1. Introduction

Wire-arc additive manufacturing (WAAM) is offering a new building perspective to the industry, enabling higher depositions rates than other additive manufacturing techniques despite having lower dimensional precision in as-built state. Compared with other additive manufacturing (AM) technologies, WAAM uses simple equipment and obtains higher deposition rates [

1]. Since this technology is based on arc welding processes with wire raw material in either robots or computer numerical control (CNC) systems, it is considered appropriate for medium-large part manufacturing. In the last years, industry has been interested in this manufacturing alternative for different applications, such as aeronautical, automotive, defence, naval, and nuclear energy industry [

2,

3]. Another beneficial aspect of this technology is the reduction of material waste, and therefore overall process cost, especially in metallic alloys with high added value. For instance, the buy-to-fly (BTF) ratio of many aeronautical parts can be usually higher than 30 when machining from billets, whereas when manufactured by WAAM, this value can be reduced to lower than 1.5, minimising the cost and maximising material savings [

3,

4].

In WAAM, solidification is a major challenge, due to the promotion of microstructure with large columnar grains. This provides lower strength, toughness, and corrosion resistance compared to a fine equiaxed microstructure, which usually is difficult to develop in WAAM and other AM technologies [

5].

Depending on the heat source used in WAAM, a classification of four process types can be done: gas metal arc welding (GMAW)-based, gas tungsten arc welding (GTAW)-based, plasma arc welding (PAW)-based, and cold metal transfer (CMT)-based [

1,

6,

7]. This last one, is a GMAW based welding technology, developed by Fronius International GmbH, Pettenbach, Austria. This technology uses a controlled-dip transfer mode mechanism which gives rise to excellent quality weld beads, with lower thermal heat input and ideally no spatter. Specifically, for aluminium, the low-heat input contributes to obtaining finer equiaxed grains and oxide cleaning [

4]. For aluminium alloys, investigations have been using mainly GMAW and CMT-based technologies.

CMT technologies reduce arc energy compared to conventional GMAW, leading to smaller, cooler, and faster cooling melt pool, which leads to pore content reduction when using aluminium alloys [

8]. The increase in the temperature can lead to cracking in addition to the usual porosity [

9].

Aluminium offers a unique combination of properties, with the good corrosion resistance and elevated strength–weight ratio being the ones to stand out. In addition, the possibility of adding small amounts of different alloying elements makes this material highly interesting, and this has historically conducted to the development of heat-treatable high-strength aluminium alloy series.

Besides hot cracking, porosity is one of the main problems in WAAM of aluminium alloys, which can severely limit the mechanical properties of the part. Porosity is generated as a result of several factors including arc welding process, process parameters, interpass temperature, wire quality, and alloy composition [

10]. In a multiple-layer WAAM process, the heat input of new superposed layer can contribute to the growth of pores [

11].

Studying the effect of arc modes in microstructure characteristics and mechanical properties, B. Lu et al. [

12] analysed the effect of CMT, CMT-P, and CMT-ADV arc modes depositing 5183 aluminium alloy in porosity formation. The results obtained of porosity area percentage of 0.63%, 0.85%, and 0.36%, respectively, demonstrated that heat input during deposition has a high influence. Moreover, CMT and CMT-A consist of interlayer fine-grain region and layer column grain size, while the CMT-P process, with the greatest heat input, contributes to generate column grains. Because of this, CMT-ADV had the best mechanical properties results with a UTS above 290 MPa, while CMT had reduced values (280 MPa), and CMT-P had the lowest ones with 270 MPa. B. Cong et al. [

13] studied the effect of CMT arc modes (CMT, CMT-P, CMT-ADV, and CMT-PADV) in the generation of porosity in walls manufactured by WAAM. Excellent superficial appearance and effective wire oxidation cleaning were obtained for the four CMT technologies but especially for those CMT modes with negative polarity cycles. However, the porosity present in each case was different, concluding that the selected CMT arc mode directly affects the generated porosity as the heat input for each one is different. CMT-PADV highly reduces the heat input, and as a consequence, less porosity is generated. K. F. Ayarkwa et al. [

14] further investigated the effect of CMT-PADV arc mode besides analysing the impact of the wire feed speed/travel speed (WFS/TS) relation to the resultant dimensions as well as to the heat input. This relation also determined resulting porosity in the part: while its value increased from 10 to 20, so did the porosity amount.

Other authors [

4,

15] have also concluded on the great benefits of using CMT-PADV for the sake of reducing porosity and improving the tensile test mechanical properties. The porosity values obtained with CMT and CMT-ADV (in [

4]) were 0.347% and 0.288%, respectively, whilst by using CMT-PADV, a 0.06% of porosity was obtained for AlMg5Mn alloy from 5xxx series. They concluded [

4,

15] that only parts manufacturing by the CMT-PADV process has an almost isotropic behaviour, since with the rest of the processes, pores concentrated at the interlayer boundaries had a detrimental effect on samples tested along the building direction. Therefore, the anisotropy that reduced the deformation capacity in the vertical direction (parallel to building direction) was attributed to the crack initiation by stress concentration and cross-sectional weakening due to this mostly lineal interlayer porosity.

B. Qi et al. [

11] reached a similar conclusion for Al-6.3%Cu alloy equivalent to AA2219, and they reported that the heat input is the key factor in order to obtain a low porosity amount and should be below 300 J/mm. In this case, thin and bulk parts were built up leading to different cooling rates and resulting porosity levels. The thin walls cooled by dissipating heat in 2D, while head dissipation was faster in bulk parts due to 3D heat-sinking paths, and as a consequence, the grains were more refined and the pore nucleation speed reduced.

Furthermore, K. Derekar et al. [

16] studied the impact of interpass temperature on the generation of porosity. X-rays revealed less porosity amounts in parts built with higher temperature between consecutive layers and dominated by small pores.

E. M. Ryan et al. [

17] studied the influence of the ER2319 wire superficial quality on the soundness of WAAM deposits. They concluded that this was the most critical parameter to avoid the generation of pores in parts, and the CMT modes, wire feed speed (WFS) or wire feed speed/travel speed (WFS/TS) ratio did not appear to induce any significant variation in porosity. According to them, process parameters do not have such a great impact on the final quality of the part as the wire surface quality. In this sense, a rough wire surface is associated with enlargement of the superficial area and preferential sites for the entrapping of humidity, contaminants, and oxides, which can increase the hydrogen absorption enhancing porosity in deposited material.

Porosity can impair the mechanical properties of WAAM aluminium parts. M. Köhler et al. [

18] observed a noticeable anisotropy in the mechanical properties of AA4047 and AA5356 WAAM deposits depending on the direction of loading. Samples parallel to the build-up direction suffered a remarkable elongation loss that the ones tested in the transversal direction did not. Authors referred to the non-equiaxed microstructure, but also the porosity of the part mostly in interlayer region to explain this behaviour.

Y. Zhao et al. [

19] reported the same behaviour with three different aluminium alloys (4043, 5356, and 2319). The anisotropy was related to the preferential growth of the grains in the vertical direction, that is, in the direction parallel to the building axis, which generated a reduction of mechanical properties determined along this testing direction. In the horizontal direction, the grains were continuous, and the dendritic structure were able to support a higher elongation and tensile strength.

Other authors who noticed this behaviour with 5xxx series aluminium when building with CMT technology were M Gierth et al. [

4]. In this study, porosity levels were below 0.5%, but the microstructural analysis showed non-equiaxed grains. This had a direct impact on the elongation of the specimens, having lower values for the ones extracted in the vertical direction, parallel to the building direction.

However, to the authors best knowledge, nobody has deeply investigated the influence of shielding conditions on the resulting porosity and mechanical properties of aluminium WAAM parts.

The current work studies the influence of shielding gas, gas flow rate, and deposition strategy on the porosity and resulting mechanical properties of Al-Mg series aluminium WAAM parts manufactured by ER5356 commercial wire filler metal.

2. Materials and Methods

In this study, cold metal transfer (CMT)-based WAAM with ER5356 filler metal of 1.2 mm diameter is investigated. Four mm thickness AA6082-T6 substrate was used. This material only has an influence in the initial layers, while the study has been focused in the analysis of soundness and porosity of additively manufactured components built by superposition of multiple layers using the described wire filler metal. The chemical compositions of the filler and base materials are shown in

Table 1.

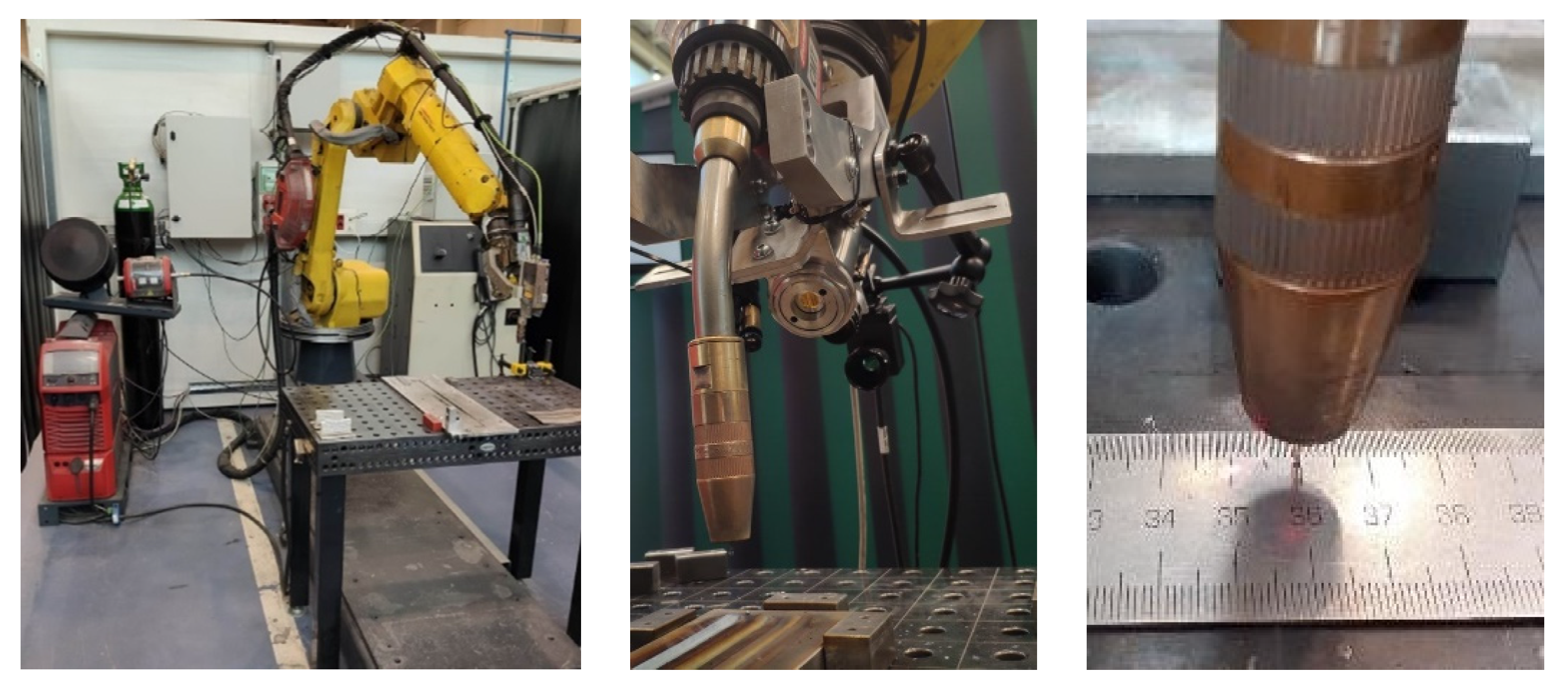

For the WAAM trials, a Fronius CMT TPS 400i welding power source and WF 60i Robacta Drive CMT/W welding torch (Fronius International GmbH, Pettenbach, Austria ) assembled in a Fanuc ARC Mate 120iC robot (Fanuc Corporation, Oshino-mura, Yamanashi Prefecture, Japan)were employed. This equipment (

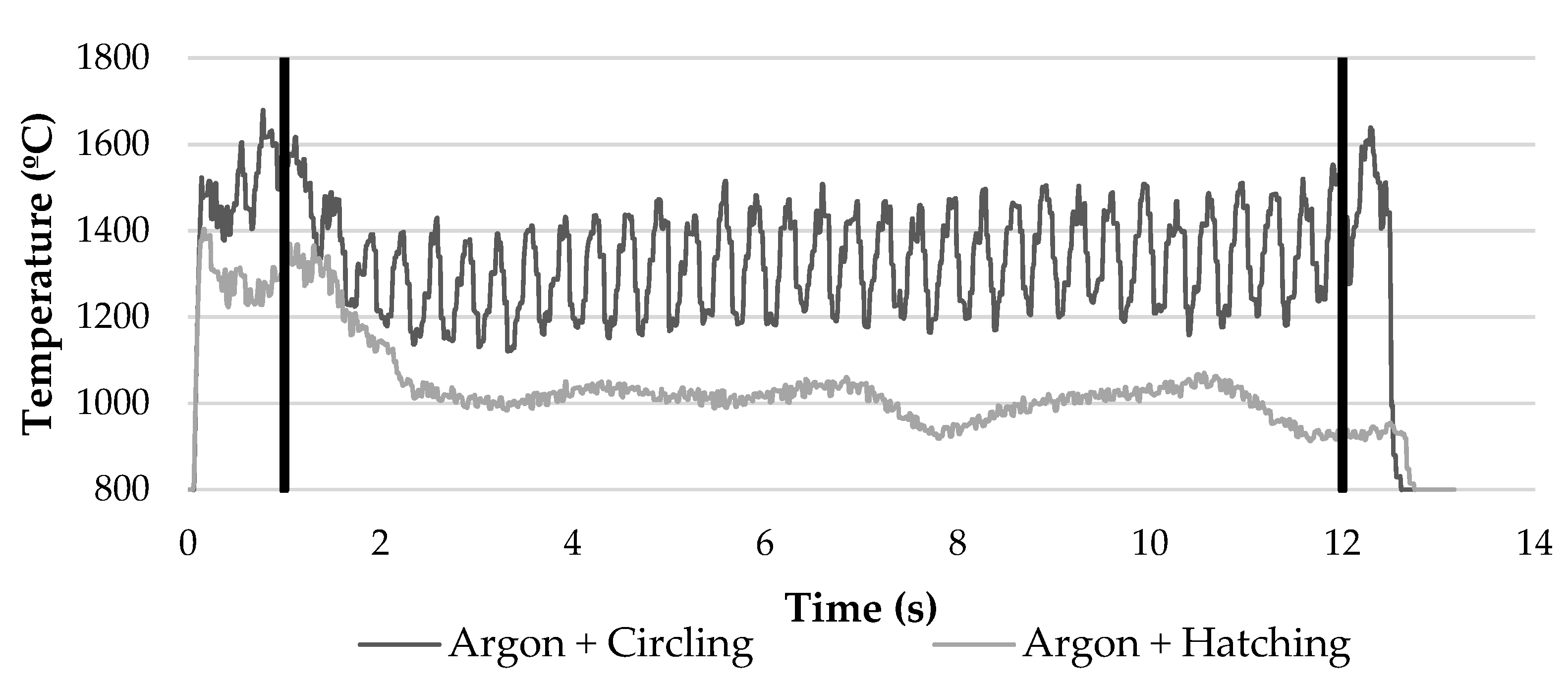

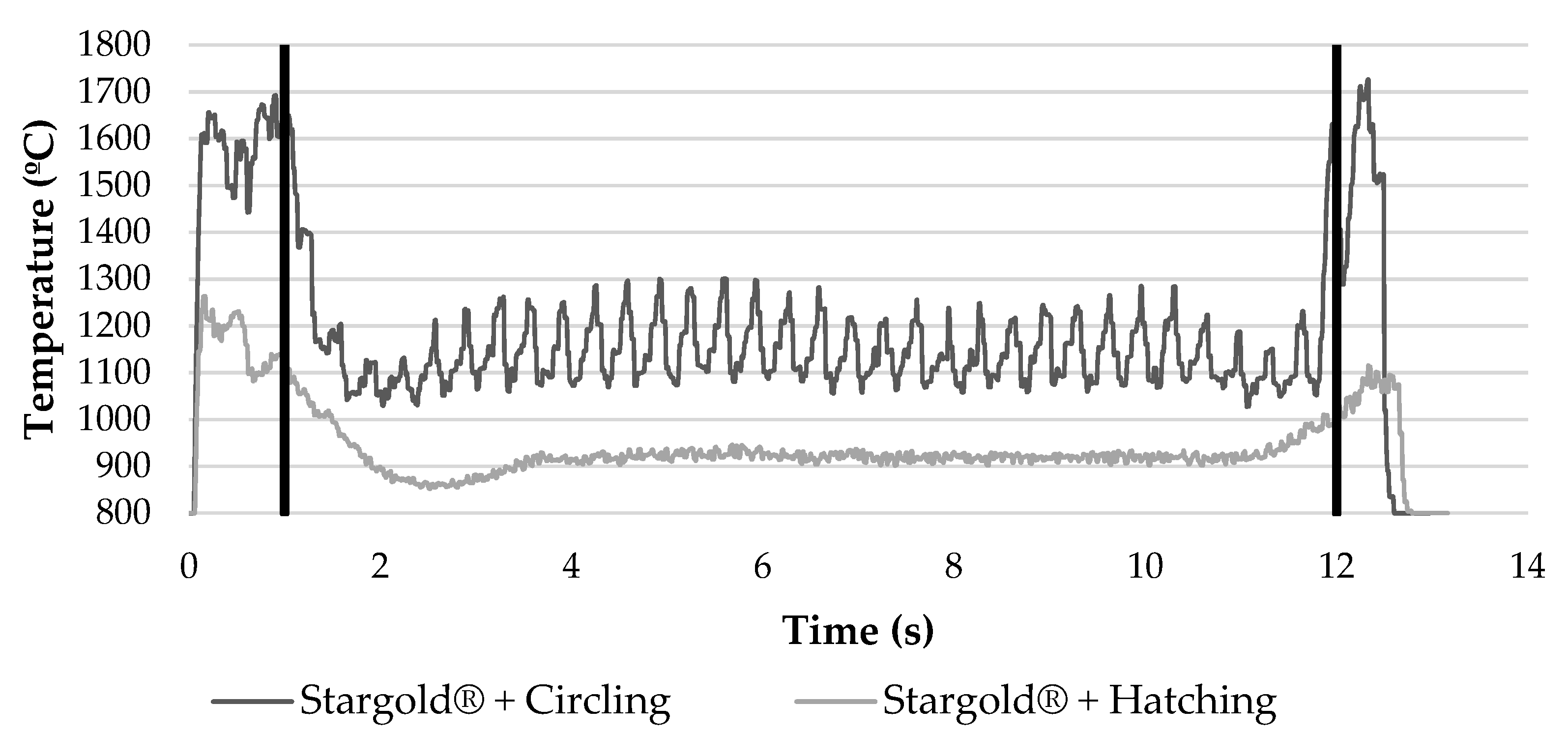

Figure 1) was mounted in the intelligent welding cell of LORTEK that includes an optris CTlaser 1MH1 (Optris GmbH, Berlin, Germany) pyrometer (lower right picture) closely pointing to the weld and a PLC CX2040 data acquisition system. The data caption system was able to capture and record the current, arc voltage, WFS, shielding gas flow rate, coordinates of the tool centre point (TCP), and temperature of the melt pool. Temperature was taken from a distance of 10 mm from the TCP and central position of the wire in the torch.

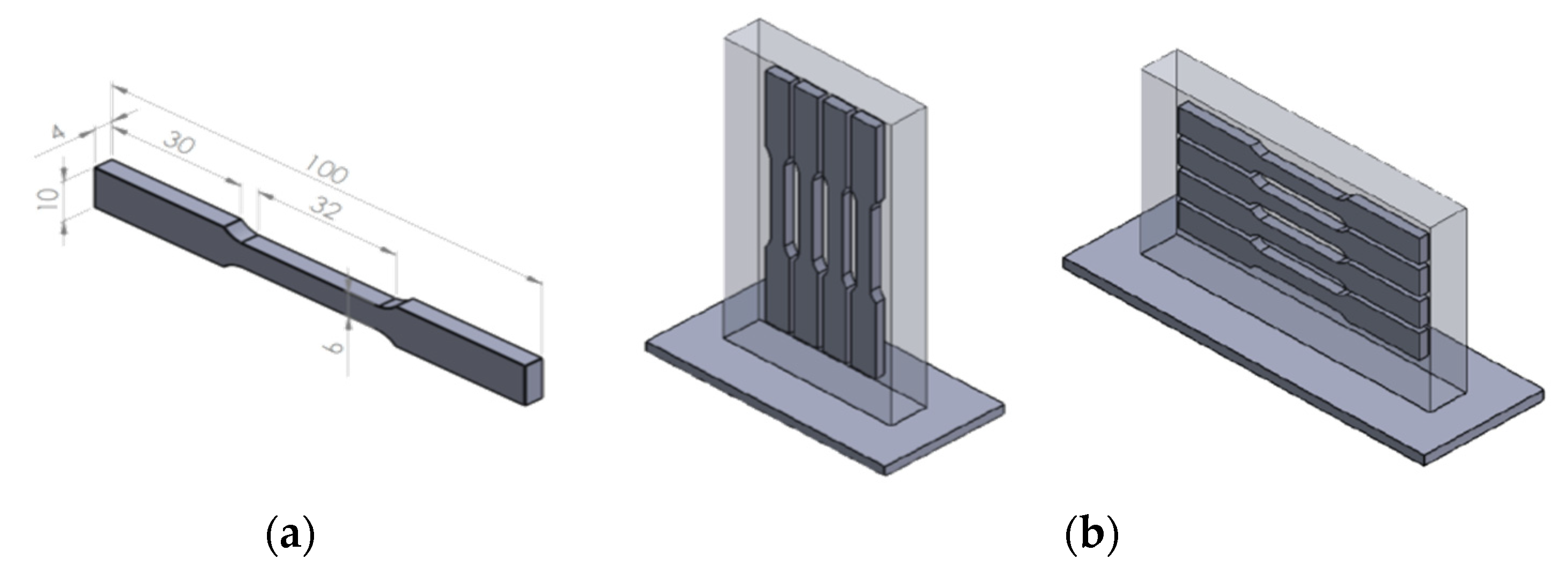

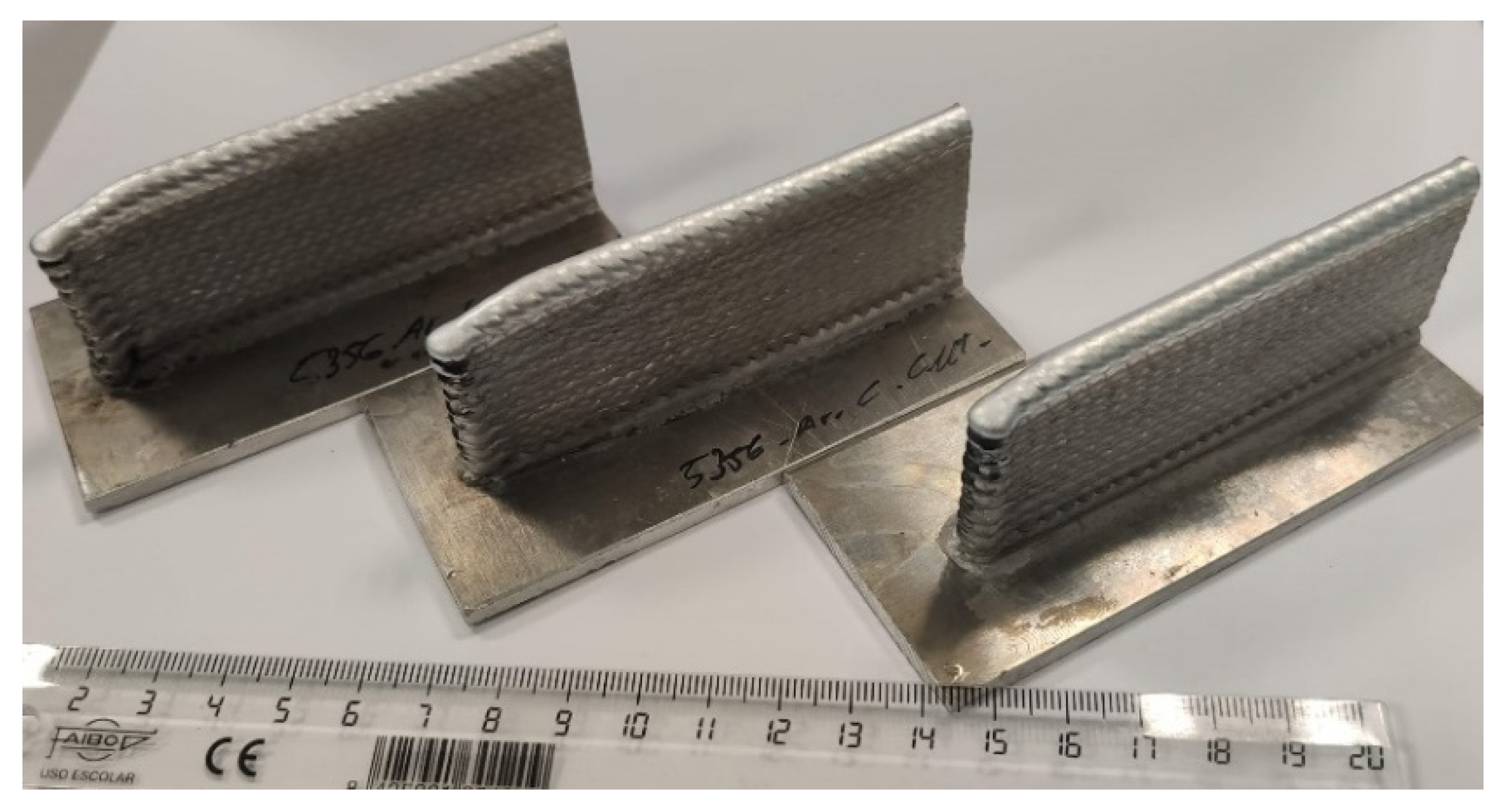

The study included the manufacturing of single-layer deposits, 20-layer height walls, and taller walls from which tensile test samples were extracted. Tensile test samples were machined both from vertical (90 mm × 130 mm) and horizontal (130 mm × 70 mm) walls, and corresponding samples were parallel and transversal to the building direction, respectively.

Single-layer weld beads were useful to analyse the effect of two shielding gases (Argon Q1 and Stargold

® three-phase Ar+O

2+N

2O mixture from Nippon Gases (

Table 2)) and corresponding flow rates on the porosity.

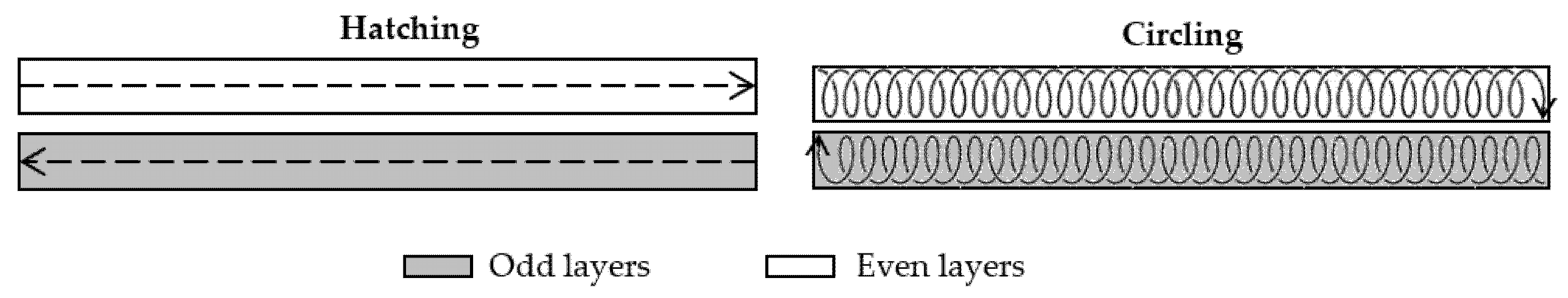

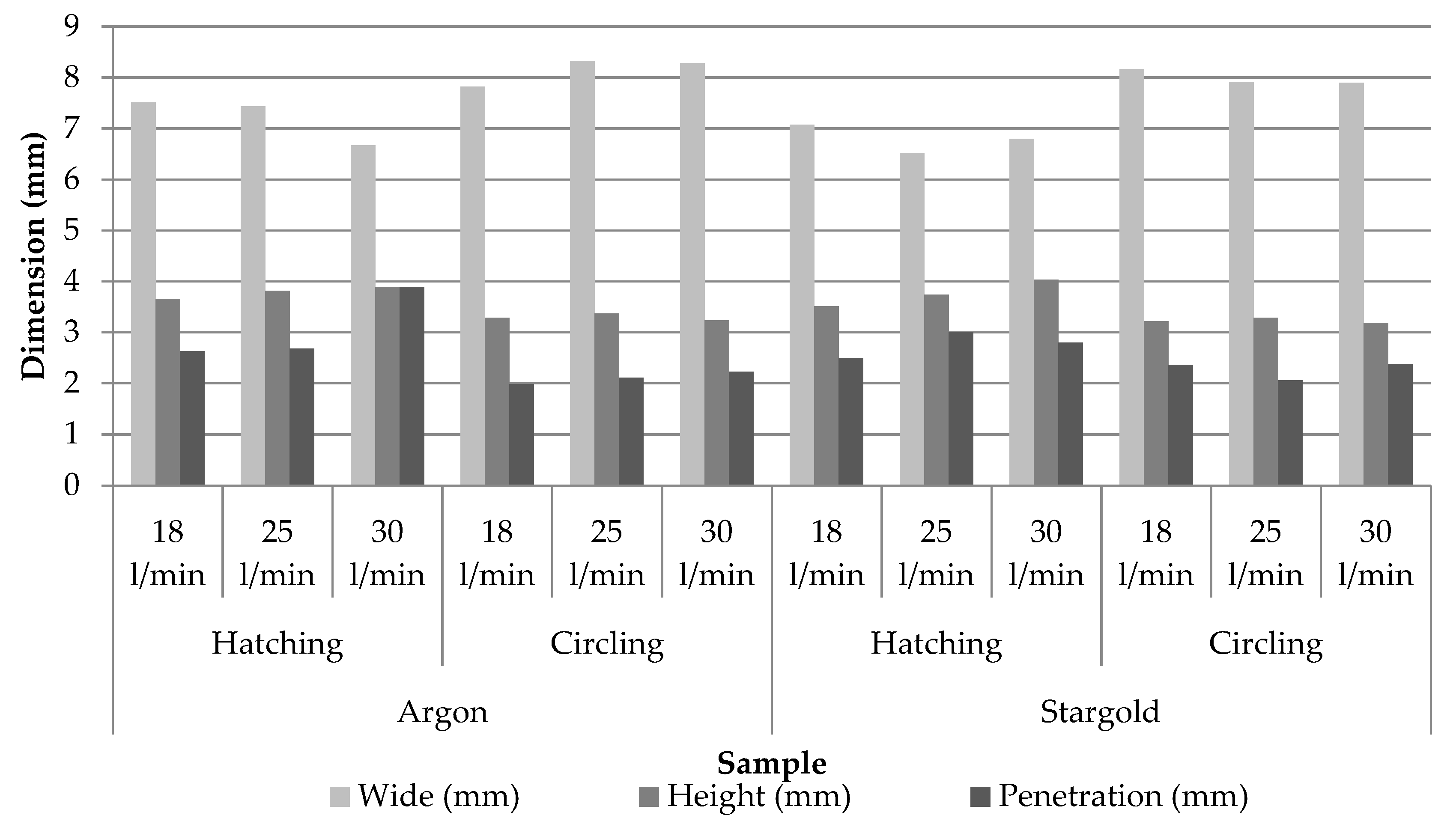

Two deposition strategies shown in

Figure 2 were tested. Hatching strategy represents straight weld bead without any weaving, whereas circling can be described as the overlapping of round circles with 2 mm amplitude and 3 Hz frequency. For both deposition strategies, travelling direction is changed from odd to even layers to provide a more stable building.

To avoid necking formation when using hatching deposition strategy, a sequential reduction of welding parameters was used reducing the welding intensity from the initial 130 A to 77 A in the fourth layer (

Table 3). Circling deposition strategy does not need this adjustment of the welding parameters and only the intensity of the first layer must be increased to ensure good wetting and fusion of the base plate. The travel speed was kept constant at 0.6 m/min, whereas the wire feed speed varied from 5.2 m/min at 77 A to 8.6 m/min at 130 A.

Taking into account the applied electrical parameters, the heat input (HI) value can be calculated (Formula (1)), having as a result 72.07 J/mm. Another factor taken into account is the WFS/TS ratio, which was kept in 8.6 below 10 to meet recommended welding parameters to reduce porosity [

14].

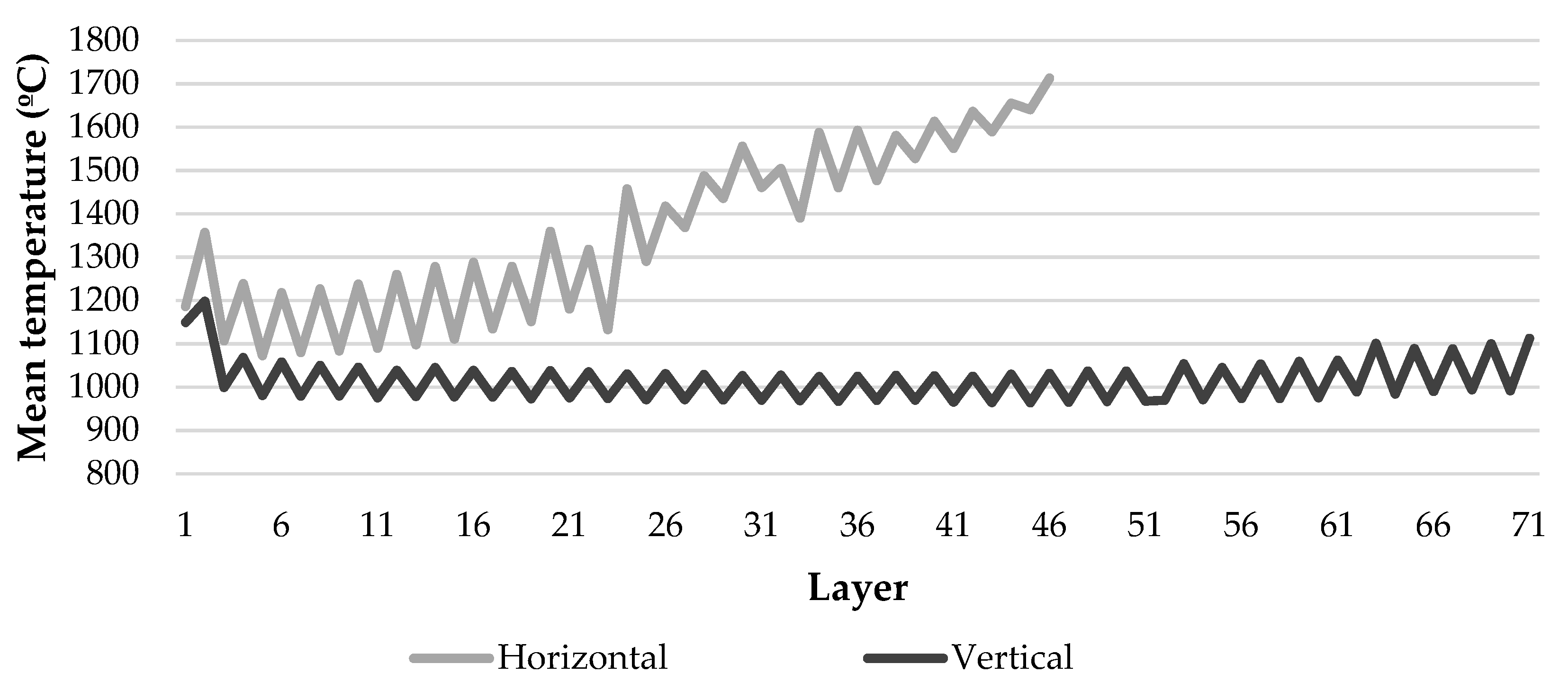

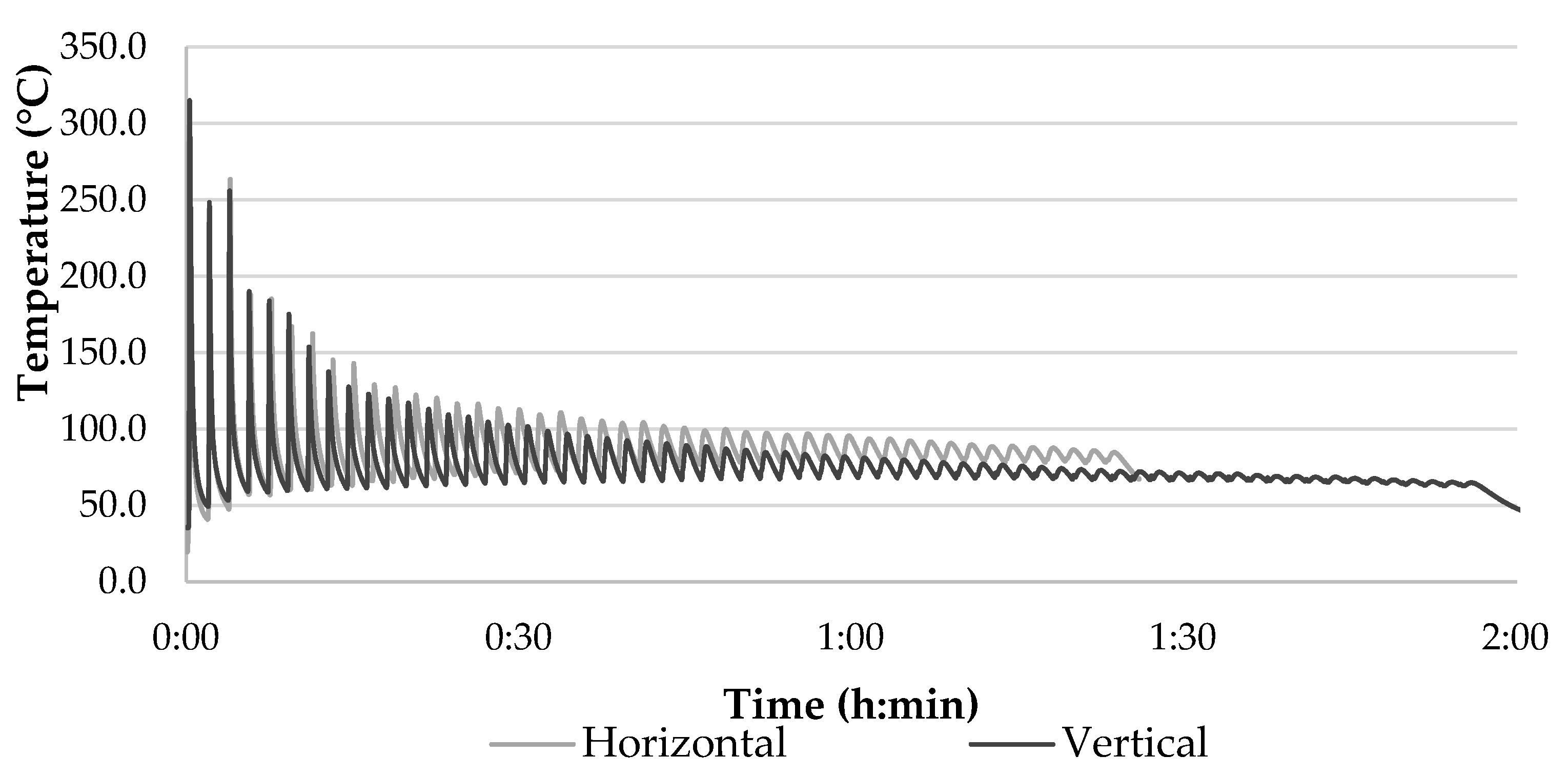

The same welding parameters, building strategies, and gases were employed for the manufacturing of multiple layered walls to check the quality in terms of porosity and pore size and determine mechanical properties. In all cases, the base metal was cleaned with a stainless-steel brush and acetone before welding. In order to ensure a stable growth, an interlayer waiting time of 90 s was applied between layers. Main process parameters and melt pool temperature were recorded during these deposition trials.

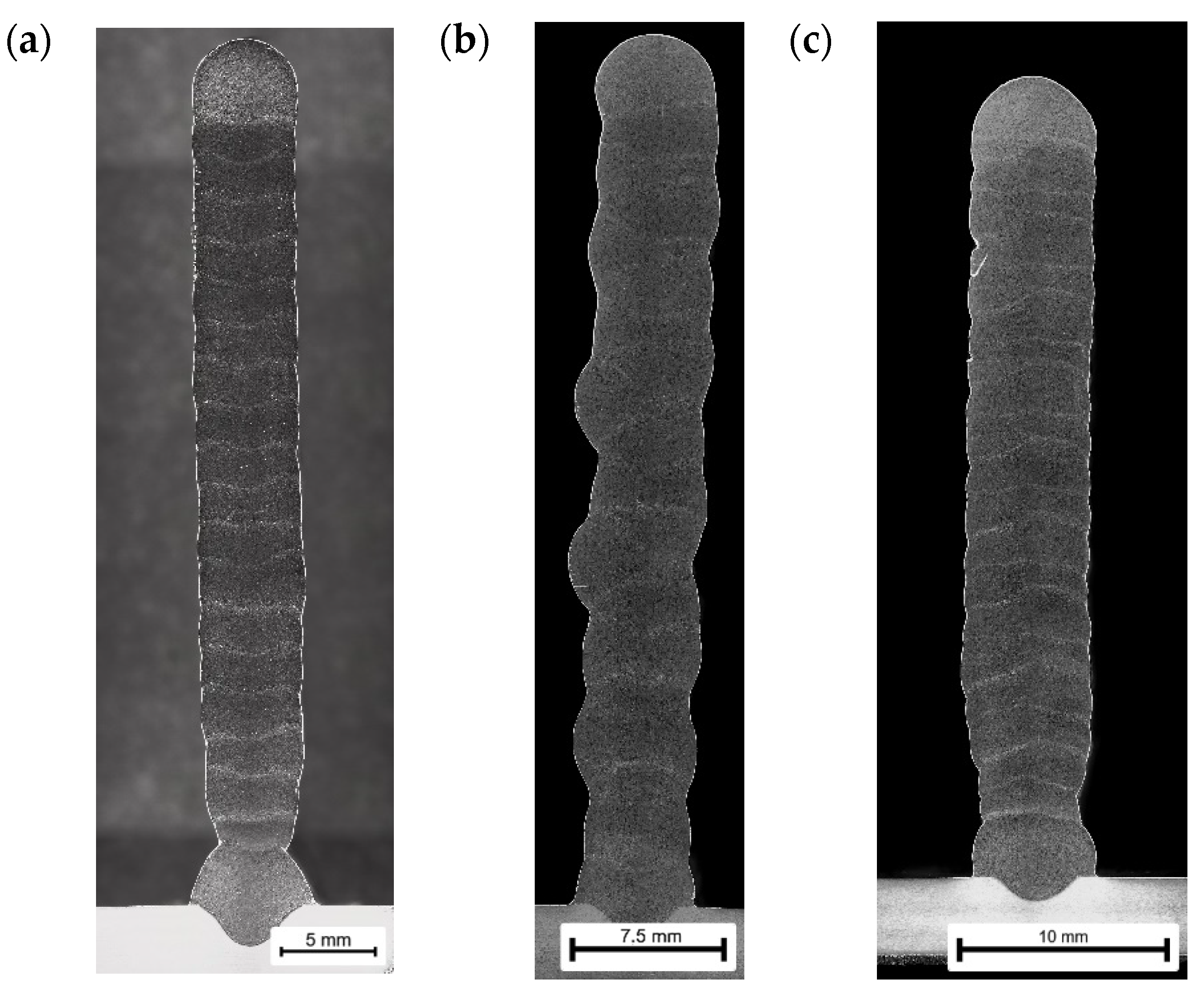

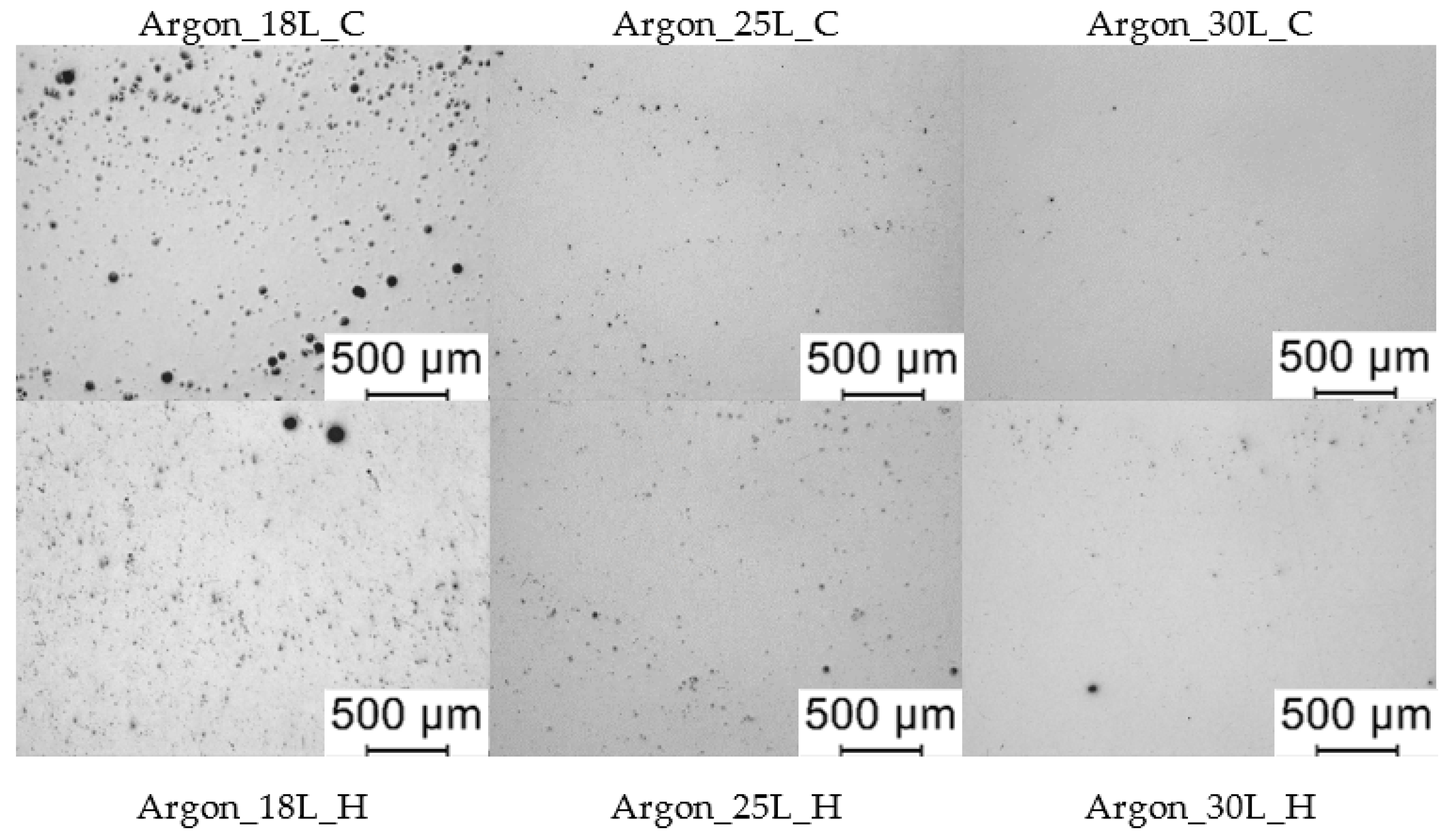

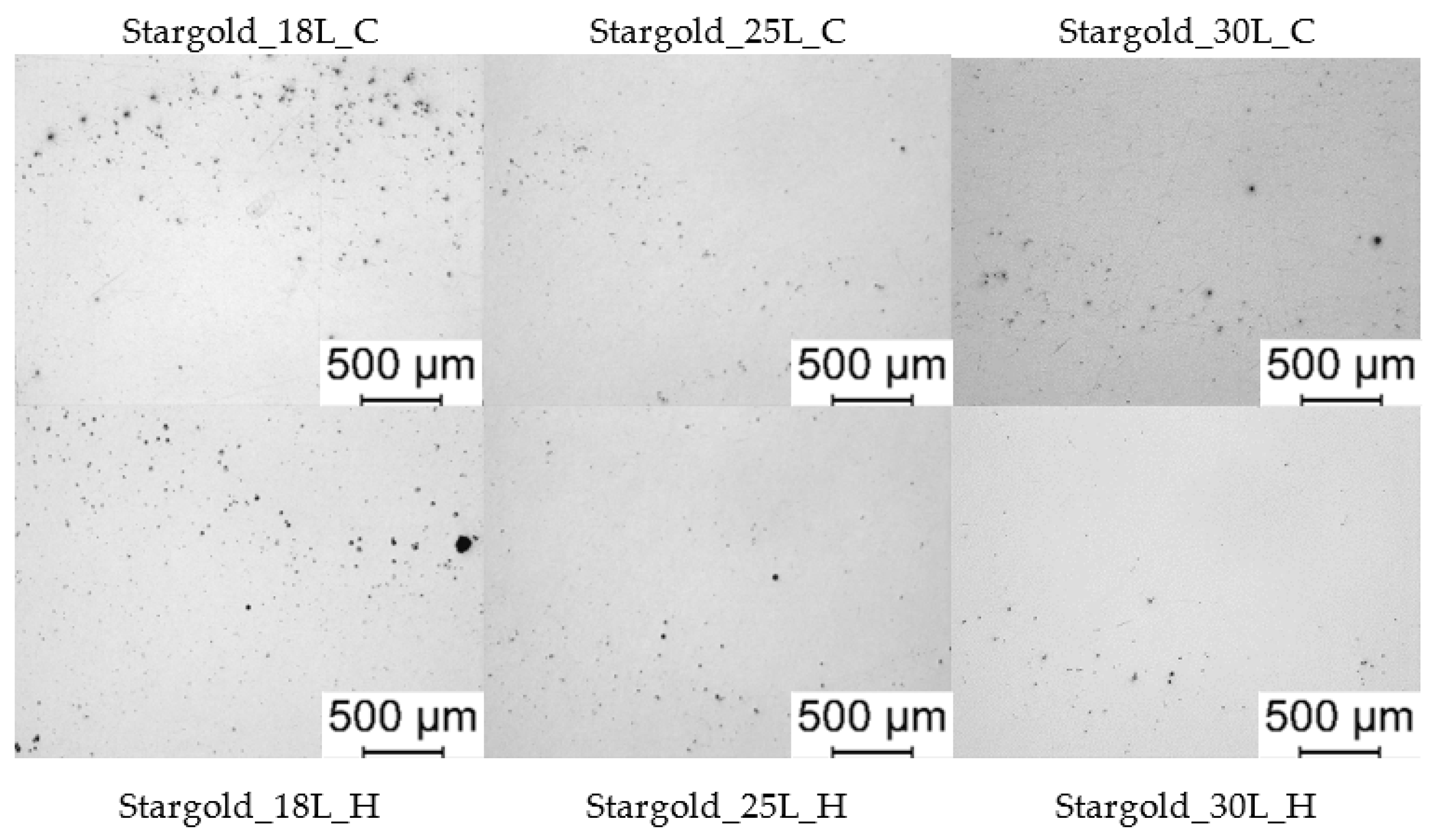

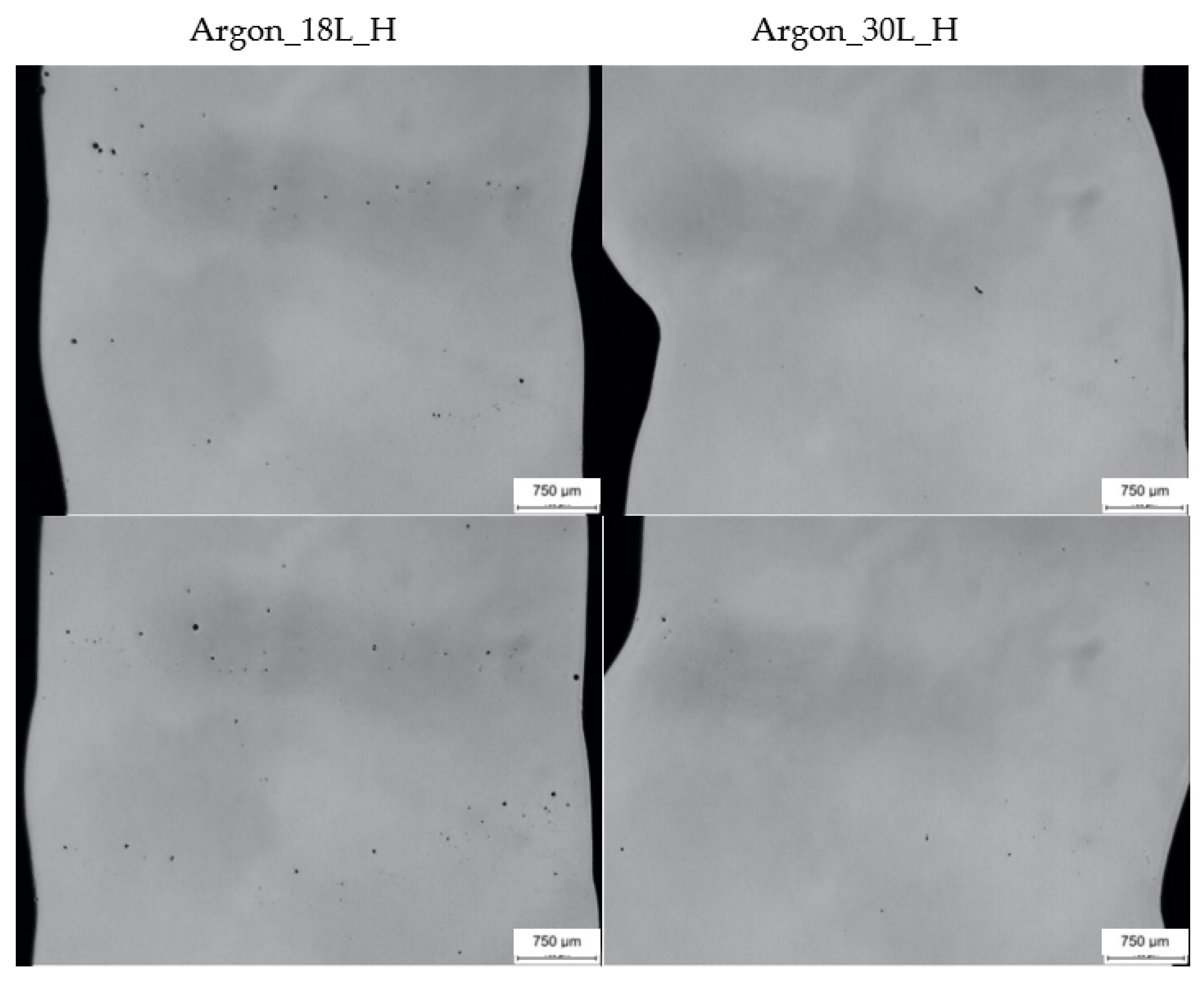

After the visual examination, metallographic samples were taken from the bottom, middle, and top part of the samples for porosity analysis. To do so, an Olympus Gx51 microscope and ImageJ program were used, where pores smaller than 10 µm were dismissed. Taking images from the middle part of the sample along the wall length. A minimum of three images with a magnification of 5× were taken from the overall studied part, meaning a total inspection area of 6.12 mm2 was analysed for each part.

The walls built to analyse the mechanical properties were inspected with X-rays previous to the extraction of the specimens and after surface milling to reduce roughness and facilitate inspection. For the X-rays, a ISOVOLT Titán X-ray emission equipment (Waygate Technologies, Hürth, North Thine-Westphalia, Germany) was used perpendicular to the parts, with 100 kV and 15.7 mA. Three specimens were extracted from each building condition, and they were extracted according to ASTM E8M from the core of the walls (

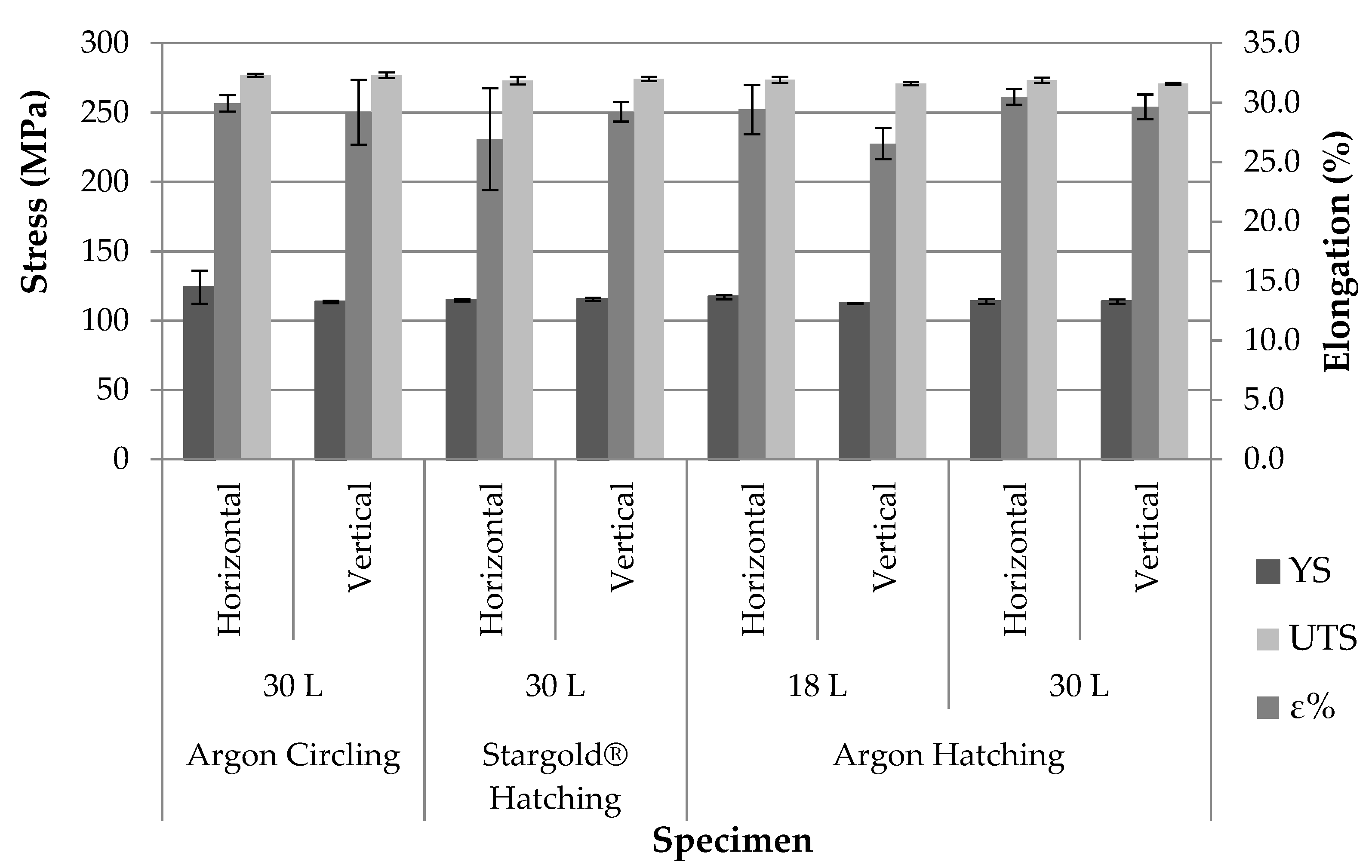

Figure 3) avoiding the arc start and end regions. To test these samples a ZwickRoell Z100 tensile test machine (ZwickRoell GmbH & Co. KG, Ulm, Germany) was used. To study the anisotropy of the part, some specimens were prepared parallel to build-up direction (vertically) and others perpendicularly (horizontally).

4. Discussion

According to the selected welding parameters, the heat input (HI) value was 72.07 J/mm, which is below 300 J/mm as B. Qi et al. [

16] recommended. Another factor taken into account is the WFS/TS ratio, which was kept below 10 as K. F Ayarkwa et al. [

14] recommended to avoid the increase of porosity formation in aluminium WAAM parts.

The influence of the shielding gas flow rate on the generation of porosity was not so evident in single weld beads, but it resulted critical in multilayered walls.

In the case of single-weld-bead deposition, porosity at the edges of the welding were analysed. No accumulation of porosity at the edges was observed, and good wetting and adhesion with the substrate were achieved. Evidence of aligned and continuous oxide layers was not found, meaning that the applied preweld cleaning treatment was effective. The welds were shown to be clean of pores greater than 100 µm in diameter, and pores were randomly distributed throughout all the welding beads, irrespective of the shielding gas and gas flow.

The use of different shielding gas and flow rate did not directly affect welding dimensions, but the deposition strategy clearly changed its dimensions. Circling generated wider beads but less penetration and height than hatching.

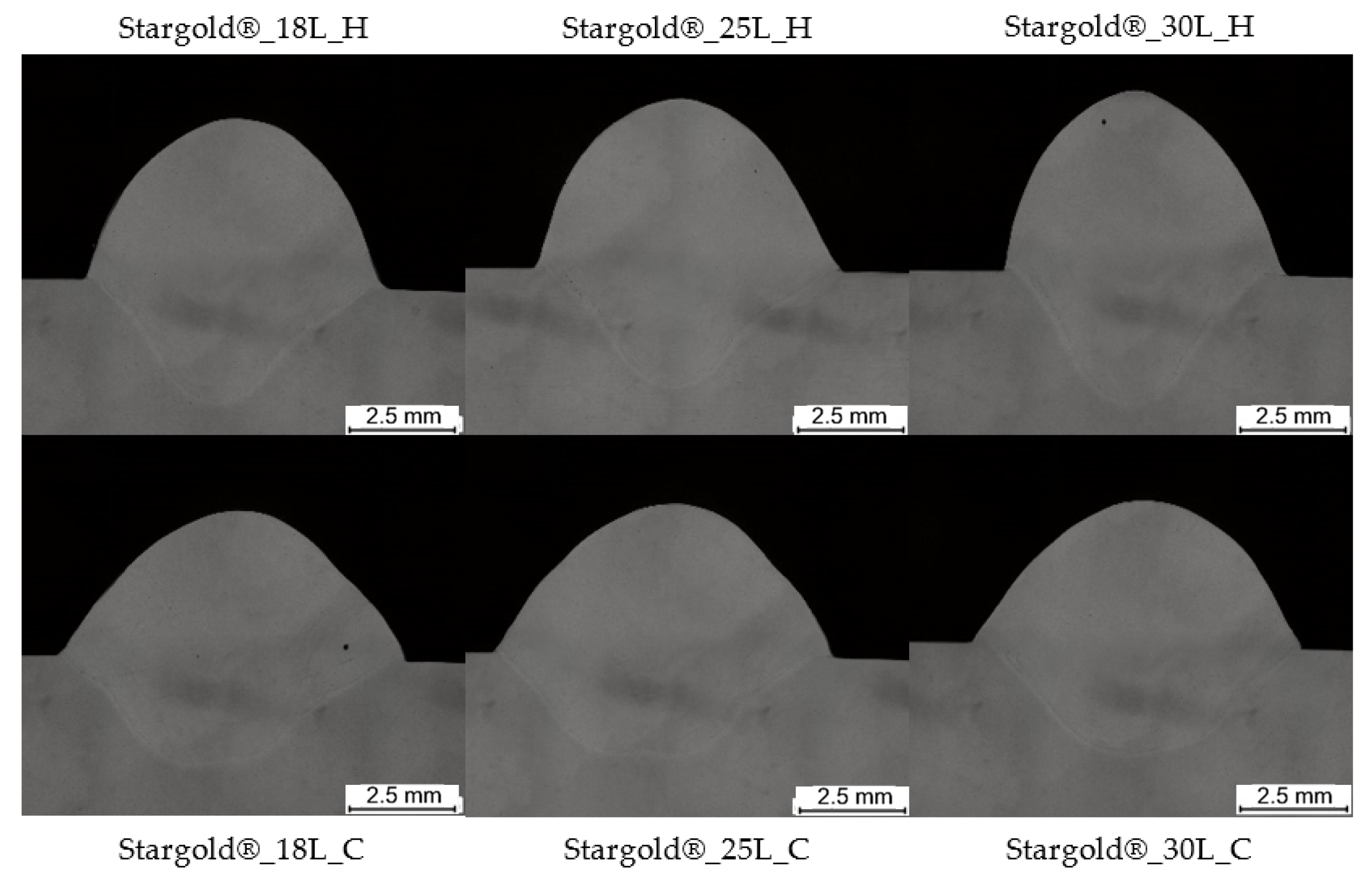

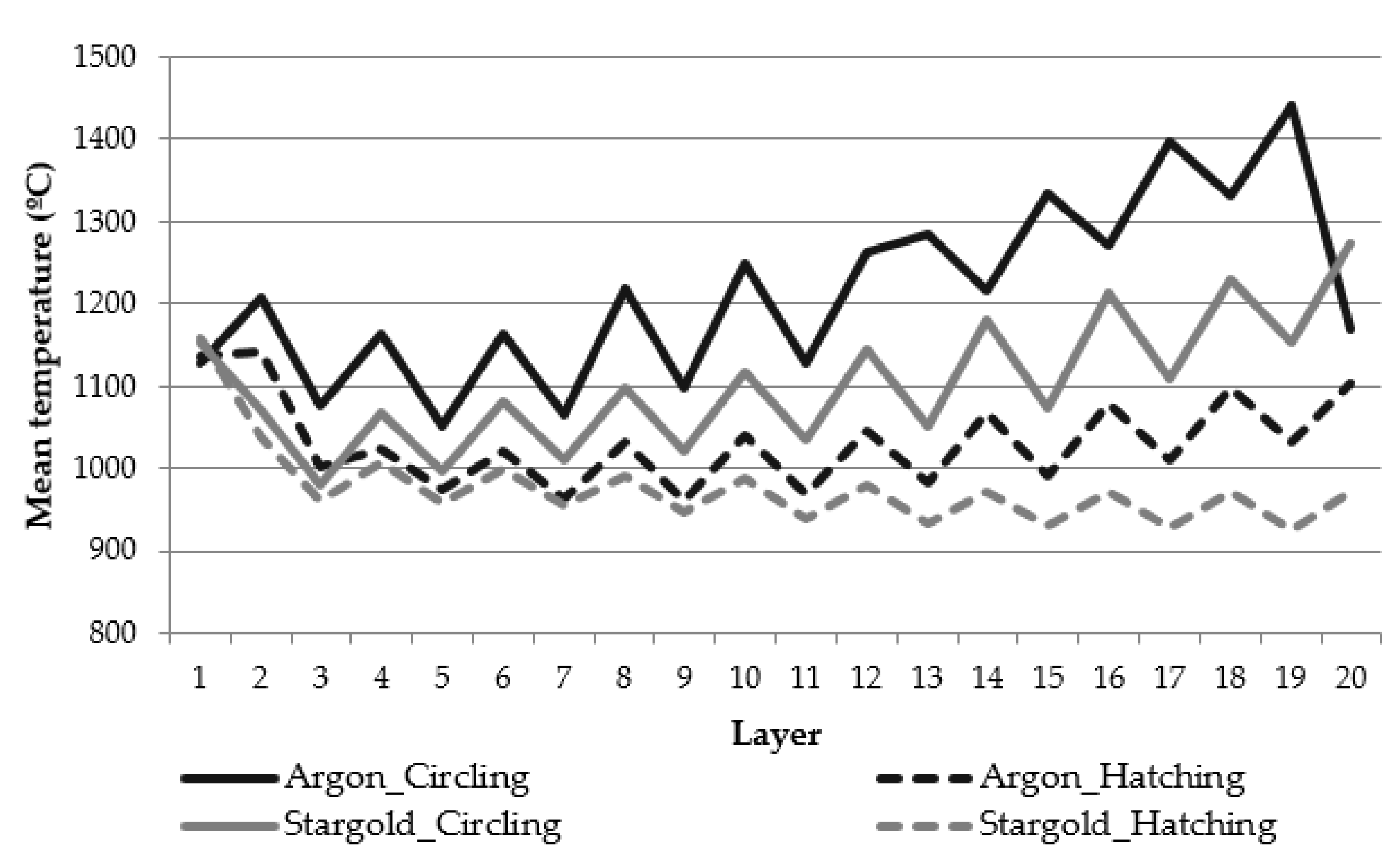

Qualitative differences multilayer walls with beneficial impact of Stargold® when using hatching and the need of increasing gas flow rate to 30 L/min for Ar and circling combination were determined.

According to current results, using high gas flow rates close to 30 L/min contributes to effectively reducing porosity and maximum pore size, being the best conditions the combination of Ar + circling and Stargold® + hatching.

Circling deposition strategy was demonstrated to be a very stable building condition, ensuring a flat and even layer height and reduction of humping. Hatching, on the other hand, required a sequential reduction of welding parameters in the initial four layers to avoid necking in the initial layers due to enhanced heat sinking through the base plate and due to the relatively lower temperature generated during the welding process.

It has to be noted, that in the parts manufactured to test mechanical properties, there was a difference in porosity area percentage between the different geometries: horizontal and vertical. The one with the most notable effect was the 18 L/min gas flow rate of Argon Q1 and hatching deposition strategy. The increasing temperature accumulation described in

Figure 16 for the horizontal geometry leading to an increase of the melt pool size and a lack of proper shielding from the atmosphere before solidification can explain this behaviour. For the higher shielding gas flow rates, the enhancement of the porosity in longitudinal walls was avoided due to the better shielding conditions provided through the torch.

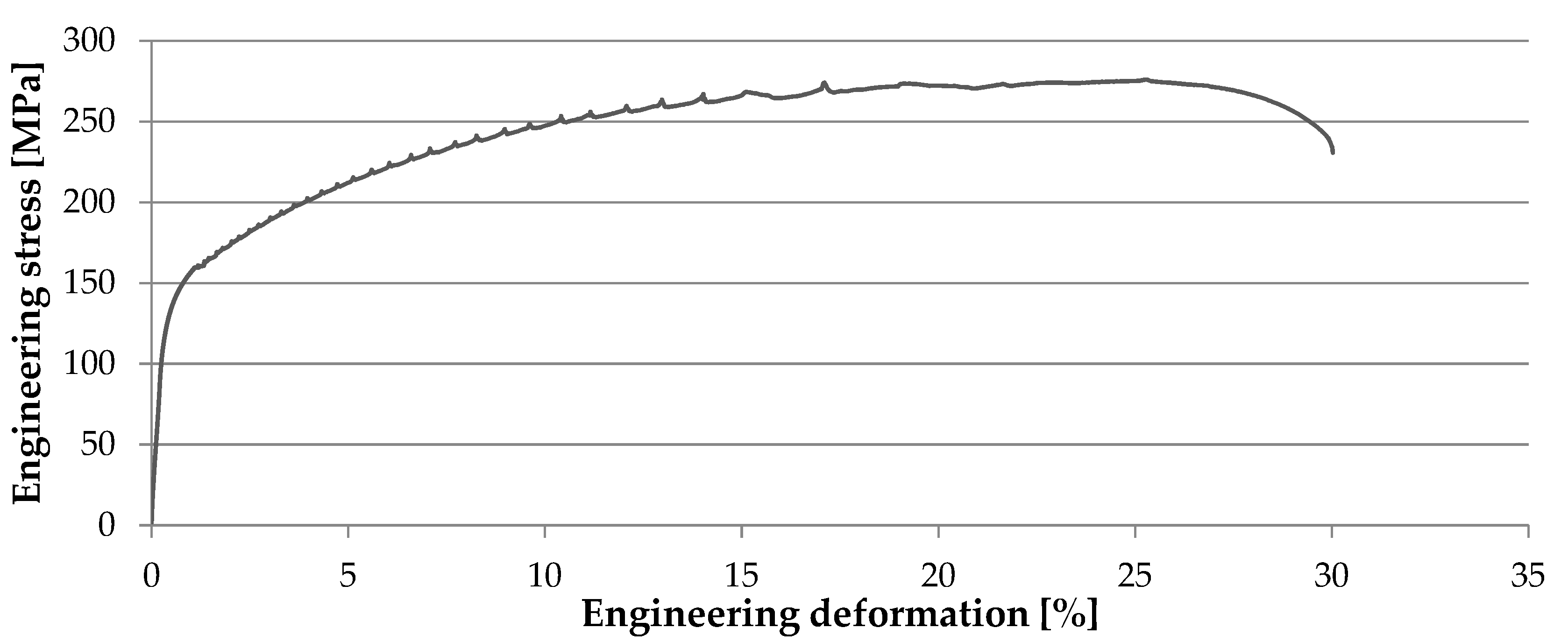

Despite the different levels of porosity in the WAAM walls manufactured to test the mechanical properties, there was a minor influence on the final yield stress, ultimate tensile strength, and elongation of the specimens. In addition, the randomly distributed pores which are not aligned or grouped in interlayer boundaries and the equiaxed grains led to a reduced anisotropy below 11%.

In previously reported works by Köhler et al. [

18] and Zhao et al. [

19], anisotropy was very high in WAAM parts with AA5356. Elongation and ultimate tensile strength were lower in the vertical direction. This was due to the un-uniformly distributed wall chemical composition and dendritic microstructure with elongated grains along building direction. The poor mechanical properties in vertical direction were associated to the likeliness of having weaker areas in the interlayer region, while in the horizontal direction the dendritic structure was intact, and the growth was continuous. The difference between these two papers and the results obtained in this study rely on the welding parameters. Zhao et al. [

19] analysed the arc penetration and observed that the three previously deposited layers were re-melted, changing their microstructure. The repetitively re-melting process increased the solubility of alloying element in the aluminium matrix, and as these elements gradually dissolved in the matrix, the fusion line show a bright stripe-like band, that made the composition un-uniformly distributed in the longitudinal direction.

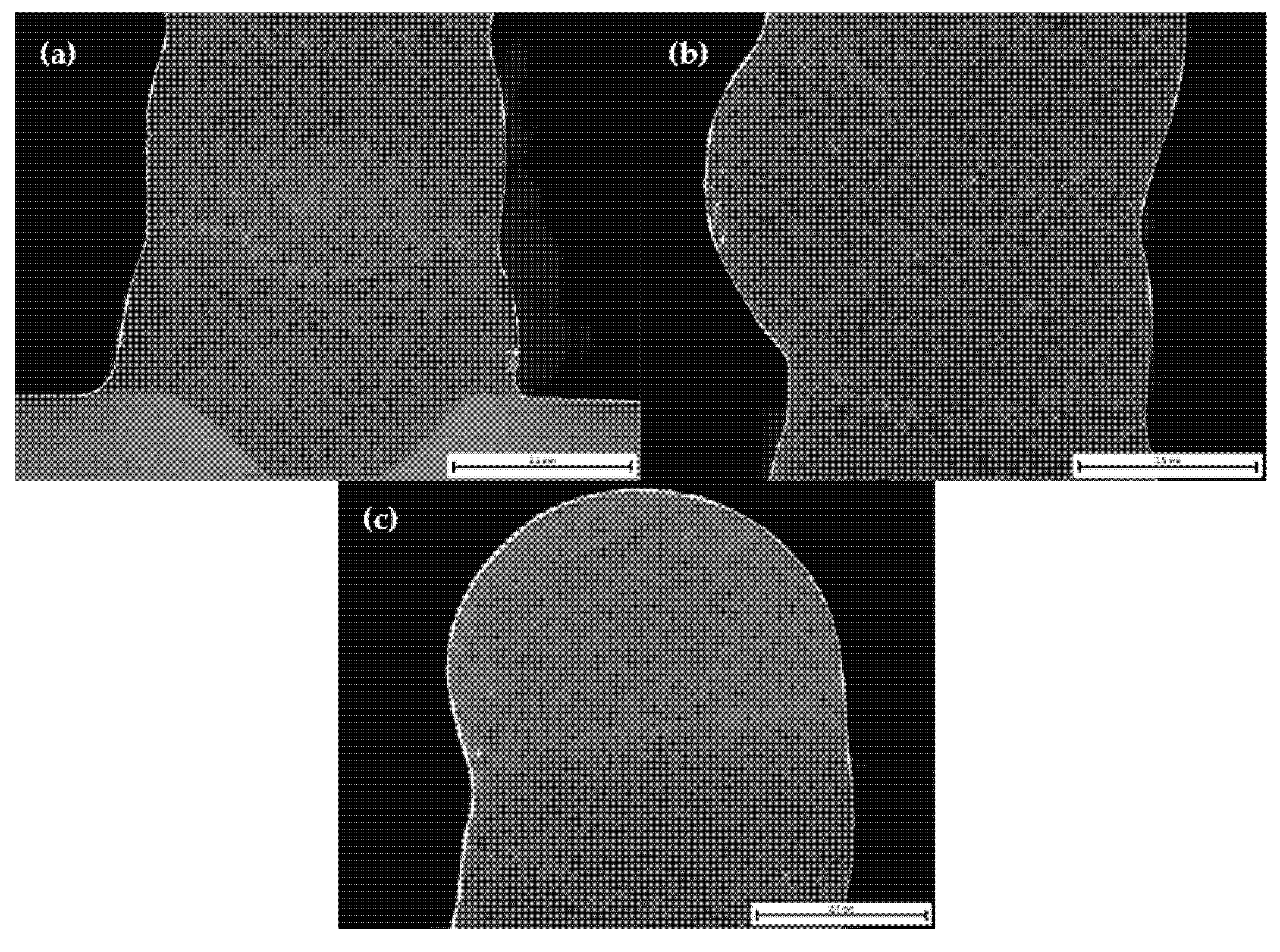

Our microstructural images in

Figure 20 show an equiaxed grain structure in the previously deposited layers, while there is only a dendritic structure in the last layer at the top. The microstructure is not fully uniform in the interlayer section, but clusters of pores are not observed as in other works [

4]. Because of the selected deposition strategy and resulting weld bead height of approximately 3.75 mm, a complete re-melting of the previously deposited layer and thermal treatment of the prior bottom layer happened, which refined grain size and removed the original dendritic structure, leading to highly isotropic mechanical properties.