Influence of Deposition Patterns on Distortion of H13 Steel by Wire-Arc Additive Manufacturing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Equipment

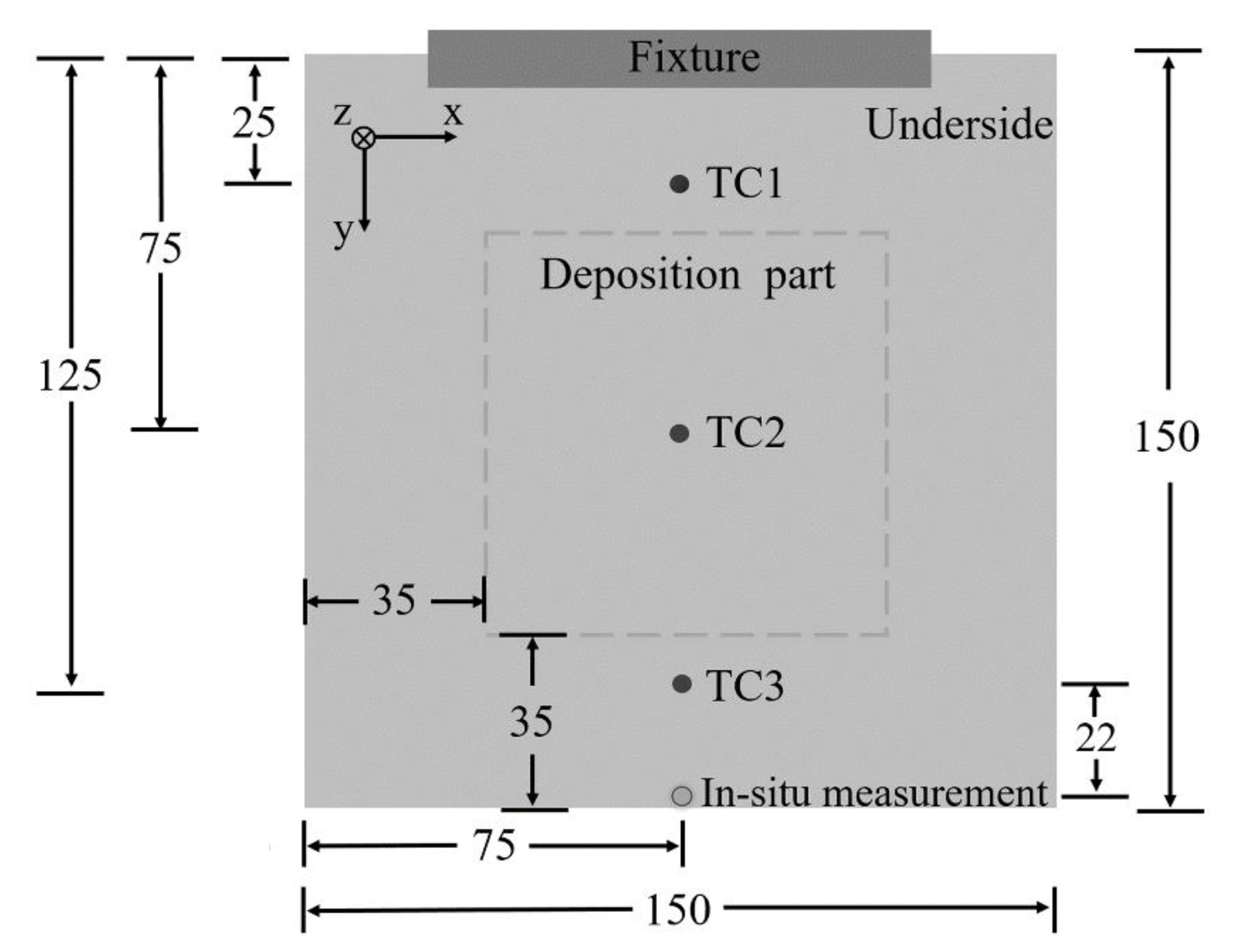

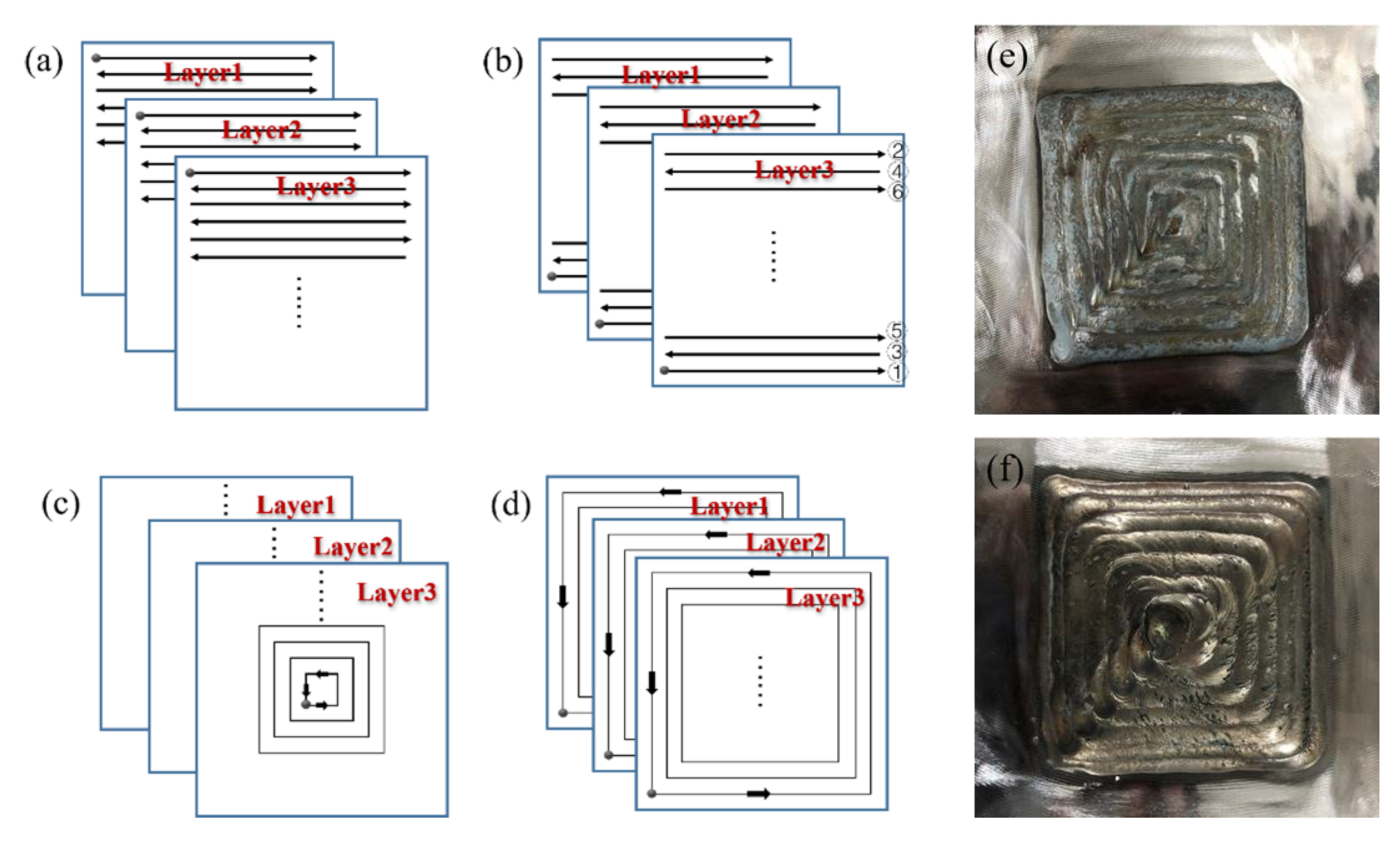

2.2. Experiment Setup

3. Results

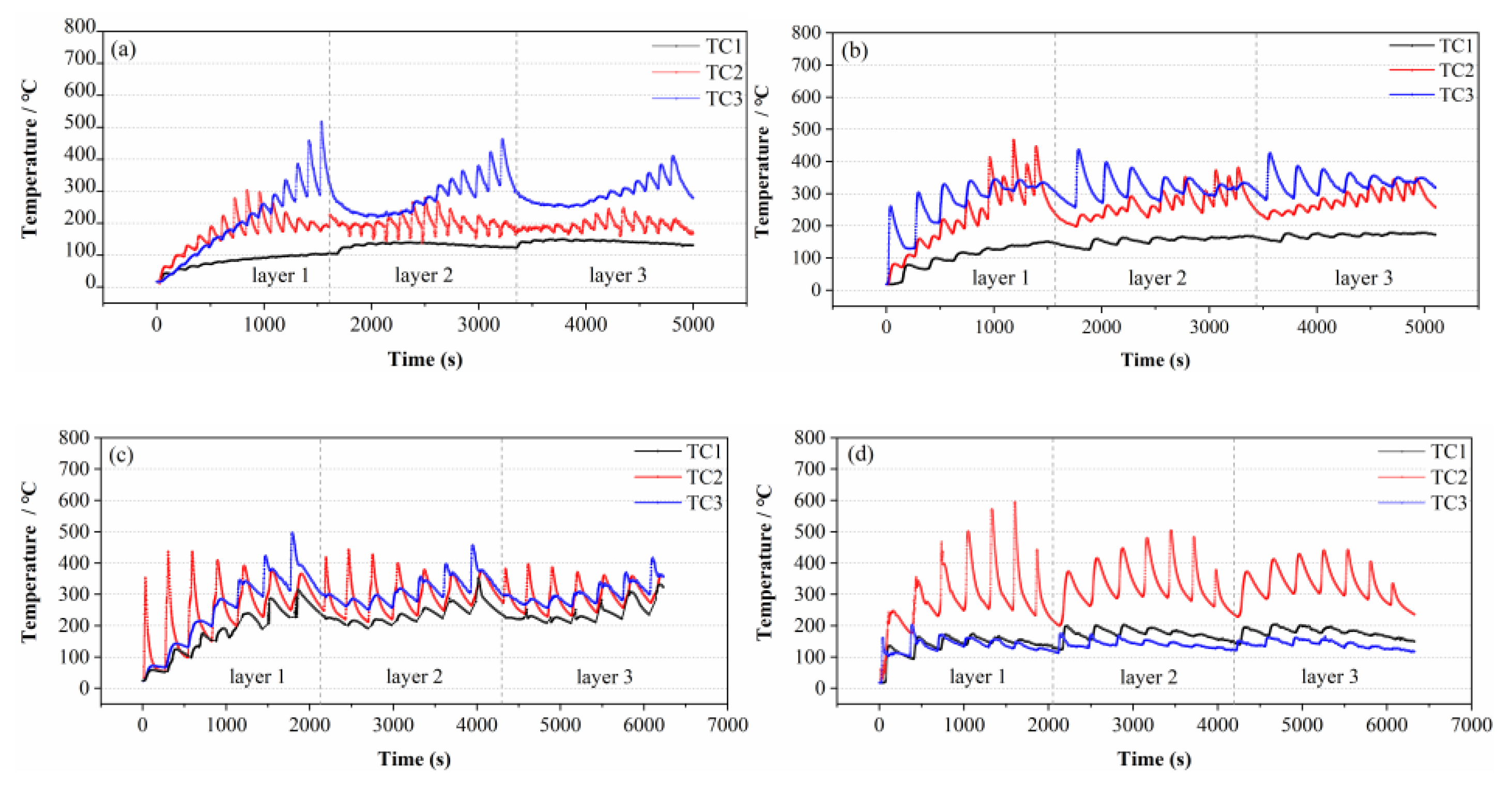

3.1. Temperature History

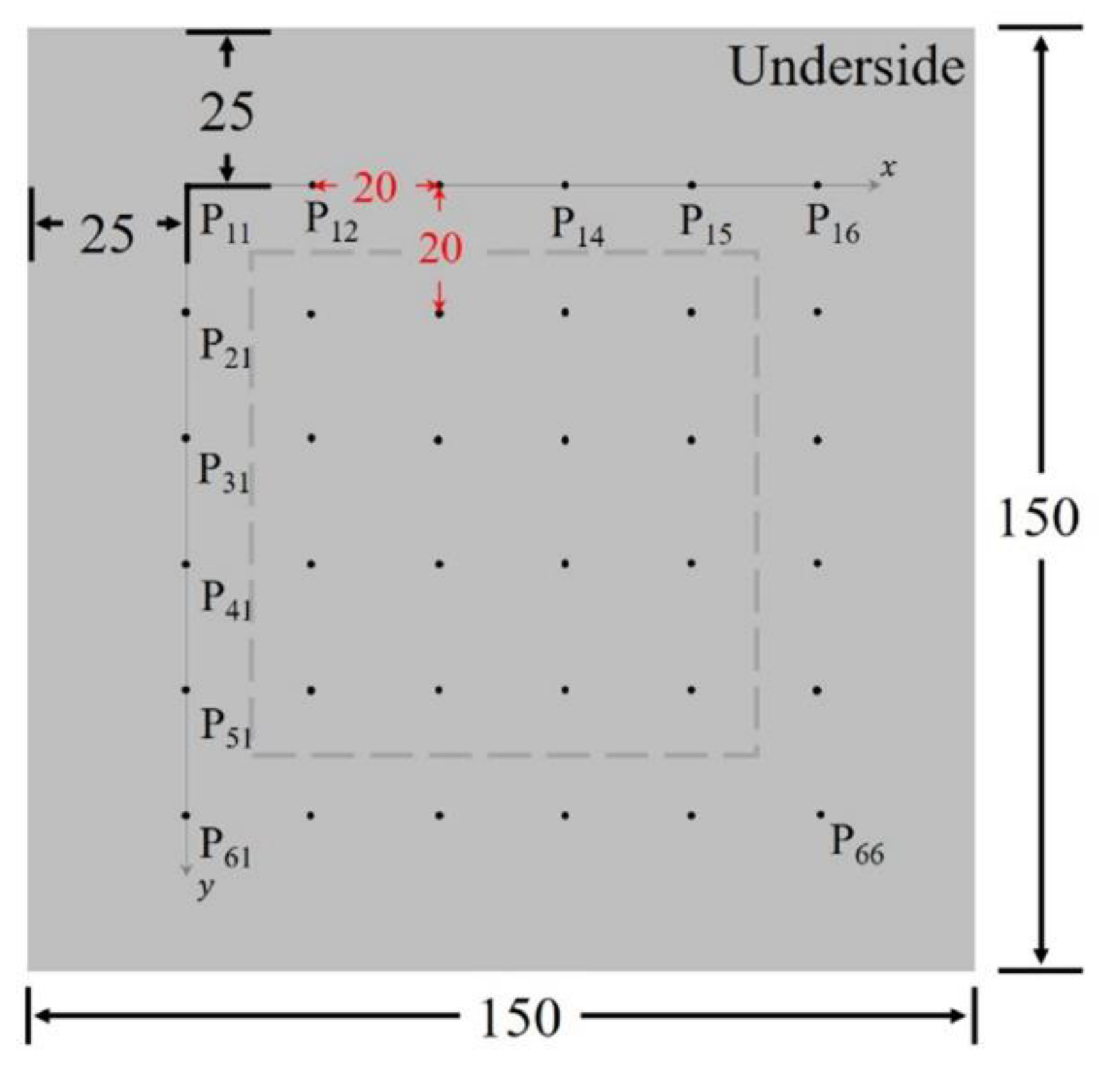

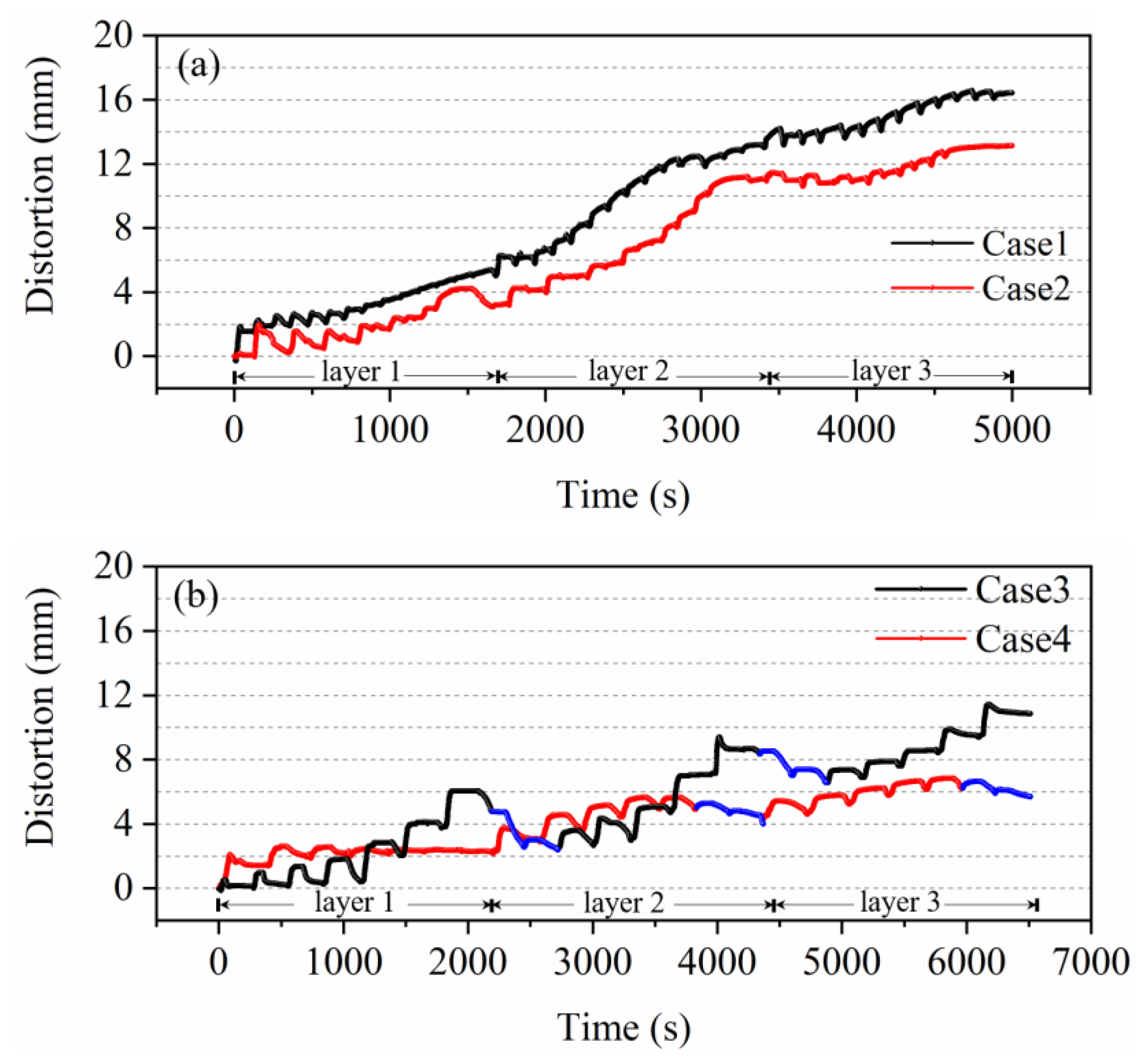

3.2. In Situ Measurements of Distortion

3.3. Postprocess Distortion

4. Discussion

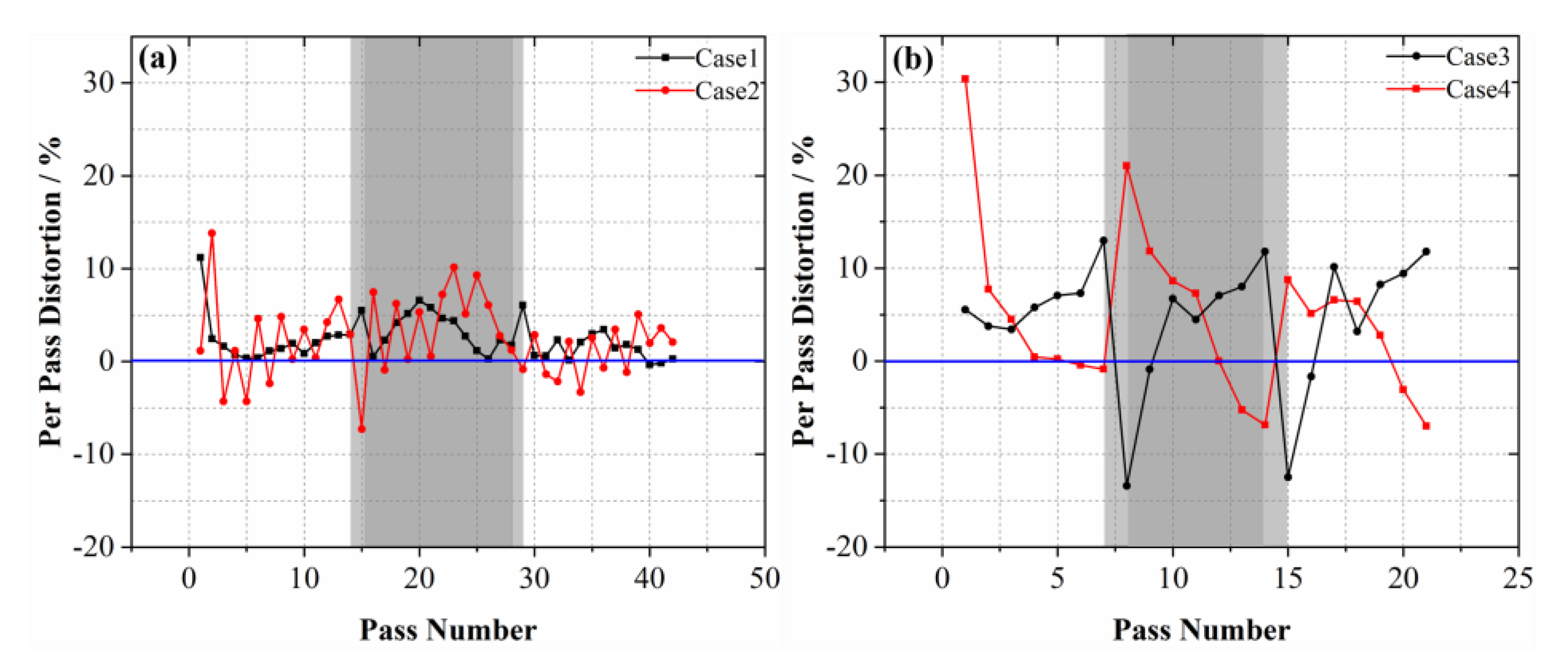

4.1. Contribution of Single Pass to the Total Distortion

4.2. Effect of Sequence of Heat Source

4.3. Effect of Structure Features

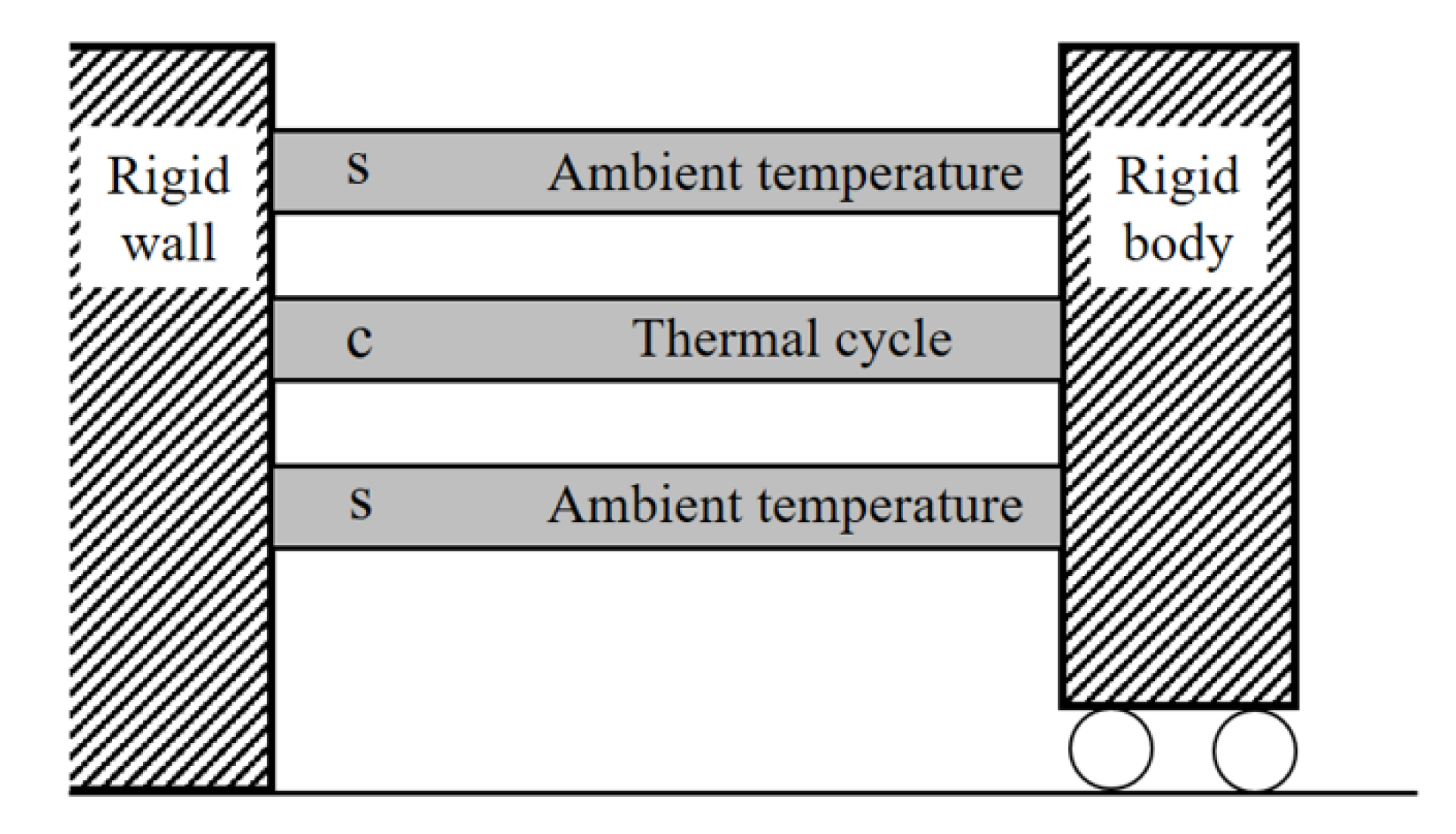

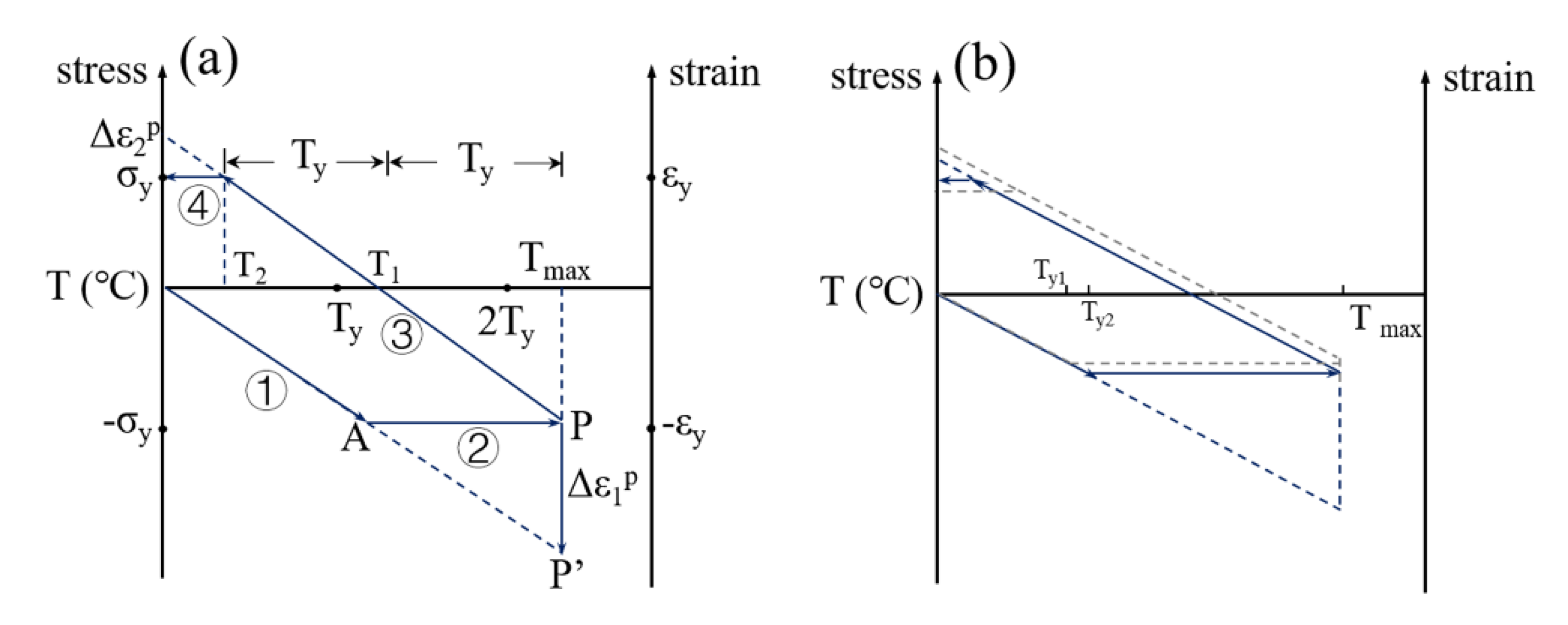

4.4. Application of Inherent Strain Analysis

5. Conclusions

- The highest peak temperature of 598 °C was obtained in the center of the substrate when the out–in pattern was employed, and severe temperature fluctuations occurred near the free end of the substrate in the sequence pattern.

- The distortion accumulated with deposition time using raster patterns (Cases 1 and 2). For spiral patterns (Cases 3 and 4), the distortion accumulated from previous layers could be decreased by about 14%, caused by the passes deposited near the center of the substrate.

- The S value was proposed to evaluate the distortion for all cases. For raster patterns, the distortion could be decreased by reducing the heated area. A 39.1% reduction of distortion could be obtained by the symmetry pattern. For spiral patterns, the existence of the passes along the y-direction increased the moment of inertia, resulting in enhancement of the ability of the substrate to resist bending distortion. A 68.6% reduction of distortion could be obtained by the out–in pattern.

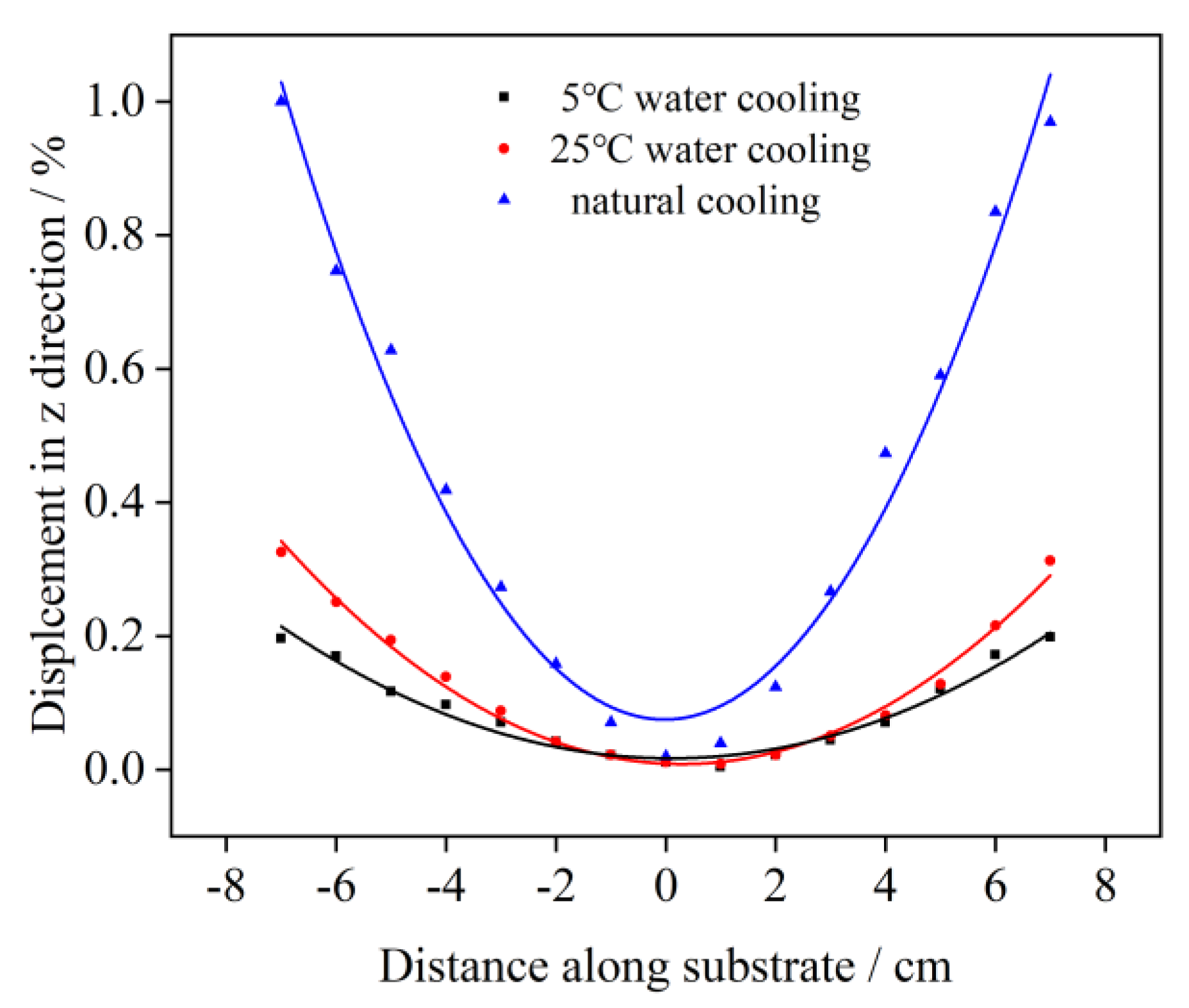

- Additional water-cooling lead to the least distortion. By reducing the heated area and forming a narrower weld bead, a 77.6% maximum reduction of distortion could be obtained when 5 °C cooling water was used.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| ε* | Inherent strain |

| εy | Yield strain |

| σy | Yield stress |

| β | Coefficient of thermal expansion |

| Ty | Yield temperature |

| Ty1 | Yield temperature for Case 1 |

| Ty2 | Yield temperature for Case 2 |

| A | Cross-sectional areas of c-bar |

| A0/2 | Cross-sectional areas of s-bar |

| E | Young’s modulus |

| Tmax | Maximum temperature |

| ρ | Density of the alloy wire |

| α | Thermal diffusivity |

| t | Characteristic time |

| H | Heat input per unit length |

| I | Moment of inertia of the substrate |

| F | Fourier number |

| Δt | Maximum rise in temperature |

References

- Michel, F.; Lockett, H.; Ding, J.; Martina, F.; Marinelli, G. A modular path planning solution for Wire + Arc Additive Manufacturing. Robot. Comput. Int. Manuf. 2019, 60, 1–11. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. A tool-path generation strategy for wire and arc additive manufacturing. Int. J. Adv. Manuf. Technol. 2014, 73, 173–183. [Google Scholar] [CrossRef]

- Gu, J.; Ding, J.; Williams, S.W.; Gu, H.; Ma, P. The effect of inter-layer cold working and post-deposition heat treatment on porosity in additively manufactured aluminum alloys. J. Mater. Process. Technol. 2016, 230, 26–34. [Google Scholar] [CrossRef]

- Calleja, A.; Tabernero, I.; Ealo, J.A.; Campa, F.J.; Lamikiz, A.; de Lacalle, L.N.L. Feed rate calculation algorithm for the homogeneous material deposition of blisk blades by 5-axis laser cladding. Int. J. Adv. Manuf. Technol. 2014, 74, 1219–1228. [Google Scholar] [CrossRef]

- Hönnige, J.R.; Colegrove, P.A.; Ganguly, S.; Eimer, E. Control of residual stress and distortion in aluminium wire + arc additive manufacture with rolling. Addit. Manuf. 2018, 22, 775–783. [Google Scholar] [CrossRef]

- Wu, B.T.; Pan, Z.X.; Ding, D.; Cuiuri, D.; Li, H. A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- Panwisawas, C.; Tang, Y.T.; Reed, R.C. Metal 3D printing as a disruptive technology for superalloys. Nat. Commun. 2020, 11, 1–4. [Google Scholar] [CrossRef]

- Aurrekoetxea, M.; López De Lacalle, L.N.; Llanos, I. Machining Stresses and Initial Geometry on Bulk Residual Stresses Characterization by On-Machine Layer Removal. Materials 2020, 13, 1445. [Google Scholar] [CrossRef]

- Lu, X.F.; Lin, X.; Michele, C. In-situ measurements and thermo-mechanical simulation of Ti-6Al-4V laser solid forming processes. Int. J. Mech. Sci. 2019, 153–154, 119–130. [Google Scholar] [CrossRef]

- Denlinger, E.R.; Heigel, J.C.; Michaleris, P. Effect of inter-layer dwell time on distortion and residual stress in additive manufacturing of titanium and nickel alloys. J. Mater. Process. Technol. 2015, 215, 123–131. [Google Scholar] [CrossRef]

- Lu, X.F.; Lin, X.; Chiumenti, M.; Cervera, M.; Li, J.; Ma, L. Finite element analysis and experimental validation of the thermomechanical behavior in laser solid forming of Ti-6Al-4V. Addit. Manuf. 2018, 21, 30–40. [Google Scholar] [CrossRef]

- Xie, R.; Chen, G.; Zhao, Y.; Zhang, S.; Yan, W. In-situ observation and numerical simulation on the transient strain and distortion prediction during additive manufacturing. J. Manuf. Process. 2019, 38, 494–501. [Google Scholar] [CrossRef]

- Cheng, B.; Shrestha, S.; Chou, K. Stress and deformation evaluations of scanning strategy effect in selective laser melting. Addit. Manuf. 2016, 12, 240–251. [Google Scholar]

- Chen, K.; Wang, X.; Li, Y. Numerical Simulation of WAAM Temperature Field under Water Cooling. Mater. Rep. 2021, 35, 4165–4169. [Google Scholar]

- Tomków, J.; Sobota, K.; Krajewski, S. Influence of Tack Welds Distribution and Welding Sequence on the Angular Distortion of TIG Weld Joint. Facta. Univ. Ser. Mech. Eng. 2020, 18, 611–621. [Google Scholar]

- Nie, Z.; Wang, G.; Mcguffin-Cawley, J.D.; Narayanan, B.; Zhang, S. Experimental study and modeling of H13 steel deposition using laser hot-wire additive manufacturing. J. Mater. Process. Technol. 2016, 235, 171–186. [Google Scholar] [CrossRef]

- Yu, J.; Lin, X.; Ma, L.; Wang, J.; Fu, X. Influence of laser deposition patterns on part distortion, interior quality and mechanical properties by laser solid forming (LSF). Mater. Sci. Eng. A 2011, 528, 1094–1104. [Google Scholar] [CrossRef]

- Gao, M.; Wang, Z.; Li, X.; Zeng, X. The effect of deposition patterns on the deformation of substrates during direct laser fabrication. J. Eng. Mater. Technol. 2013, 135, 034502. [Google Scholar] [CrossRef]

- Wu, B.T.; Pan, Z.; Chen, G.; Ding, D.; Yuan, L.; Cuiuri, D. Mitigation of thermal distortion in wire arc additively manufactured Ti6Al4V part using active interpass cooling. Sci. Technol. Weld. Join. Addit. Manuf. 3D Print. 2019, 24, 484–494. [Google Scholar] [CrossRef]

- Li, F.; Chen, S.; Shi, J.; Zhao, Y. In-process control of distortion in wire and arc additive manufacturing based on a flexible multi-point support fixture. Sci. Technol. Weld. Join. 2019, 24, 36–42. [Google Scholar] [CrossRef]

- Denlinger, E.R.; Michaleris, P. Mitigation of distortion in large additive manufacturing parts. Proc. Inst. Mech. Eng. Part B 2015, 231, 983–993. [Google Scholar] [CrossRef]

- Mukherjee, T.; Manvatkar, V.; De, A.; DeRoy, T. Mitigation of thermal distortion during additive manufacturing. Scr. Mater. 2017, 127, 79–83. [Google Scholar] [CrossRef]

- Rodríguez-Barrero, S.; Fernández-Larrinoa, J.; Azkona, I.; López De Lacalle, L.N.; Polvorosa, R. Enhanced Performance of Nanostructured Coatings for Drilling by Droplet Elimination. Mater. Manuf. Process. 2016, 31, 593–602. [Google Scholar] [CrossRef]

- Ma, N.; Wang, J.; Okumoto, Y. Out-of-plane welding distortion prediction and mitigation in stiffened welded structures. Int. J. Adv. Manuf. Technol. 2016, 84, 1371–1389. [Google Scholar] [CrossRef]

- Yukio, U.; Murakawa, H.; Ma, N. Introduction to Measurement and Prediction of Residual Stresses with the Help of Inherent Strains. In Welding Deformation and Residual Stress Prevention; Butterworth-Heinemann: Oxford, UK, 2012; pp. 35–53. [Google Scholar] [CrossRef]

- Lu, X.; Lin, X.; Ma, L.; Cao, Y. Effect of Scanning Path on Thermal-Mechanical Field of Laser Solid Forming TC4 Part. J. Mater. Eng. 2019, 47, 55–62. [Google Scholar]

| Deposited Materials | AM Technics | Thickness of Substrate | Structure of Part | Maximum Distortion | Literature |

|---|---|---|---|---|---|

| H13 | LHW | 19 mm | Block | 2.52 mm | [16] |

| Ti6Al4V | LBM | 12.7 mm | Wall | 2.07 mm | [10] |

| Inconel® 625 | 2.76 mm | ||||

| AlSi-316L | LSM | 8 mm | Block | 7.03 mm | [17] |

| Ti6Al4V | LSM | 6 mm | Wall | 3.37 mm | [11] |

| IN718 | DLF | 5 mm | Cylinder | 9.37 mm | [18] |

| Element | C | S | P | Si | Mn | Cr | Mo | V | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Substrate | 0.130 | 0.006 | 0.016 | 0.290 | 0.650 | 0.016 | 0.003 | 0.001 | Bal. |

| Wire | 0.450 | 0.030 | 0.030 | 0.820 | 0.500 | 4.750 | 1.100 | 0.800 | Bal. |

| Depositing Parameters | Depositing Speed | Depositing Current | Depositing Voltage | Wire Feed Speed | Distance Per Pass | Dwelling Time Per Layer |

|---|---|---|---|---|---|---|

| Value | 0.2 m/min | 144 A | 19 V | 5 m/min | 5.75 mm | 300 s |

| Case Number | Equation of the Fitting Plane | S Value/mm |

|---|---|---|

| Case 1 | 0.0121x − 0.0127y − 0.9998z − 5.1119 = 0 | 90.4 |

| Case 2 | −0.0134x − 0.00024y + 0.9999z + 6.732 = 0 | 54.92 |

| Case 3 | 0.0062x − 0.0031y + z + 5.2682 = 0 | 30.54 |

| Case 4 | −0.0074x − 0.0102y + 0.9999z + 7.2311 = 0 | 28.38 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Lin, J.; Xia, Z.; Zhang, Y.; Fu, H. Influence of Deposition Patterns on Distortion of H13 Steel by Wire-Arc Additive Manufacturing. Metals 2021, 11, 485. https://doi.org/10.3390/met11030485

Li X, Lin J, Xia Z, Zhang Y, Fu H. Influence of Deposition Patterns on Distortion of H13 Steel by Wire-Arc Additive Manufacturing. Metals. 2021; 11(3):485. https://doi.org/10.3390/met11030485

Chicago/Turabian StyleLi, Xufeng, Jian Lin, Zhidong Xia, Yongqiang Zhang, and Hanguang Fu. 2021. "Influence of Deposition Patterns on Distortion of H13 Steel by Wire-Arc Additive Manufacturing" Metals 11, no. 3: 485. https://doi.org/10.3390/met11030485

APA StyleLi, X., Lin, J., Xia, Z., Zhang, Y., & Fu, H. (2021). Influence of Deposition Patterns on Distortion of H13 Steel by Wire-Arc Additive Manufacturing. Metals, 11(3), 485. https://doi.org/10.3390/met11030485