Influence of Post-Deposition Heat Treatments on the Microstructure and Tensile Properties of Ti-6Al-4V Parts Manufactured by CMT-WAAM

Abstract

:1. Introduction

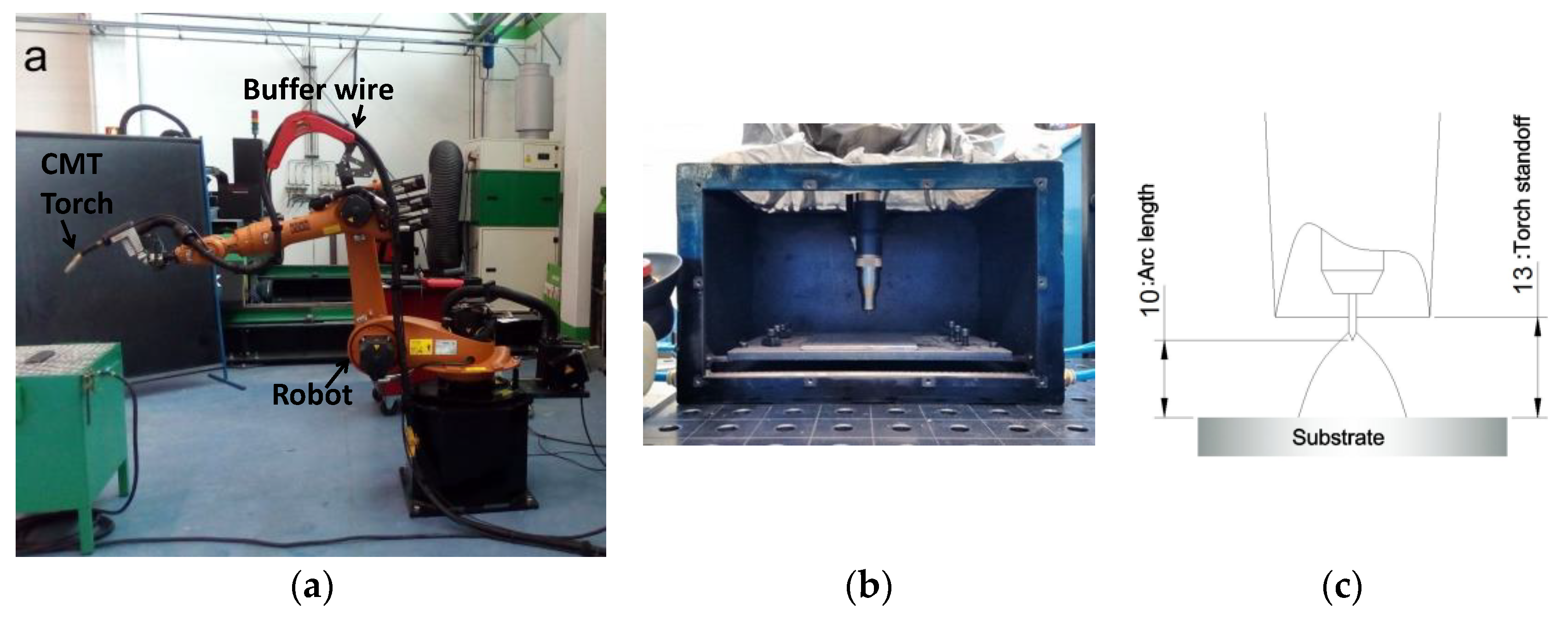

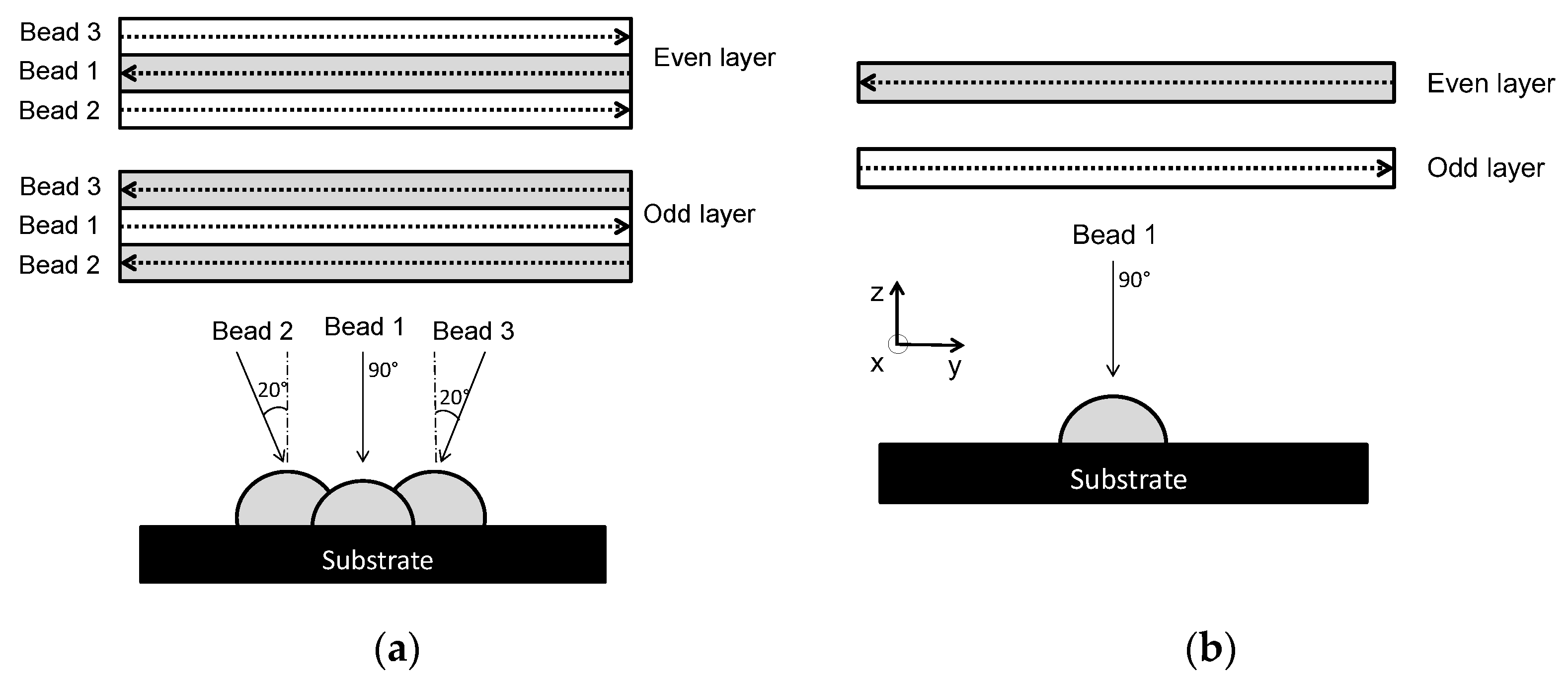

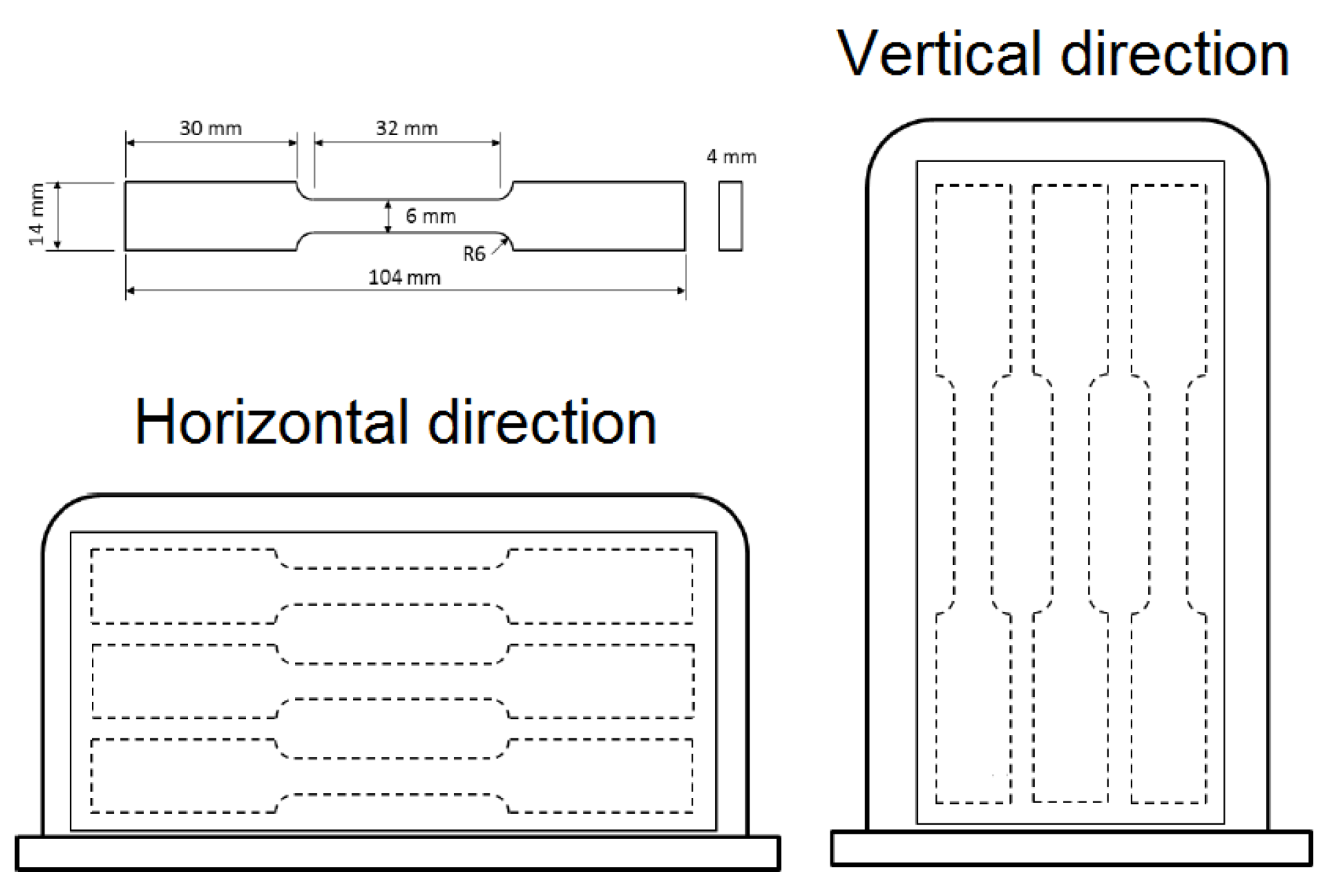

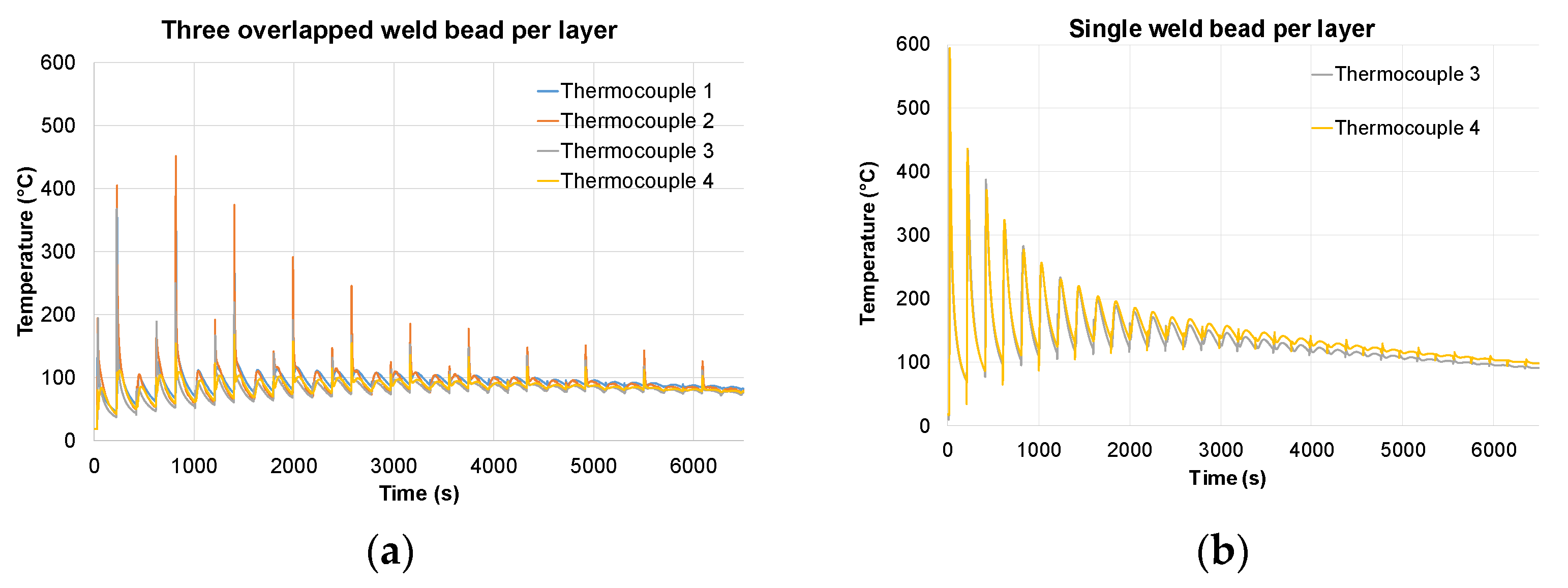

2. Materials and Methods

3. Results

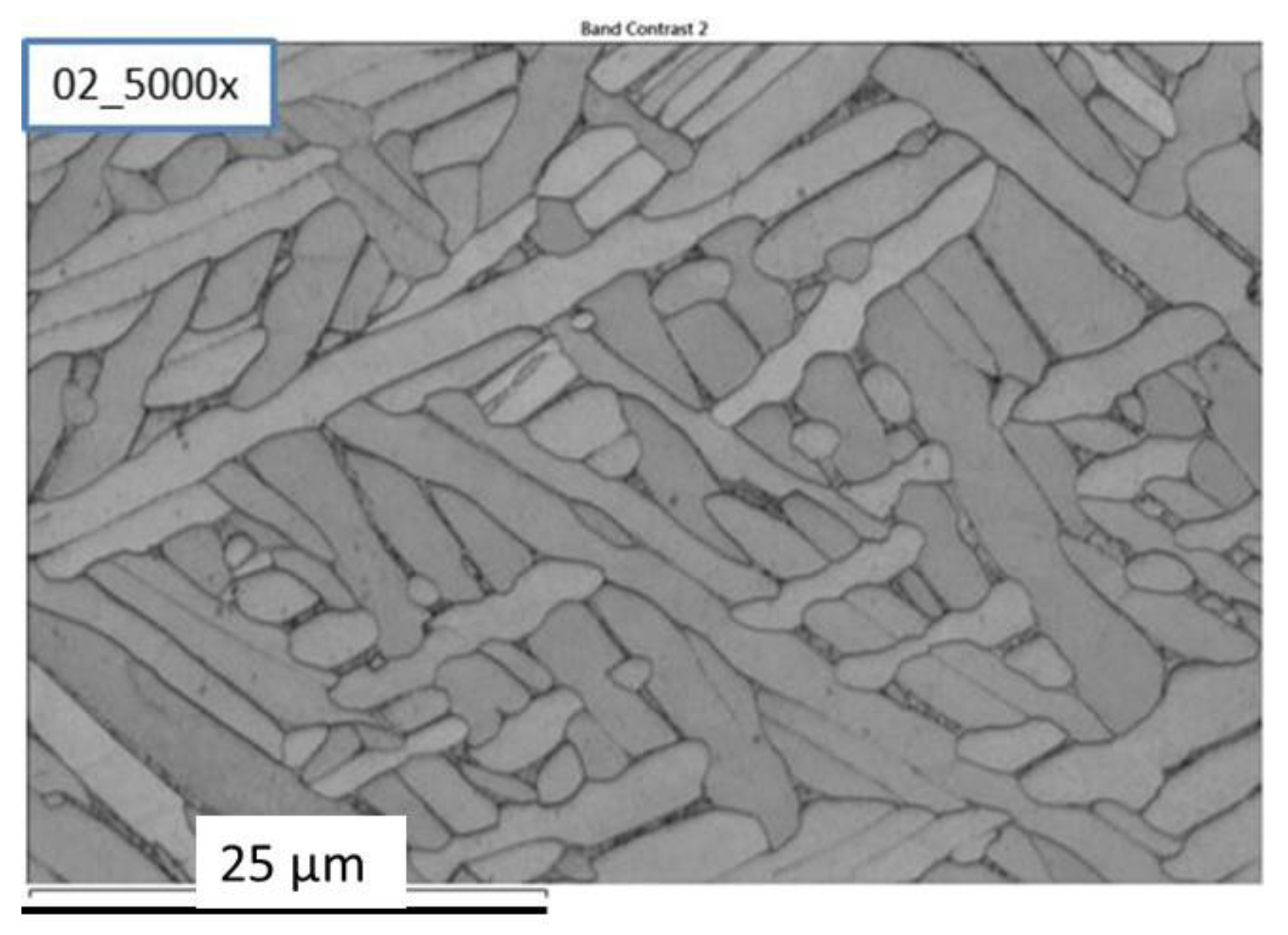

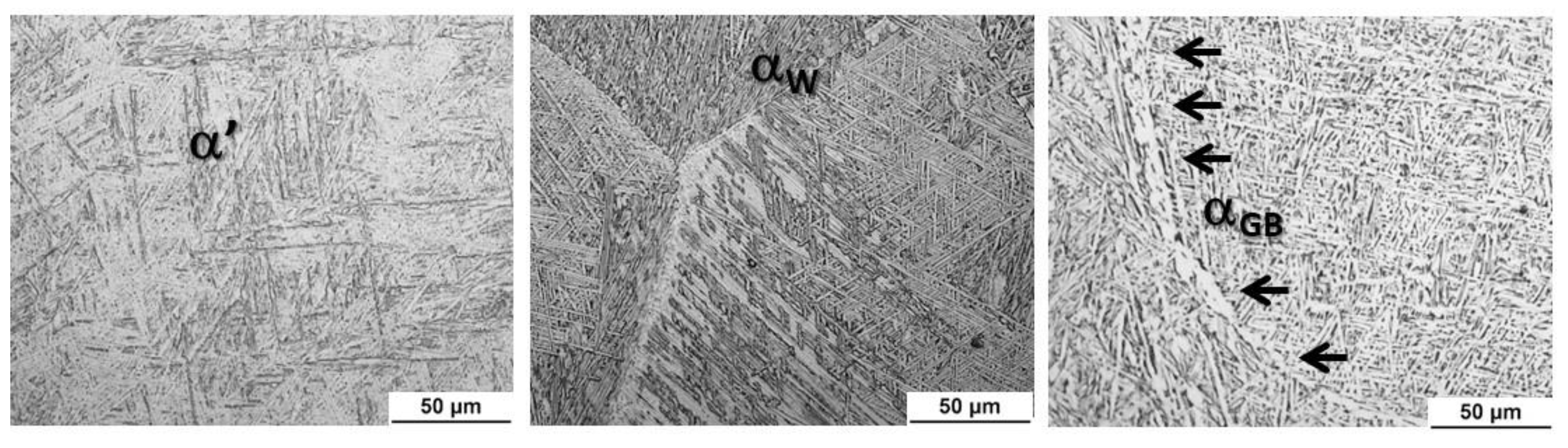

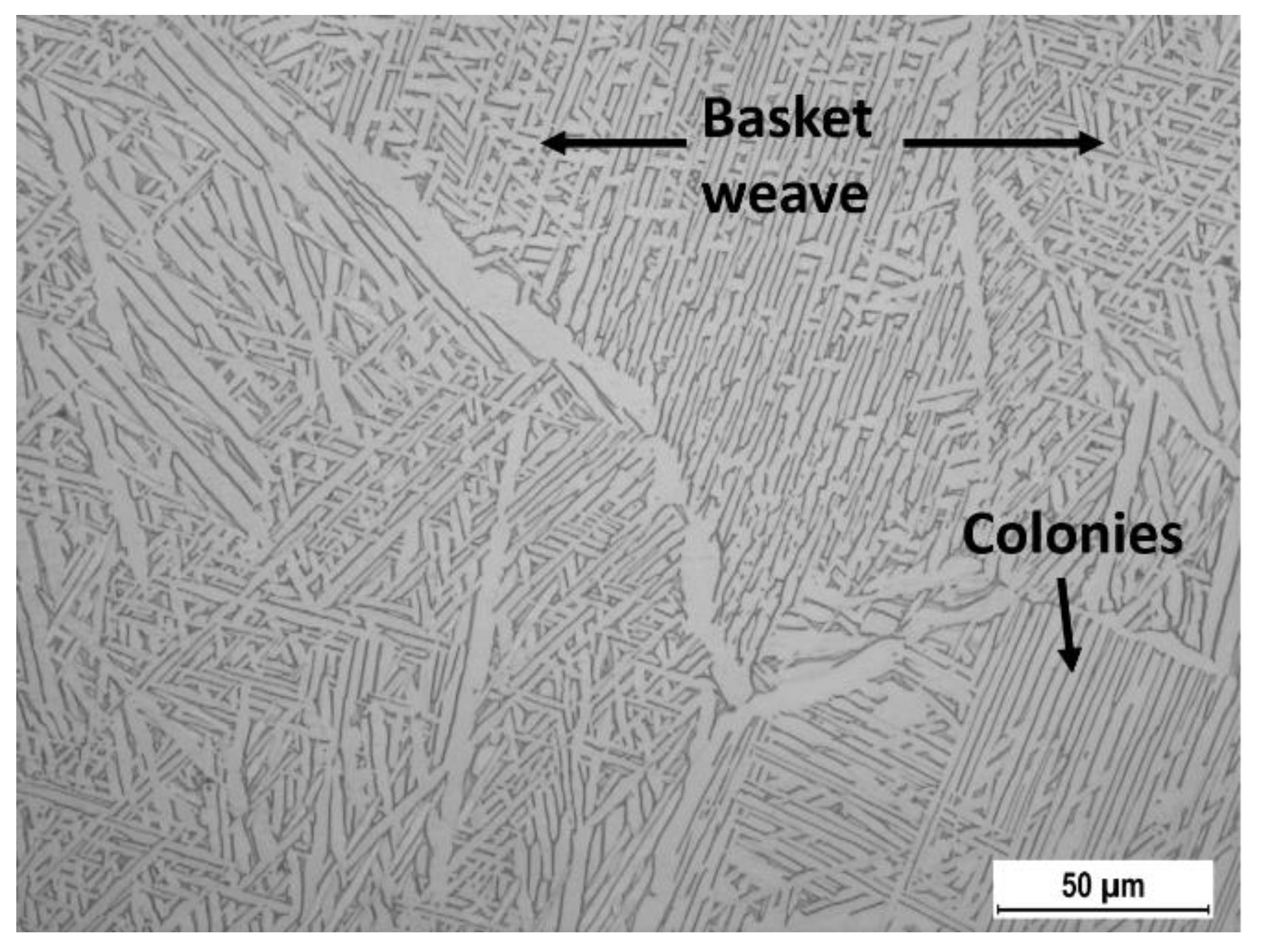

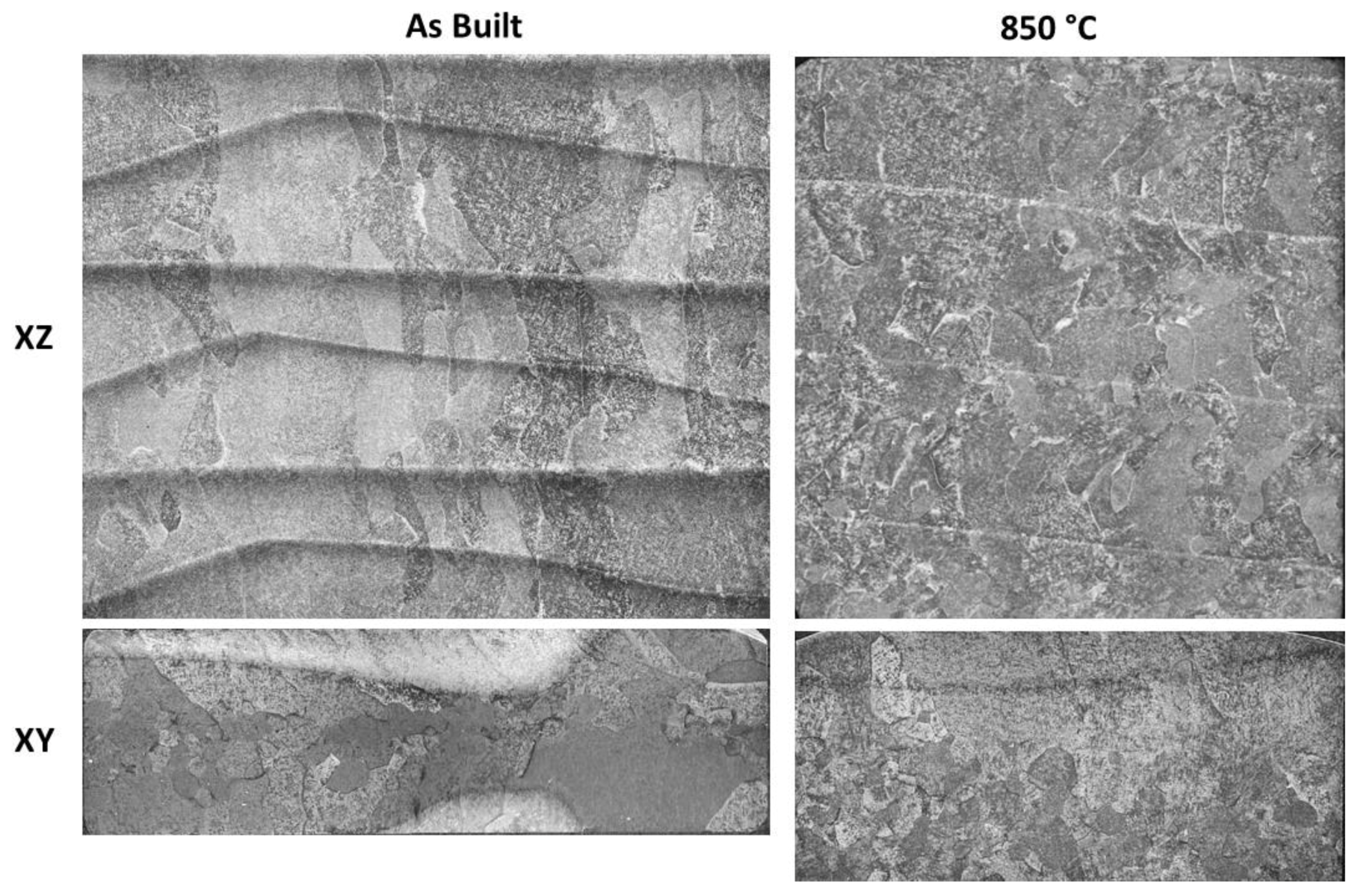

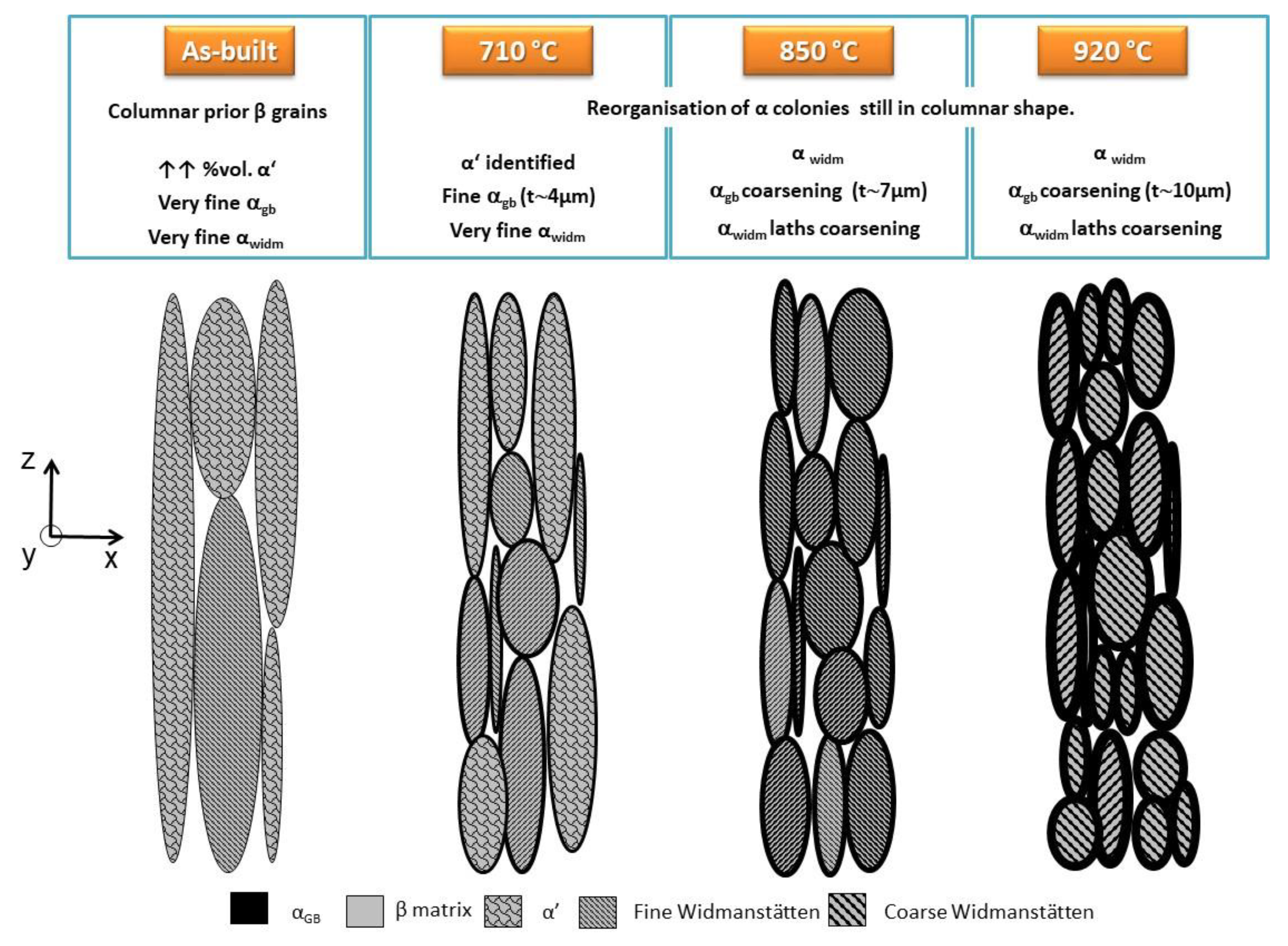

3.1. Microstructural Characterization

3.2. Mechanical Characterization of Three Overlapped Weld Beads per Layer WAAM Parts

3.3. Mechanical Characterization of Single Weld Bead per Layer WAAM Parts

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Baufeld, B.; Van der Biest, O.; Gault, R. Additive manufacturing of Ti-6Al-4V components by shaped metal deposition: Microstructure and mechanical properties. Mater. Des. 2010, 31, S106–S111. [Google Scholar] [CrossRef]

- McAndrew, A.R.; Alvarez Rosales, M.; Colegrove, P.A.; Hönnige, J.R.; Ho, A.; Fayolle, R.; Eyitayo, K.; Stan, I.; Sukrongpang, P.; Crochemore, A.; et al. Interpass rolling of Ti-6Al-4V WAAM features for microstructural refinement. Addit. Manuf. 2018, 21, 340–349. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. A multi-bead overlapping model for robotic wire and arc additive manufacturing (WAAM). Robot. Comput. Integr. Manuf. 2015, 31, 101–110. [Google Scholar] [CrossRef] [Green Version]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-feed additive manufacturing of metal components: Technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Gefertec GmbH. Available online: http://www.gefertec.com/ (accessed on 8 May 2018).

- Sequeira Almeida, P.M.; Williams, S. Innovative process model of Ti-6Al-4V additive layer manufacturing using cold metal transfer (CMT). In Proceedings of the 21st Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 9–11 August 2010; pp. 25–36. [Google Scholar]

- Rodriguez, N.; Vázquez, L.; Huarte, I.; Arruti, E.; Tabernero, I.; Alvarez, P. Wire and Arc Additive Manufacturing: A comparison between CMT and TopTIG processes applied to Stainless Steel. Weld. World 2018, 62. [Google Scholar] [CrossRef]

- Wang, F.; Williams, S.; Colegrove, P.; Antonysamy, A.A. Microstructure and mechanical properties of wire and arc additive manufactured Ti-6Al-4V. Metall. Mater. Trans. A 2013, 44, 10. [Google Scholar] [CrossRef]

- Antonysamy, A.A. Microstructure, Texture and Mechanical Property Evolution during Additive Manufacturing of Ti6Al4V Alloy for Aerospace Applications. Ph.D. Thesis, University of Manchester, Manchester, UK, 2012. [Google Scholar]

- Xie, Y.; Gao, M.; Wang, F.; Zhang, C.; Hao, K.; Wang, H.; Zeng, X. Anisotropy of fatigue crack growth in wire arc additive manufactured Ti-6Al-4V. Mater. Sci. Eng. A 2018, 709, 265–269. [Google Scholar] [CrossRef]

- Donoghue, J.; Antonysamy, A.A.; Martina, F.; Colegrove, P.A.; Williams, S.W.; Prangnell, P.B. The effectiveness of combining rolling deformation with Wire-Arc Additive Manufacture on β-grain refinement and texture modification in Ti-6Al-4V. Mater. Charact. 2016, 114, 103–114. [Google Scholar] [CrossRef]

- Hönnige, J.R.; Davis, A.E.; Ho, A.; Kennedy, J.R.; Neto, L.; Prangnell, P.B.; Williams, S. The Effectiveness of Grain Refinement by Machine Hammer Peening in High Deposition Rate Wire-Arc AM Ti-6Al-4V. Metall. Mater. Trans. A. 2020, 51, 3692–3703. [Google Scholar] [CrossRef]

- Colegrove, P.A.; Donoghue, J.; Martina, F.; Gu, J.; Prangnell, P.; Hönnige, J. Application of bulk deformation methods for microstructural and material property improvement and residual stress and distortion control in additively manufactured components. Scr. Mater. 2017, 135, 111–118. [Google Scholar] [CrossRef]

- Hönnige, J.; Colegrove, P.A.; Fitzpatrick, M.E.; Ganguly, S.; Lee, T.; Williams, S. Residual stress and texture control in Ti-6Al-4V wire + arc additively manufactured intersections by stress relief and rolling. Mater. Des. 2018, 150, 14. [Google Scholar] [CrossRef] [Green Version]

- Ding, J.; Colegrove, P.A.; Mehnen, J.; Ganguly, S.; Sequeira Almeida, P.M.; Wang, F.; Williams, S. Thermo-mechanical analysis of Wire and Arc Additive Layer Manufacturing process on large multi-layer parts. Comput. Mater. Sci. 2011, 50, 3315–3322. [Google Scholar] [CrossRef] [Green Version]

- Brandl, E.; Greitemeier, D. Microstructure of additive layer manufactured Ti-6Al-4V after exceptional post heat treatments. Mater. Lett. 2012, 81, 84–87. [Google Scholar] [CrossRef]

- Prado-Cerqueiram, J.L.; Camacho, A.M.; Diéguez, J.L.; Rodríguez-Prieto, A.; Aragón, A.M.; Lorenzo-Martín, C.; Yanguas-Gil, A. Analysis of Favorable Process Conditions for the Manufacturing of Thin-Wall Pieces of Mild Steel Obtained by Wire and Arc Additive Manufacturing (WAAM). Materials 2018, 11, 1449. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Montero Sistiaga, M.L.; Nardone, S.; Hautfenne, C.; van Humbeeck, A. Effect of Heat Treatment of 316L Stainless Steel Produced by Selective Laser Melting (SLM). In Proceedings of the 27th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 10–12 August 2016; p. 8. [Google Scholar]

- Gou, J.; Shen, J.; Hu, S.; Tian, Y.; Liang, Y. Microstructure and mechanical properties of as-built and heat-treated Ti-6Al-4V alloy prepared by cold metal transfer additive manufacturing. J. Manuf. Process. 2019, 42, 41–50. [Google Scholar] [CrossRef]

- Bermingham, M.J.; Nicastro, L.; Kent, D.; Chen, Y.; Dargusch, M.S. Optimising the mechanical properties of Ti-6Al-4V components produced by wire + arc additive manufacturing with post-process heat treatments. J. Alloys Compd. 2018, 753, 247–255. [Google Scholar] [CrossRef]

- Zhao, Z.; Chen, J.; Lu, X.; Tan, H.; Lin, X.; Huang, W. Formation mechanism of the α variant and its influence on the tensile properties of laser solid formed Ti-6Al-4V titanium alloy. Mater. Sci. Eng. A 2019, 691, 16–24. [Google Scholar] [CrossRef]

- Babu, B. Physically Based Model for Plasticity and Creep of Ti-6Al-4V. Ph.D. Thesis, Luleå University of Technology, Luleå, Sweden, 2008. [Google Scholar]

- Carroll, B.E.; Palmer, T.A.; Beese, A.M. Anisotropic tensile behavior of Ti-6Al-4V components fabricated with directed energy deposition additive manufacturing. Acta Mater. 2015, 87, 309–320. [Google Scholar] [CrossRef]

- Brandl, E.; Baufeld, B.; Leyens, C.; Gault, R. Additive manufactured Ti-6Al-4V using welding wire: Comparison of laser and arc beam deposition and evaluation with respect to aerospace material specifications. Phys. Procedia 2010, 5, 595–606. [Google Scholar] [CrossRef] [Green Version]

- Vázquez, L.; Rodríguez, N.; Rodríguez, I.; Alberdi, E.; Álvarez, P. Influence of interpass cooling conditions on microstructure and tensile properties of Ti-6Al-4V parts manufactured by WAAM. Weld. World 2020, 64, 1377–1388. [Google Scholar] [CrossRef]

| Mode | Current (A) | Wire Feed Speed (m/min) | Voltage (V) | Travel Speed (cm/min) | Arc Length (mm) |

|---|---|---|---|---|---|

| Continuous | 140 | 8.5 | 15.8 | 40/50 | 10 |

| Filler Wire | Al | V | Ti | Fe | C | O | N | H | Y | Other |

|---|---|---|---|---|---|---|---|---|---|---|

| Ti-6Al-4V grade 5 | 6.26 | 4.17 | Balance | 0.15 | 0.024 | 0.14 | 0.006 | 0.003 | 0.002 | <0.2 |

| Temperature of Thermal Treatment | Orientation | Rp0.2 (MPa) | Rm (MPa) | e (%) |

|---|---|---|---|---|

| As built | Z | 946.9 ± 8.1 | 1038.5 ± 8.3 | 8.2 ± 1.4 |

| X | 958.8 ± 3.4 | 1046.1 ± 3.2 | 6.1 ± 0.7 | |

| 710 °C | Z | 970.5 ± 4.2 | 1027.3 ± 5.1 | 5.5 ± 0.9 |

| X | 967.2 ± 7.6 | 1030.2 ± 9.2 | 5.8 ± 0.6 | |

| 850 °C | Z | 902.9 ± 5.0 | 989.1 ± 4.4 | 11.2 ± 0.9 |

| X | 922.5 ± 1.0 | 1005.0 ± 2.2 | 6.1 ± 0.3 | |

| 920 °C | Z | 859.7 ± 2.6 | 973.1 ± 2.7 | 15.8 ± 1.3 |

| X | 880.5 ± 3.9 | 981.0 ± 6.5 | 10.6 ± 1.8 |

| Temperature of Thermal Treatment | Orientation | Rp0.2 (MPa) | Rm (MPa) | e (%) |

|---|---|---|---|---|

| As-built | Z | 917.5 ± 8.1 | 1007.0 ± 4.7 | 9.4 ± 5.6 |

| X | 884.9 ± 10.3 | 986.0 ± 13.2 | 8.2 ± 2.0 | |

| 850 °C | Z | 911.6 ± 11.1 | 994.5 ± 13.9 | 14.3 ± 1.6 |

| X | 866.9 ± 4.8 | 948.8 ± 3.5 | 11.1 ± 0.8 | |

| 920 °C | Z | 855.2 ± 9.5 | 968.7 ± 10.6 | 17.5 ± 1.1 |

| X | 809.8 ± 12.2 | 919.4 ± 5.0 | 15.2 ± 1.5 |

| Reference | Rp0.2 (MPa) | Rm (MPa) | e (%) |

|---|---|---|---|

| AMS 4985C-2003 (investment casting) | >827 | >896 | >6 |

| ISO 5832-3 (wrought) | >780 | >860 | >10 |

| ASTM F1108 (casting) | >758 | >860 | >8 |

| ASTM F1472 (wrought) | >860 | >930 | >10 |

| Temperature of Thermal Treatment | Anisotropy (%) | ||

|---|---|---|---|

| Rp0.2 (MPa) | Rm (MPa) | e (%) | |

| AB | 1 | 0 | 15 |

| 710 °C | 0 | 0 | 3 |

| 850 °C | 1 | 1 | 29 |

| 920 °C | 1 | 0 | 20 |

| Temperature of Thermal Treatment | Anisotropy (%) | ||

|---|---|---|---|

| Rp0.2 (MPa) | Rm (MPa) | e (%) | |

| AB | 2 | 1 | 7 |

| 850 °C | 3 | 2 | 13 |

| 920 °C | 2 | 3 | 7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vazquez, L.; Rodriguez, M.N.; Rodriguez, I.; Alvarez, P. Influence of Post-Deposition Heat Treatments on the Microstructure and Tensile Properties of Ti-6Al-4V Parts Manufactured by CMT-WAAM. Metals 2021, 11, 1161. https://doi.org/10.3390/met11081161

Vazquez L, Rodriguez MN, Rodriguez I, Alvarez P. Influence of Post-Deposition Heat Treatments on the Microstructure and Tensile Properties of Ti-6Al-4V Parts Manufactured by CMT-WAAM. Metals. 2021; 11(8):1161. https://doi.org/10.3390/met11081161

Chicago/Turabian StyleVazquez, Lexuri, Maria Nieves Rodriguez, Iker Rodriguez, and Pedro Alvarez. 2021. "Influence of Post-Deposition Heat Treatments on the Microstructure and Tensile Properties of Ti-6Al-4V Parts Manufactured by CMT-WAAM" Metals 11, no. 8: 1161. https://doi.org/10.3390/met11081161

APA StyleVazquez, L., Rodriguez, M. N., Rodriguez, I., & Alvarez, P. (2021). Influence of Post-Deposition Heat Treatments on the Microstructure and Tensile Properties of Ti-6Al-4V Parts Manufactured by CMT-WAAM. Metals, 11(8), 1161. https://doi.org/10.3390/met11081161