Analysis of Hydrogen-Induced Changes in the Cyclic Deformation Behavior of AISI 300–Series Austenitic Stainless Steels Using Cyclic Indentation Testing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fatigue Tests

2.3. PhyBaLCHT

2.4. Nanoindentation Fatigue Tests

2.5. TEM Investigations

3. Results

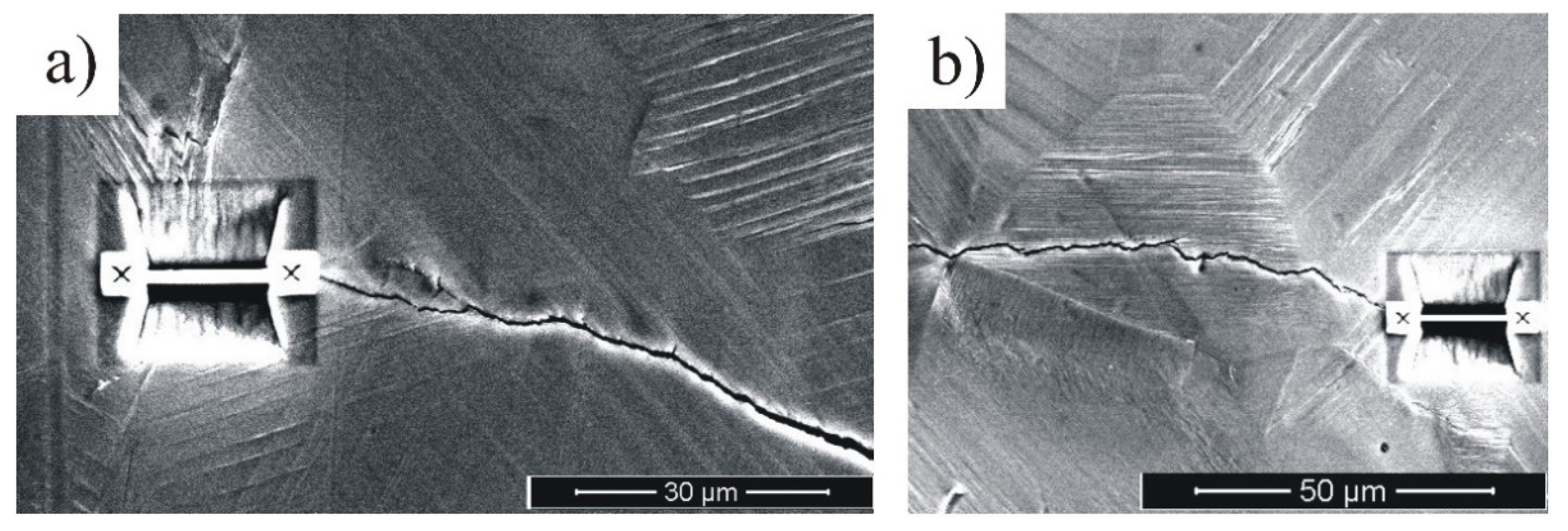

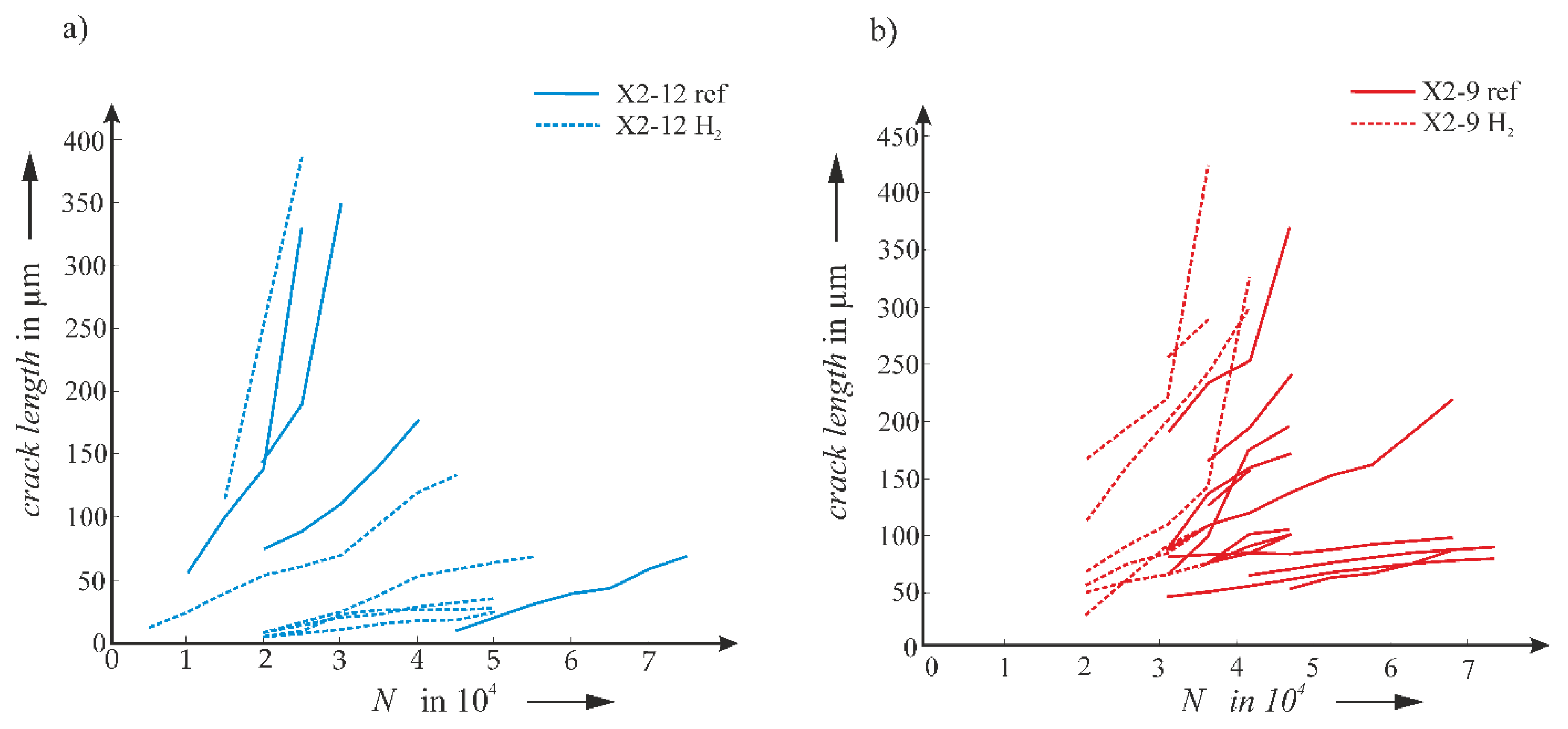

3.1. Previous Fatigue Tests

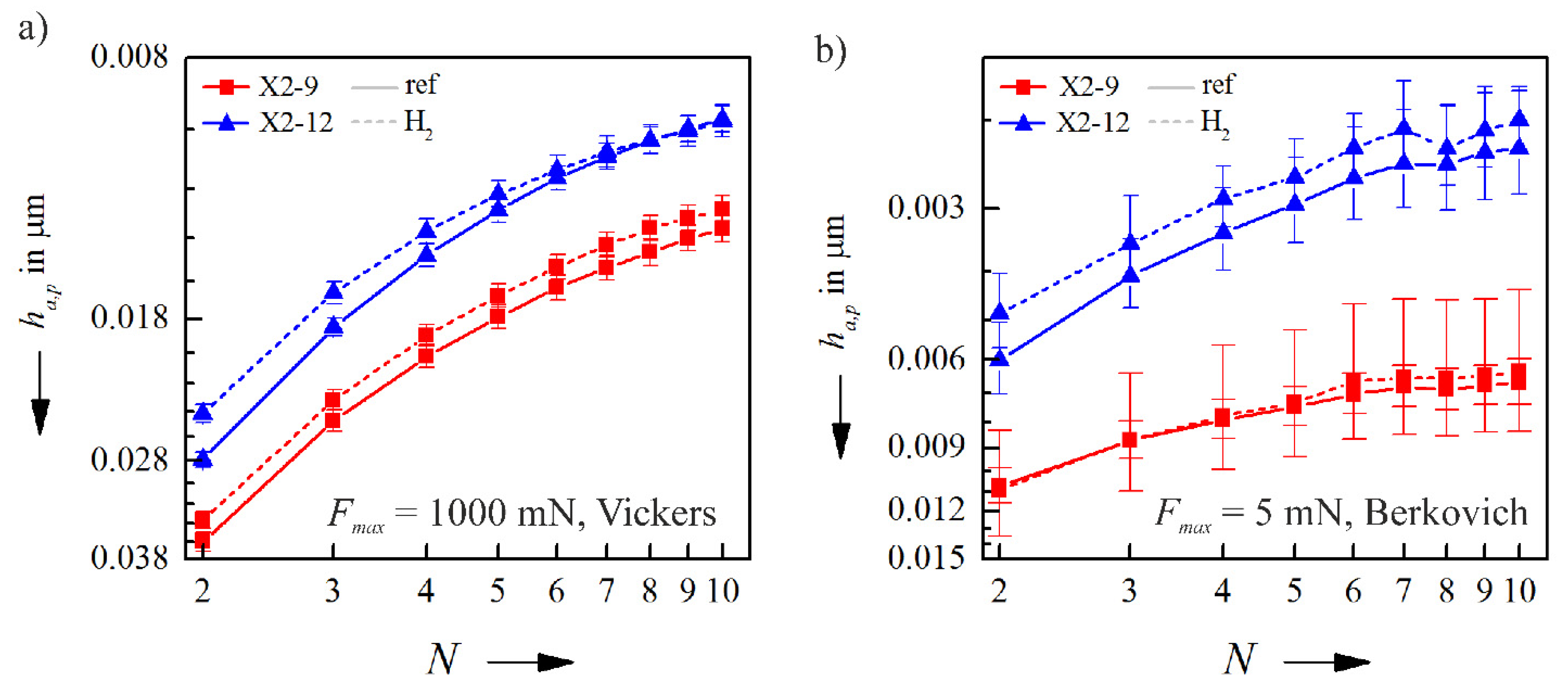

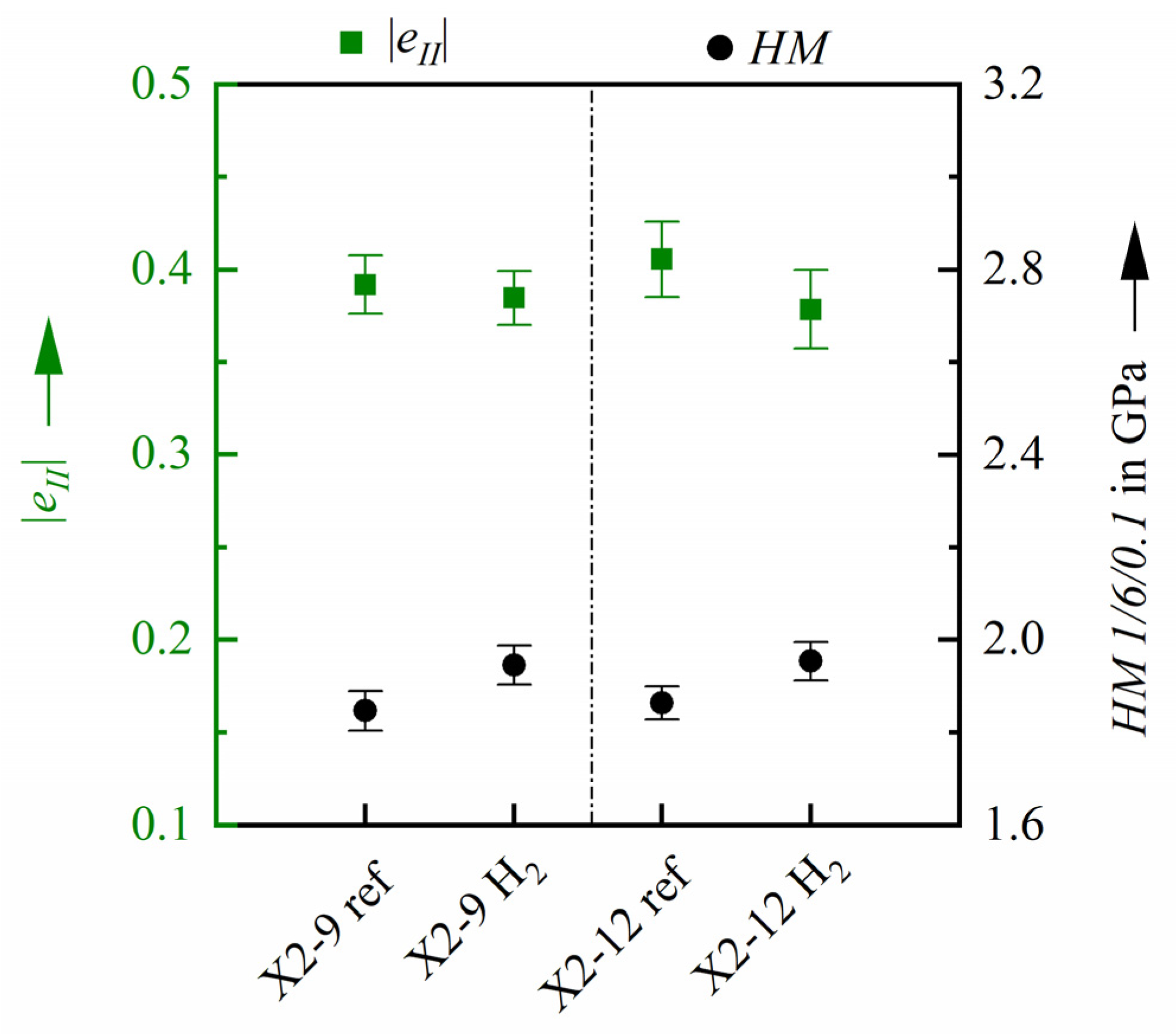

3.2. Results Obtained with the PhyBaLCHT Method

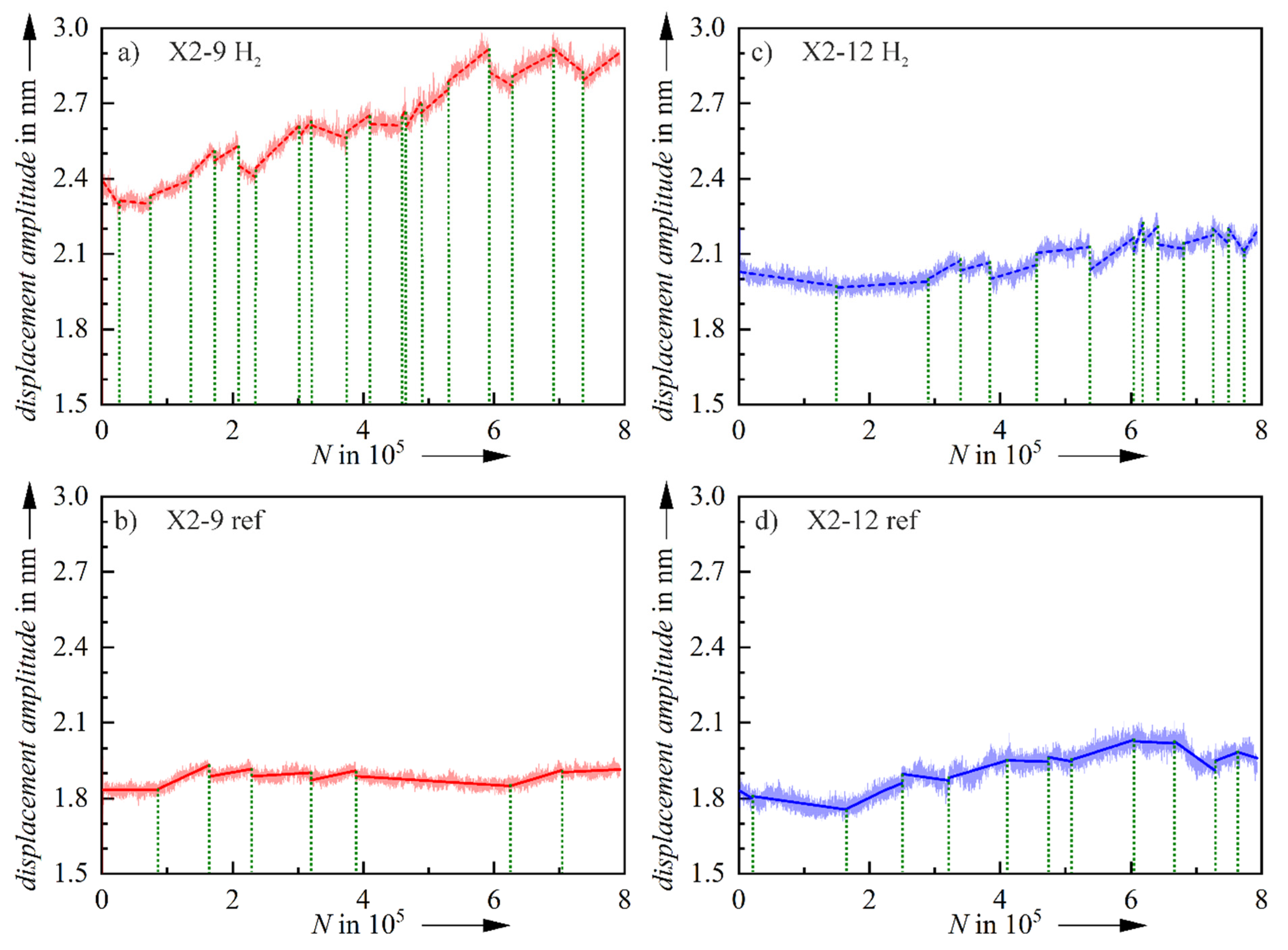

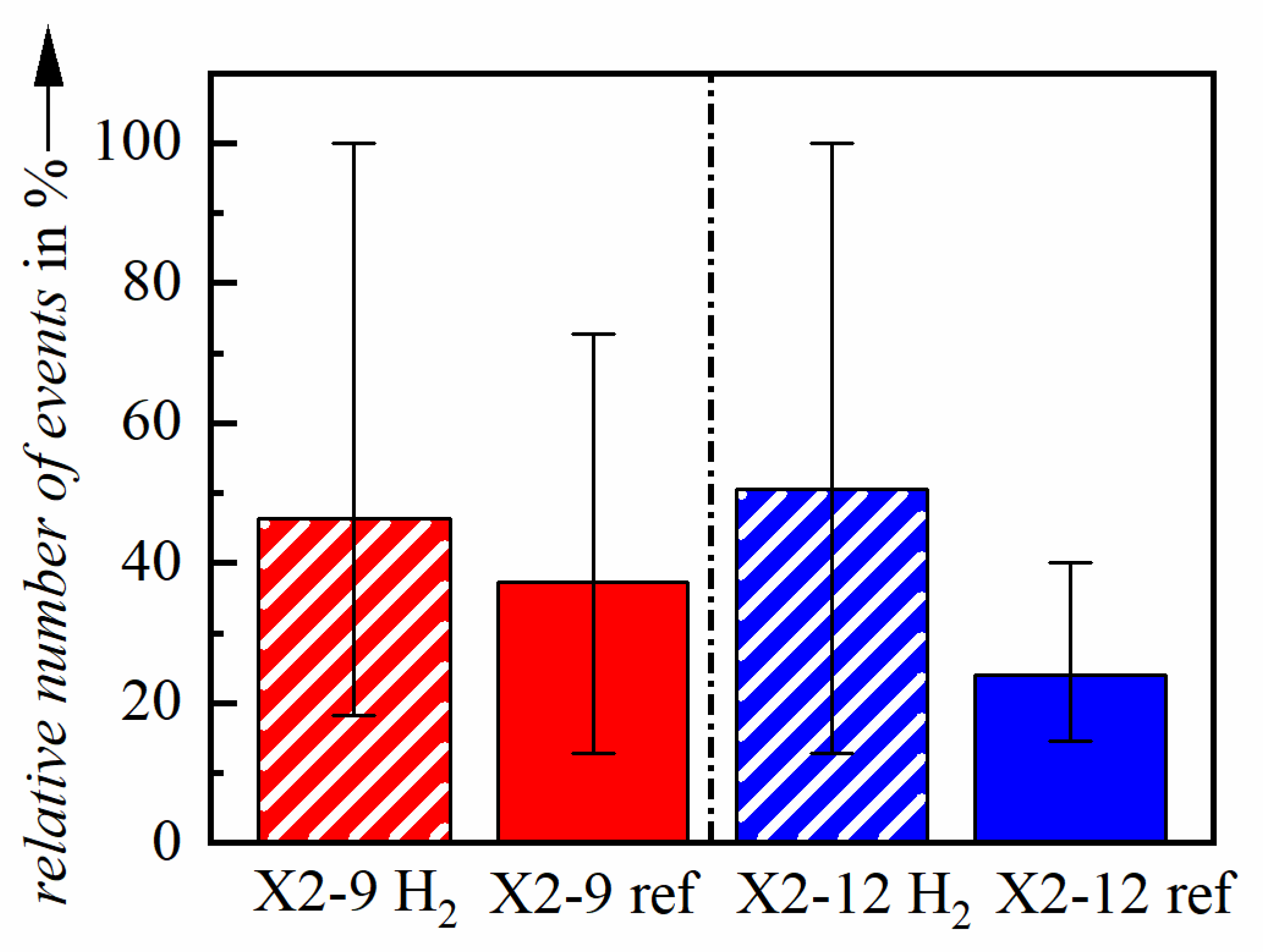

3.3. Nanoindentation Fatigue Tests

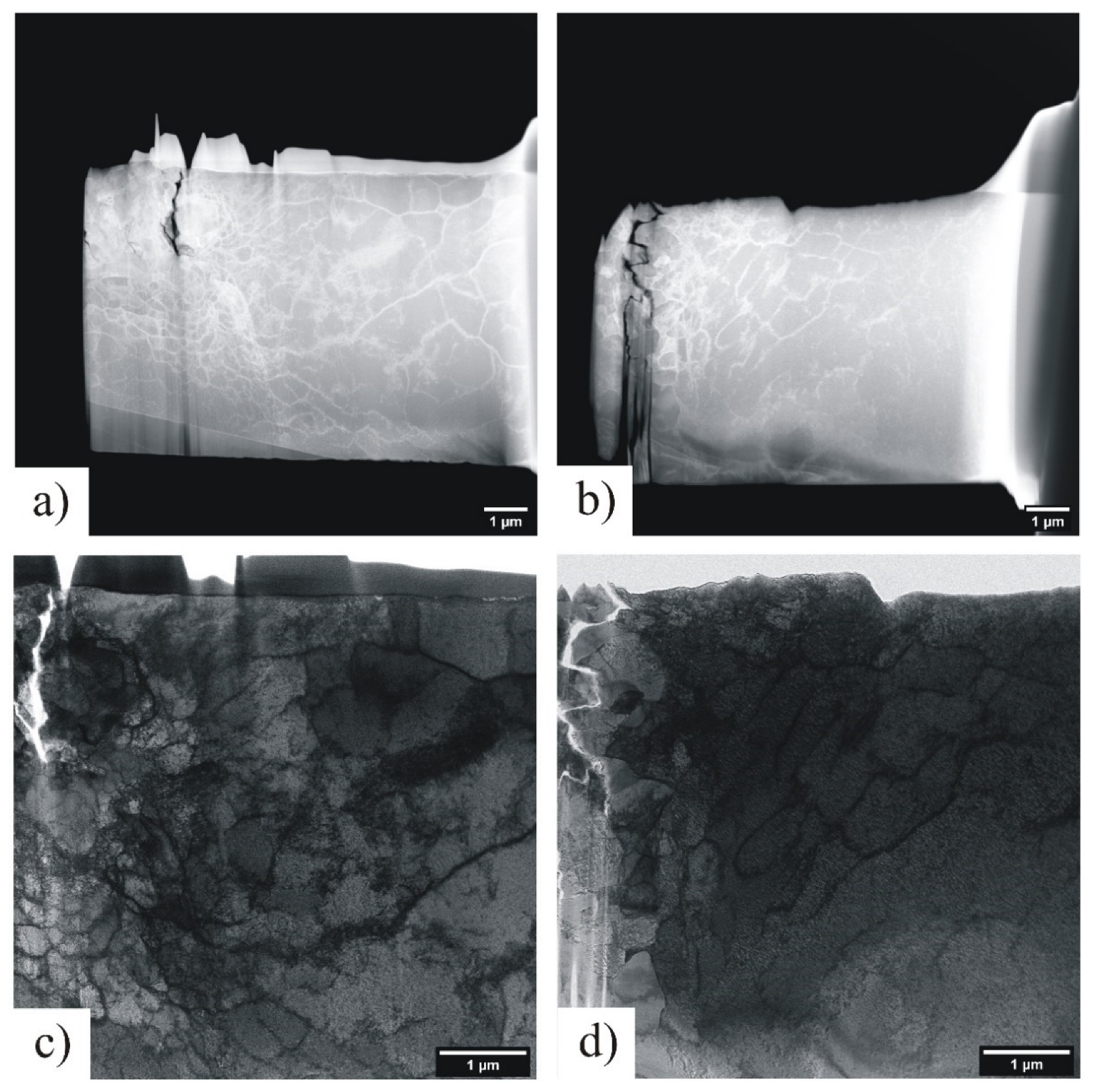

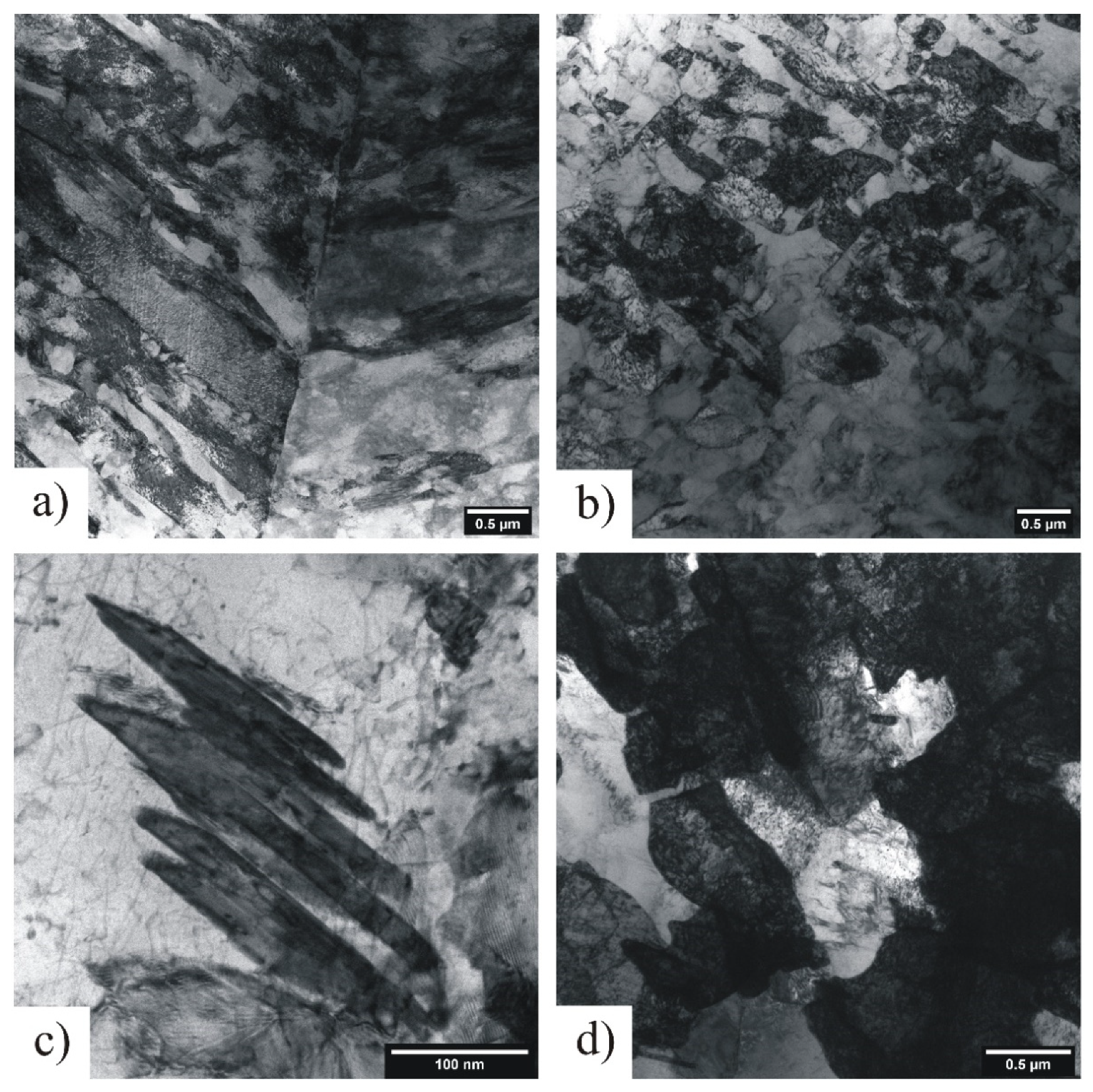

3.4. TEM Analyzes

4. Discussion

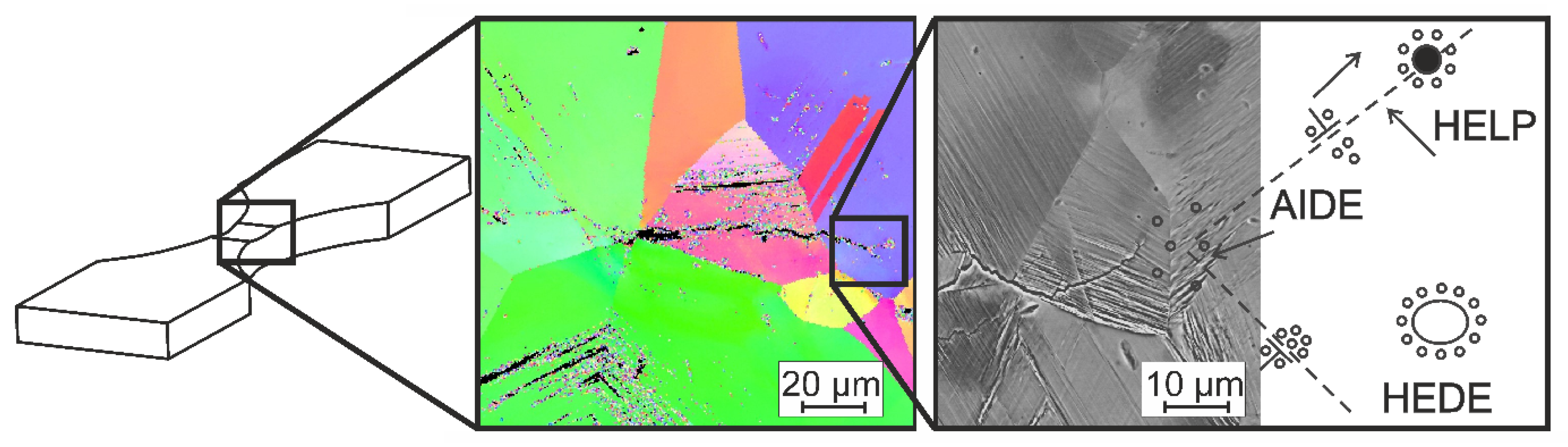

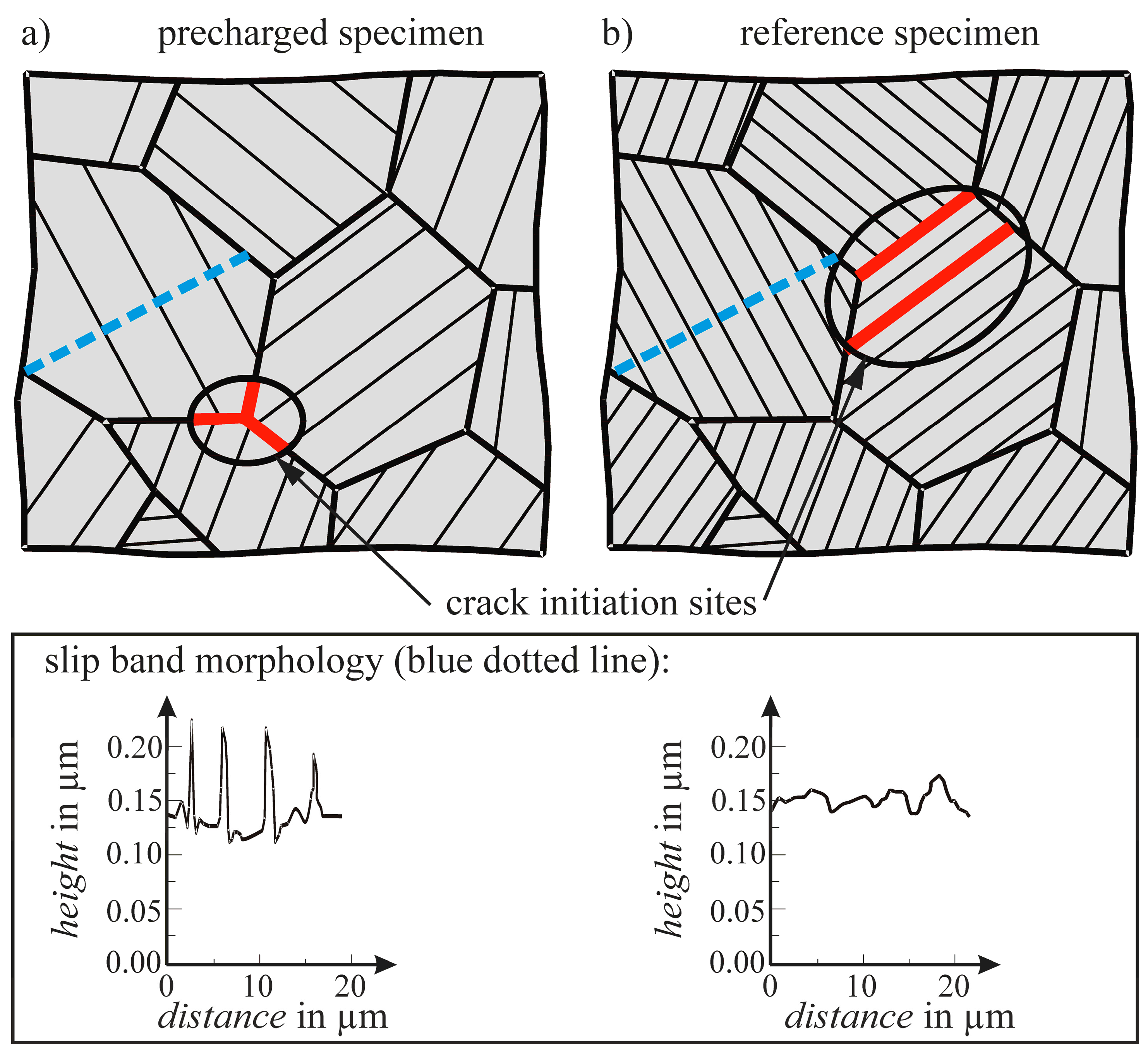

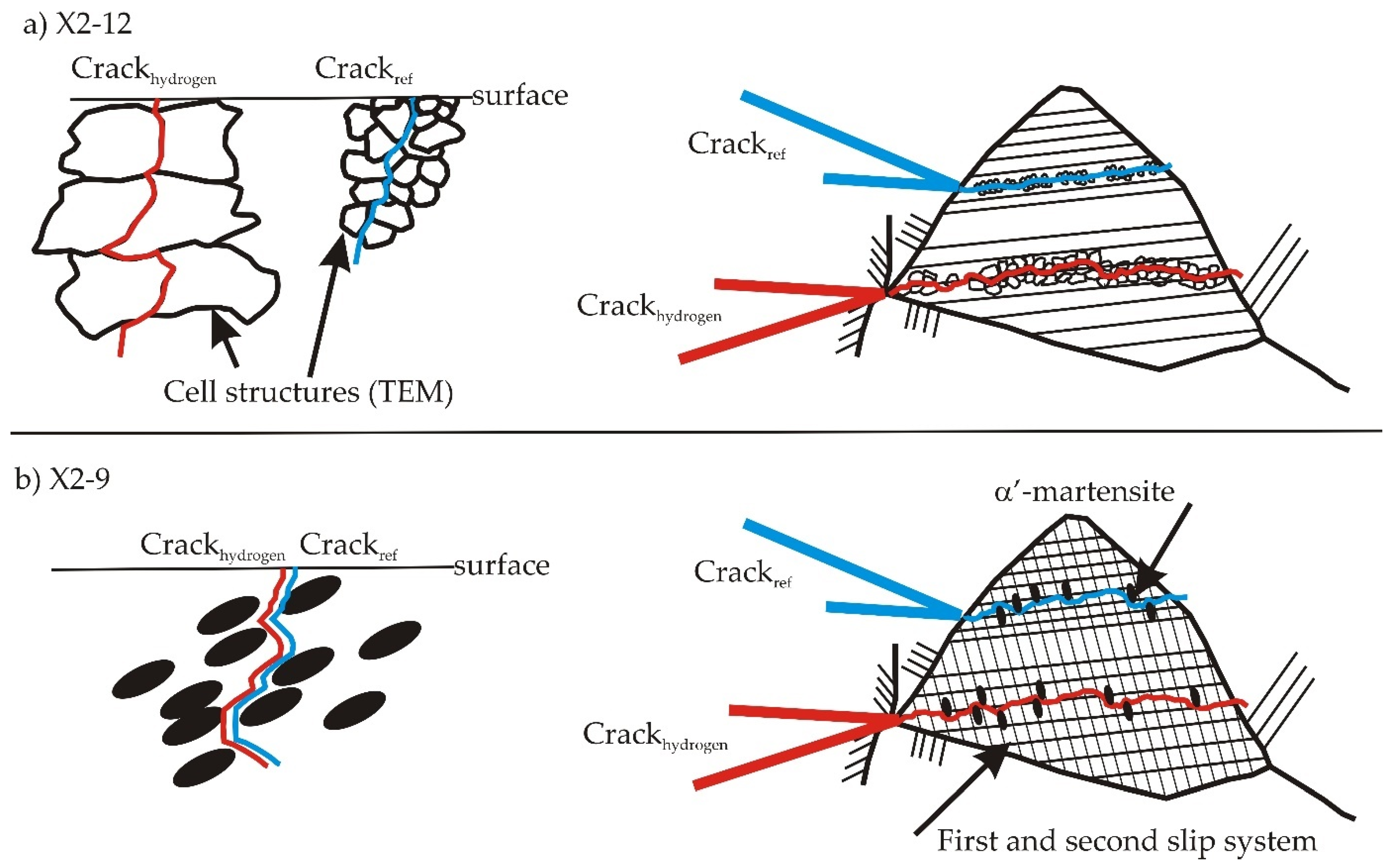

4.1. Fatigue Crack Initiation and Propagation

4.2. Local Cyclic Deformation Behavior in Indentation Tests

4.3. TEM Analyses

5. Summary and Conclusions

- In accordance with the different crack morphology observed in fatigue tests, the TEM analyses at X2-12 revealed coarser dislocation cell structures for the hydrogen precharged condition, which indicate an enhanced local plasticity. The more pronounced plasticity on a local level and thus, at small (micro and nano) length scale is also shown by the cyclic indentation, as well as nanoindentation fatigue tests. The increased plasticity at these length scales can be explained with the hydrogen enhanced localized plasticity (HELP) mechanism, which is assumed to be active for X2-12 and to cause the differences in fatigue crack morphology.

- For X2-9, the TEM analyses showed no differences between the reference and hydrogen precharged condition, which is caused by pronounced phase transformation, disabling thorough analyses of deformation-induced dislocation structure. However, the indentation tests also indicate higher local plasticity for the precharged condition of X2-9. Consequently, also for X2-9 the HELP mechanism is assumed to be active during fatigue crack propagation. Combined with the increased diffusion rate after phase transformation, resulting in a higher amount of hydrogen in the vicinity of the crack tip, the HELP mechanism is expected to lead to a significantly faster crack propagation rate of precharged condition compared to the hydrogen-free material.

- The indentation tests performed in this work enabled a valid analysis of the influence of hydrogen on the local cyclic deformation behavior and consequently, the presented indentation testing approaches are powerful means for analyzing hydrogen-induced effects on a local level.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lynch, S. Hydrogen embrittlement phenomena and mechanisms. Corros. Rev. 2012, 30, 105–123. [Google Scholar] [CrossRef]

- Beachem, C.D. A new model for hydrogen-assisted cracking (hydrogen “embrittlement”). Metall. Mater. Trans. B 1972, 3, 441–455. [Google Scholar] [CrossRef]

- Pöpperling, R.; Schwenk, W. Einflußgrößen der H-induzierten Spannungsrißkorrosion bei niedriglegierten Stählen. Mater. Corros. 1980, 31, 15–20. [Google Scholar] [CrossRef]

- Brück, S.; Schippl, V.; Schwarz, M.; Christ, H.-J.; Fritzen, C.-P.; Weihe, S. Hydrogen Embrittlement Mechanism in Fatigue Behavior of Austenitic and Martensitic Stainless Steels. Metals 2018, 8, 339. [Google Scholar] [CrossRef]

- Petch, N.J.; Stables, P. Delayed Fracture of Metals under Static Load. Nature 1952, 169, 842–843. [Google Scholar] [CrossRef]

- Cotterill, P. The hydrogen embrittlement of metals. Prog. Mater. Sci. 1961, 9, 205–301. [Google Scholar] [CrossRef]

- Griffiths, A.J.; Turnbull, A. On the effective diffusivity of hydrogen in low alloy steels. Corros. Sci. 1995, 37, 1879–1881. [Google Scholar] [CrossRef]

- Lynch, S.P. Hydrogen embrittlement and liquid-metal embrittlement in nickel single crystals. Scr. Metall. 1979, 13, 1051–1056. [Google Scholar] [CrossRef]

- Lynch, S.P. Environmentally assisted cracking: Overview of evidence for an adsorption-induced localised-slip process. Acta Metall. 1988, 36, 2639–2661. [Google Scholar] [CrossRef]

- Lynch, S.P. Metallographic contributions to understanding mechanisms of environmentally assisted cracking. Metallography 1989, 23, 147–171. [Google Scholar] [CrossRef]

- Lynch, S.P. Comments on “A unified model of environment-assisted cracking”. Scr. Mater. 2009, 61, 331–334. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Gong, J.; Shen, L.; Dong, W. Hydrogen embrittlement of catholically hydrogen-precharged 304L austenitic stainless steel: Effect of plastic pre-strain. Int. J. Hydrog. Energy 2014, 39, 13909–13918. [Google Scholar] [CrossRef]

- Li, X.; Gong, B.; Deng, C.; Li, Y. Failure mechanism transition of hydrogen embrittlement in AISI 304 K-TIG weld metal under tensile loading. Corros. Sci. 2018, 130, 241–251. [Google Scholar] [CrossRef]

- Djukic, M.B.; Bakic, G.M.; Zeravcic, V.S.; Sedmak, A.; Rajicic, B. The synergistic action and interplay of hydrogen embrittlement mechanisms in steels and iron: Localized plasticity and decohesion. Eng. Fract. Mech. 2019, 216, 106528. [Google Scholar] [CrossRef]

- Zhao, Y.; Seok, M.-Y.; Choi, I.-C.; Lee, Y.-H.; Park, S.-J.; Ramamurty, U.; Suh, J.-Y.; Jang, J.-i. The role of hydrogen in hardening/softening steel: Influence of the charging process. Scr. Mater. 2015, 107, 46–49. [Google Scholar] [CrossRef]

- Weidner, A.; Biermann, H. Case studies on the application of high-resolution electron channelling contrast imaging–investigation of defects and defect arrangements in metallic materials. Philos. Mag. 2015, 95, 759–793. [Google Scholar] [CrossRef]

- Lynch, S.P. Revealing the fundamental processes controlling hydrogen embrittlment. In Effects of Hydrogen on Materials, Proceedings of the 2008 International Hydrogen Conference, WY, USA, 7–10 September 2008; Somerday, B., Sofronis, P., Jones, R., Eds.; ASM International: Cleveland, OH, USA, 2009. [Google Scholar]

- Gerberich, W.W.; Marsh, P.G.; Hoehn, J.W.; Venkataraman, S.; Huang, H. Hydrogen/plasticity interactions in stress corrosion cracking. Corros. Deform. Interact. 1993, 325–353. [Google Scholar]

- Nibur, K.; Bahr, D.; Somerday, B. Hydrogen effects on dislocation activity in austenitic stainless steel. Acta Mater. 2006, 54, 2677–2684. [Google Scholar] [CrossRef]

- Barnoush, A.; Asgari, M.; Johnsen, R. Resolving the hydrogen effect on dislocation nucleation and mobility by electrochemical nanoindentation. Scr. Mater. 2012, 66, 414–417. [Google Scholar] [CrossRef]

- Godoi, W.; Kuromoto, N.K.; Guimarães, A.S.; Lepienski, C.M. Effect of the hydrogen outgassing time on the hardness of austenitic stainless steels welds. Mater. Sci. Eng. A 2003, 354, 251–256. [Google Scholar] [CrossRef]

- Iost, A.; Vogt, J.B. Hardness variation in a cathodic hydrogen-charged austenitic stainless steel. Scr. Mater. 1997, 37, 1499–1504. [Google Scholar] [CrossRef]

- Zhang, L.; An, B.; Iijima, T.; Marchi, C.S. Effect of Gaseous Hydrogen Charging on Nanohardness of Austenitic Stainless Steels. In Proceedings of the ASME 2016 Pressure Vessels and Piping Conference, Vancouver, BC, Canada. Volume 6B: Materials and Fabrication; ASME: New York, NY, USA, 2016. [Google Scholar]

- Hong, Y.; Zhou, C.; Zheng, Y.; Zhang, L.; Zheng, J.; An, B.; Chen, X.; Wang, X. Hydrogen effect on the deformation evolution process in situ detected by nanoindentation continuous stiffness measurement. Mater. Charact. 2017, 127, 35–40. [Google Scholar] [CrossRef]

- Mine, Y.; Horita, Z.; Murakami, Y. Effect of hydrogen on martensite formation in austenitic stainless steels in high-pressure torsion. Acta Mater. 2009, 57, 2993–3002. [Google Scholar] [CrossRef]

- Pharr, G.M. Measurement of mechanical properties by ultra-low load indentation. Mater. Sci. Eng. A 1998, 253, 151–159. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Xu, B.X.; Yue, Z.F.; Wang, J. Indentation fatigue behaviour of polycrystalline copper. Mech. Mater. 2007, 39, 1066–1080. [Google Scholar] [CrossRef]

- Xu, B.; Yue, Z.; Chen, X. An indentation fatigue depth propagation law. Scr. Mater. 2009, 60, 854–857. [Google Scholar] [CrossRef]

- Saraswati, T.; Sritharan, T.; Mhaisalkar, S.; Breach, C.D.; Wulff, F. Cyclic loading as an extended nanoindentation technique. Mater. Sci. Eng. A 2006, 423, 14–18. [Google Scholar] [CrossRef]

- Kramer, H.S.; Starke, P.; Klein, M.; Eifler, D. Cyclic hardness test PHYBALCHT–Short-time procedure to evaluate fatigue properties of metallic materials. Int. J. Fatigue 2014, 63, 78–84. [Google Scholar] [CrossRef]

- Görzen, D.; Schwich, H.; Blinn, B.; Song, W.; Krupp, U.; Bleck, W.; Beck, T. Influence of Cu precipitates and C content on the defect tolerance of steels. Int. J. Fatigue 2021, 144, 106042. [Google Scholar] [CrossRef]

- Nix, W.D.; Gao, H. Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 1998, 46, 411–425. [Google Scholar] [CrossRef]

- Durst, K.; Backes, B.; Göken, M. Indentation size effect in metallic materials: Correcting for the size of the plastic zone. Scr. Mater. 2005, 52, 1093–1097. [Google Scholar] [CrossRef]

- Sadrabadi, P.; Durst, K.; Göken, M. Study on the indentation size effect in CaF2: Dislocation structure and hardness. Acta Mater. 2009, 57, 1281–1289. [Google Scholar] [CrossRef]

- Blinn, B.; Görzen, D.; Klein, M.; Eifler, D.; Beck, T. PhyBaLCHT–Influence of indentation force on the results of cyclic hardness tests and investigations of comparability to uniaxial fatigue loading. Int. J. Fatigue 2019, 119, 78–88. [Google Scholar] [CrossRef]

- Blinn, B.; Klein, M.; Gläßner, C.; Smaga, M.; Aurich, J.; Beck, T. An Investigation of the Microstructure and Fatigue Behavior of Additively Manufactured AISI 316L Stainless Steel with Regard to the Influence of Heat Treatment. Metals 2018, 8, 220. [Google Scholar] [CrossRef]

- Grigorescu, A.C.; Hilgendorff, P.-M.; Zimmermann, M.; Fritzen, C.-P.; Christ, H.-J. Cyclic deformation behavior of austenitic Cr–Ni-steels in the VHCF regime: Part I–Experimental study. Int. J. Fatigue 2016, 93, 250–260. [Google Scholar] [CrossRef]

- Angel, T. Formation of martensite in austenitic stainless steel-Effects of deformation, temperature and composition. J. Iron Steel Inst. 1954, 177, 165–174. [Google Scholar]

- Schramm, R.E.; Reed, R.P. Stacking fault energies of seven commercial austenitic stainless steels. Metall. Trans. A 1975, 6, 1345–1351. [Google Scholar] [CrossRef]

- Faisal, N.H.; Prathuru, A.K.; Goel, S.; Ahmed, R.; Droubi, M.G.; Beake, B.D.; Fu, Y.Q. Cyclic Nanoindentation and Nano-Impact Fatigue Mechanisms of Functionally Graded TiN/TiNi Film. Shape Mem. Superelasticity 2017, 3, 149–167. [Google Scholar] [CrossRef]

- Kesten, M.; Gräfen, H. Druckwasserstoffangriff auf unlegierte und niedriglegierte Stähle im Temperaturbereich unterhalb 200 C. In Wasserstoff und Korrosion, 2nd ed.; Kuron, D., Ed.; Bonner Studien Reihe: Bonn, Germany, 2000; pp. 101–126. [Google Scholar]

- Pircher, H.; Großterlinden, R. Wasserstoffinduzierte Korrosion von niedriglegierten Stählen in wäßrigen Medien. Mater. Corros. 1987, 38, 57–64. [Google Scholar] [CrossRef]

- Murakami, Y.; Kanezaki, T.; Mine, Y. Hydrogen Effect against Hydrogen Embrittlement. Metall. Trans. A 2010, 41, 2548–2562. [Google Scholar] [CrossRef]

- Christ, H.-J. Materialermüdung und Werkstoffmikrostruktur. In Ermüdungsverhalten Metallischer Werkstoffe; Christ, H.-J., Ed.; Wiley-VCH: Weinheim, Germany, 2009; pp. 35–51. [Google Scholar]

- Pontini, A.E.; Hermida, J.D. X-Ray diffraction measurement of the stacking fault energy reduction induced by hydrogen in an AISI 304 steel. Scr. Mater. 1997, 37, 1831–1837. [Google Scholar] [CrossRef]

| Elements in wt% | C | Si | Mn | Cr | Mo | Nb | Ni | N | Ti |

|---|---|---|---|---|---|---|---|---|---|

| X2-9 | 0.014 | 0.53 | 1.71 | 18.05 | 0.02 | 0.01 | 9.07 | 0.016 | 0.005 |

| X2-12 | 0.016 | 0.48 | 1.75 | 17.78 | 0.02 | 0.01 | 12.36 | 0.017 | 0.005 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brück, S.; Blinn, B.; Diehl, K.; Wissing, Y.; Müller, J.; Schwarz, M.; Christ, H.-J.; Beck, T.; Staedler, T.; Jiang, X.; et al. Analysis of Hydrogen-Induced Changes in the Cyclic Deformation Behavior of AISI 300–Series Austenitic Stainless Steels Using Cyclic Indentation Testing. Metals 2021, 11, 923. https://doi.org/10.3390/met11060923

Brück S, Blinn B, Diehl K, Wissing Y, Müller J, Schwarz M, Christ H-J, Beck T, Staedler T, Jiang X, et al. Analysis of Hydrogen-Induced Changes in the Cyclic Deformation Behavior of AISI 300–Series Austenitic Stainless Steels Using Cyclic Indentation Testing. Metals. 2021; 11(6):923. https://doi.org/10.3390/met11060923

Chicago/Turabian StyleBrück, Sven, Bastian Blinn, Katharina Diehl, Yannick Wissing, Julian Müller, Martina Schwarz, Hans-Jürgen Christ, Tilmann Beck, Thorsten Staedler, Xin Jiang, and et al. 2021. "Analysis of Hydrogen-Induced Changes in the Cyclic Deformation Behavior of AISI 300–Series Austenitic Stainless Steels Using Cyclic Indentation Testing" Metals 11, no. 6: 923. https://doi.org/10.3390/met11060923

APA StyleBrück, S., Blinn, B., Diehl, K., Wissing, Y., Müller, J., Schwarz, M., Christ, H.-J., Beck, T., Staedler, T., Jiang, X., Butz, B., & Weihe, S. (2021). Analysis of Hydrogen-Induced Changes in the Cyclic Deformation Behavior of AISI 300–Series Austenitic Stainless Steels Using Cyclic Indentation Testing. Metals, 11(6), 923. https://doi.org/10.3390/met11060923