1. Introduction

The creation of new technological methods of exposure, which ensure the formation of structures of materials with the required properties [

1,

2,

3], is one of the possibilities that can solve the task of increasing the operational characteristics of mechanical engineering products. It is known that the development of such processes in metal alloys, such as recovery and recrystallization, homogenization, and relaxation, determine the rates and mechanisms of diffusion, which are essential for the formation of their structures and properties [

4,

5]. In addition to changes in the grain size and microstructure of metals and alloys, diffusion processes cause the appearance of nanostructural effects: a change in the angular misorientations of subgrains in the grain composition, crushing of blocks, the formation of an ordered distribution of nanosized inclusions and pores, a change in the level of microdistortions, and dislocation density. These effects have the potential to improve not only such structure-dependent properties as mechanical strength, hardness, and plasticity, but also electrical conductivity, thermal conductivity, optical characteristics, etc. Increasing the temperature is an effective way to increase the mobility of atoms, since the diffusion coefficient is exponentially related to temperature, but in some cases this method has significant limitations, for example, due to grain growth and material embrittlement [

6,

7].

Investigations of behaviour of metallic materials under mechanical shock compression have substantiated a notable increase in the rate of atoms movement in the solid phase [

8]. Occurrence of enhanced mass transfer due to non-equilibrium conditions under pulsed deformations in the elastic as well as plastic range has been observed during mechanochemical thermal treatment of the following types: ultrasonic, laser, electro-hydropulses, pulsed magnetic fields, electrical discharge, deformations during reversible structural changes of martensite, and several other sorts of pulsed strain [

9,

10,

11]. External energy influences at high levels including periodic laser pulses [

12,

13] significantly increase the mobility of atoms in alloys and metals of solid phase. Non-stationary deformation limited to a local zone of the material is a necessary prerequisite for the occurrence of a general thermodynamic force effectuating rapid mass transfer [

14]. It should be noted that the physics of the procedure displaying vibrations in the material at its natural frequency and such frequencies that are proportionally related to the forced fundamental are explained in [

15,

16,

17]. Nevertheless, the profound nature of the processes determining formation of gradient conditions and subsequent evolution of structural phased states of metallic materials needs further investigation [

18,

19]. That can be attributed to the number of physical influences and factors, like structural modifications in the metal, manifestation and disappearance of crystalline defects, arising of stress, etc., all simultaneously contributing to the mass transfer in the greatly non-equilibrium condition.

The study of the mechanisms and regularities of physical processes responsible for the intensification of mass transfer in metallic materials using an external high-energy exposure is of considerable scientific and practical interest, since a targeted influence on mass transfer and the accompanying relaxation processes will allow us to increase the efficiency of methods for processing metals and alloys. This opens up the possibility of creating new materials with the desired complex of physical and mechanical properties. One of the progressive methods is laser processing. An increasing interest of researchers in the search for new methods of laser processing [

20,

21,

22,

23,

24,

25,

26] and welding [

27,

28,

29,

30], which are widely used to control the properties and microstructures of advanced materials, can be observed. The feasibility of using methods of laser exposure is determined by the possibility of a non-contact, strictly dosed intensive supply of energy to the surface of the product. During laser irradiation on a metal material, its temperature significantly increases over a short period of time, which leads to the diffusion enhancement [

31,

32,

33,

34,

35]. The mechanisms of heat transfer during laser heating take into account the heat transfer into the bulk of the material. An important parameter for laser heating processes is the characteristic time of propagation of the thermal field within the spatial scale. This parameter depends on the coefficient of thermal diffusivity, if heat transfer is carried out by a diffusion mechanism, i.e., the mechanism of heat conduction, as it happens in solids [

36,

37]. In [

38,

39] it was shown that pulsed periodic laser irradiation ensures the formation of a stable stress state on the samples surface, which is the reason for a significant intensification of mass transfer. A range of nanomaterials from nanoporous to layered based on ZnO nanowires were synthesized by periodically pulsed laser irradiation. For the first time, a notable increase in the diffusion coefficient (several times as compared to heat exposure of the laser beam only) in the metallic material, caused by the synergy of heat exposure and vibrations induced by laser, predominantly in the range of sound frequencies, as a result of a pulse-periodic laser irradiation with a pulse duration in the milli- and microsecond range, was described.

Expanding the application area of laser irradiation as a progressive method for modifying the properties of metals and alloys in modern production requires a detailed and comprehensive study of new possibilities for improving technologies for processing metallic materials. The main purpose of this article is to provide systematized information on the possibility of using laser irradiation to enhance mass transfer in the solid phase of metallic materials in order to form structures with improved physical and mechanical properties.

2. Increasing the Atom Diffusion Rate in the Solid Phase of Metallic Materials

Mass transfer in crystalline materials that are in the solid state is one of the most important and general physical processes. Thus, the rates and mechanisms of diffusion determine the course of many processes in metal alloys, such as recrystallization, homogenization, relaxation, and a number of others, i.e., they are essential for the formation of their structures and properties [

40,

41,

42]. The diffusion processes underlying such technologies such as thermal and chemical-thermal (carburizing, nitriding, etc.) processing of metal alloys, diffusion hardening, etc., are strongly influenced by temperature, grain size, density of crystal lattice defects, the associated value of internal stresses, and the type and distribution of impurities along the grain boundaries [

43,

44].

A significant increase of the atom diffusion rate in the solid phase of metallic materials was discovered and highlighted as a new effect in the study of processes occurring under shock compression [

8,

45]. The manifestation of this acceleration effect of mass transfer in unsteady state conditions, which is caused by pulsed elastic or plastic deformations, was recorded in the processes of mechanical-chemical-thermal treatment of various types: ultrasonic shock; pulsed laser; electrohydropulse; electrospark; pulsed magnetic field; high-speed rolling; shock compression from the energy of the explosion; and deformation in the process of reversible martensitic transformations and a number of other types of impulse loading. A necessary condition for the manifestation of a generalized thermodynamic driving force, which ensures the acceleration of mass transfer in unsteady state conditions, is a nonstationary local deformation caused by an external high-energy influence. This exposure leads to a non-equilibrium state of the material, which causes a significant acceleration of the mobility of atoms in metals and alloys in the solid state. As a result, diffusion zones are formed, the length of which is hundreds (and more) micrometers.

Mazanko [

46] et al. studied diffusion processes in copper, nickel, and their alloys subjected to high-speed compression at elevated temperatures by methods based on the use of radioactive indicators (

63Ni) and ion mass spectrometry. This compression was performed by imposing powerful pulses of electric current on the quasi-statically deformed metals. This loading method is associated with the discharge of a powerful capacitor bank onto statically deformable samples. The applied load was ~1–3 kN. The capacitor was charged up to an amplitude value of the voltage of 250–400 V. The energy accumulated in the process of capacitor charging was supplied to the samples, while the duration of the discharge, and, accordingly, the pulsed deformation, was 0.02 ms. The effect of the structure defectiveness and the rate of plastic deformation on the mobility of atoms, the depth of penetration, and the shape of the concentration profile were established. It is known that at the moment of time when the current passes through statically deformed metals, an electroplastic effect is observed, i.e., material softening occurs. With a deformation of no more than 2–10%, the rate of plastic deformation of the near-surface layers, depending on the loading conditions, ranges from 10 to 10

4 s

−1, which contributes to the manifestation of the effect of accelerating mass transfer in the solid phase. Investigations carried out during the stretching of metals in a pulsed electromagnetic field in the absence of heating at a deformation rate of up to 50–100 s

−1 showed that the diffusion coefficients reach values of ~2 × 10

−5, 9 × 10

−6, 6 × 10

−5 cm

2/s, respectively, with the penetration of nickel atoms into copper, copper into nickel, and titanium into aluminum. The presence of the field imparted an additional acceleration of ~40–50% to the migration of atoms in comparison with deformation at the same rate, but under conditions of pulsed mechanical loading.

In [

18], it was established theoretically and experimentally by autoradiography methods that under pulsed loading, the mobility of atoms in the upper part of the sample is higher than in the lower one; moreover, in the volume of the diffusion zone, the mass transfer is greater than in the surface layers. A correlation was established between the rate of mass transfer and the distribution of deformation in the sample under pulsed loading. In [

47], diffusion along migrating grain boundaries interacting with an impurity was taken into account in order to interpret the intensification of mass transfer in metallic materials subjected to high-energy exposure.

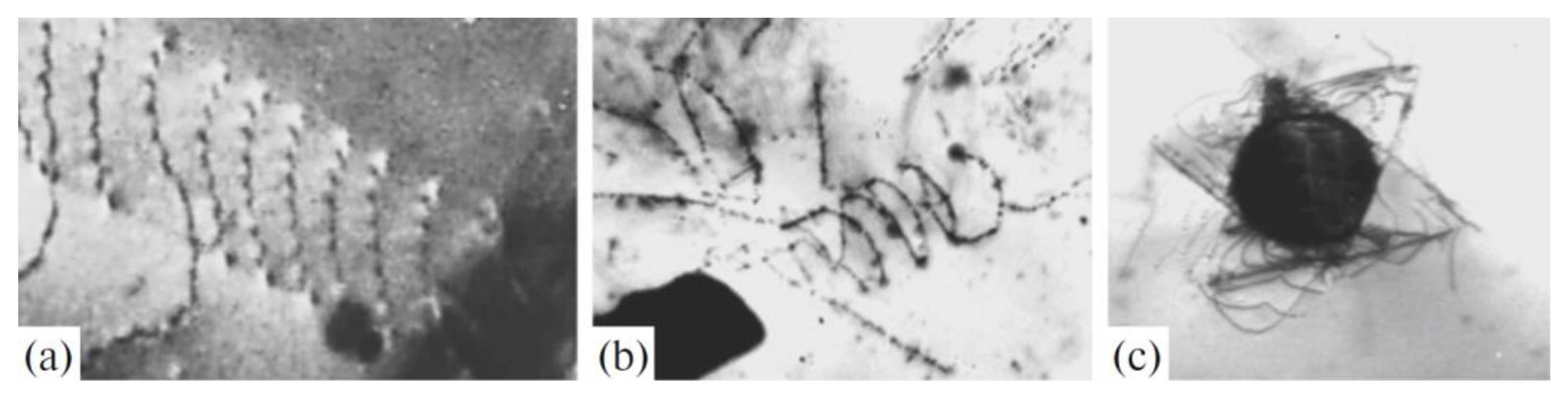

Vasil’ev [

48] investigated the features of diffusion mass transfer in metals under mechanical shock exposure. Diffusion flows arising during severe plastic deformation of the material were also determined. It was shown that, under certain conditions, the diffusion of impurities from the outer surface into the bulk of the metal can develop as a wave process, in which mass transfer occurs in the form of convective motion of atoms through the crystal lattice of a solid. The propagation speed of diffusion waves was determined. It was noted that during shock and explosive processes of plastic deformation of metals and alloys, a fast mass transfer of atoms was experimentally recorded, and it took place under conditions of insignificant heating (

Figure 1) [

18]. In

Figure 1 are shown [

48]: F

ex—vector indicating the direction of the shock exposure;

I—the depth of penetration of the impurity, in the usual (non-shock) mode of diffusion mass transfer for a time equal to the shock time T

ex;

II—The depth of penetration of the impurity during the shock exposure.

It was pointed out that there are currently several different interpretations of this effect. In [

19,

49], the opinion was expressed that fast mass transfer can be associated with the ordinary diffusion under conditions of an increase in the density of linear defects of the crystal structure and subsequent processes of stress relaxation in the defective subsystem. In this case, a significant increase in temperature was assumed during the impact of the shock load and the possibility of aftereffects when the load was removed. In [

18,

50], the influence of aftereffect and elevated temperatures on the rate of mass transfer was practically excluded, relying mainly on the corresponding experimental data. At the same time, an assumption was made about non-thermal fluctuation kinetics of diffusion mass transfer under low-temperature shock exposures. However, no constructive mechanism for this process was proposed. In [

51], the possibility of accelerated mass transfer during severe plastic deformation of metals was shown and was explained by the generation of unsteady point defects (vacancies and interstitial atoms) and their subsequent relaxation after shock exposure. However, this approach does not take into account all the features of plastic deformation of metals under powerful shock effects. The problem of mass transfer of interstitial defects under the exposure of elastic and shock waves was also considered [

52].

In solving the problem of finding mechanisms for accelerating mass transfer, there are many alternative approaches, and so far, there is no single generally accepted point of view on the physical essence of this effect. It is assumed that intensive mass transfer is a complex and multifactorial process in which each of the above factors plays a distinct role. And only all of them, considered in a complex, can give a physically substantiated picture of the effect of acceleration of mass transfer. In [

48], the main physical factors were investigated, the combined effect of which determines the high rate of diffusion mass transfer during plastic shock deformation of metals. This shows that, within the framework of the traditional diffusion theory, there are opportunities sufficient to explain all the features of this effect. It was demonstrated that under shock exposures on materials, the rate of diffusion processes of mass transfer can be significantly increased by a force field acting on atoms from the side of deforming external stresses. Under certain conditions, the processes of mass transfer of impurities can be of a wave nature. Diffusion mass transfer under powerful shock exposures is possible even in the absence of an impurity concentration gradient. In this case, it has the character of a perforating convective flow of an impurity through the deformable crystal lattice of atoms of the main element.

In [

14], the features of the diffusion mass transfer in metals under mechanical shock exposure were investigated. The influence of shear stresses on diffusion processes was considered. It was noted that shock loads acting on alloys with polymorphic modifications lead to the development of structural-phase transformations occurring as a consequence of the martensitic mechanism and multiple generation of vacancies. In combination with high temperatures and significant shear stresses in the diffusion zone, these processes significantly accelerate the processes of diffusion mass transfer. The main result of the shock exposure is the transfer of the medium into a strongly unsteady state, which is characterized by the experimentally observed high velocities of movement of diffusion fronts. It was found that shear stresses can play a decisive role in accelerating the processes of diffusion mass transfer under shock exposures. Shock exposures can lead to a significant change in the temperature regime of the diffusion zone of metals. In particular, a local increase in temperature due to the dissipation of mechanical energy during plastic deformation can reach values close to the melting point of the metal. In metals with polymorphism, shock exposures cause structural-phase transformations of the martensitic type. This leads to a high vacancy supersaturation of the near-surface layers of the metal, which significantly affects the rate of mass transfer in the diffusion zone. The combined effect of these factors completely determines the high rate of diffusion mass transfer during plastic shock deformation of metals.

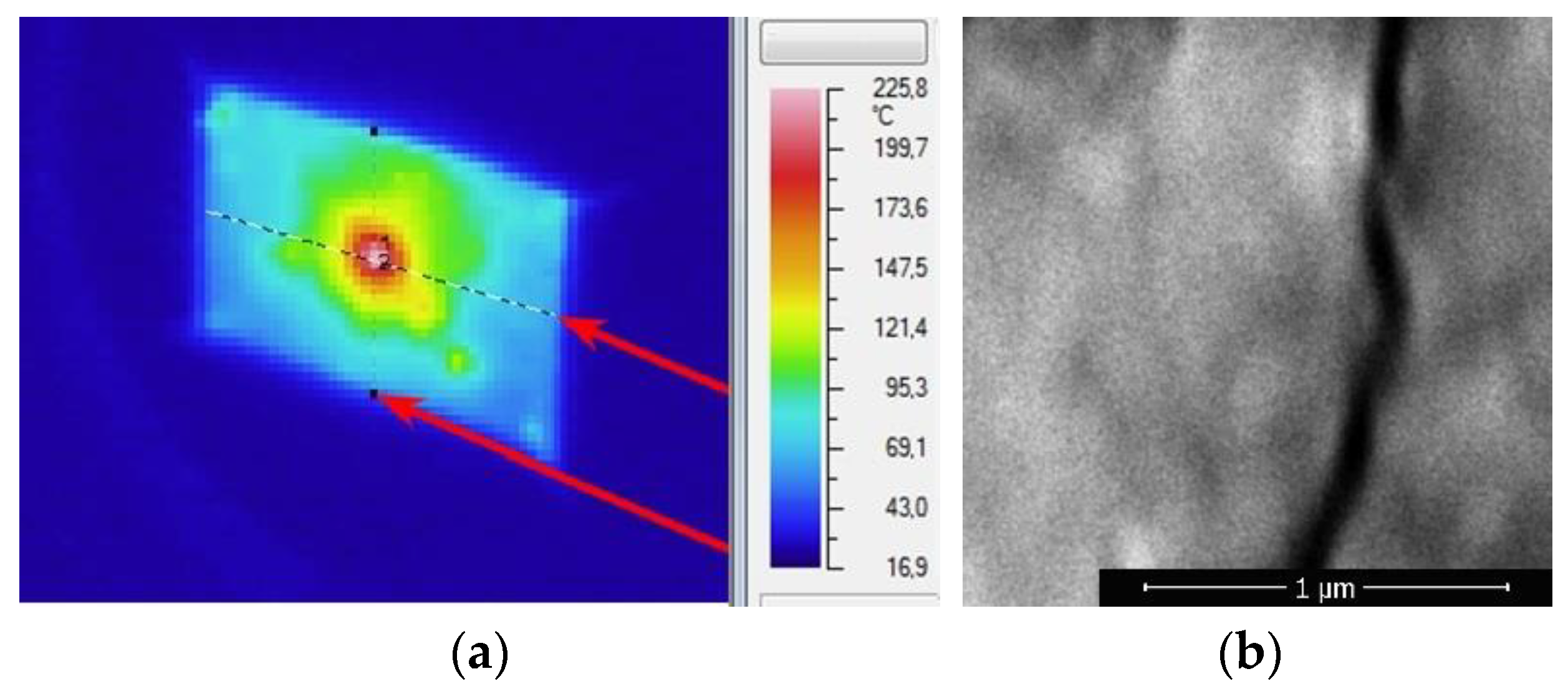

In [

53,

54], structural changes in a steel matrix near inclusions of various types during laser treatment were investigated. It was shown that under laser irradiation, between the inclusion and the steel matrix, there is a high-speed exchange of atoms across the interface under conditions of high mobility of atoms, which does not meet the conditions of classical diffusion. Any pulsed loading is characterized by the so-called acceleration of mass transfer, which, under pulsed laser irradiation, is intensified by heating to high temperatures, the movement of crystal structure defects arising from thermal shock, melting and convective mass transfer, electronic and electromagnetic interaction of inclusions and a matrix, as well as the formation of surface areas of inclusions of zones with increased density of dislocations.

Figure 2 shows deformation stress-induced local structures of the steel matrix near inclusions. Under unsteady state conditions of laser irradiation, the directed mass transfer of elements across the inclusion-matrix boundaries is a complex quantity that depends on the level and inhomogeneity of the reached temperatures, stresses, chemical potentials of elements, and other factors. As a result of alloying local regions of the matrix under conditions of accelerated mass transfer from internal sources, such as non-metallic inclusions, hardened zones are created in the matrix near the inclusions. By mutual alloying in the inclusion-matrix system, composite layers are created that have a heterogeneous structure and consist either of solid solutions of different degrees of alloying, or of a solid plastic matrix and solid plastic dispersed inclusions. The presence of cascade layers in the matrix and (or) inclusion indicates the wave nature of the contact interaction of these phases in the process of mass transfer during laser irradiation. The features of micro-inhomogeneous hardening of steels during laser processing were investigated. The total hardening effect from the action of various factors in the vicinity of non-metallic inclusions was determined.

The intensification of mass transfer in the solid phase is promising for solving the urgent problem of degassing metallic materials for structural purposes. Gases can be in metals not only in the form of interstitial solid solutions, but also in the form of excess phases (both condensed and gaseous), accumulations around dislocations, and sorption layers on inner surfaces [

55]. In a real metal, the transition of an impurity from the gas phase through the surface to the condensed phase can be represented by several successive stages: adsorption, dissociation, formation of a surface solution, diffusion, dissolution, distribution of impurities between the solid solution and structural defects, nucleation, and release of excess phases. At various stages of production and technical exploitation of metals, there is a redistribution of gas-forming elements between different forms of their presence.

3. Mutual Mass Transfer of Contacting Solid Metallic Substances under External Energy Influences

Panin et al. [

56] described the regularities of mutual penetration of particles in composites “steel-copper-lead slip” and “iron-lead” under electrical impulse or shock-wave action. A theoretical interpretation of the observed effect was proposed on the basis of a multilevel approach of physical mesomechanics and the concept of atom-vacancy configurational excitations in strongly nonequilibrium systems. It was noted that the so far observed effect of superdeep penetration of solid particles into the metal target without violating its continuity has no clear physical explanation and does not fit into the traditional concepts of physics and mechanics of a deformable solid.

In the physical meaning, the model developed in [

57] is the closest to reality. It was proposed to take into account the exposure on the target of the entire flow of projectile particles, which should cause changes in the state of the target itself. In [

57], a special state of the target was associated with strong atom-vacancy excitations. A model was proposed to explain the effect of superdeep penetration of microparticles into the target. This effect is associated with the development of hydrodynamic instabilities in local regions of the target surface loaded by a flow of high-speed microparticles, microcumulation processes initiated by a background shock wave, and the formation of transport microvortices in the front of this wave. These microvortices move together with the shock front and can collect microparticles in the vortex flow. Thus, the material of the microparticles can be moved to a considerable depth inside the barrier. It was noted that the proposed model also explains all effects accompanying superdeep penetration. So, recrystallization and amorphization of material in the vicinity of tracks—traces of material transfer of microparticles, are explained by high temperature and pressure in the microcumulation areas. However, firstly, the very assumption about the influence of the entire flow of projectile particles on the state of the target required direct experimental confirmation. Second, the microcumulation model proposed in [

57] was studied in the one-level approximation of deformable solid mechanics. Therefore, in [

57] assumptions were introduced such as the formation of an elongated cylindrical pore in the target, the occurrence of high temperatures and pressures in the regions of microcumulation for the development of processes of recrystallization, and amorphization of the material in the vicinity of the tracks.

These assumptions can be avoided within the framework of a different formulation of the experiment—a multilevel description of the motion of a high-energy exposure front on the target and the consistent application of the concept of atom-vacancy configurational excitations [

56]. When describing the two-level system “strongly excited crystal—equilibrium substrate”, it is fundamentally important to consider the condition for compatibility of deformation at the interface between them. According to [

58], at this interface, a “checkerboard” character of the distribution of compressive and tensile stresses arose. In the zones of compressive stresses, the material was intruded, and a system of grooves distributed in the form of a “checkerboard” appeared along the entire interface. The motion of such a front under conditions of atom-vacancy configurational excitations can provide viscous penetration of solid particles into the substrate without violating its continuity.

The effect of superdeep penetration of solid microparticles with a size of several micrometers to depths exceeding their initial diameters by 10

2–10

4 times, when the surface of metals is exposed to a flow of micropowder, is known [

57]. One of the main questions in explaining the effect of superdeep penetration of particles into a substrate without violating its continuity is to substantiate the concept of a radical change in the state of the substrate itself under conditions of high-energy exposure at the shock loading front. To answer this question, it is necessary to set up an experiment in which the high-energy exposure on the substrate is set independently of its interaction with solid particles. During experimental studies in [

56], instead of throwing the powder by an explosion onto an equilibrium metal barrier, the metal powder was placed on the surface of the target, then the target was exposed to high-energy pulses of electric current or explosive loading. In this formulation of the experiment, the task was reduced to a multilevel analysis of the interaction between solid particles and a target at the “highly excited layer—substrate” interface. During the cyclic high-energy exposure, not only superdeep penetration of solid particles to the entire depth of the target was detected, but also mutual penetration of two dissimilar media with fragmentation of the entire material of the metal substrate.

When a solid body is exposed to concentrated flows of energy of any nature, the state of the solid body changes radically. The superdeep particle penetration model cannot be built on the basis of the material in the initial state. Under conditions of strong excitation, new structural states appear at the interstices of the crystal lattice, which correspond to an excited nonequilibrium crystal. According to [

59,

60], for N atoms of a solid under conditions of strong excitation, there are 2N structural states, half of which are vacant. When such a material is loaded, collective atom-vacancy configurational excitations arise, which cause hydrodynamic mass transfer when atoms collectively move through interstices.

The concept of atom–vacancy states has become widespread [

61,

62,

63,

64,

65]. Various authors use different terms to classify such states: precursor states [

61,

62], excited states [

63], reversible transformations of the martensitic type [

64], and pairs of inversely populated electronic states [

65]. However, their nature is the same: these arise in solids naturally under conditions of their strong deviation from thermodynamic equilibrium.

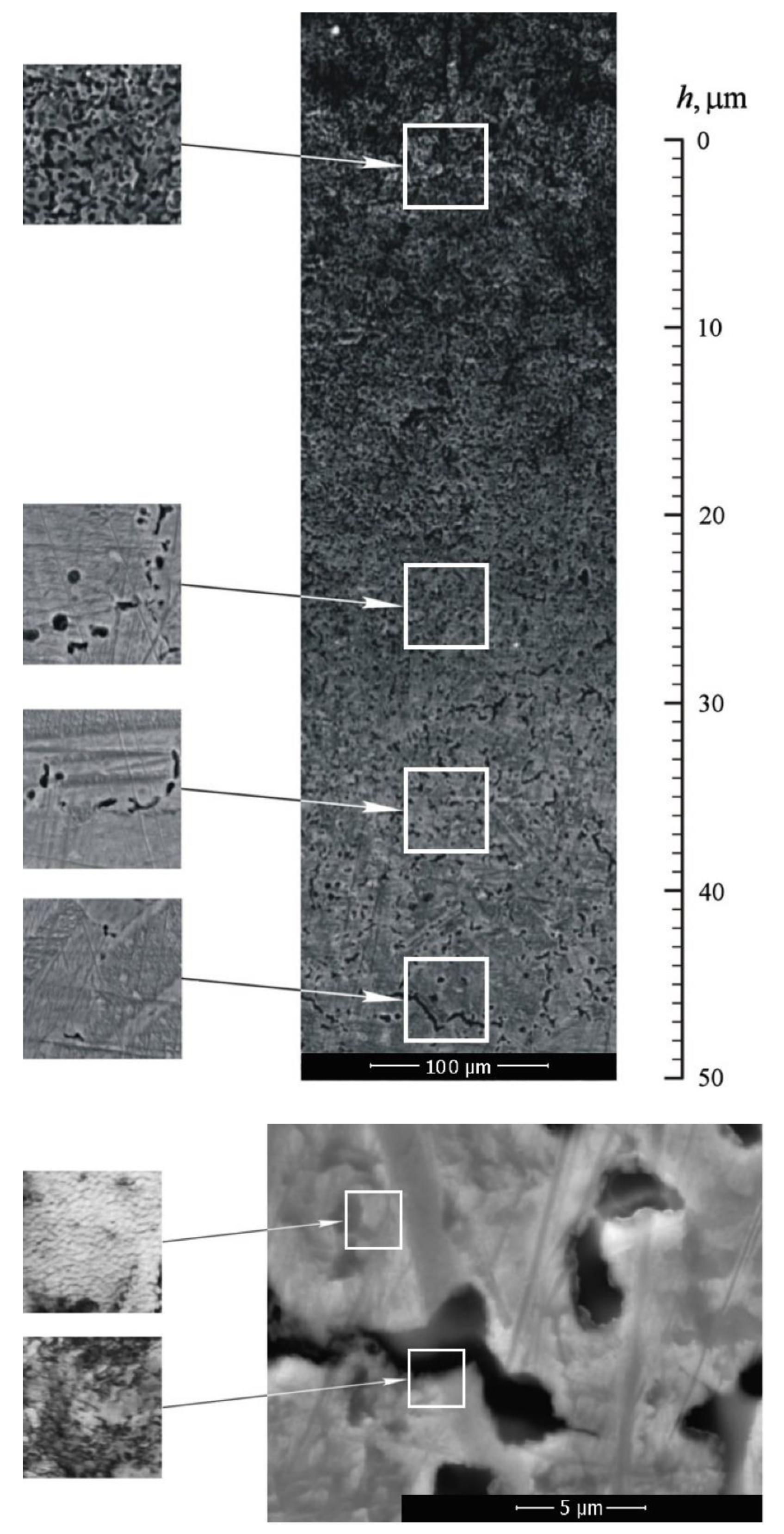

Figure 3 shows the results of a structural analysis of a steel sheet after applying on its surface a slip layer containing a powder of lead and copper in a ratio of 50:50 and processing it with electric current pulses [

56,

66]. In the upper part of the sheet (

Figure 3a), a mechanical mixture of copper, lead, and steel fragments is clearly visible. A new result in

Figure 3a is the detection of copper-lead fragments in the composition of the steel sheet. Meaning that not only superdeep penetration of copper and lead particles into the substrate was recorded, but the mutual penetration of copper, lead, and steel particles. The main matrix is a supersaturated solid solution of copper in iron.

Figure 3b shows the microstructure of the middle part of a steel specimen with a well-visible inclusion of copper, while completely preserving the continuity of the surrounding material.

Figure 3c shows a micrograph of the same steel plate from the opposite side, on which inclusions of copper particles that have passed through the steel sheet while maintaining the continuity of the material are clearly visible. A mechanical mixture of copper, lead, and steel fragments was also formed in the lower layer of the sheet. This indicates the fragmentation of the sheet material caused by the passage of a front of copper and lead particles through it, which is confirmed by the X-ray spectral microanalysis of the sample after the electric pulse treatment.

The performed theoretical analysis made it possible to conclude that the effect of penetration of one solid metallic substance into another without disrupting the continuity of the latest under the influence of concentrated energy flows is based on the following fundamentally important provisions:

- -

the effect of the “checkerboard” in the distribution of stresses and strains at the interface of two dissimilar media in the fields of external influences;

- -

the emergence of highly excited states and associated atom-vacancy configuration excitations in the interface zone under the influence of concentrated energy flows;

- -

multilevel vortex mass transfer in a highly excited medium under conditions of the appearance of collective atom-vacancy configurational excitations.

Thus, in [

56,

66], the effect of mutual mass transfer of contacting solid metallic substances under pulse energy influence was discovered. This effect consists in the fact that during intense pulse influence (shockwave, electrical, electromechanical, etc.) on the contact zone, mutual mass transfer of the contacting substances occurs while maintaining their continuity at a distance from the original contact surface, determined by the energy and duration of the pulses. The results obtained indicate that superdeep penetration can occur not only upon collision with a metal matrix of microparticles accelerated to high speeds, but also under fundamentally different conditions. The action of high-energy impulses of various natures (shockwave exposure, electric impulse, electromechanical impulse) on the contact zone of solid metallic substances leads to an increased mass transfer. In addition, under such conditions, mutual mass transfer occurs. Experimental facts confirming the penetration of alloying metal microparticles into the metal matrix were obtained. This was confirmed by metallography and micro-X-ray spectral analysis on a whole group of various combinations of contacting metallic substances: Fe-Pb, Cu-Pb, Fe-Cu-Pb, Fe-Pb-W, Al-Pb, Al-Cu, Fe-Sn, Fe-Sn-Pb, and Fe-Bi-Pb. From the point of view of the theory of physical materials science, the discovered effect means the establishment of a specific interaction in unsteady state multicomponent systems. In applied terms, the effect of rapid mass transfer actually provides a basis for the development of fundamentally new methods of purposefully changing the structure and operational characteristics of materials.

Varavka [

67] reported on the study of the behavior of vacancies and dislocations, as the most mobile elements of a defect medium in a metal, under substantially unsteady state conditions, which are created in the surface layer of a metal during ultrafast cooling as a result of processing with concentrated energy flows. Using dynamic analysis techniques, the stage that precedes the phase transformation in the metal alloy during the cooling phase was studied. The theoretical possibility of the formation of a specific dislocation configuration facilitating the phase transition was shown. According to the research results, diagrams of the mechanisms of unsteady state transformations in steel were developed, differentiating the known diagrams of isothermal decomposition of supercooled austenite in the region of hyperspeed cooling. On their basis, it was shown that the phenomenological transformation mechanism, the main stage of which is nonequilibrium vacancy-dislocation interactions, will increasingly dominate over the classical martensitic one as the carbon content in the steel increases, cooling accelerates, the heating temperature increases, and the steel defectiveness grows. It was found that under pulsed thermal-power exposure, the deformation of the ferrite matrix, which precedes the phase transition, occurs according to the mechanism of grain-boundary sliding with the participation of nonequilibrium vacancy-dislocation interactions in near-boundary microvolumes. In this case, the degree of deformation does not exceed the value of 5–6%. Dissolved carbon prevents deformation processes by the mechanism of grain boundary sliding, which contributes to an increase in the tendency of steel to form cracks. On the basis of experimental data on various types of pulsed thermal power treatment of steel, a parametric description of the conditions for unsteady state high-temperature phase transitions, structure formation, and deformation was carried out. The values of thermal and deformation control parameters characterizing the degree of non-equilibrium of processes during hardening treatment with concentrated energy flows were determined. This made it possible to simulate structure formation by mathematical and computer methods.

4. Intensification of Mass Transfer for the Formation of Nanoporous Structures in Metallic Materials

Kazanskiy et al. [

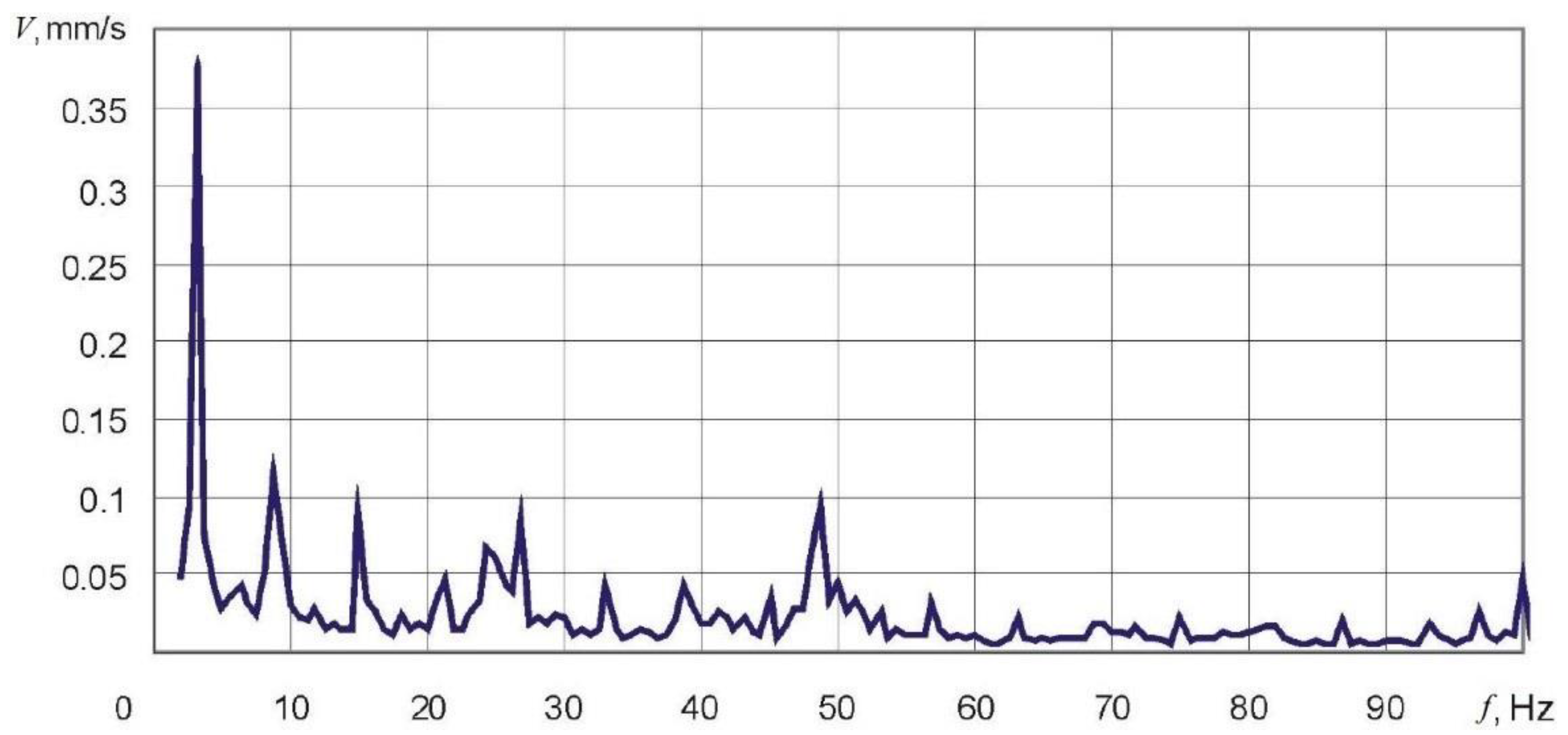

38] showed that the intensification of mass transfer in the solid phase of metallic materials is a condition for the formation of nanoporous structures. Laser pulse-periodic irradiation at a frequency of up to 5 × 10

3 Hz for brass with a copper content of 62% was applied. Laser processing modes that allow us to modify the structure of the metallic material at a nanoscale level were identified. With this heating, the temperature of the material was below the melting point. SEM studies of the samples have shown that laser irradiation of a crystalline material leads to a change in the surface relief. Depending on the magnitude and distribution of the power density in the laser spot and the duration of exposure, these changes influenced both the development of the relief (formation of wedge-shaped pits) and its smoothing. It was established that uniform laser exposure at depths of up to 25–30 μm activates the formation mechanisms of nanopores. Chemical analysis of the material showed an increase in the relative surface content of Cu and a decrease in the proportion of Zn.

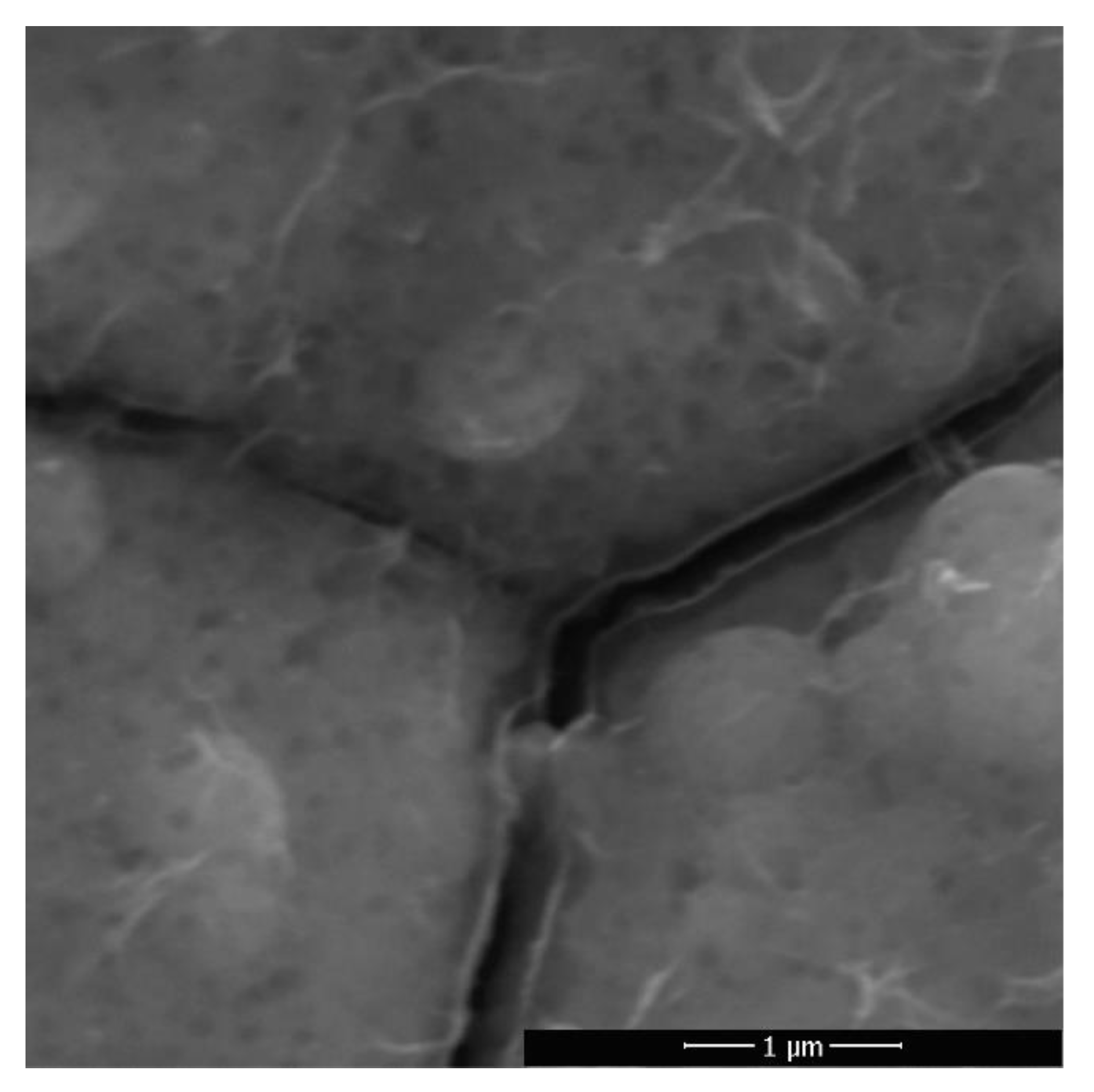

For comparison, the near-surface structures of the material samples in the initial state and after laser exposure were investigated on a transmission electron microscope.

Figure 4a shows the initial structure of the material, which was a subgrain structure with insignificant angular misorientation. The subgrains had a multifaceted shape and a low density of dislocations. The density of dislocations in metallic materials after recrystallization reached values of 10

6–10

8 cm

−2, and in heavily deformed materials it was 10

11–10

12 cm

−2 [

68].

The structure of the material after laser processing is shown in

Figure 4b. It was determined that the intensity of pore formation, as well as the size and shape of the resulting pores, depend on the temperature conditions of processing, which are determined by the magnitude and distribution of the power density of the laser beam in the heating zone. In addition, these also depend on the duration of exposure when the material is exposed to periodic laser pulses.

The nanopores size ranged from 40 to 50 nm. The nanopores were evenly distributed within the subgrains and had an almost stable size and shape. At the boundaries of the subgrains, a larger spread in the sizes and shapes of nanopores was observed. This structure was formed due to the formation of vacancies and their coagulation as a result of zinc sublimation from the material surface, as well as due to the development of a concentration and diffusion gradient to the material surface with a relatively high vapour pressure (Zn).

In [

69], the conditions that ensure the predominant formation of channel-type nanopores in the Cu–Zn alloy with an increase in the depth of the formation zone of nanoporous structures up to a value of 40–45 µm were identified. It was found that pulsed-periodic laser irradiation makes it possible to form a stable stressed state on the surface of the samples. Laser treatment was carried out within a rectangular area of 20 × 5 mm

2 on the surface of a metallic material. It was determined that laser irradiation with a uniform power density, which varied in the range (3–4) × 10

6 W/m

2, on a two-component Cu–Zn metal alloy, caused a change in the surface relief. After laser irradiation, open pores of various shapes, from spherical to irregular, were formed in the subsurface layer of the metallic material, with structures fairly uniformly distributed over the area. Besides these, branched pores with a characteristic dendritic structure were also formed as result of this treatment.

In the process of heating by laser irradiation, a change in the colour of the brass samples from the initial yellow to red was observed, which indicated a decrease in the concentration of zinc on their surface. Elemental analysis of the surface composition of samples of a two-component metallic Cu–Zn alloy after laser pulse-periodic exposure was made using an analytical scanning electron microscope, which was equipped with an electron probe energy dispersive microanalysis system, which showed an increase in the relative copper content from 63% to 92% and decrease in the proportion of zinc from 36% to 7%. The results of surface analysis of the elemental composition and the ratio of alloy components in terms of compact material before and after exposure to laser radiation are presented in

Table 1.

The study of the microstructure showed that the concentration of pores decreases with increasing distance from the surface of the processed material.

Figure 5 shows the distribution of pores in the depth of the processed material. Laser treatment has created a nanoporous structure in the subsurface layer, in which nanopores uniformly located on the surface of subgrains have relatively stable sizes and shapes. An image of typical channel-type nanopores with a width of up to 100 nm is shown in

Figure 6.

It was assumed that the main mechanism for the formation of a nanoporous structure was zinc sublimation, which was the alloy component with a higher vapour pressure. A concentration gradient was created in the material, and in the further development this component was sublimated to such an extent to ensure its diffusional delivery to the surface. Over time, the thickness of the layer, in which the amount of zinc was reduced, increased and diffusion became the factor that limited the sublimation process. A condition for increasing the mass transfer that was in the solid phase of metallic materials was the nonstationary local deformation, which was caused by the external high-energy laser exposure.

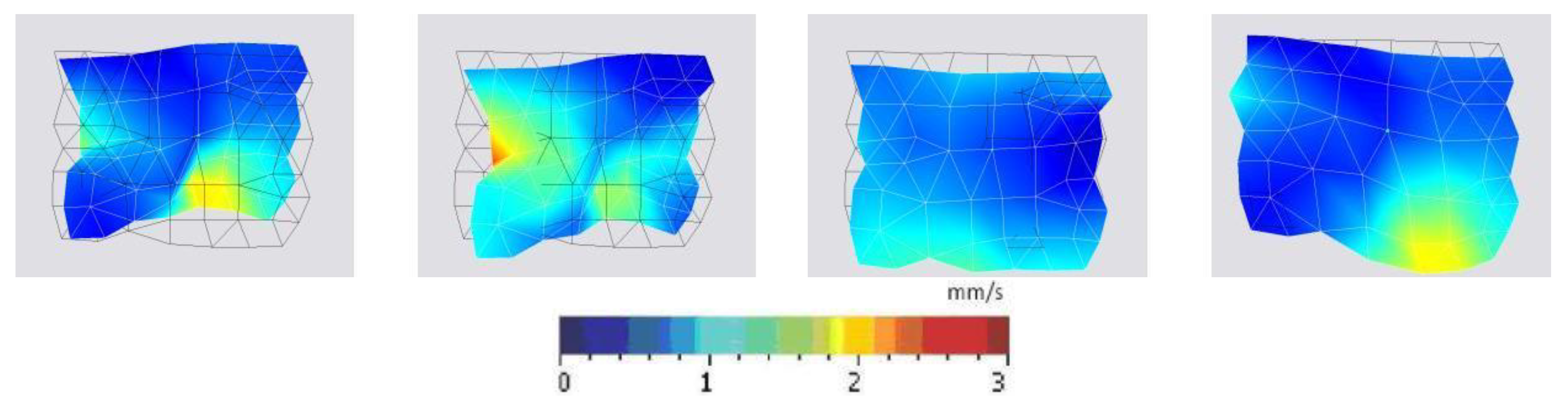

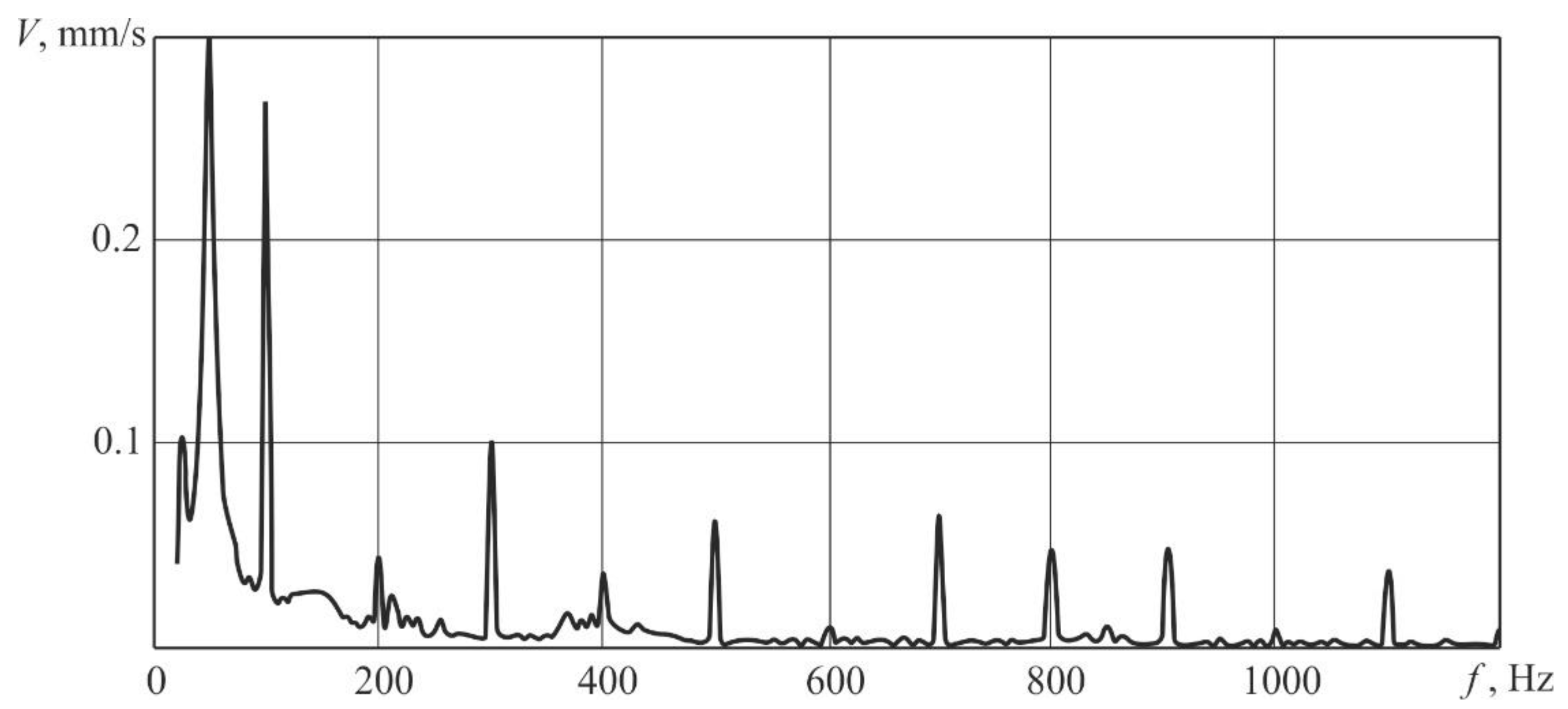

In [

70], the possibility of the formation of nanoporous structures in a metallic material of 50 µm thick samples was investigated during pulse-periodic laser treatment with thermal cycling. Variations in the average laser power in the range of 150–300 W, pulse frequency from 3 to 6 Hz, and laser spot diameter on the sample surface from 5 to 15 mm were chosen as the modes of laser treatment in order to obtain nanoporous structures. The modes of pulse-periodic laser treatment were chosen in such a way that in the center of the heat-affected zone, a section with a corrugated relief and a clear boundary was formed. The corrugated relief was formed under the following conditions: a laser power of 250 W, a pulse frequency of 5 Hz, and a laser spot diameter on the sample surface of 7 mm. The reverse side of the samples had a relatively smoother surface relief. The peripheral section of the heat-affected zone was characterized by the presence of corrugations, which were oriented in the radial direction. The formation of corrugations indicated an increase in the volume of local areas of multicomponent aluminum-iron brass in areas of high temperature differences.

A dislocation structure was discovered during studies of the metallic material by means of transmission electron microscopy.

Figure 7 shows the cross-sectional structure of a multicomponent aluminum-iron brass after pulse-periodic laser treatment with thermal cycling. After laser treatment, an increase in the dislocation density in comparison with the initial structure was observed, which led to the formation of nanosized cavities. The reason for the formation of nanopores was internal stresses arising as a result of cyclic heating and cooling at high rates, under the influence of which there was an increase in the number of vacancies, dislocations, and their accumulations in the material. Solid phase transformations in the multicomponent alloy intensified the formation of nanoporous structures. Taking into account the distribution of alloy components in the heat-affected zone, there was a high-speed change of microvolumes with a predominance of tensile and compressive stresses, which led to the formation of nano-sized cavities.

During scanning electron microscopic investigations of the fine structure of the material, it was established that during thermal cycling in the center of the heat-affected zone, a dendritic structure of the α-solid solution was formed. In this central region of the heat-affected zone on the surface of the metallic material, a phase precipitate with a higher phase transformation temperature, enriched in Fe, was observed. Channel-type pores were formed with an average width of 80–100 nm over the entire cross section of the material in this region as a result of laser treatment. The resulting nanoporous materials can be used as catalysts for improved electrochemical reduction of carbon dioxide [

71,

72].

8. Discussion of the Presented Results

The intensity of mass transfer in metals and alloys determines such processes as recrystallization, homogenization, aging, and a number of others, i.e., these are essential for the formation of structures and properties in such materials. An increase in temperature as a result of external influence is an effective way to accelerate the movement of atoms, since the diffusion coefficient is related to temperature exponentially. At the same time, heating the material above certain temperatures is not always rational, since it can lead to grain growth, as well as negatively affect the structure and phase composition. For example, for steels, the burning is an irreversible defect in metal heating. It occurs when the steel is heated to temperatures below the temperature of the onset of melting by 50–100 °C. Excessive overheating of brass (above the temperature of 1100–1200 °C) is also not allowed.

The effect of displacement of atoms in solids over distances of up to tens and hundreds of micrometers in an extremely short time was recorded in the study of processes occurring in metals under conditions of various types of pulse treatment. Non-stationary deformation, which is localized only in a part of the sample, is a necessary condition that contributes to the manifestation of the generalized thermodynamic driving force, which ensures accelerated mass transfer. The successful solution to the problem of effective application of this effect requires a search for fundamentally new and promising areas for the use of pulsed loadings for the formation of structures of metallic materials with a given set of physical and mechanical properties [

85,

86,

87].

The complexity of studying the processes of mass transfer under substantially unsteady state conditions is determined by the fact that mass transfer is the result of the simultaneous action of several processes of different physical nature, such as a change in the structural state of a metallic material, manifestation and disappearance of crystalline defects, the appearance of stresses, and others. High-energy external influences, which include laser-pulsed processing, lead to a significant acceleration of the mobility of atoms in metals and alloys in the solid state. However, the profound nature of the processes occurring during the formation and subsequent evolution of gradient structural-phase states needs further investigation. In addition, the corresponding scientific direction is currently at the stage of intensive accumulation and comprehension of experimental and theoretical material [

88,

89,

90]. The dynamic processes that occur in the near-surface layers of metallic materials exposed to pulsed laser irradiation without any destruction of the crystal structure were investigated in sufficient detail. Based on the idea of the interaction of structural defects in dynamically deformed condensed media, a dislocation-interstitial mechanism of laser-stimulated mass transfer in real crystals was proposed. It was demonstrated that pulsed Q-switched laser irradiation stimulates deep penetration of atoms from the surface into the depth of the irradiated metal, the value of which significantly exceeds the thermal penetration. Within the framework of the proposed model of laser-stimulated mass transfer, it was shown that the directed migration of atoms from the surface into the crystal occurred as a result of relaxation of thermal stresses caused by unsteady heating processes [

53,

91].

A method for intensifying diffusion processes in the solid phase of metallic materials by pulse-periodic laser irradiation was developed [

38,

70]. Applying such exposure, the conditions that contributed to the formation of nanoporous structures in the metallic material, a two-component Cu–Zn alloy, were identified. Laser irradiation with a pulse frequency mainly in the range of sound frequencies during simultaneous heating of the material in vacuum below the melting temperature made it possible to form a stable stressed state on the surface of the samples. The sublimation of the alloy component with a higher vapour pressure was assumed as the main mechanism for the formation of a nanoporous structure during treatment in vacuum. In the material, a concentration gradient was created, and the further sublimation of this component ensured its diffusional delivery to the surface. The diffusion was the limiting factor of the sublimation process. The nonstationary local deformation, which was caused by an external high-energy exposure was a condition for increasing the mass that was transferred in the solid phase of metallic materials.

Thus, as a result of laser irradiation, nanopores were formed in the surface layer of the material. These nanopores were both single and multichannel with branchings that were fairly uniformly distributed over the area. This structure was formed due to the appearance of vacancies and their coagulation as a result of zinc sublimation from the surface of the material, as well as the creation of a concentration and diffusion gradient to the surface of this component. Laser treatment made it possible to create a nanoporous structure in the surface layer of a metallic material with an average pore size of 40–50 nm and an increased size of about 100 nm, while the nanopores were uniformly distributed within the subgrains and had relatively stable sizes and shapes. In addition, for the formation of nanoporous structures of metallic materials, a method was developed, which involves cyclic elastoplastic deformation. It was realized with a pulsed-periodic laser irradiation with a frequency of the order of several units of Hertz. In this case, the reason for the formation of nano-sized cavities in alloys was the formation and coagulation of vacancies under the action of internal stresses arising as a result of high-energy exposure in various zones, which was accompanied by significant heating of the metal.

Such processing of brass not in vacuum, but in air, leads to the formation of zinc oxide nanowires on the material surface [

39,

75]. Different laser frequency has practically no effect on the growth rate and geometric dimensions of nanowires. The values of vibration intensity are significantly reduced by the vibration damping and in this case the growth rate of nanowires reduces as well. Using spectral microanalysis, a change in the concentration of alloy components in the near-surface layer was registered. It was established that the surface of the samples after laser treatment was a layer enriched with copper and with a reduced zinc content.

Internal tensions in the near-surface layer of brass were assessed pre and post laser treatment by X-ray diffraction analysis. Pulsed laser treatment caused an increase in intensity of the α (311) line by 1.9 times in the central part of the heat affected area, while it was decreased by a factor of approximately 0.7 in the fringe area, revealing a substantial redistribution in grain orientation of the alloy. As a result of laser treatment in the near-surface layer of the metallic material, relative internal stresses of approximately σ = 2.8 GPa were formed. It was established that during laser pulse-periodic irradiation on brass, the component of the metal alloy, namely zinc, will oxidize on the surface in the extent that its diffusion to the surface will be ensured. A significant increase of the diffusion coefficient in a metallic material in comparison to plain exposure to laser beam heating was described.

The application of the intensification effect of mass transfer in the solid phase of metallic materials by laser irradiation is promising for increasing the efficiency of thermochemical treatment of metallic materials. As a technological operation, thermochemical treatment is a combination of the following stages: the formation of a saturating medium, the adsorption of active atoms of the saturating medium by the surface, and the subsequent diffusional transition of the adsorbed atoms into the lattice of the metallic material that is being processed. The processing of materials by laser irradiation offers the possibility to increase the speed of the formation of active atoms, which depends on the composition and aggregation state of the saturating medium, on the interaction of individual components with each other, as well as on pressure and temperature. The main distinguishing feature of this approach is the use of laser-induced vibrations, making it possible to intensify diffusion processes in the solid phase of metallic materials. The implementation of this, with such a high feasibility of enhancing efficiency, is also very beneficial for almost any laser processing, including everyday industry applications (

Table 2).

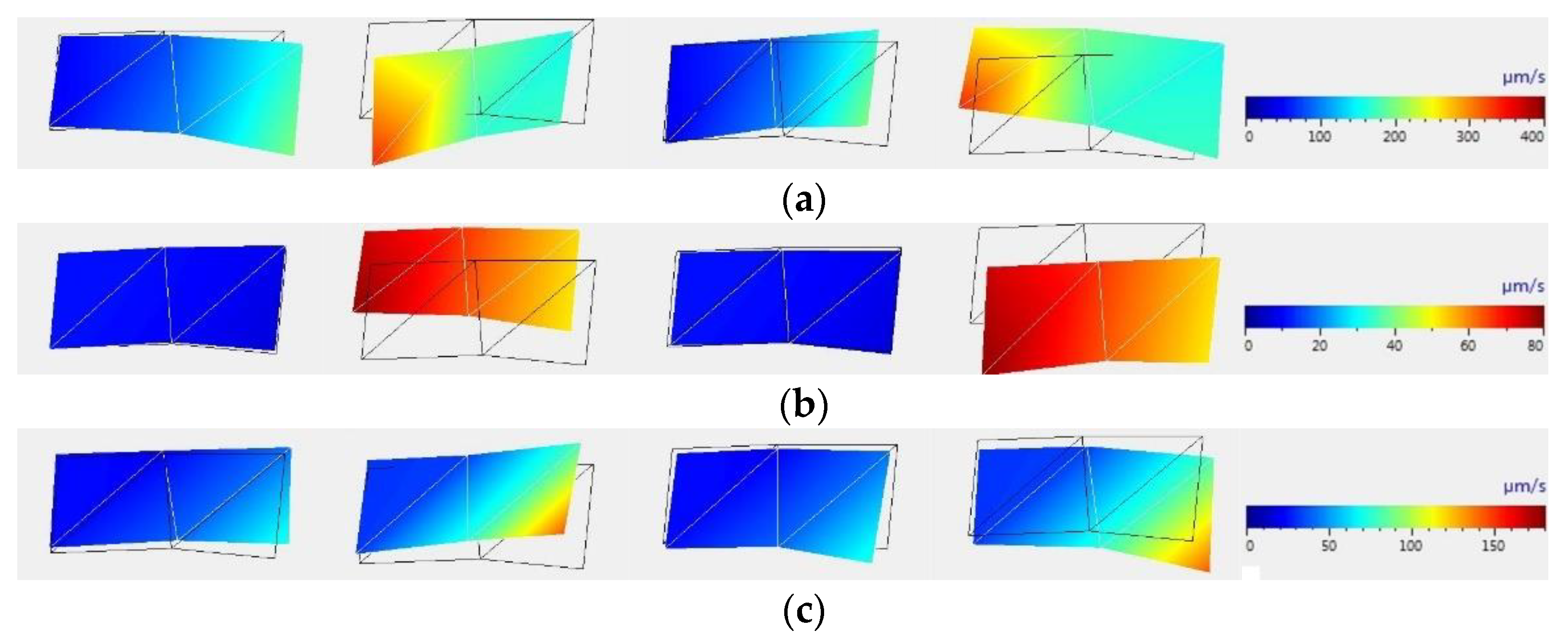

The application of such methods of combined laser processing, which implement the effect on a metallic surface of the thermal power of a laser beam and the energy of sound or acoustic vibrations, is promising in the development of laser technologies. With such a combined treatment by means of dosed introduction of mechanical vibrations into the base material, it is also possible to control the hydrodynamic motion in the melt [

92]. The laser welding process is carried out with mechanical acoustic vibrations, with the help of which an additional effect is exerted on the surface of the material under processing, leads to an improvement in the granular structure of the welds, as well as affects their microhardness in specific areas of the heat-affected zone [

93,

94]. There is a change in the kinetics of diffusion processes and phase transformations, which has a positive effect on the structurally stressed state of the treated material.

Additional effects arise if the intensity of acoustic vibrations is sufficient to excite cavitation in the laser melt. It is known that cavitation leads to more intensive mixing and refinement of the melt structure, a decrease in the surface tension coefficient, leveling of temperature gradients, and, as a consequence, to a smoothing of the surface relief and an increase in the depth of the melt [

95,

96,

97]. Cavitation is possible with pulse-periodic laser irradiation. For example, when using low-frequency ultrasonic vibrations, the development of cavitation occurs within a few tenths of a millisecond. Since, with decreasing frequency, the dimensions of cavitation voids tend to increase [

98], the use of the energy of sound or acoustic vibrations instead of ultrasonic ones will lead to an increase in the intensity of cavitation in the melt.

Surface laser alloying consists in obtaining alloyed layers with forced supply of filler materials directly into the action zone of the focused laser irradiation. Usually, only the melting of the surfaces of metals and alloys allows this process to be carried out [

99]. Due to the short duration of the laser thermal exposure, the diffusion of elements from the reflow zone to the heat-affected zone, as a rule, occurs at a distance of less than 10 μm. Carrying out the processes of laser alloying with the application of the intensification effect of mass transfer without melting the surface, it becomes possible to ensure the achievement of diffusion saturation with alloying elements to a greater depth. Redistribution of alloying elements in the solid phase near the reflow zone at a distance of up to 300 μm was experimentally found in [

100]. The processes of such mass transfer in the solid phase occur due to the dislocation movement of atoms as a result of rapid local deformations. The formation of a non-stationary stress-strain state caused by laser sound waves and the use of the synergy of the plain effects of laser pulses and laser-induced vibrations will make it possible to implement a new approach for the creation of structures of metallic materials.