Wettability in Metal Matrix Composites

Abstract

1. Introduction

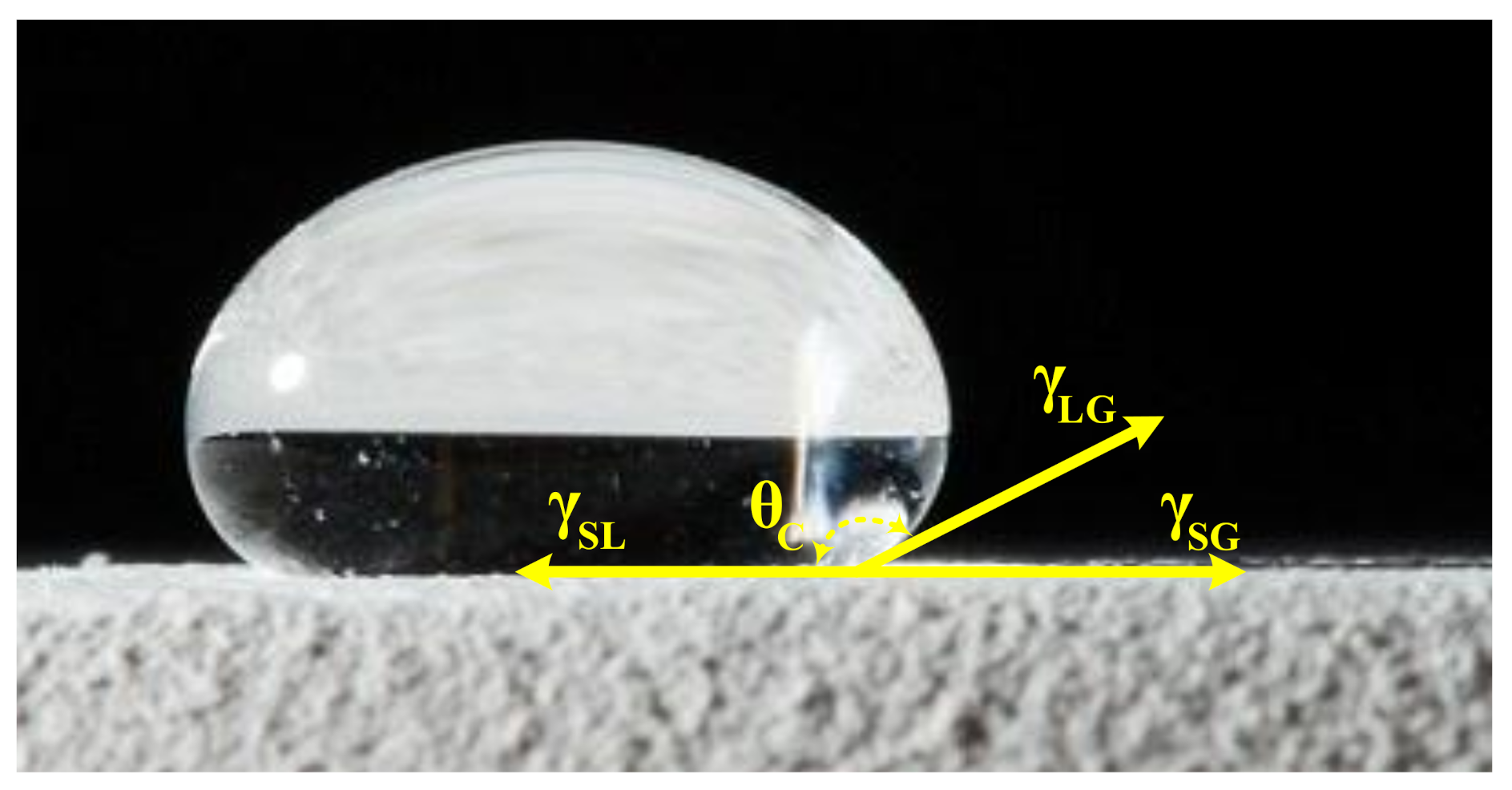

2. Wettability

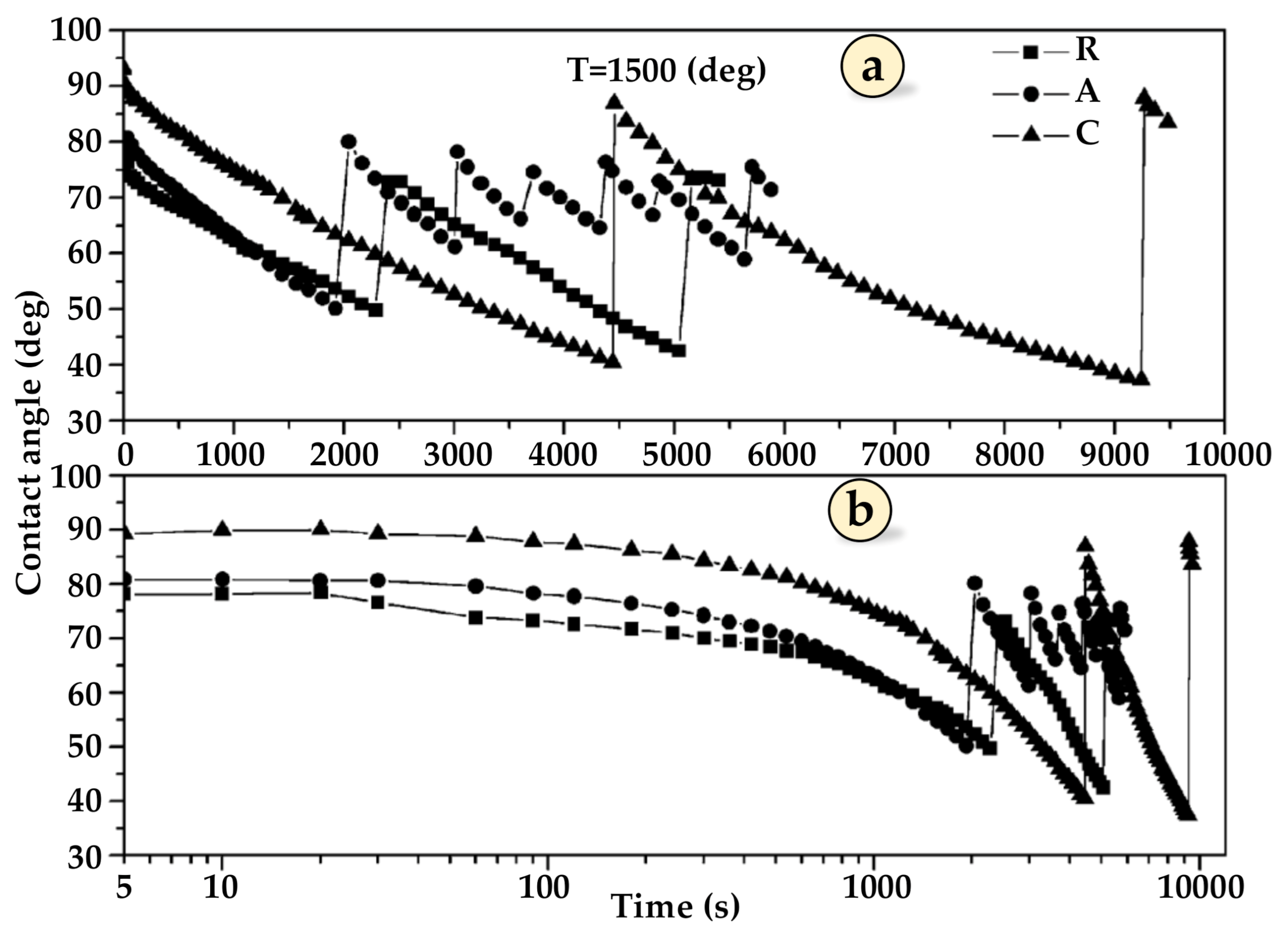

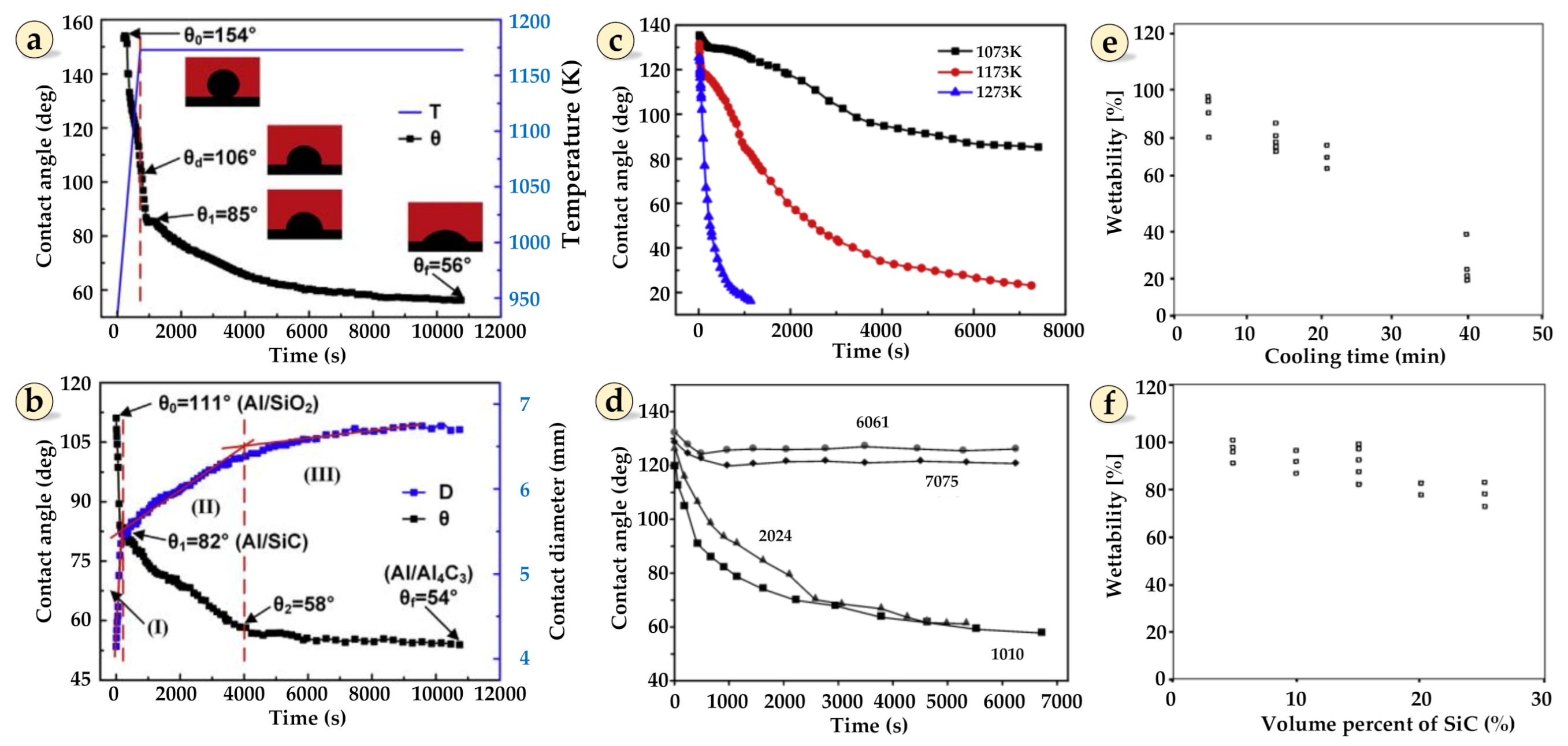

3. Thermal Treatment and Temperature

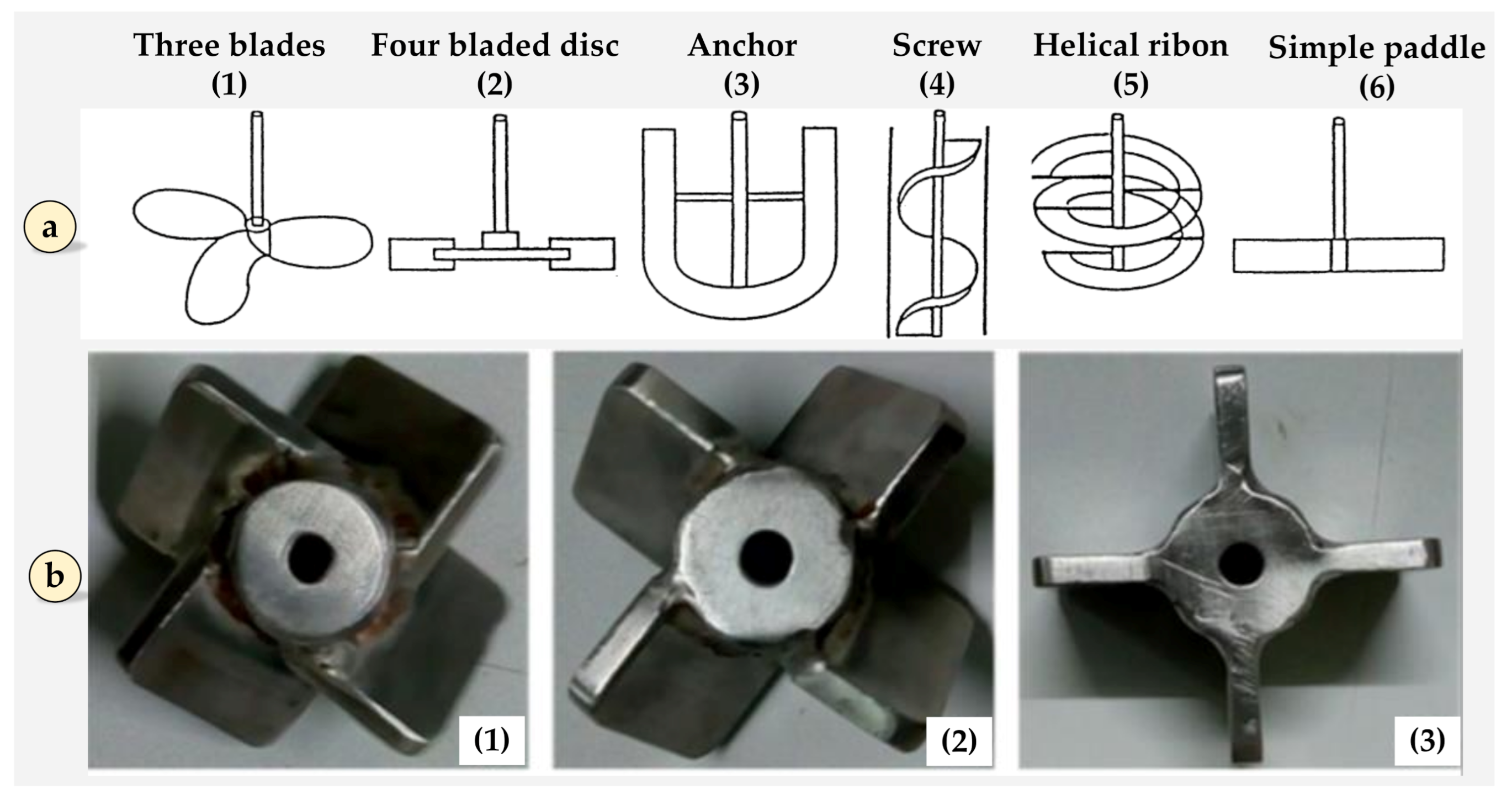

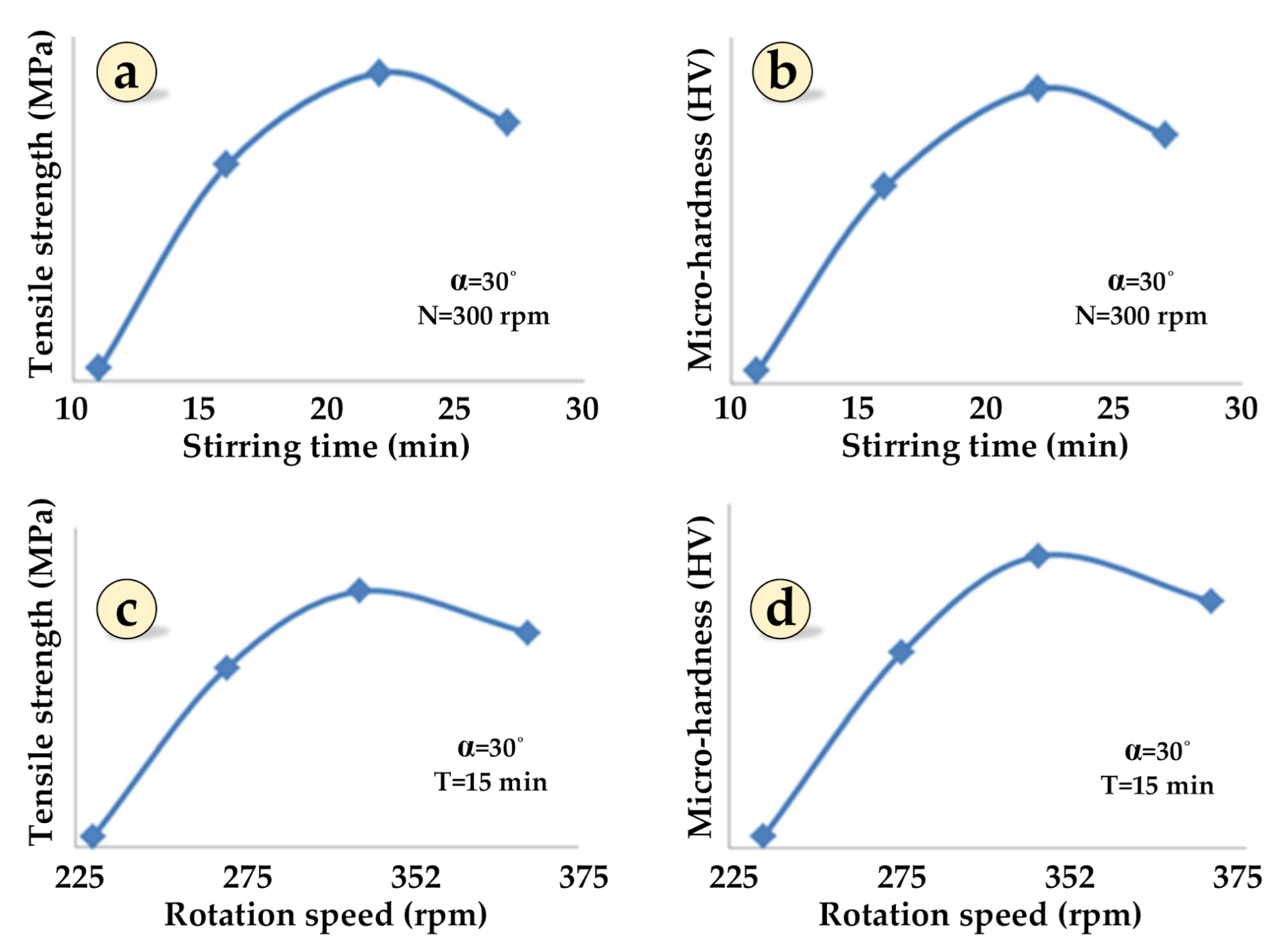

4. Mechanical Treatment

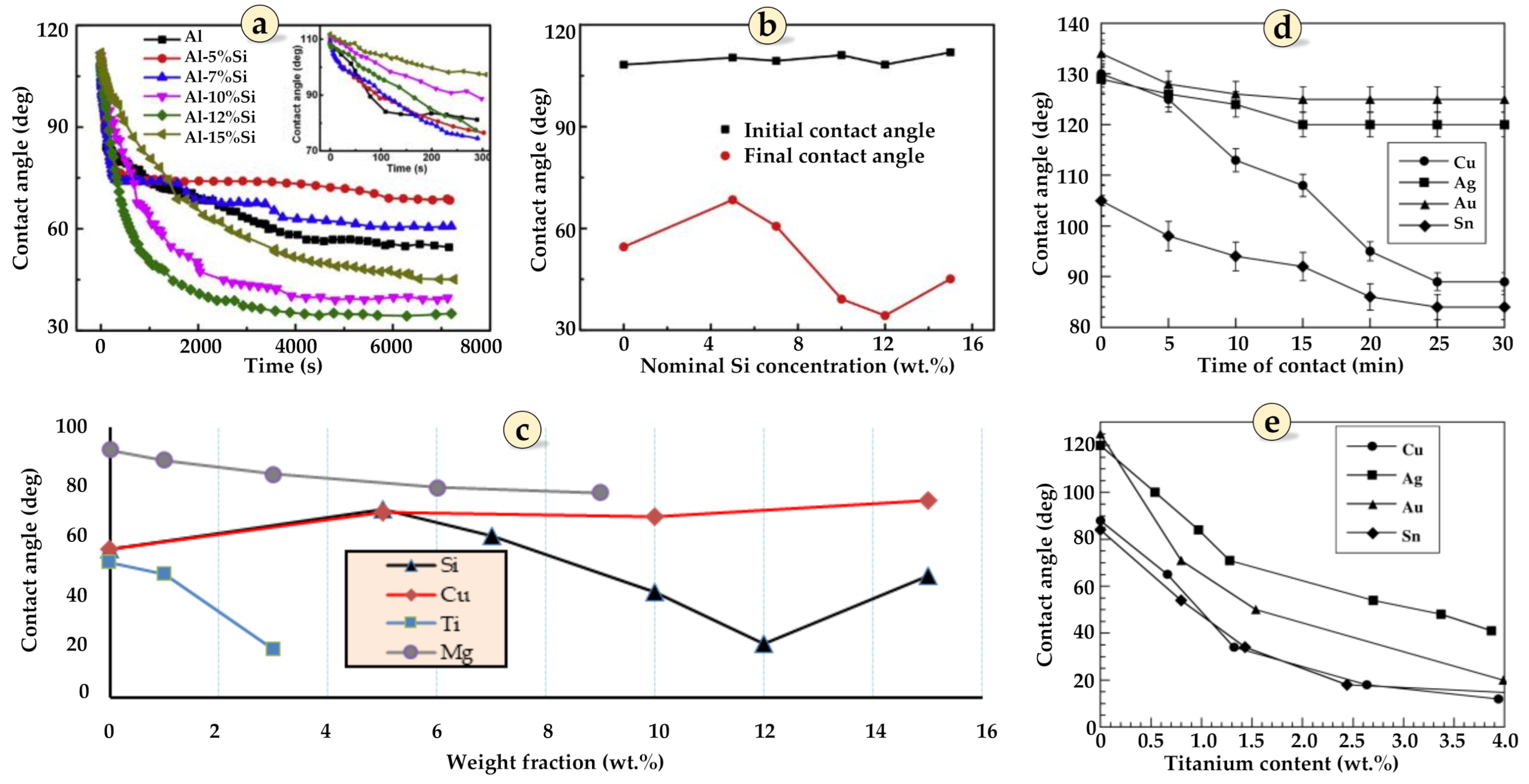

5. Chemical Agent Addition

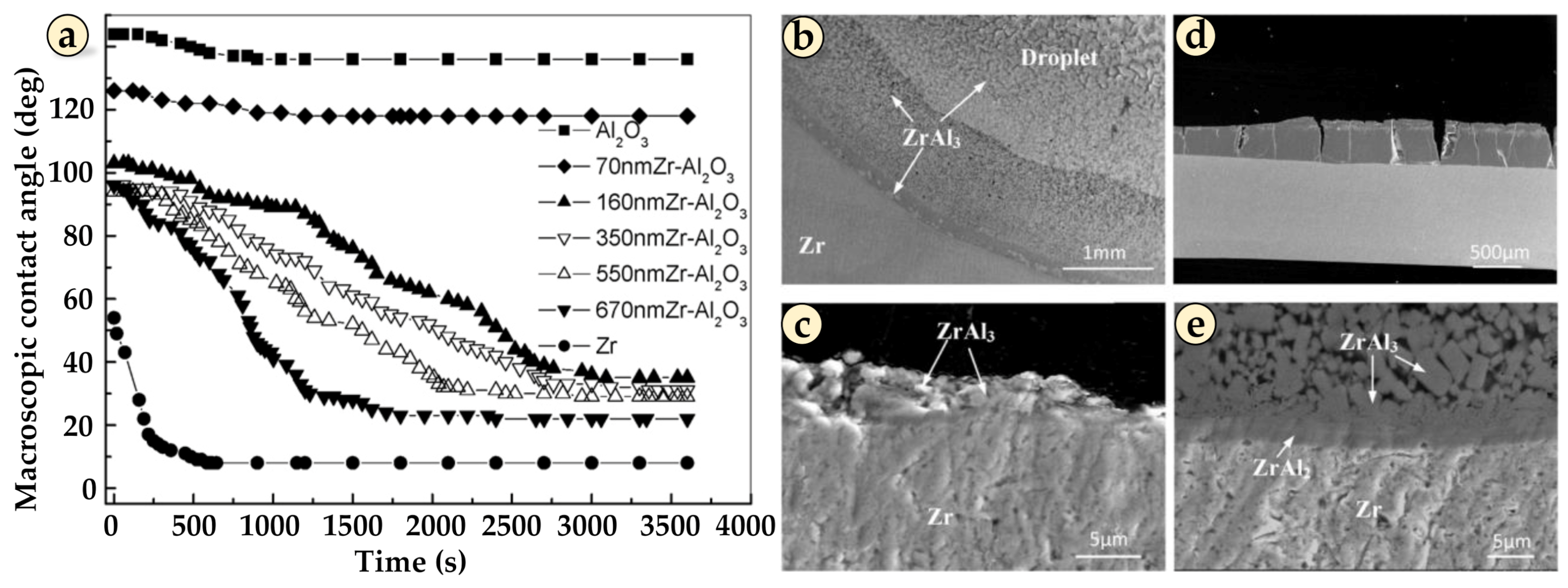

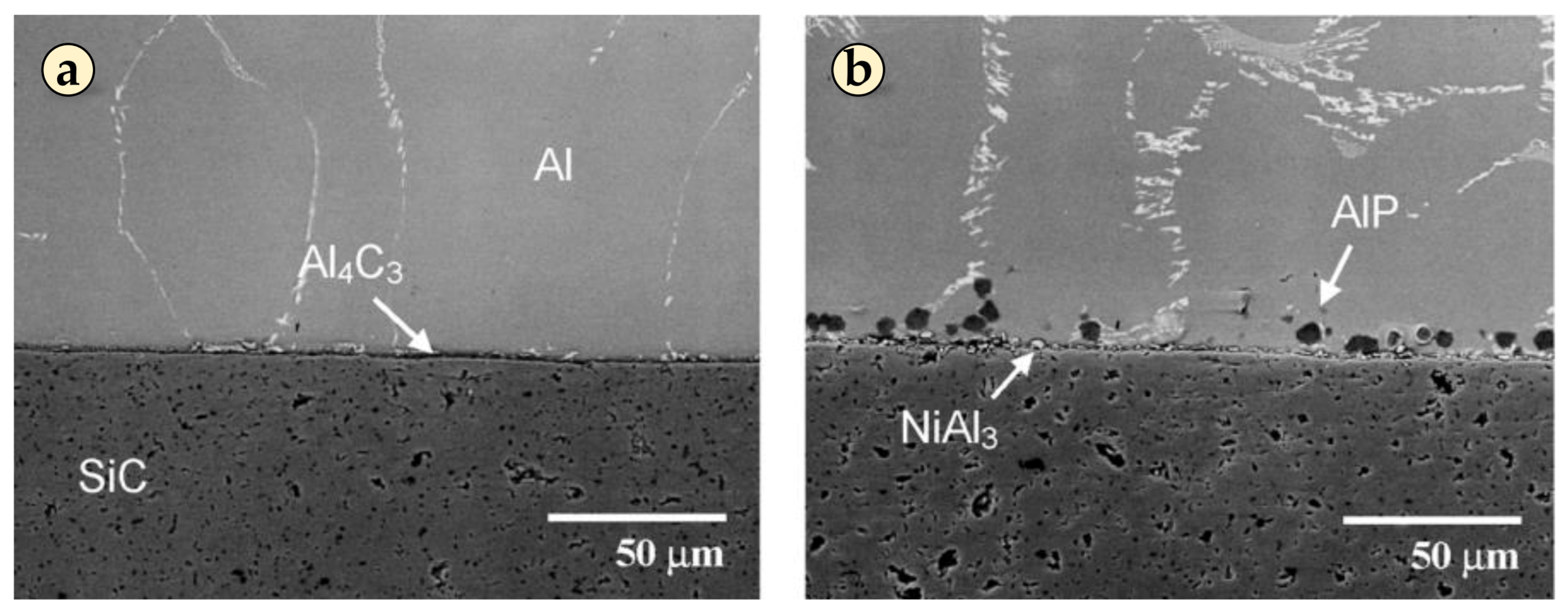

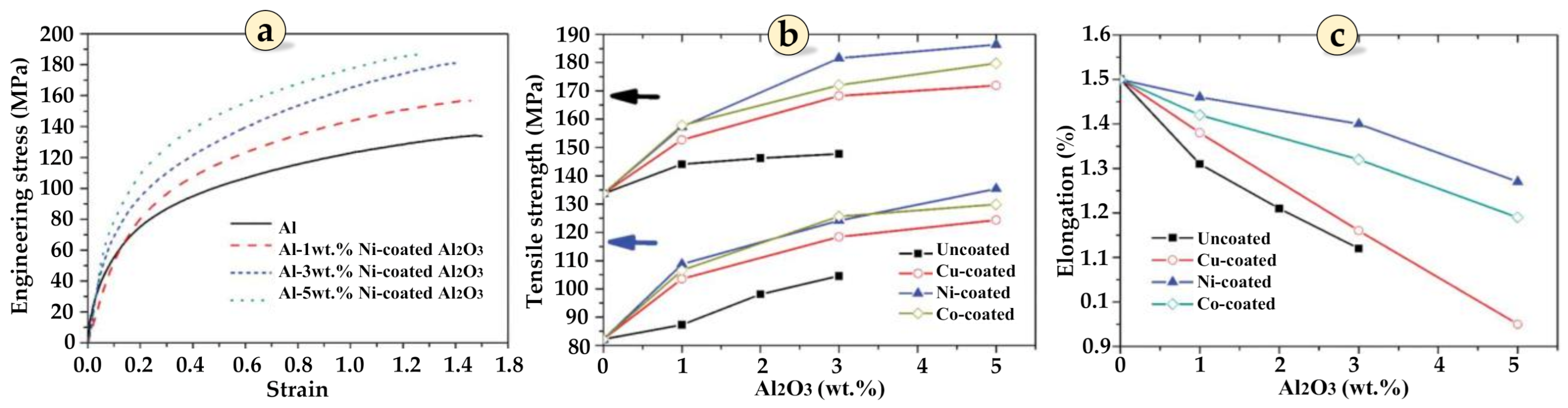

6. Coating

7. Summary and Research Pitfalls

Funding

Conflicts of Interest

References

- Cuevas, A.C.; Bercerril, E.; Martínez, M.S. Metal Matric Composites: Wetting and Infiltration; Springer: Cham, Switzerland, 2018; p. 221. [Google Scholar]

- Abbasipour, B.; Niroumand, B.; Vaghefi, S.M.M.; Abedi, M. Tribological behavior of A356− CNT nanocomposites fabricated by various casting techniques. Trans. Nonferrous Met. Soc. China 2019, 29, 1993–2004. [Google Scholar] [CrossRef]

- Shayan, M.; Eghbali, B.; Niroumand, B. Fabrication of AA2024−TiO2 nanocomposites through stir casting process. Trans. Nonferrous Met. Soc. China 2020, 30, 2891–2903. [Google Scholar] [CrossRef]

- Shayan, M.; Eghbali, B.; Niroumand, B. Synthesis and characterization of AA2024-SiO2 nanocomposites through the vortex method. Int. J. Met. 2021, 15, 1–14. [Google Scholar]

- Amirkhanlou, S.; Jamaati, R.; Niroumand, B.; Toroghinejad, M.R. Fabrication and characterization of Al/SiCp composites by CAR process. Mater. Sci. Eng. A 2011, 528, 4462–4467. [Google Scholar] [CrossRef]

- Shayan, M.; Eghbali, B.; Niroumand, B. The role of accumulative roll bonding after stir casting process to fabricate high-strength and nanostructured AA2024-(SiO2+TiO2) hybrid nanocomposite. J. Alloys Compd. 2020, 845, 156281. [Google Scholar] [CrossRef]

- Pramod, S.L.; Bakshi, S.R.; Murty, B.S. Aluminum-based cast in situ composites: A review. J. Mater. Eng. Perform. 2015, 24, 2185–2207. [Google Scholar] [CrossRef]

- Malaki, M.; Xu, W.; Kasar, A.K.; Menezes, P.L.; Dieringa, H.; Varma, R.S.; Gupta, M. Advanced metal matrix nanocomposites. Metals 2019, 9, 330. [Google Scholar] [CrossRef]

- Eustathopoulos, N.; Voytovych, R. The role of reactivity in wetting by liquid metals: A review. J. Mater. Sci. 2016, 51, 425–437. [Google Scholar] [CrossRef]

- Saiz, E.; Tomsia, A.P.; Cannon, R.M. Ridging effects on wetting and spreading of liquids on solids. Acta Mater. 1998, 46, 2349–2361. [Google Scholar] [CrossRef]

- Malaki, M.; Tehrani, A.F.; Niroumand, B. Fatgiue behavior of metal matrix nanocomposites. Ceram. Int. 2020, 46, 23326–23336. [Google Scholar] [CrossRef]

- Liu, G.W.; Muolo, M.L.; Valenza, F.; Passerone, A. Survey on wetting of SiC by molten metals. Ceram. Int. 2010, 36, 1177–1188. [Google Scholar] [CrossRef]

- Chatain, D.; Carter, W.C. Spreading of metallic drops. Nat. Mater. 2004, 3, 843–845. [Google Scholar] [CrossRef]

- Laurent, V.; Chatain, D.; Eustathopoulos, N. Wettability of SiO2 and oxidized SiC by aluminium. Mater. Sci. Eng. A 1991, 135, 89–94. [Google Scholar] [CrossRef]

- Xiao, P.; Derby, B. Wetting of titanium nitride and titanium carbide by liquid metals. Acta Mater. 1996, 44, 307–314. [Google Scholar] [CrossRef]

- Rado, C.; Kalogeropoulou, S.; Eustathopoulos, N. Wetting and adhesion in metal-silicon carbide systems: The effect of surface polarity of SiC. Scr. Mater. 1999, 42, 203–208. [Google Scholar] [CrossRef]

- Chatain, D. Anisotropy of wetting. Annu. Rev. Mater. Res. 2008, 38, 45–70. [Google Scholar] [CrossRef]

- Muolo, M.; Ferrera, E.; Novakovic, R.; Passerone, A. Wettability of zirconium diboride ceramics by Ag, Cu and their alloys with Zr. Scr. Mater. 2003, 48, 191–196. [Google Scholar] [CrossRef]

- Kumar, G.; Prabhu, K.N. Review of non-reactive and reactive wetting of liquids on surfaces. Adv. Colloid Interface Sci. 2007, 133, 61–89. [Google Scholar] [CrossRef]

- Earvolino, P.A.; Fine, M.E.; Weertman, J.R.; Parameswaran, V.R. Processing an AlAl3Zr0.25Ti0.75 metal-matrix composite by conventional melting, casting and rolling. Scr. Metall. Mater. 1992, 26, 945–948. [Google Scholar] [CrossRef]

- Tekmen, C.; Saday, F.; Cocen, U.; Ljungberg, L.Y. An Investigation of the Effect of SiC Reinforcement Coating on the Wettability of Al/SiC System. J. Compos. Mater. 2008, 42, 1671–1679. [Google Scholar] [CrossRef]

- Leon, C.; Drew, R. The influence of nickel coating on the wettability of aluminum on ceramics. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1429–1432. [Google Scholar] [CrossRef]

- Huang, Z.; Zhang, X.; Wang, T.; Liu, G.; Shao, H.; Wan, Y.; Qiao, G. Effects of Pd ion implantation and Si addition on wettability of Al/SiC system. Surf. Coat. Technol. 2018, 335, 198–204. [Google Scholar] [CrossRef]

- Zhao, S.T.; Valenza, F.; Liu, G.W.; Muolo, M.L.; Qiao, G.J.; Passerone, A. Surface characterization of Mo-implanted 6H–SiC by high temperature non-reactive wetting tests with the Ni–56Si alloy. Ceram. Int. 2014, 40, 7227–7234. [Google Scholar] [CrossRef]

- Barlak, M.; Piekoszewski, J.; Werner, Z.; Stanislawski, J.; Skladnik-Sadowska, E.; Borkowska, K.; Miskiewicz, M.; Kolitsch, A.; Grötzschel, R.; Starosta, W.; et al. Wettability improvement of carbon ceramic materials by mono and multi energy plasma pulses. Surf. Coat. Technol. 2009, 203, 2536–2540. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, X.; Liu, G.; Valenza, F.; Muolo, M.; Qiao, G.; Passerone, A. Wetting and interfacial behavior of molten Cu on Co–Si (–Mo) coated SiC. Ceram. Int. 2015, 41, 13493–13501. [Google Scholar] [CrossRef]

- Pai, B.; Ramani, G.; Pillai, R.; Satyanarayana, K. Role of magnesium in cast aluminium alloy matrix composites. J. Mater. Sci. 1995, 30, 1903–1911. [Google Scholar] [CrossRef]

- Nakae, H.; Fujii, H.; Sato, K. Reactive wetting of ceramics by liquid metals. Mater. Trans. JIM 1992, 33, 400–406. [Google Scholar] [CrossRef][Green Version]

- Laurent, V.; Rado, C.; Eustathopoulos, N. Wetting kinetics and bonding of Al and Al alloys on α-SiC. Mater. Sci. Eng. A 1996, 205, 1–8. [Google Scholar] [CrossRef]

- An, Q.; Cong, X.-S.; Shen, P.; Jiang, Q.-C. Roles of alloying elements in wetting of SiC by Al. J. Alloys Compd. 2019, 784, 1212–1220. [Google Scholar] [CrossRef]

- Hashim, J.; Looney, L.; Hashmi, M.S.J. The wettability of SiC particles by molten aluminium alloy. J. Mater. Process. Technol. 2001, 119, 324–328. [Google Scholar] [CrossRef]

- Feng, A.; McCoy, B.J.; Munir, Z.A.; Cagliostro, D. Wettability of transition metal oxide surfaces. Mater. Sci. Eng. A 1998, 242, 50–56. [Google Scholar] [CrossRef]

- Ray, S. Casting of composite components. In Proceedings of the 1995 Conference on Inorganic Matrix Composites, Delhi, India, 5 June 1996; pp. 69–89. [Google Scholar]

- Zhou, W.; Xu, Z.M. Casting of SiC reinforced metal matrix composites. J. Mater. Process. Technol. 1997, 63, 358–363. [Google Scholar] [CrossRef]

- Warren, R.; Andersson, C. Silicon carbide fibres and their potential for use in composite materials. Part II. Composites 1984, 15, 101–111. [Google Scholar] [CrossRef]

- Aguilar, E.; León, C.; Contreras, A.; López, V.; Drew, R.; Bedolla, E. Wettability and phase formation in TiC/Al-alloys assemblies. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1425–1428. [Google Scholar] [CrossRef]

- Jebeen Moses, J.; Joseph Sekhar, S. Investigation on the Tensile Strength and Microhardness of AA6061/TiC Composites by Stir Casting. Trans. Indian Inst. Met. 2017, 70, 1035–1046. [Google Scholar] [CrossRef]

- Naher, S.; Brabazon, D.; Looney, L. Computational and experimental analysis of particulate distribution during Al–SiC MMC fabrication. Compos. Part A Appl. Sci. Manuf. 2007, 38, 719–729. [Google Scholar] [CrossRef]

- Naidich, Y.V. The wettability of solids by liquid metals. Prog. Surf. Membr. Sci. 1972, 14, 353–484. [Google Scholar]

- Kohler, W. Investigations into the Wetting of Al2O3- and SiC- Crystals by Aluminum and Aluminum Alloys. Aluminium 1975, 51, 443–447. [Google Scholar]

- Halverson, D.C.; Pyzik, A.J.; Aksay, I.A. Processing and microstructural characterization of B4C-AI cermets. In Proceedings of the 9th Annual Conference on Composites and Advanced Ceramic Materials: Ceramic Engineering and Science Proceedings; Wiley: New York, NY, USA, 1985; pp. 736–744. [Google Scholar]

- Brennan, J.J.; Pask, J.A. Effect of nature of surfaces on wetting of sapphire by liquid aluminum. J. Am. Ceram. Soc. 1968, 51, 569–573. [Google Scholar] [CrossRef]

- Wolf, S.; Levitt, A.; Brown, J. Whisker-metal matrix bonding. Chem. Eng. Prog. 1966, 62, 74. [Google Scholar]

- Champion, J.; Keene, B.; Sillwood, J. Wetting of aluminium oxide by molten aluminium and other metals. J. Mater. Sci. 1969, 4, 39–49. [Google Scholar] [CrossRef]

- Rohatgi, P.; Asthana, R.; Das, S. Solidification, structures, and properties of cast metal-ceramic particle composites. Int. Met. Rev. 1986, 31, 115–139. [Google Scholar] [CrossRef]

- Eskin, G.I.; Eskin, D.G. Ultrasonic Treatment of Light Alloy Melts, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2015; p. 346. [Google Scholar]

- Egry, I.; Ricci, E.; Novakovic, R.; Ozawa, S. Surface tension of liquid metals and alloys—Recent developments. Adv. Colloid Interface Sci. 2010, 159, 198–212. [Google Scholar] [CrossRef]

- Shen, P.; Fujii, H.; Matsumoto, T.; Nogi, K. The influence of surface structure on wetting of α-Al2O3 by aluminum in a reduced atmosphere. Acta Mater. 2003, 51, 4897–4906. [Google Scholar] [CrossRef]

- Park, J.; Lucas, J. Moisture effect on SiCp/6061 Al MMC: Dissolution of interfacial Al4C3. Scr. Mater. 1997, 37, 511–516. [Google Scholar] [CrossRef]

- Hashim, J.; Looney, L.; Hashmi, M.S.J. The enhancement of wettability of SiC particles in cast aluminium matrix composites. J. Mater. Process. Technol. 2001, 119, 329–335. [Google Scholar] [CrossRef]

- Thanh, L.N.; Suéry, M. Influence of oxide coating on chemical stability of SiC particles in liquid aluminium. Scr. Metall. Mater. 1991, 25, 2781–2786. [Google Scholar] [CrossRef]

- Prabu, S.B.; Karunamoorthy, L.; Kathiresan, S.; Mohan, B. Influence of stirring speed and stirring time on distribution of particles in cast metal matrix composite. J. Mater. Process. Technol. 2006, 171, 268–273. [Google Scholar] [CrossRef]

- Wang, X.; Wang, L.; Gao, X.; Hu, Q.-G.; Talha, M.; Liu, H.; Chai, S. Study on Interface Behavior of SiC/SiO2/Al and SiC/Ni/Al. Trans. Indian Inst. Met. 2019, 72, 3171–3178. [Google Scholar] [CrossRef]

- Nowak, R.; Sobczak, N.; Bruzda, G.; Wojewoda-Budka, J.; Litynska-Dobrzynska, L.; Homa, M.; Kaban, I.; Xi, L.; Jaworska, L. Wettability and Reactivity of ZrB2 Substrates with Liquid Al. J. Mater. Eng. Perform. 2016, 25, 3310–3316. [Google Scholar] [CrossRef][Green Version]

- Řeháčková, L.; Novák, V.; Váňová, P.; Matýsek, D.; Konečná, K.; Smetana, B.; Dobrovská, J. High-temperature interaction of molten Fe–C–O–Cr alloys with corundum. J. Alloys Compd. 2021, 854, 157128. [Google Scholar] [CrossRef]

- Nogi, K.; Ogino, K. Wettability of SiC by liquid pure metals. Trans. Jpn. Inst. Met. 1988, 29, 742–747. [Google Scholar] [CrossRef]

- Kalogeropoulou, S.; Baud, L.; Eustathopoulos, N. Relationship between wettability and reactivity in Fe/SiC system. Acta Metall. Mater. 1995, 43, 907–912. [Google Scholar] [CrossRef]

- Nikolopoulos, P.; Los, S.A.P.; Angelopoulos, G.; Naoumidis, A.; Grübmeier, H. Wettability and interfacial energies in SiC-liquid metal systems. J. Mater. Sci. 1992, 27, 139–145. [Google Scholar] [CrossRef]

- Li, J.; Hausner, H. Wettability of silicon carbide by gold, germanium and silicon. J. Mater. Sci. Lett. 1991, 10, 1275–1276. [Google Scholar] [CrossRef]

- Ferro, A.; Derby, B. Development of a micro-droplet technique for wettability studies: Application to the Al-Si/SiC system. Scr. Metall. Mater. 1995, 33, 837–842. [Google Scholar] [CrossRef]

- Jones, H.; Atkinson, H. The wettability of silicon carbide by liquid aluminium: The effect of free silicon in the carbide and of magnesium, silicon and copper alloy additions to the aluminium. J. Mater. Sci. 1993, 28, 2654–2658. [Google Scholar]

- Takahashi, S.; Kuboi, O. Study on contact angles of Au, Ag, Cu, Sn, Al and Al alloys to SiC. J. Mater. Sci. 1996, 31, 1797–1802. [Google Scholar] [CrossRef]

- Rado, C.; Drevet, B.; Eustathopoulos, N. The role of compound formation in reactive wetting: The Cu/SiC system. Acta Mater. 2000, 48, 4483–4491. [Google Scholar] [CrossRef]

- Gnesin, G.; Naidich, Y.V. Contact reaction of silicon carbide with fused copper. Sov. Powder Metall. Met. Ceram. 1969, 8, 128–132. [Google Scholar] [CrossRef]

- Li, S.; Zhou, Y.; Duan, H. Wettability and interfacial reaction in SiC/Ni plus Ti system. J. Mater. Sci. 2002, 37, 2575–2579. [Google Scholar] [CrossRef]

- Kaiser, N.; Cröll, A.; Szofran, F.; Cobb, S.; Benz, K. Wetting angle and surface tension of germanium melts on different substrate materials. J. Cryst. Growth 2001, 231, 448–457. [Google Scholar] [CrossRef]

- Fu, W.; Song, X.; Tian, R.; Lei, Y.; Long, W.; Zhong, S.; Feng, J. Wettability and joining of SiC by Sn-Ti: Microstructure and mechanical properties. J. Mater. Sci. Technol. 2020, 40, 15–23. [Google Scholar] [CrossRef]

- Jian-Guo, L. Wettability of silicon carbide by liquid silver and binary silver-silicon alloy. Mater. Lett. 1994, 18, 291–298. [Google Scholar] [CrossRef]

- Naidich, Y.V.; Zhuravlev, V.; Krasovskaya, N. The wettability of silicon carbide by Au–Si alloys. Mater. Sci. Eng. A 1998, 245, 293–299. [Google Scholar] [CrossRef]

- Zhang, W.Y.; Du, Y.H.; Zhang, P.; Wang, Y.J. Air-isolated stir casting of homogeneous Al-SiC composite with no air entrapment and Al4C3. J. Mater. Process. Technol. 2019, 271, 226–236. [Google Scholar] [CrossRef]

- Andersson, C.; Warren, R. Silicon carbide fibres and their potential for use in composite materials. Part 1. Composites 1984, 15, 16–24. [Google Scholar] [CrossRef]

- Salvo, L.; L’Espérance, G.; Suéry, M.; Legoux, J.G. Interfacial reactions and age hardening in Al-Mg-Si metal matrix composites reinforced with SiC particles. Mater. Sci. Eng. A 1994, 177, 173–183. [Google Scholar] [CrossRef]

- Eustathopoulos, N.; Sobczak, N.; Passerone, A.; Nogi, K. Measurement of contact angle and work of adhesion at high temperature. J. Mater. Sci. 2005, 40, 2271–2280. [Google Scholar] [CrossRef]

- Rajan, T.; Pillai, R.; Pai, B. Reinforcement coatings and interfaces in aluminium metal matrix composites. J. Mater. Sci. 1998, 33, 3491–3503. [Google Scholar] [CrossRef]

- Levi, G.; Kaplan, W.D. Oxygen induced interfacial phenomena during wetting of alumina by liquid aluminium. Acta Mater. 2002, 50, 75–88. [Google Scholar] [CrossRef]

- Yu, Z.; Wu, G.; Sun, D.; Jiang, L. Coating of Y2O3 additive on Al2O3 powder and its effect on the wetting behaviour in the system Al2O3p/Al. Mater. Lett. 2003, 57, 3111–3116. [Google Scholar] [CrossRef]

- Sangghaleh, A.; Halali, M. Effect of magnesium addition on the wetting of alumina by aluminium. Appl. Surf. Sci. 2009, 255, 8202–8206. [Google Scholar] [CrossRef]

- Naher, S.; Brabazon, D.; Looney, L. Development and assessment of a new quick quench stir caster design for the production of metal matrix composites. J. Mater. Process. Technol. 2005, 166, 430–439. [Google Scholar] [CrossRef]

- Naher, S.; Brabazon, D.; Looney, L. Simulation of the stir casting process. J. Mater. Process. Technol. 2003, 143, 567–571. [Google Scholar] [CrossRef]

- Shabani, M.O.; Heydari, F.; Khorram, A. The effect of electromagnetic stirrer on the size and morphology of intermetallic particles in Al-Si metal matrix composite. Silicon 2019, 11, 2539–2546. [Google Scholar] [CrossRef]

- Dehnavi, M.R. Effects of Sequentional Ultrasonic Treatment on Mechanical Properties and Microstructural Characteristics of Cast Al413-SiCnp Nanocomposites. Ph.D Thesis, Isfahan University of Technology, , Isfahan, Iran; p. 2015.

- Shayan, M.; Eghbali, B.; Niroumand, B. Synthesis of AA2024-(SiO2np + TiO2np) hybrid nanocomposite via stir casting process. Mater. Sci. Eng. A 2019, 756, 484–491. [Google Scholar] [CrossRef]

- Krishnan, P.K.; Arunachalam, R.; Husain, A.; Al-Maharbi, M. Studies on the Influence of Stirrer Blade Design on the Microstructure and Mechanical Properties of a Novel Aluminum Metal Matrix Composite. J. Manuf. Sci. Eng. 2021, 143, 021008. [Google Scholar] [CrossRef]

- Mehta, V.R.; Sutaria, M.P. Investigation on the Effect of Stirring Process Parameters on the Dispersion of SiC Particles inside Melting Crucible. Met. Mater. Int. 2020, 26, 1–14. [Google Scholar] [CrossRef]

- Yamamoto, T.; Suzuki, A.; Komarov, S.V.; Ishiwata, Y. Investigation of impeller design and flow structures in mechanical stirring of molten aluminum. J. Mater. Process. Technol. 2018, 261, 164–172. [Google Scholar] [CrossRef]

- Rohatgi, P.; Sobczak, J.; Asthana, R.; Kim, J. Inhomogeneities in silicon carbide distribution in stirred liquids—a water model study for synthesis of composites. Mater. Sci. Eng. A 1998, 252, 98–108. [Google Scholar] [CrossRef]

- Hashim, J.; Looney, L.; Hashmi, M. Metal matrix composites: Production by the stir casting method. J. Mater. Process. Technol. 1999, 92, 1–7. [Google Scholar] [CrossRef]

- Ghosh, P.; Ray, S. Fabrication and properties of compocast aluminium-alumina particulate composite. Indian J. Technol. 1988, 26, 83–94. [Google Scholar]

- Saternus, M. Influence of impeller shape on the gas bubbles dispersion in aluminium refining process. J. Achiev. Mater. Manuf. Eng. 2012, 55, 285–290. [Google Scholar]

- Nagata, S. Mixing Principles and Applications; Wiley: New York, NY, USA, 1975. [Google Scholar]

- Moon, H.-K. Rheological Behavior and Microstructure of Ceramic Particulate/Aluminum Alloy Com Posites. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1990. [Google Scholar]

- Bui, R.T.; Ouellet, R.; Kocaefe, D. A two-phase flow model of the stirring of Al-SiC composite melt. Metall. Mater. Trans. B 1994, 25, 607–618. [Google Scholar] [CrossRef]

- Torotwa, I.; Ji, C. A study of the mixing performance of different impeller designs in stirred vessels using computational fluid dynamics. Designs 2018, 2, 10. [Google Scholar] [CrossRef]

- Wu, J.; Pullum, L. Performance analysis of axial-flow mixing impellers. AIChE J. 2000, 46, 489–498. [Google Scholar] [CrossRef]

- Hashim, J.; Looney, L.; Hashmi, M. Particle distribution in cast metal matrix composites—Part II. J. Mater. Process. Technol. 2002, 123, 258–263. [Google Scholar] [CrossRef]

- Ravi, K.R.; Sreekumar, V.M.; Pillai, R.M.; Mahato, C.; Amaranathan, K.R.; Arul kumar, R.; Pai, B.C. Optimization of mixing parameters through a water model for metal matrix composites synthesis. Mater. Des. 2007, 28, 871–881. [Google Scholar] [CrossRef]

- Bhandare, R.G.; Sonawane, P.M. Preparation of aluminium matrix composite by using stir casting method. Int. J. Eng. Adv. Technol. (IJEAT) 2013, 3, 61–65. [Google Scholar]

- Sajjadi, S.A.; Ezatpour, H.R.; Beygi, H. Microstructure and mechanical properties of Al–Al2O3 micro and nano composites fabricated by stir casting. Mater. Sci. Eng. A 2011, 528, 8765–8771. [Google Scholar] [CrossRef]

- Eskin, G.; Eskin, D. Production of natural and synthesized aluminum-based composite materials with the aid of ultrasonic (cavitation) treatment of the melt. Ultrason. Sonochem. 2003, 10, 297–301. [Google Scholar] [CrossRef]

- Abdullah, A.; Malaki, M.; Baghizadeh, E. On the impact of ultrasonic cavitation bubbles. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2012, 226, 681–694. [Google Scholar] [CrossRef]

- Dehnavi, M.; Niroumand, B.; Ashrafizadeh, F.; Rohatgi, P. Effects of continuous and discontinuous ultrasonic treatments on mechanical properties and microstructural characteristics of cast Al413–SiCnp nanocomposite. Mater. Sci. Eng. A 2014, 617, 73–83. [Google Scholar] [CrossRef]

- Zhao, J.; Jiang, Z.; Zhu, J.; Zhang, S.; Li, Y. Wetting of carbon by molten aluminum under ultrasonic field. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Nanning, China, 22–24 May 2021; p. 012008. [Google Scholar]

- Puga, H.; Barbosa, J.; Teixeira, J.C.; Prokic, M. A new approach to ultrasonic degassing to improve the mechanical properties of aluminum alloys. J. Mater. Eng. Perform. 2014, 23, 3736–3744. [Google Scholar] [CrossRef]

- Kudryashova, O.; Vorozhtsov, S. On the Mechanism of Ultrasound-Driven Deagglomeration of Nanoparticle Agglomerates in Aluminum Melt. JOM 2016, 68, 1307–1311. [Google Scholar] [CrossRef]

- Tzanakis, I.; Xu, W.W.; Eskin, D.G.; Lee, P.D.; Kotsovinos, N. In situ observation and analysis of ultrasonic capillary effect in molten aluminium. Ultrason. Sonochem. 2015, 27, 72–80. [Google Scholar] [CrossRef]

- Chen, L.-Y.; Xu, J.-Q.; Choi, H.; Pozuelo, M.; Ma, X.; Bhowmick, S.; Yang, J.-M.; Mathaudhu, S.; Li, X.-C. Processing and properties of magnesium containing a dense uniform dispersion of nanoparticles. Nature 2015, 528, 539. [Google Scholar] [CrossRef]

- Shen, P.; Wang, Y.; Ren, L.; Li, S.; Liu, Y.; Jiang, Q. Influence of SiC surface polarity on the wettability and reactivity in an Al/SiC system. Appl. Surf. Sci. 2015, 355, 930–938. [Google Scholar] [CrossRef]

- Dieringa, H. Properties of magnesium alloys reinforced with nanoparticles and carbon nanotubes: A review. J. Mater. Sci. 2011, 46, 289–306. [Google Scholar] [CrossRef]

- Tjong, S.C. Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets. Mater. Sci. Eng. R Rep. 2013, 74, 281–350. [Google Scholar] [CrossRef]

- Kobashi, M.; Choh, T. The wettability and the reaction for SiC particle/Al alloy system. J. Mater. Sci. 1993, 28, 684–690. [Google Scholar] [CrossRef]

- Glass, S.J.; RolfWaesche, K.U.; Naito, M. Effects of titanium on wettability and interfaces in aluminum/ceramic systems. Charact. Control. Interfaces High Qual. Adv. Mater. 2005, 83, 81–91. [Google Scholar]

- Mao, Y.; Mombello, D.; Baroni, C. Wettability of Ni–Cr filler on SiC ceramic and interfacial reactions for the SiC/Ni–51Cr system. Scr. Mater. 2011, 64, 1087–1090. [Google Scholar] [CrossRef]

- Xiong, H.-P.; Chen, B.; Kang, Y.-S.; Mao, W.; Kawasaki, A.; Okamura, H.; Watanabe, R. Wettability of Co–V, and PdNi–Cr–V system alloys on SiC ceramic and interfacial reactions. Scr. Mater. 2007, 56, 173–176. [Google Scholar] [CrossRef]

- Tao, Z.; Guo, Q.; Gao, X.; Liu, L. The wettability and interface thermal resistance of copper/graphite system with an addition of chromium. Mater. Chem. Phys. 2011, 128, 228–232. [Google Scholar] [CrossRef]

- Nosko, M.; Nagy, Š.; Weber, L.; Maťko, I.; Mihalkovič, M.; Iždinský, K.; Orovčík, Ľ. Effect of Ca addition on interface formation in Al(Ca)/Al2O3 composites prepared by gas pressure assisted infiltration. Mater. Des. 2016, 108, 618–623. [Google Scholar] [CrossRef]

- Garcia-Hinojosa, J.A.; Gonzalez, C.R.; Juárez, J.I.; Surappa, M.K. Effect of Sr addition on an Al–7Si–10 vol.% SiCp cast composites. Mater. Sci. Eng. A 2004, 382, 315–320. [Google Scholar] [CrossRef]

- Lashgari, H.R.; Sufizadeh, A.R.; Emamy, M. The effect of strontium on the microstructure and wear properties of A356–10%B4C cast composites. Mater. Des. 2010, 31, 2187–2195. [Google Scholar] [CrossRef]

- Abedi, K.; Emamy, M. The effect of Fe, Mn and Sr on the microstructure and tensile properties of A356–10% SiC composite. Mater. Sci. Eng. A 2010, 527, 3733–3740. [Google Scholar] [CrossRef]

- Agarwala, V.; Dixit, D. Fabrication of aluminium base composite by foundry technique. Trans. Jpn. Inst. Met. 1981, 22, 521–526. [Google Scholar] [CrossRef]

- Cao, C.; Chen, L.; Xu, J.; Choi, H.; Li, X. Strengthening Al–Bi–TiC0. 7N0. 3 nanocomposites by Cu addition and grain refinement. Mater. Sci. Eng. A 2016, 651, 332–335. [Google Scholar] [CrossRef]

- Wójcik-Grzybek, D.; Frydman, K.; Sobczak, N.; Nowak, R.; Piątkowska, A.; Pietrzak, K. Effect of Ti and Zr additions on wettability and work of adhesion in Ag/c system. Mater. Elektron. 2017, 45, 4–11. [Google Scholar]

- Cong, X.S.; Shen, P.; Wang, Y.; Jiang, Q. Wetting of polycrystalline SiC by molten Al and Al− Si alloys. Appl. Surf. Sci. 2014, 317, 140–146. [Google Scholar] [CrossRef]

- Ashok Kumar, B.; Murugan, N. Metallurgical and mechanical characterization of stir cast AA6061-T6–AlNp composite. Mater. Des. 2012, 40, 52–58. [Google Scholar] [CrossRef]

- McLeod, A.; Gabryel, C. Kinetics of the growth of spinel, MgAl2O4, on alumina particulate in aluminum alloys containing magnesium. Metall. Trans. A 1992, 23, 1279–1283. [Google Scholar] [CrossRef]

- Sukumaran, K.; Pillai, S.; Pillai, R.; Kelukutty, V.; Pai, B.; Satyanarayana, K.; Ravikumar, K. The effects of magnesium additions on the structure and properties of Al-7 Si-10 SiC p composites. J. Mater. Sci. 1995, 30, 1469–1472. [Google Scholar] [CrossRef]

- Korol’kov, A.M. Casting Properties of Metals and Alloys; Consultants Bureau: New York, NY, USA, 1963. [Google Scholar]

- Contreras, A.; Bedolla, E.; Pérez, R. Interfacial phenomena in wettability of TiC by Al–Mg alloys. Acta Mater. 2004, 52, 985–994. [Google Scholar] [CrossRef]

- Fujii, H.; Nakae, H.; Okada, K. Interfacial reaction wetting in the boron nitride/molten aluminum system. Acta Metall. Mater. 1993, 41, 2963–2971. [Google Scholar] [CrossRef]

- Pashmforoosh, S.; Shahriyari, S.; Mirzaee, O. Evaluation of Mechanical and Microstructure Properties of Mg-Modified Aluminum Matrix Composite by Vortical Casting Method. Met. Mater. Int. 2020, 26, 1–13. [Google Scholar] [CrossRef]

- Shao, N.; Dai, J.; Li, G.; Nakae, H.; Hane, T. Effect of La on the wettability of Al2O3 by molten aluminum. Mater. Lett. 2004, 58, 2041–2044. [Google Scholar] [CrossRef]

- Froumin, N.; Frage, N.; Polak, M.; Dariel, M. Wetting phenomena in the TiC/(Cu–Al) system. Acta Mater. 2000, 48, 1435–1441. [Google Scholar] [CrossRef]

- Lee, J.-C.; Park, S.-B.; Seok, H.-K.; Oh, C.-S.; Lee, H.-I. Prediction of Si contents to suppress the interfacial reaction in the SiCp/2014 Al composite. Acta Mater. 1998, 46, 2635–2643. [Google Scholar] [CrossRef]

- Lee, J.-C.; Byun, J.-Y.; Park, S.-B.; Lee, H.-I. Prediction of Si contents to suppress the formation of Al4C3 in the SiCp/Al composite. Acta Mater. 1998, 46, 1771–1780. [Google Scholar] [CrossRef]

- Ferro, A.C.; Derby, B. Wetting behaviour in the Al-Si/SiC system: Interface reactions and solubility effects. Acta Metall. Mater. 1995, 43, 3061–3073. [Google Scholar] [CrossRef]

- Nakae, H.; Yamamoto, K.; Sato, K. Measurement of wetting of graphite by Al and Al–Si alloys using meniscography. Mater. Trans. JIM 1991, 32, 531–538. [Google Scholar] [CrossRef]

- Shen, P.; Fujii, H.; Nogi, K. Wetting, Adhesion and Adsorption in Al-Si/(0112) α-Alumina System at 1723 K. Mater. Trans. 2004, 45, 2857–2863. [Google Scholar] [CrossRef][Green Version]

- Frage, N.; Froumin, N.; Aizenshtein, M.; Kutsenko, L.; Fuks, D.; Dariel, M.P. Reactive wetting in titanium carbide/non-reactive metal systems. Curr. Opin. Solid State Mater. Sci. 2005, 9, 189–195. [Google Scholar] [CrossRef]

- Zhao, B.; Cai, Q.; Li, X.; Li, B.; Cheng, J. Effect of TiC Nanoparticles Supported by Ti Powders on the Solidification Behavior and Microstructure of Pure Aluminum. Met. Mater. Int. 2018, 24, 945–954. [Google Scholar] [CrossRef]

- Schuster, J.C.; Palm, M. Reassessment of the binary Aluminum-Titanium phase diagram. J. Phase Equilibria Diffus. 2006, 27, 255–277. [Google Scholar] [CrossRef]

- Kumar, A.; Gautam, R.; Tyagi, R. Dry sliding wear characteristics of in situ synthesized Al-TiC composites. Compos. Interfaces 2016, 23, 469–480. [Google Scholar] [CrossRef]

- Zheng, B.; Li, W.; Tu, X.; Xu, F.; Liu, K.; Song, S. Effect of titanium binder addition on the interface structure and three-body abrasive wear behavior of ZTA ceramic particles-reinforced high chromium cast iron. Ceram. Int. 2020, 46, 13798–13806. [Google Scholar] [CrossRef]

- Xu, Q.-G.; Guo, L.-W.; Zhang, L.; Liu, H. Wettability of zirconium-coated alumina by molten aluminum. Surf. Coat. Technol. 2016, 302, 150–157. [Google Scholar] [CrossRef]

- Kennedy, A.; Wood, J.; Weager, B. The wetting and spontaneous infiltration of ceramics by molten copper. J. Mater. Sci. 2000, 35, 2909–2912. [Google Scholar] [CrossRef]

- Pan, S.; Guan, Z.; Yao, G.; Yuan, J.; Li, X. Mo-enhanced chemical stability of TiC nanoparticles in molten Al. J. Alloys Compd. 2021, 856, 158169. [Google Scholar] [CrossRef]

- Auger, J.M.; Martin, S.; Gruy, F. Wettability-enabling coating on oxide particles through controlled milling. Powder Technol. 2019, 344, 302–306. [Google Scholar] [CrossRef]

- Zhao, S.T.; Zhang, X.Z.; Liu, G.W.; Xia, H.Y.; Shi, Z.Q.; Qiao, G.J. Wetting and Interfacial Behavior of Molten Al on Mo-Ni (Co)-Si Coated SiC Ceramic. In Key Engineering Materials; Trans Tech Publications Ltd.: Stafa, Switzerland, 2016; pp. 481–484. [Google Scholar]

- Santuan, Z.; Xiangzhao, Z.; Guiwu, L.; Fabrizio, V.; MariaLuigia, M.; Guanjun, Q.; Alberto, P. Surface Metallization of SiC Ceramic by Mo-Ni-Si Coatings for Improving Its Wettability by Molten Ag. Rare Met. Mater. Eng. 2018, 47, 759–765. [Google Scholar] [CrossRef]

- Yu, J.; Li, H.; Shang, B. A functionally gradient coating on carbon fibre for C/Al composites. J. Mater. Sci. 1994, 29, 2641–2647. [Google Scholar] [CrossRef]

- Ko, Y.J.; Yoon, J.; Lee, J.; Han, J.H. Effects of Cu interlayer on the wettability of aluminum on carbon. J. Alloys Compd. 2013, 574, 526–531. [Google Scholar] [CrossRef]

- Warrier, S.; Blue, C.; Lin, R. Control of interfaces in Al-C fibre composites. J. Mater. Sci. 1993, 28, 760–768. [Google Scholar] [CrossRef]

- Mousavian, R.T.; Damadi, S.R.; Khosroshahi, R.A.; Brabazon, D.; Mohammadpour, M. A comparison study of applying metallic coating on SiC particles for manufacturing of cast aluminum matrix composites. Int. J. Adv. Manuf. Technol. 2015, 81, 433–444. [Google Scholar] [CrossRef]

- Bardal, A. The effect of antimony on the interfaces of cast AlSi-SiC composites. J. Mater. Sci. 1993, 28, 2699–2705. [Google Scholar] [CrossRef]

- Warrier, S.; Lin, R. Silver coating on carbon and SiC fibres. J. Mater. Sci. 1993, 28, 4868–4877. [Google Scholar] [CrossRef]

- Zhang, L.-J.; Yang, D.-L.; Qiu, F.; Wang, J.-G.; Jiang, Q.-C. Effects of reinforcement surface modification on the microstructures and tensile properties of SiCp/Al2014 composites. Mater. Sci. Eng. A 2015, 624, 102–109. [Google Scholar] [CrossRef]

- Singh, B.B.; Balasubramanian, M. Processing and properties of copper-coated carbon fibre reinforced aluminium alloy composites. J. Mater. Process. Technol. 2009, 209, 2104–2110. [Google Scholar] [CrossRef]

- Maqbool, A.; Hussain, M.A.; Khalid, F.A.; Bakhsh, N.; Hussain, A.; Kim, M.H. Mechanical characterization of copper coated carbon nanotubes reinforced aluminum matrix composites. Mater. Charact. 2013, 86, 39–48. [Google Scholar] [CrossRef]

- León, C.A.; Mendoza-Suarez, G.; Drew, R.A.L. Wettability and spreading kinetics of molten aluminum on copper-coated ceramics. J. Mater. Sci. 2006, 41, 5081–5087. [Google Scholar] [CrossRef]

- Carotenuto, G.; Gallo, A.; Nicolais, L. Stability of nickel coatings on carbon fiber preforms: A SEM investigation. Appl. Compos. Mater. 1994, 1, 231–245. [Google Scholar] [CrossRef]

- Asthana, R.; Mileiko, S.; Sobczak, N. Wettability and interface considerations in advanced heat-resistant Ni-base composites. Bull. Pol. Acad. Sci. Tech. Sci. 2006, 54, 147–166. [Google Scholar]

- Surappa, M.; Rohatgi, P. Technical note. Met. Technol. 1978, 5, 358–361. [Google Scholar] [CrossRef]

- Ciby, S.; Pai, B.; Satyanarayana, K.; Vaidyan, V.; Rohatgi, P. Structure formation during processing short carbon fiber-reinforced aluminum alloy matrix composites. J. Mater. Eng. Perform. 1993, 2, 353–357. [Google Scholar] [CrossRef]

- Ip, S.; Sridhar, R.; Toguri, J.; Stephenson, T.; Warner, A. Wettability of nickel coated graphite by aluminum. Mater. Sci. Eng. A 1998, 244, 31–38. [Google Scholar] [CrossRef]

- Elahinejad, S.; Sharifi, H.; Tayebi, M.; Rajaee, A. The influence of nickel coating on the interface of pressureless infiltrated with vibration Al–SiC composites. Mater. Res. Express 2017, 4, 116506. [Google Scholar] [CrossRef]

- Xie, J.-F.; Liu, T.-S.; Li, Q.; Li, Q.-Y.; Xu, Z.-H.; Qiu, F.; Tang, J.; Yang, H.-Y.; Jiang, Q.-C. Nanoparticulate dispersion, microstructure refinement and strengthening mechanisms in Ni-coated SiCp/Al-Cu nanocomposites. Mater. Sci. Eng. A 2019, 762, 138092. [Google Scholar] [CrossRef]

- Sameer Kumar, D.; Suman, K.; Poddar, P. A study on the impact and fatigue failure of AZ91E–Ni coated alumina composites. Can. Metall. Q. 2020, 59, 316–323. [Google Scholar] [CrossRef]

- Ru, J.; Jia, Y.; Jiang, Y.; Feng, J.; Zhou, R.; Hua, Y.; Wang, D. Modification of ZTA particles with Ni coating by electroless deposition. Surf. Eng. 2017, 33, 353–361. [Google Scholar] [CrossRef]

- Ru, J.; He, H.; Jiang, Y.; Zhou, R.; Hua, Y. Wettability and interaction mechanism for Ni-modified ZTA particles reinforced iron matrix composites. J. Alloys Compd. 2019, 786, 321–329. [Google Scholar] [CrossRef]

- Pourhosseini, S.; Beygi, H.; Sajjadi, S.A. Effect of metal coating of reinforcements on the microstructure and mechanical properties of Al-Al2O3 nanocomposites. Mater. Sci. Technol. 2018, 34, 145–152. [Google Scholar] [CrossRef]

- Wang, Y.-Q.; Zheng, J.-H.; Wang, Z.-M.; Zhou, B.-L.; Zhou, L.-J.; Zhang, F.-Q. SiC coated carbon fibres by solution coating and their application to preparing Cf/Al composite. Acta Metall. Sin. 1994, 30, 194–197. [Google Scholar]

- Kitahara, A.; Akiyama, S.; Ueno, H. Effects of alumina coating on degradation, wettability and bonding ability of carbon fiber with aluminum. Jpn. Inst. Light Met. J. 1990, 40, 305–311. [Google Scholar] [CrossRef]

- Carpenter, G.; Lo, S. Characterization of graphite-aluminium composites using analytical electron microscopy. J. Mater. Sci. 1992, 27, 1827–1841. [Google Scholar] [CrossRef]

- Clement, J.; Rack, H.; Wu, K.; Spencer, H. Interfacial modification in metal matrix composites by the sol-gel process. Mater. Manuf. Process. 1990, 5, 17–33. [Google Scholar] [CrossRef]

- Pierson, H.O.; Randich, E. Titanium diboride coatings and their interaction with the substrates. Thin Solid Film. 1978, 54, 119–128. [Google Scholar] [CrossRef]

- Ribes, H.; Da Silva, R.; Suery, M.; Bretheau, T. Effect of interfacial oxide layer in Al–SiC particle composites on bond strength and mechanical behaviour. Mater. Sci. Technol. 1990, 6, 621–628. [Google Scholar] [CrossRef]

- Arslan, G.; Kalemtas, A. Processing of silicon carbide–boron carbide–aluminium composites. J. Eur. Ceram. Soc. 2009, 29, 473–480. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, R.; Liu, M. Improved sintering ability of SiC ceramics from SiC@Al2O3 core-shell nanoparticles prepared by a slow precipitation method. Ceram. Int. 2019, 45, 8032–8036. [Google Scholar] [CrossRef]

- Suéry, M.; L’Espérance, G.; Hong, B.; Thanh, L.N.; Bordeaux, F. Development of particulate treatments and coatings to reduce SiC degradation by liquid aluminum. J. Mater. Eng. Perform. 1993, 2, 365–373. [Google Scholar] [CrossRef]

- Patankar, S.; Gopinathan, V.; Ramakrishnan, P. Processing of carbon fibre reinforced aluminium composite using K2ZrF6 treated carbon fibres: A degradation study. J. Mater. Sci. Lett. 1990, 9, 912–913. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malaki, M.; Fadaei Tehrani, A.; Niroumand, B.; Gupta, M. Wettability in Metal Matrix Composites. Metals 2021, 11, 1034. https://doi.org/10.3390/met11071034

Malaki M, Fadaei Tehrani A, Niroumand B, Gupta M. Wettability in Metal Matrix Composites. Metals. 2021; 11(7):1034. https://doi.org/10.3390/met11071034

Chicago/Turabian StyleMalaki, Massoud, Alireza Fadaei Tehrani, Behzad Niroumand, and Manoj Gupta. 2021. "Wettability in Metal Matrix Composites" Metals 11, no. 7: 1034. https://doi.org/10.3390/met11071034

APA StyleMalaki, M., Fadaei Tehrani, A., Niroumand, B., & Gupta, M. (2021). Wettability in Metal Matrix Composites. Metals, 11(7), 1034. https://doi.org/10.3390/met11071034