Microstructural Characterization and Crack Propagation Behavior of a Novel β-Solidifying TiAl Alloy

Abstract

:1. Introduction

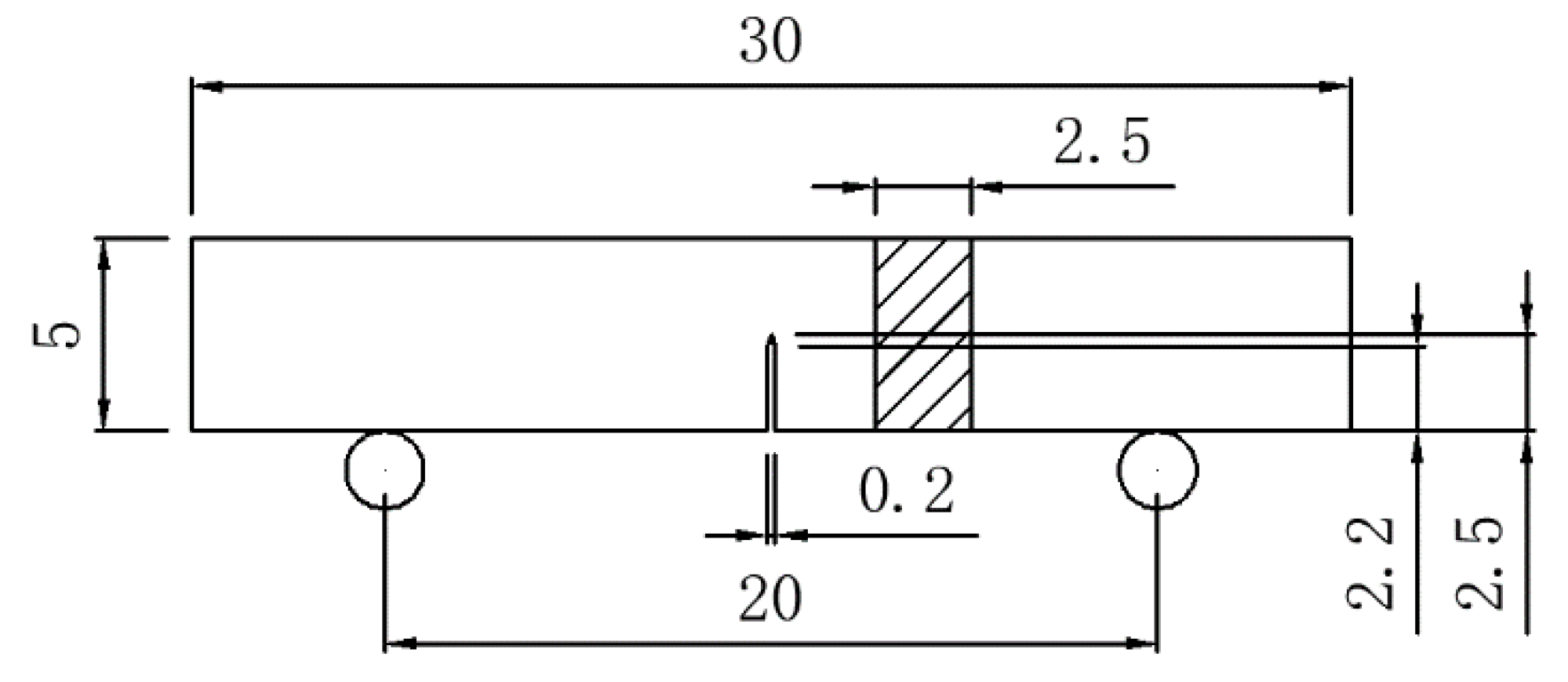

2. Materials and Methods

3. Results

3.1. Initial Microstructure of the Ti-43Al-2Cr-1.5Mn-0.1Y Ingot

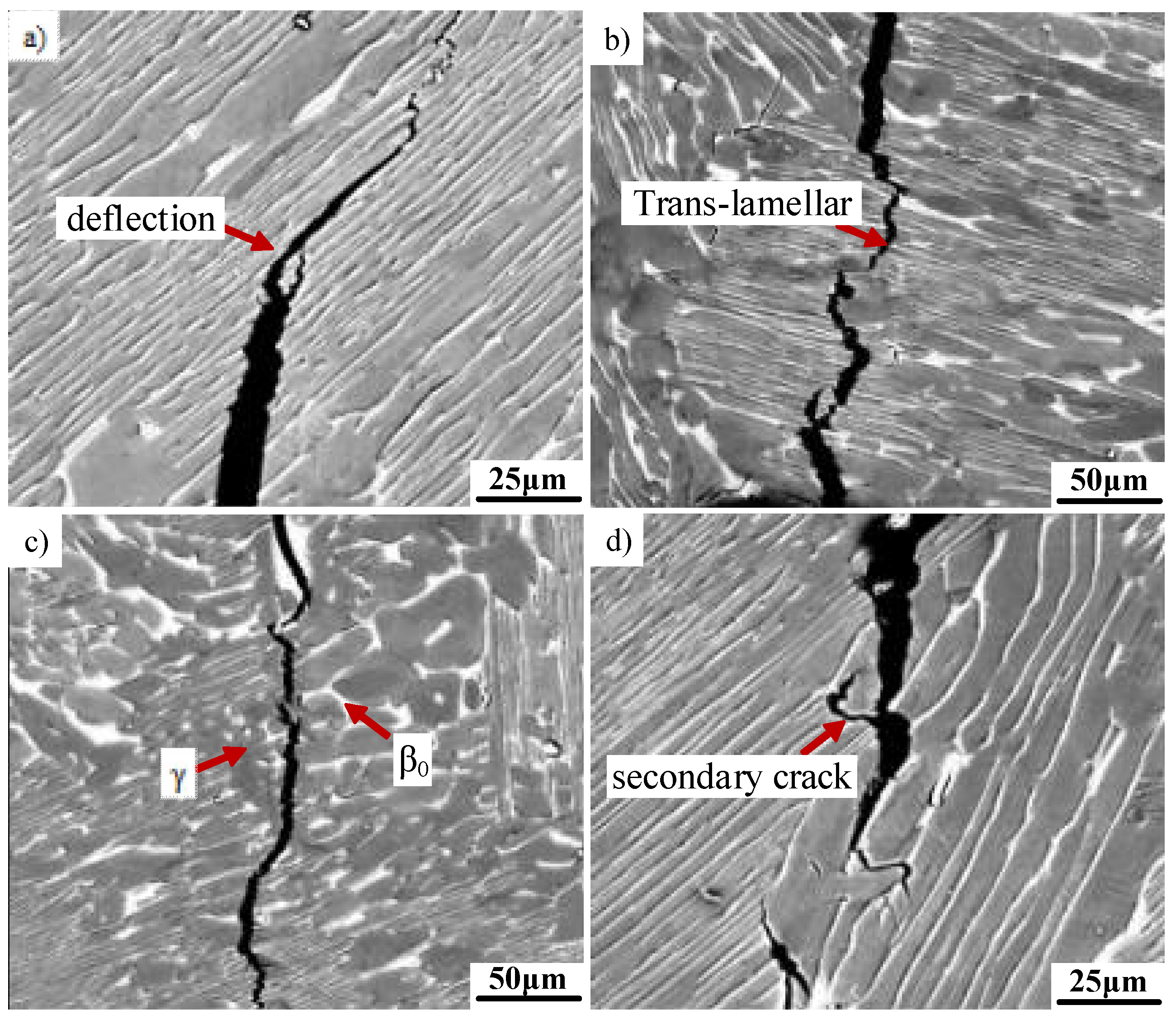

3.2. Crack Propagation Behavior in the Coarse Lamellar Microstructure

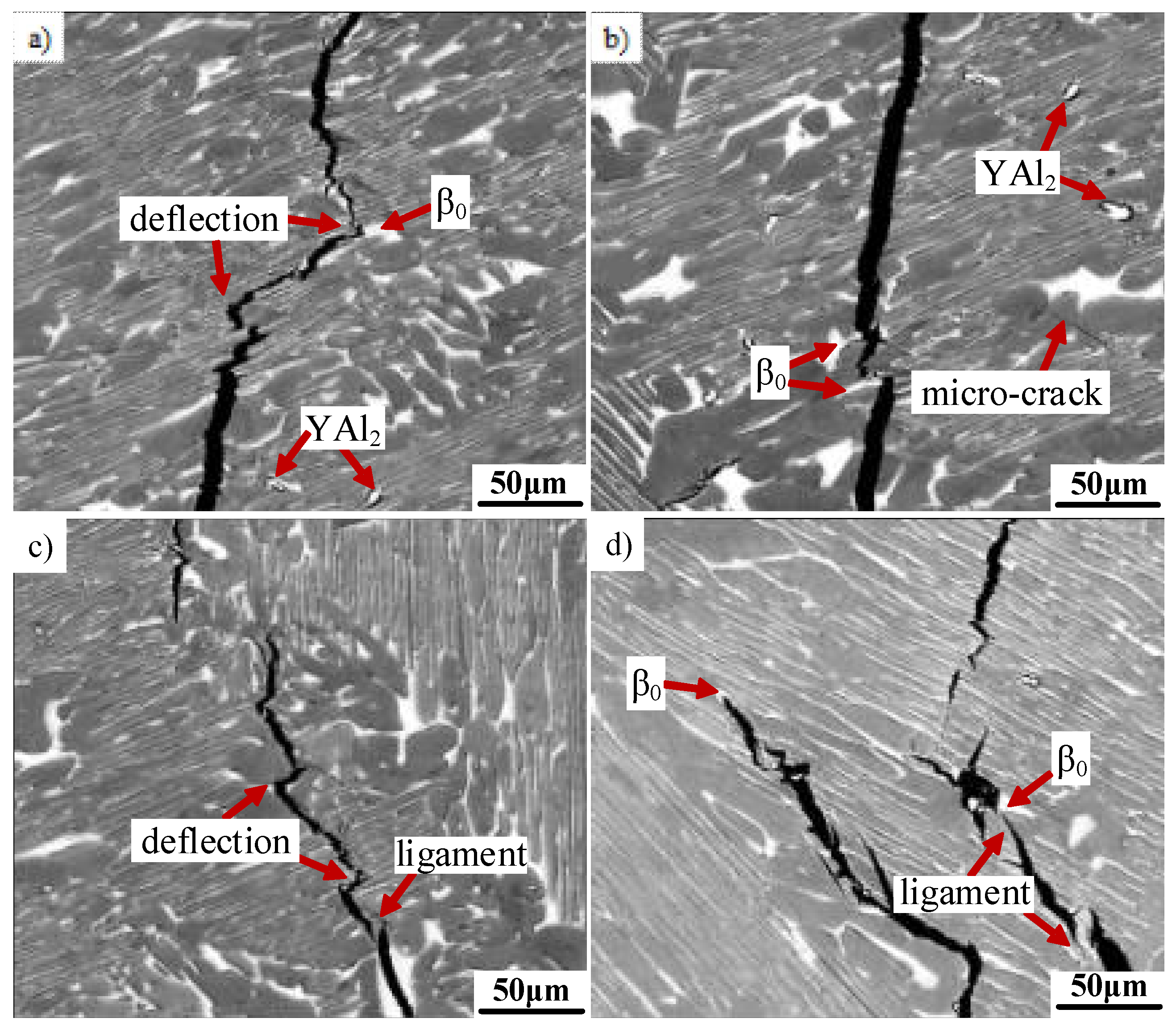

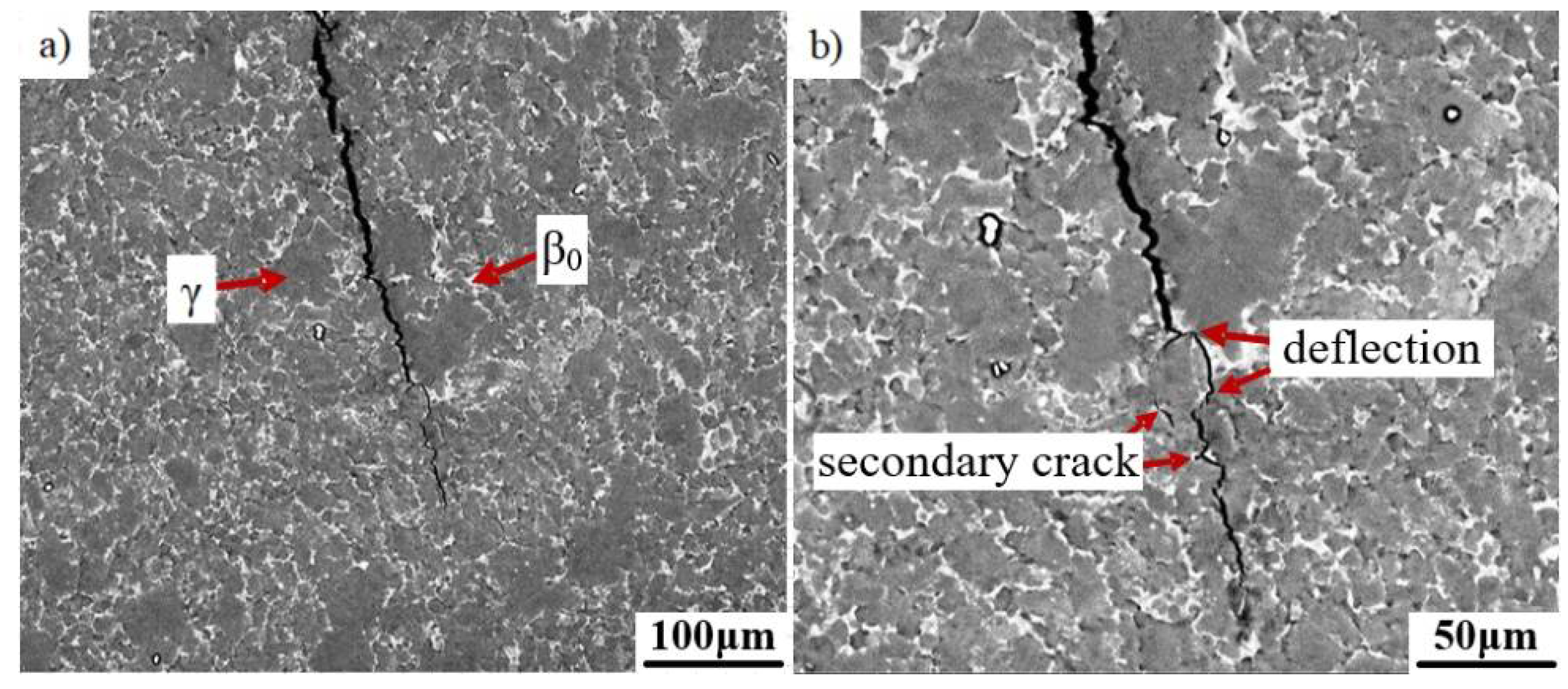

3.3. Crack Propagation Behavior in the Fine (γ+β0) Microstructure

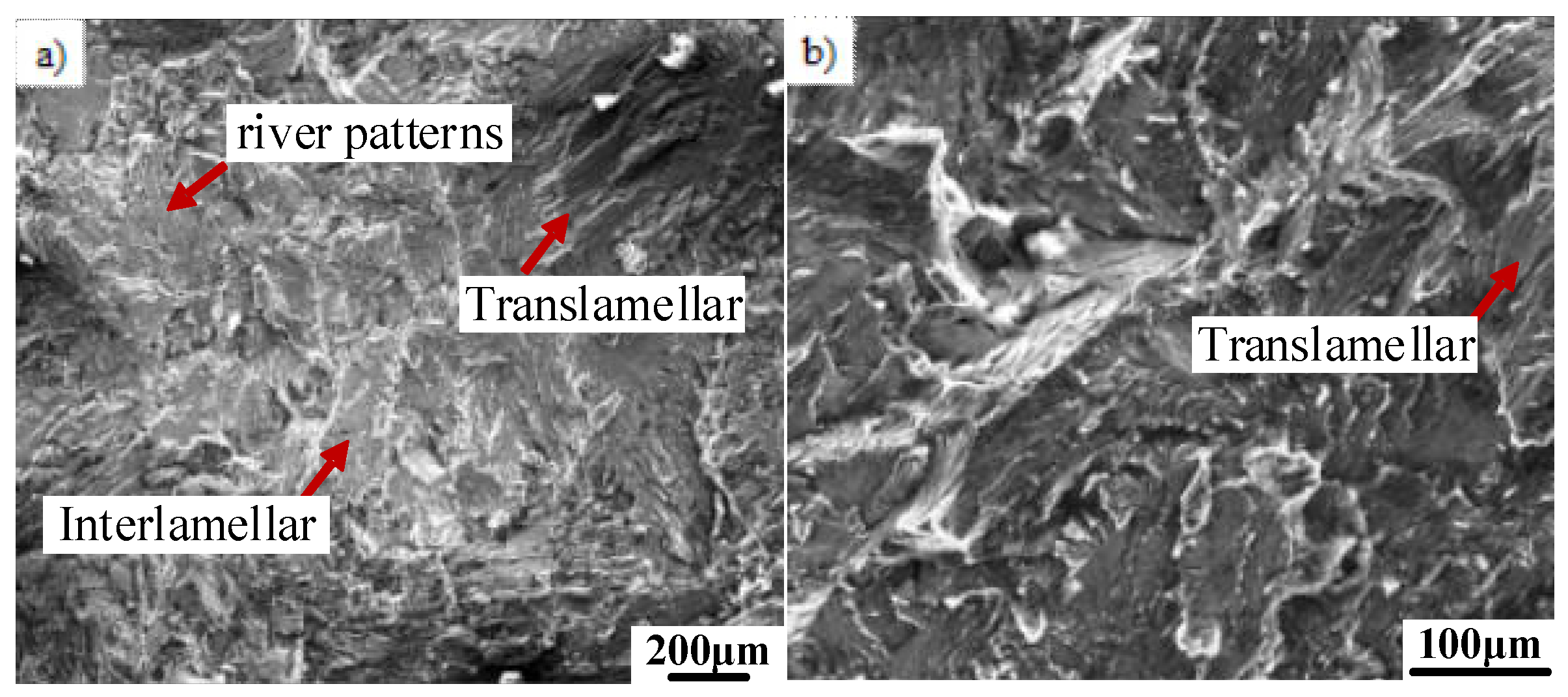

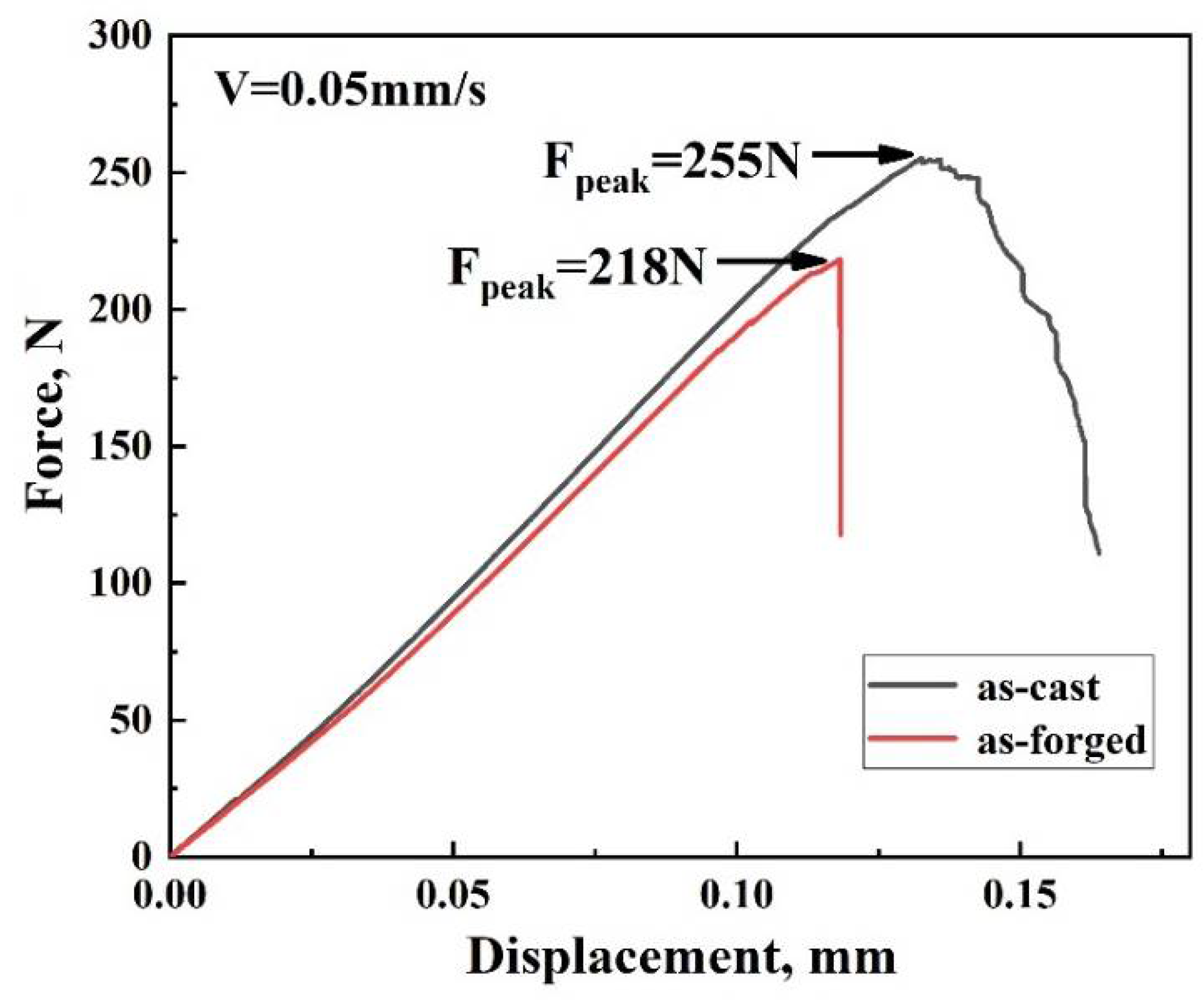

3.4. Fracture Toughness of the β-Solidifying TiAl Alloy with Different Microstructure

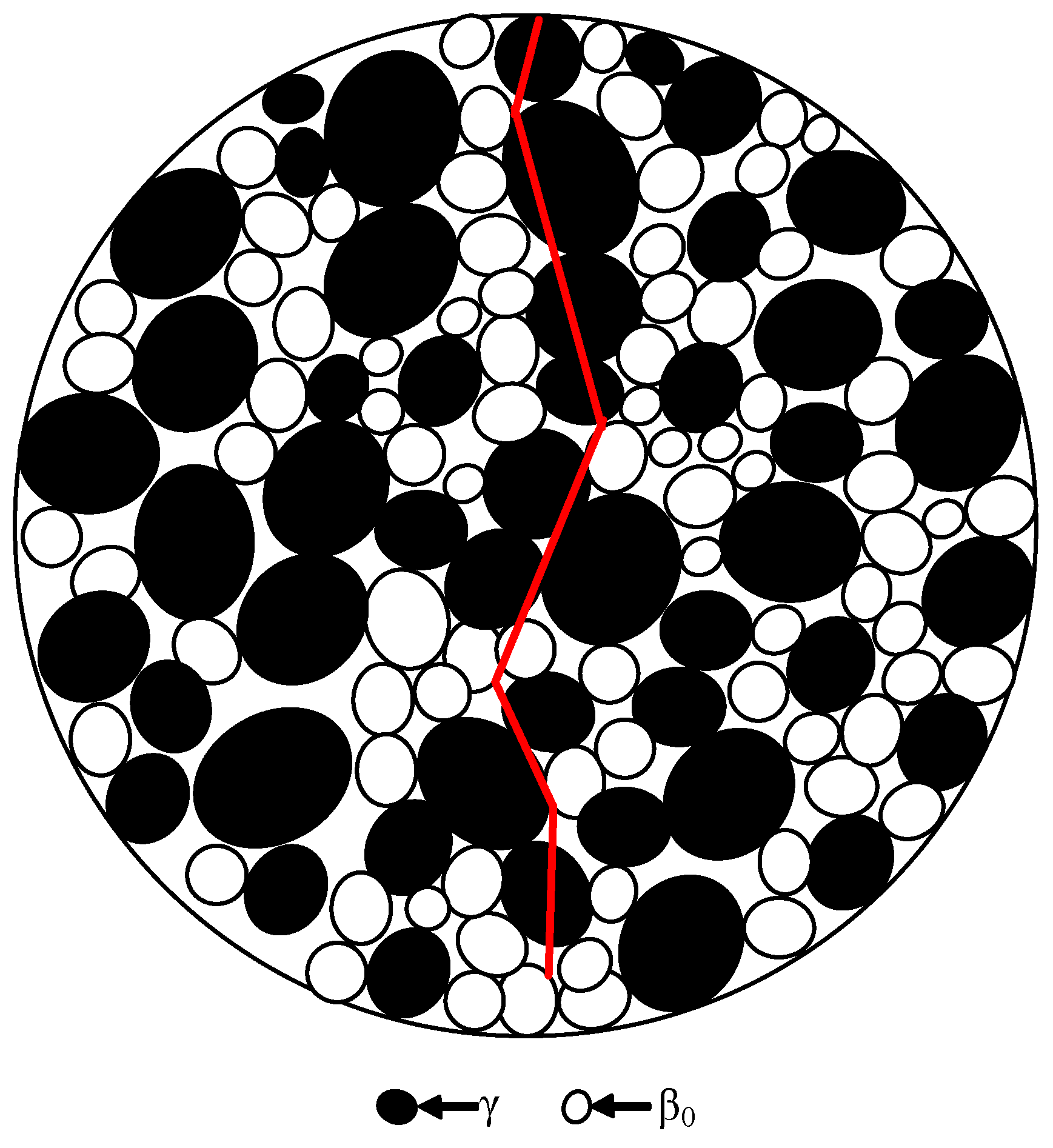

3.5. Crack Propagation Model of the β-Solidifying TiAl Alloy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Clemens, H.; Mayer, S. Advanced Intermetallic TiAl Alloys. Mater. Sci. Forum 2017, 879, 113–118. [Google Scholar] [CrossRef]

- Janschek, P. Wrought TiAl Blades. Mater. Today 2015, 2, 92–97. [Google Scholar] [CrossRef]

- Appel, F.; Paul, J.D.H.; Oehring, M. Gamma Titanium Aluminide Alloys: Science and Technology; John Wiley & Sons: Weinheim, Germany, 2011. [Google Scholar]

- Appel, F.; Clemens, H.; Fischer, F.D. Modeling concepts for intermetallic titanium aluminides. Prog. Mater. Sci. 2016, 81, 55–124. [Google Scholar] [CrossRef]

- Clemens, H.; Wallgram, W.; Kremmer, S.; Güther, V.; Otto, A.; Bartels, A. Design of novel β-solidifying TiAl alloys with adjustable β/B2-phase fraction and excellent hot-workability. Adv. Eng. Mater. 2008, 10, 707–713. [Google Scholar] [CrossRef]

- Schwaighofer, E.; Rashkova, B.; Clemens, H.; Stark, A.; Mayer, S. Effect of carbon addition on solidification behavior, phase evolution and creep properties of an intermetallic β-stabilized γ-TiAl based alloy. Intermetallics 2014, 46, 173–184. [Google Scholar] [CrossRef] [Green Version]

- Kong, F.; Cui, N.; Chen, Y.; Wang, X. A novel composition design method for beta-gamma TiAl alloys with excellent hot workability. Metall. Mater. Trans. A 2018, 49, 5574–5584. [Google Scholar] [CrossRef]

- Zhang, K.; Hu, R.; Li, J.; Yang, J.; Gao, Z. Grain Refinement of 1 at.% Ta-containing cast TiAl-based alloy by cyclic air-cooling heat treatment. Mater. Lett. 2020, 274, 127940. [Google Scholar] [CrossRef]

- Yim, S.; Bian, H.; Aoyagi, K.; Chiba, A. Effect of multi-stage heat treatment on mechanical properties and microstructure transformation of Ti–48Al–2Cr–2Nb alloy. Mater. Sci. Eng. A 2021, 816, 141321. [Google Scholar] [CrossRef]

- Takeyama, M.; Kobayashi, S. Physical metallurgy for wrought gamma titanium aluminides microstructure control through phase transformations. Intermetallics 2005, 13, 993–999. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Design, processing, microstructure, properties, and applications of advanced intermetallic TiAl alloys. Adv. Eng. Mater. 2013, 15, 191–215. [Google Scholar] [CrossRef]

- Schloffer, M.; Iqbal, F.; Gabrisch, H.; Schwaighofer, E.; Schimansky, F.P.; Mayer, S.; Stark, A.; Lippmann, T.; Göken, M.; Pyczak, F.; et al. Microstructure development and hardness of a powder metallurgical multi phase γ-TiAl based alloy. Intermetallics 2012, 22, 231–240. [Google Scholar] [CrossRef] [Green Version]

- Schloffer, M.; Rashkova, B.; Schöberl, T.; Schwaighofer, E.; Zhang, Z.; Clemens, H.; Mayer, S. Evolution of the ω0 phase in a β-stabilized multi-phase TiAl alloy and its effect on hardness. Acta Mater. 2014, 64, 241–252. [Google Scholar] [CrossRef]

- Kim, Y.W.; Kim, S.L. Advances in gammalloy materials–processes–application technology: Successes, dilemmas, and future in gammalloy materials–processes–application technology. JOM 2018, 5, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Edwards, T.E.J. Recent progress in the high-cycle fatigue behaviour of gamma-TiAl alloys. Mater. Sci. Technol. 2018, 34, 1919–1939. [Google Scholar] [CrossRef] [Green Version]

- Yokoshima, S.; Yamaguchi, M. Fracture behavior and toughness of PST crystals of TiAl. Acta Mater. 1996, 44, 873–883. [Google Scholar] [CrossRef]

- Chan, K.S.; Kim, Y.W. Influence of microstructure on crack-tip micromechanics and fracture behaviors of a two-phase TiAl alloy. Metall. Trans. A 1992, 23, 1663–1677. [Google Scholar] [CrossRef]

- Wu, H.; Fan, G. An overview of tailoring strain delocalization for strength-ductility synergy. Prog. Mater. Sci. 2020, 113, 51. [Google Scholar] [CrossRef]

- Cui, N.; Wang, X.P.; Kong, F.T.; Chen, Y.Y.; Zhou, H.T. Microstructure and properties of a beta-solidifying TiAl-based alloy with different refiners. Rare Metals 2016, 35, 42–47. [Google Scholar] [CrossRef]

- Su, Y.; Kong, F.; Chen, Y.; Gao, N.; Zhang, D. Microstructure and mechanical properties of large size Ti-43Al-9V-0.2Y alloy pancake produced by pack-forging. Intermetallics 2013, 34, 29–34. [Google Scholar] [CrossRef]

- Kobayashi, Y.; Tsukihashi, F. Thermodynamics of yttrium and oxygen in molten Ti, Ti3Al, and TiAl. Metall. Mater. Trans. B 1998, 29, 1037–1042. [Google Scholar] [CrossRef]

- Cui, N.; Kong, F.; Wang, X.; Chen, Y.; Zhou, H. Microstructural evolution, hot workability, and mechanical properties of Ti–43Al–2Cr–2Mn–0.2Y alloy. Mater. Des. 2016, 89, 1020–1027. [Google Scholar] [CrossRef]

- Niu, H.Z.; Chen, Y.F.; Zhang, Y.S.; Lu, J.W.; Zhang, W.; Zhang, P.X. Phase transformation and dynamic recrystallization behavior of a β-solidifying γ-TiAl alloy and its wrought microstructure control. Mater. Des. 2016, 90, 196–203. [Google Scholar] [CrossRef]

- Wang, Y.; Ding, H.; Zhang, H.; Chen, R.; Guo, J.; Fu, H. Microstructures and fracture toughness of Ti–(43–48)Al–2Cr–2Nb prepared by electromagnetic cold crucible directional solidification. Mater. Des. 2014, 64, 153–159. [Google Scholar] [CrossRef]

- Kamat, S.V.; Gogia, A.K.; Banerjee, D. Effect of alloying elements and heat treatment on the fracture toughness of Ti–Al–Nb alloys. Acta Mater. 1998, 46, 239–251. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Cui, N.; Sun, W.; Li, Q. Microstructural Characterization and Crack Propagation Behavior of a Novel β-Solidifying TiAl Alloy. Metals 2021, 11, 1231. https://doi.org/10.3390/met11081231

Zhang S, Cui N, Sun W, Li Q. Microstructural Characterization and Crack Propagation Behavior of a Novel β-Solidifying TiAl Alloy. Metals. 2021; 11(8):1231. https://doi.org/10.3390/met11081231

Chicago/Turabian StyleZhang, Shuling, Ning Cui, Wei Sun, and Qiucheng Li. 2021. "Microstructural Characterization and Crack Propagation Behavior of a Novel β-Solidifying TiAl Alloy" Metals 11, no. 8: 1231. https://doi.org/10.3390/met11081231

APA StyleZhang, S., Cui, N., Sun, W., & Li, Q. (2021). Microstructural Characterization and Crack Propagation Behavior of a Novel β-Solidifying TiAl Alloy. Metals, 11(8), 1231. https://doi.org/10.3390/met11081231