Preparation Methods for Graphene Metal and Polymer Based Composites for EMI Shielding Materials: State of the Art Review of the Conventional and Machine Learning Methods

Abstract

1. Introduction

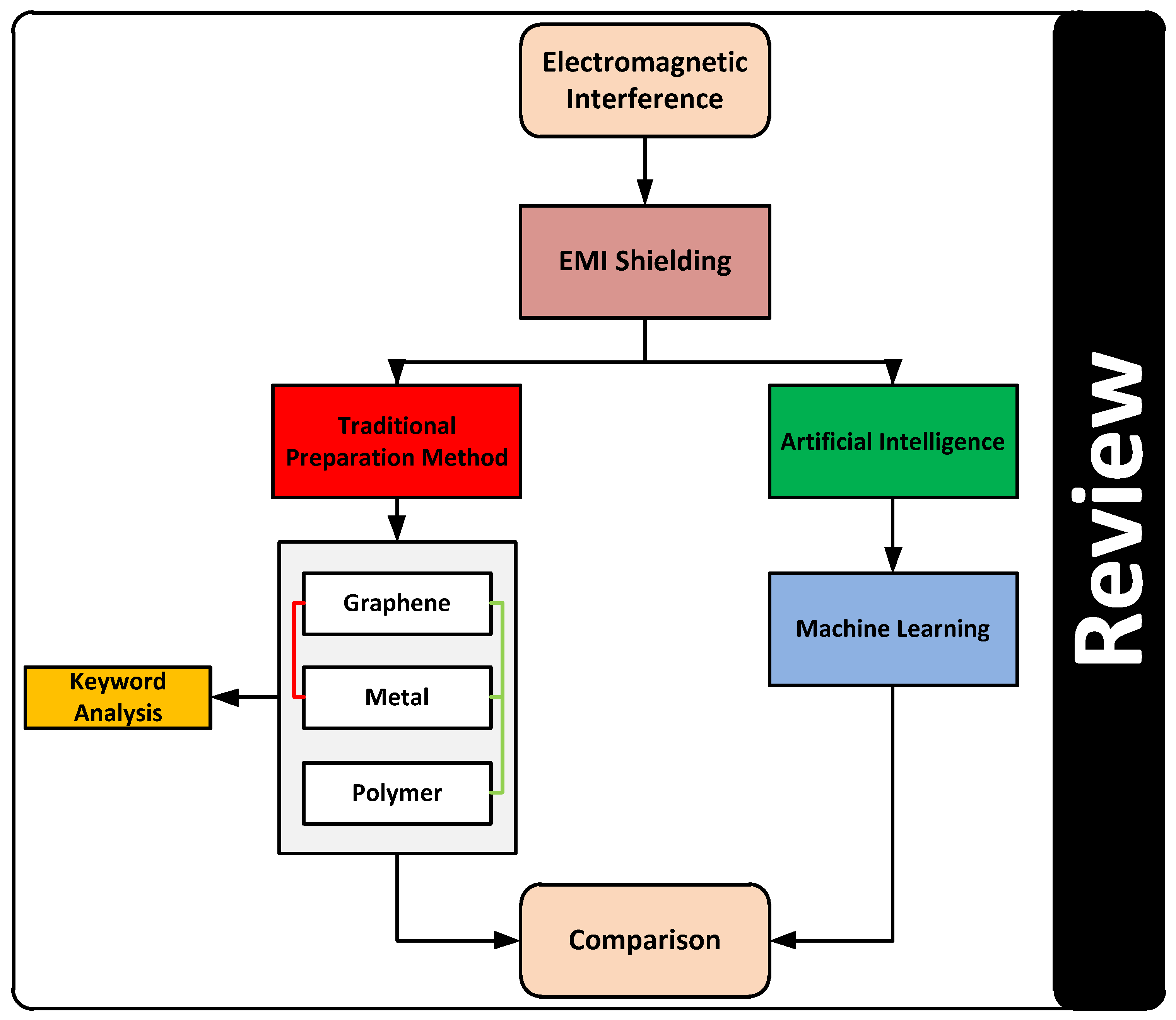

2. Review Methodology

3. Interpretation of Articles

3.1. Summary of Extracted Articles

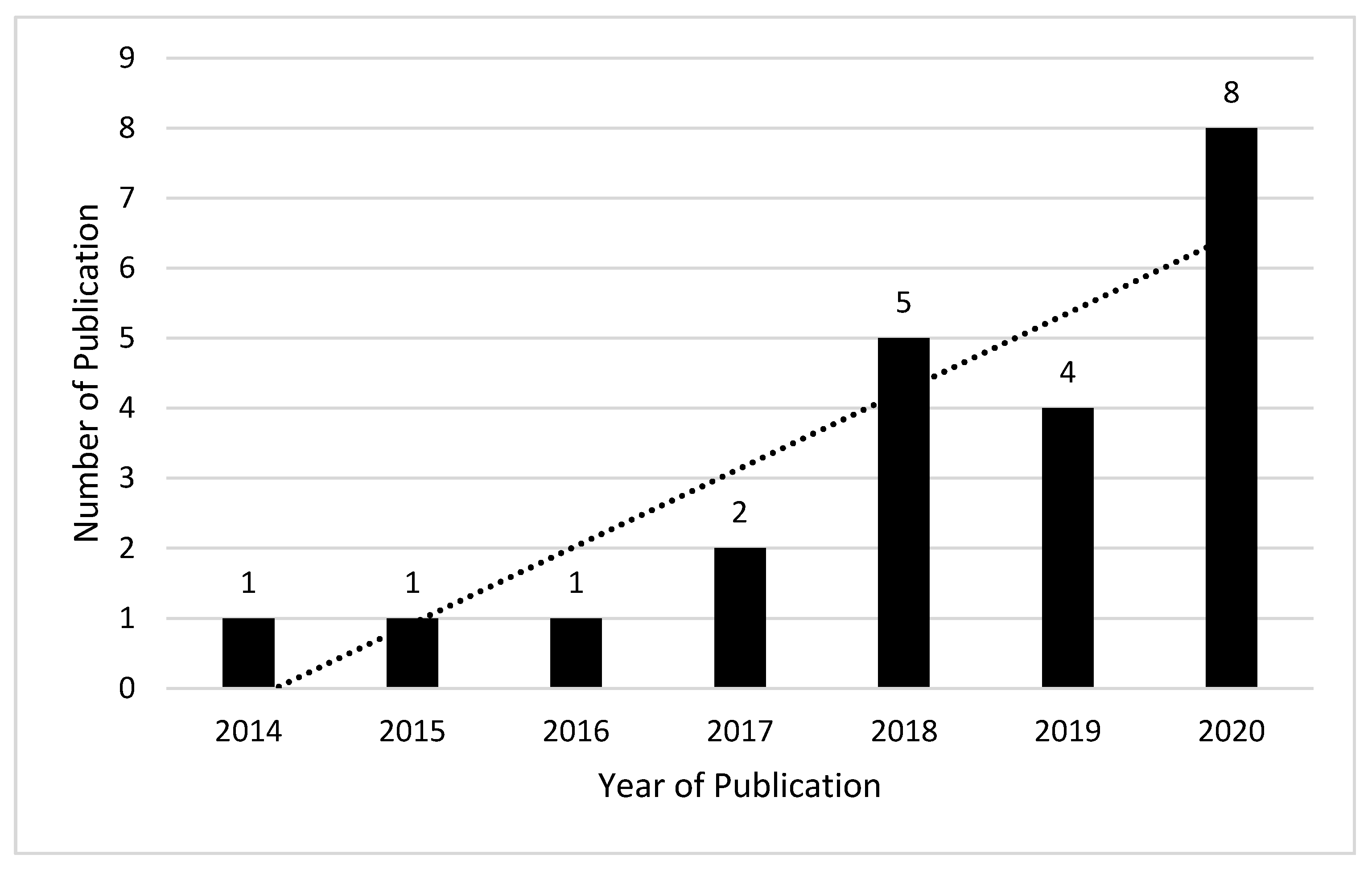

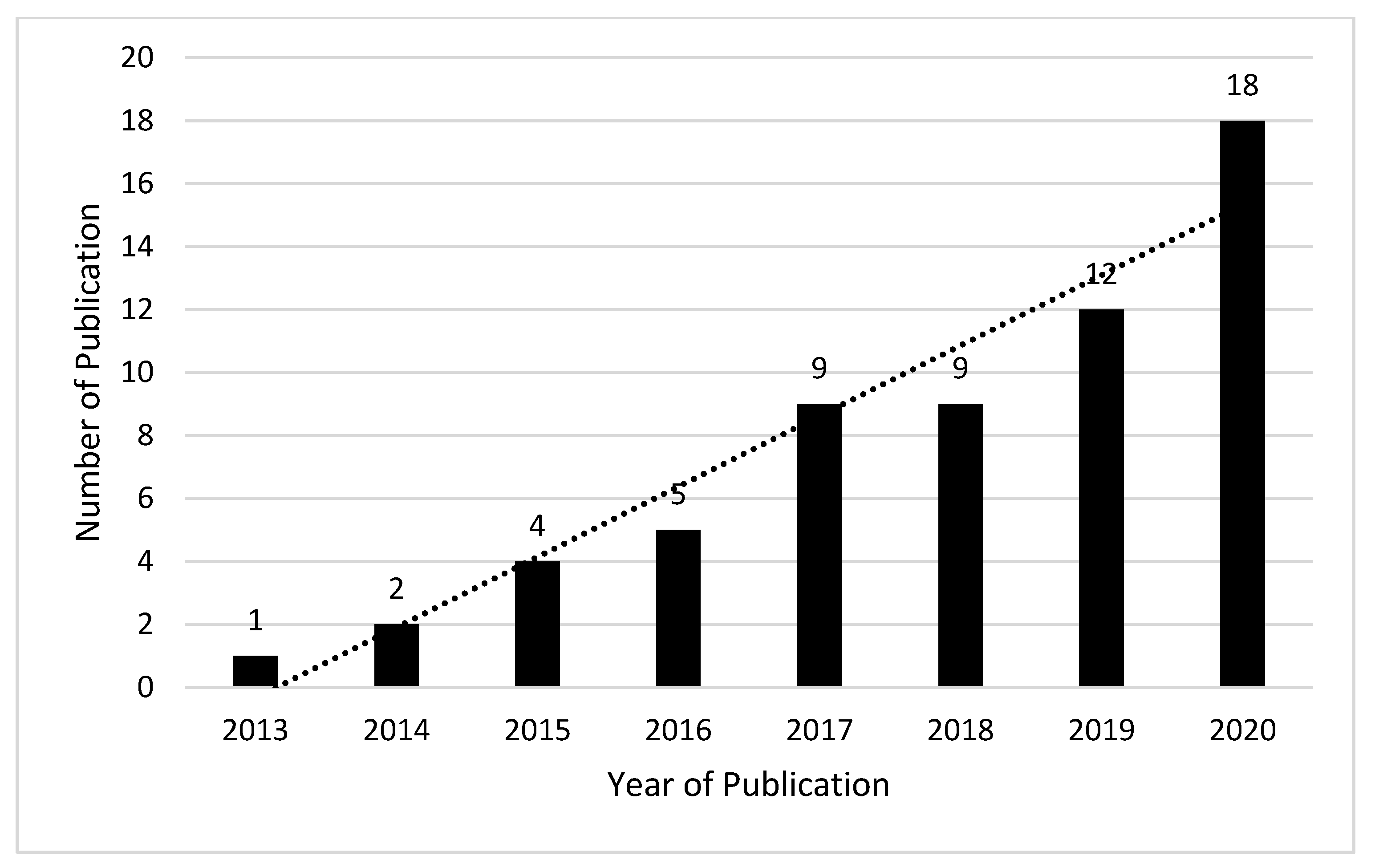

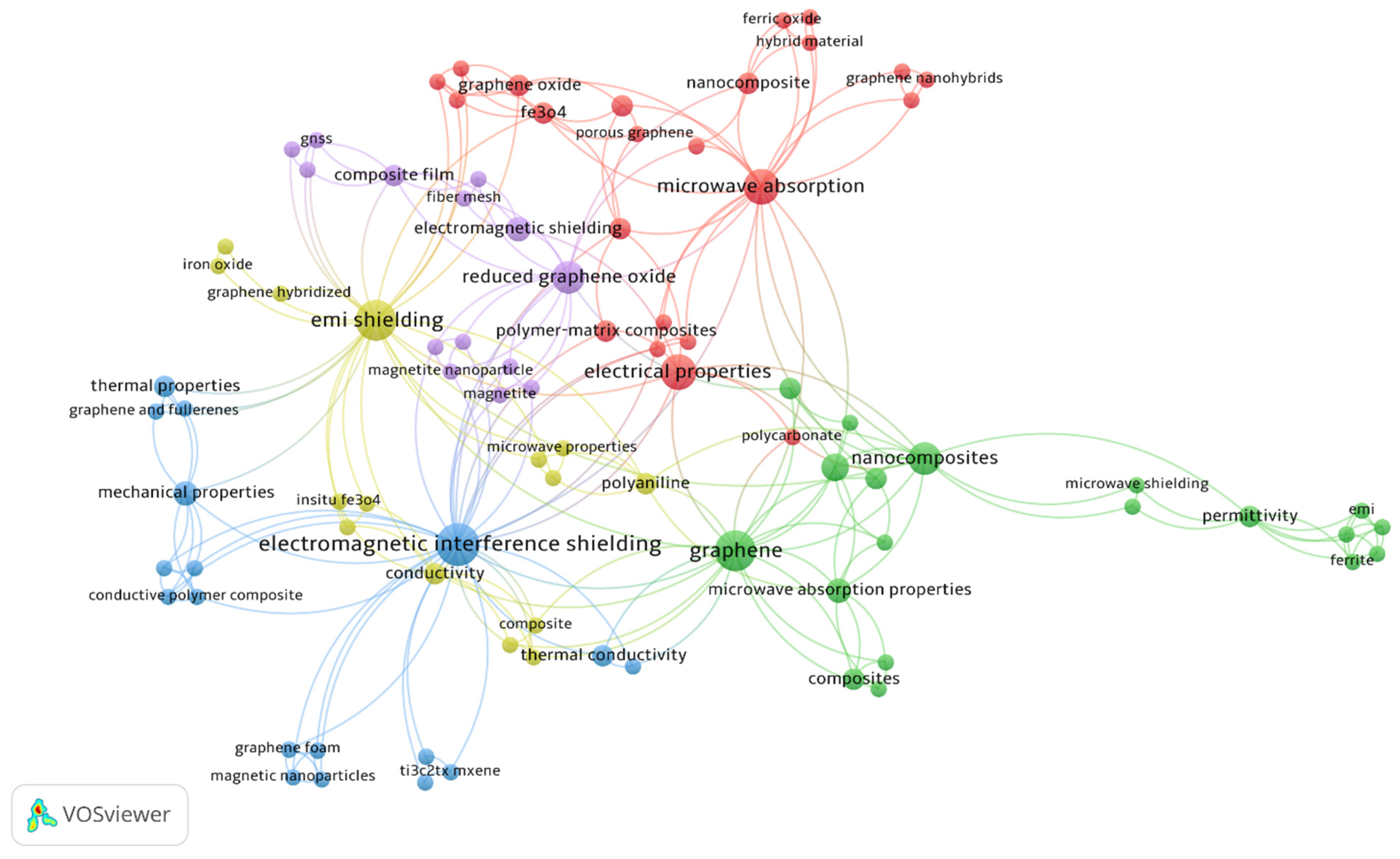

3.2. Keywords Analysis

4. Discussion of Articles

4.1. Traditional Methods

4.1.1. Methods for Preparation of Graphene- and Metal-Based Composites

4.1.2. Methods for Preparation of Polymer-Based Composites

4.2. Artificial Intelligence Methods

5. Future Direction

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Raagulan, K.; Kim, B.M.; Chai, K.Y. Recent Advancement of Electromagnetic Interference (EMI) Shielding of Two Dimensional (2D) MXene and Graphene Aerogel Composites. Nanomaterials 2020, 10, 702. [Google Scholar] [CrossRef]

- Li, Y.; Chen, S.; Zhao, K.; Gui, Y.; Fang, S.; Xu, Y.; Ma, Z. Effects of electromagnetic radiation on health and immune function of operators. Chin. J. Ind. Hyg. Occup. Dis. 2013, 31, 602–605. [Google Scholar]

- Chung, D. Electromagnetic interference shielding effectiveness of carbon materials. Carbon 2001, 39, 279–285. [Google Scholar] [CrossRef]

- Cheng, K.; Ramakrishna, S.; Lee, K. Electromagnetic shielding effectiveness of copper/glass fiber knitted fabric reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2000, 31, 1039–1045. [Google Scholar] [CrossRef]

- Joo, J.; Epstein, A. Electromagnetic radiation shielding by intrinsically conducting polymers. Appl. Phys. Lett. 1994, 65, 2278–2280. [Google Scholar] [CrossRef]

- Saini, P. Electrical properties and electromagnetic interference shielding response of electrically conducting thermosetting nanocomposites. Nanocomposites 2013. [Google Scholar] [CrossRef]

- Saini, P. Historical review of advanced materials for electromagnetic interference (EMI) shielding: Conjugated polymers, carbon nanotubes, graphene based composites. Indian J. Pure Appl. Phys. (IJPAP) 2019, 57, 338–351. [Google Scholar]

- Bellucci, S.; Bistarelli, S.; Cataldo, A.; Micciulla, F.; Kranauskaite, I.; Macutkevic, J.; Banys, J.; Volynets, N.; Paddubskaya, A.; Bychanok, D. Broadband dielectric spectroscopy of composites filled with various carbon materials. IEEE Trans. Microw. Theory Tech. 2015, 63, 2024–2031. [Google Scholar] [CrossRef]

- Wiley. Advance Materials for Electromagnetic Sheilding. 2019. Available online: https://books.google.com.my/books?id=kGVDwAAQBAJ&lpg=PA1&ots=RhoUSihwqR&dq=EMI%20related%20materials%20and%20graphs&lr&pg=PP21#v=onepage&q=EMI%20related%20materials%20and%20graphs&f=false (accessed on 8 April 2021).

- Yang, S.; Lozano, K.; Lomeli, A.; Foltz, H.D.; Jones, R. Electromagnetic interference shielding effectiveness of carbon nanofiber/LCP composites. Compos. Part A Appl. Sci. Manuf. 2005, 36, 691–697. [Google Scholar] [CrossRef]

- Von Klemperer, C.J.; Maharaj, D. Composite electromagnetic interference shielding materials for aerospace applications. Compos. Struct. 2009, 91, 467–472. [Google Scholar] [CrossRef]

- Wanasinghe, D.; Aslani, F. A review on recent advancement of electromagnetic interference shielding novel metallic materials and processes. Compos. Part B Eng. 2019, 176, 107207. [Google Scholar] [CrossRef]

- Geetha, S.; Satheesh Kumar, K.; Rao, C.R.; Vijayan, M.; Trivedi, D. EMI shielding: Methods and materials—A review. J. Appl. Polym. Sci. 2009, 112, 2073–2086. [Google Scholar] [CrossRef]

- Tolvanen, J.; Hannu, J.; Hietala, M.; Kordas, K.; Jantunen, H. Biodegradable multiphase poly (lactic acid)/biochar/graphite composites for electromagnetic interference shielding. Compos. Sci. Technol. 2019, 181, 107704. [Google Scholar] [CrossRef]

- Wu, J.; Chen, J.; Zhao, Y.; Liu, W.; Zhang, W. Effect of electrophoretic condition on the electromagnetic interference shielding performance of reduced graphene oxide-carbon fiber/epoxy resin composites. Compos. Part B Eng. 2016, 105, 167–175. [Google Scholar] [CrossRef]

- Cheaptubes.com. Graphene Synthesis, Properties, and Applications. 2020. Available online: https://www.cheaptubes.com/graphene-synthesis-properties-and-applications/ (accessed on 8 April 2021).

- Ayub, S.; Guan, B.H.; Ahmad, F. Graphene and Iron based composites as EMI shielding: A Systematic Review. In Proceedings of the 2020 Second International Sustainability and Resilience Conference: Technology and Innovation in Building Designs (51154), Sakheer, Bahrain, 11–12 November 2020; pp. 1–5. [Google Scholar]

- Tjaronge, M.W.; Musarat, M.A.; Law, K.; Alaloul, W.S.; Ayub, S. Effect of Graphene Oxide on Mechanical Properties of Rubberized Concrete: A Review. In Proceedings of the International Conference on Civil, Offshore and Environmental Engineering; Springer: Singapore, 2021. [Google Scholar]

- Plyushch, A.; Macutkevic, J.; Kuzhir, P.; Banys, J.; Bychanok, D.; Lambin, P.; Bistarelli, S.; Cataldo, A.; Micciulla, F.; Bellucci, S. Electromagnetic properties of graphene nanoplatelets/epoxy composites. Compos. Sci. Technol. 2016, 128, 75–83. [Google Scholar] [CrossRef]

- Santhosi, B.; Ramji, K.; Rao, N.M. Design and development of polymeric nanocomposite reinforced with graphene for effective EMI shielding in X-band. Phys. B Condens. Matter 2020, 586, 412144. [Google Scholar] [CrossRef]

- Kim, B.-J.; Bae, K.-M.; Lee, Y.S.; An, K.-H.; Park, S.-J. EMI shielding behaviors of Ni-coated MWCNTs-filled epoxy matrix nanocomposites. Surf. Coat. Technol. 2014, 242, 125–131. [Google Scholar] [CrossRef]

- Ma, Z. Friction stir processing technology: A review. Metall. Mater. Trans. A 2008, 39, 642–658. [Google Scholar] [CrossRef]

- Chen, L.-Y.; Konishi, H.; Fehrenbacher, A.; Ma, C.; Xu, J.-Q.; Choi, H.; Xu, H.-F.; Pfefferkorn, F.E.; Li, X.-C. Novel nanoprocessing route for bulk graphene nanoplatelets reinforced metal matrix nanocomposites. Scr. Mater. 2012, 67, 29–32. [Google Scholar] [CrossRef]

- Ayub, S.; Guan, B.H.; Ahmad, F.; Oluwatobi, Y.A.; Nisa, Z.U.; Javed, M.F.; Mosavi, A. Graphene and Iron Reinforced Polymer Composite Electromagnetic Shielding Applications: A Review. Polymers 2021. [Google Scholar] [CrossRef]

- Ao, D.; Tang, Y.; Xu, X.; Xiang, X.; Yu, J.; Li, S.; Zu, X. Highly Conductive PDMS Composite Mechanically Enhanced with 3D-Graphene Network for High-Performance EMI Shielding Application. Nanomaterials 2020, 10, 768. [Google Scholar] [CrossRef]

- Nguyen, V.-T.; Min, B.K.; Yi, Y.; Kim, S.J.; Choi, C.-G. MXene (Ti3C2TX)/graphene/PDMS composites for multifunctional broadband electromagnetic interference shielding skins. Chem. Eng. J. 2020, 393, 124608. [Google Scholar] [CrossRef]

- Cheng, K.; Xiong, W.; Li, Y.; Hao, L.; Yan, C.; Li, Z.; Liu, Z.; Wang, Y.; Essa, K.; Lee, L. In-situ deposition of three-dimensional graphene on selective laser melted copper scaffolds for high performance applications. Compos. Part A Appl. Sci. Manuf. 2020, 135, 105904. [Google Scholar] [CrossRef]

- Hou, S.; Ma, W.; Li, G.; Zhang, Y.; Ji, Y.; Fan, F.; Huang, Y. Excellent Terahertz shielding performance of ultrathin flexible Cu/graphene nanolayered composites with high stability. J. Mater. Sci. Technol. 2020, 52, 136–144. [Google Scholar] [CrossRef]

- Ji, K.; Zhao, H.; Huang, Z.; Dai, Z. Performance of open-cell foam of Cu–Ni alloy integrated with graphene as a shield against electromagnetic interference. Mater. Lett. 2014, 122, 244–247. [Google Scholar] [CrossRef]

- Khasim, S. Polyaniline-Graphene nanoplatelet composite films with improved conductivity for high performance X-band microwave shielding applications. Results Phys. 2019, 12, 1073–1081. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, X.; Zhang, W.; Luo, C.; Li, J. Synthesis of ferromagnetic sandwich FeCo@ graphene@ PPy and enhanced electromagnetic wave absorption properties. J. Magn. Magn. Mater. 2017, 443, 358–365. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, W.; Pan, Z.; Zhao, B. Graphene-doped polyaniline nanocomposites as electromagnetic wave absorbing materials. J. Mater. Sci. Mater. Electron. 2017, 28, 10921–10928. [Google Scholar] [CrossRef]

- Singh, A.P.; Mishra, M.; Sambyal, P.; Gupta, B.K.; Singh, B.P.; Chandra, A.; Dhawan, S. Encapsulation of γ-Fe2O3 decorated reduced graphene oxide in polyaniline core–shell tubes as an exceptional tracker for electromagnetic environmental pollution. J. Mater. Chem. A 2014, 2, 3581–3593. [Google Scholar] [CrossRef]

- Jia, Q.; Wang, W.; Zhao, J.; Xiao, J.; Lu, L.; Fan, H. Synthesis and characterization of TiO2/polyaniline/graphene oxide bouquet-like composites for enhanced microwave absorption performance. J. Alloys Compd. 2017, 710, 717–724. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Y.; Yip, M.; Tai, N. Electromagnetic interference shielding efficiency of polyaniline composites filled with graphene decorated with metallic nanoparticles. Compos. Sci. Technol. 2013, 80, 80–86. [Google Scholar] [CrossRef]

- Dar, M.A.; Majid, K.; Farukh, M.; Dhawan, S.; Kotnala, R.; Shah, J. Electromagnetic attributes a dominant factor for the enhanced EMI shielding of PANI/Li0. 5Fe2. 5−xGdxO4 core shell structured nanomaterial. Arab. J. Chem. 2019, 12, 5111–5119. [Google Scholar] [CrossRef]

- Chen, D.; Quan, H.; Huang, Z.; Luo, S.; Luo, X.; Deng, F.; Jiang, H.; Zeng, G. Electromagnetic and microwave absorbing properties of RGO@ hematite core–shell nanostructure/PVDF composites. Compos. Sci. Technol. 2014, 102, 126–131. [Google Scholar]

- Dalal, J.; Lather, S.; Gupta, A.; Tripathi, R.; Maan, A.S.; Singh, K.; Ohlan, A. Reduced Graphene Oxide Functionalized Strontium Ferrite in Poly (3, 4–ethylenedioxythiophene) Conducting Network: A High-Performance EMI Shielding Material. Adv. Mater. Technol. 2019, 4, 1900023. [Google Scholar] [CrossRef]

- Wu, S.; Zou, M.; Li, Z.; Chen, D.; Zhang, H.; Yuan, Y.; Pei, Y.; Cao, A. Robust and stable Cu Nanowire@ Graphene core–shell aerogels for ultraeffective electromagnetic interference shielding. Small 2018, 14, 1800634. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Wang, Y.; Ran, Q.; Fu, Q.; Gu, Y. Electromagnetic interference shielding property of polybenzoxazine/graphene/nickel composites. React. Funct. Polym. 2019, 143, 104324. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, X.; Wei, S.; Zhang, B.; Yu, M.; Zhao, W.; Liu, J. Fabrication of porous graphene-Fe3O4 hybrid composites with outstanding microwave absorption performance. Compos. Part A Appl. Sci. Manuf. 2017, 95, 237–247. [Google Scholar] [CrossRef]

- Yang, X.; Fan, S.; Li, Y.; Guo, Y.; Li, Y.; Ruan, K.; Zhang, S.; Zhang, J.; Kong, J.; Gu, J. Synchronously improved electromagnetic interference shielding and thermal conductivity for epoxy nanocomposites by constructing 3D copper nanowires/thermally annealed graphene aerogel framework. Compos. Part A Appl. Sci. Manuf. 2020, 128, 105670. [Google Scholar] [CrossRef]

- Tran, V.V.; Nguyen, D.D.; Nguyen, A.T.; Hofmann, M.; Hsieh, Y.-P.; Kan, H.-C.; Hsu, C.-C. Electromagnetic Interference Shielding by Transparent Graphene/Nickel Mesh Films. ACS Appl. Nano Mater. 2020, 3, 7474–7481. [Google Scholar] [CrossRef]

- Nimbalkar, P.; Korde, A.; Goyal, R. Electromagnetic interference shielding of polycarbonate/GNP nanocomposites in X-band. Mater. Chem. Phys. 2018, 206, 251–258. [Google Scholar] [CrossRef]

- Ma, Y.; Zhou, Y.; Xiong, Z.; Sun, Y.; Qi, C.; Zhang, Y.; Liu, Y. Facile synthesis of Fe3O4/PANI rod/rGO nanocomposites with giant microwave absorption bandwidth. J. Mater. Sci. Mater. Electron. 2019, 30, 4819–4830. [Google Scholar] [CrossRef]

- Guo, Z.; Ren, P.; Fu, B.; Ren, F.; Jin, Y.; Sun, Z. Multi-layered graphene-Fe3O4/poly (vinylidene fluoride) hybrid composite films for high-efficient electromagnetic shielding. Polym. Test. 2020, 89, 106652. [Google Scholar] [CrossRef]

- Xu, W.; Wang, G.-S.; Yin, P.-G. Designed fabrication of reduced graphene oxides/Ni hybrids for effective electromagnetic absorption and shielding. Carbon 2018, 139, 759–767. [Google Scholar] [CrossRef]

- Liu, P.; Huang, Y.; Yan, J.; Zhao, Y. Magnetic graphene@ PANI@ porous TiO2 ternary composites for high-performance electromagnetic wave absorption. J. Mater. Chem. C 2016, 4, 6362–6370. [Google Scholar] [CrossRef]

- Ni, J.; Zhan, R.; Qiu, J.; Fan, J.; Dong, B.; Guo, Z. Multi-interfaced graphene aerogel/polydimethylsiloxane metacomposites with tunable electrical conductivity for enhanced electromagnetic interference shielding. J. Mater. Chem. C 2020, 8, 11748–11759. [Google Scholar] [CrossRef]

- Sharma, D.; Menon, A.V.; Bose, S. Graphene templated growth of copper sulphide ‘flowers’ can suppress electromagnetic interference. Nanoscale Adv. 2020, 2, 3292–3303. [Google Scholar] [CrossRef]

- Hu, Z.; Ji, X.; Li, B.; Luo, Y. A self-assembled graphene/polyurethane sponge for excellent electromagnetic interference shielding performance. RSC Adv. 2019, 9, 25829–25835. [Google Scholar] [CrossRef]

- Wang, X.; Shu, J.-C.; He, X.-M.; Zhang, M.; Wang, X.-X.; Gao, C.; Yuan, J.; Cao, M.-S. Green approach to conductive PEDOT: PSS decorating magnetic-graphene to recover conductivity for highly efficient absorption. ACS Sustain. Chem. Eng. 2018, 6, 14017–14025. [Google Scholar] [CrossRef]

- Prasad, J.; Singh, A.K.; Haldar, K.K.; Tomar, M.; Gupta, V.; Singh, K. CoFe2O4 nanoparticles decorated MoS2-reduced graphene oxide nanocomposite for improved microwave absorption and shielding performance. RSC Adv. 2019, 9, 21881–21892. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, Q.; Gao, X.; Chen, X.; Shi, J.; Wu, J. Ellipsoidal Fe 3 O 4@ C nanoparticles decorated fluffy structured graphene nanocomposites and their enhanced microwave absorption properties. J. Mater. Sci. Mater. Electron. 2018, 29, 6785–6796. [Google Scholar] [CrossRef]

- Liu, L.; Bian, X.-M.; Hou, Z.-L.; Wang, C.-Y.; Li, Z.S.; Hu, H.D.; Qi, X.; Zhang, X. Electromagnetic response of magnetic graphene hybrid fillers and their evolutionary behaviors. J. Mater. Sci. Mater. Electron. 2016, 27, 2760–2772. [Google Scholar] [CrossRef]

- Yin, P.; Deng, Y.; Zhang, L.; Wu, W.; Wang, J.; Feng, X.; Sun, X.; Li, H.; Tao, Y. One-step hydrothermal synthesis and enhanced microwave absorption properties of Ni0. 5Co0. 5Fe2O4/graphene composites in low frequency band. Ceram. Int. 2018, 44, 20896–20905. [Google Scholar] [CrossRef]

- Chen, Y.; Pötschke, P.; Pionteck, J.; Voit, B.; Qi, H. Multifunctional Cellulose/rGO/Fe3O4 Composite Aerogels for Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2020, 12, 22088–22098. [Google Scholar] [CrossRef]

- Fang, H.; Guo, H.; Hu, Y.; Ren, Y.; Hsu, P.-C.; Bai, S.-L. In-situ grown hollow Fe3O4 onto graphene foam nanocomposites with high EMI shielding effectiveness and thermal conductivity. Compos. Sci. Technol. 2020, 188, 107975. [Google Scholar] [CrossRef]

- Yan, J.; Huang, Y.; Chen, X.; Wei, C. Conducting polymers-NiFe2O4 coated on reduced graphene oxide sheets as electromagnetic (EM) wave absorption materials. Synth. Met. 2016, 221, 291–298. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, A.K.; Tomar, M.; Gupta, V.; Kumar, P.; Singh, K. Electromagnetic interference shielding performance of lightweight NiFe2O4/rGO nanocomposite in X-band frequency range. Ceram. Int. 2020, 46, 15473–15481. [Google Scholar] [CrossRef]

- Jiang, S.; Qian, K.; Yu, K.; Zhou, H.; Weng, Y.; Zhang, Z. Controllable synthesis and microwave absorption properties of Fe3O4@ f-GNPs nanocomposites. Compos. Commun. 2020, 20, 100363. [Google Scholar] [CrossRef]

- Liu, G.; Jiang, W.; Wang, Y.; Zhong, S.; Sun, D.; Liu, J.; Li, F. One-pot synthesis of Ag@ Fe3O4/reduced graphene oxide composite with excellent electromagnetic absorption properties. Ceram. Int. 2015, 41, 4982–4988. [Google Scholar] [CrossRef]

- Zhang, H.; Jia, Z.; Feng, A.; Zhou, Z.; Chen, L.; Zhang, C.; Liu, X.; Wu, G. In situ deposition of pitaya-like Fe3O4@ C magnetic microspheres on reduced graphene oxide nanosheets for electromagnetic wave absorber. Compos. Part B Eng. 2020, 199, 108261. [Google Scholar] [CrossRef]

- Fei, Y.; Liang, M.; Chen, Y.; Zou, H. Sandwich-like Magnetic Graphene Papers Prepared with MOF-Derived Fe3O4–C for Absorption-Dominated Electromagnetic Interference Shielding. Ind. Eng. Chem. Res. 2020, 59, 154–165. [Google Scholar] [CrossRef]

- Jeon, S.; Kim, J.; Kim, K.H. Microwave absorption properties of graphene oxide capsulated carbonyl iron particles. Appl. Surf. Sci. 2019, 475, 1065–1069. [Google Scholar] [CrossRef]

- Sharif, F.; Arjmand, M.; Moud, A.A.; Sundararaj, U.; Roberts, E.P. Segregated hybrid poly (methyl methacrylate)/graphene/magnetite nanocomposites for electromagnetic interference shielding. Acs Appl. Mater. Interfaces 2017, 9, 14171–14179. [Google Scholar] [CrossRef] [PubMed]

- Guo, T.; Li, C.; Wang, Y.; Wang, Y.; Yue, J.; Tang, X.-Z. A highly flexible and porous graphene-based hybrid film with superior mechanical strength for effective electromagnetic interference shielding. Appl. Phys. A 2020, 126, 1–8. [Google Scholar] [CrossRef]

- Liang, C.; Hamidinejad, M.; Ma, L.; Wang, Z.; Park, C.B. Lightweight and flexible graphene/SiC-nanowires/poly (vinylidene fluoride) composites for electromagnetic interference shielding and thermal management. Carbon 2020, 156, 58–66. [Google Scholar] [CrossRef]

- Sabira, K.; Jayakrishnan, M.; Saheeda, P.; Jayalekshmi, S. On the absorption dominated EMI shielding effects in free standing and flexible films of poly (vinylidene fluoride)/graphene nanocomposite. Eur. Polym. J. 2018, 99, 437–444. [Google Scholar] [CrossRef]

- Hong, S.Y.; Kim, Y.C.; Wang, M.; Nam, J.-D.; Suhr, J. Anisotropic electromagnetic interference shielding properties of polymer-based composites with magnetically-responsive aligned Fe3O4 decorated reduced graphene oxide. Eur. Polym. J. 2020, 127, 109595. [Google Scholar] [CrossRef]

- Zubair, K.; Shakir, M.F.; Afzal, A.; Rehan, Z.; Nawab, Y. Effect of Barium Hexaferrites and Thermally Reduced Graphene Oxide on EMI Shielding Properties in Polymer Composites. J. Supercond. Nov. Magn. 2020, 34, 201–210. [Google Scholar] [CrossRef]

- Rao, B.B.; Yadav, P.; Aepuru, R.; Panda, H.; Ogale, S.; Kale, S. Single-layer graphene-assembled 3D porous carbon composites with PVA and Fe3O4 nano-fillers: An interface-mediated superior dielectric and EMI shielding performance. Phys. Chem. Chem. Phys. 2015, 17, 18353–18363. [Google Scholar] [PubMed]

- Qi, Q.; Ma, L.; Zhao, B.; Wang, S.; Liu, X.; Lei, Y.; Park, C.B. An effective design strategy for the sandwich structure of PVDF/GNP-Ni-CNT composites with remarkable electromagnetic interference shielding effectiveness. ACS Appl. Mater. Interfaces 2020, 12, 36568–36577. [Google Scholar] [CrossRef] [PubMed]

- Shakir, M.F.; Khan, A.N.; Khan, R.; Javed, S.; Tariq, A.; Azeem, M.; Riaz, A.; Shafqat, A.; Cheema, H.M.; Akram, M.A. EMI shielding properties of polymer blends with inclusion of graphene nano platelets. Results Phys. 2019, 14, 102365. [Google Scholar] [CrossRef]

- Bera, R.; Das, A.K.; Maitra, A.; Paria, S.; Karan, S.K.; Khatua, B.B. Salt leached viable porous Fe3O4 decorated polyaniline–SWCNH/PVDF composite spectacles as an admirable electromagnetic shielding efficiency in extended Ku-band region. Compos. Part B Eng. 2017, 129, 210–220. [Google Scholar] [CrossRef]

- Bansala, T.; Joshi, M.; Mukhopadhyay, S.; Doong, R.-A.; Chaudhary, M. Electrically conducting graphene-based polyurethane nanocomposites for microwave shielding applications in the Ku band. J. Mater. Sci. 2017, 52, 1546–1560. [Google Scholar] [CrossRef]

- Jaiswal, R.; Agarwal, K.; Kumar, R.; Kumar, R.; Mukhopadhyay, K.; Prasad, N.E. EMI and microwave absorbing efficiency of polyaniline-functionalized reduced graphene oxide/γ-Fe2O3/epoxy nanocomposite. Soft Matter 2020, 16, 6643–6653. [Google Scholar] [CrossRef] [PubMed]

- Sambyal, P.; Dhawan, S.; Gairola, P.; Chauhan, S.S.; Gairola, S. Synergistic effect of polypyrrole/BST/RGO/Fe3O4 composite for enhanced microwave absorption and EMI shielding in X-Band. Curr. Appl. Phys. 2018, 18, 611–618. [Google Scholar] [CrossRef]

- Dalal, J.; Lather, S.; Gupta, A.; Dahiya, S.; Maan, A.; Singh, K.; Dhawan, S.; Ohlan, A. EMI shielding properties of laminated graphene and PbTiO3 reinforced poly (3, 4-ethylenedioxythiophene) nanocomposites. Compos. Sci. Technol. 2018, 165, 222–230. [Google Scholar] [CrossRef]

- Shukla, V. Role of spin disorder in magnetic and EMI shielding properties of Fe3O4/C/PPy core/shell composites. J. Mater. Sci. 2020, 55, 2826–2835. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, X.; Zhang, W.; Luo, C.; Li, J.; Wang, Q. 3D heterostructure of graphene@ Fe3O4@ WO3@ PANI: Preparation and excellent microwave absorption performance. Synth. Met. 2017, 231, 7–14. [Google Scholar] [CrossRef]

- Wang, Z.; Cheng, Z.; Xie, L.; Hou, X.; Fang, C. Flexible and lightweight Ti3C2Tx MXene/Fe3O4@ PANI composite films for high-performance electromagnetic interference shielding. Ceram. Int. 2020. [Google Scholar] [CrossRef]

- Liu, H.; Liang, C.; Chen, J.; Huang, Y.; Cheng, F.; Wen, F.; Xu, B.; Wang, B. Novel 3D network porous graphene nanoplatelets/Fe3O4/epoxy nanocomposites with enhanced electromagnetic interference shielding efficiency. Compos. Sci. Technol. 2019, 169, 103–109. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, H.-B.; Huang, Y.; Jiang, Y.; Zheng, W.-G.; Yu, Z.-Z. Magnetic and electrically conductive epoxy/graphene/carbonyl iron nanocomposites for efficient electromagnetic interference shielding. Compos. Sci. Technol. 2015, 118, 178–185. [Google Scholar] [CrossRef]

- Preeti, S.; Dhawan, S.K.; Singh, A.P.; Singh, K.; Ohlan, A. Nano-ferrite and Reduced Graphene Oxide Embedded in Polyaniline Matrix for EMI Shielding Applications. Composites 2016, 12, 16. [Google Scholar]

- Gargama, H.; Thakur, A.; Chaturvedi, S. Polyvinylidene fluoride/nanocrystalline iron composite materials for EMI shielding and absorption applications. J. Alloys Compd. 2016, 654, 209–215. [Google Scholar] [CrossRef]

- Zdrojek, M.; Bomba, J.; Łapińska, A.; Dużyńska, A.; Żerańska-Chudek, K.; Suszek, J.; Stobiński, L.; Taube, A.; Sypek, M.; Judek, J. Graphene-based plastic absorber for total sub-terahertz radiation shielding. Nanoscale 2018, 10, 13426–13431. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Zhu, J.; Yang, H.; Wang, F.; Qin, Y.; Zhao, T.; Zhang, P. Fabrication of hierarchical graphene@ Fe3O4@ SiO2@ polyaniline quaternary composite and its improved electrochemical performance. J. Alloys Compd. 2015, 634, 232–238. [Google Scholar] [CrossRef]

- Hamidinejad, M.; Zhao, B.; Zandieh, A.; Moghimian, N.; Filleter, T.; Park, C.B. Enhanced electrical and electromagnetic interference shielding properties of polymer–graphene nanoplatelet composites fabricated via supercritical-fluid treatment and physical foaming. ACS Appl. Mater. Interfaces 2018, 10, 30752–30761. [Google Scholar] [CrossRef] [PubMed]

- Lu, S.; Bai, Y.; Wang, J.; Chen, D.; Ma, K.; Meng, Q.; Liu, X. Flexible GnPs/EPDM with excellent thermal conductivity and electromagnetic interference shielding properties. Nano 2019, 14, 1950075. [Google Scholar] [CrossRef]

- Liang, L.; Xu, P.; Wang, Y.; Shang, Y.; Ma, J.; Su, F.; Feng, Y.; He, C.; Wang, Y.; Liu, C. Flexible polyvinylidene fluoride film with alternating oriented graphene/Ni nanochains for electromagnetic interference shielding and thermal management. Chem. Eng. J. 2020, 395, 125209. [Google Scholar] [CrossRef]

- Vovchenko, L.L.; Lozitsky, O.; Oliynyk, V.; Zagorodnii, V.; Len, T.; Matzui, L.; Milovanov, Y.S. Dielectric and microwave shielding properties of three-phase composites graphite nanoplatelets/carbonyl iron/epoxy resin. Appl. Nanosci. 2020, 10, 4781–4790. [Google Scholar] [CrossRef]

- Zhao, J.; Lin, J.; Xiao, J.; Fan, H. Synthesis and electromagnetic, microwave absorbing properties of polyaniline/graphene oxide/Fe 3 O 4 nanocomposites. RSC Adv. 2015, 5, 19345–19352. [Google Scholar] [CrossRef]

- Li, M.; Yang, K.; Zhu, W.; Shen, J.; Rollinson, J.; Hella, M.; Lian, J. Copper-Coated Reduced Graphene Oxide Fiber Mesh-Polymer Composite Films for Electromagnetic Interference Shielding. ACS Appl. Nano Mater. 2020, 3, 5565–5574. [Google Scholar] [CrossRef]

- Wu, J.; Ye, Z.; Ge, H.; Chen, J.; Liu, W.; Liu, Z. Modified carbon fiber/magnetic graphene/epoxy composites with synergistic effect for electromagnetic interference shielding over broad frequency band. J. Colloid Interface Sci. 2017, 506, 217–226. [Google Scholar] [CrossRef] [PubMed]

- Sawai, P.; Chattopadhaya, P.; Banerjee, S. Synthesized reduce Graphene Oxide (rGO) filled Polyetherimide based nanocomposites for EMI Shielding applications. Mater. Today: Proc. 2018, 5, 9989–9999. [Google Scholar] [CrossRef]

- Khodiri, A.A.; Al-Ashry, M.Y.; El-Shamy, A.G. Novel hybrid nanocomposites based on polyvinyl alcohol/graphene/magnetite nanoparticles for high electromagnetic shielding performance. J. Alloys Compd. 2020, 847, 156430. [Google Scholar] [CrossRef]

- Shahzad, F.; Lee, S.H.; Hong, S.M.; Koo, C.M. Segregated reduced graphene oxide polymer composite as a high performance electromagnetic interference shield. Res. Chem. Intermed. 2018, 44, 4707–4719. [Google Scholar] [CrossRef]

- Joseph, J.; Koroth, A.K.; John, D.A.; Sidpara, A.M.; Paul, J. Highly filled multilayer thermoplastic/graphene conducting composite structures with high strength and thermal stability for electromagnetic interference shielding applications. J. Appl. Polym. Sci. 2019, 136, 47792. [Google Scholar] [CrossRef]

- Yadav, R.S.; Kuřitka, I.; Vilčáková, J.; Machovský, M.; Škoda, D.; Urbánek, P.; Masař, M.; Gořalik, M.; Urbánek, M.; Kalina, L. Polypropylene nanocomposite filled with spinel ferrite NiFe2O4 nanoparticles and in-situ thermally-reduced graphene oxide for electromagnetic interference shielding application. Nanomaterials 2019, 9, 621. [Google Scholar] [CrossRef]

- Li, S.; Li, W.; Nie, J.; Liu, D.; Sui, G. Synergistic effect of graphene nanoplate and carbonized loofah fiber on the electromagnetic shielding effectiveness of PEEK-based composites. Carbon 2019, 143, 154–161. [Google Scholar] [CrossRef]

- Zuo, Y.; Su, X.; Li, X.; Yao, Z.; Yu, T.; Zhou, J.; Li, J.; Lu, J.; Ding, J. Multimaterial 3D-Printing of Graphene/Li0.35 Zn0.3Fe2.35O4 and graphene/carbonyl iron composites with superior microwave absorption properties and adjustable bandwidth. Carbon 2020, 167, 62–74. [Google Scholar] [CrossRef]

- Sur, U.K. Graphene: A Rising Star on the Horizon of Materials Science. Int. J. Electrochem. 2012, 2012, 1–12. [Google Scholar] [CrossRef]

- Hansora, D.; Shimpi, N.; Mishra, S. Graphite to graphene via graphene oxide: An overview on synthesis, properties, and applications. Jom 2015, 67, 2855–2868. [Google Scholar] [CrossRef]

- Wohlford, T.; Schaaf, J.; Taylor, L.; Furtsch, T.; Khor, E.; St. Clair, A.; Seymour, R. Conductive Polymers. In Plenum, New York; Springer: Boston, MA, USA, 1981. [Google Scholar]

- Yasufuku, S. Technical progress of EMI shielding materials in Japan. IEEE Electr. Insul. Mag. 1990, 6, 21–30. [Google Scholar] [CrossRef]

- Chandra, R.J.; Shivamurthy, B.; Kulkarni, S.D.; Kumar, M.S. Hybrid polymer composites for EMI shielding application—A review. Mater. Res. Express 2019, 6, 082008. [Google Scholar] [CrossRef]

- Luo, X.; Chung, D. Electromagnetic interference shielding using continuous carbon-fiber carbon-matrix and polymer-matrix composites. Compos. Part B Eng. 1999, 30, 227–231. [Google Scholar] [CrossRef]

- Mannodi-Kanakkithodi, A.; Chandrasekaran, A.; Kim, C.; Huan, T.D.; Pilania, G.; Botu, V.; Ramprasad, R. Scoping the polymer genome: A roadmap for rational polymer dielectrics design and beyond. Mater. Today 2018, 21, 785–796. [Google Scholar] [CrossRef]

- Sanchez-Lengeling, B.; Aspuru-Guzik, A. Inverse molecular design using machine learning: Generative models for matter engineering. Science 2018, 361, 360–365. [Google Scholar] [CrossRef] [PubMed]

- Butler, K.T.; Davies, D.W.; Cartwright, H.; Isayev, O.; Walsh, A. Machine learning for molecular and materials science. Nature 2018, 559, 547–555. [Google Scholar] [CrossRef]

- Hamidi, Y.K.; Berrado, A.; Altan, M.C. Machine learning applications in polymer composites. In Proceedings of the 35th International Conference Of The Polymer Processing Society (PPS-35), Cesme-Izmir, Turkey, 26–30 May 2019; AIP Publishing: Oslo, Norway, 2020; Volume 2205, p. 020031. [Google Scholar]

- Wu, S.; Kondo, Y.; Kakimoto, M.-a.; Yang, B.; Yamada, H.; Kuwajima, I.; Lambard, G.; Hongo, K.; Xu, Y.; Shiomi, J. Machine-learning-assisted discovery of polymers with high thermal conductivity using a molecular design algorithm. NPJ Comput. Mater. 2019, 5, 1–11. [Google Scholar] [CrossRef]

- Kim, C.; Batra, R.; Chen, L.; Tran, H.; Ramprasad, R. Polymer design using genetic algorithm and machine learning. Comput. Mater. Sci. 2021, 186, 110067. [Google Scholar] [CrossRef]

- Venkatram, S.; Batra, R.; Chen, L.; Kim, C.; Shelton, M.; Ramprasad, R. Predicting crystallization tendency of polymers using multifidelity information fusion and machine learning. J. Phys. Chem. B 2020, 124, 6046–6054. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Kim, C.; Batra, R.; Lightstone, J.P.; Wu, C.; Li, Z.; Deshmukh, A.A.; Wang, Y.; Tran, H.D.; Vashishta, P. Frequency-dependent dielectric constant prediction of polymers using machine learning. NPJ Comput. Mater. 2020, 6, 1–9. [Google Scholar] [CrossRef]

- Sharma, V.; Wang, C.; Lorenzini, R.G.; Ma, R.; Zhu, Q.; Sinkovits, D.W.; Pilania, G.; Oganov, A.R.; Kumar, S.; Sotzing, G.A. Rational design of all organic polymer dielectrics. Nat. Commun. 2014, 5, 1–8. [Google Scholar] [CrossRef]

- Huan, T.D.; Mannodi-Kanakkithodi, A.; Ramprasad, R. Accelerated materials property predictions and design using motif-based fingerprints. Phys. Rev. B 2015, 92, 014106. [Google Scholar] [CrossRef]

- d’Avezac, M.; Luo, J.-W.; Chanier, T.; Zunger, A. Genetic-algorithm discovery of a direct-gap and optically allowed superstructure from indirect-gap Si and Ge semiconductors. Phys. Rev. Lett. 2012, 108, 027401. [Google Scholar] [CrossRef] [PubMed]

- Mannodi-Kanakkithodi, A.; Pilania, G.; Huan, T.D.; Lookman, T.; Ramprasad, R. Machine learning strategy for accelerated design of polymer dielectrics. Sci. Rep. 2016, 6, 1–10. [Google Scholar] [CrossRef]

- Zhou, T.; Song, Z.; Sundmacher, K. Big data creates new opportunities for materials research: A review on methods and applications of machine learning for materials design. Engineering 2019, 5, 1017–1026. [Google Scholar] [CrossRef]

- Tian, H.; Zhao, Y.; Kang, L.; Shang, Y.; Liu, X. Electromagnetic Interference Diagnosis Based on HPLC Timing Sequence Topology and Machine Learning. In Proceedings of IOP Conference Series: Earth and Environmental Science; IOP: NewYork, NY, USA, 2019; Volume 375, p. 052015. [Google Scholar]

- Eliardsson, P.; Stenumgaard, P. Artificial Intelligence for Automatic Classification of Unintentional Electromagnetic Interference in Air Traffic Control Communications. In Proceedings of the 2019 International Symposium on Electromagnetic Compatibility-EMC EUROPE, Barcelona, Spain, 2–6 September 2019; pp. 896–901. [Google Scholar]

- Wei, X.; Shu, Y.; Hu, Z.; Zhong, Y.; Wang, Y. A Summary of Artificial Neural Networks on Electromagnetic Interference Diagnosis. In Proceedings of the 2019 International Conference on Microwave and Millimeter Wave Technology (ICMMT), Guangzhou, China, 19–22 May 2019; pp. 1–3. [Google Scholar]

- Shu, Y.-F.; Wei, X.-C.; Fan, J.; Yang, R.; Yang, Y.-B. An equivalent dipole model hybrid with artificial neural network for electromagnetic interference prediction. IEEE Trans. Microw. Theory Tech. 2019, 67, 1790–1797. [Google Scholar] [CrossRef]

- Hu, Z.-K.; Zhong, Y.-H.; Wei, X.-C.; Wang, Y.-W.; Shu, Y.-F. A Novel Electromagnetic Interference Source Reconstruction Method based on Artificial Neural Network. In Proceedings of the 2018 12th International Symposium on Antennas, Propagation and EM Theory (ISAPE), Hangzhou, China, 3–6 December 2018; pp. 1–4. [Google Scholar]

- Yan, L.; Zhao, X.; Zhao, H.; Zhou, H.; Huang, K. Artificial neural network modeling of electromagnetic interference caused by nonlinear devices inside a metal enclosure. J. Electromagn. Waves Appl. 2015, 29, 992–1004. [Google Scholar] [CrossRef]

- Ellithy, K.; Al-Badi, A.; Al-Alawi, S. An artificial neural network model for predicting electromagnetic interference effects on gas pipelines built in power lines row. Eng. Intell. Syst. 2004, 12, 229–235. [Google Scholar]

- Zhou, C.; Wang, Z.; Liu, T.; Zhao, S.; Liang, Z. Low dropout linear regulator’s electromagnetic interference damage model based on BP neural network. High Volt. Eng. 2016, 42, 973–979. [Google Scholar]

- Qishuang, Y.T.M.; Qingming, X. Prediction of electromagnetic interference based on neural network. J. Beijing Univ. Aeronaut. Astronaut. 2013, 5, 152–158. [Google Scholar]

- Li, H.; Zhao, D.; Xu, S.; Wang, P.; Chen, J. High Dimensional Electromagnetic Interference Signal Clustering Based On SOM Neural Network. Electronics 2016, 20, 27–31. [Google Scholar] [CrossRef][Green Version]

- Masugi, M. Self-organizing neural network-based analysis of electrostatic discharge for electromagnetic interference assessment. IEICE Trans. Commun. 2003, 86, 1991–2000. [Google Scholar]

- Micu, D.D.; Czumbil, L.; Christoforidis, G.; Simion, E. Neural networks applied in electromagnetic interference problems. Rev. Roum. Sci. Tech. Ser. Electrotech. Energetique 2012, 57, 162–171. [Google Scholar]

- Micu, D.D.; Czumbil, L.; Christoforidis, G.; Ceclan, A. Layer recurrent neural network solution for an electromagnetic interference problem. IEEE Trans. Magn. 2011, 47, 1410–1413. [Google Scholar] [CrossRef]

- Micu, D.D.; Czumbil, L.; Ceclan, A.; Darabant, L.; Stet, D.; Christoforidis, G. Electromagnetic interferences between HV power lines and metallic pipelines evaluated with neural network technique. In Proceedings of the 2009 10th International Conference on Electrical Power Quality and Utilisation, Lodz, Poland, 15–17 September 2009; pp. 1–5. [Google Scholar]

- Micu, D.D.; Czumbil, L.; Ceclan, A.; Simion, E.; Stet, D.; Cîmpan, L. Neural Network Evaluation of Electromagnetic Interferences between HV Power Lines and Underground Metallic Pipelines. J. Electr. Electron. Eng. 2009, 1, 73. [Google Scholar]

- Czumbil, L.; Micu, D.; Ceclan, A. Artificial Intelligence Techniques Applied to Electromagnetic Interference Problems. In Proceedings of the International Conference on Advancements of Medicine and Health Care through Technology, Paraná, Argentina, 29–31 October 2014; pp. 339–344. [Google Scholar]

- Micu, D.D.; Czumbil, L.; Polycarpou, A.; Ceclan, A.; Cimpan, L. Analysis of electromagnetic interference problems proposed to be through an innovative Monte Carlo-Neural Network method. In Proceedings of the 7th Mediterranean Conference and Exhibition on Power Generation, Transmission, Distribution and Energy Conversion (MedPower 2010), Agia Napa, Cyprus, 7–10 November 2010; pp. 1–6. [Google Scholar]

- Micu, D.D.; Czumbil, L.; Christoforidis, G.; Ceclan, A. Proposed Monte Carlo-Neural Network method for solving electromagnetic interference problems. In Proceedings of the 45th International Universities Power Engineering Conference UPEC2010, Cardiff, UK, 31 August–3 September 2010; pp. 1–6. [Google Scholar]

- Mosavi, A.; Rabczuk, T.; Varkonyi-Koczy, A.R. Reviewing the novel machine learning tools for materials design. In International Conference on Global Research and Education; Springer: Cham, Switzerland, September 2017; pp. 50–58. [Google Scholar]

- Mosavi, A.; Rabczuk, T. Learning and intelligent optimization for material design innovation. In International Conference on Learning and Intelligent Optimization; Springer: Cham, Switzerland, June 2017; pp. 358–363. [Google Scholar]

| S. No | Method | Reference | Remarks | Advantage | Disadvantage |

|---|---|---|---|---|---|

| 1 | Chemical vapor deposition | [25,26,27] | A deposition process performed at high temperature and gas pressure and provides better optical and electrical properties in graphene-based composites. |

|

|

| 2 | Alternating deposition | [28] | Need further exploration. | ||

| 3 | Electrophoretic deposition | [29] | Most used process for material coating |

|

|

| 4 | In situ growth | [30,31,32,33,34,35,36,37,38,39,40,41] | This technique is a novel way to implant graphene layers on metal without any damage to graphene. However, structural control by this technique needs further investigation. |

|

|

| 5 | Thermal annealing method | [42,43] | This thermal annealing method used to modify the surface morphology of materials with temperature and time. It is a mostly useable method for intrinsic, structure improving and surface roughness control in materials and is well used for stress liberation. |

|

|

| 6 | Facile synthetic route | [44,45,46,47] | Mostly a commonly used method to synthesize porous structures. |

|

|

| 7 | Hydrothermal method | [41,48,49,50,51,52,53,54,55,56] | Involves substance crystallization at high temperature and pressure. |

|

|

| 8 | Scalable method | [57] | Need further exploration. | ||

| 9 | Solvothermal method | [58,59,60,61,62,63] | This technique is used to form a chemical composite. The benefit of using this technique is that it involves the usage of sol-gel and hydrothermal routes, providing precise control over the shape, size and crystallinity of composites. |

|

|

| 10 | Filtration-assisted self-assembly method | [64] | Need further exploration. | ||

| 11 | Wet stirring process | [65] | A simple technique of stirring which deals with homogenous mixing of liquids and stir up the solid particle into liquid by using water as a solvent. |

|

|

| 12 | Self-assembly technique | [54,66] | In this method without using any external direction among components the disordered system and pre-existing components make it to an organized structure or pattern, it is a low-cost approach for nanofabrication. |

|

|

| 13 | Vacuum-assisted filtration method | [67] | Need further exploration. | ||

| 14 | Solution processing method | [68,69,70,71,72,73,74,75,76,77] | A promising method to produce low-cost composites. This method is used mostly in organic materials such as polymer-based composites. It is used in different ways through high-speed shear mixing, ultrasonication and as well stirring for the formation of polymer nanocomposites where the mixing depends on the solvent. A good dispersion of carbon nanofiller in polymer matrixes can also be achieved. |

|

|

| 15 | Chemical oxidative polymerization | [78,79,80,81] | In this method, oxidizing agents are used to forming a polymer-based composite. |

|

|

| 16 | Co-precipitation method | [82,83] | Used to synthesized iron nanoparticles. |

|

|

| 17 | Centrifugal mixing method | [84] | Need further exploration. | ||

| 18 | Citrate precursor method | [85] | A chelate-based method that is efficient to reduce the metal ions for nanoparticles fabrication and also stimulate reaction conditions. |

|

|

| 19 | Chemical reduction | [15] | A cost-effective method and widely used in for mass production of reduced graphene oxide in which reduction agent used in the form of gas or liquid in graphene oxide for the elimination of functional group. |

|

|

| 20 | Hot-molding process | [86] | This process is useful for adding thermoplastic binders to the metallic and ceramic powder to make it fluent. In all this process temperature used above then the melting point. |

|

|

| 21 | Mechanical mixing | [87] | Used to form a uniform coat of the particles on the material surface where pellets are followed by a cooling process. |

|

|

| 22 | Dilute polymerization | [88] | Need further exploration. | ||

| 23 | High-pressure solid-phase compression molding | [88] | An old material processing technique. In industrial methods which are used for plastic, it was a commonly used method. |

|

|

| 24 | Injection molding process | [89] | A high volume and low-pressure process which is performed with filled thermoplastics. |

|

|

| 25 | Ultrasonication technique | [90,91,92] | A technique used for the preparation of nanoparticles. It has good control over the structure of the material. Moreover, with this technique the size of a previously formed composite can also be reduced. |

|

|

| 26 | Hummer’s method | [93,94,95,96,97] | A chemical process mostly used to produce graphene from graphite. |

|

|

| 27 | Hot compressed method | [14,98,99,100,101] | The hot compression method cannot work at room temperature like the cold compression method as it takes place by applying heat to the mold. |

|

|

| 28 | 3D printing method | [102] | A new method to form a shielding material followed by Object’s PolyJet Matric printing technology, where a couple of materials are built simultaneously. |

|

|

| S. No | Method | Material Composite | SE (dB) | Frequency | Reference |

|---|---|---|---|---|---|

| 1 | Chemical vapor deposition | 3DG/Cu | 32.3 | Ku-band | [27] |

| 3D Graphene Network@PDMS | 90 | X-band | [25] | ||

| MXene(Ti3C2TX)/graphene/PDMS | 80 | X-band | [26] | ||

| 77 | Ka-band | ||||

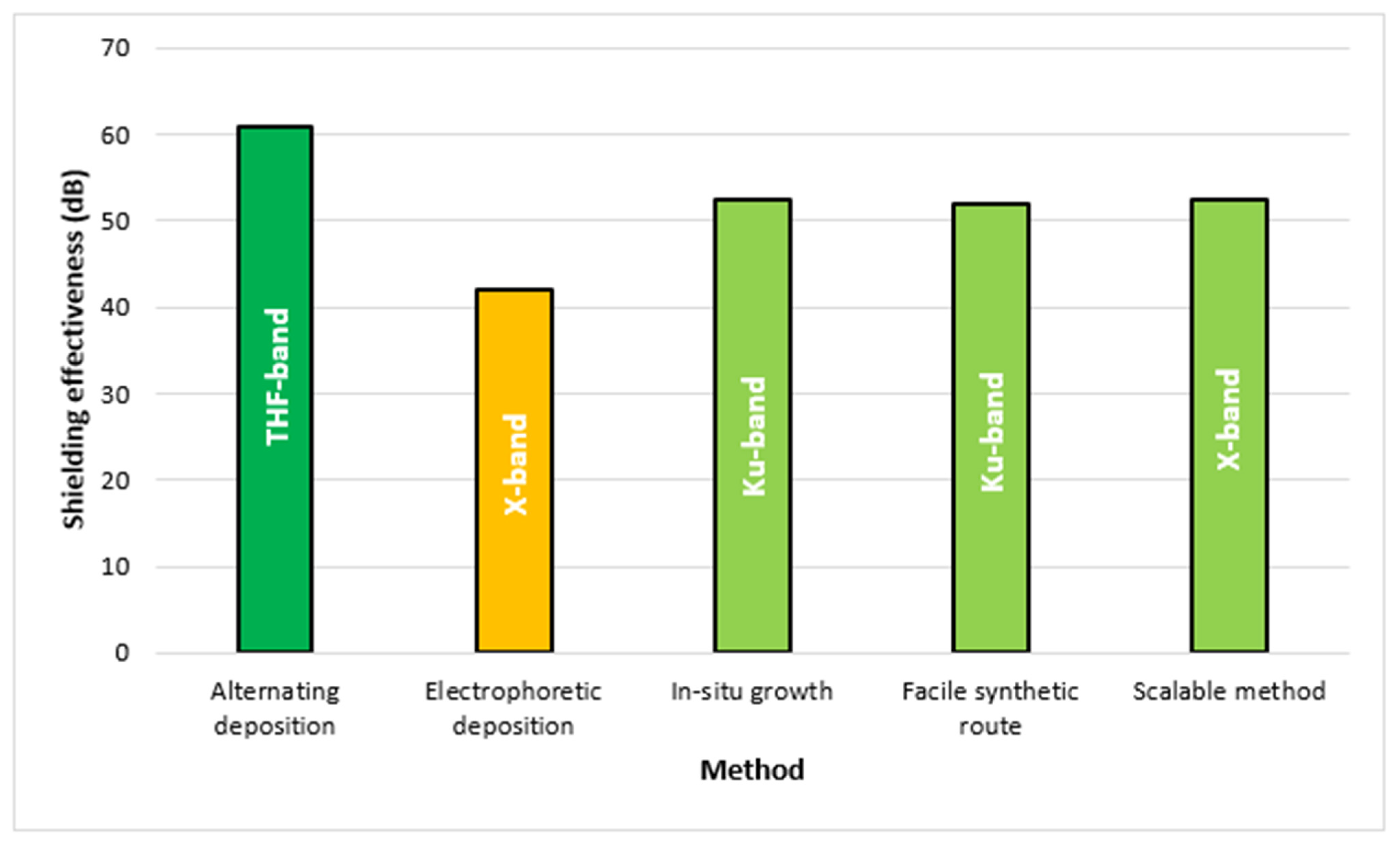

| 2 | Alternating deposition | Cu/Gr | 60.95 | THF-band | [28] |

| 3 | Electrophoretic deposition | Cu–Ni–GNS | 42 | X-band | [29] |

| 4 | In situ growth | CuNW@G | 52.5 | Ku-band | [39] |

| GNP@PANI | −14.5 | X-band | [30] | ||

| Graphene@NiO@PANI@Ag | −37.5 | Ku-band | [31] | ||

| TiO2/PANI/GO | −51.7 | Ku-band | [34] | ||

| Ag@Graphene/PANI | 29.33 | L-band | [35] | ||

| PANI/Li0.5Fe0.5−xGdxO4 | 42 | X-band | [36] | ||

| RGO@Hematite/PVDF | −43.97 | Ku-band | [37] | ||

| γ-Fe2O3/RGO/PANI | 51 | X-band | [33] | ||

| PEDOT/RGO/SrFe12O19 | 62 | X-band | [38] | ||

| FeCo@RGO@PPy | −40.7 | Ku-band | [31] | ||

| Graphene/Ni | 20 | X-band | [40] | ||

| PG-Fe3O4 | −53 | C-band | [41] | ||

| G-PANI | 32.5 | Ku-band | [32] | ||

| 5 | Thermal annealing method | Graphene/Ni hybrid mesh | 26.6 | UHF-band | [43] |

| CuNWs-TAGA/Epoxy | 47 | X-band | [42] | ||

| 6 | Facile synthetic route | RGO/Ni hybrid | 52 | Ku-band | [47] |

| Polycarbonate/GNP | 47 | X-band | [44] | ||

| Fe3O4/PANI rod/RGO | −33.3 | Ku-band | [45] | ||

| GNSs-Fe3O4/PVDF | 52 | X-band | [46] | ||

| 7 | Hydrothermal method | ZnFe2O4@graphene@TiO2 | −55 | S-band | [41] |

| MoS2-RGO/CoFe2O4 | 19.26 | X-band | [53] | ||

| Fe3O4@C@Graphene | −55.02 | Ku-band | [54] | ||

| G-F | 20 | Ku-band | [55] | ||

| Ni0.5Co0.5Fe2O4/graphene | −30.92 | L-band | [56] | ||

| Graphene@PANI@TiO2 | −45.4 | Ku-band | [48] | ||

| GA/PDMS | 60 | Ku-band | [49] | ||

| RGO@CuS@PVDF | −25 | Ku-band | [50] | ||

| G/Polyurethane sponge | 35 | X-band | [51] | ||

| PEDOT:PSS-Fe3O4-RGO | −61.4 | Ku-band | [52] | ||

| 8 | Scalable method | Cellulose/reduced graphene oxide (RGO)/Fe3O4 aerogels | 52.4 | X-band | [57] |

| 9 | Solvothermal method | NiFe2O4/RGO | 38.2 | X-band | [60] |

| Fe3O4@f-GNPs | 25 | X-band | [61] | ||

| Ag@Fe3O4@RGO | −40.05 | Ku-band | [62] | ||

| Fe3O4@C/RGO | −59.23 | Ku-band | [63] | ||

| Hollow Fe3O4@GF@PDMS | 70.3 | X-band | [58] | ||

| RGO-PEDOT-NiFe2O4 | −45.4 | Ku-band | [59] | ||

| RGO-PANI-NiFe2O4 | −49.7 | ||||

| RGO-PPy-NiFe2O4 | −44.8 | ||||

| 10 | Filtration-assisted self-assembly method | Fe3O4-C, C-MIL-88B/GNP | 28 | X-band | [64] |

| 11 | Wet stirring process | GO@CIP | −56.4 | Ku-band | [65] |

| 12 | Self-assembly method | NRMG | 26.4 | X-band | |

| PMMA/RGO | 63.2 | X-band | [66] | ||

| 13 | Vacuum-assisted filtration method | RGO/CNF@Ag-Fe3O4 | 21 | X-band | [67] |

| 14 | Solution processing method | PVC/PANI/GNP | 51 | K-band | [74] |

| Gn/SiCnw/PVDF | 32.5 | X-band | [68] | ||

| PVDF/graphene | 47 | X-band | [69] | ||

| Fe3O4@RGO/TPU | ~15.51 ± 1.6 | X-band | [70] | ||

| BaFe@TRGO@TPU | −61 | K-band | [71] | ||

| Fe3O4@SLGAPC@PVA | 20 | X-band | [72] | ||

| PVDF/GNP-Ni-CNT | 46.4 | Ku-band | [73] | ||

| PVDF/PFC | −29.7 | Ku-band | [75] | ||

| TPU/TRG | 32 | Ku-band | [76] | ||

| 15 | Chemical oxidative polymerization | Graphene@Fe3O4@PANI@WO3 | −46.7 | X-band | [81] |

| PEDOT/RGO/PbTiO3 | 51.94 | Ku-band | [79] | ||

| Fe3O4/C:PPy | >28 | C-band | [80] | ||

| Polypyrrole/BST/RGO/Fe3O4 | 48 | X-band | [78] | ||

| 16 | Co-precipitation method | Ti3C2Tx/Fe3O4@PANI | 58.8 | X-band | [82] |

| GNP/Fe3O4/Epoxy | 37.03 | X-band | [83] | ||

| 17 | Centrifugal mixing method | TGO/CI/Epoxy | 40 | X-band | [84] |

| 18 | Citrate precursor method | PANI/BF/RGO | 31.1 | X-band | [85] |

| 19 | Chemical reduction | RGO-CF/EP | 37.6 | X-band | [15] |

| 20 | Hot-molding process | PVDF/n-Fe | 40.21 | Ku-band | [86] |

| 21 | Mechanical mixing | Graphene flakes@PDMS | 31 | THF-band | [87] |

| 22 | Dilute polymerization | Graphene@Fe3O4@SiO2@polyaniline | −40.7 | X-band | [88] |

| 23 | High-pressure solid-phase compression molding | RGO@polystyrene | 45.1 | X-band | [88] |

| 24 | Injection molding process | Polyethylene@GNP | 31 | K-band | [89] |

| 25 | Ultrasonication technique | GNP/EPDM | 35 | Ku-band | [90] |

| Ni@GNS@PVDF | 51.4 | K-band | [91] | ||

| GNP/Fe/Epoxy | −78 | V-band | [92] | ||

| 26 | Hummer’s method | PANI/GO/Fe3O4 | −53.5 | Ku-band | [93] |

| Cu@RGOFM@PDMS | 74.2 | X-band | [94] | ||

| GCF/MG3/EP | 51.1 | K-band | [95] | ||

| RGO@PEI | 26 | X-band | [96] | ||

| PVA/Gr/Fe3O4 | 40.7 | X-band | [97] | ||

| 27 | Hot compressed method | PMMA/graphene | 21 | X-band | [99] |

| PVC/graphene | 31 | X-band | |||

| Polylactic acid/Biochar/Graphite | 30 | K-band | [14] | ||

| NiFe2O4-RGO-Polypropylene | 29.4 | C-band | [100] | ||

| GNP/CLF/PEEK | 27.1 | X-band | [101] | ||

| Conventional RGO/PS | 14.2 | K-band | [98] | ||

| Segregated RGO/PS | 29.7 | K-band | |||

| 28 | 3D printing method | Graphene/Li0.35Zn0.3Fe0.35O4/PMMA | −46.1 | Ku-band | [102] |

| S. No | Machine Learning Method | Reference | Remarks | Advantage | Disadvantage |

|---|---|---|---|---|---|

| 1 | Association rule learning and decision tree algorithm | [122] | Effective in dealing with electromagnetic interference in high power line communication and helps to eliminate the troubleshooting |

|

|

| 2 | K-nearest neighbors (k-NN) algorithm | [123] | Continuous monitoring in air traffic control communication is applicable against electromagnetic interference |

|

|

| 3 | Artificial Neural Networks | [124,125,126,127,128] | An effective approach to eliminate electromagnetic interference problems |

|

|

| 4 | Back-propagation Neural Network | [129,130] | Use backward pass approach for parameters adjustment |

|

|

| 5 | Self-Organizing Feature Map Neural Network | [131,132] | Effective in evaluating the global features of electromagnetic inferences factors |

|

|

| 6 | Neural Networks | [133,134,135,136,137] | Effective for electromagnetic interference generated underground metallic pipelines, high voltage power lines and other problems |

|

|

| 7 | Monte Carlo Method | [138,139] | Effective in electromagnetic interference problems solving especially in power lines |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ayub, S.; Guan, B.H.; Ahmad, F.; Javed, M.F.; Mosavi, A.; Felde, I. Preparation Methods for Graphene Metal and Polymer Based Composites for EMI Shielding Materials: State of the Art Review of the Conventional and Machine Learning Methods. Metals 2021, 11, 1164. https://doi.org/10.3390/met11081164

Ayub S, Guan BH, Ahmad F, Javed MF, Mosavi A, Felde I. Preparation Methods for Graphene Metal and Polymer Based Composites for EMI Shielding Materials: State of the Art Review of the Conventional and Machine Learning Methods. Metals. 2021; 11(8):1164. https://doi.org/10.3390/met11081164

Chicago/Turabian StyleAyub, Saba, Beh Hoe Guan, Faiz Ahmad, Muhammad Faisal Javed, Amir Mosavi, and Imre Felde. 2021. "Preparation Methods for Graphene Metal and Polymer Based Composites for EMI Shielding Materials: State of the Art Review of the Conventional and Machine Learning Methods" Metals 11, no. 8: 1164. https://doi.org/10.3390/met11081164

APA StyleAyub, S., Guan, B. H., Ahmad, F., Javed, M. F., Mosavi, A., & Felde, I. (2021). Preparation Methods for Graphene Metal and Polymer Based Composites for EMI Shielding Materials: State of the Art Review of the Conventional and Machine Learning Methods. Metals, 11(8), 1164. https://doi.org/10.3390/met11081164