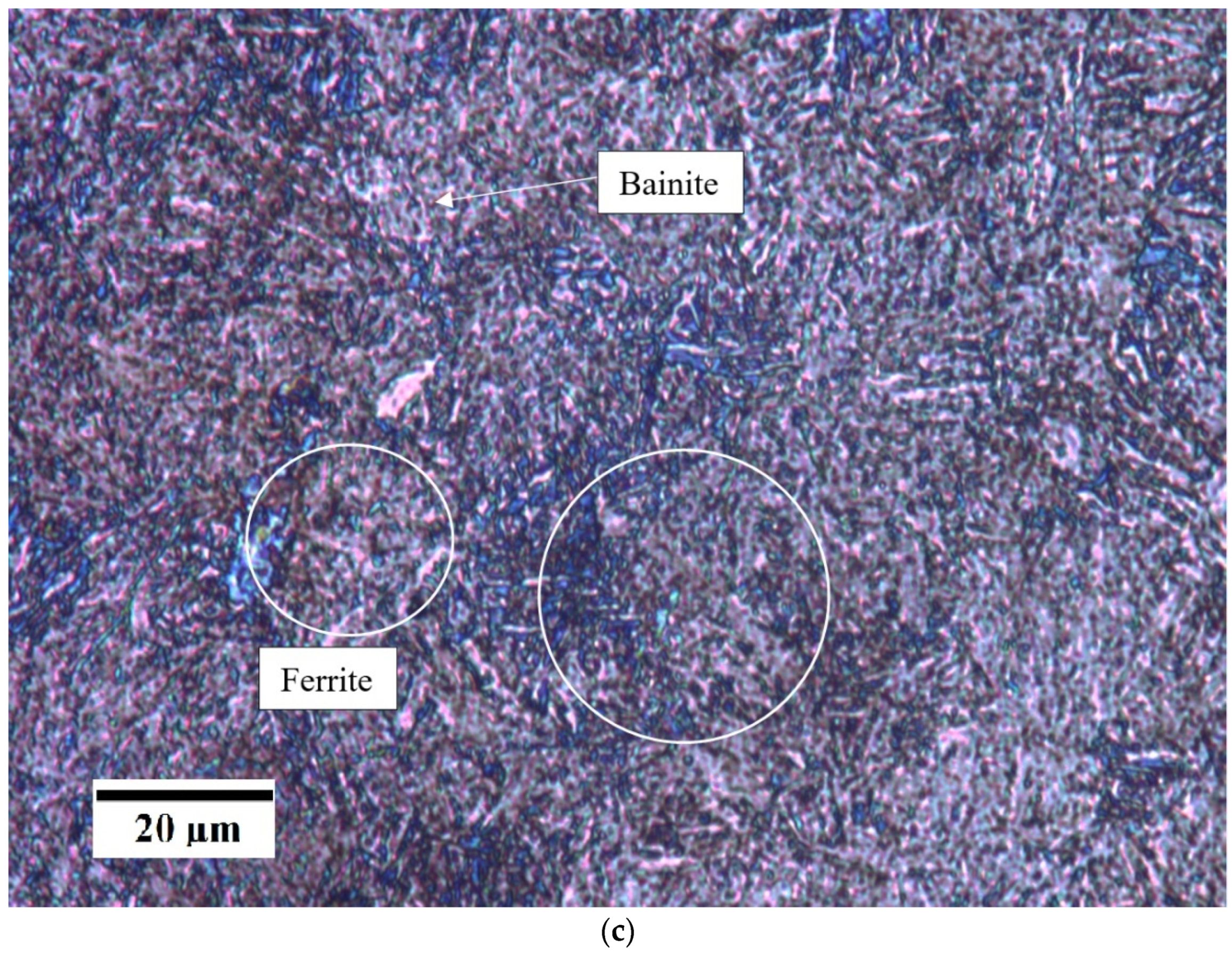

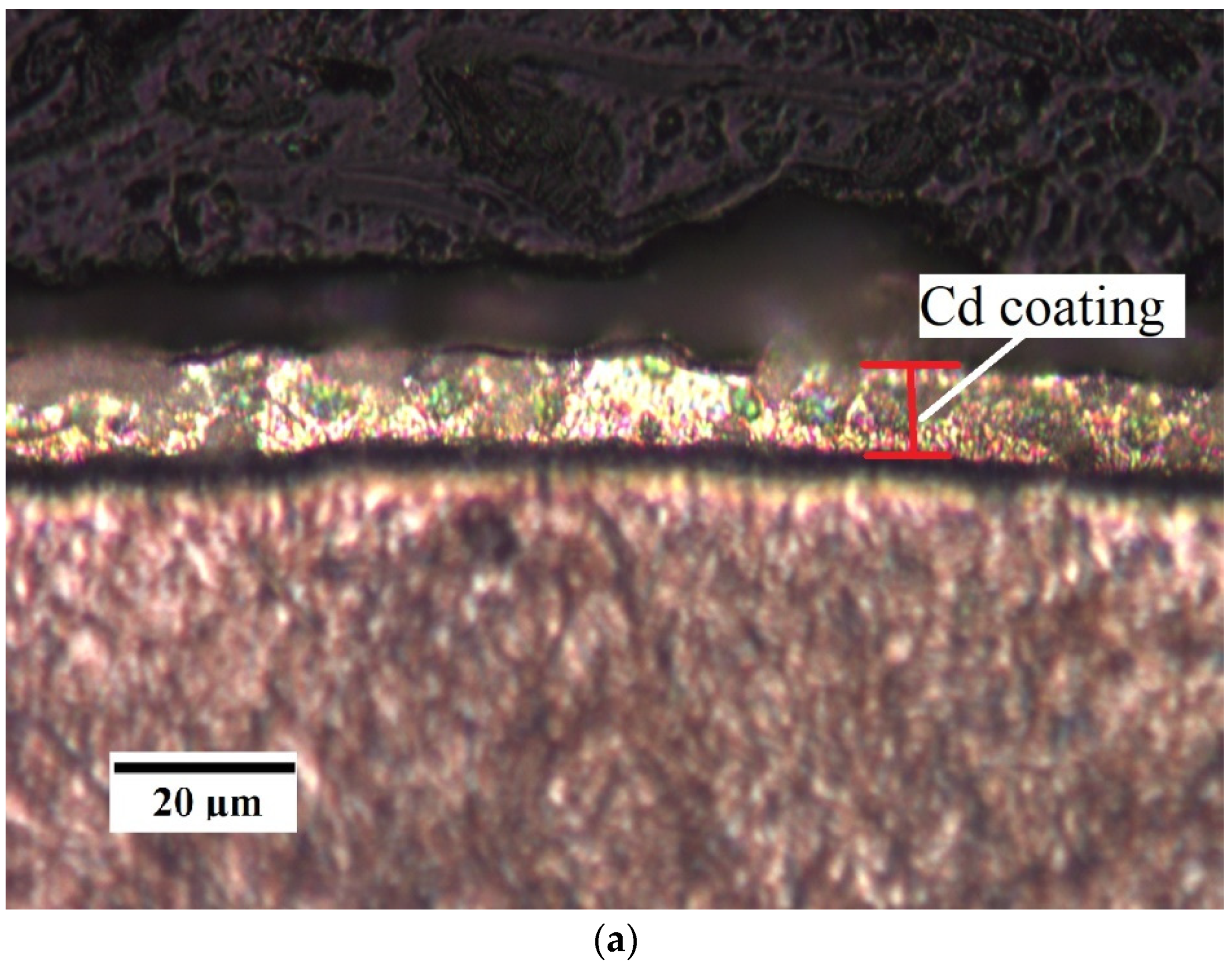

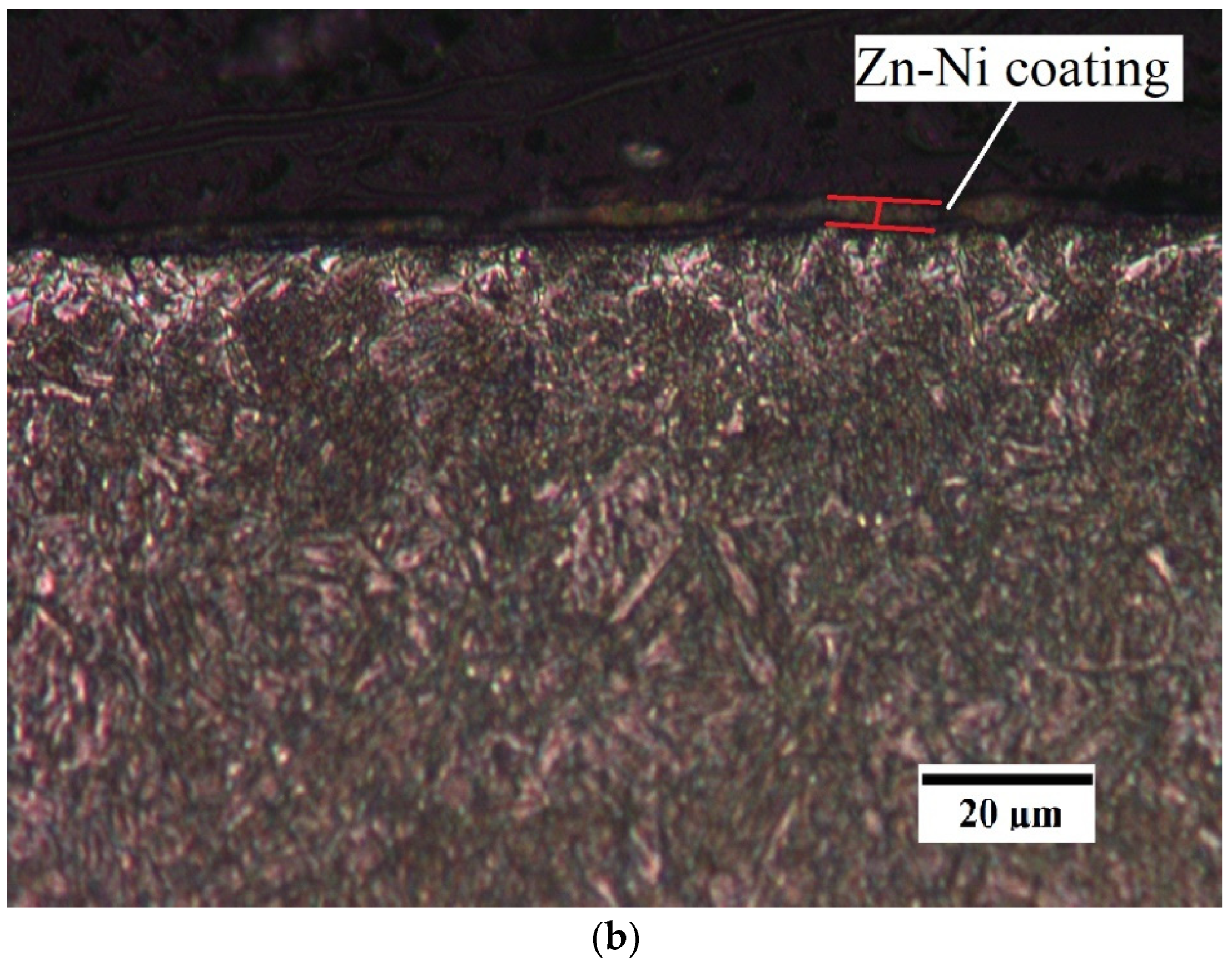

3.1. Microstructure and Coating Characterization

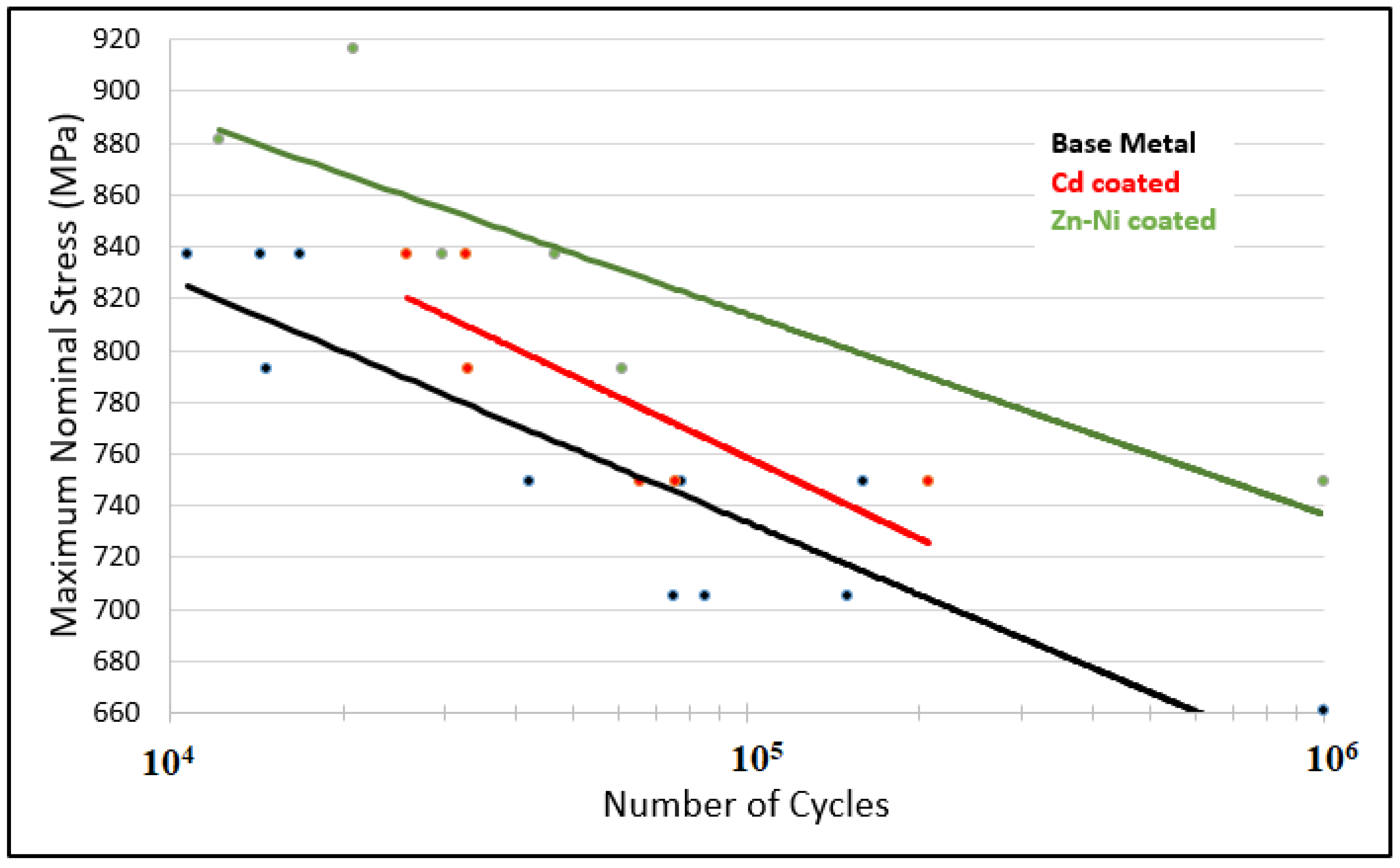

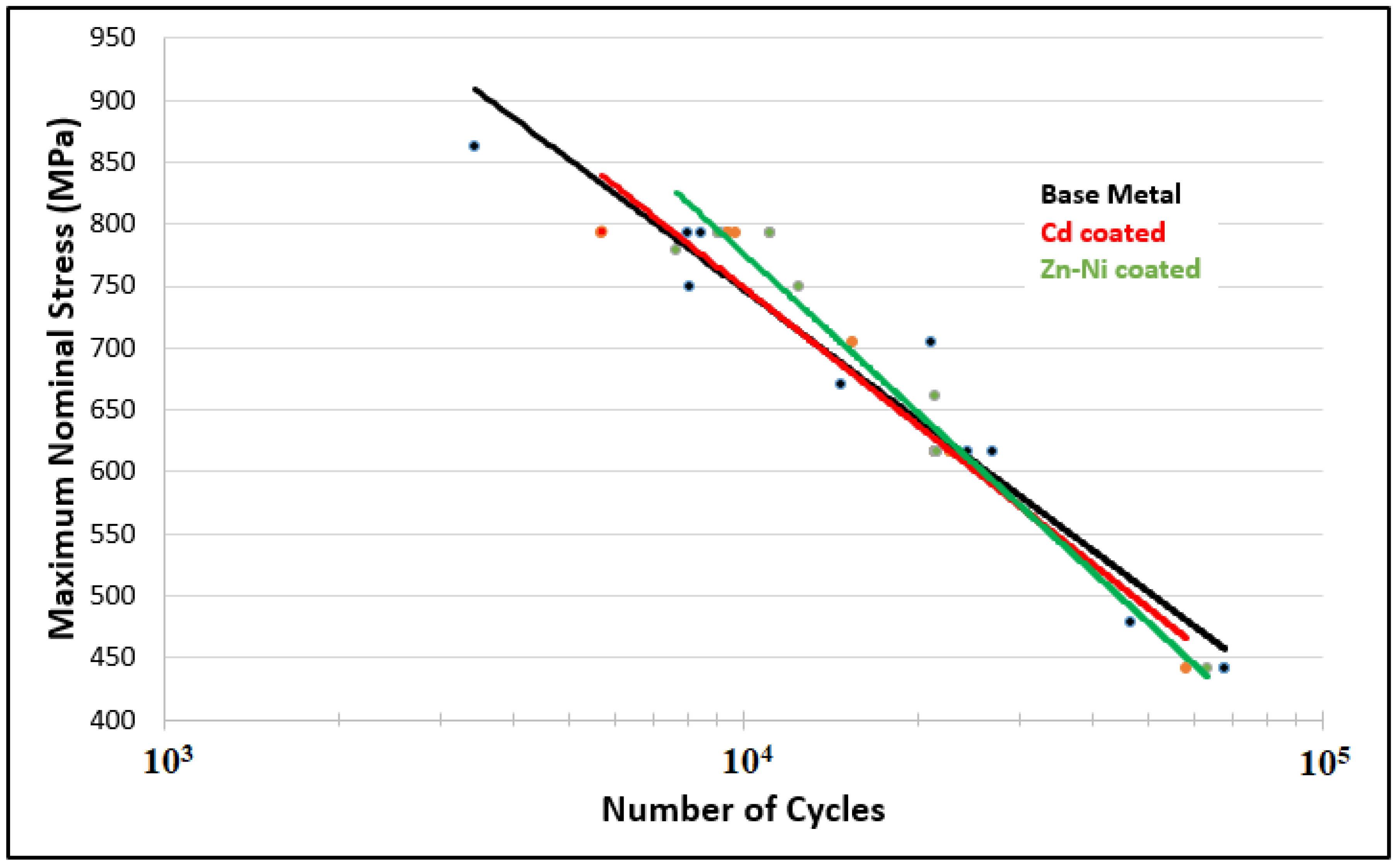

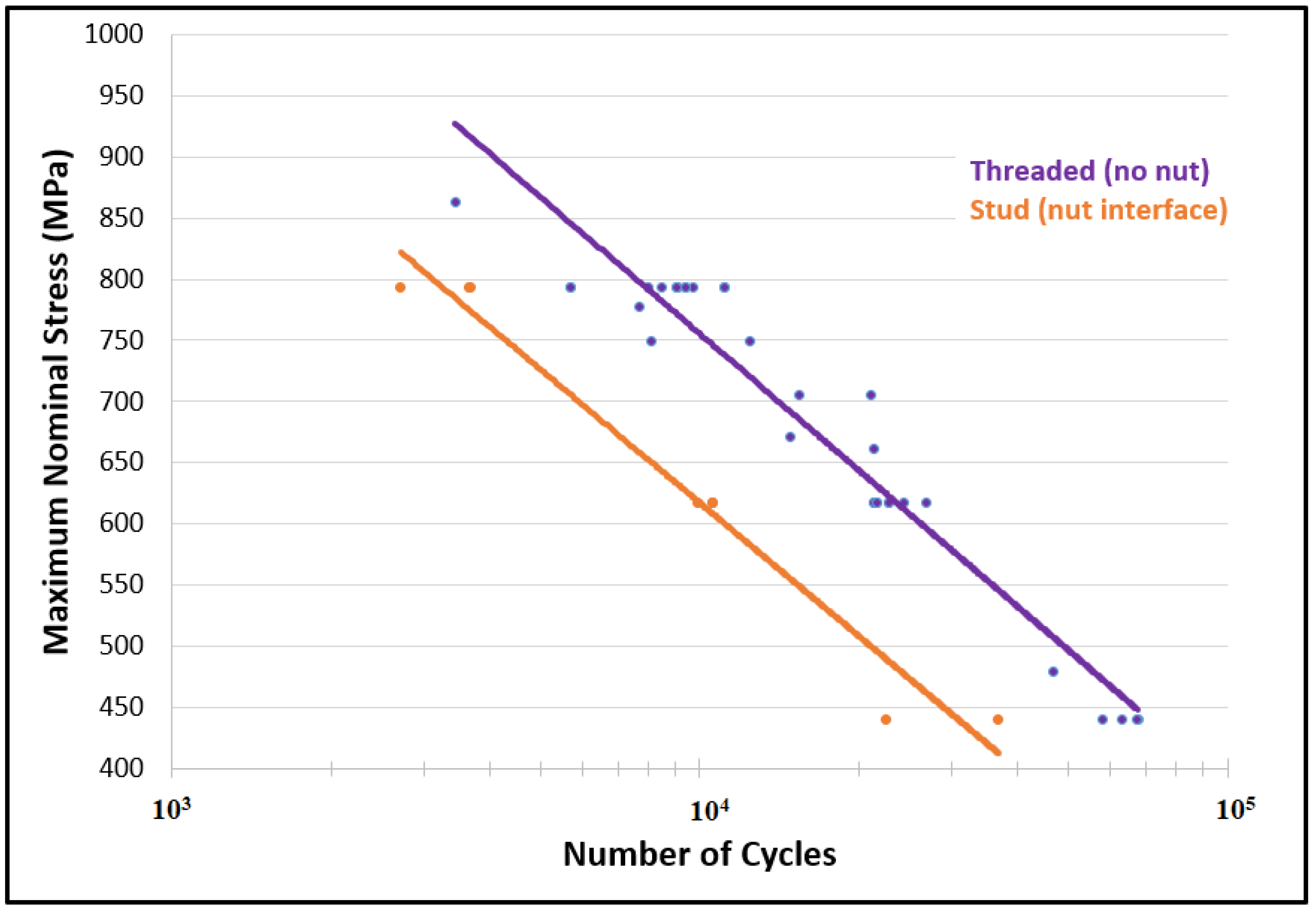

3.2. Fatigue Data

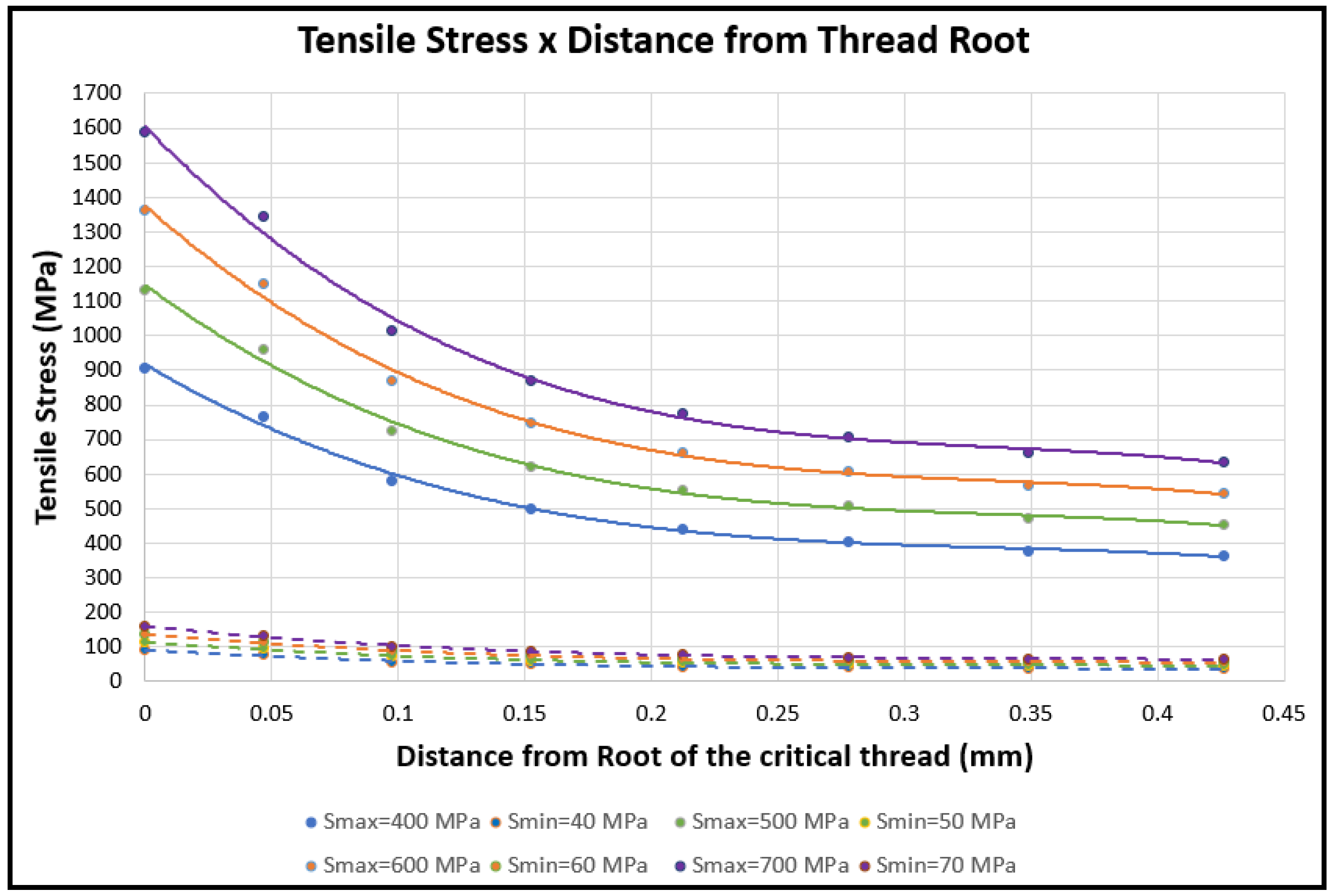

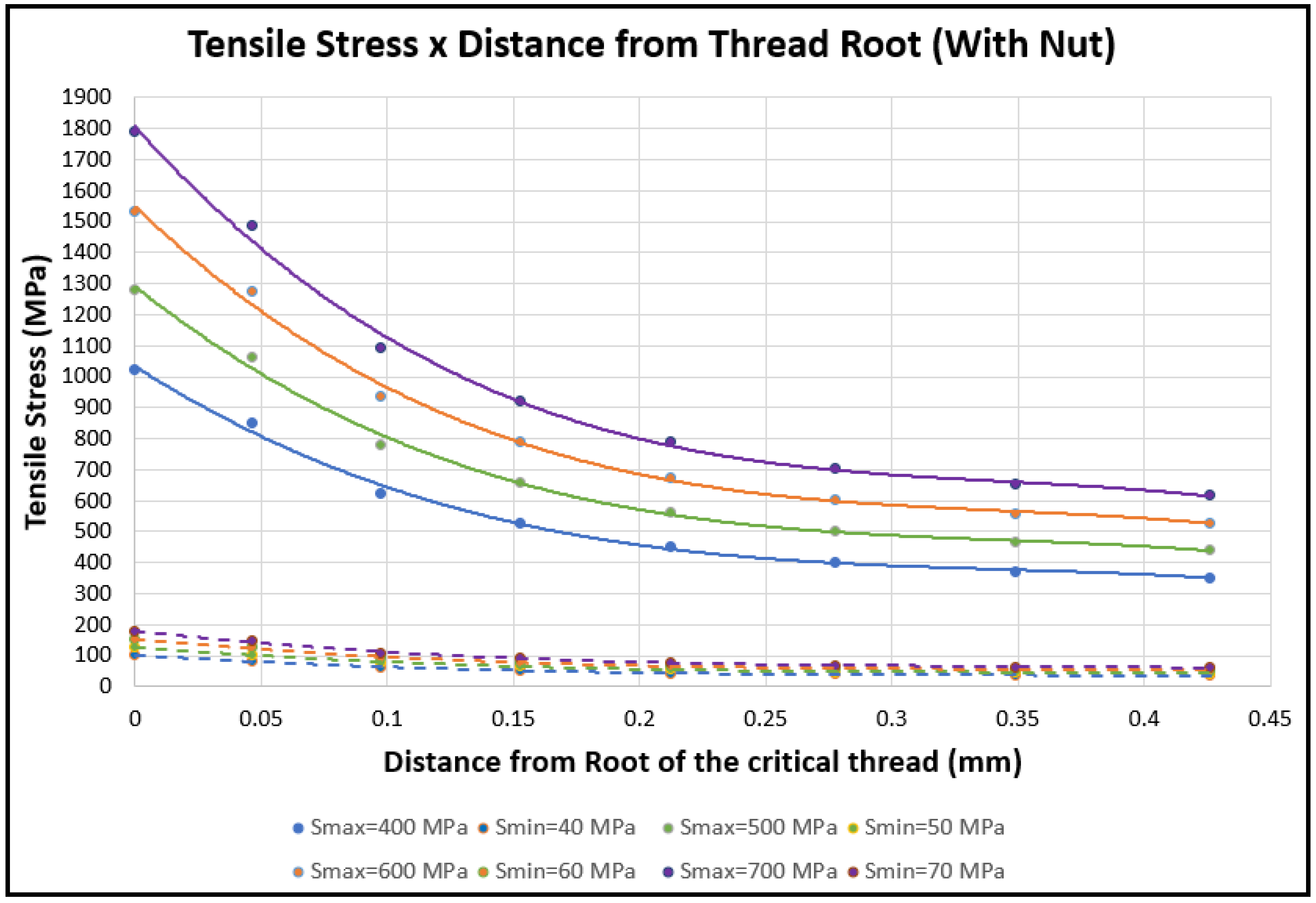

3.3. Finite Element Analysis

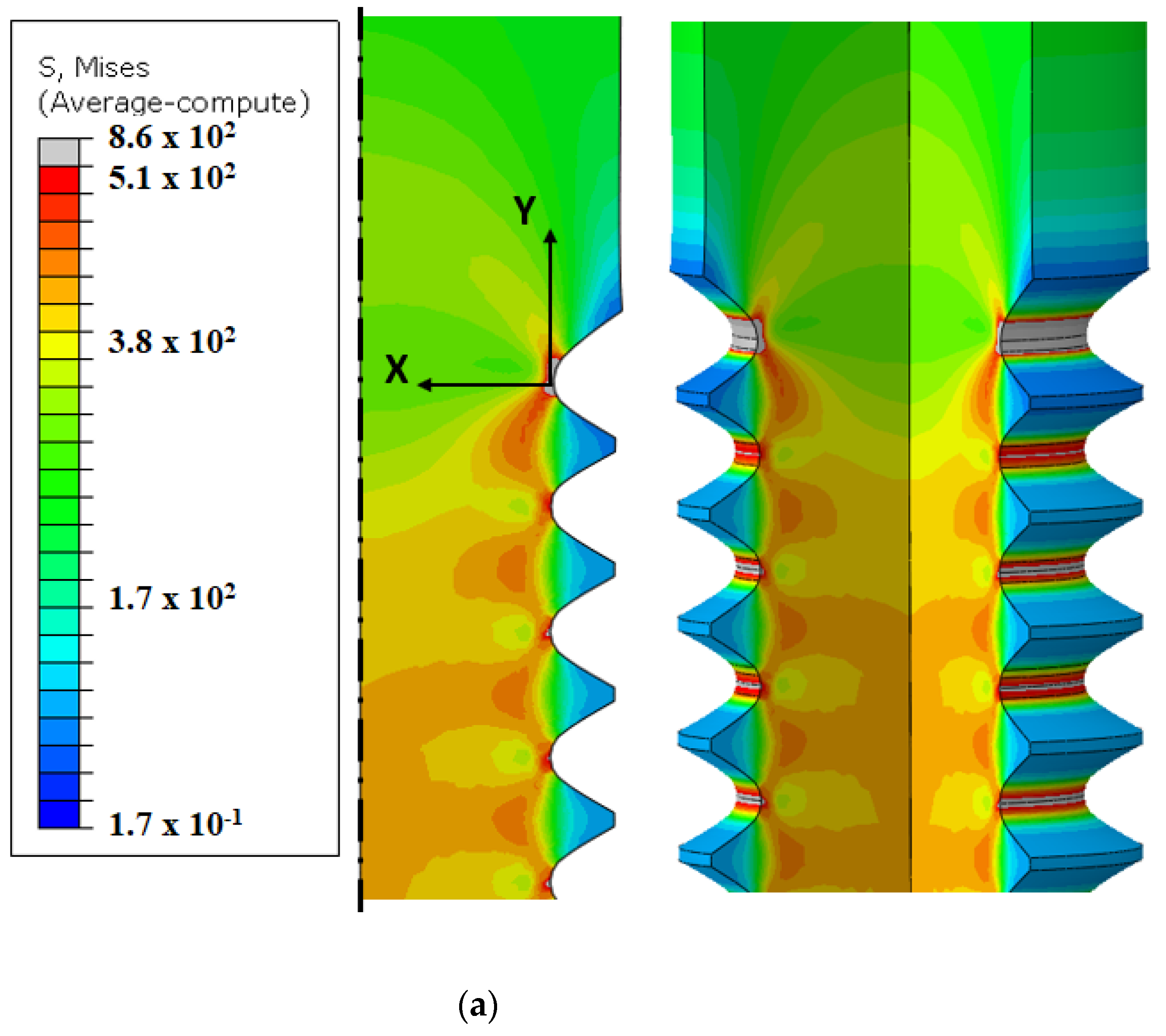

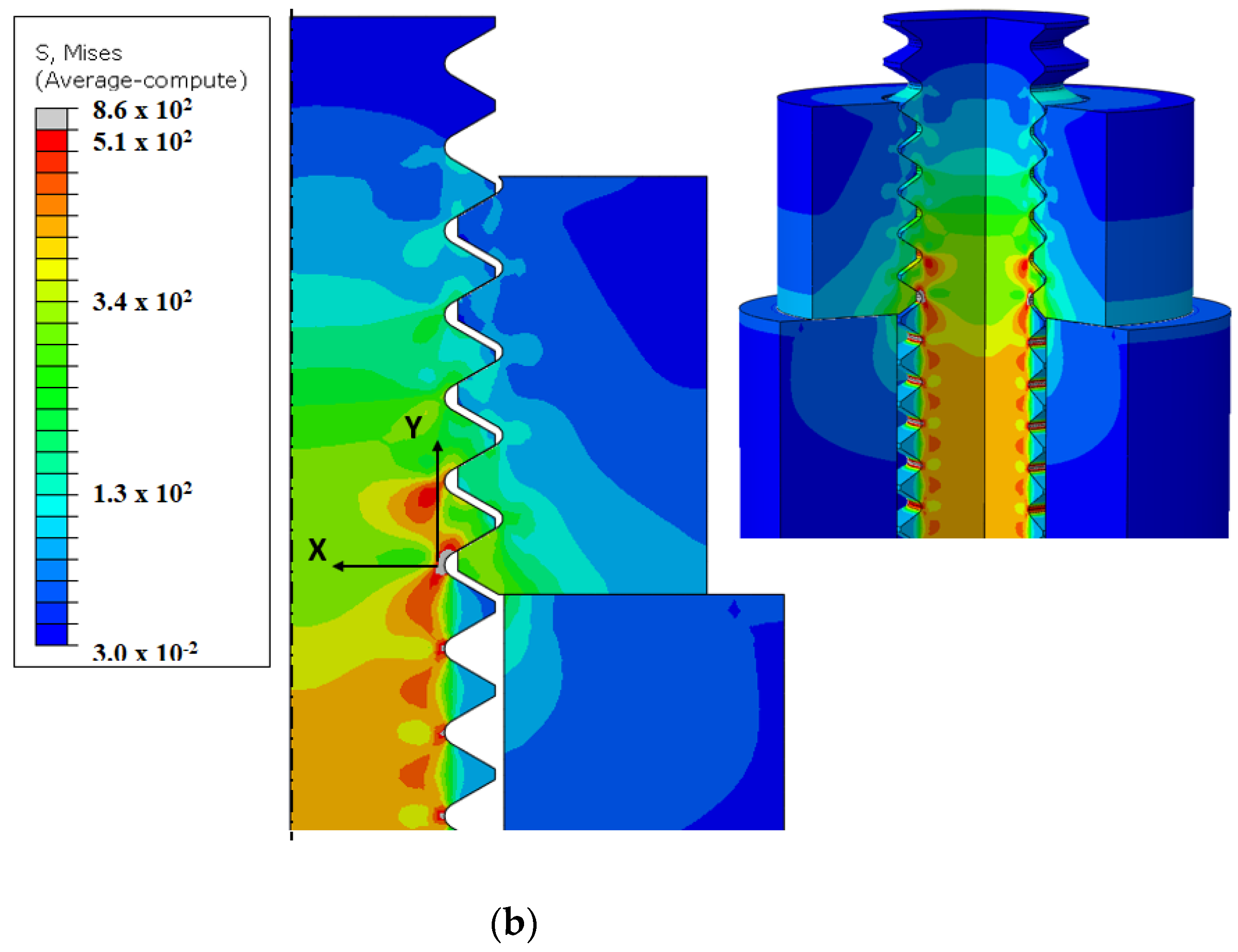

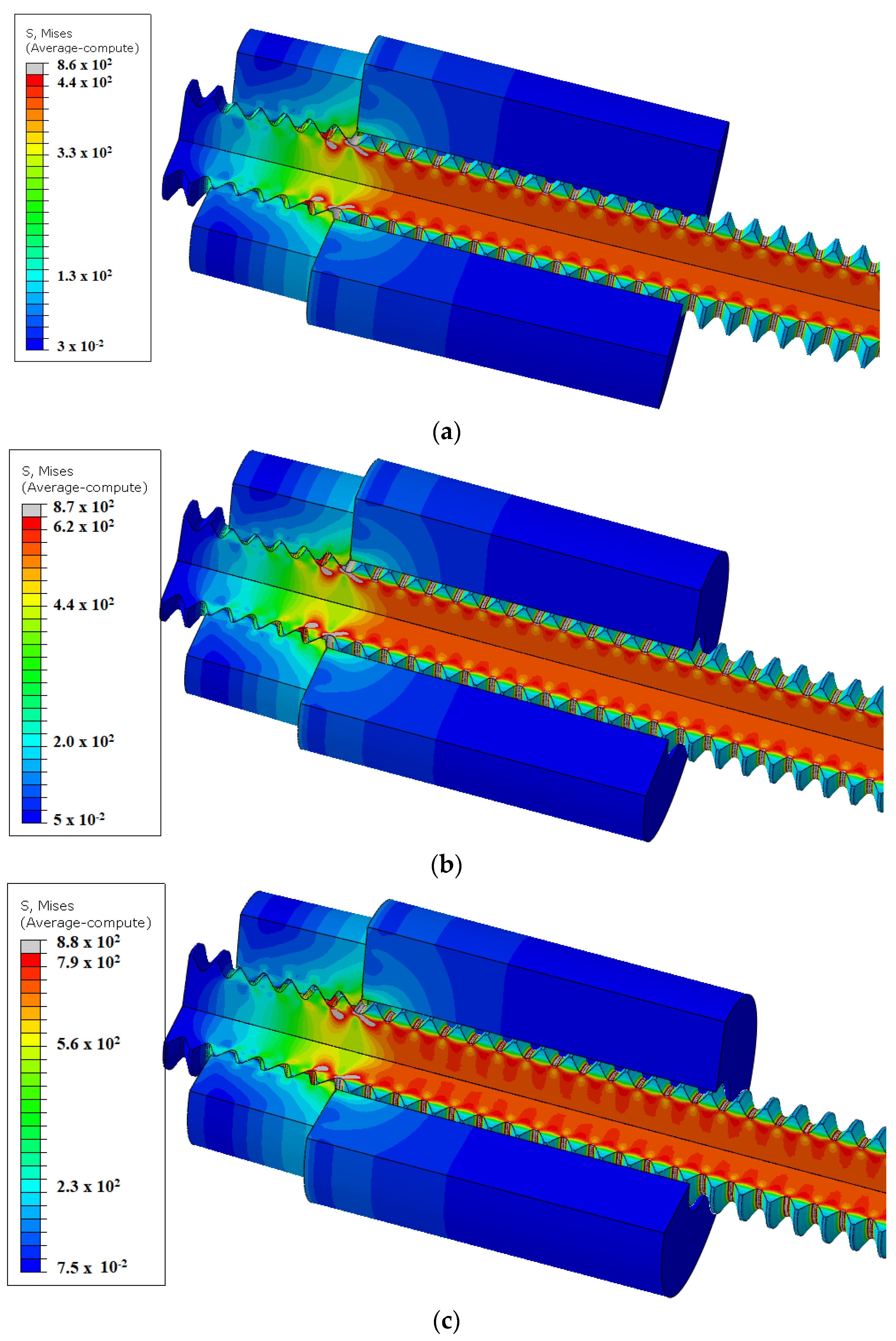

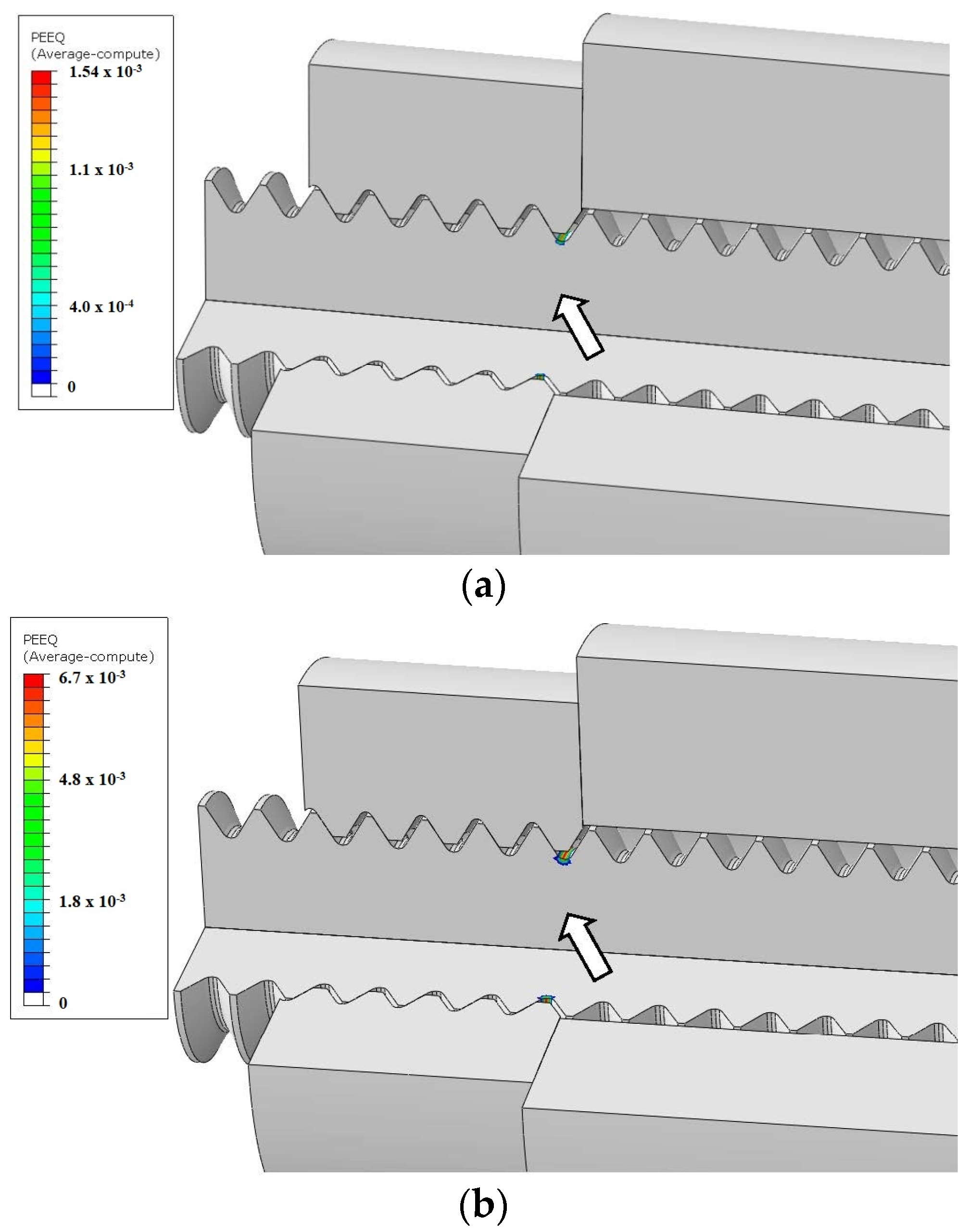

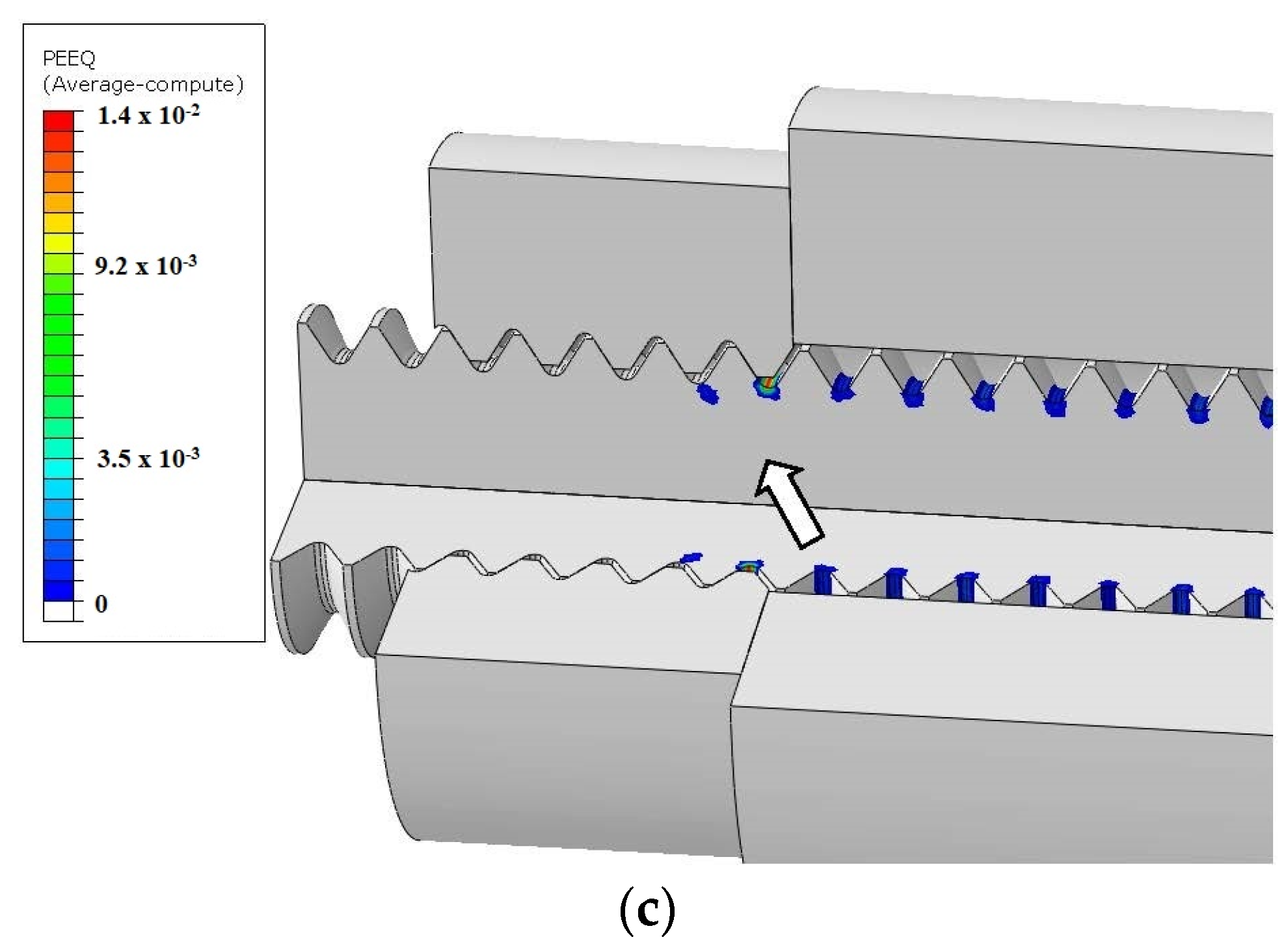

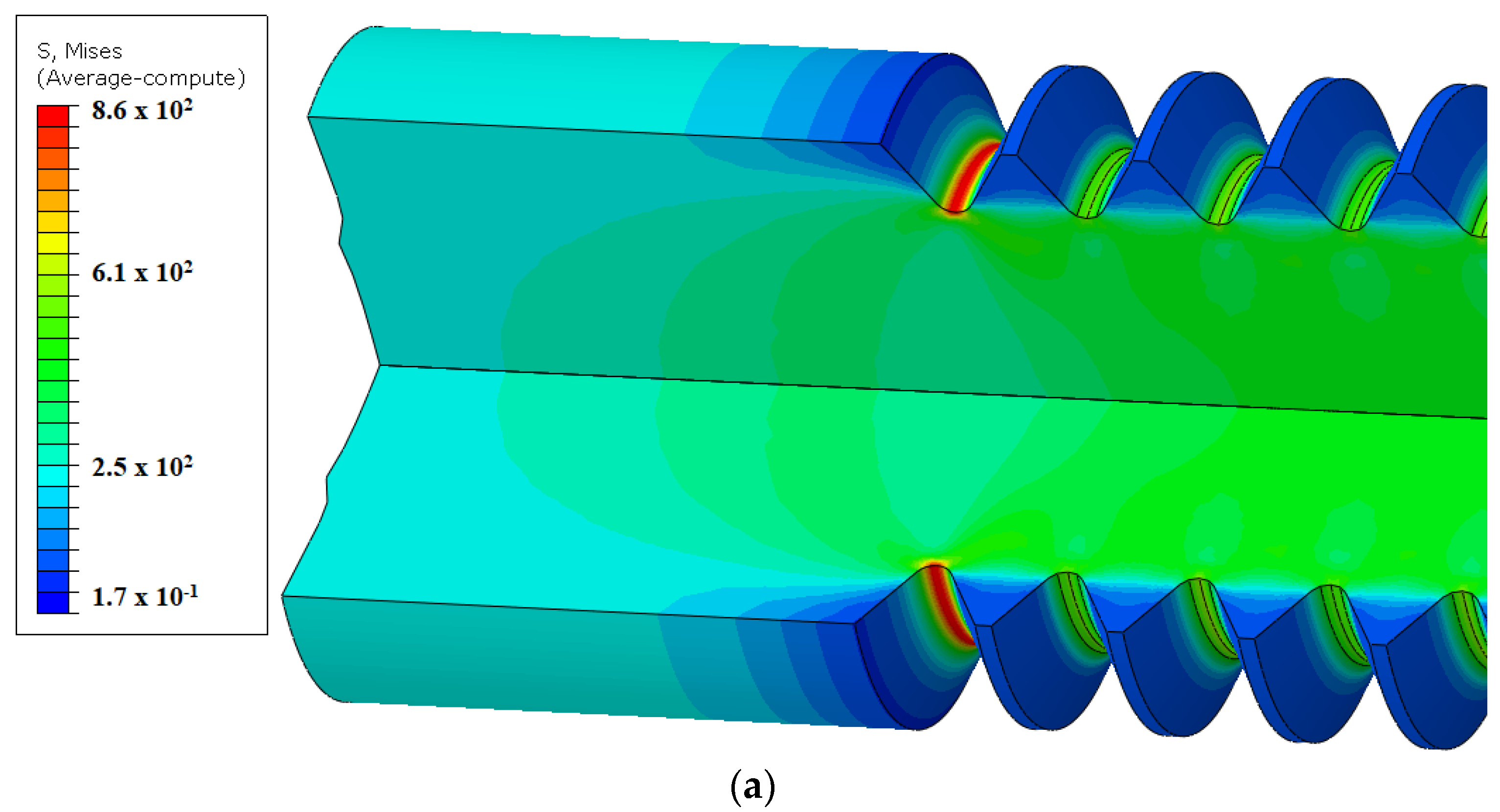

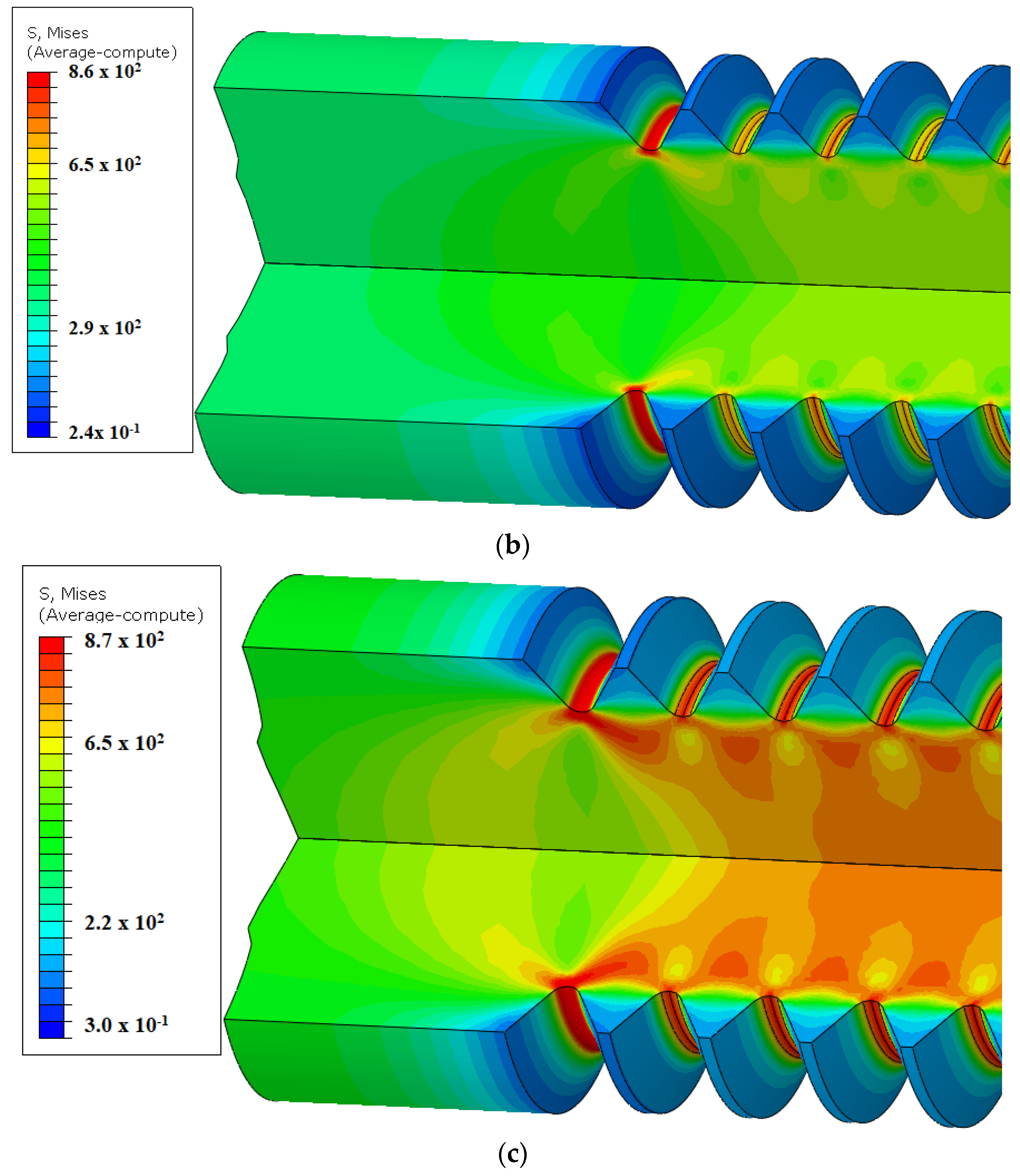

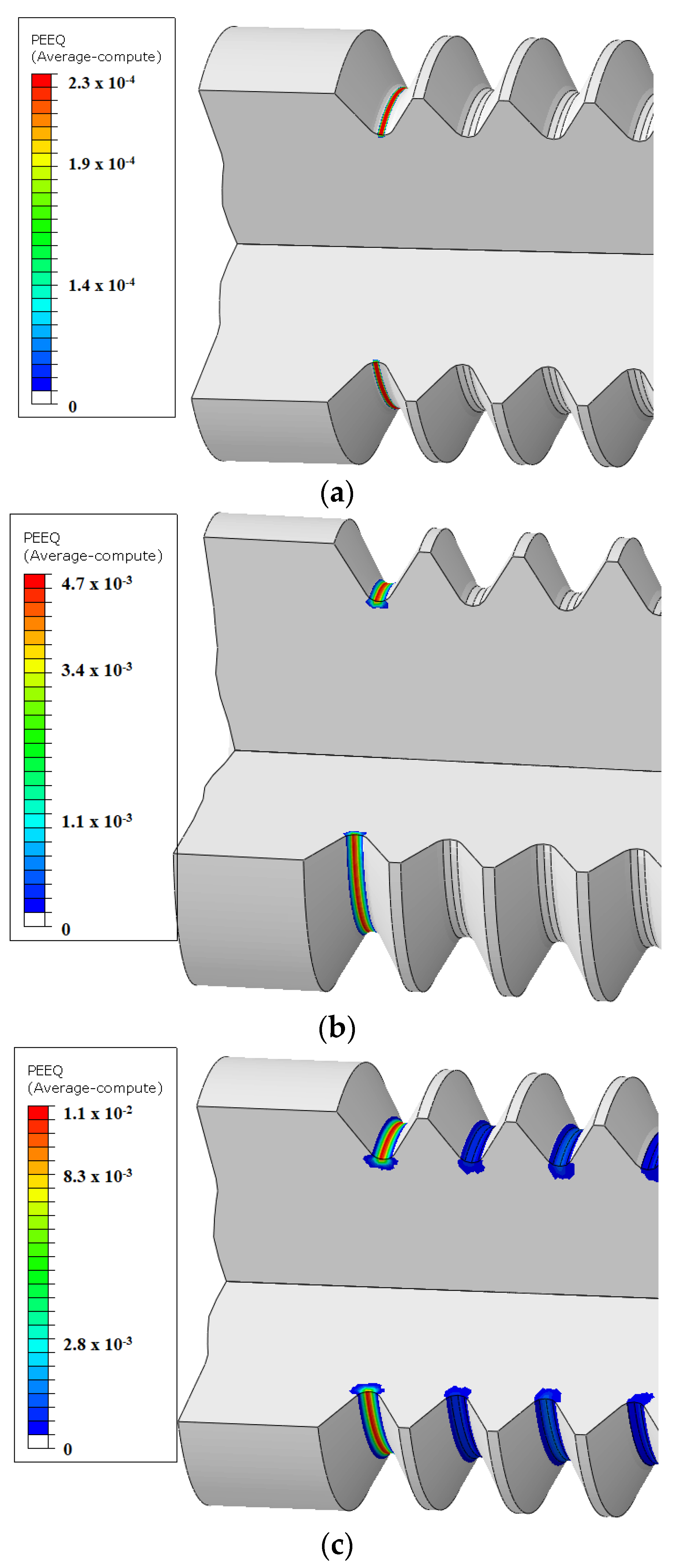

3.3.1. Elastoplastic Analysis

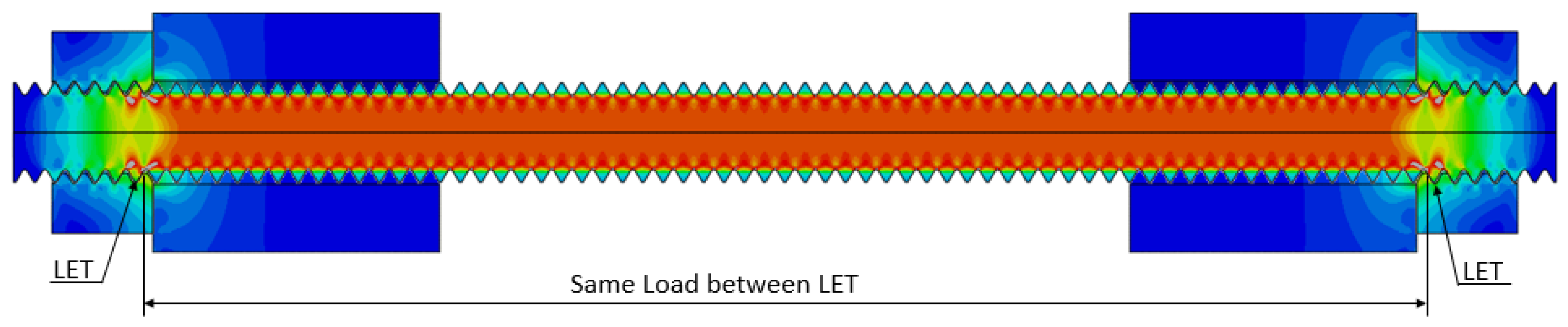

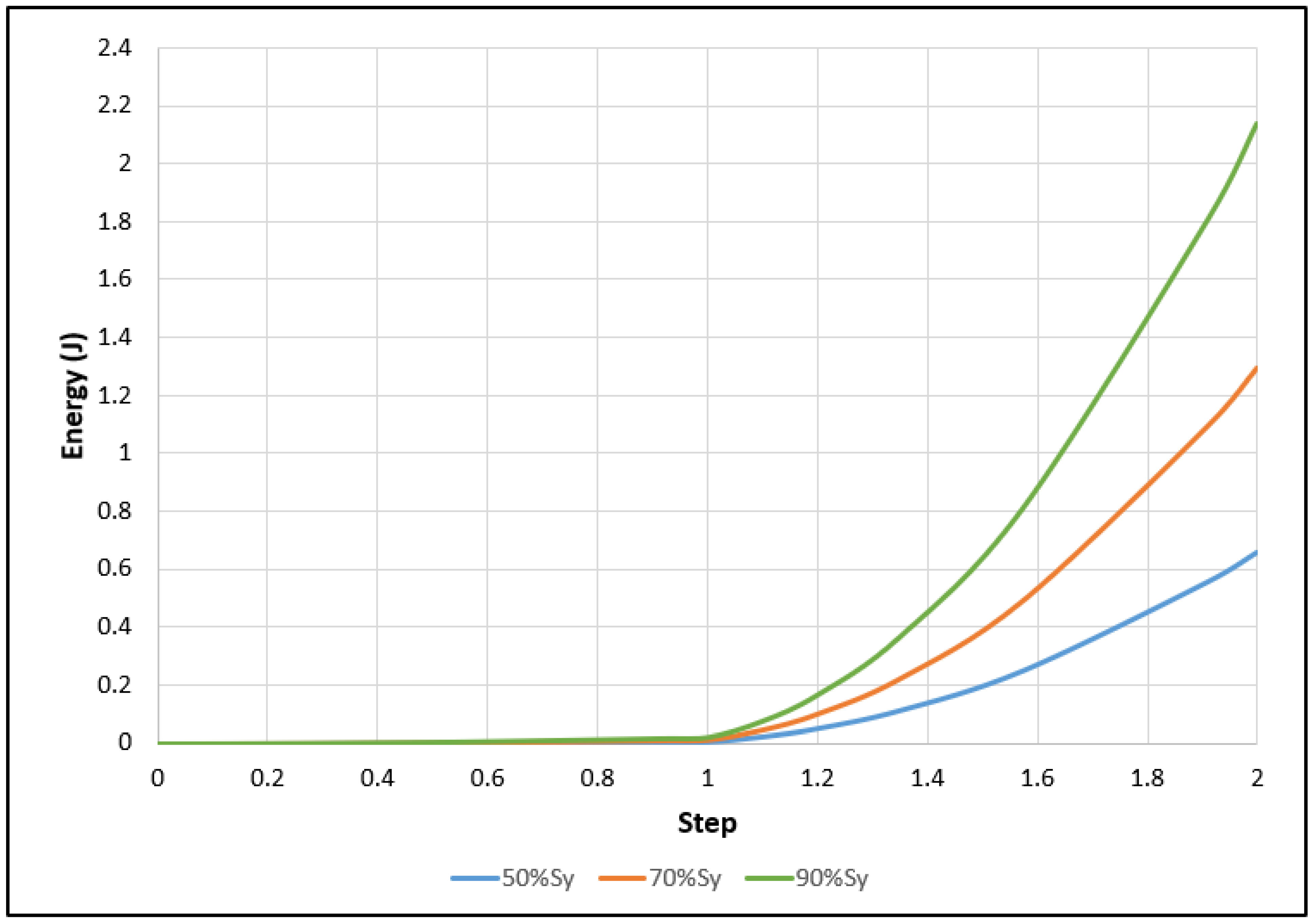

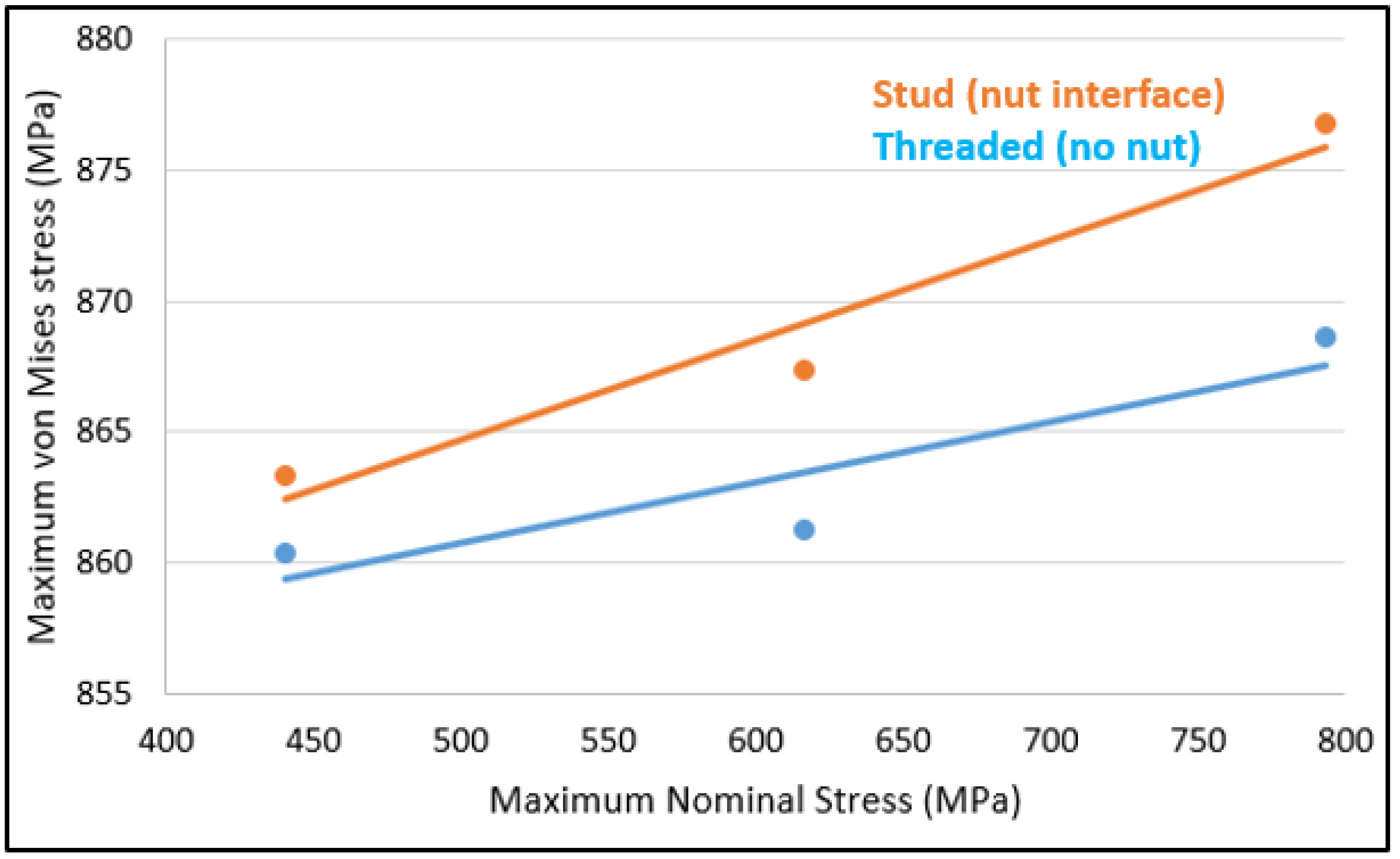

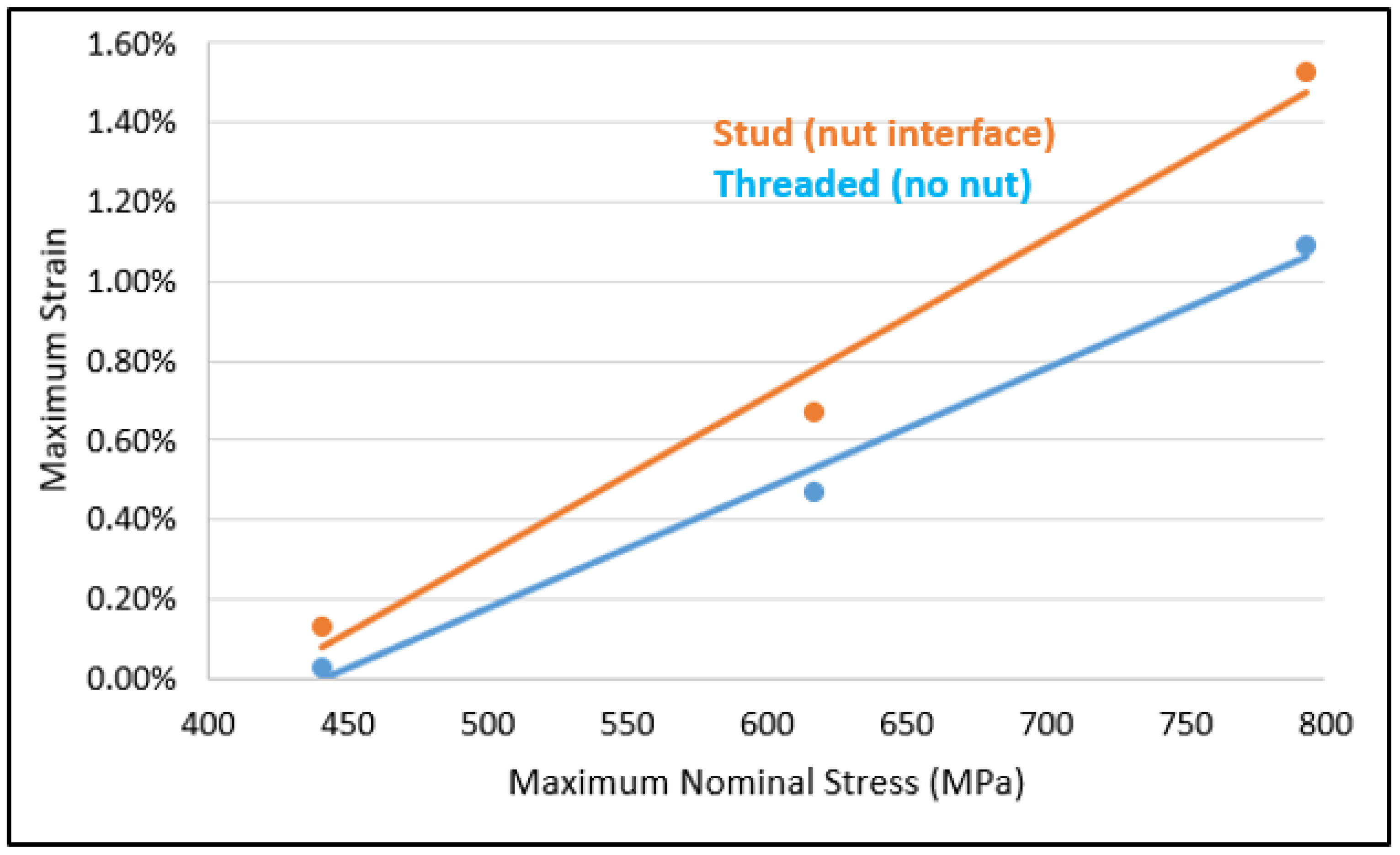

3.3.2. Elastic Analysis

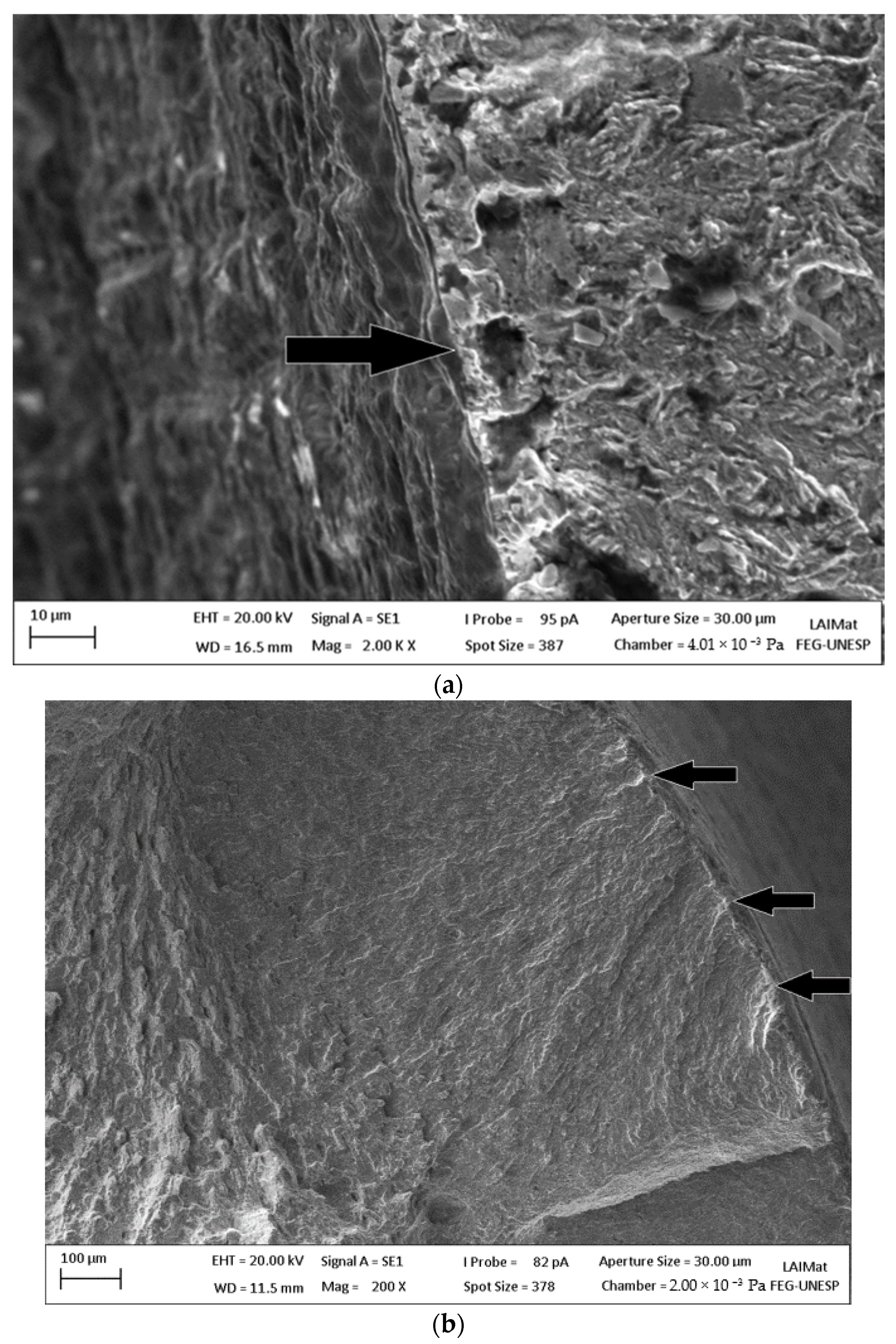

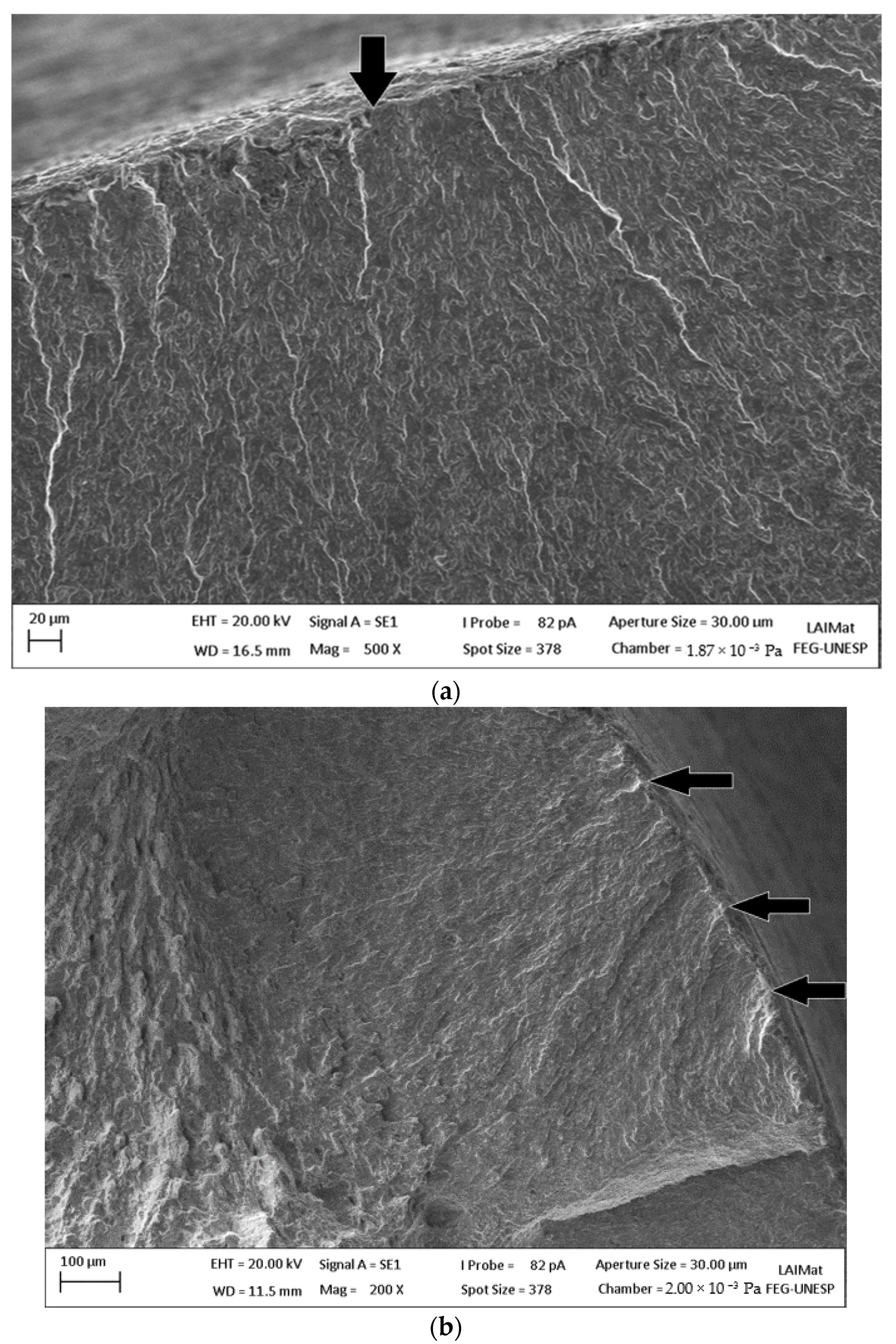

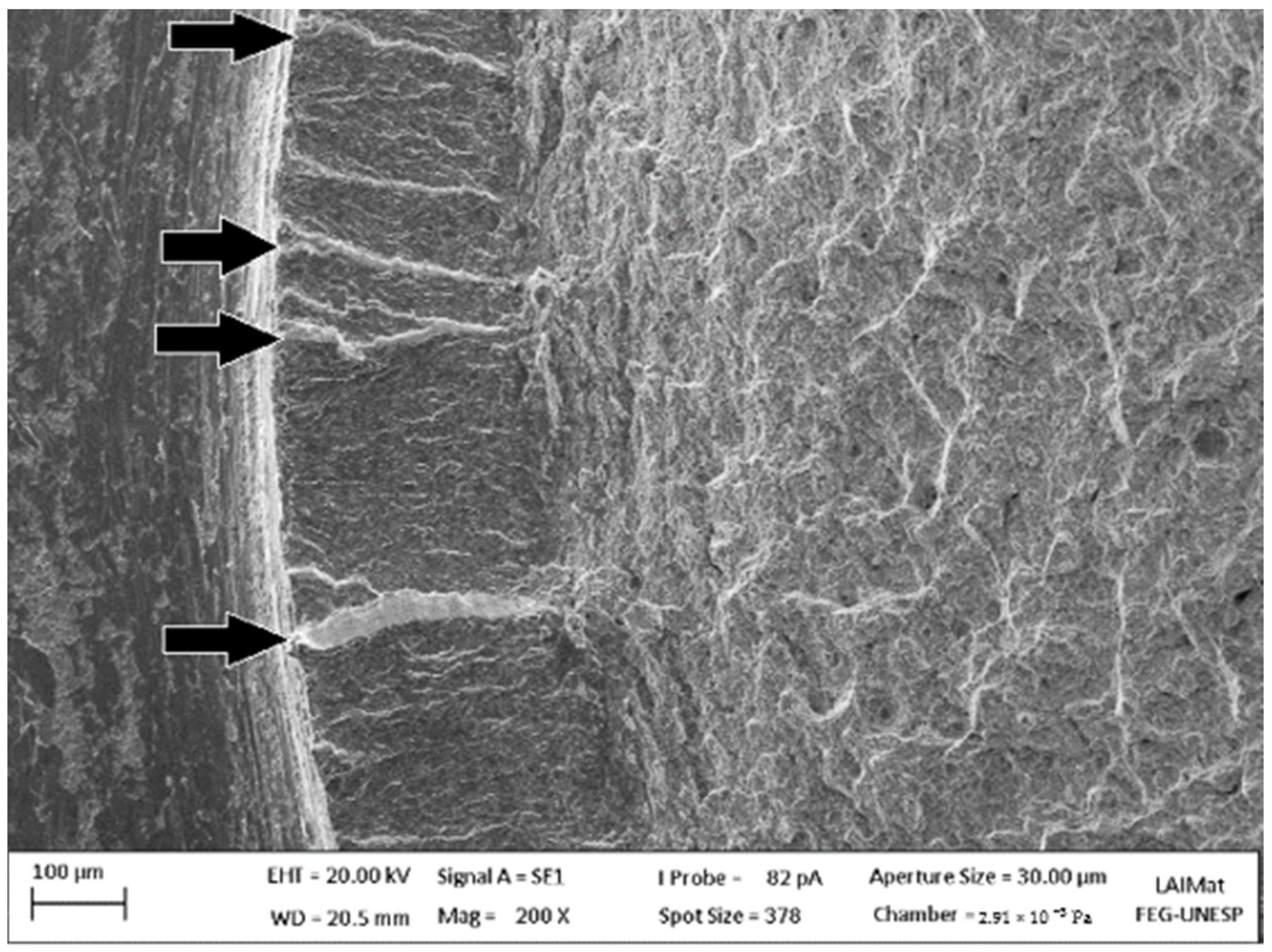

3.4. Fractography

4. Conclusions

- The substitution of electroplated Cd for a Zn-Ni coating is feasible regarding the axial fatigue strength. The fatigue strength of Cd and Zn-Ni threaded components was similar to the uncoated threaded base material. Therefore, there was no fatigue life debit due to the application of Cd and Zn-Ni coatings on steel threaded components. Furthermore, both smooth specimens coated with Cd and Zn-Ni have shown better fatigue life than the uncoated condition.

- The influence of the stress concentration factor was much greater than the influence of the electrodeposition process on the fatigue performance of AISI 4140 steel threaded components.

- The experimental fatigue life data showed a high contribution to reducing the fatigue life when there was contact between male and female threads, achieving a reduction of 58% with the nut/stud interface compared to threaded components without nuts.

- The studs (with stud/nut interface) had higher stress/strain values than the threaded specimens (without nut interface) in the elastoplastic FEA. The elastoplastic FEA showed the highest stress and strain concentration regions that correspond to the fatigue crack nucleation sites observed through SEM.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Voorwald, H.; Vieira, L.; Cioffi, M. Evaluation of WC 10Ni thermal spraying coating by HVOF on the fatigue and corrosion AISI, 4340 steel. Procedia Eng. 2010, 2, 331–340. [Google Scholar] [CrossRef][Green Version]

- Sriraman, K.; Strauss, H.; Brahimi, S.; Chromik, R.; Szpunar, J.; Osborne, J.; Yue, S. Tribological behavior of electrodeposited Zn, Zn–Ni, Cd and Cd–Ti coatings on low carbon steel substrates. Tribol. Int. 2012, 56, 107–120. [Google Scholar] [CrossRef]

- Costa, M.Y.P.; Venditti, M.L.R.; Cioffi, M.O.H.; Voorwald, H.J.C.; Guimarães, V.A.; Ruas, R. Fatigue Behavior of PVD Coated Ti–6Al–4 V Alloy. Int. J. Fatigue 2011, 33, 759–765. [Google Scholar] [CrossRef]

- Yonekura, D.; Fujita, J.; Miki, K. Fatigue and Wear Properties of Ti–6Al–4 V Alloy with Cr/CrN Multilayer Coating. Surf. Coat. Technol. 2015, 275, 232–238. [Google Scholar] [CrossRef]

- Fernandes, M.F.; Torres, M.A.S.; Fonseca, M.P.C.; Baptista, C.A.R.P. Investigation of residual stress, stress relaxation and work hardening effects induced by shot peening on the fatigue life of AA6005-T6 aluminum alloy Mater. Res. Express 2020, 6, 1265i2. [Google Scholar] [CrossRef]

- Bastos, Y.C.; Fernandes, M.F.; de Oliveira Velloso, V.M.; Minto, T.A.; Voorwald, H.J.C. Plasma immersion ion implanttation and shot peening influence on the fatigue strength of AA7050-T7451 aluminum alloy Eng. Res. Express 2020, 2, 015015. [Google Scholar] [CrossRef]

- Nascimento, M. Effects of surface treatments on the fatigue strength of AISI 4340 aeronautical steel. Int. J. Fatigue 2001, 23, 607–618. [Google Scholar] [CrossRef]

- Voorwald, H.J.C.; Miguel, I.M.; Peres, M.P.; Cioffi, M.O.H. Effects of Electroplated Zinc-Nickel Alloy Coatings on the Fatigue Strength of AISI 4340 High-Strength Steel. J. Mater. Eng. Perform. 2005, 14, 249–257. [Google Scholar] [CrossRef]

- Conde, A.; Arenas, M.A.; de Damborenea, J. Electrodeposition of Zn–Ni coatings as Cd replacement for corrosion protection of high strength steel. Corros. Sci. 2011, 53, 1489–1497. [Google Scholar] [CrossRef]

- Sabelkin, V.; Misak, H.; Mall, S. Fatigue behavior of Zn–Ni and Cd coated AISI 4340 steel with scribed damage in saltwater environment. Int. J. Fatigue 2016, 90, 158–165. [Google Scholar] [CrossRef]

- Brooman, E. Corrosion behavior of environmentally acceptable alternatives to cadmium and chromium coatings: Cadmium. Part I. Met. Finish. 2000, 98, 42–50. [Google Scholar] [CrossRef]

- Bielawski, M. Development of unbalanced magnetron sputtered Al–Mo coatings for cadmium replacement. Surf. Coatings Technol. 2004, 179, 10–17. [Google Scholar] [CrossRef]

- Agüero, A.; Del Hoyo, J.; De Blas, J.G.; García, M.; Gutiérrez, M.; Madueño, L.; Ulargui, S. Aluminum slurry coatings to replace cadmium for aeronautic applications. Surf. Coatings Technol. 2012, 213, 229–238. [Google Scholar] [CrossRef]

- El-Lateef, H.M.A.; El-Sayed, A.-R.; Mohran, H.S. Role of Ni content in improvement of corrosion resistance of Zn–Ni alloy in 3.5% NaCl solution. Part I: Polarization and impedance studies. Trans. Nonferrous Met. Soc. China 2015, 25, 2807–2816. [Google Scholar] [CrossRef]

- Sriraman, K.; Brahimi, S.; Szpunar, J.; Osborne, J.; Yue, S. Characterization of corrosion resistance of electrodeposited Zn–Ni Zn and Cd coatings. Electrochim. Acta 2013, 105, 314–323. [Google Scholar] [CrossRef]

- Sriraman, K.R.; Brahimi, S.; Szpunar, J.A.; Osborne, J.H.; Yue, S. Tribocorrosion Behavior of Zn, Zn–Ni, Cd and Cd–Ti Electrodeposited on Low Carbon Steel Substrates. Surf. Coat. Technol. 2013, 224, 126–137. [Google Scholar] [CrossRef]

- Fernandes, M.F.; Dos Santos, J.R.M.; Velloso, V.M.D.O.; Voorwald, H.J.C. AISI 4140 Steel Fatigue Performance: Cd Replacement by Electroplated Zn-Ni Alloy Coating. J. Mater. Eng. Perform. 2020, 29, 1567–1578. [Google Scholar] [CrossRef]

- Owolabi, G.; Okeyoyin, O.; Bamiduro, O.; Olasumboye, A.; Whitworth, H. The effects of notch size and material microstructure on the notch sensitivity factor for notched components. Eng. Fract. Mech. 2015, 145, 181–196. [Google Scholar] [CrossRef]

- Chaves, V.; Madrigal, C.; Navarro, A. Fatigue limit predictions at stress concentrations using FEA and microstructural fracture mechanics. Theor. Appl. Fract. Mech. 2017, 87, 11–20. [Google Scholar] [CrossRef]

- Gao, Y. Fatigue stress concentration sensitivity and stress ratio effect of a 40CrNi2Si2MoVA steel. Mater. Lett. 2017, 186, 235–238. [Google Scholar] [CrossRef]

- de Bomfim, A.S.C.; Voorwald, H.J.C.; Benini, K.C.C.D.C.; de Oliveira, D.M.; Fernandes, M.F.; Cioffi, M.O.H. Sustainable application of recycled espresso coffee capsules: Natural composite development for a home composter product. J. Clean. Prod. 2021, 297, 126647. [Google Scholar] [CrossRef]

- DET NORSKE VERITAS—DNV-RP-C203—Fatigue Design of Offshore Steel Structures. Available online: https://rules.dnv.com/docs/pdf/DNVPM/codes/docs/2011-10/RP-C203.pdf (accessed on 1 June 2021).

| C | Mn | P | S | Si | Cr | Mo | V | B | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 0.38 | 0.75/1.00 | <0.035 | <0.04 | 0.15/0.35 | 0.8/1.10 | 0.15/0.25 | <0.05 | 0.0005 | Base |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marcelino dos Santos, J.R.; Fernandes, M.F.; Velloso, V.M.d.O.; Voorwald, H.J.C. Fatigue Analysis of Threaded Components with Cd and Zn-Ni Anticorrosive Coatings. Metals 2021, 11, 1455. https://doi.org/10.3390/met11091455

Marcelino dos Santos JR, Fernandes MF, Velloso VMdO, Voorwald HJC. Fatigue Analysis of Threaded Components with Cd and Zn-Ni Anticorrosive Coatings. Metals. 2021; 11(9):1455. https://doi.org/10.3390/met11091455

Chicago/Turabian StyleMarcelino dos Santos, Jefferson Rodrigo, Martin Ferreira Fernandes, Verônica Mara de Oliveira Velloso, and Herman Jacobus Cornelis Voorwald. 2021. "Fatigue Analysis of Threaded Components with Cd and Zn-Ni Anticorrosive Coatings" Metals 11, no. 9: 1455. https://doi.org/10.3390/met11091455

APA StyleMarcelino dos Santos, J. R., Fernandes, M. F., Velloso, V. M. d. O., & Voorwald, H. J. C. (2021). Fatigue Analysis of Threaded Components with Cd and Zn-Ni Anticorrosive Coatings. Metals, 11(9), 1455. https://doi.org/10.3390/met11091455