Increasing the Durability of Trimming Dies Used to Clean Anodes in the Aluminum Industry

Abstract

:1. Introduction

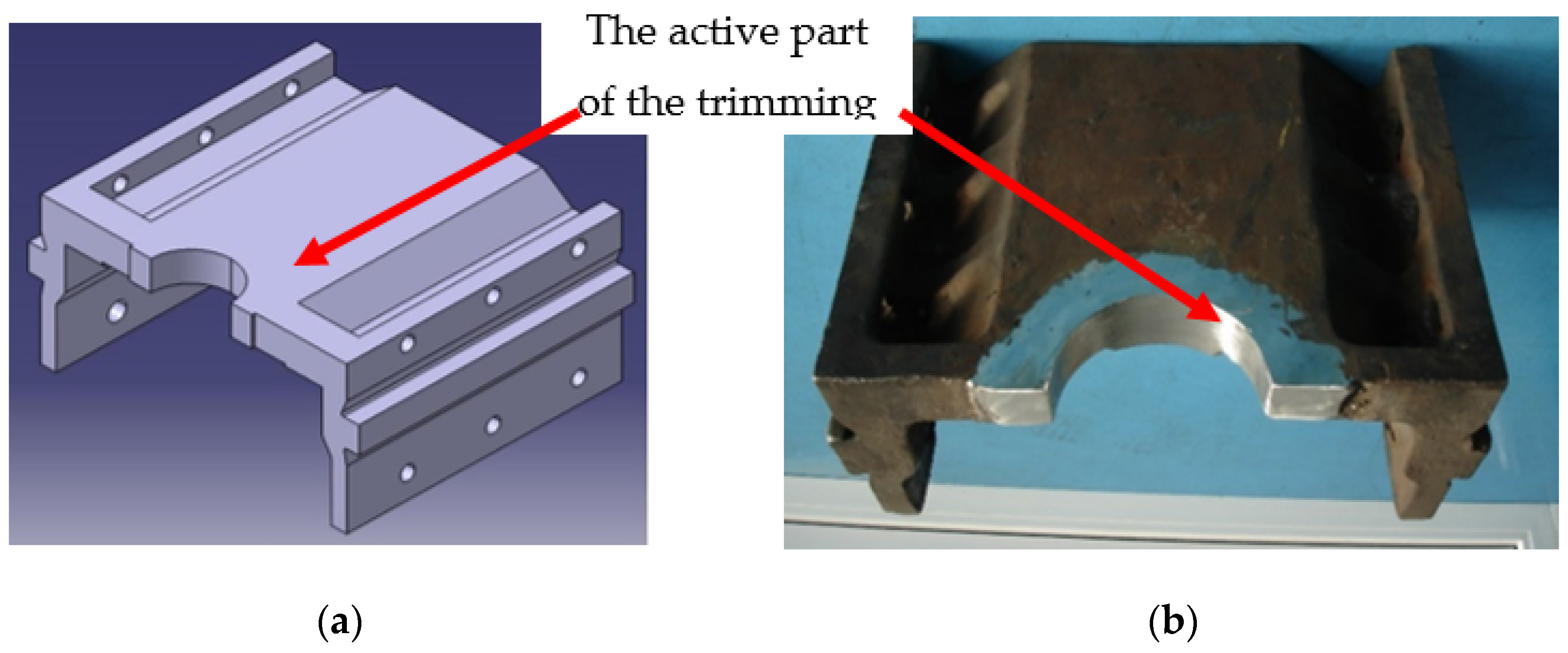

2. Materials and Methods

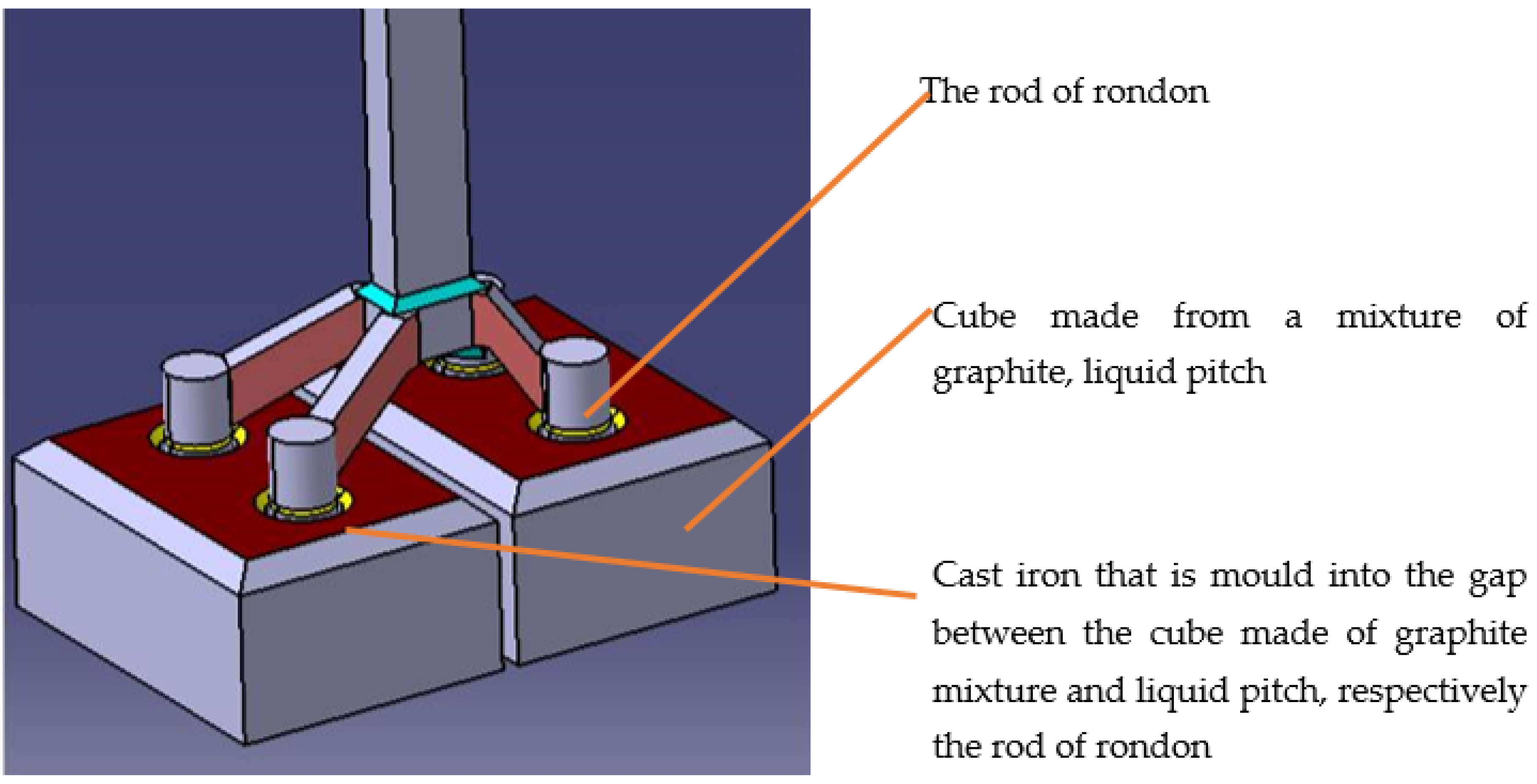

2.1. Characterization of Anodes Used in the Aluminum Industry

- Replacement of the material from which the trimming dies are made;

- Designing a welding technology by welding the active part of the trimming dies;

- Redesigning the geometry of the active area of the trimming dies.

2.2. Choosing the Optimal Material for Making the Trimming Dies of Cleaning

2.3. The Plating Technology Parameters Through Welding

2.3.1. Hot Plating Welding of the Trimming Die

- Heating the trimming die up to a temperature of 550 °C in the oven; the heating time was about 5 h;

- Loading by welding the active area of the trimming die; the deposition of the welding seams on the active surface of the trimming die was performed on a warm bed (an additional heat source was provided during the technological welding process she maintained the material of the trimming die at a temperature of 500 °C). The deposition of the material layer by welding was performed using Tooltrode60 electrodes with diameter Ø = 4 mm, being taken into account the following parameters of the welding regime: welding current—Iw = 170 A; welding voltage—Uw = 28 V;

- Following the deposition of the welding seams, the trimming die was subjected to an annealing heat treatment that consisted of heating at a temperature of 500 °C, followed by maintenance for a duration of 2.5 h and a controlled cooling with the oven, with a speed of 100 °C/h (cooling time 5 h).

2.3.2. Cold Plating Welding of the Trimming Die

- Heating the trimming die material to a temperature in the range 150–180 °C;

- The deposition by welding an intermediate layer of stainless steel (STARINOX 309L with diameter Ø = 4 mm) on the active surface of the trimming die. This intermediate layer was deposited in two passes, considering the following parameters of the welding regime: welding current—Iw = 140–150 A, welding voltage—Uw = 23–25 V;

- Depositing by welding a new layer of material using Tooltrode60 electrodes with diameter Ø = 4 mm, taking into account the following parameters of the welding regime: welding current—Iw = 170 A; welding voltage—Uw = 28 V;

- Coating the trimming die after welding with a thermal insulating material (glass wool), which allowed a slow cooling of its material at a speed of 50 °C/h.

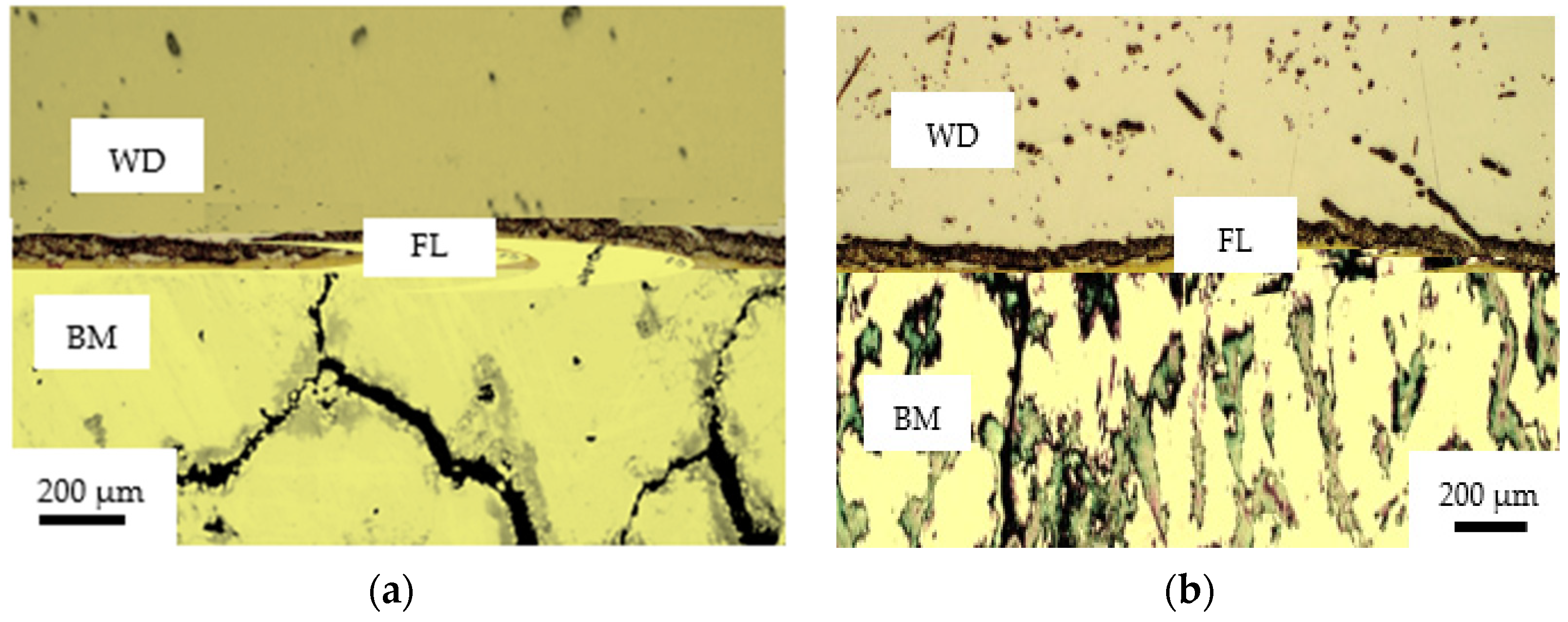

2.3.3. Analysis of the Metallographic Structure of the Transition Area between the Metal Deposited by Welding and the Base Material

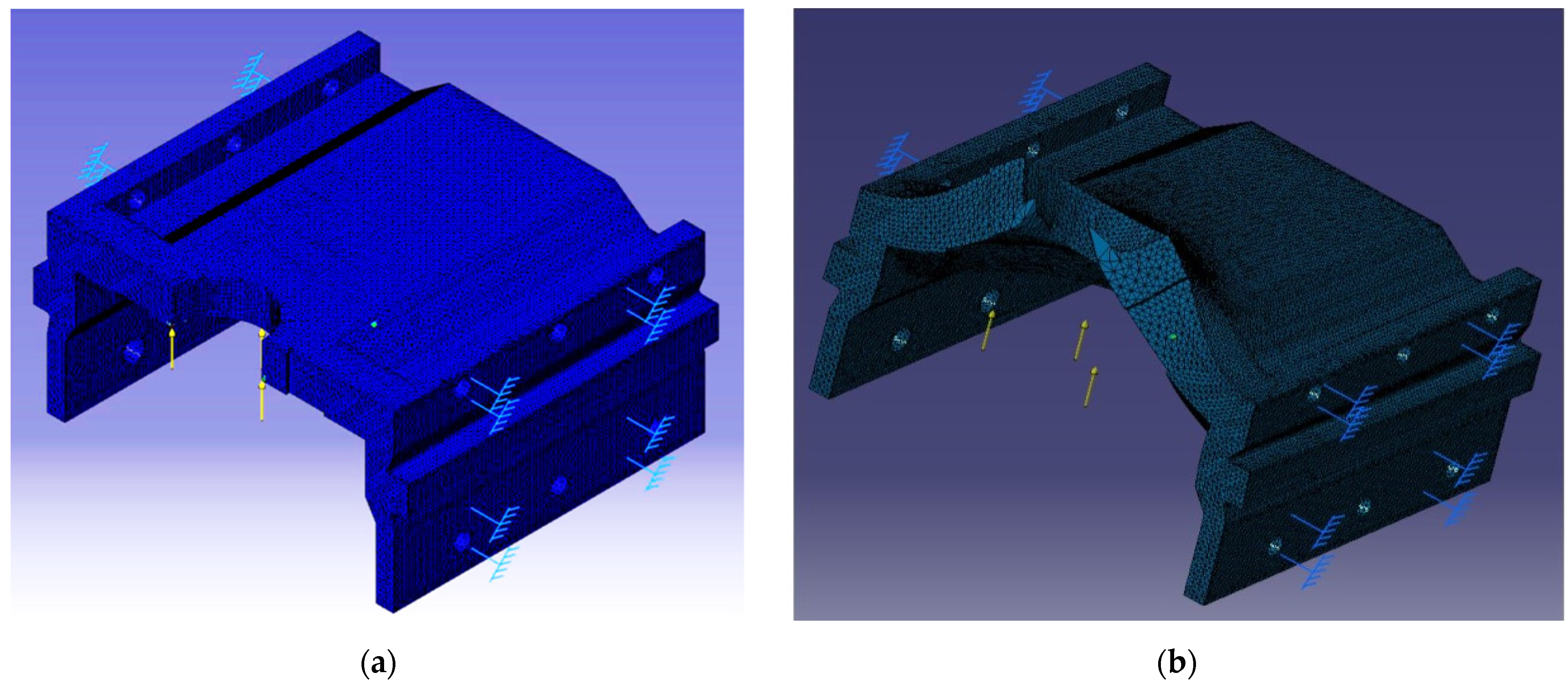

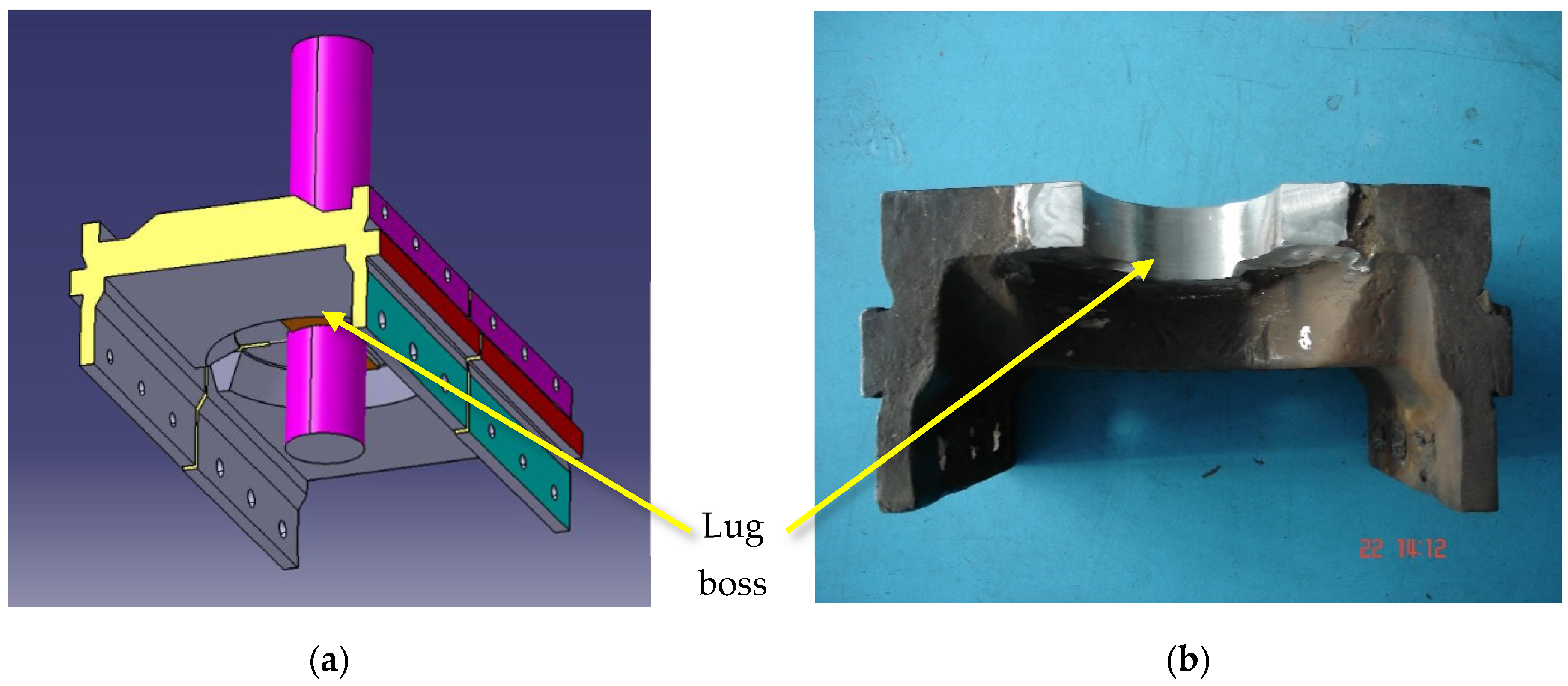

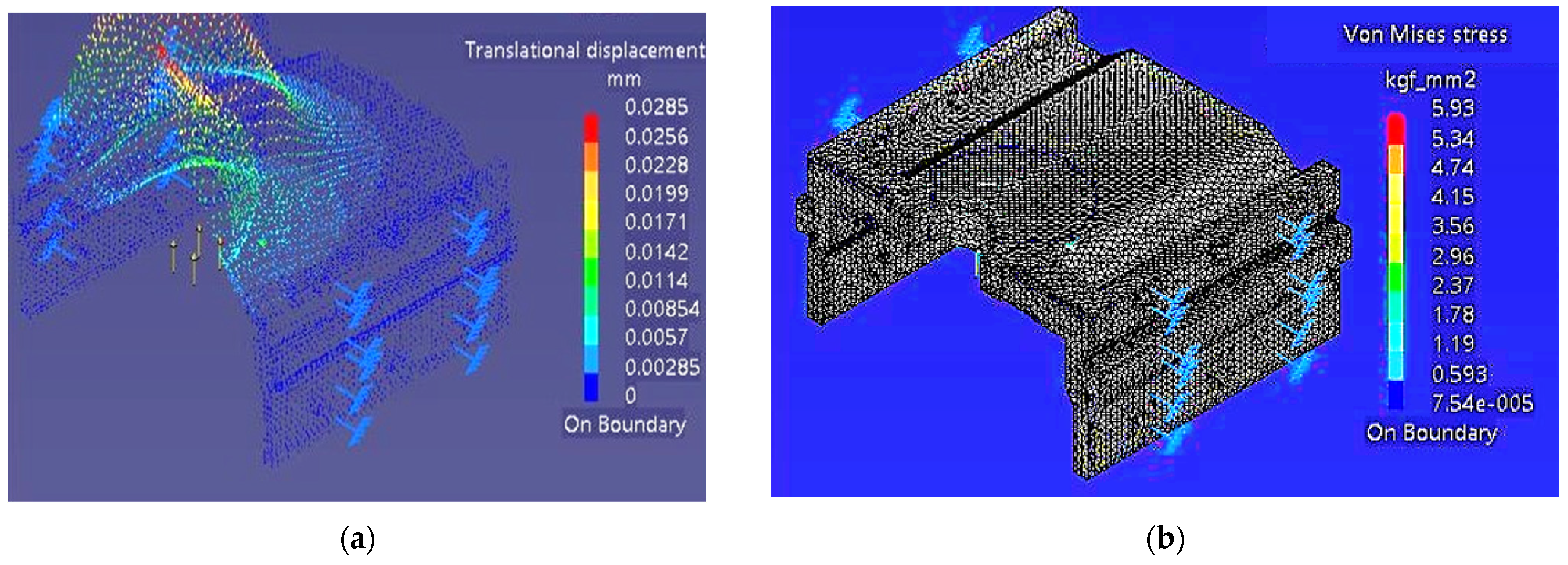

2.4. Redesigning the Trimming Die Geometry Using FEM

3. Results and Discussions

3.1. Analysis of the Durability of Trimming Dies Made of Different Materials

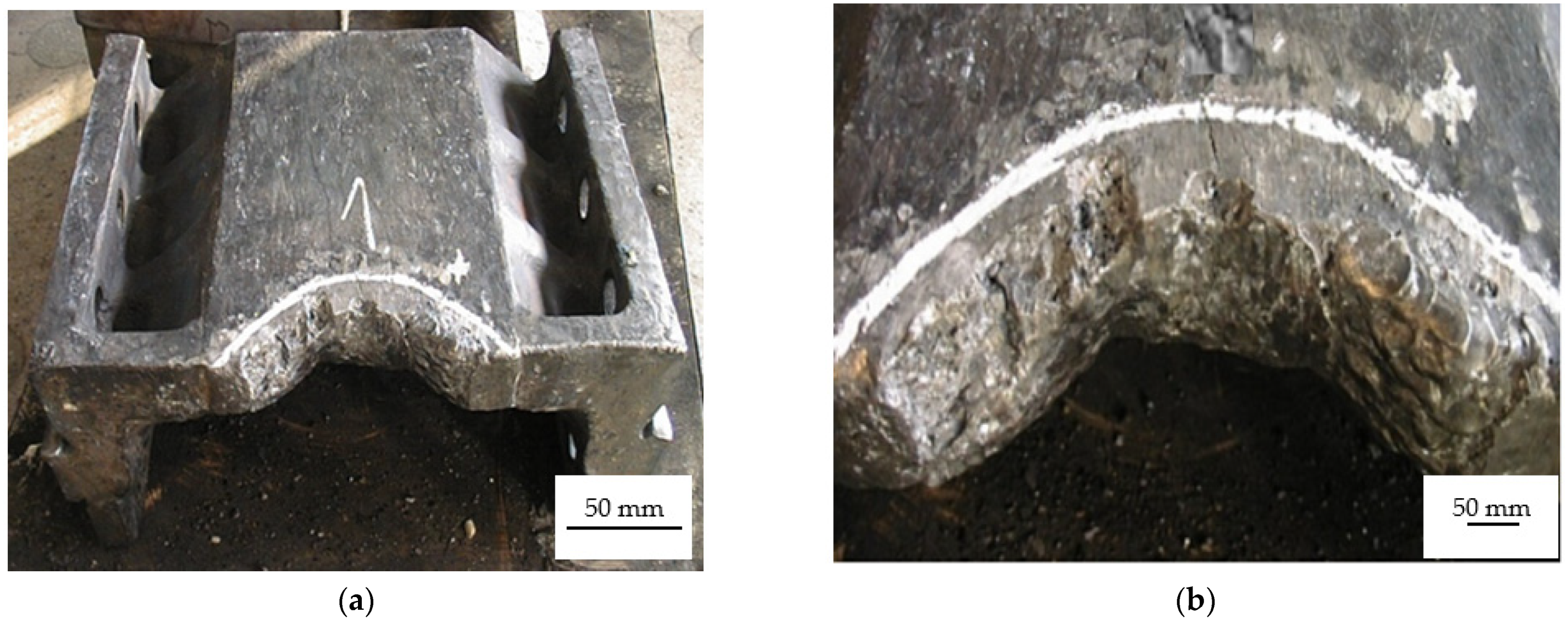

3.2. The Influence of Plating Technology Through Welding on the Durability of Trimming Dies

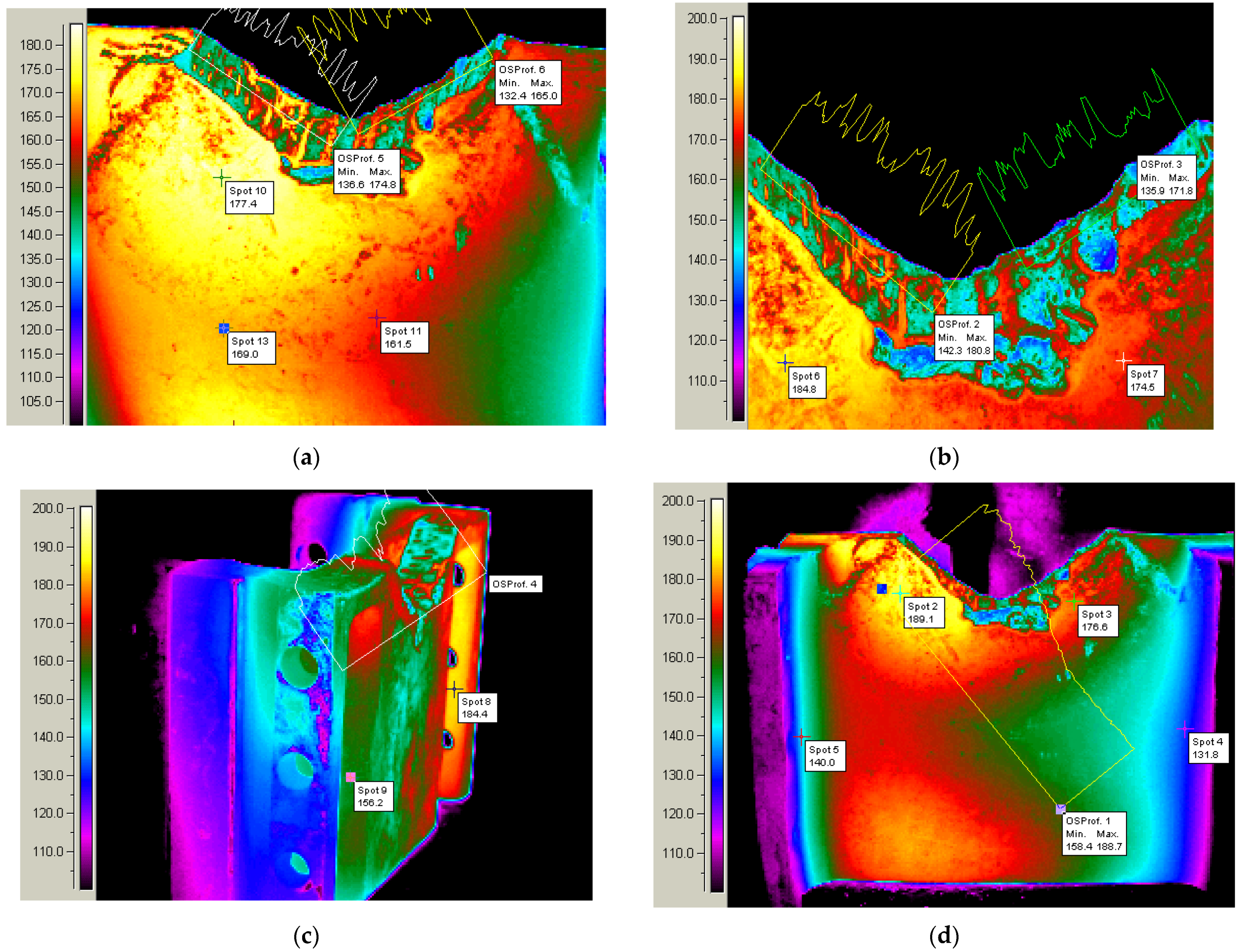

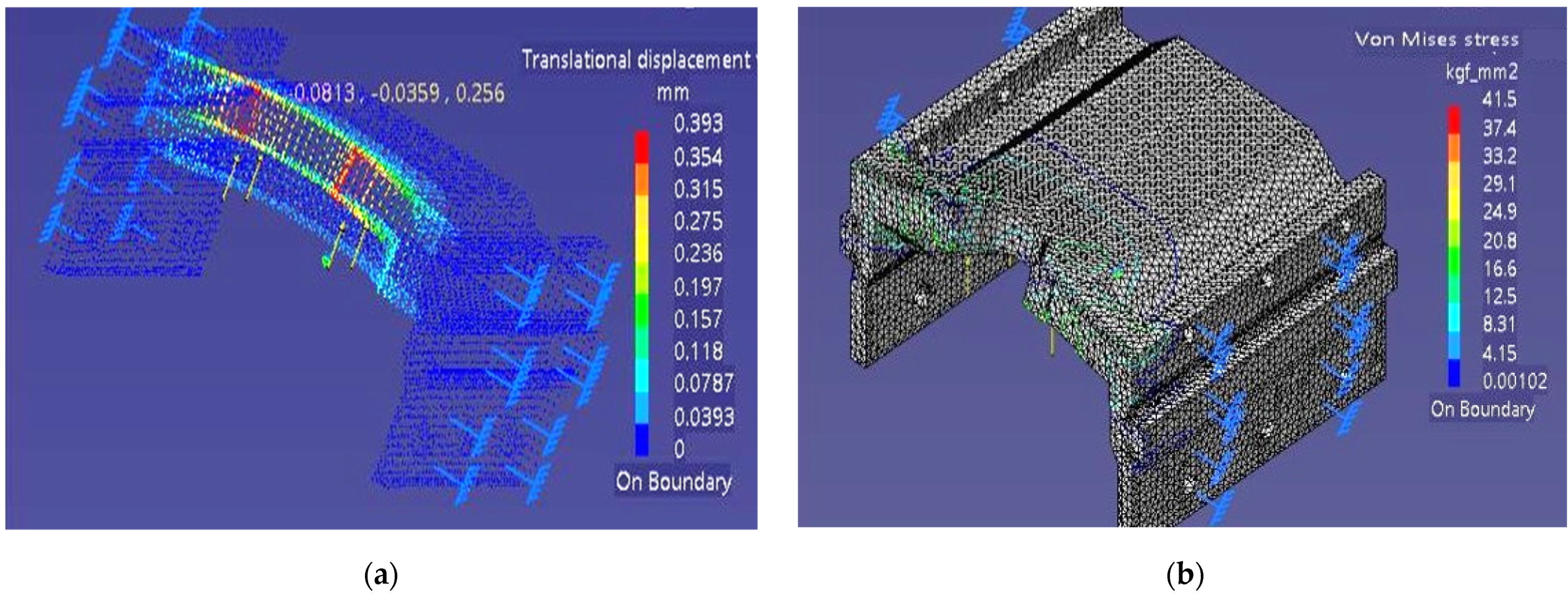

3.3. FEM Modeling of Trimming Die Geometry

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Boqiang, L.; Lin, X. Energy conservation of electrolytic aluminium industry in China Renew. Sustain. Energy Rev. 2015, 43, 676–686. [Google Scholar]

- Yue, W.; Chen, X.; Gui, W.; Xie, Y.; Zhang, H. A knowledge reasoning fuzzy-Bayesian network for root cause analysis of abnormal aluminium electrolysis cell condition. Front. Chem. Sci. Eng. 2017, 11, 414–428. [Google Scholar] [CrossRef]

- Sysoev, I.A.; Ershov, V.A.; Kondrat’ev, V.V. Method of Controlling the Energy Balance of Electrolytic Cells for Aluminum Production. Metallurgist 2015, 59, 518–525. [Google Scholar] [CrossRef]

- Das, S.K.; Green, J.A.S. Aluminum industry and climate change—Assessment and responses. JOM 2010, 62, 27–31. [Google Scholar] [CrossRef]

- Goupil, G.; Bonnefont, G.; Idrissi, H.; Guay, D.; Roué, L. Consolidation of mechanically alloyed Cu–Ni–Fe material by spark plasma sintering and evaluation as inert anode for aluminum electrolysis. J. Alloy. Compd. 2013, 580, 256–261. [Google Scholar] [CrossRef]

- Helle, S.; Tresse, M.; Davis, B.; Guay, D.; Roué, L. Mechanically Alloyed Cu-Ni-Fe-O Based Materials as Oxygen-Evolving Anodes for Aluminium Electrolysis. J. Electrochem. Soc. 2012, 159, E62. [Google Scholar] [CrossRef]

- TUPY. Continuous Cast Iron Bars. 2018. Available online: http://www.tupy.com.br/ingles/produtos/perfisprocesso.php (accessed on 25 May 2021).

- Da Silva, R.B.; Lima, M.L.S.; Pereira, M.F.; Abrão, B.S.; da Silva, L.R.R.; Bianchi, E.C.; Machado, A.R. A surface and sub-surface quality evaluation of three cast iron grades after grinding under various cutting conditions. Int. J. Adv. Manuf. Technol. 2018, 99, 1839–1852. [Google Scholar] [CrossRef]

- Kumar, K.; Arun, K.; Sathishkumar, N.; Narayanan, M.P.; Raviraj, E. Experimental investigation on the machinability of nodular ductile iron with cubic boron nitride and tungsten carbide inserts. Mater. Today Proc. 2021, 39, 1386–1389. [Google Scholar] [CrossRef]

- Kumar, K.; Hariharan, P. Prediction and investigation of surface roughness while turning sg iron with cubic boron nitride (cbn) and tungsten carbide inserts. Trans. Can. Soc. Mech. Eng. 2017, 41, 129–141. [Google Scholar] [CrossRef]

- Nayyar, V.; Kamiński, J.; Kinnander, A.; Nyborg, L. An Experimental Investigation of Machinability of Graphitic Cast Iron Grades; Flake, Compacted and Spheroidal Graphite Iron in Continuous Machining Operations. Procedia CIRP 2012, 1, 488–493. [Google Scholar] [CrossRef]

- Fiorini, P.; Byrne, G. The influence of built-up layer formation on cutting performance of GG25 grey cast iron. CIRP Ann. 2016, 65, 93–96. [Google Scholar] [CrossRef] [Green Version]

- Kalyon, A.; Günay, M.; Özyürek, D. Application of grey relational analysis based on Taguchi method for optimizing machining parameters in hard turning of high chrome cast iron. Adv. Manuf. 2018, 6, 419–429. [Google Scholar] [CrossRef]

- Ravi, A.M.; Murigendrappa, S.M.; Mukunda, P.G. Machinability Investigations on High Chrome White Cast Iron Using Multi Coated Hard Carbide Tools. Trans. Indian Inst. Met. 2014, 67, 485–502. [Google Scholar] [CrossRef]

- Sahoo, A.K.; Sahoo, B. Performance studies of multilayer hard surface coating (TiN/TiCN/Al2O3/TiN) of indexeble carbide insert in hard machining: Part-II (RSM, grey relational and techno economical approach). Measurement 2013, 46, 2868–2884. [Google Scholar] [CrossRef]

- Tu, L.; Shi, W. Establish Using FEM Method of Constitutive Model for Chip Formation in the Cutting Process of Gray Cast Iron. Metals 2019, 10, 33. [Google Scholar] [CrossRef] [Green Version]

- Savkovic, B.; Kovac, P.; Dudic, B.; Gregus, M.; Rodic, D.; Strbac, B.; Ducic, N. Comparative Characteristics of Ductile Iron and Austempered Ductile Iron Modeled by Neural Network. Materials 2019, 12, 2864. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, H.; Li, T.; Gong, M.; Wang, Z.; Wang, G. Finite Element Analysis of Dynamic Recrystallization of Casting Slabs during Hot-Core Heavy Reduction Rolling Process. Metals 2020, 10, 181. [Google Scholar] [CrossRef] [Green Version]

- Haines-Gadd, M.; Chapman, J.; Lloyd, P.; Mason, J.; Aliakseyeu, D. Emotional Durability Design Nine—A Tool for Product Longevity. Sustainability 2018, 10, 1948. [Google Scholar] [CrossRef] [Green Version]

- Voestalpine Delstahl. Available online: https://www.bohler-edelstahl.com/en/products (accessed on 25 May 2021).

- Hawryluk, M.; Dobras, D.; Kaszuba, M.; Widomski, P.; Ziemba, J. Influence of the different variants of the surface treatment on the durability of forging dies made of Unimax steel. Int. J. Adv. Manuf. Technol. 2020, 107, 4725–4739. [Google Scholar] [CrossRef]

- Kaszuba, M. The application of a new, innovative, hybrid technology combining hardfacing and nitriding to increase the durability of forging tools. Arch. Civ. Mech. Eng. 2020, 20, 122. [Google Scholar] [CrossRef]

- Smirnov, A.E.; Plokhikh, A.I.; Ryzhova, M.Y.; Akinin, A.B.; Boev, S.V. Improving the Durability of Stamping Tools from Kh12MF Steel by Quenching in High-Pressure Nitrogen and Thermal Cycling. Met. Sci. Heat Treat. 2020, 62, 133–138. [Google Scholar] [CrossRef]

- Dhar, V.; Provino, A. Ferromagnetism in the orthorhombic PrPd and SmPd. J. Alloy. Compd. 2018, 762, 254–259. [Google Scholar] [CrossRef]

- Villalobos, J.C.; Del-Pozo, A.; Campillo, B.; Mayén, J.; Serna, S. Microalloyed Steels through History until 2018: Review of Chemical Composition, Processing and Hydrogen Service. Metals 2018, 8, 351. [Google Scholar] [CrossRef] [Green Version]

- Zorko, D.; Kulovec, S.; Duhovnik, J.; Tavčar, J. Durability and design parameters of a Steel/PEEK gear pair. Mech. Mach. Theory 2019, 140, 825–846. [Google Scholar] [CrossRef]

- Neamtu, G.V.; Mohora, C.; Anania, D.; Dobrotă, D. Research Regarding the Increase of Durability of Flexible Die Made from 50CrMo4 Used in the Typographic Industry. Metals 2021, 11, 996. [Google Scholar] [CrossRef]

- Dobrota, D. Optimizing the Shape of Welded Constructions Made through the Technique “Temper Bead Welding”. Metals 2020, 10, 1655. [Google Scholar] [CrossRef]

- Oliaei, S.N.B.; Karpat, Y.; Davim, J.P.; Perveen, A. Micro tool design and fabrication: A review. J. Manuf. Process. 2018, 36, 496–519. [Google Scholar] [CrossRef]

- Bobzin, K. High-performance coatings for cutting tools. CIRP J. Manuf. Sci. Technol. 2017, 18, 1–9. [Google Scholar] [CrossRef]

- Jiang, L.; Wang, D. Finite-element-analysis of the effect of different wiper tool edge geometries during the hard turning of AISI 4340 steel. Simul. Model. Pract. Theory 2019, 94, 250–263. [Google Scholar] [CrossRef]

| C | Cr | Mn | Si | Ni | P | S |

|---|---|---|---|---|---|---|

| 1.8 | 11 | 0.2 | 0.2 | 0.5 | 0.03 | 0.035 |

| Physical Properties | 20 °C | 200 °C | 400 °C |

| Density, Kg/dm3 | 7.70 | 7.65 | 7.60 |

| Coefficient for thermal expansion (per °C from 0 °C) | - | 11.0 × 10−6 | 10.8 × 10−6 |

| Thermal conductivity (cal/cm·s °C) | 49 × 10−3 | 51.3 × 10−3 | 54.9 × 10−3 |

| Specific heat | 0.110 | - | - |

| Modulus of elasticity, MPa | 194,000 | 189,000 | 173,000 |

| Material | C | Si | Mn | Cr | Mo | V | W | Co |

|---|---|---|---|---|---|---|---|---|

| K105 | 1.60 | 0.35 | 0.30 | 11.50 | 0.6 | 0.3 | 0.5 | - |

| K107 | 2.1 | 0.25 | 0.4 | 11.5 | - | - | 0.7 | - |

| K110 | 1.55 | 0.3 | 0.3 | 11.3 | 0.75 | 0.75 | - | - |

| K360 | 1.25 | 0.9 | 0.35 | 8.75 | 2.7 | 1.18 | - | - |

| K460 | 0.19 | 0.41 | 1.39 | 0.32 | 0.8 | 0.03 | 1 | 2 |

| Material | Yeld, Rp0,2, MPa | Impact, KV/Ku J | Elongation, A, % | Brinell Hardness, HBW | Modulus of Elasticity, GPa |

|---|---|---|---|---|---|

| K105 | ≥497 | ≥151 | 12 | 123 | 894 (463 °C) |

| K107 | ≥347 | ≥223 | 34 | 242 | 474 (571 °C) |

| K110 | ≥212 | ≥32 | 13 | 433 | 967 (448 °C) |

| K360 | ≥595 | ≥13 | 32 | 213 | 763 (423 °C) |

| K460 | ≥731 | ≥22 | 41 | 413 | 755 (736 °C) |

| Material | Number of Stress Cycles, N, Up to Which Maximum Allowable Wear Has Been Reached |

|---|---|

| K105 | 357,458 |

| K107 | 369,573 |

| K110 | 376,231 |

| K360 | 384,598 |

| K460 | 373,435 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gârleanu, D.; Borda, C.; Gârleanu, G.; Modrogan, C.; Dumitraș, M.; Dobrotă, D.; Racz, S.-G.; Dascălu, L.C. Increasing the Durability of Trimming Dies Used to Clean Anodes in the Aluminum Industry. Metals 2021, 11, 1157. https://doi.org/10.3390/met11081157

Gârleanu D, Borda C, Gârleanu G, Modrogan C, Dumitraș M, Dobrotă D, Racz S-G, Dascălu LC. Increasing the Durability of Trimming Dies Used to Clean Anodes in the Aluminum Industry. Metals. 2021; 11(8):1157. https://doi.org/10.3390/met11081157

Chicago/Turabian StyleGârleanu, Delia, Claudia Borda, Gabriel Gârleanu, Cristina Modrogan, Marius Dumitraș, Dan Dobrotă, Sever-Gabriel Racz, and Loredana Cristina Dascălu. 2021. "Increasing the Durability of Trimming Dies Used to Clean Anodes in the Aluminum Industry" Metals 11, no. 8: 1157. https://doi.org/10.3390/met11081157

APA StyleGârleanu, D., Borda, C., Gârleanu, G., Modrogan, C., Dumitraș, M., Dobrotă, D., Racz, S.-G., & Dascălu, L. C. (2021). Increasing the Durability of Trimming Dies Used to Clean Anodes in the Aluminum Industry. Metals, 11(8), 1157. https://doi.org/10.3390/met11081157