Friction Stir Welding of AA2099-T83 and AA2060-T8E30 Aluminium Alloys with New Cr-Free Surface Treatments and Sealant Application

Abstract

1. Introduction

2. Materials and Methods

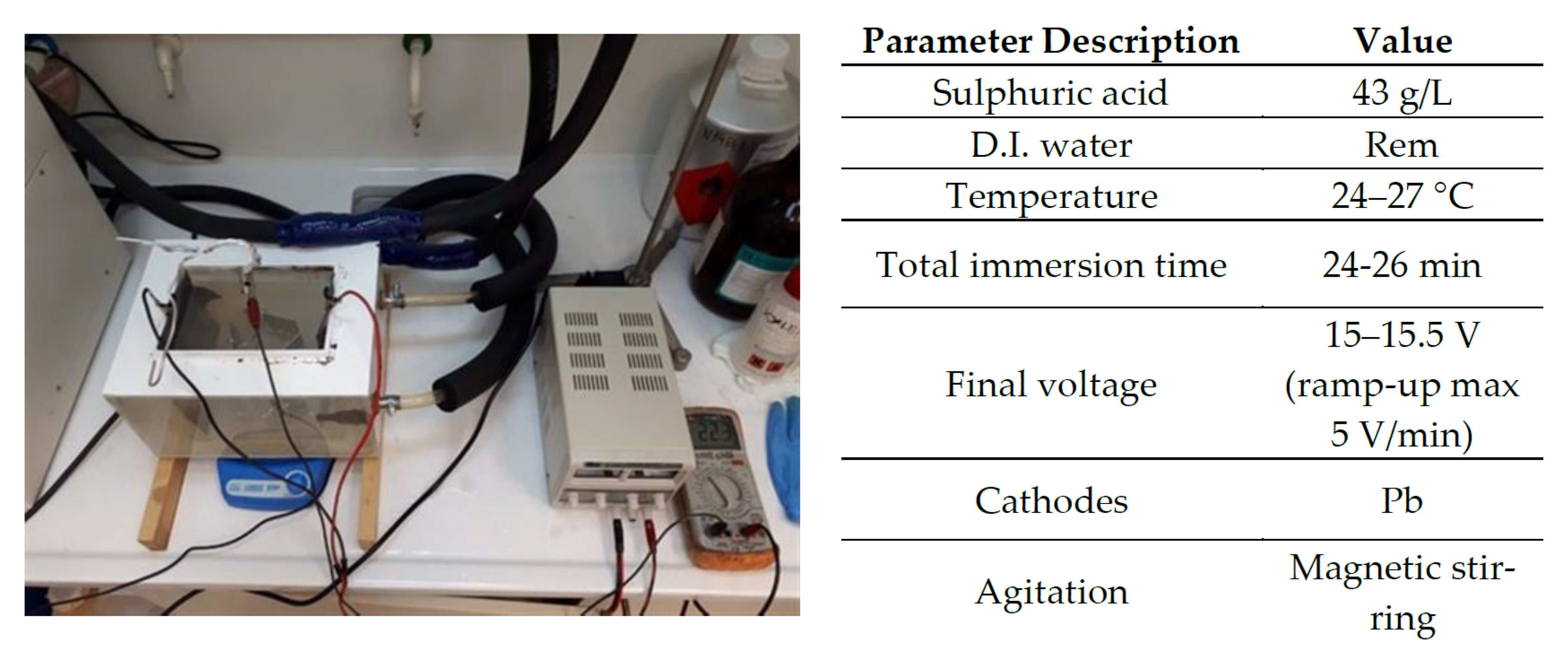

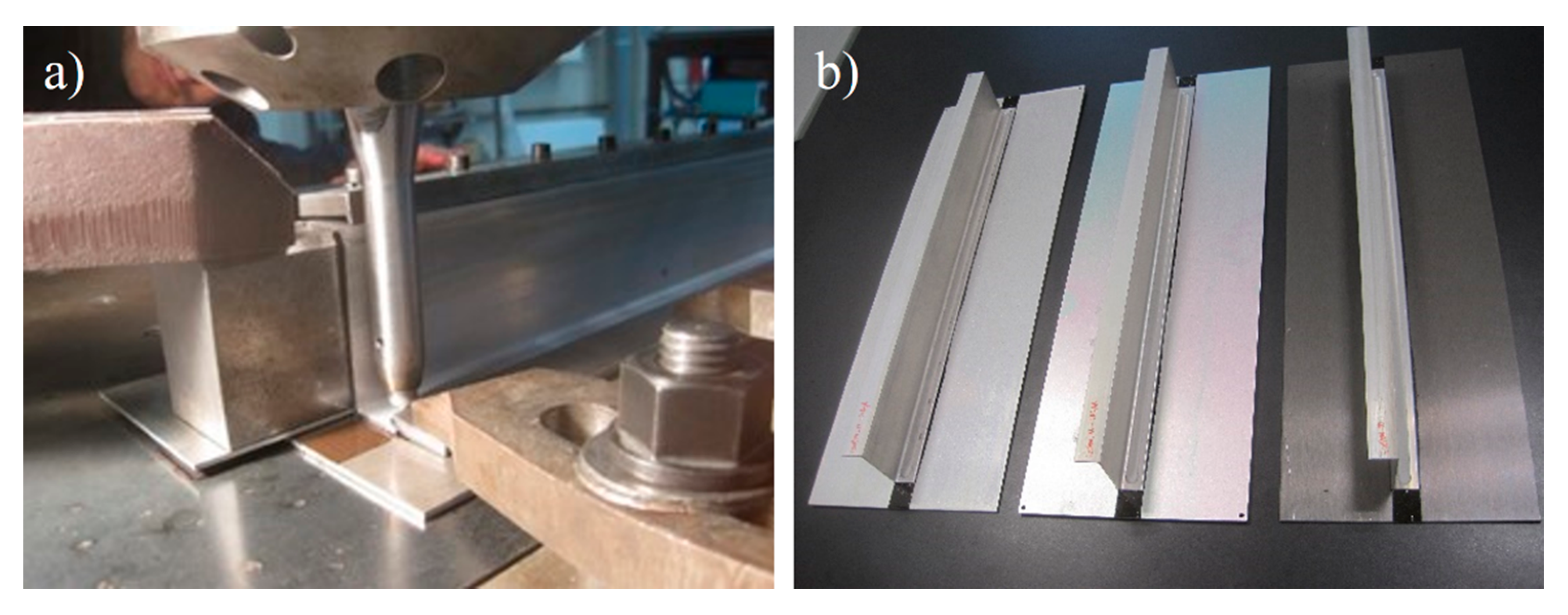

2.1. Base Materials and Surface Treatments

2.2. Friction Stir Welding Procedure

2.3. FSW Weld Property Characterisation

3. Results

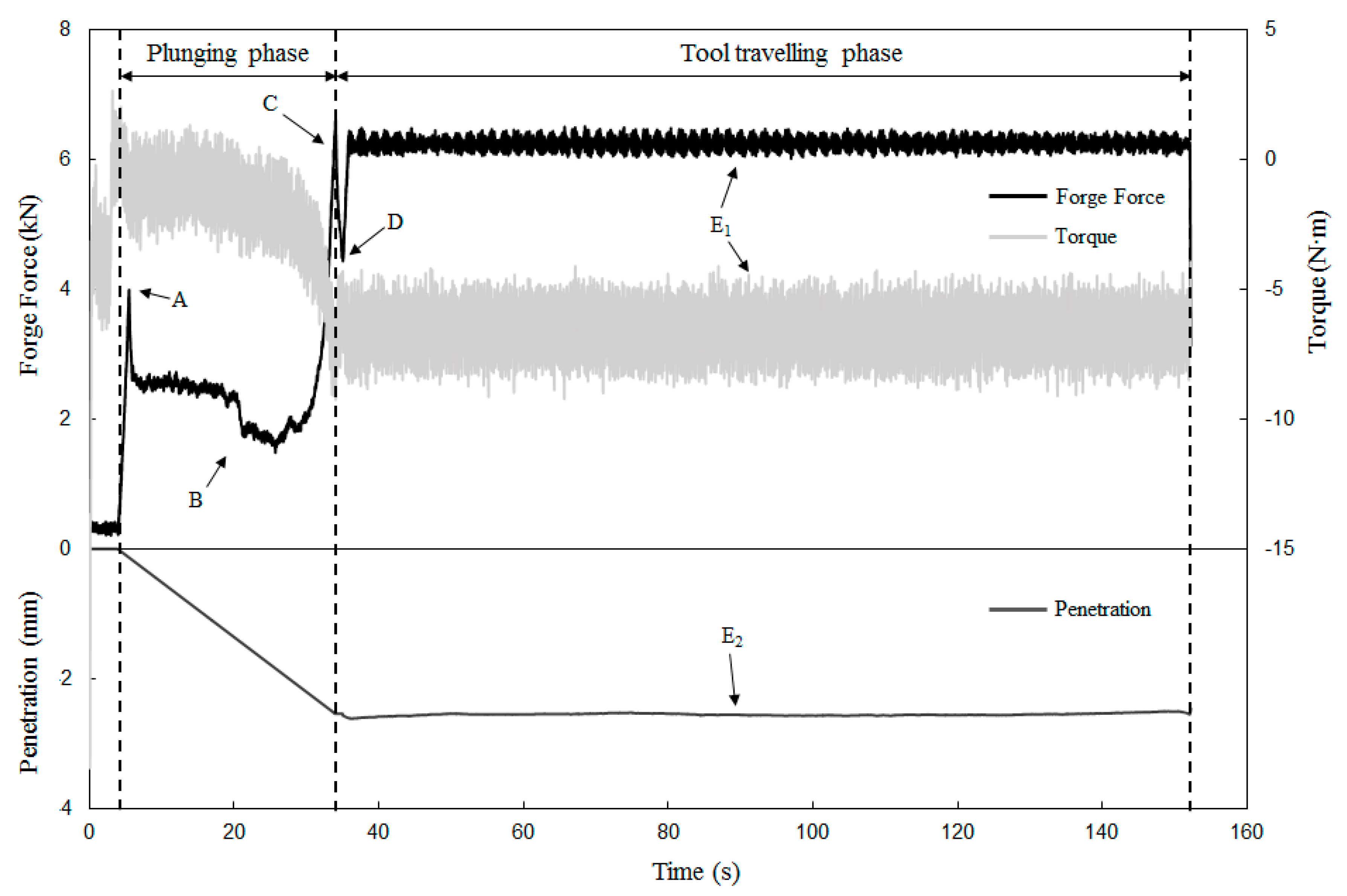

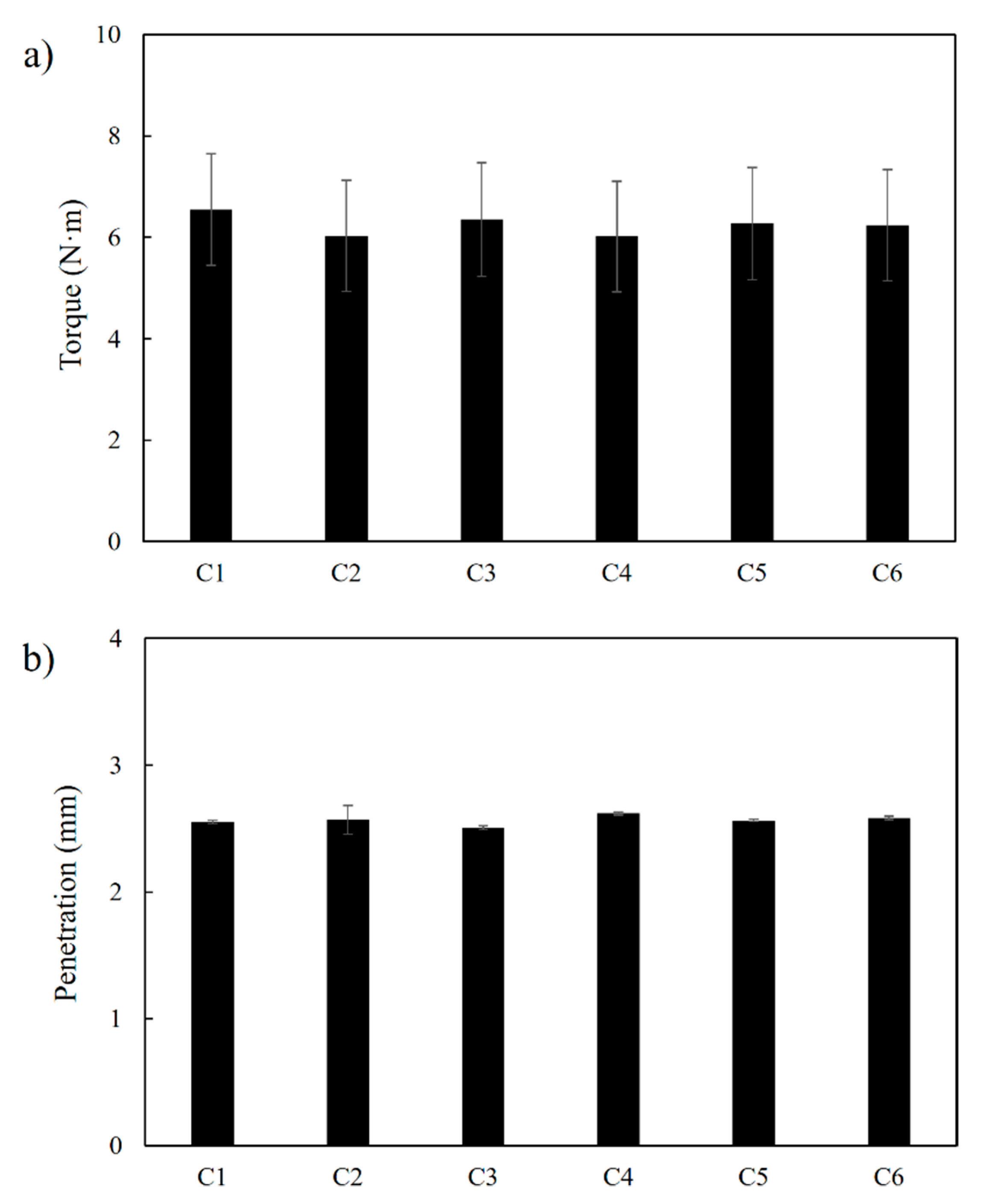

3.1. Reaction Forces and Tool Penetration during FSW

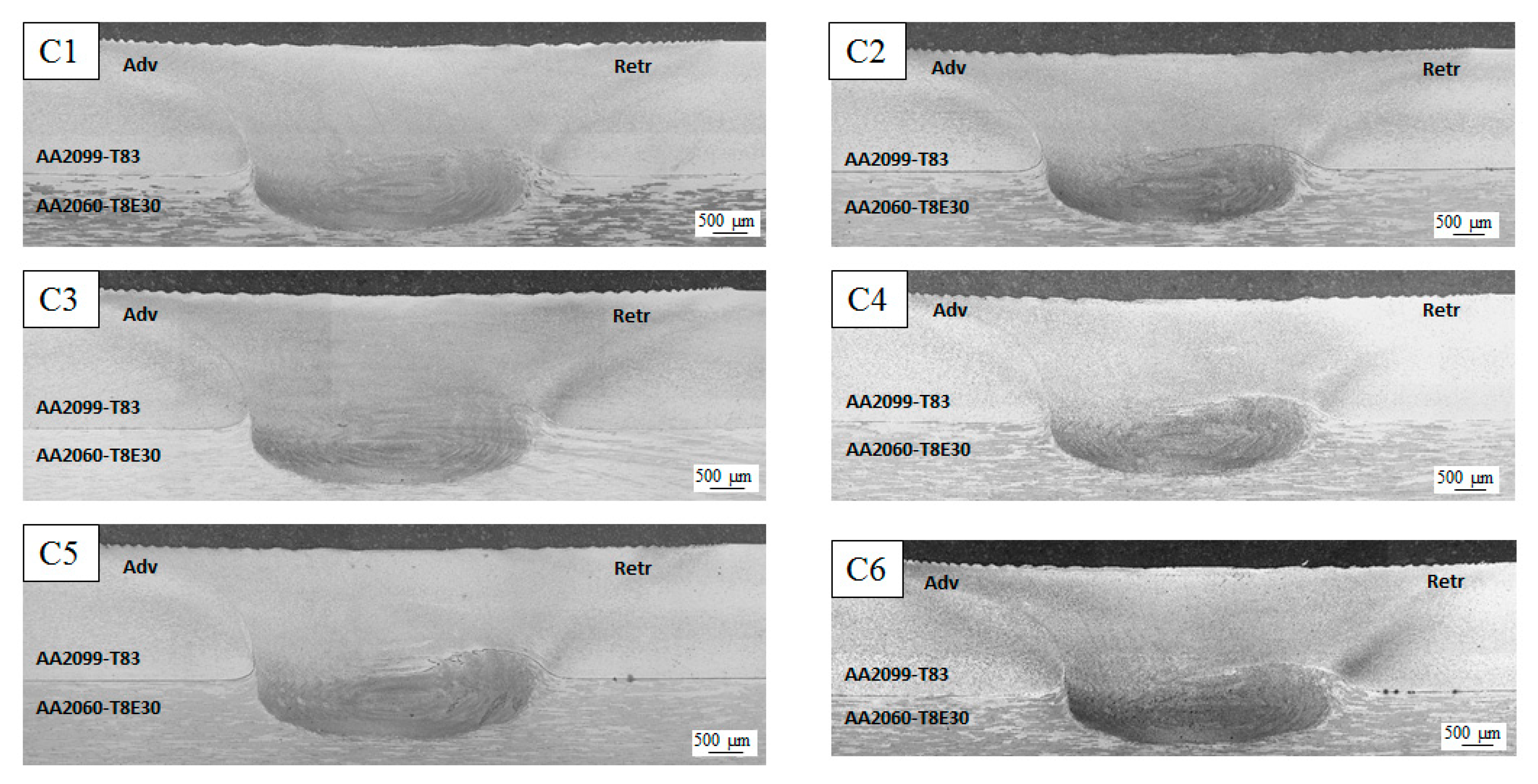

3.2. Metallographic Characterisation

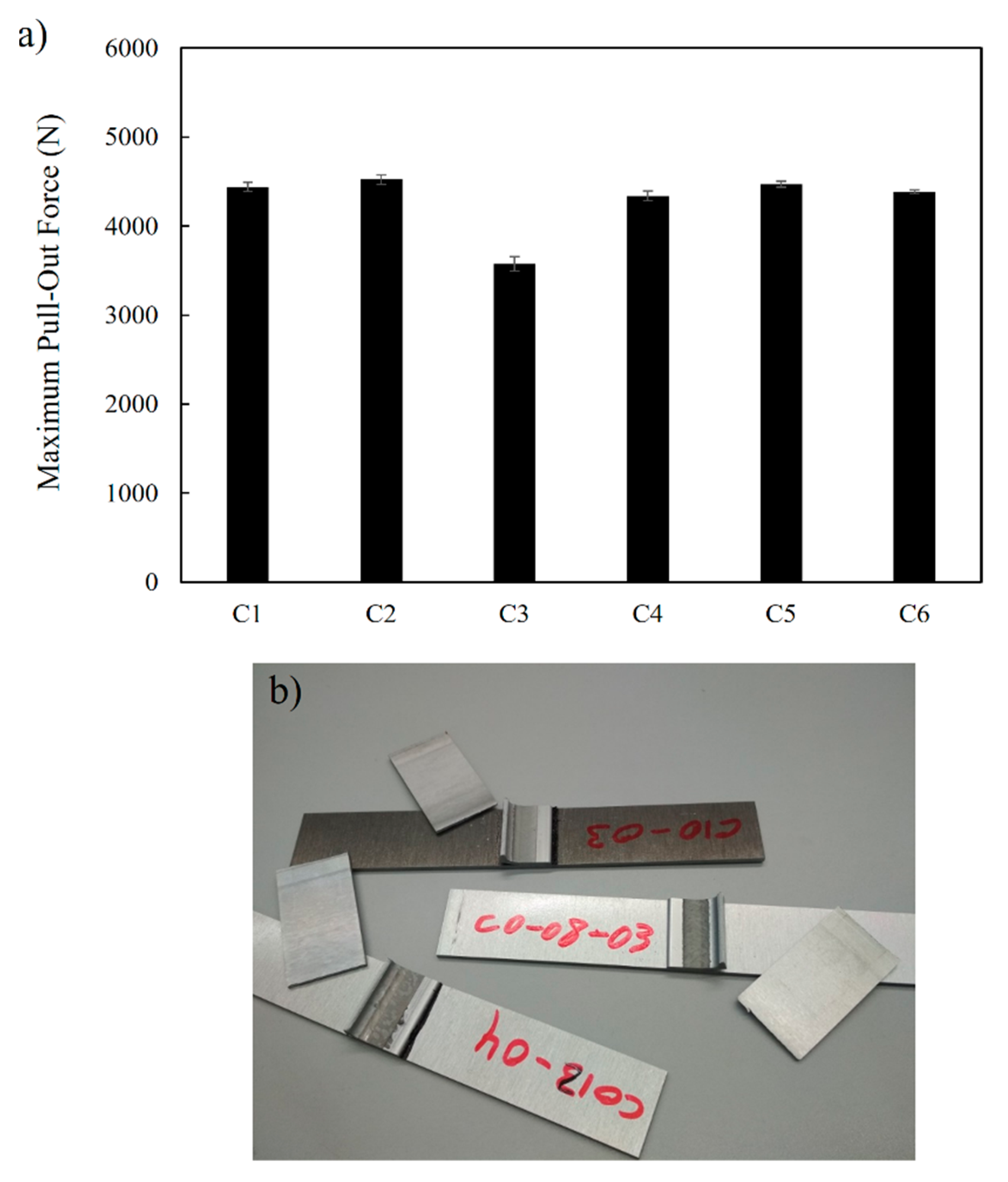

3.3. Pull-Out Strength

4. Conclusions

- No significant differences were observed in the force controlled FSW process after comparing the resulting torque and tool penetration during welding of non-treated, TFSAA treated, and Sol–Gel treated aluminium components (coupons C1, C2, and C3). The FSW process is similar and stable for all these conditions.

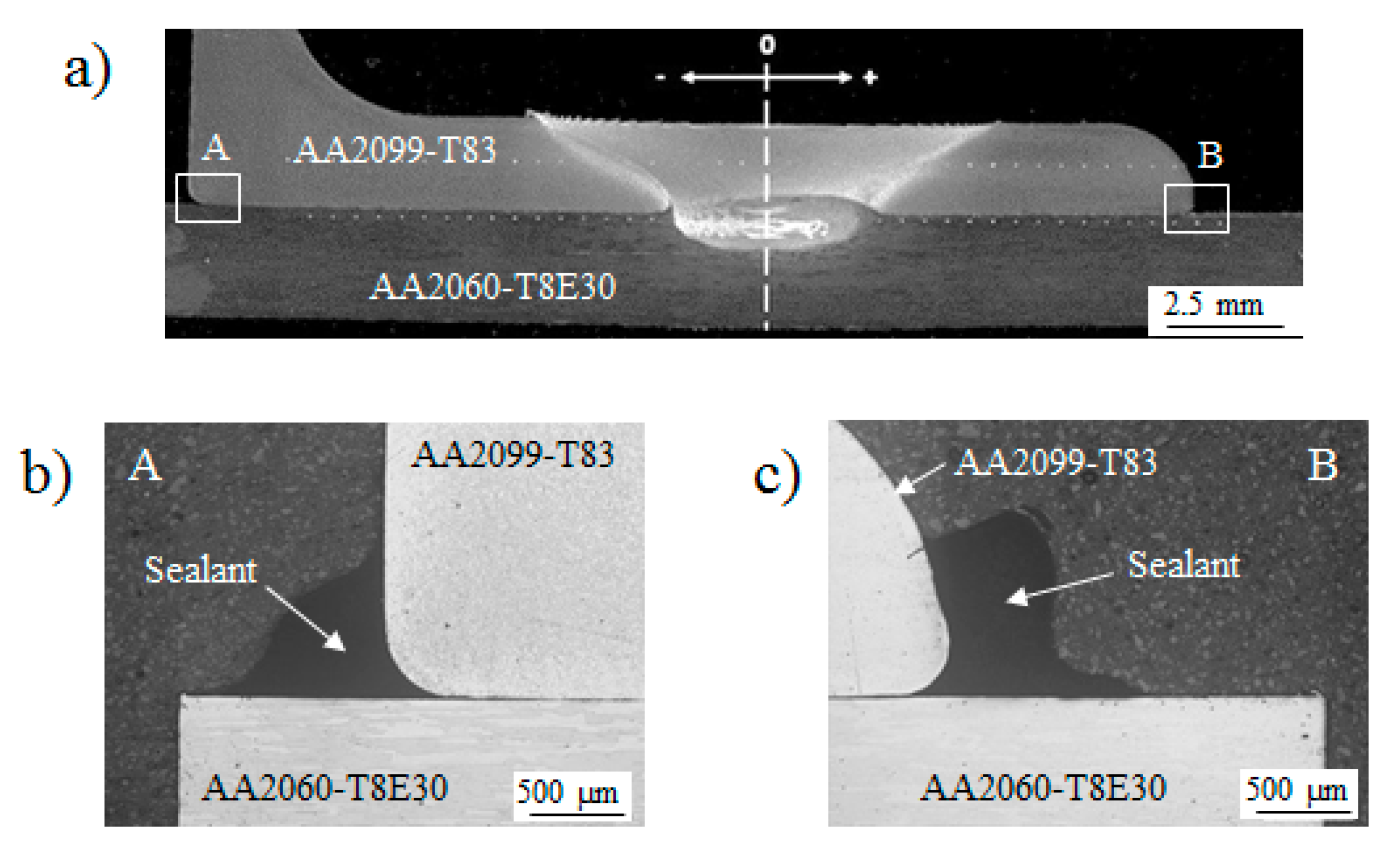

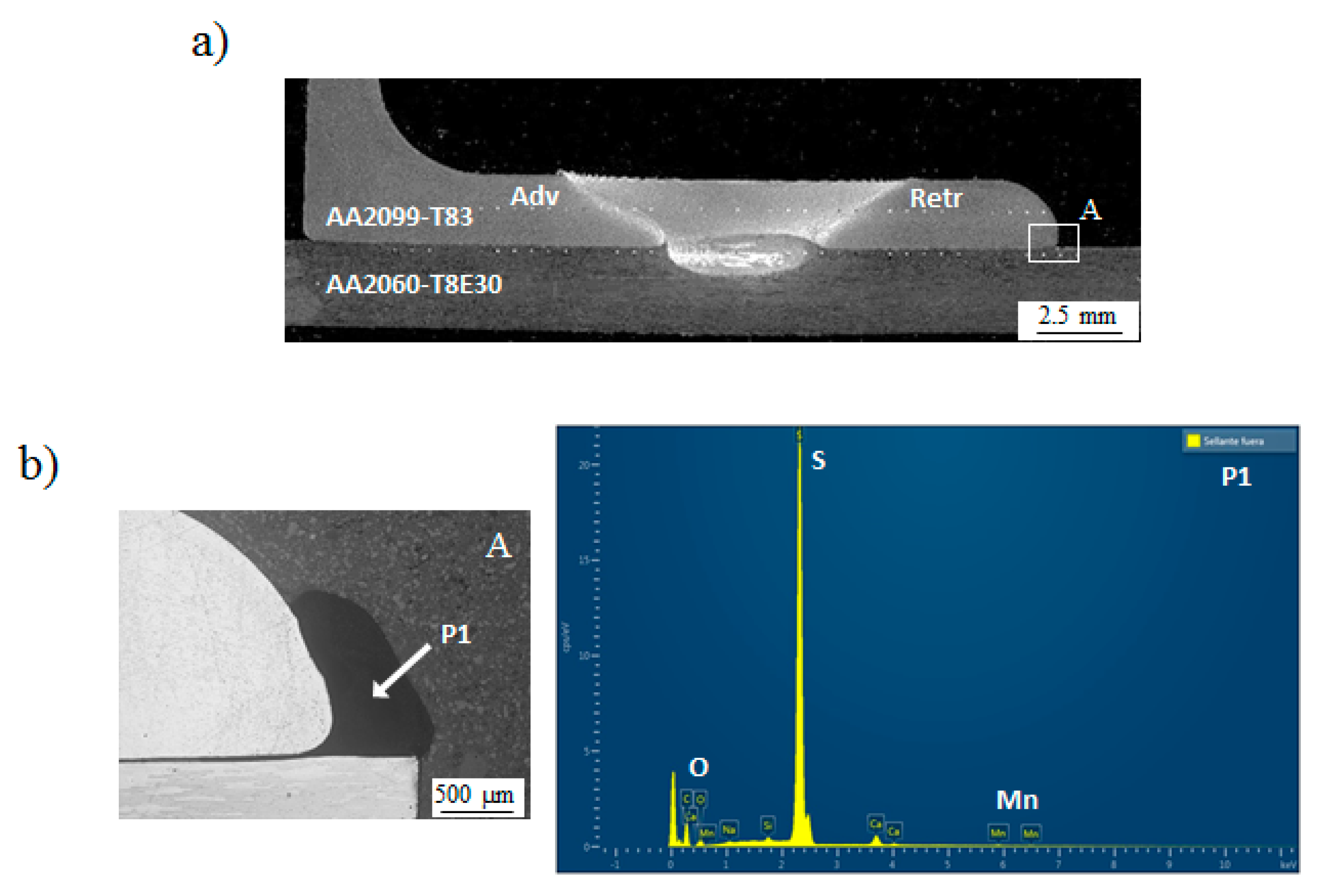

- No significant differences were observed in the FSW process after comparing welding with and without sealant application at the interface of aluminium extrusions and sheets (C1, C2, C3 vs. C4, C5, and C6). The FSW process is similar and stable for all investigated surface treatments and sealant application conditions. The consistent accumulation of sealant observed at the stringer–skin crevice region at the edge of the matching interface between overlapping parent materials could provide good protection against corrosion for this type of joints and structures.

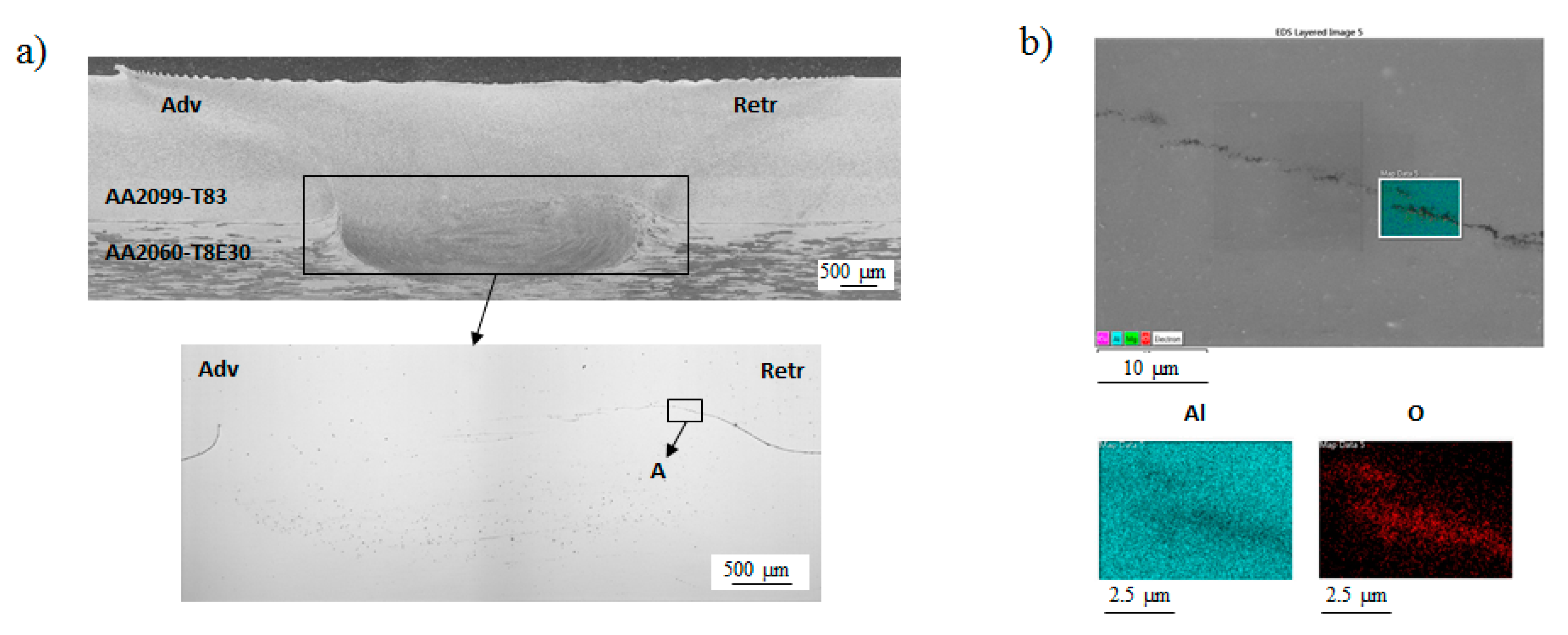

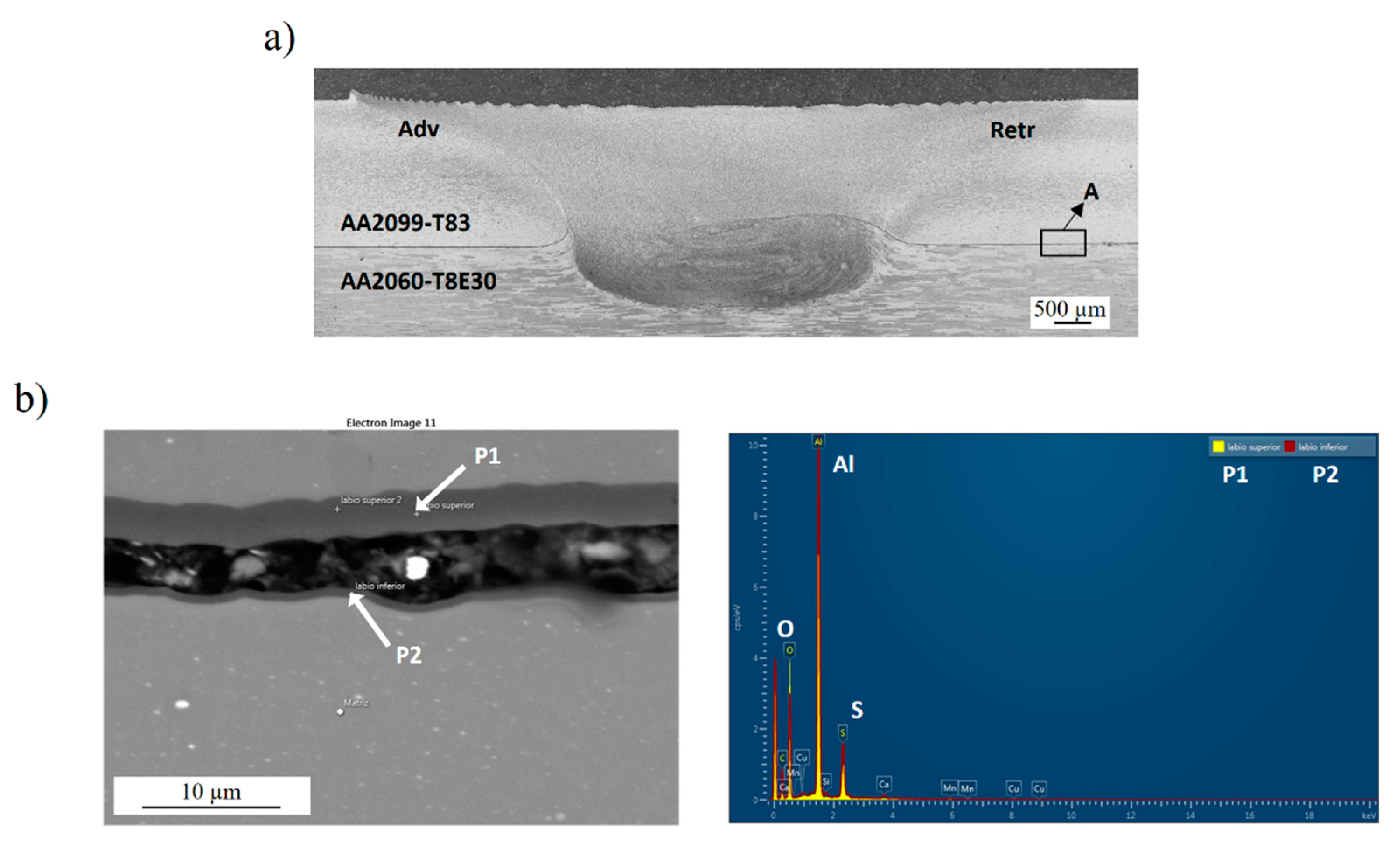

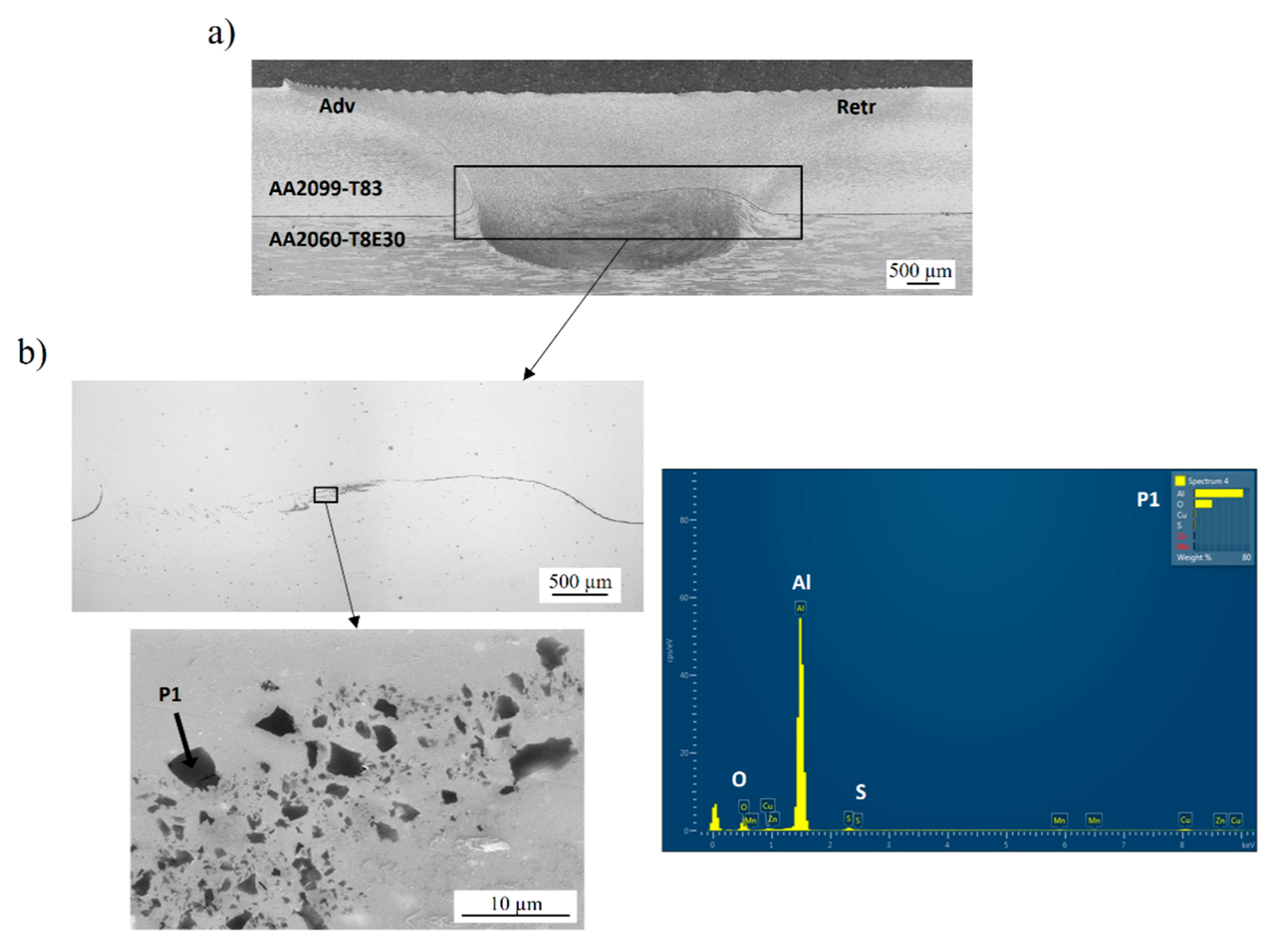

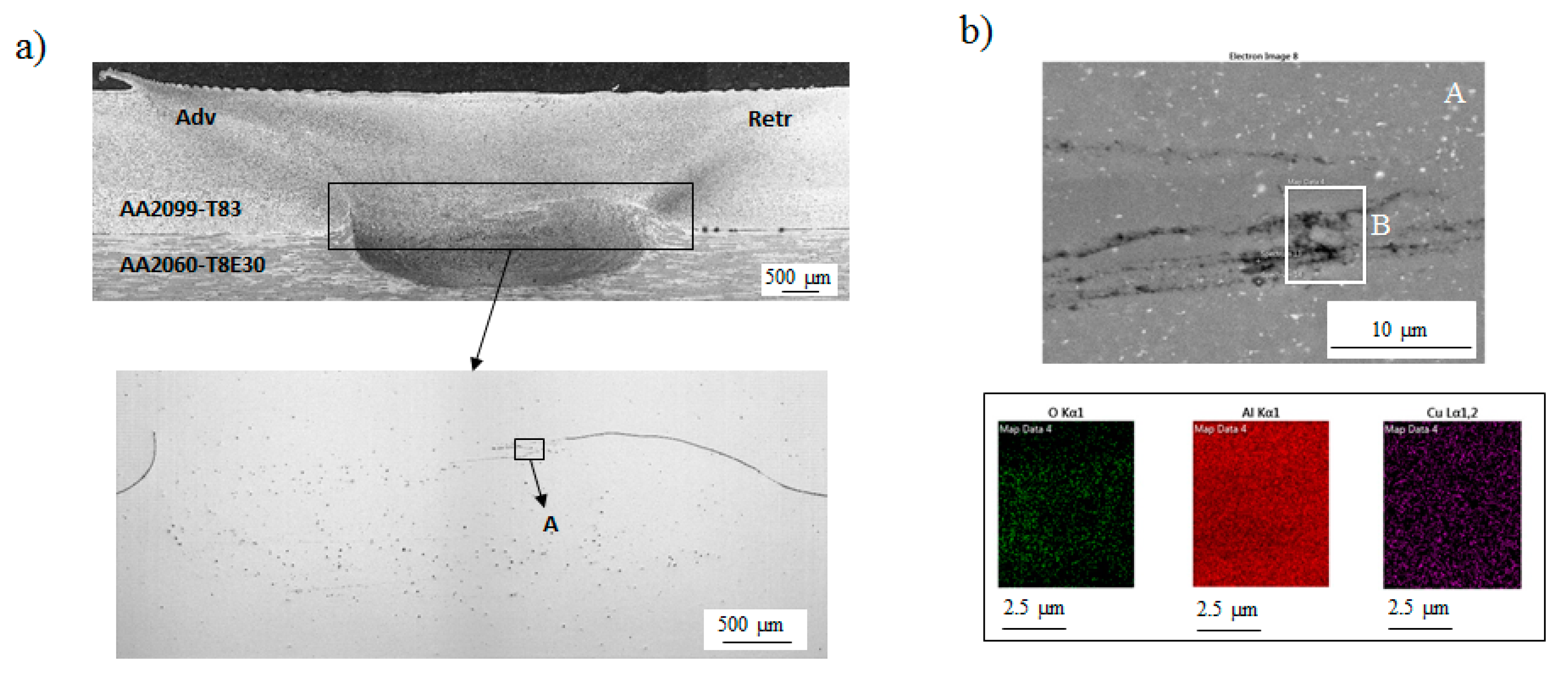

- All investigated welds (C1–C6) presented similar macrostructural characteristics, such as a small hook imperfection, and no measurable volumetric defects were observed in any of them. However, the use of surface-treated parent materials, especially those with the TFSAA treatment, showed aluminium oxide fragment remnants at the retreating region of the SZ in the welds.

- No sealant remnants were observed in any of the welds of the investigated FSW coupons. The sealant seems to be displaced from the weld region towards the edges by the pressure applied by the tool during the FSW process.

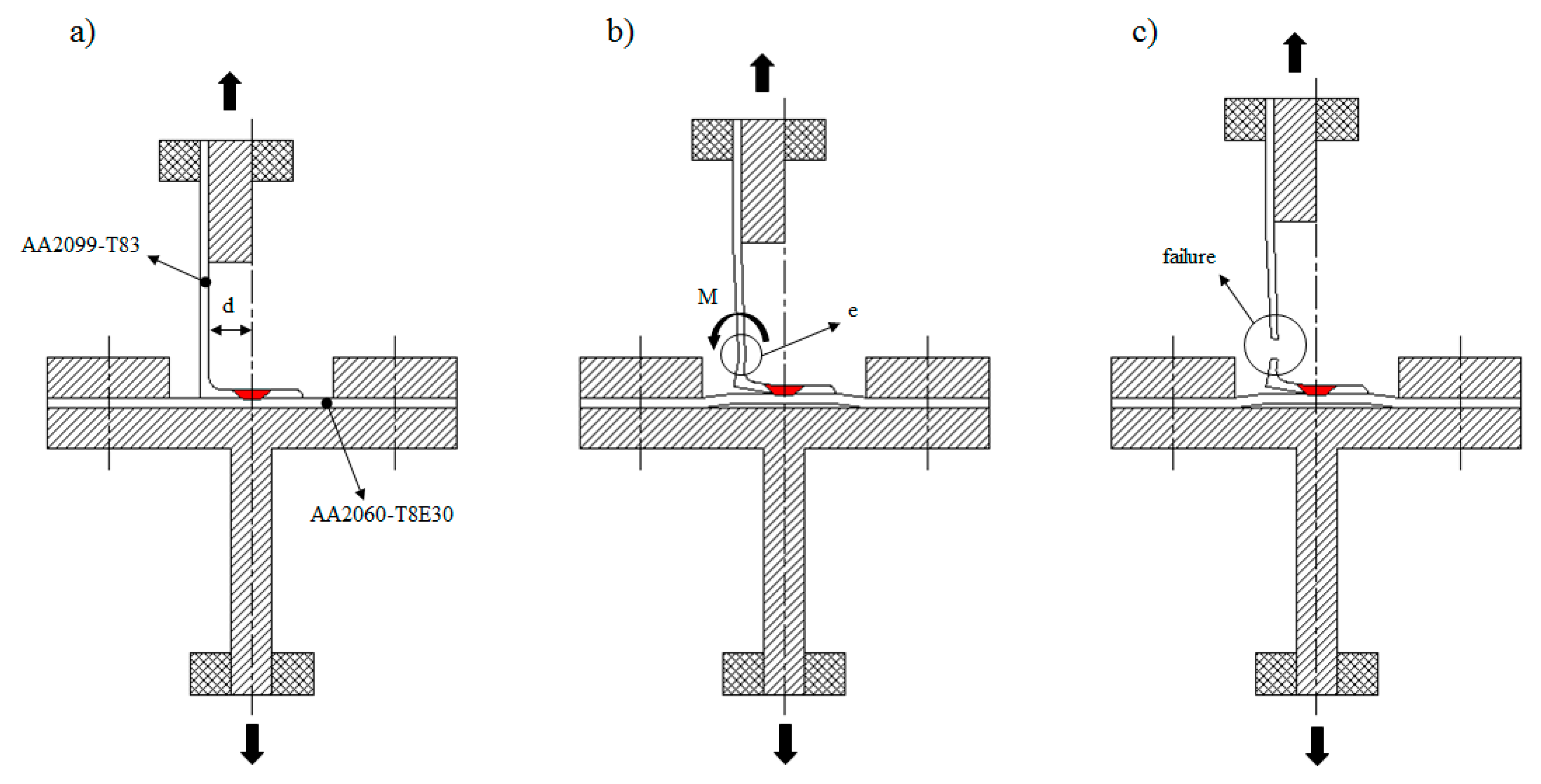

- Consistent failures at the stringer (AA2099-T83 extrusion) outside the weld region and comparable failure loads were observed in pull-out static tests for all FSW specimens due to the bending effect and stress concentration at this point. Therefore, all tested FSW welds showed higher strength than the most stressed point of the joints despite the presence of the aluminium oxide remnants observed in some cases (C2 and C5).

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rendings, K.H. Aluminium structures used in aerospace—Status and prospects. Mater. Sci. Forum 2001, 242, 11–24. [Google Scholar] [CrossRef]

- Starke, E.A.; Staley, J.T. Application of modern aluminum alloys to aircraft. Prog. Aerosp. Sci. 1996, 32, 131–172. [Google Scholar] [CrossRef]

- Mendez, P.; Eagar, T. New trends in welding in the aeronautic industry. In Proceedings of the 2nd Conference of New Manufacturing Trends, Bilbao, Spain, 19–20 November 2002. [Google Scholar]

- Tavares, S.M. Design and Advanced Manufacturing of Aircraft Structures Using Friction Stir Welding. Ph.D. Thesis, Universidade do Porto, Porto, Portugal, July 2011. [Google Scholar]

- Murphy, A.; McCune, W.; Quinn, D.; Price, M. The characterization of friction stir welding process effects on stiffened panel structures. Thin Walled Struct. 2007, 45, 339–351. [Google Scholar] [CrossRef]

- Talwar, R.; Bolser, D.; Lederich, R.J.; Baumann, J. Friction stir welding of airframe structures. In Proceedings of the 2nd International Symposium on Friction Stir Welding, Gothenburg, Sweden, 27–29 June 2000. [Google Scholar]

- Assler, H.; Telgkamp, J. Design of aircraft structures under special consideration of NDT. In Proceedings of the 9th European Conference on NDT, Berlin, Germany, 25–29 September 2006. [Google Scholar]

- Freeman, J.; Moore, G.; Thomas, B.; Kok, L. Advances in FSW for commercial aircraft applications. In Proceedings of the 6th International Symposium on Friction Stir Welding, Toronto, ON, Canada, 10–13 October 2006. [Google Scholar]

- Christner, B. A friction stir welded jet aircraft: From concept to reality. In Proceedings of the 11th International Symposium on Friction Stir Welding, Cambridge, UK, 17 May 2016. [Google Scholar]

- Fernandez, F. FSW applied on mid-size aircraft. In Proceedings of the 8th International Symposium on Friction Stir Welding, Timmendorfer Strand, Germany, 18–20 May 2010. [Google Scholar]

- Cederquist, L.; Reynolds, A.P. Factors affecting the properties of friction stir welded aluminium lap joints. Weld. J. Res. Suppl. 2001, 80, 281. [Google Scholar]

- Dubourg, L.; Merati, A.; Jahazi, M. Process optimisation and mechanical properties of friction stir lap welds of 7075-T6 stringers on 2024-T3 skin. Mater. Des. 2010, 31, 3324–3330. [Google Scholar] [CrossRef]

- Buffa, G.; Campanile, G.; Fratini, L.; Prisco, A. Friction stir welding of lap joints: Influence of process parameters on the metallurgical and mechanical properties. Mater. Sci. Eng. A 2009, 519, 19–26. [Google Scholar] [CrossRef]

- Song, Y.; Yang, X.; Cui, L.; Hou, X.; Shen, Z.; Xu, Y. Defect features and mechanical properties of friction stir lap welded dissimilar AA2024-AA7075 aluminum alloy sheets. Mater. Des. 2014, 55, 9–18. [Google Scholar] [CrossRef]

- Liu, H.; Hu, Y.; Peng, Y.; Dou, C.; Wang, Z. The effect of interface defect on mechanical properties and its formation mechanism in friction stir lap welded joints of aluminum alloys. J. Mater. Process. Technol. 2016, 238, 244–254. [Google Scholar] [CrossRef]

- Balakrishnan, M.; Leitão, C.; Arruti, E.; Aldanondo, E.; Rodrigues, D.M. Influence of pin imperfections on the tensile and fatigue behaviour of AA 7075-T6 friction stir lap welds. Int. J. Adv. Manuf. Technol. 2018, 97, 3129–3139. [Google Scholar] [CrossRef]

- Aldanondo, E.; Arruti, E.; Echeverria, A. Friction stir weld lap joint properties in aeronautic aluminium alloys. In Friction Stir Welding and Processing IX; Hovanski, Y., Mishra, R., Sato, Y., Upadhyay, P., Yan, D., Eds.; The Minerals, Metals & Materials Series; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Meng, X.; Xu, Z.; Huang, Y.; Xie, Y.; Wang, Y.; Wan, L.; Lv, Z.; Cao, J. Interface characteristic and tensile property of friction stir lap welding of dissimilar aircraft 2060-T8 and 2099-T83 Al-Li alloys. Int. J. Adv. Manuf. Technol. 2018, 94, 1253–1261. [Google Scholar] [CrossRef]

- Pacchione, M.; Telgkamp, J. Challenges of the metallic fuselage. In Proceedings of the 25th International Congress of the Aeronautical Sciences, Hamburg, Germany, 3–8 September 2006. [Google Scholar]

- Prasad, N.E.; Gokhale, A.A.; Wanhill, R.J.H.; Merken, S.; Freeland, J. (Eds.) Aluminium-Lithium Alloys: Processing, Properties and Applications; Elsevier Inc.: Oxford, UK, 2014. [Google Scholar]

- Aldanondo, E.; Vivas, J.; Álvarez, P.; Hurtado, I. Effect of tool geometry and welding parameters on friction stir welded lap joint formation with AA2099-T83 and AA2060-T8E30 aluminium alloys. Metals 2020, 10, 872. [Google Scholar] [CrossRef]

- Jandaghi, M.R.; Pouraliakbar, H.; Hong, S.I.; Pavese, M. Grain boundary transition associated intergra nular failure analysis at TMAZ/SZ interface of dissimilar AA7475-AA2198 joints by friction stir welding. Mater. Lett. 2020, 280, 128557. [Google Scholar] [CrossRef]

- Jandaghi, M.R.; Badini, C.; Pavese, M. Dissimilar friction stir welding of AA2198 and AA7475: Effect of solution treatment and aging on the microstructure and mechanical strength. J. Manuf. Process. 2020, 57, 712–724. [Google Scholar] [CrossRef]

- Shahzad, M.; Chaussumier, M.; Chieragatti, R.; Mabru, C.; Rezai-Aria, F. Influence of anodising process on fatigue life of machined aluminium alloy. Procedia Eng. 2010, 2, 1015–1024. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminum alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- European Aeronautics. A Vision for 2020 Aircraft and an Air Transport System that Are Responding to Society’s Needs; Report of the group of personalities; European Aeronautics: Brussels, Belgium, 2001. [Google Scholar]

- Karanika, A.; Vourdas, N.; Makrikostas, A.; Marini, R.; Plagianakos, T.; Kalogeropoulos, S. Development of new environmentally friendly anticorrosive surface treatments for new Al-Li alloys protection within the frame of Clean Sky2. Procedia Struct. Integr. 2018, 10, 66–72. [Google Scholar] [CrossRef]

- Boldsaikhan, E.; Fukada, S.; Fujimoto, M.; Kamimuki, K.; Okada, H. Refill friction stir spot welding of surface-treated aerospace aluminium alloys with faying-surface sealant. J. Manuf. Process. 2019, 42, 113–120. [Google Scholar] [CrossRef]

- Kubit, A.; Wydrzynski, D.; Trzepiecinski, T. Refill friction stir spot welding of 7075-T6 aluminium alloy single-lap joints with polymer sealant interlayer. Compos. Struct. 2018, 201, 389–397. [Google Scholar] [CrossRef]

- Maciel, R.; Bento, T.; Braga, D.F.O.; da Silva, L.F.M.; Moreira, P.M.G.P.; Infante, V. Fatigue properties of combined friction stir and adhesively bonded AA6082-T6 overlap joints. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 1–12. [Google Scholar] [CrossRef]

- Gibson, B.T.; Wilkes, D.M.; Cook, G.E.; Strauss, A.M. In-process detection of faying surface sealant application flaws in friction stir welding. J. Aircr. 2013, 50, 567–575. [Google Scholar] [CrossRef]

- Gibson, B.T.; Cox, C.D.; Ballun, M.C.; Cook, G.E.; Strauss, A.M. Automatic tracking of blind sealant paths in friction stir lap joining. J. Aircr. 2014, 51, 824–832. [Google Scholar] [CrossRef]

- ISO25239. Friction Stir Welding-Aluminium, Part 5: Quality and Inspection Requirements; The International Organization for Standardization (ISO): Geneva, Switzerland, 2011. [Google Scholar]

- Mota de Siqueira, R.H.; Capella de Oliveira, A.; Riva, R.; Abdalla, A.J.; Fernandes de Lima, M.S. Comparing mechanical behaviour of aluminium welds produced by laser beam welding (LBW), friction stir welding (FSW), and riveting for aeronautical structures. Weld. Int. 2016, 30, 497–503. [Google Scholar] [CrossRef]

| Alloy | Al | Si | Fe | Cu | Mn | Mg | Zn | Ti | Ag | Li | Zr |

|---|---|---|---|---|---|---|---|---|---|---|---|

| AA2060-T8E30 | Bal. | 0.07 | 0.07 | 3.4–4.5 | 0.1–0.5 | 0.6–1.1 | 0.3–0.5 | 0.1 | 0.05–0.5 | 0.6–0.9 | 0.05–0.15 |

| AA2099-T83 | Bal. | 0.05 | 0.07 | 2.4–3.0 | 0.1–0.5 | 0.1–0.5 | 0.4–1 | 0.1 | - | 1.6–2.0 | 0.05–0.12 |

| Coupon Code ID | Surface Treatment | Sealant |

|---|---|---|

| C1 | - | - |

| C2 | TFSAA | - |

| C3 | Sol Gel | - |

| C4 | - | Naftoseal® MC-780-Class C |

| C5 | TFSAA | Naftoseal® MC-780-Class C |

| C6 | Sol Gel | Naftoseal® MC-780-Class C |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aldanondo, E.; Vivas, J.; Álvarez, P.; Hurtado, I.; Karanika, A. Friction Stir Welding of AA2099-T83 and AA2060-T8E30 Aluminium Alloys with New Cr-Free Surface Treatments and Sealant Application. Metals 2021, 11, 644. https://doi.org/10.3390/met11040644

Aldanondo E, Vivas J, Álvarez P, Hurtado I, Karanika A. Friction Stir Welding of AA2099-T83 and AA2060-T8E30 Aluminium Alloys with New Cr-Free Surface Treatments and Sealant Application. Metals. 2021; 11(4):644. https://doi.org/10.3390/met11040644

Chicago/Turabian StyleAldanondo, Egoitz, Javier Vivas, Pedro Álvarez, Iñaki Hurtado, and Alexandra Karanika. 2021. "Friction Stir Welding of AA2099-T83 and AA2060-T8E30 Aluminium Alloys with New Cr-Free Surface Treatments and Sealant Application" Metals 11, no. 4: 644. https://doi.org/10.3390/met11040644

APA StyleAldanondo, E., Vivas, J., Álvarez, P., Hurtado, I., & Karanika, A. (2021). Friction Stir Welding of AA2099-T83 and AA2060-T8E30 Aluminium Alloys with New Cr-Free Surface Treatments and Sealant Application. Metals, 11(4), 644. https://doi.org/10.3390/met11040644