Mechanism of Electromagnetic Field in the Sub-RapidSolidification of High-Strength Al-Cu-Li Alloy Produced by Twin-Roll Casting

Abstract

1. Introduction

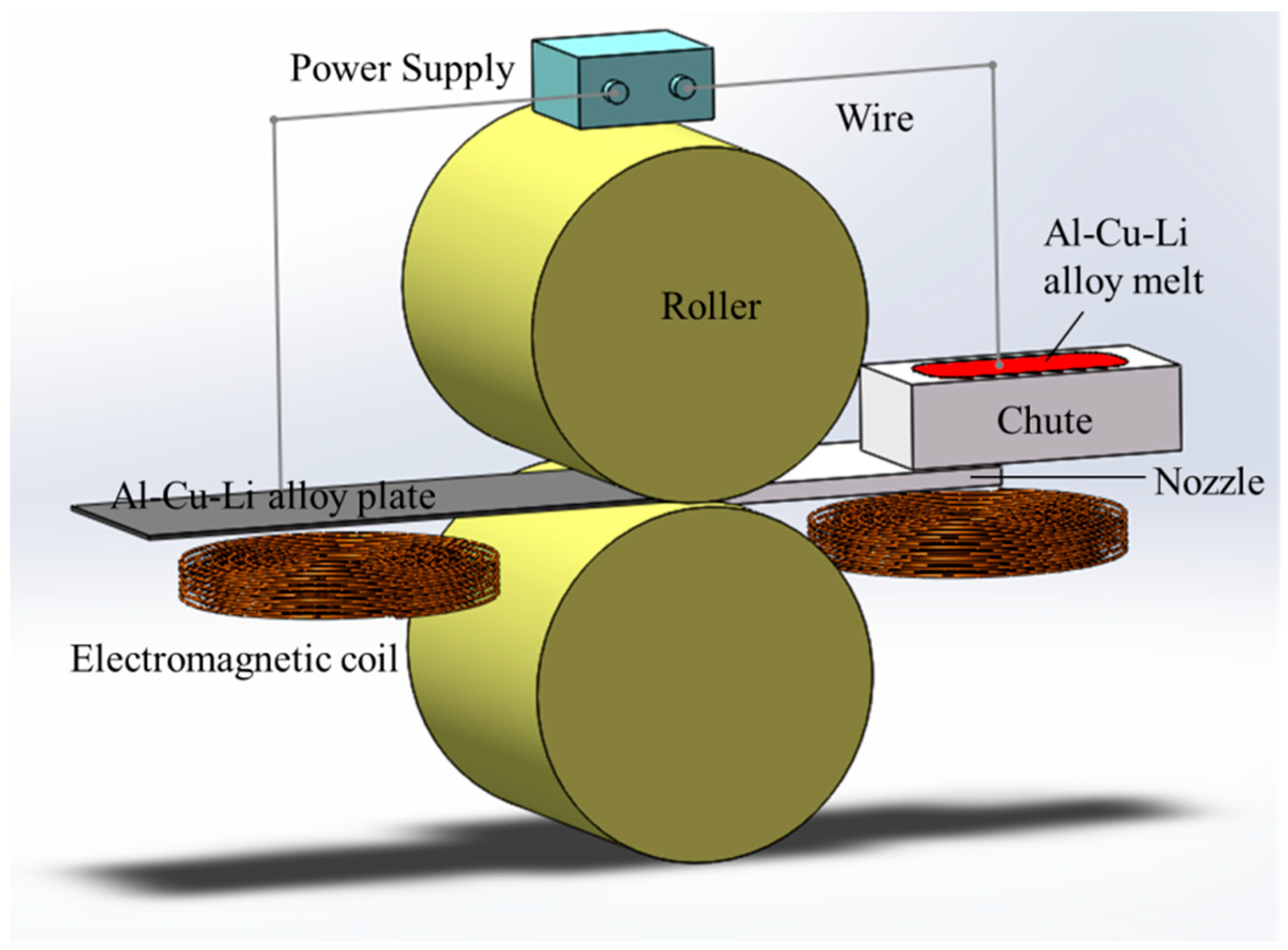

2. Experiments

3. Results

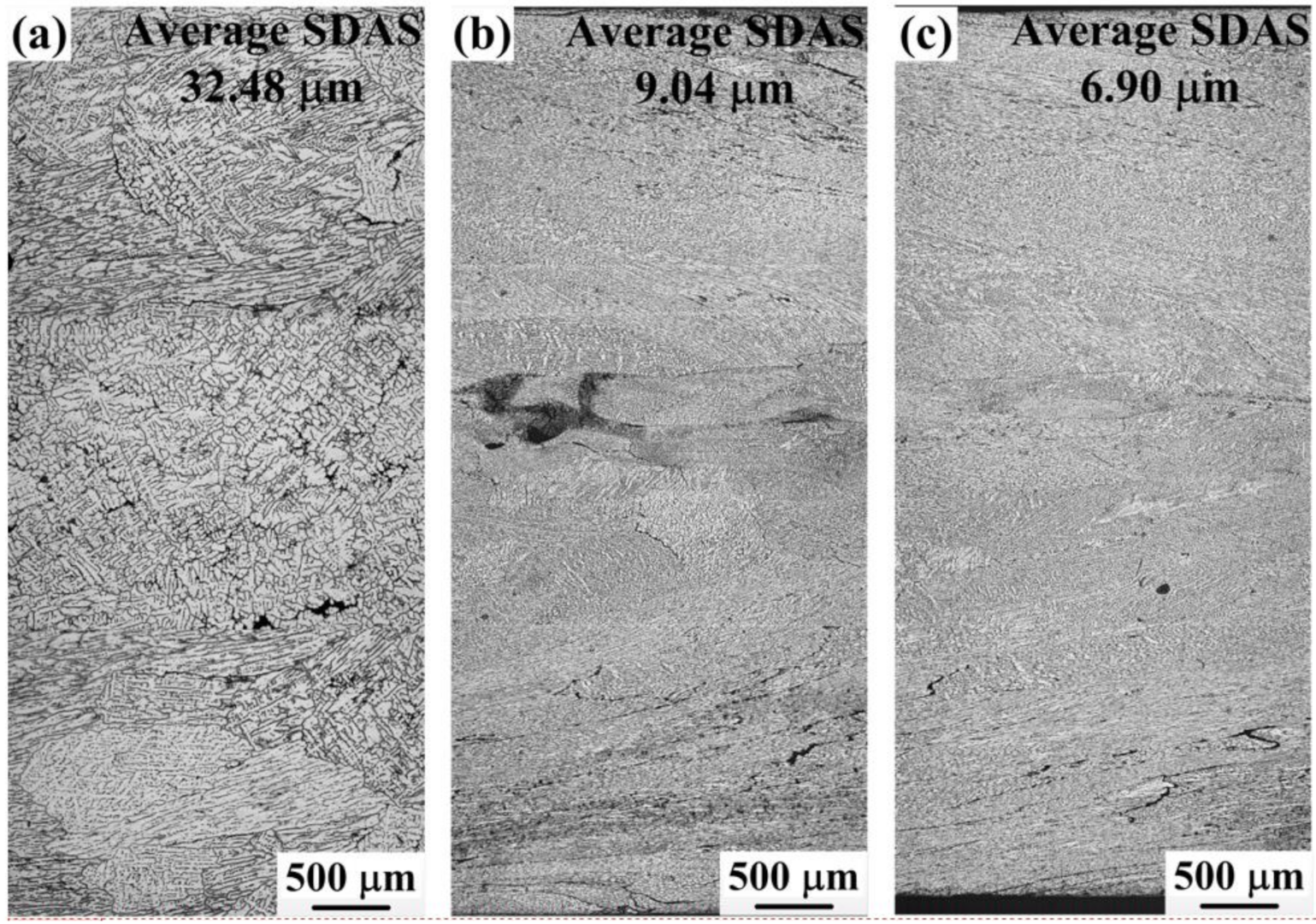

3.1. Microstructures of the Al-Cu-Li Alloy

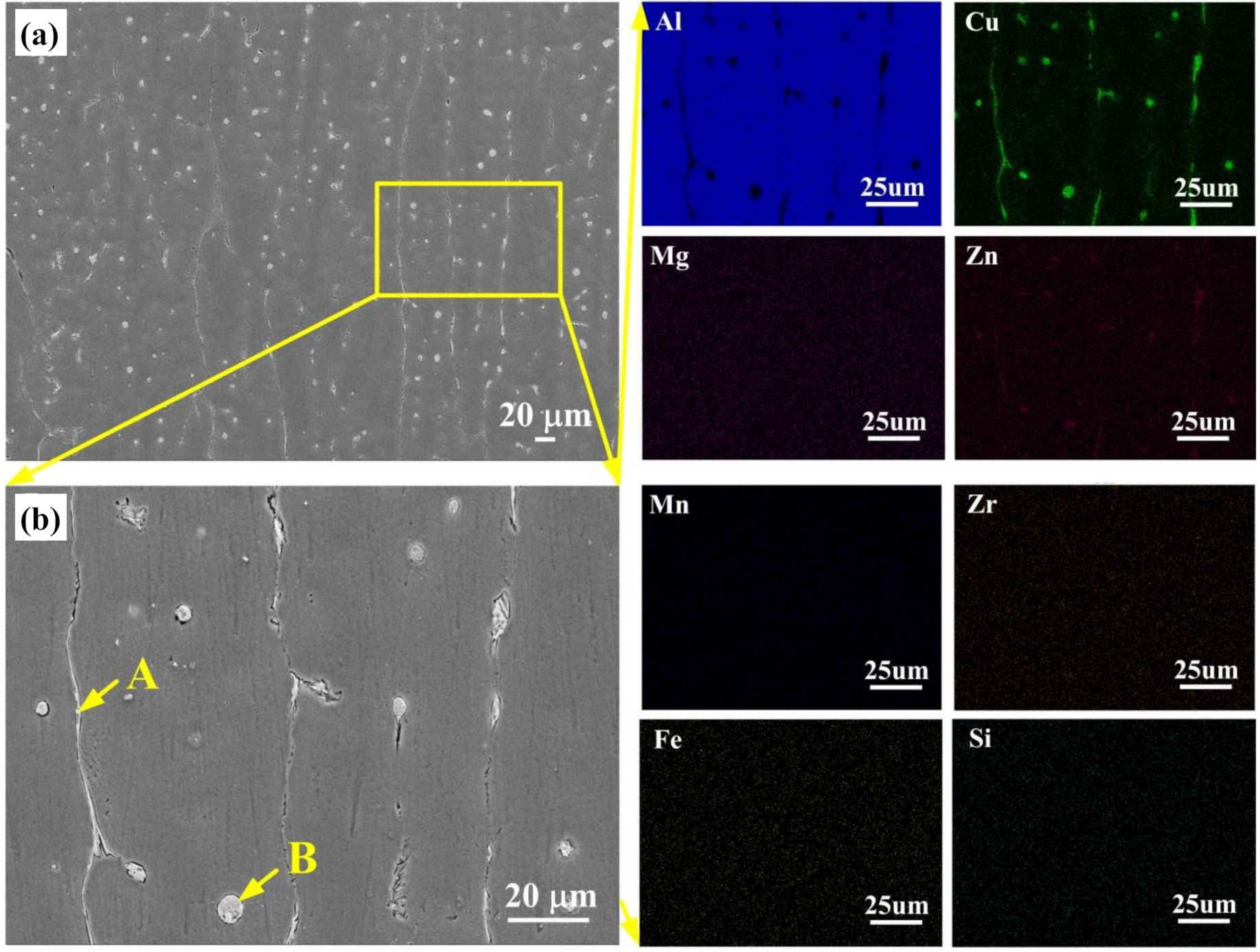

3.2. Segregation in Al-Cu-Li Alloy

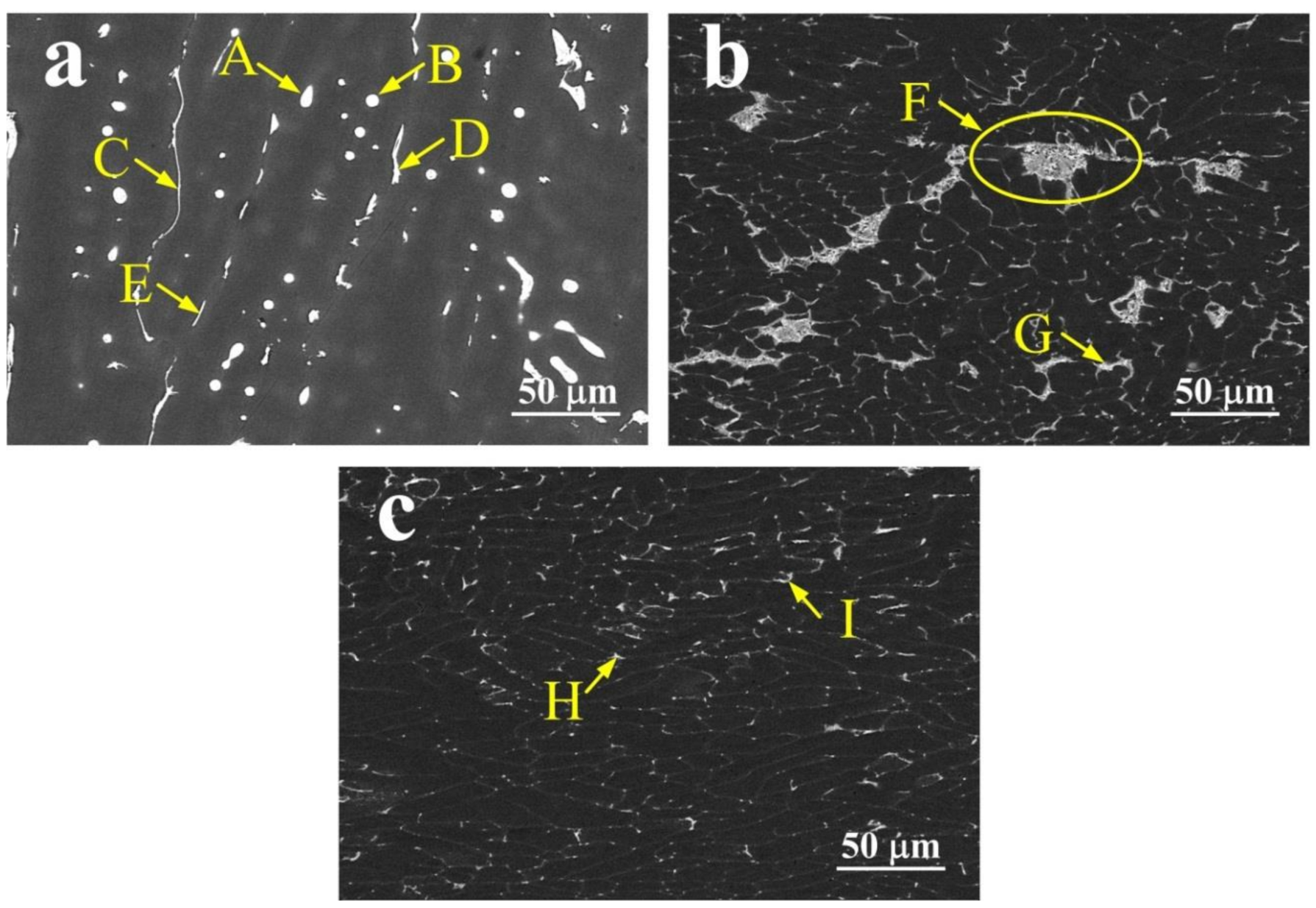

3.3. The Eutectic Phases in Al-Cu-Li Alloy

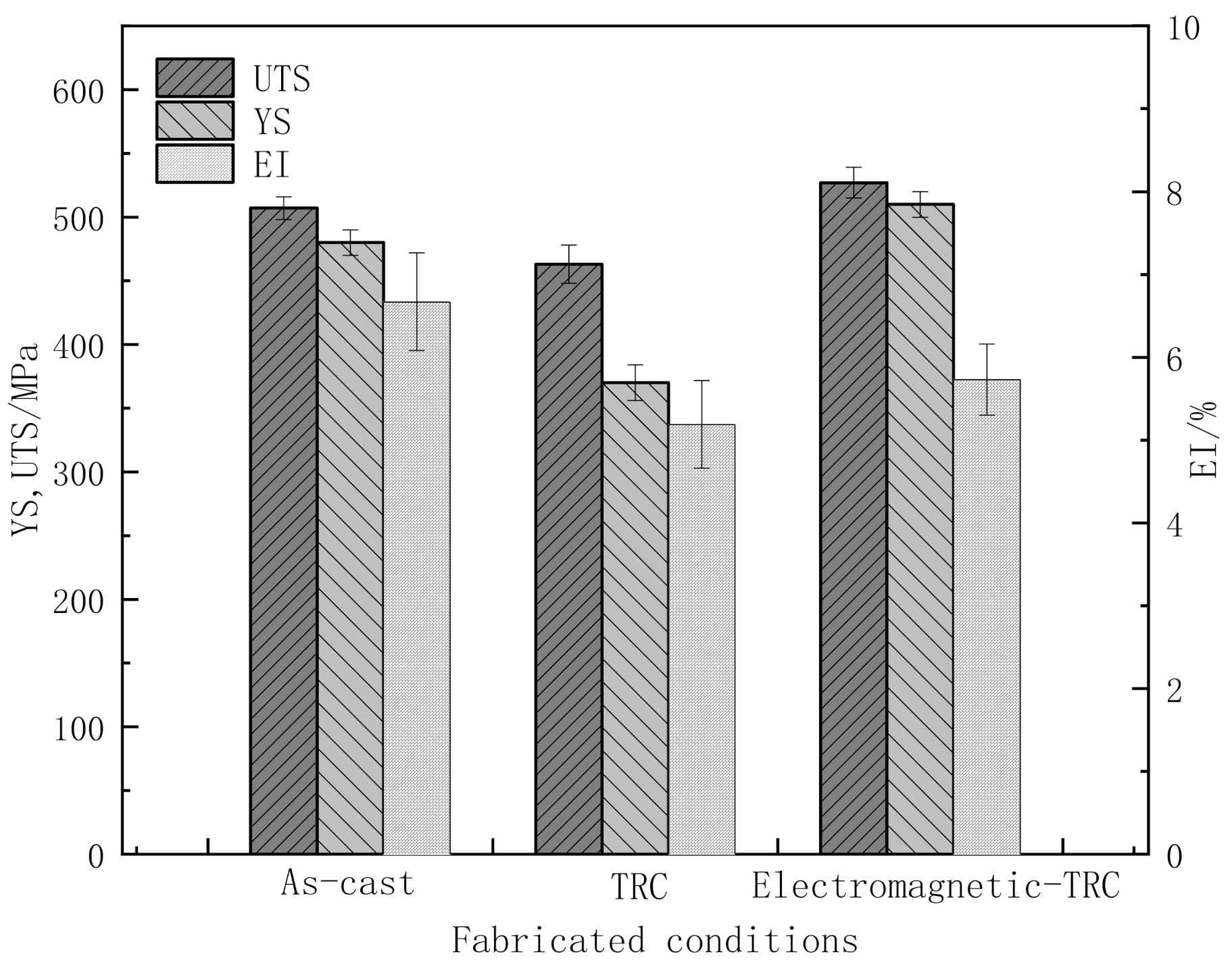

3.4. Mechanical Properties of the Al-Cu-Li Alloy

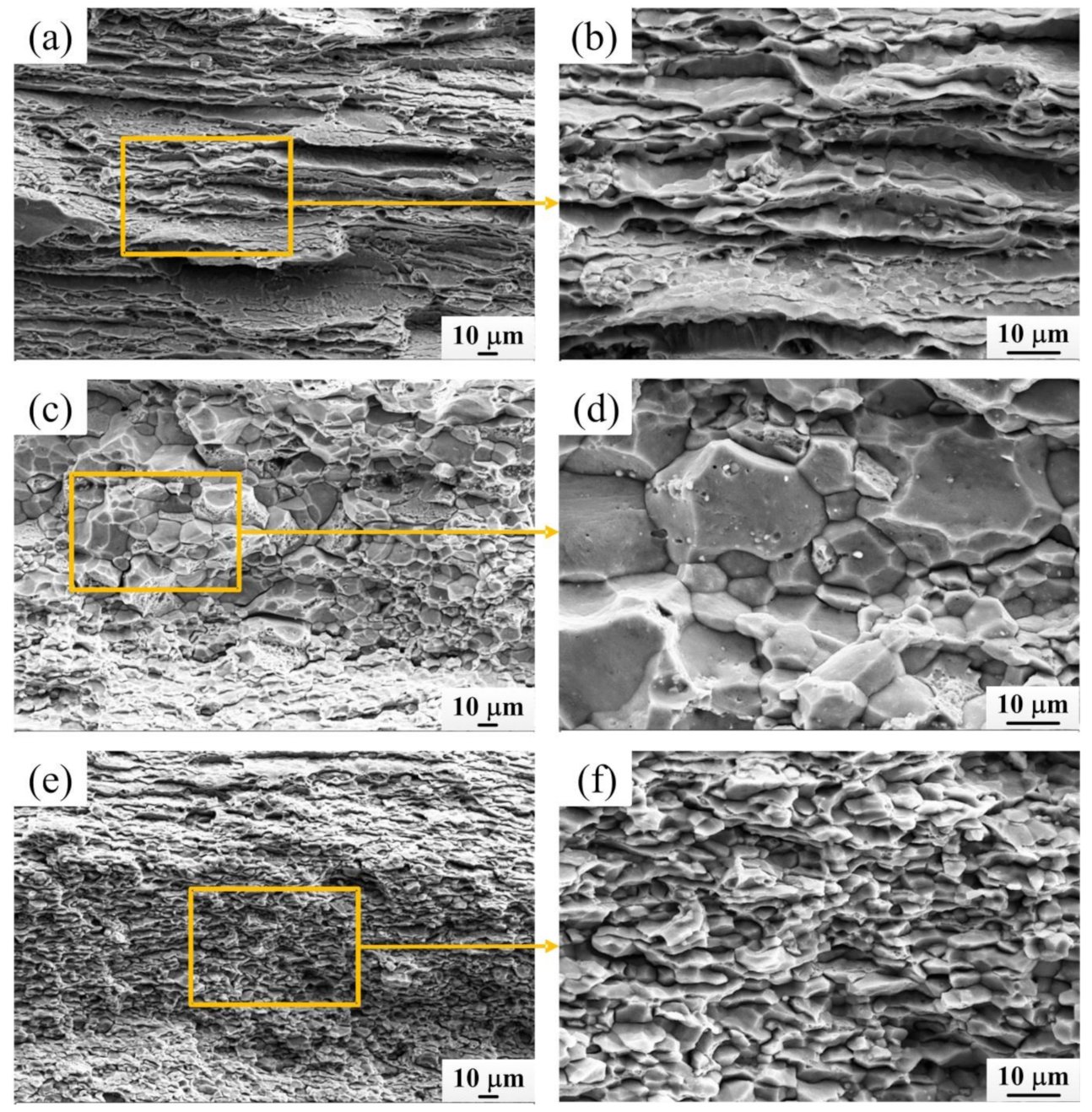

3.5. Fracture Morphologies of the Al-Cu-Li Alloy

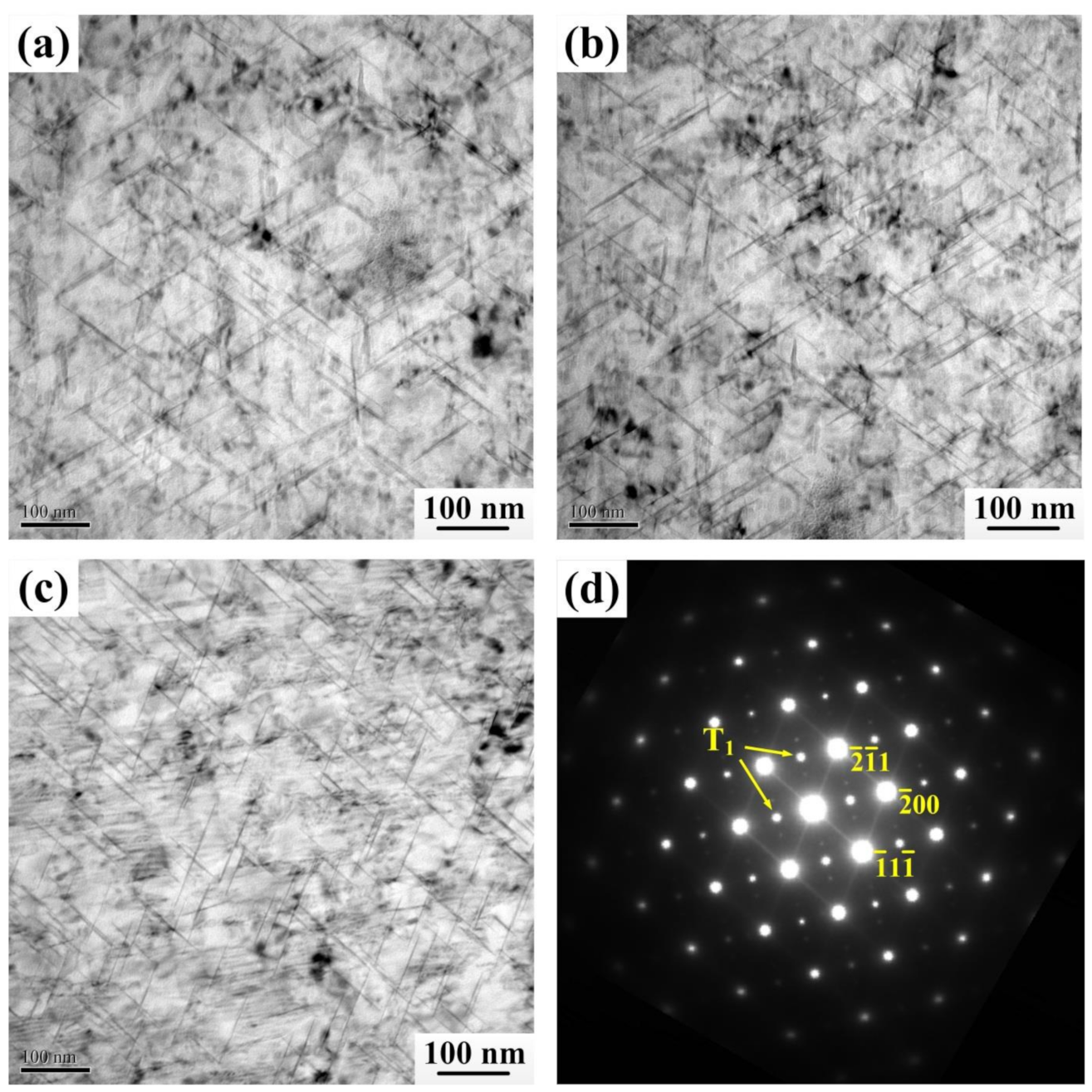

4. Discussion

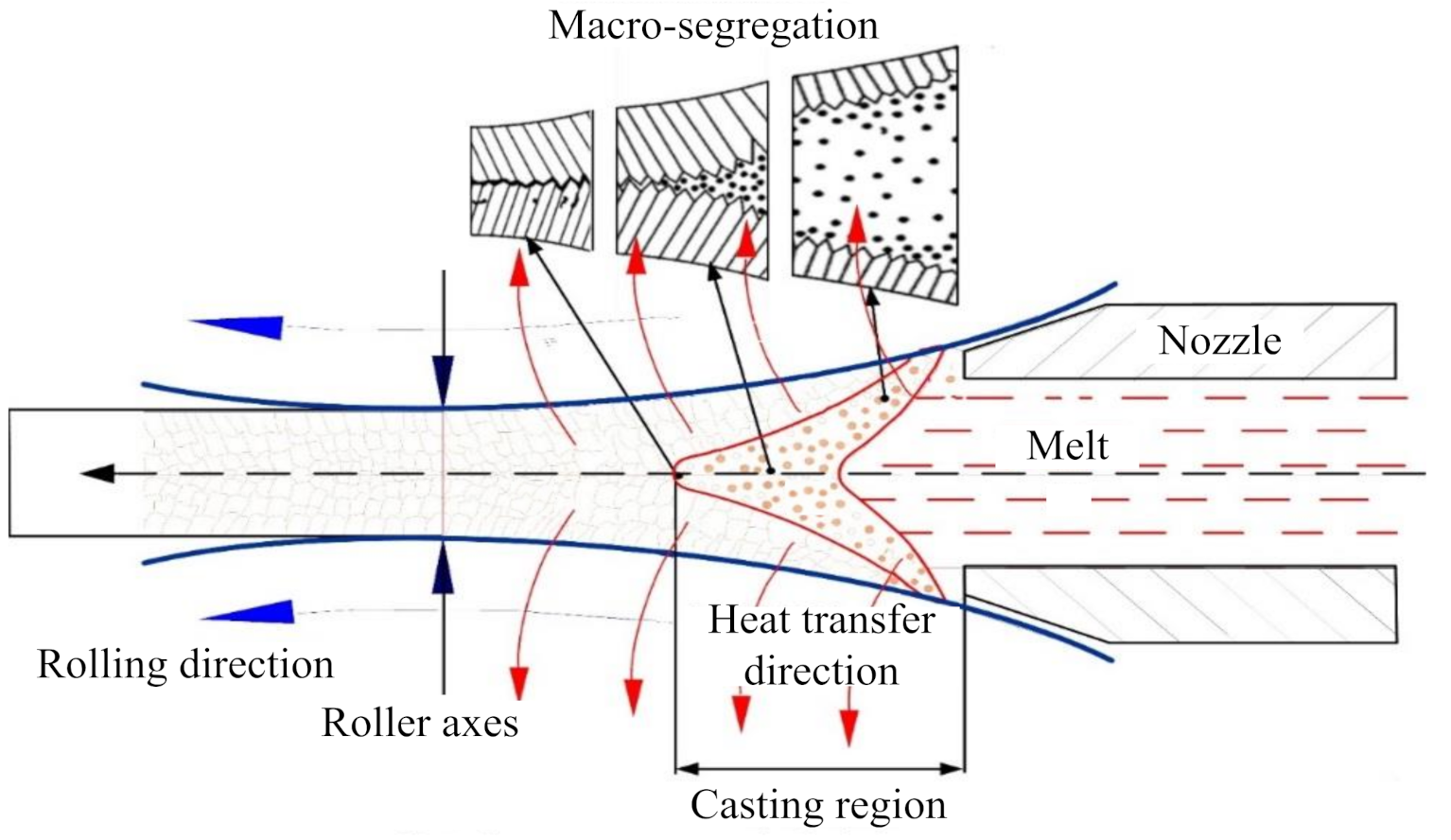

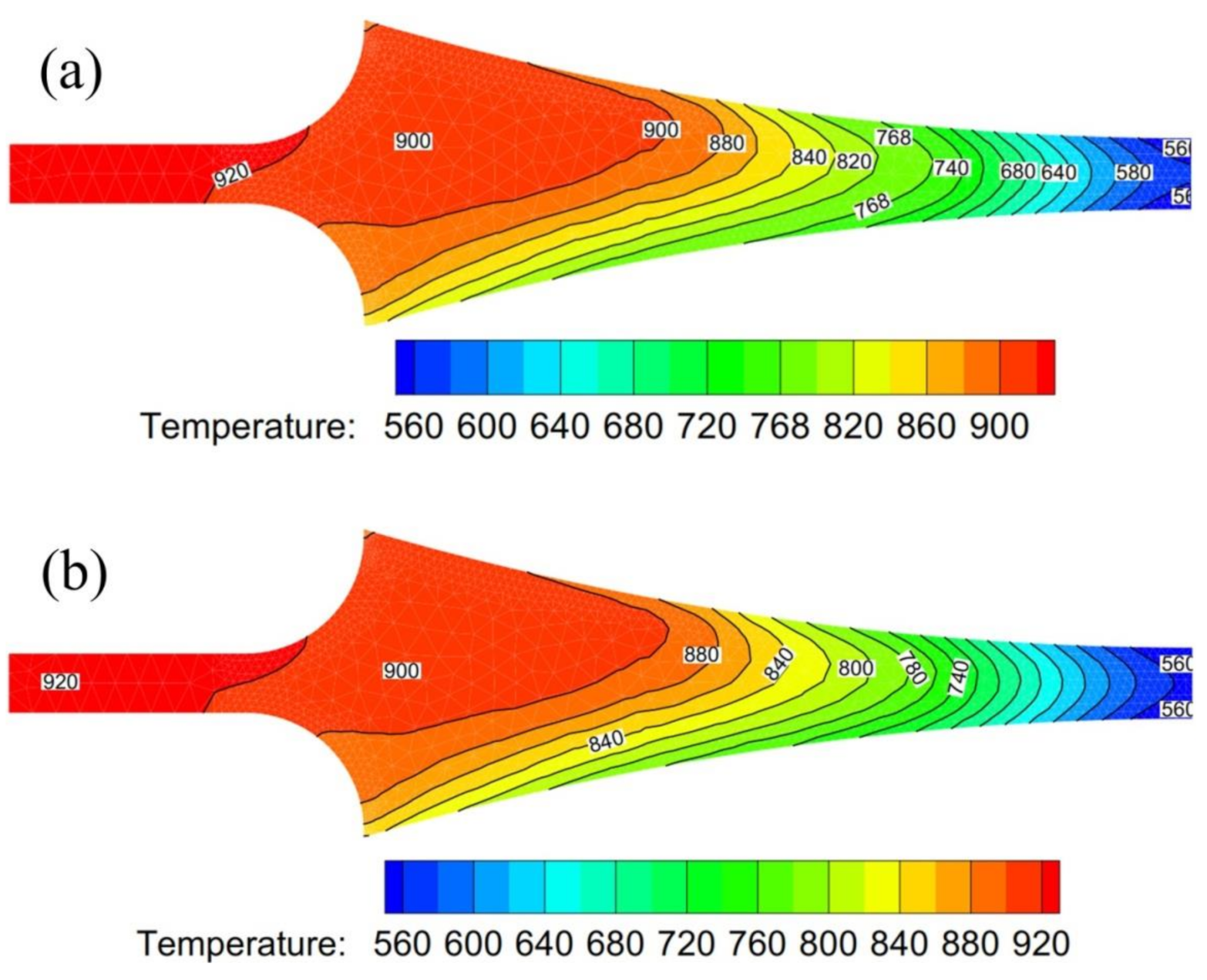

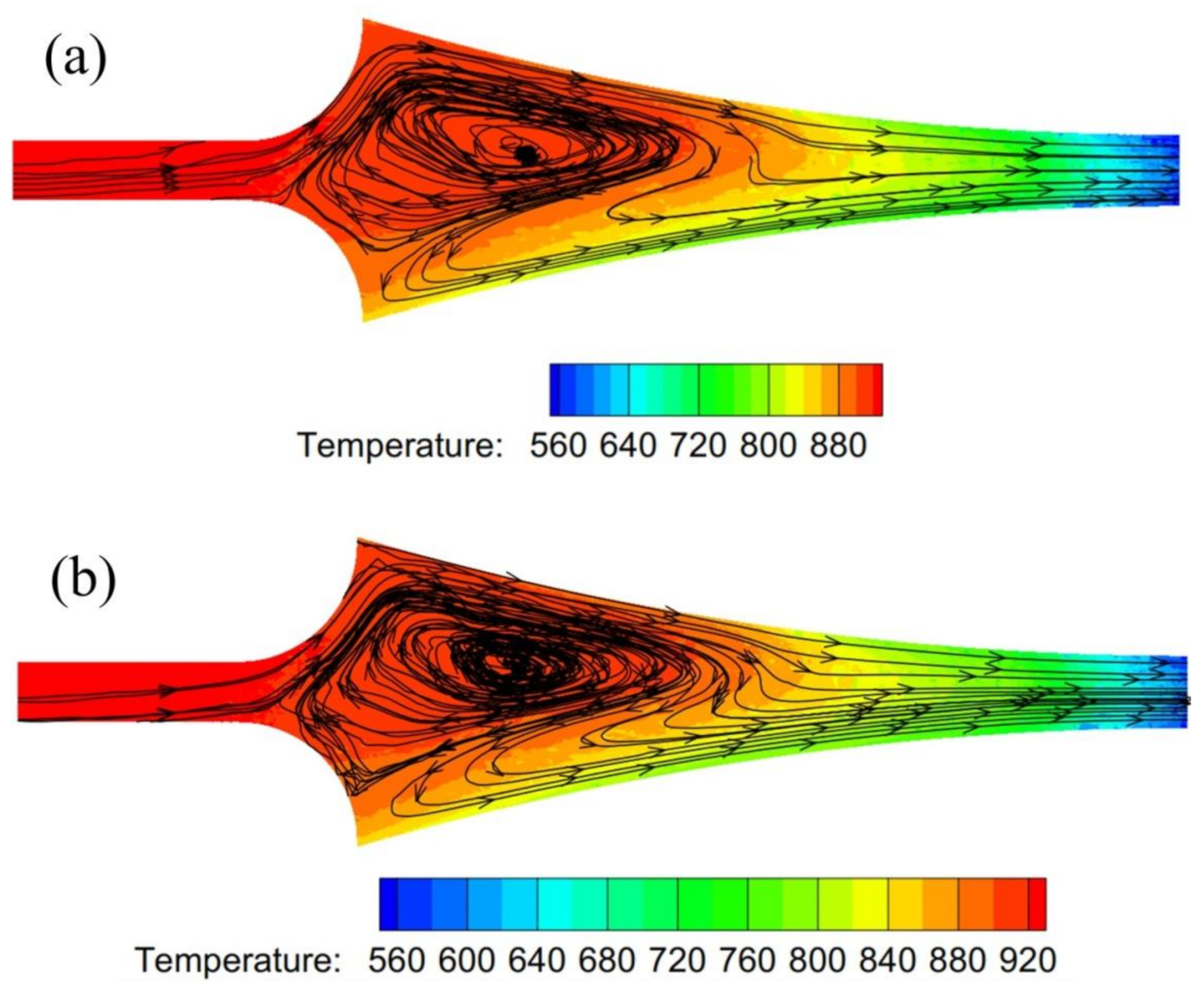

4.1. Generation Mechanism of the Macro-Segregation in Al-Cu-Li Alloy TRC Plate

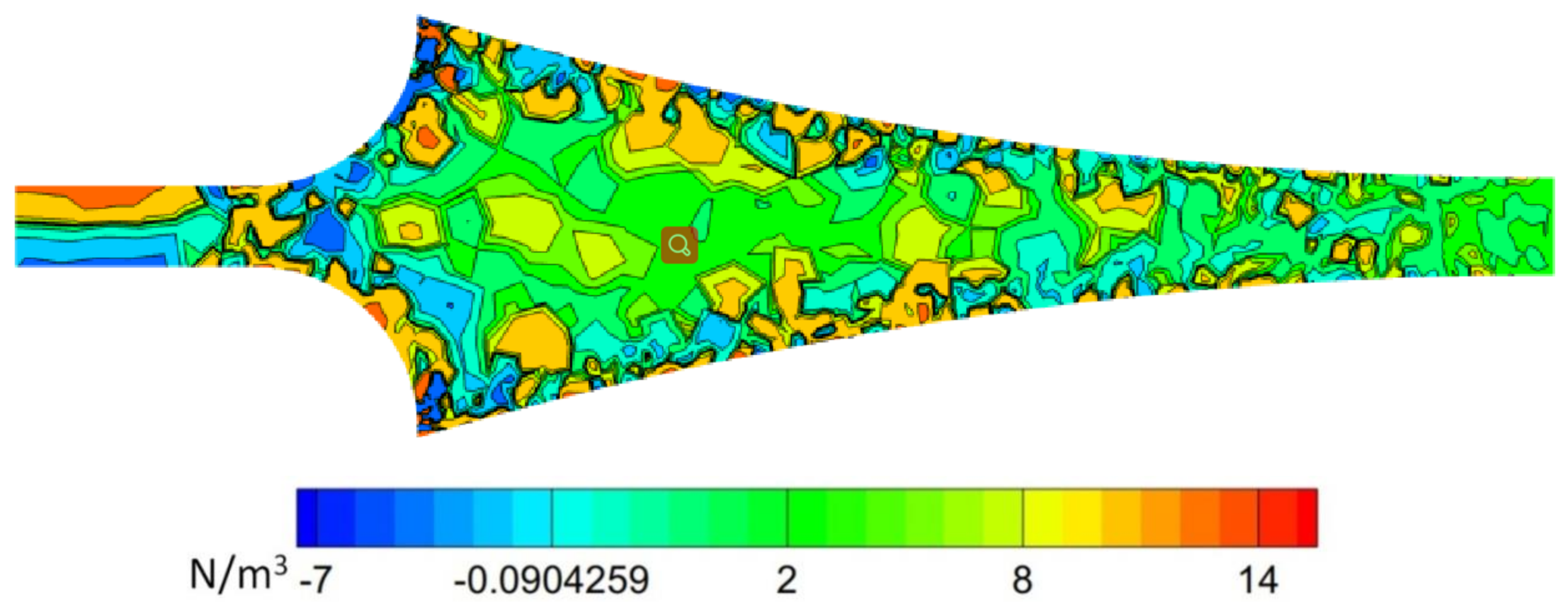

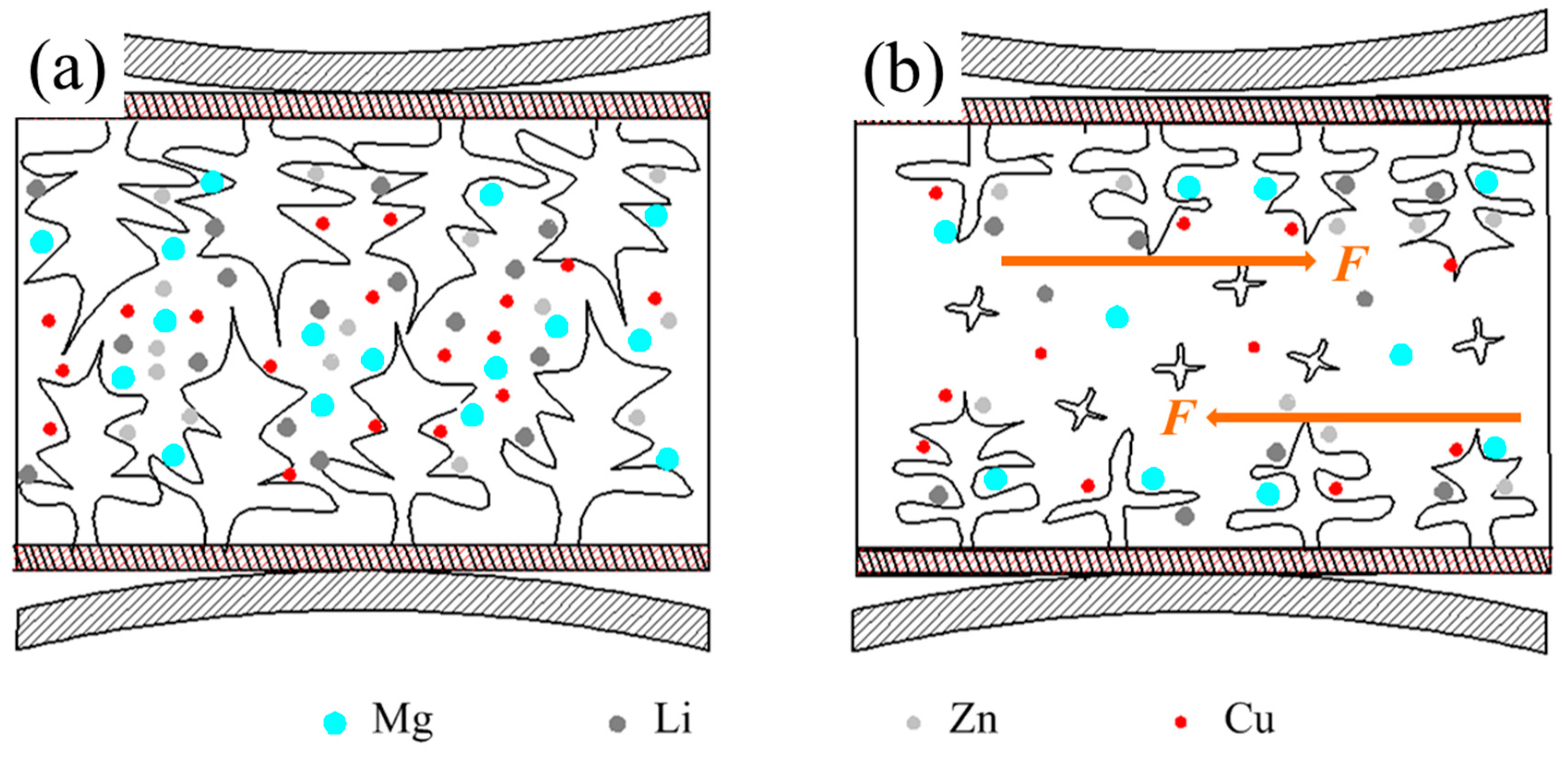

4.2. Mechanism of EOF in TRC Process

5. Conclusion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Duan, S.Y.; Wu, C.L.; Gao, Z.; Cha, L.M.; Fan, T.W.; Chen, J.H. Interfacial structure evolution of the growing composite precipitates in Al-Cu-Li alloys. Acta Mater. 2017, 129, 352–360. [Google Scholar] [CrossRef]

- Gumbmann, E.; Lefebvre, W.; De Geuser, F.; Sigli, C.; Deschamps, A. The effect of minor solute additions on the precipitation path of an Al Cu Li alloy. Acta Mater. 2016, 115, 104–114. [Google Scholar] [CrossRef]

- Gumbmann, E.; De Geuser, F.; Sigli, C.; Deschamps, A. Influence of Mg, Ag and Zn minor solute additions on the precipitation kinetics and strengthening of an Al-Cu-Li alloy. Acta Mater. 2017, 133, 172–185. [Google Scholar] [CrossRef]

- Rodgers, B.I.; Prangnell, P.B. Quantification of the influence of increased pre-stretching on microstructure-strength relationships in the Al–Cu–Li alloy AA2195. Acta Mater. 2016, 108, 55–67. [Google Scholar] [CrossRef]

- De, P.S.; Mishar, R.S.; Baumann, J.A. Characterization of high cycle fatigue behavior of a new generation aluminum lithium alloy. Acta Mater. 2011, 59, 5946–5960. [Google Scholar] [CrossRef]

- Rioja, R.J.; Liu, J. The Evolution of Al-Li Base Products for Aerospace and Space Applications. Metall. Mater. Trans. A 2012, 43, 3325–3337. [Google Scholar] [CrossRef]

- Ma, Y.; Zhou, X.; Thompson, G.; Hashimoto, T.; Thomson, P.; Fowles, M. Distribution of intermetallics in an AA 2099-T8 aluminium alloy extrusion. Mater. Chem. Phys. 2011, 126, 46–53. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- El-Aty, A.A.; Xu, Y.; Guo, X.Z.; Zhang, S.H.; Ma, Y.; Chen, D.Y. Strengthening mechanisms, deformation behavior, and anisotropic mechanical properties of Al-Li alloys: A review. J. Adv. Res. 2018, 10, 49–67. [Google Scholar] [CrossRef]

- Alexopoulos, N.D.; Migklis, E.; Stylianos, A.; Myriounis, D.P. Fatigue behavior of the aeronautical Al–Li (2198) aluminum alloy under constant amplitude loading. Int. J. Fatigue 2013, 56, 95–105. [Google Scholar] [CrossRef]

- Birol, Y. Analysis of macro segregation in twin-roll cast aluminium strips via solidification curves. J. Alloys Compd. 2009, 486, 168–172. [Google Scholar] [CrossRef]

- Jia, P.F.; Cao, Y.H.; Geng, Y.D.; He, L.Z.; Xiao, N.; Cui, J.Z. Effects of dc current on the phase transformation in 7050 alloy during homogenization. Mater. Char. 2014, 96, 21–27. [Google Scholar] [CrossRef]

- Feng, G.H.; Zhou, S.X.; Yang, G.; Lu, Z.C. Effect of stable magnetic field on grain refinement of low carbon Mn-Nb steel. J. Iron Steel Res. 2000, 12, 27–30. [Google Scholar] [CrossRef]

- Li, C.S.; Hu, S.D.; Ren, Z.M.; Fautrelle, Y.; Li, X. Effect of the simultaneous application of a high static magnetic field and a low alternating current on grain structure and grain boundary of pure aluminum. J. Mater. Sci. Technol. 2018, 34, 2431–2438. [Google Scholar] [CrossRef]

- Shao, Z.W.; Le, Q.C.; Zhang, Z.Q.; Cui, J.Z. A new method of semi-continuous casting of AZ80 Mg alloy billets by a combination of electromagnetic and ultrasonic fields. Mater. Des. 2011, 32, 4216–4224. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Miao, X.C.; Shen, Z.Y.; Han, Q.Y.; Song, C.J.; Zhai, Q.J. Macro segregation formation mechanism of the primary silicon phase in directionally solidified Al–Si hypereutectic alloys under the impact of electric currents. Acta Mater. 2015, 97, 357–366. [Google Scholar] [CrossRef]

- Edry, I.; Frage, N.; Hayun, S. The effect of pulse magneto-oscillation treatment on the structure of aluminum solidified under controlled convection. Mater. Lett. 2016, 182, 118–120. [Google Scholar] [CrossRef]

- Liu, W.; Cui, J.Z. A study on the ageing treatment of 2091 Al–Li alloy with an electric field. J. Mater. Sci. Lett. 1997, 16, 1410–1411. [Google Scholar] [CrossRef]

- Wang, X.L.; Dai, W.B.; Wang, R.; Tian, X.Z.; Zhao, X. Enhanced phase transformation and variant selection by electric current pulses in a Cu–Zn alloy. J. Mater. Res. 2014, 29, 975–980. [Google Scholar] [CrossRef]

- Barekar, N.S.; Dhindaw, B.K. Twin-Roll Casting of Aluminum Alloys–An Overview. Adv. Manuf. Process 2014, 29, 651–661. [Google Scholar] [CrossRef]

- Li, H.Y.; Huang, D.S.; Kang, W.; Liu, J.J.; OuYang, X.; Li, D.W. Effect of different aging processes on the microstructure and mechanical properties of a novel Al-Cu-Li alloy. J. Mater. Sci. Technol. 2016, 32, 1049–1053. [Google Scholar] [CrossRef]

- Yoshimura, R.; Konnom, T.J.; Abe, E.; Hiraga, K. Transmission electron microscopy study of the evolution of precipitates in aged Al-Li-Cu alloys: The θ’ and T1 phases. Acta Mater. 2003, 51, 4251–4266. [Google Scholar] [CrossRef]

- Hekmat-Ardakan, A.; Elgallad, E.M.; Ajersch, F.; Chen, X.G. Microstructural evolution and mechanical properties of as-cast and T6-treated AA2195 DC cast alloy. Mater. Sci. Eng. A 2012, 558, 76–81. [Google Scholar] [CrossRef]

- Mahathaninwong, N.; Plookphol, T.; Wannasin, J.; Wisutmethangoon, S. T6 heat treatment of rheocasting 7075 Al alloy. Mater. Sci. Eng. A 2012, 532, 91–99. [Google Scholar] [CrossRef]

- Stiller, K.; Warren, P.J.; Hansen, V.; Angenete, J.; Gjønnes, J. Investigation of precipitation in an Al-Zn-Mg alloy after two-step ageing treatment at 100 °C and 150 °C. Mater. Sci. Eng. A 2019, 270, 55–63. [Google Scholar] [CrossRef]

- Chen, X.X.; Zhao, G.Q.; Liu, G.L.; Sun, L.; Chen, L.; Zhang, C.S. Microstructure evolution and mechanical properties of 2196 Al-Li alloy in hot extrusion process. J. Mater. Process. Technol. 2019, 275, 116348. [Google Scholar] [CrossRef]

- Xie, Y.K.; Deng, Y.L.; Wang, Y.; Guo, X.B. Effect of asymmetric rolling and subsequent ageing on the microstructure, texture and mechanical properties of the Al-Cu-Li alloy. J. Alloy Comp. 2020, 836, 155445. [Google Scholar] [CrossRef]

- Ronco, N.R.; Menestrina, F.; Romero, L.M.; Castells, C.B. Determination of gas–liquid partition coefficients of several organic solutes in trihexyl (tetradecyl) phosphonium bromide using capillary gas chromatography columns. J. Chromatogr. A 2019, 1584, 179–186. [Google Scholar] [CrossRef]

- Gäumann, M.; Trivedi, R.; Kurz, W. Nucleation ahead of the advancing interface in directional solidification. Mater. Sci. Eng. A 1997, 226-228, 763–769. [Google Scholar] [CrossRef]

- Chen, G.; Li, J.T.; Yin, Z.K.; Xu, G.M. Improvement of microstructure and properties in twin-roll casting 7075 sheet by lower casting speed and compound field. Mater. Char. 2017, 127, 325–332. [Google Scholar] [CrossRef]

- Jian, X.; Xu, H.; Meek, T.; Han, Q. Effect of power ultrasound on solidification of aluminum A356 alloy. Mater. Lett. 2005, 59, 190–193. [Google Scholar] [CrossRef]

- Chen, D.D.; Zhang, H.T.; Jiang, H.X.; Cui, J.Z. Experimental investigation of microsegregation in low frequency electromagnetic casting 7075 aluminum alloy. Mater. Sci. Eng. Technol. 2011, 42, 500–505. [Google Scholar] [CrossRef]

- Su, X.; Wang, S.J.; Ouyang, X.; Song, P.; Xu, G.M.; Jiang, D.H. Physical and mechanical properties of 7075 sheets produced by EP electro- and electromagnetic cast rolling. Mater. Sci. Eng. A 2014, 607, 10–16. [Google Scholar] [CrossRef]

- Sun, K.M.; Li, L.; Chen, S.D. A new approach to control centerline macrosegregation in Al-Mg-Si alloys during twin roll continuous casting. Mater. Lett. 2017, 190, 205–208. [Google Scholar] [CrossRef]

| Point | Al | Cu | Mg | Zn | Mn | Fe | Zr |

|---|---|---|---|---|---|---|---|

| A | 60.17 | 37.16 | 0.62 | 1.21 | 0.04 | 0.52 | 0.29 |

| B | 78.53 | 14.36 | 0.14 | 0.05 | 2.64 | 3.89 | 0.02 |

| Sample | Point | at.% | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Mg | Al | Mn | Cu | Zn | Zr | Fe | |||

| Ingot | A | 2.53 | 76.88 | 0.1 | 18.47 | 1.13 | 0.04 | 0.05 | AlCuMgZn |

| B | 0.32 | 67.07 | 1.44 | 22.35 | 0.49 | – | 7.79 | AlCuMnFe | |

| C | 0.5 | 87.87 | 0.11 | 10.51 | 0.68 | – | – | AlCu | |

| D | 0.58 | 65.32 | 0.35 | 29.83 | 1.03 | 0.14 | 2.09 | AlCuFe | |

| E | 2.74 | 76.44 | 0.05 | 18.57 | 0.52 | – | 0.53 | AlCuMg | |

| TRC plate | F | 3.45 | 69.56 | 0.20 | 23.51 | 1.69 | 0.05 | 0.79 | AlCuMgZn |

| G | 2.63 | 75.32 | 0.06 | 19.77 | 1.27 | 0.03 | 0.22 | AlCuMgZn | |

| Electromagnetic-TRC plate | H | 1.04 | 84.90 | 0.19 | 12.07 | 1.16 | – | 0.51 | AlCuMgZn |

| I | 1.55 | 87.38 | 0.42 | 8.14 | 0.85 | 0.04 | 1.25 | AlCuMgFe | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Wei, B.; Yu, W.; He, C.; Li, Y.; Xu, G.; Wang, Z. Mechanism of Electromagnetic Field in the Sub-RapidSolidification of High-Strength Al-Cu-Li Alloy Produced by Twin-Roll Casting. Metals 2021, 11, 952. https://doi.org/10.3390/met11060952

Li S, Wei B, Yu W, He C, Li Y, Xu G, Wang Z. Mechanism of Electromagnetic Field in the Sub-RapidSolidification of High-Strength Al-Cu-Li Alloy Produced by Twin-Roll Casting. Metals. 2021; 11(6):952. https://doi.org/10.3390/met11060952

Chicago/Turabian StyleLi, Shiju, Bowen Wei, Wei Yu, Chen He, Yong Li, Guangming Xu, and Zhaodong Wang. 2021. "Mechanism of Electromagnetic Field in the Sub-RapidSolidification of High-Strength Al-Cu-Li Alloy Produced by Twin-Roll Casting" Metals 11, no. 6: 952. https://doi.org/10.3390/met11060952

APA StyleLi, S., Wei, B., Yu, W., He, C., Li, Y., Xu, G., & Wang, Z. (2021). Mechanism of Electromagnetic Field in the Sub-RapidSolidification of High-Strength Al-Cu-Li Alloy Produced by Twin-Roll Casting. Metals, 11(6), 952. https://doi.org/10.3390/met11060952