Investigation of Dissimilar Resistance Spot Welding Process of AISI 304 and AISI 1060 Steels with TLBO-ANFIS and Sensitivity Analysis

Abstract

:1. Introduction

2. Material and Method

2.1. Optimized Intelligent Modeling

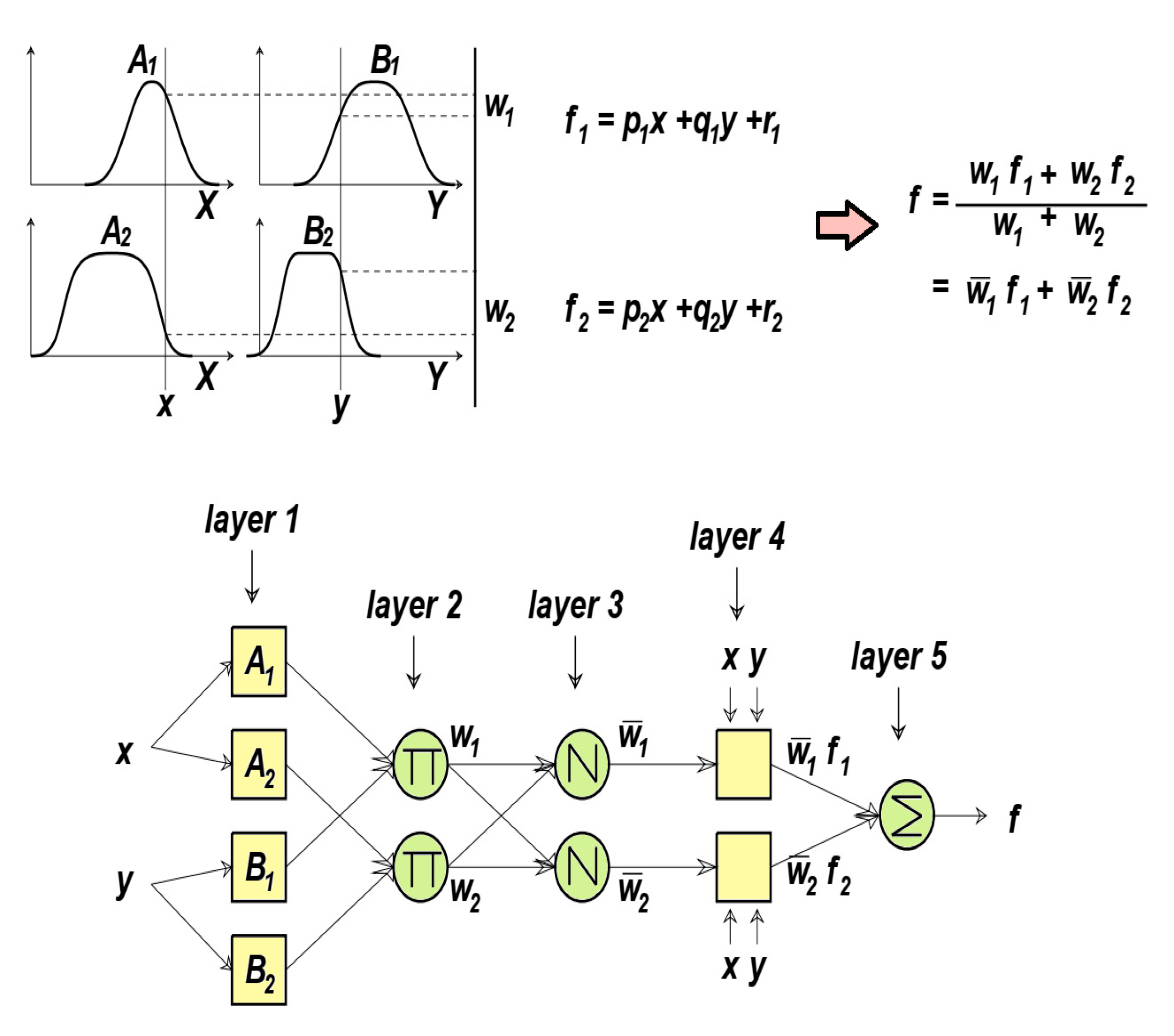

2.1.1. Adaptive Neuro-Fuzzy Inference System (ANFIS)

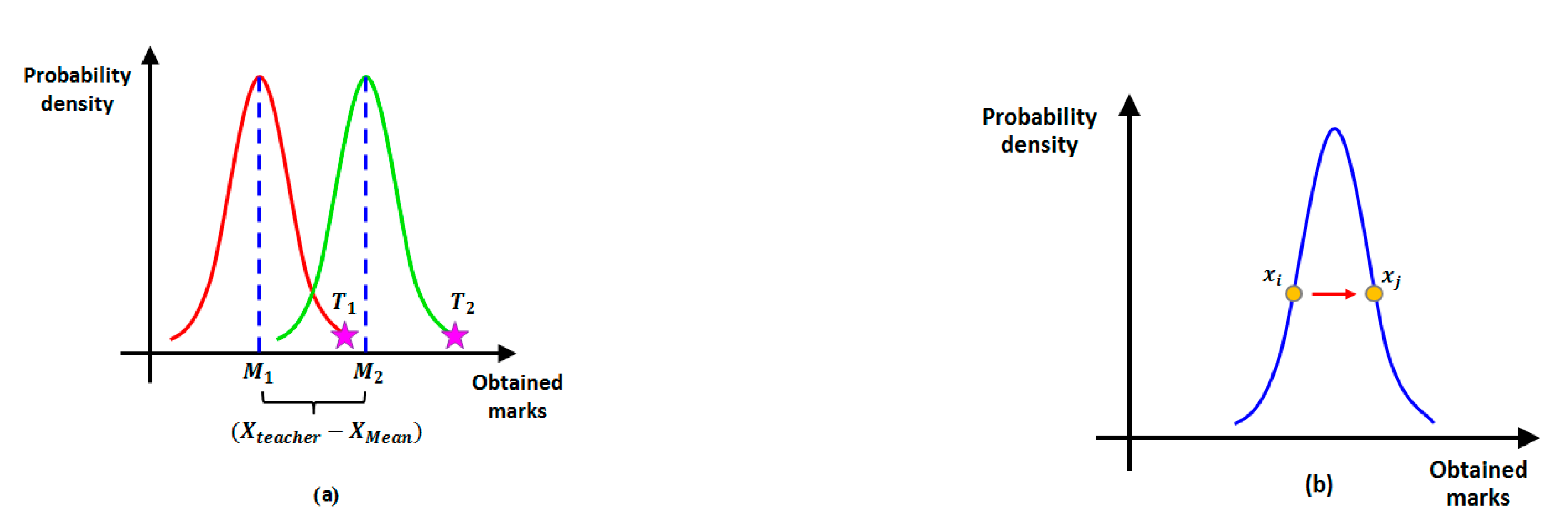

2.1.2. Teaching-Learning-Based Optimization (TLBO) Algorithm

2.1.3. Sensitivity Analysis

2.1.4. Sobol Sensitivity Analysis

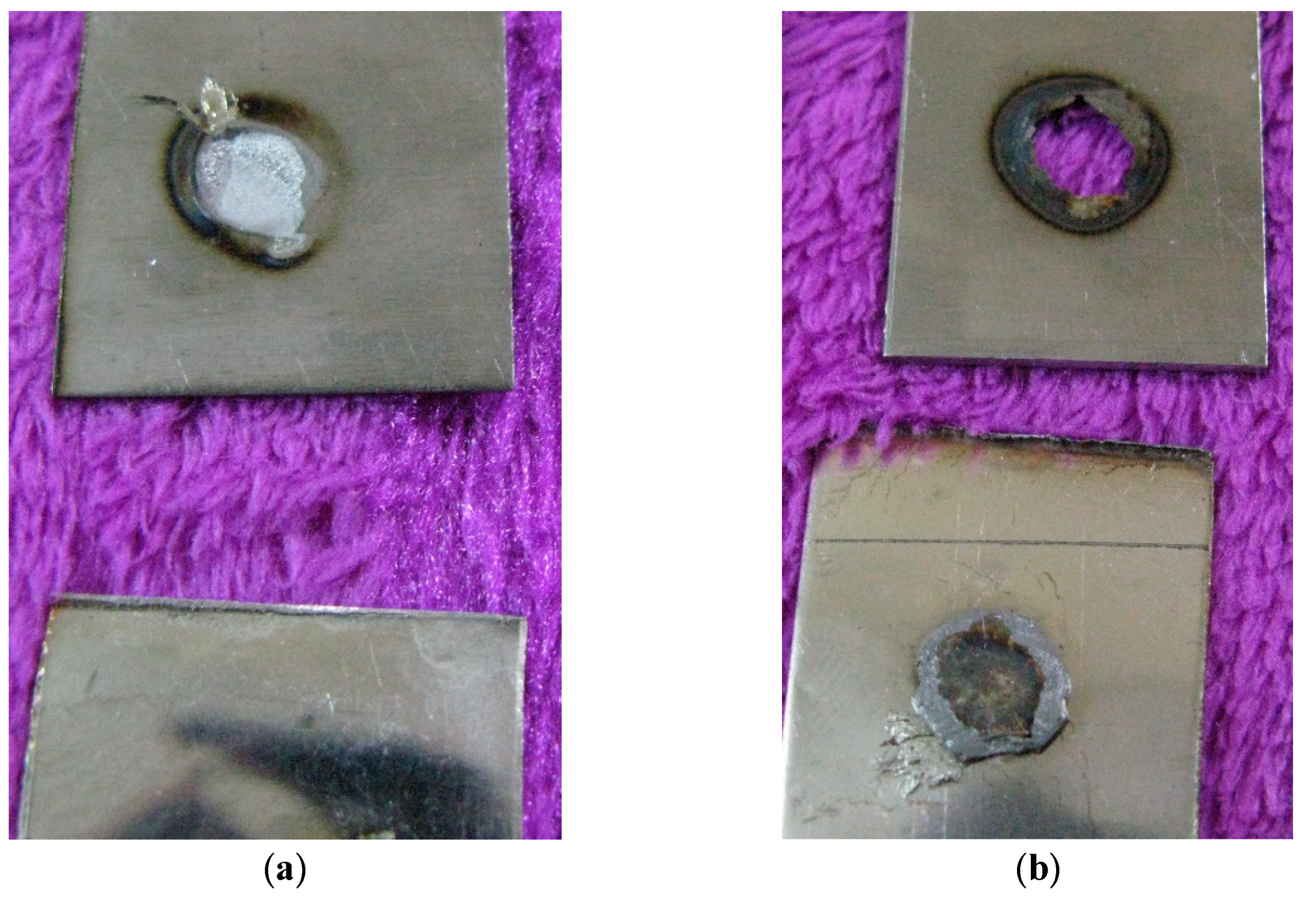

2.2. Dissimilar RSW Process

2.3. Analysis of Variance (ANOVA)

3. Results and Discussion

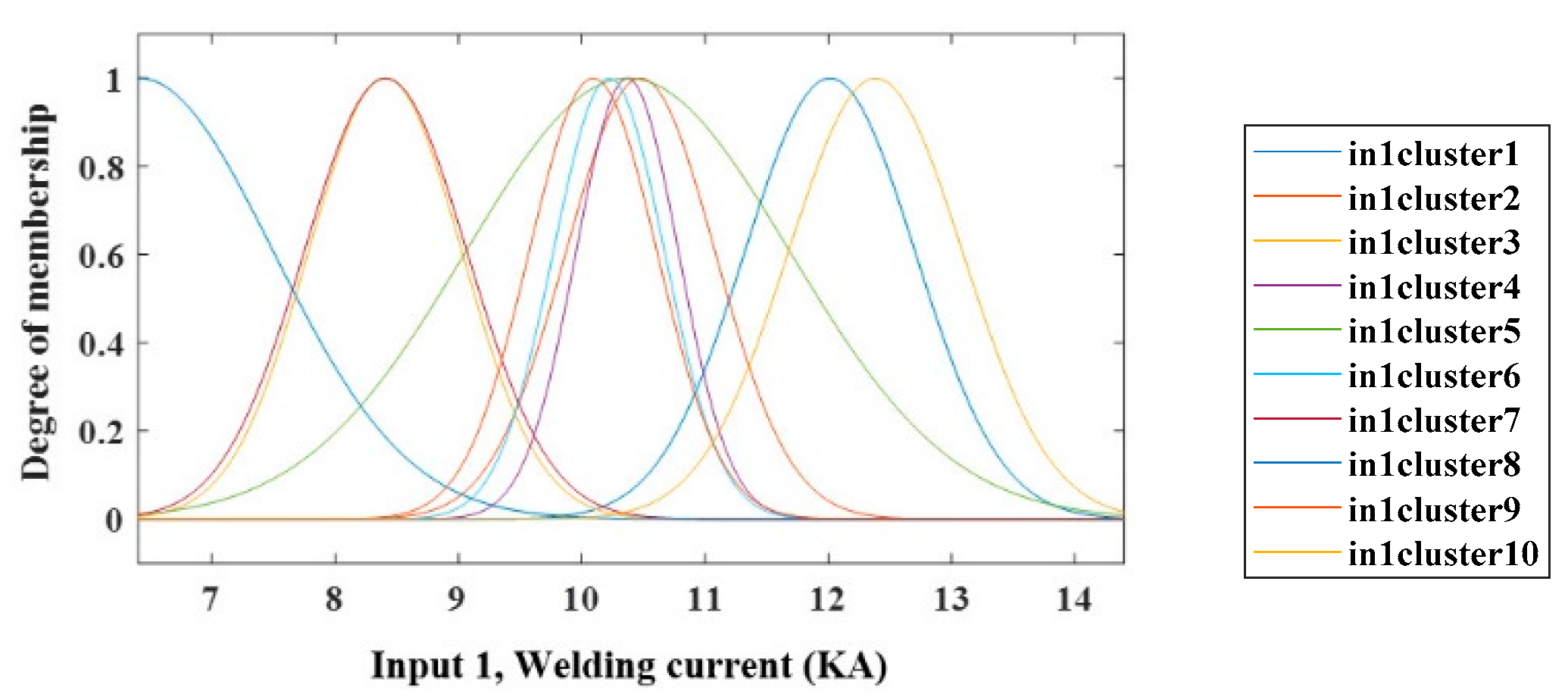

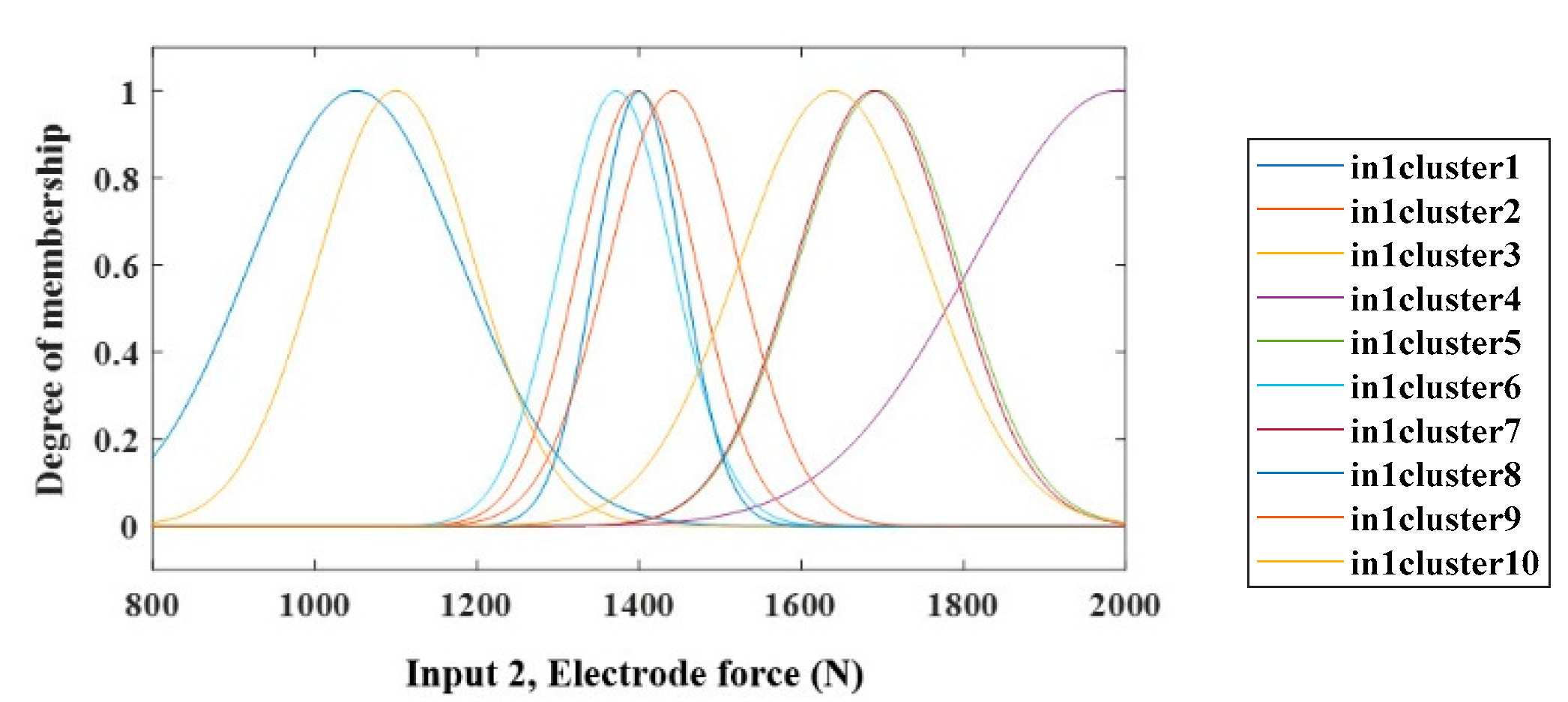

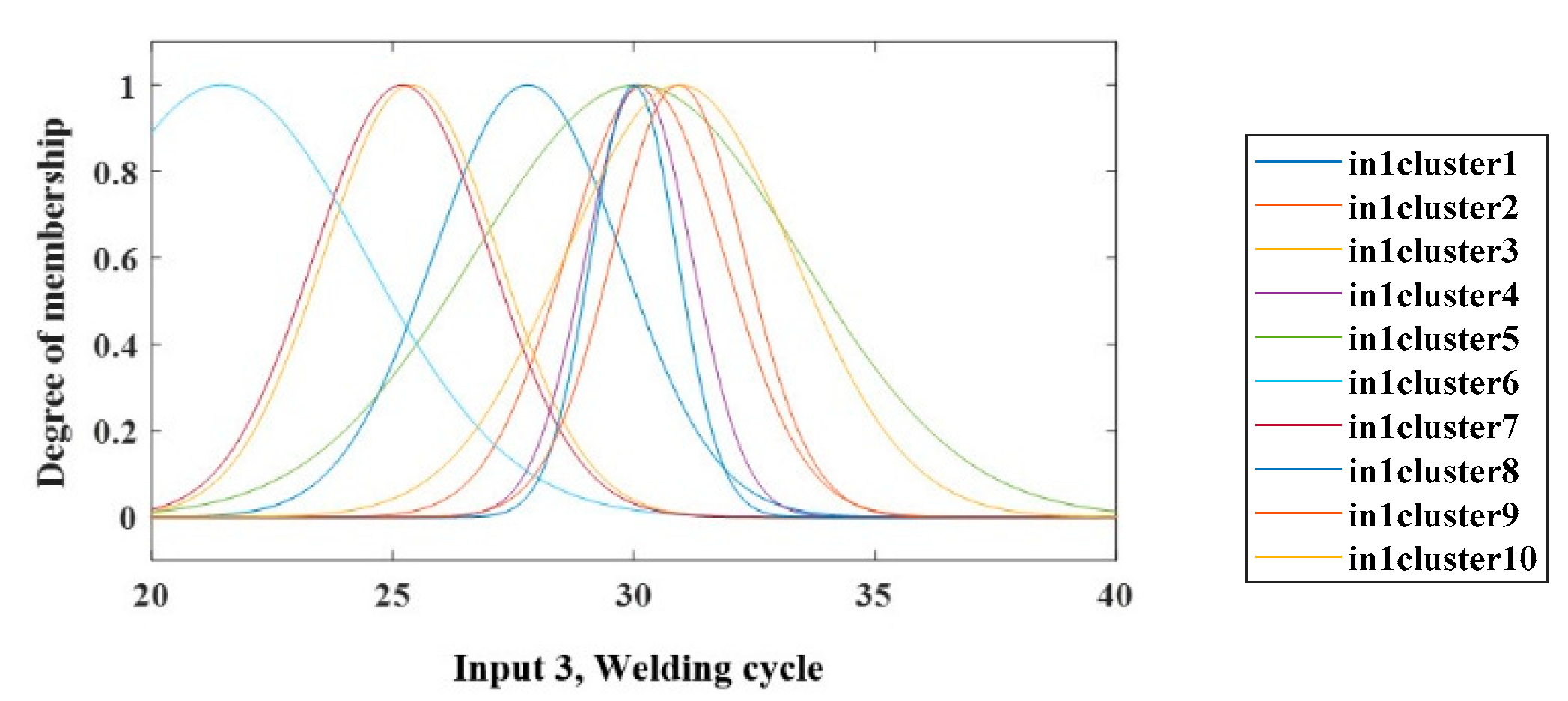

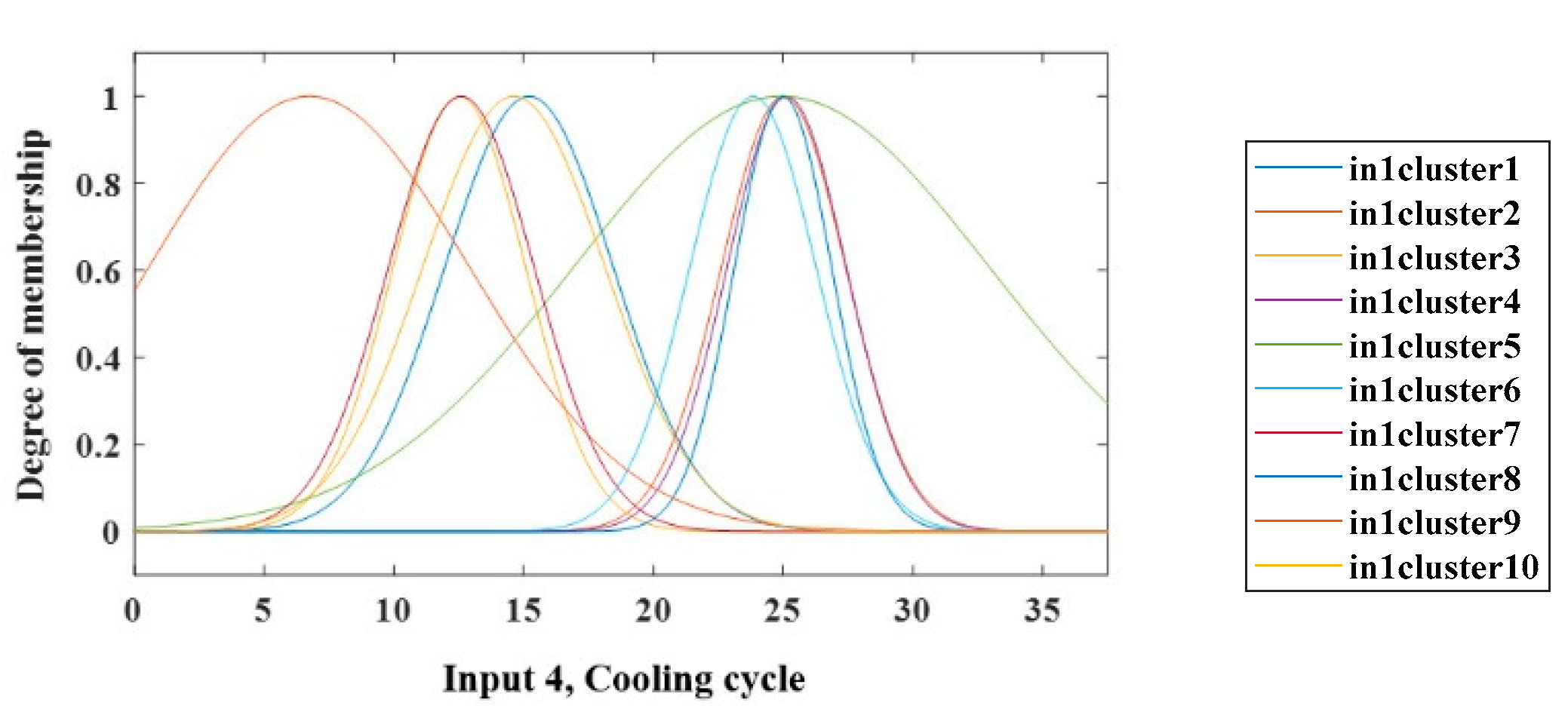

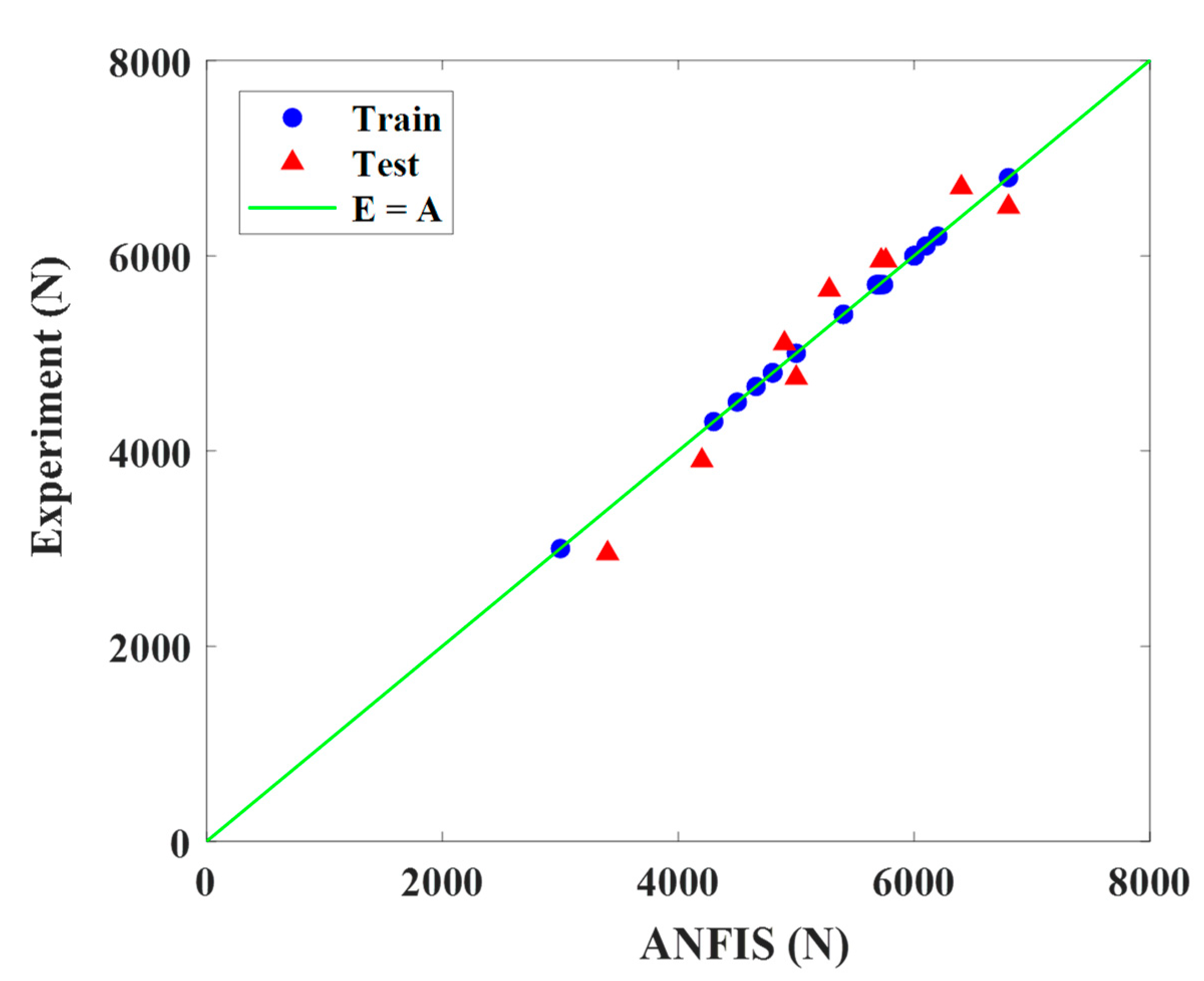

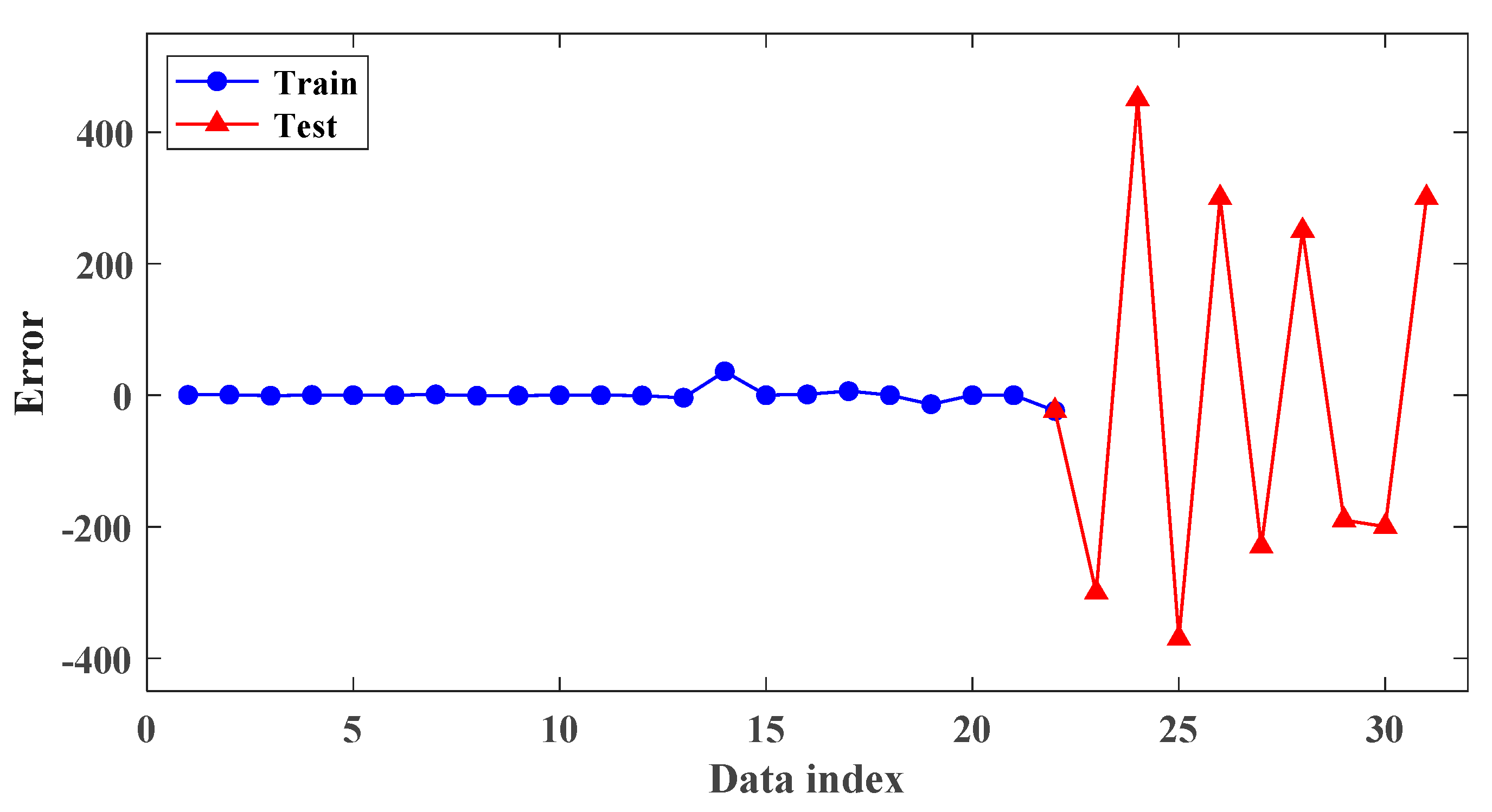

3.1. The Results of TLBO-ANFIS System

3.2. Analysis of the Effects of Input Parameters on TSS Based on Sensitivity Analysis

3.2.1. The Effect of Welding Current

3.2.2. The Effect of Welding Cycle

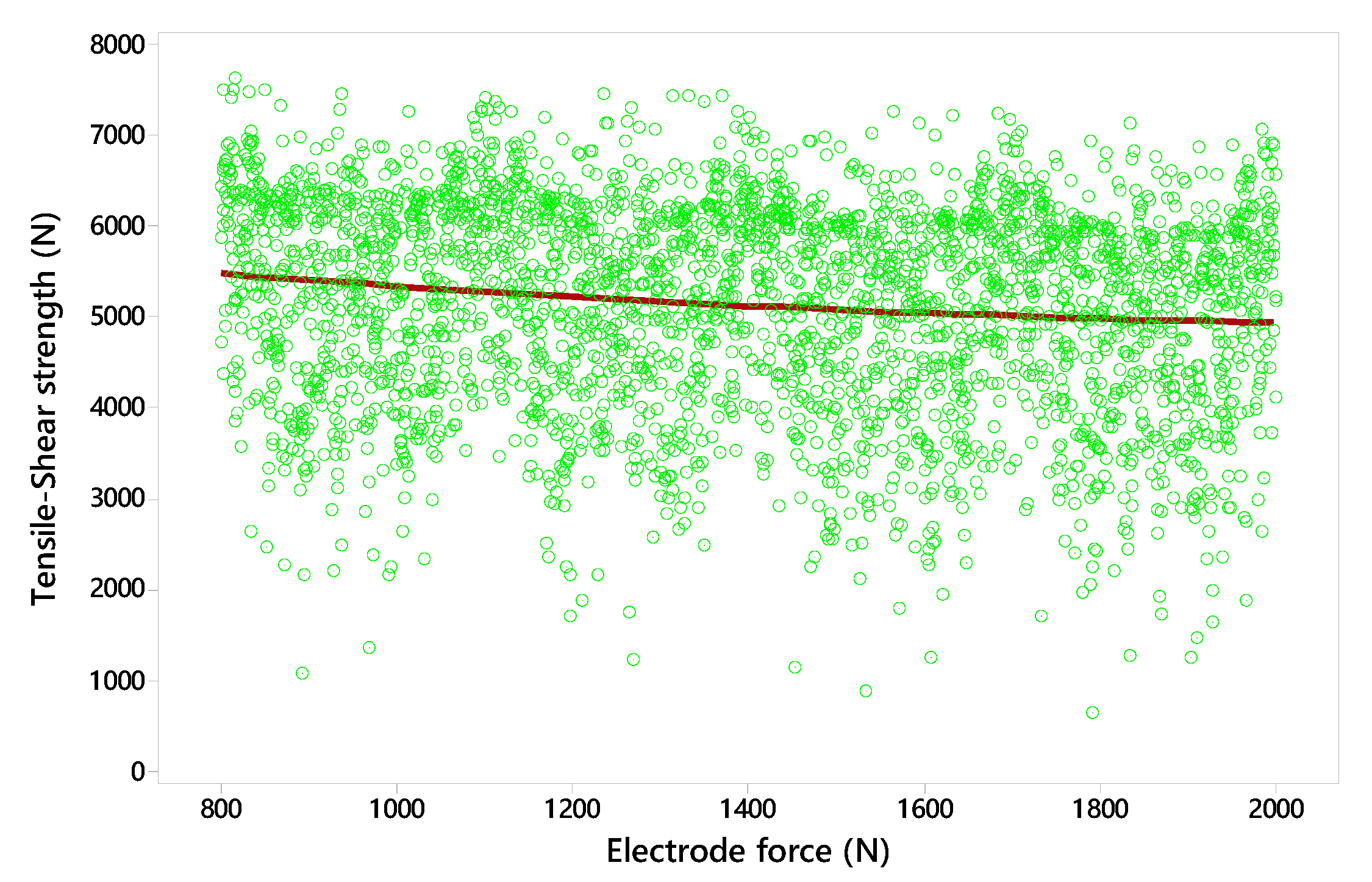

3.2.3. Effect of Electrode Force

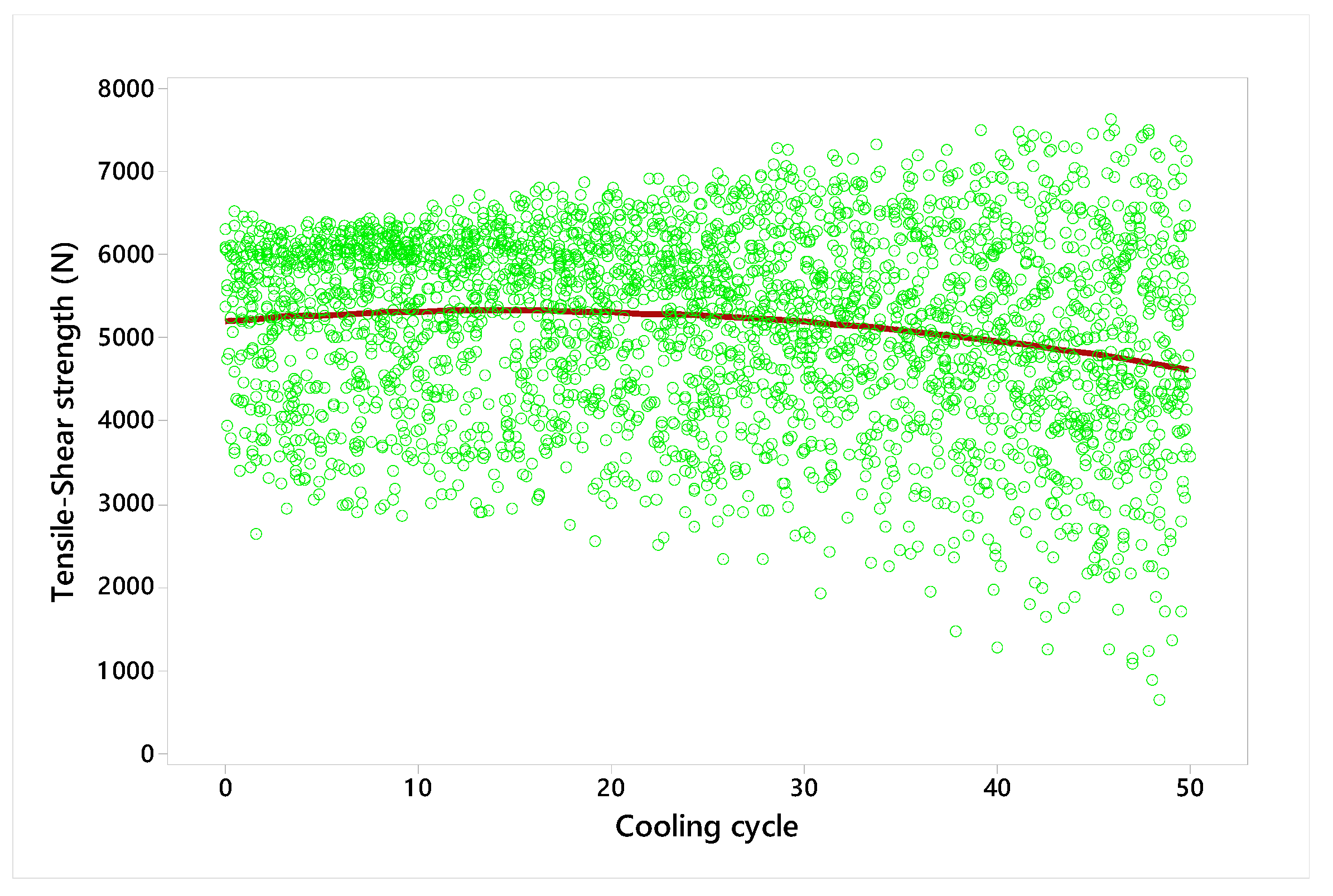

3.2.4. Effect of Cooling Cycle

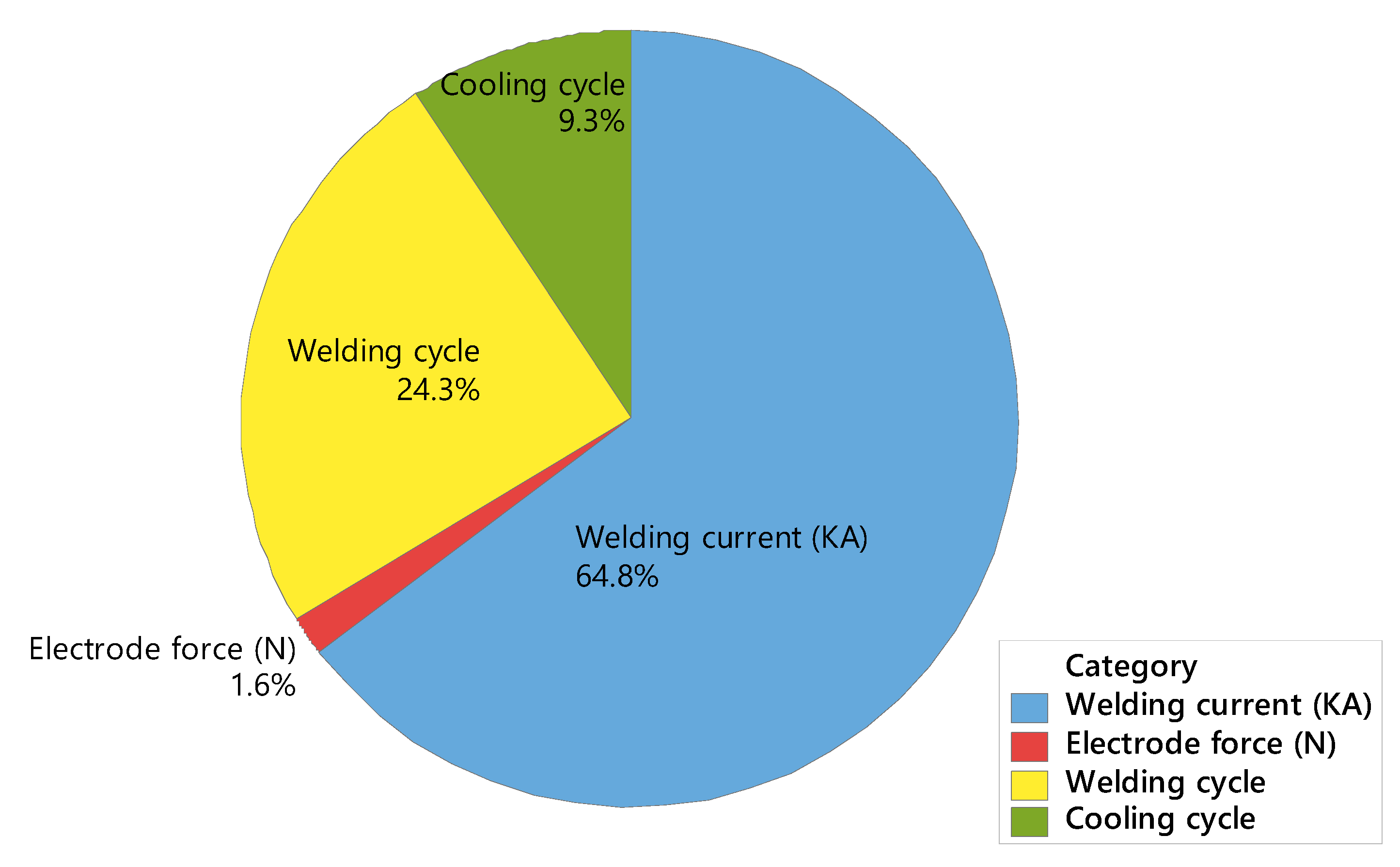

3.3. Sobol Sensitivity Analysis of Tensile-Shear of RSW Joints

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Taufiqurrahman, I.; Ginta, T.L.; Mustapha, M. The effect of holding time on dissimilar resistance spot welding of stainless steel 316L and Ti6Al4V titanium alloy with aluminum interlayer. Mater. Today Proc. 2020, 46, 1563–1568. [Google Scholar] [CrossRef]

- Chen, G.; Xue, W.; Jia, Y.; Shen, S.; Liu, G. Microstructure and mechanical property of WC-10Co/RM80 steel dissimilar resistance spot welding joint. Mater. Sci. Eng. A 2020, 776, 139008. [Google Scholar] [CrossRef]

- Taufiqurrahman, I.; Ahmad, A.; Mustapha, M.; Lenggo Ginta, T.; Ady Farizan Haryoko, L.; Ahmed Shozib, I. The Effect of Welding Current and Electrode Force on the Heat Input, Weld Diameter, and Physical and Mechanical Properties of SS316L/Ti6Al4V Dissimilar Resistance Spot Welding with Aluminum Interlayer. Materials 2021, 14, 1129. [Google Scholar] [CrossRef] [PubMed]

- Jaber, H.; Kovacs, T. Dissimilar Resistance Spot Welding of Ferrite-Martensite Dual Phase Steel/low Carbon Steel: Phase Transformations and Mechanical Properties, Vehicle and Automotive Engineering; Springer: Miskolc, Hungary, 2018; pp. 709–718. [Google Scholar]

- Bemani, M.; Pouranvari, M. Microstructure and mechanical properties of dissimilar nickel-based superalloys resistance spot welds. Mater. Sci. Eng. A 2020, 773, 138825. [Google Scholar] [CrossRef]

- Noh, W.; Kim, W.; Yang, X.; Kang, M.; Lee, M.G.; Chung, K. Simple and effective failure analysis of dissimilar resistance spot welded advanced high strength steel sheets. Int. J. Mech. Sci. 2017, 121, 76–89. [Google Scholar] [CrossRef]

- Shi, L.; Kang, J.; Chen, X.; Haselhuhn, A.S.; Sigler, D.R.; Carlson, B.E. Carlson, Determination of fracture modes in novel aluminum-steel dissimilar resistance spot welds. Procedia Struct. Integr. 2019, 17, 355–362. [Google Scholar] [CrossRef]

- Rikka, V.R.; Sahu, S.R.; Roy, A.; Jana, S.N.; Sivaprahasam, D.; Prakash, R.; Gopalan, R.; Sundararajan, G. Tailoring micro resistance spot welding parameters for joining nickel tab to inner aluminium casing in a cylindrical lithium ion cell and its influence on the electrochemical performance. J. Manuf. Process. 2020, 49, 463–471. [Google Scholar] [CrossRef]

- Das, T.; Das, R.; Paul, J. Resistance spot welding of dissimilar AISI-1008 steel/Al-1100 alloy lap joints with a graphene interlayer. J. Manuf. Process. 2020, 53, 260–274. [Google Scholar] [CrossRef]

- Azhari-Saray, H.; Sarkari-Khorrami, M.; Nademi-Babahadi, A.; Kashani-Bozorg, S.F. Dissimilar resistance spot welding of 6061-T6 aluminum alloy/St-12 carbon steel using a high entropy alloy interlayer. Intermetallics 2020, 124, 106876. [Google Scholar] [CrossRef]

- Essoussi, H.; Elmouhri, S.; Ettaqi, S.; Essadiqi, E. Microstructure and mechanical performance of resistance spot welding of AISI 304 stainless steel and AISI 1000 series steel. Procedia Manuf. 2019, 32, 872–876. [Google Scholar] [CrossRef]

- Neystani, R.; Beidokhti, B.; Amelzadeh, M. Fabrication of dissimilar Fe-Cu-C powder metallurgy compact/steel joint using the optimized resistance spot welding. J. Manuf. Process. 2019, 43, 200–206. [Google Scholar] [CrossRef]

- Valera, J.; Miguel, V.; Martínez, A.; Naranjo, J.; Cañas, M. Optimization of electrical parameters in Resistance Spot Welding of dissimilar joints of micro-alloyed steels TRIP sheets. Procedia Manuf. 2017, 13, 291–298. [Google Scholar] [CrossRef]

- Vignesh, K.; Perumal, A.E.; Velmurugan, P. Optimization of resistance spot welding process parameters and microstructural examination for dissimilar welding of AISI 316L austenitic stainless steel and 2205 duplex stainless steel. Int. J. Adv. Manuf. Technol. 2017, 93, 455–465. [Google Scholar] [CrossRef]

- Mansor, M.S.M.; Yusof, F.; Ariga, T.; Miyashita, Y. Microstructure and mechanical properties of micro-resistance spot welding between stainless steel 316L and Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2018, 96, 2567–2581. [Google Scholar] [CrossRef]

- Anijdan, S.M.; Sabzi, M.; Ghobeiti-Hasab, M.; Roshan-Ghiyas, A. Optimization of spot welding process parameters in dissimilar joint of dual phase steel DP600 and AISI 304 stainless steel to achieve the highest level of shear-tensile strength. Mater. Sci. Eng. A 2018, 726, 120–125. [Google Scholar] [CrossRef]

- Chen, F.; Wang, Y.; Sun, S.; Ma, Z.; Huang, X. Multi-objective optimization of mechanical quality and stability during micro resistance spot welding. Int. J. Adv. Manuf. Technol. 2019, 101, 1903–1913. [Google Scholar] [CrossRef]

- Mirzaei, F.; Ghorbani, H.; Kolahan, F. Numerical modeling and optimization of joint strength in resistance spot welding of galvanized steel sheets. Int. J. Adv. Manuf. Technol. 2017, 92, 3489–3501. [Google Scholar] [CrossRef]

- Ma, Y.; Takikawa, A.; Nakanishi, J.; Doira, K.; Shimizu, T.; Lu, Y.; Ma, N. Measurement of local material properties and failure analysis of resistance spot welds of advanced high-strength steel sheets. Mater. Des. 2021, 201, 109505. [Google Scholar] [CrossRef]

- Sureshkumar, B.; Vijayan, V.; Dinesh, S.; Rajaguru, K. Neural network modeling for face milling operation. Int. J. Veh. Struct. Syst. 2019, 11, 214–219. [Google Scholar] [CrossRef]

- Radha Krishnan, B.; Vijayan, V.; Parameshwaran Pillai, T.; Sathish, T. Influence of surface roughness in turning process—An analysis using artificial neural network. Trans. Can. Soc. Mech. Eng. 2019, 43, 509–514. [Google Scholar] [CrossRef]

- Vukman, J.; Lukic, D.; Borojevic, S.; Rodic, D.; Milosevic, M. Application of Fuzzy Logic in the Analysis of Surface Roughness of Thin-Walled Aluminum Parts. Int. J. Precis. Eng. Manuf. 2020, 21, 91–102. [Google Scholar] [CrossRef]

- Dambatta, Y.S.; Sayuti, M.; Sarhan, A.A.; Ab Shukor, H.B.; binti Derahman, N.A.; Manladan, S.M. Prediction of specific grinding forces and surface roughness in machining of AL6061-T6 alloy using ANFIS technique. Ind. Lubr. Tribol. 2019, 71, 309–317. [Google Scholar] [CrossRef]

- Xu, L.; Huang, C.; Li, C.; Wang, J.; Liu, H.; Wang, X. Estimation of tool wear and optimization of cutting parameters based on novel ANFIS-PSO method toward intelligent machining. J. Intell. Manuf. 2021, 32, 77–90. [Google Scholar] [CrossRef]

- Rao, R.V.; Savsani, V.J.; Vakharia, D.P. Teaching–Learning-based optimization: A novel method for constrained mechanical design optimization problems. Comput.-Aided Des. 2011, 43, 303–315. [Google Scholar] [CrossRef]

- Rao, R.V.; Savsani, V.J.; Vakharia, D.P. Teaching–Learning-based optimization: An optimization method for continuous non-linear large scale problems. Inf. Sci. 2012, 183, 1–15. [Google Scholar] [CrossRef]

- Sobol, I.M. Sensitivity analysis for non-linear mathematical models. Math. Model. Comput. Exp. 1993, 1, 407–414. [Google Scholar]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

| Elements | C | Si | Mn | P | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|---|

| AISI 1060 | 0.62 | 0.42 | 0.71 | ≤0.03 | ≤0.05 | 0.21 | 0.08 | - |

| AISI 304 | 0.12 | 0.42 | 6.2 | ≤0.05 | ≤0.03 | 17.1 | - | 4.7 |

| Parameter | Limits | ||||

|---|---|---|---|---|---|

| −2 | −1 | 0 | +1 | +2 | |

| Welding current (KA) | 6.4 | 8.4 | 10.4 | 12.4 | 14.4 |

| Welding cycle (cycle) | 20 | 25 | 30 | 35 | 40 |

| Cooling cycle (cycle) | 0 | 12.5 | 25 | 37.5 | 50 |

| Electrode force (N) | 800 | 1100 | 1400 | 1700 | 2000 |

| Scheme | Welding Current (KA) | Electrode Force (N) | Welding Cycle | Cooling Cycle |

|---|---|---|---|---|

| 1 | 8.4 | 1100 | 25 | 12.5 |

| 2 | 12.4 | 1100 | 25 | 12.5 |

| 3 | 8.4 | 1700 | 25 | 12.5 |

| 4 | 12.4 | 1700 | 25 | 12.5 |

| 5 | 8.4 | 1100 | 35 | 12.5 |

| 6 | 12.4 | 1100 | 35 | 12.5 |

| 7 | 8.4 | 1700 | 35 | 12.5 |

| 8 | 12.4 | 1700 | 35 | 12.5 |

| 9 | 8.4 | 1100 | 25 | 37.5 |

| 10 | 12.4 | 1100 | 25 | 37.5 |

| 11 | 8.4 | 1700 | 25 | 37.5 |

| 12 | 12.4 | 1700 | 25 | 37.5 |

| 13 | 8.4 | 1100 | 35 | 37.5 |

| 14 | 12.4 | 1100 | 35 | 37.5 |

| 15 | 8.4 | 1700 | 35 | 37.5 |

| 16 | 12.4 | 1700 | 35 | 37.5 |

| 17 | 6.4 | 1400 | 30 | 25.0 |

| 18 | 14.4 | 1400 | 30 | 25.0 |

| 19 | 10.4 | 800 | 30 | 25.0 |

| 20 | 10.4 | 2000 | 30 | 25.0 |

| 21 | 10.4 | 1400 | 20 | 25.0 |

| 22 | 10.4 | 1400 | 40 | 25.0 |

| 23 | 10.4 | 1400 | 30 | 0.00 |

| 24 | 10.4 | 1400 | 30 | 50.0 |

| 25 | 10.4 | 1400 | 30 | 25.0 |

| 26 | 10.4 | 1400 | 30 | 25.0 |

| 27 | 10.4 | 1400 | 30 | 25.0 |

| 28 | 10.4 | 1400 | 30 | 25.0 |

| 29 | 10.4 | 1400 | 30 | 25.0 |

| 30 | 10.4 | 1400 | 30 | 25.0 |

| 31 | 10.4 | 1400 | 30 | 25.0 |

| Sample | Tensile-Shear Strength (N) | Failure Mode |

|---|---|---|

| 1 | 4280 | Interfacial |

| 2 | 6100 | Pullout |

| 3 | 4720 | Interfacial |

| 4 | 6050 | Pullout |

| 5 | 4740 | Interfacial |

| 6 | 6830 | Pullout |

| 7 | 4770 | Interfacial |

| 8 | 6048 | Pullout |

| 9 | 4150 | Interfacial |

| 10 | 5300 | Pullout |

| 11 | 3450 | Interfacial |

| 12 | 4810 | Pullout |

| 13 | 5090 | Pullout |

| 14 | 6340 | Pullout |

| 15 | 5300 | Pullout |

| 16 | 6900 | Pullout |

| 17 | 2940 | Interfacial |

| 18 | 6030 | Pullout |

| 19 | 6037 | Pullout |

| 20 | 5100 | Pullout |

| 21 | 4600 | Interfcial |

| 22 | 5910 | Pullout |

| 23 | 5300 | Pullout |

| 24 | 5000 | Pullout |

| 25 | 5740 | Pullout |

| 26 | 5680 | Pullout |

| 27 | 5700 | Pullout |

| 28 | 5660 | Pullout |

| 29 | 5700 | Pullout |

| 30 | 5730 | Pullout |

| 31 | 5770 | Pullout |

| Source | DF | Adj SS | Adj MS | f-Value | p-Value |

|---|---|---|---|---|---|

| Model | 7 | 21907927 | 3129704 | 44.36 | 0.000 |

| Linear | 4 | 18475843 | 4618961 | 65.47 | 0.000 |

| Welding current (KA) | 1 | 13232835 | 13232835 | 187.55 | 0.000 |

| Electrode force (N) | 1 | 380268 | 380268 | 5.39 | 0.029 |

| Welding cycle | 1 | 4387005 | 4387005 | 62.18 | 0.000 |

| Cooling cycle | 1 | 475735 | 475735 | 6.74 | 0.016 |

| Square | 2 | 2121631 | 1060815 | 15.04 | 0.000 |

| Welding current (KA) × Welding current (KA) | 1 | 1960822 | 1960822 | 27.79 | 0.000 |

| Cooling cycle × Cooling cycle | 1 | 272794 | 272794 | 3.87 | 0.061 |

| 2-Way Interaction | 1 | 1310453 | 1310453 | 18.57 | 0.000 |

| Welding cycle × Cooling cycle | 1 | 1310453 | 1310453 | 18.57 | 0.000 |

| Error | 23 | 1622757 | 70555 | - | - |

| Lack-of-Fit | 17 | 1617985 | 95176 | 119.68 | 0.000 |

| Pure Error | 6 | 4771 | 795 | - | - |

| Total | 30 | 23530684 | - | - | - |

| RMSE | MAPE (%) | |||

|---|---|---|---|---|

| Training | 9.82 | 0.99 | 0.08 | |

| Test | 298 | 0.96 | 5.87 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Safari, M.; Alves de Sousa, R.J.; Rabiee, A.H.; Tahmasbi, V. Investigation of Dissimilar Resistance Spot Welding Process of AISI 304 and AISI 1060 Steels with TLBO-ANFIS and Sensitivity Analysis. Metals 2021, 11, 1324. https://doi.org/10.3390/met11081324

Safari M, Alves de Sousa RJ, Rabiee AH, Tahmasbi V. Investigation of Dissimilar Resistance Spot Welding Process of AISI 304 and AISI 1060 Steels with TLBO-ANFIS and Sensitivity Analysis. Metals. 2021; 11(8):1324. https://doi.org/10.3390/met11081324

Chicago/Turabian StyleSafari, Mehdi, Ricardo J. Alves de Sousa, Amir Hossein Rabiee, and Vahid Tahmasbi. 2021. "Investigation of Dissimilar Resistance Spot Welding Process of AISI 304 and AISI 1060 Steels with TLBO-ANFIS and Sensitivity Analysis" Metals 11, no. 8: 1324. https://doi.org/10.3390/met11081324

APA StyleSafari, M., Alves de Sousa, R. J., Rabiee, A. H., & Tahmasbi, V. (2021). Investigation of Dissimilar Resistance Spot Welding Process of AISI 304 and AISI 1060 Steels with TLBO-ANFIS and Sensitivity Analysis. Metals, 11(8), 1324. https://doi.org/10.3390/met11081324