Hot Processing Map of an Al–4.30 Mg Alloy under High One-Pass Deformation

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

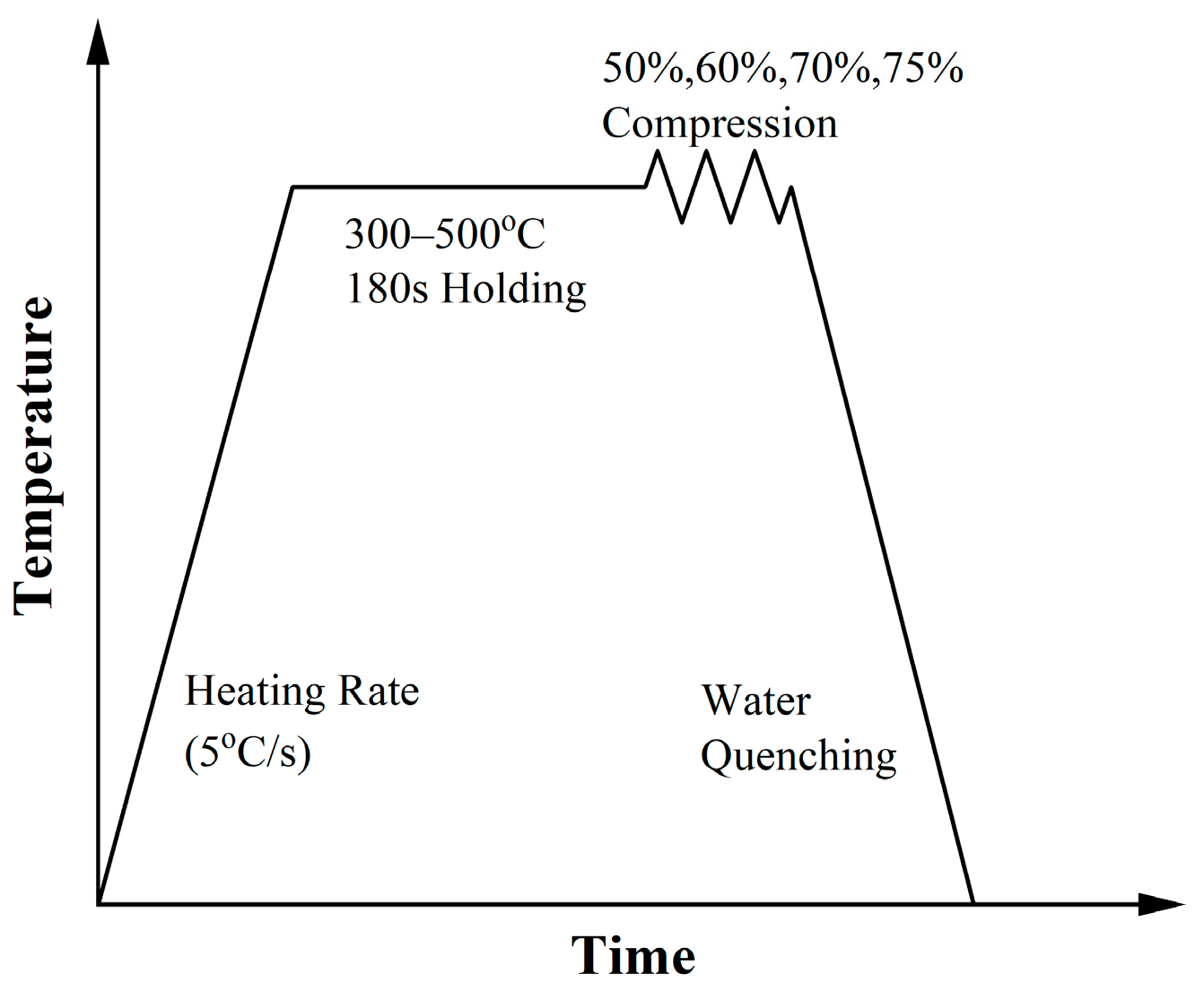

2.2. Hot Compression

2.3. Microstructure Characterization

2.4. Activation Energy Determined by Constitutive Equation

2.5. Development of Processing Maps Using Dynamic Material Modeling

3. Results

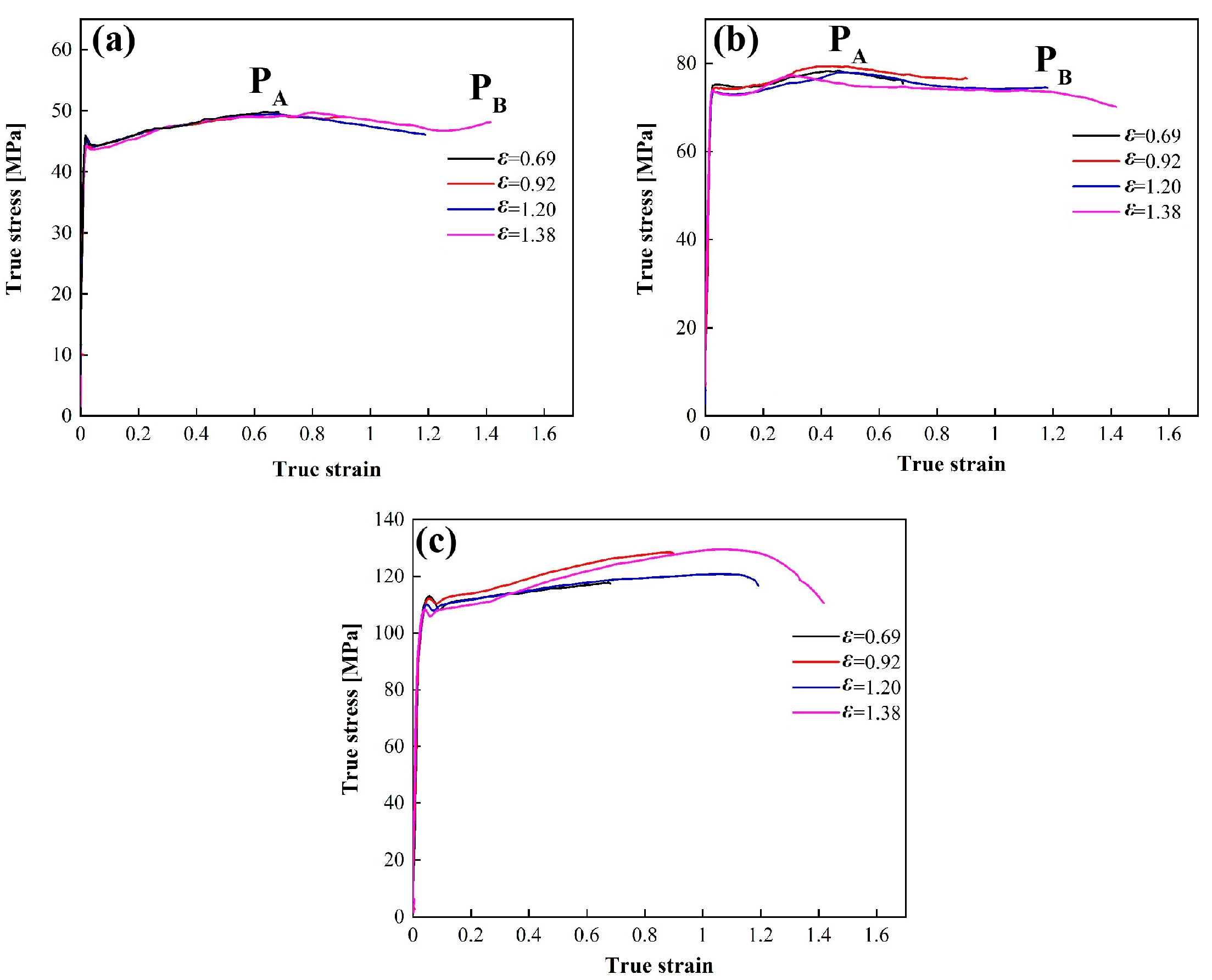

3.1. True Stress–Strain Curves

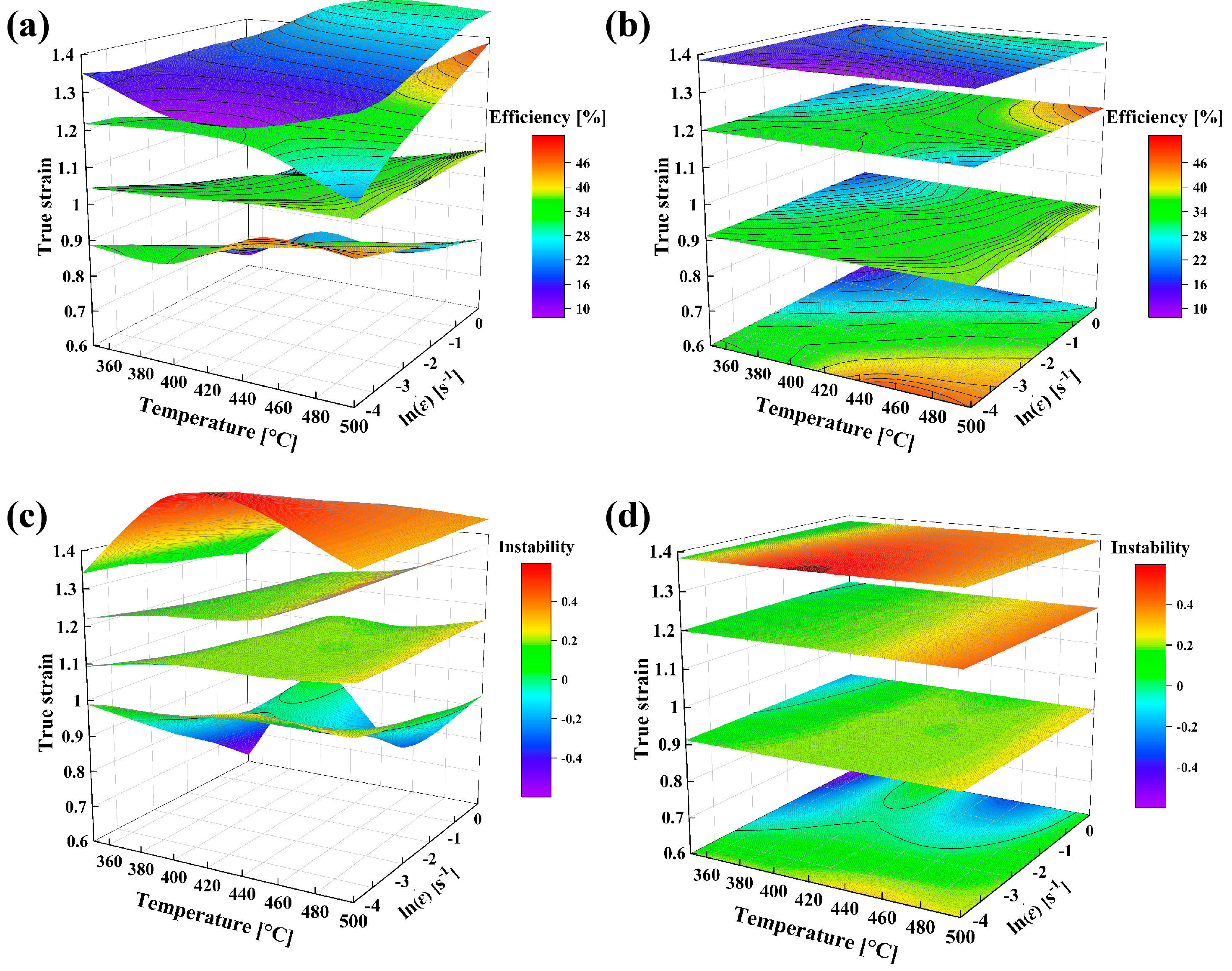

3.2. Development of 3D Hot Processing Map

3.3. Verification of Hot Processing Maps via Apparent Activation Energy

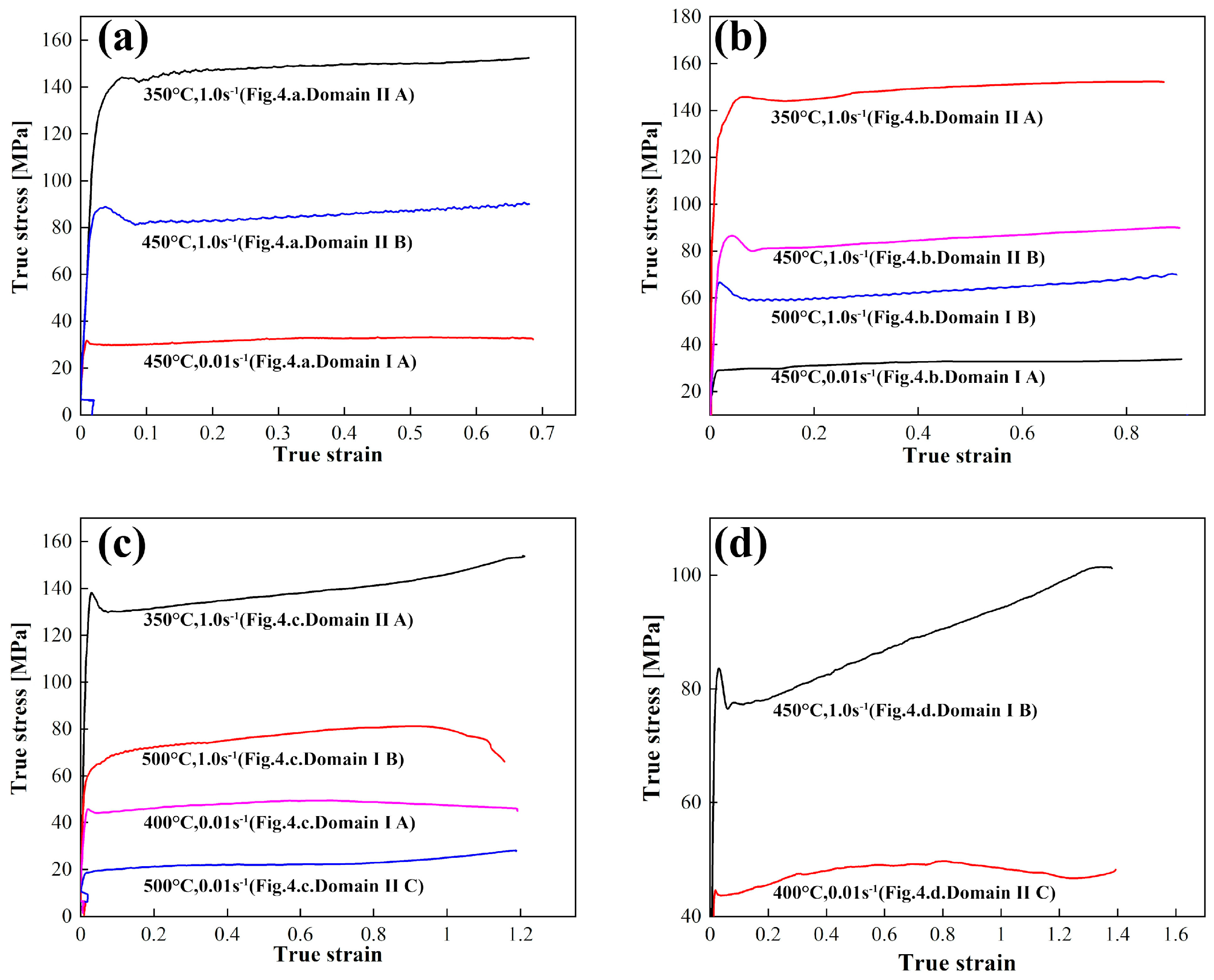

3.4. Verification of Hot Processing Maps via Stress-Strain Curves

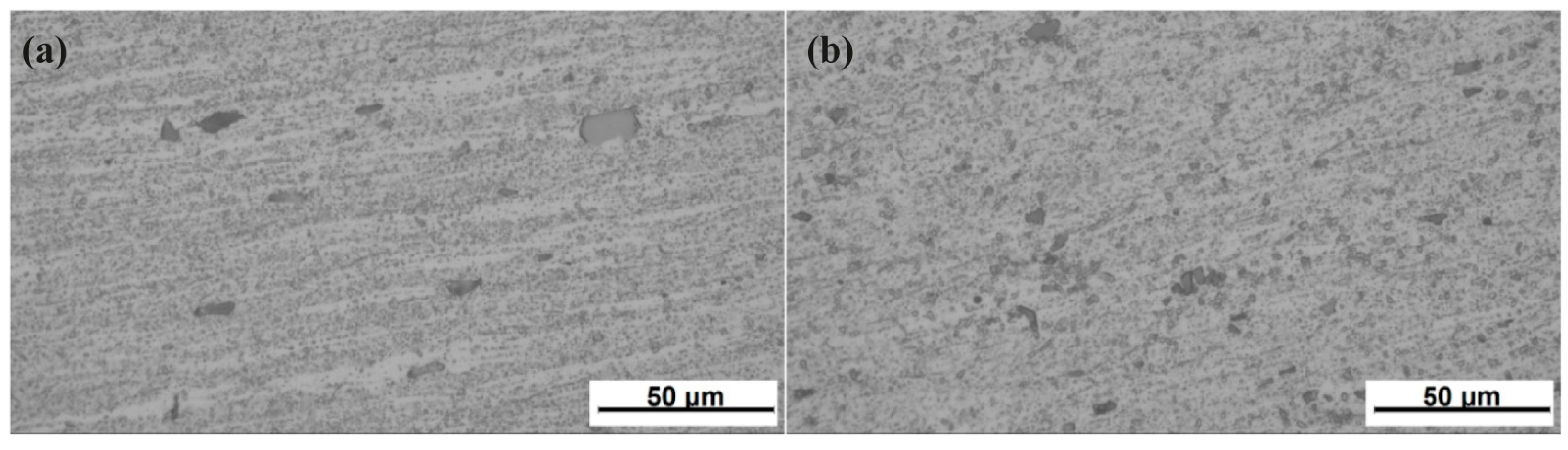

4. Discussion

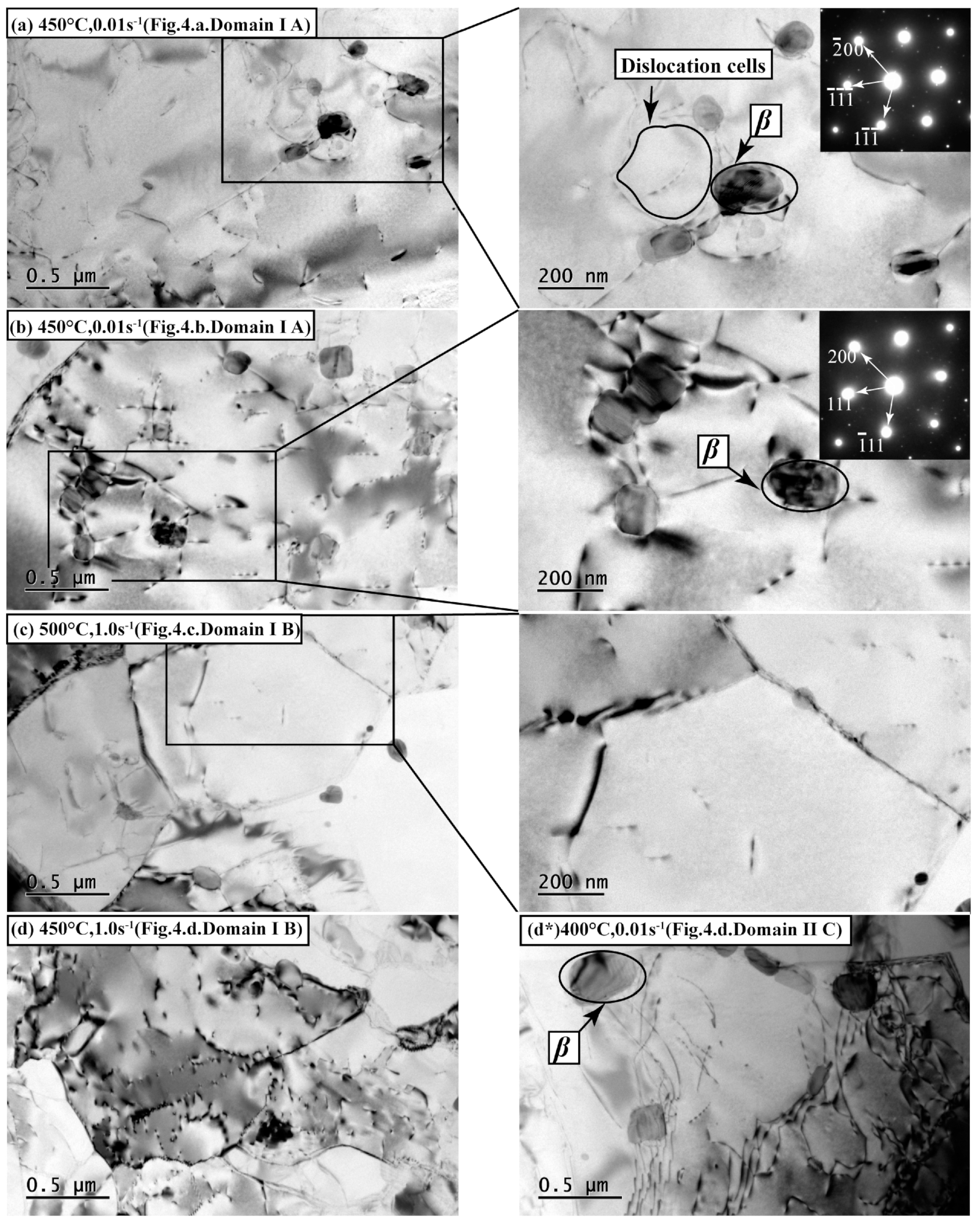

4.1. Efficiency Domain I A (about 450 °C, 0.01 s−1/0.69 Strain)

4.2. Efficiency Domain I A (about 450 °C, 0.01 s−1/0.92 Strain)

4.3. Efficiency Domain I B (about 500 °C, 1.0 s−1/1.2 Strain)

4.4. Efficiency Domain I B (about 450 °C, 1.0 s−1/1.38 Strain)

4.5. Low-Efficiency Domain II C (about 400 °C, 0.01 s−1/1.38 Strain)

5. Conclusions

- (1)

- The apparent activation energy (Q) decreases obviously with increasing the strain. The activation energy decreases from 140 to 136 kJ/mol when strain increases from 0.69 to 0.92. When the strain increases from 0.92 to 1.20 and from 1.20 to 1.38, the apparent activation energy changes from 136 to 124 kJ/mol and from 124 to 112 kJ/mol, respectively. The difference of Q is nearly 12 kJ/mol, which greatly affects the processing maps. The activation energy changes with the amount of deformation, indicating the dependence of deformation mechanisms on the strain.

- (2)

- The optimized hot processing parameters are the two efficiency regions with the maximum power efficiency η of 48%. The domain I A (440–480 °C/0.01–0.05 s−1, ε = 0.69) is considered as a result of dynamic recrystallization (DRX) at the high temperature and low strain rate. The domain I B (470–500 °C/0.3–1.0 s−1, ε = 1.20) is the result of DRX at high temperature and a large deformation heat caused by both large strain and high strain rate.

- (3)

- There are two types of instability regions in hot processing maps of Al–4.30 Mg alloy. The instability domain II A (350–390 °C/1.0 s−1) appears at strains less than 1.20; another instability domain II B (410–490 °C/1.0 s−1) only appears at a stain of 0.69. The appearance of domain II A and domain II B attributes to the obvious strain hardening and low deformation energy under low temperature, low strain and high strain rate, which cannot provide enough driving force for dislocation movement.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Scamans, G.M.; Holroyd, N.J.H.; Tuck, C.D.S. The role of magnesium segregation in the intergranular stress corrosion cracking of aluminium alloys. Corros. Sci. 1987, 27, 329–347. [Google Scholar] [CrossRef]

- Wang, Y.; Gupta, R.K.; Sukiman, N.L.; Zhang, R.; Davies, C.H.J.; Birbilis, N. Influence of alloyed Nd content on the corrosion of an Al-5Mg alloy. Corros. Sci. 2013, 73, 181–187. [Google Scholar] [CrossRef]

- Maitra, S.; English, G.C. Mechanism of localized corrosion of 7075 alloy plate. Metall. Trans. A 1981, 12, 535–541. [Google Scholar] [CrossRef]

- Gao, X.; Zhang, T.; Hayden, M.; Roe, C. Effects of the stress state on plasticity and ductile failure of an aluminum 5083 alloy. Int. J. Plast 2009, 25, 2366–2382. [Google Scholar] [CrossRef]

- Lu, G.; Zhao, M.; Li, J.; Wu, W.; Feng, W. Effect of Microalloying with La and Y on Microstructure and Corrosion Resistance of Al-Si Alloy. Foundry Technol. 2014, 35, 225–227. (In Chinese) [Google Scholar]

- Zhou, S.a.; Zhang, Z.; Li, M.; Pan, D.; Su, H.; Du, X.; Li, P.; Wu, Y. Effect of Sc on microstructure and mechanical properties of as-cast Al-Mg alloys. Mater. Des. 2016, 90, 1077–1084. [Google Scholar] [CrossRef]

- Zhemchuzhnikova, D.; Kaibyshev, R. Mechanical Behavior of an Al–Mg–Mn–Sc Alloy with an Ultrafine Grain Structure at Cryogenic Temperatures. Adv. Eng. Mater. 2016, 17, 1804–1811. [Google Scholar] [CrossRef]

- Liu, Y.G.; Huang, H.; Lin, S.P.; Liu, Y.B.; Nie, Z.R. Effect of Rare Earth Element Er on the Microstructure and Properties of 5083 Alloy. Nonferrous Met. 2008, 6, 27–30. [Google Scholar]

- Hu, H.; Zhen, L.; Zhang, B.Y.; Yang, L.; Chen, J.Z. Microstructure characterization of 7050 aluminum alloy during dynamic recrystallization and dynamic recovery. Mater. Charact. 2008, 59, 1185–1189. [Google Scholar] [CrossRef]

- Agnew, S.R.; Duygulu, Ö. Plastic anisotropy and the role of non-basal slip in magnesium alloy AZ31B. Int. J. Plast 2005, 21, 1161–1193. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Zhang, H.; Li, L.; Yuan, D.; Peng, D. Hot deformation behavior of the new Al-Mg-Si-Cu aluminum alloy during compression at elevated temperatures. Mater. Charact. 2007, 58, 168–173. [Google Scholar] [CrossRef]

- Liu, J.; Cui, Z.; Li, C. Modelling of flow stress characterizing dynamic recrystallization for magnesium alloy AZ31B. Comput. Mater. Sci. 2008, 41, 375–382. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, H.; Han, Y.; Wu, W.; Chen, J. Hot deformation behavior of 2026 aluminum alloy during compression at elevated temperature. Mater. Sci. Eng. A 2010, 527, 485–490. [Google Scholar] [CrossRef]

- Liu, W.; Zhao, H.; Li, D.; Zhang, Z.; Huang, G.; Liu, Q. Hot deformation behavior of AA7085 aluminum alloy during isothermal compression at elevated temperature. Mater. Sci. Eng. A 2014, 596, 176–182. [Google Scholar] [CrossRef]

- Zhu, R.; Liu, Q.; Li, J.; Xiang, S.; Chen, Y.; Zhang, X. Dynamic restoration mechanism and physically based constitutive model of 2050 Al–Li alloy during hot compression. J. Alloys Compd. 2015. [Google Scholar] [CrossRef]

- Johnson, G.R.; Hoegfeldt, J.M.; Lindholm, U.S.; Nagy, A. Response of Various Metals to Large Torsional Strains Over a Large Range of Strain Rates—Part 1: Ductile Metals. J. Eng. Mater. Technol. 1983, 105, 42. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

- Zerilli, F.J.; Armstrong, R.W. Dislocation-mechanics-based constitutive relations for material dynamics calculations. J. Appl. Phys. 1987, 61, 1816–1825. [Google Scholar] [CrossRef]

- Lin, Y.C.; Li, L.T.; Fu, Y.X.; Jiang, Y.Q. Hot compressive deformation behavior of 7075 Al alloy under elevated temperature. J. Mater. Sci. 2012, 47, 1306–1318. [Google Scholar] [CrossRef]

- Li, H.Y.; Wang, X.F.; Duan, J.Y.; Liu, J.J. A modified Johnson Cook model for elevated temperature flow behavior of T24 steel. Mater. Sci. Eng. A 2013, 577, 138–146. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, G.; Yu, J. Hot deformation behavior and constitutive modeling of homogenized 6026 aluminum alloy. Mater. Des. 2015, 74, 25–35. [Google Scholar] [CrossRef]

- Haghdadi, N.; Zarei-Hanzaki, A.; Abedi, H.R. The flow behavior modeling of cast A356 aluminum alloy at elevated temperatures considering the effect of strain. Mater. Sci. Eng. A 2012, 535, 252–257. [Google Scholar] [CrossRef]

- Yuan, X.; Wen, S.; Hou, J.; Wu, X.; Bolong, L.; Gao, K.; Huang, H.; Nie, Z. Hot deformation behavior and dynamic precipitation in Al-Er-Zr alloy. Rare Metal Mater. Eng. 2020, 49, 2305–2313. [Google Scholar]

- Sang, D.; Fu, R.; Li, Y. The Hot Deformation Activation Energy of 7050 Aluminum Alloy under Three Different Deformation Modes. Metals 2016, 6, 49. [Google Scholar] [CrossRef]

- Odoh, D.; Mahmoodkhani, Y.; Wells, M. Effect of alloy composition on hot deformation behavior of some Al-Mg-Si alloys. Vacuum 2018, 149, 248–255. [Google Scholar] [CrossRef]

- Reddy, G.J.; Srinivasan, N.; Gokhale, A.A.; Kashyap, B.P. Processing map for hot working of spray formed and hot isostatically pressed Al–Li alloy (UL40). J. Mater. Process. Technol. 2009, 209, 5964–5972. [Google Scholar] [CrossRef]

- Meng, G.; Li, B.; Li, H.; Huang, H.; Nie, Z. Hot deformation and processing maps of an Al–5.7 wt.%Mg alloy with erbium. Mater. Sci. Eng. A 2009, 517, 132–137. [Google Scholar] [CrossRef]

- Ganesan, G.; Raghukandan, K.; Karthikeyan, R.; Pai, B.C. Development of processing maps for 6061 Al/15% SiCp composite material. Mater. Sci. Eng. A 2004, 369, 230–235. [Google Scholar] [CrossRef]

- Mohamadizadeh, A.; Zarei-Hanzaki, A.; Abedi, H.R.; Mehtonen, S.; Porter, D. Hot deformation characterization of duplex low-density steel through 3D processing map development. Mater. Charact. 2015, 293–301. [Google Scholar] [CrossRef]

- Kai, X.; Chen, C.; Sun, X.; Wang, C.; Zhao, Y. Hot deformation behavior and optimization of processing parameters of a typical high-strength Al–Mg–Si alloy. Mater Des. 2015, 90, 1151–1158. [Google Scholar] [CrossRef]

- Peng, J.; Wang, Y.; Zhong, L.; Peng, L.; Pan, F. Hot deformation behavior of homogenized al-3.2mg-0.4er aluminum alloy. Trans. Nonferrous Metals Soc. China 2016, 26, 945–955. [Google Scholar] [CrossRef]

- Sellars, C.M.; Mctegart, W.J. On the mechanism of hot deformation. Acta Metall. 1966, 14, 1136–1138. [Google Scholar] [CrossRef]

- Zener, C.; Hollomon, J.H. Effect of Strain Rate Upon Plastic Flow of Steel. J. Appl. Phys. 1944, 15, 22–32. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Gegel, H.L.; Doraivelu, S.M.; Malas, J.C.; Morgan, J.T.; Lark, K.A.; Barker, D.R. Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242. Metall. Trans. A 1984, 15, 1883–1892. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Seshacharyulu, T. Modelling of hot deformation for microstructural control. Int. Mater. Rev. 1998, 43, 243–258. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Rao, K.P. Processing maps and rate controlling mechanisms of hot deformation of electrolytic tough pitch copper in the temperature range 300–950°C. Mater. Sci. Eng. A 2005, 391, 141–150. [Google Scholar] [CrossRef]

- Zhang, B.L.; Maclean, M.S.; Baker, T.N. Hot deformation behaviour of aluminium alloy 6061/SiCp MMCs made by powder metallurgy route. Mater. Sci. Technol. 2013, 16, 897–902. [Google Scholar] [CrossRef]

- Liu, S.; Pan, Q.; Li, H.; Huang, Z.; Li, K.; He, X.; Li, X. Characterization of hot deformation behavior and constitutive modeling of al–mg–si–mn–cr alloy. J. Mater. Sci. 2019, 54, 4366–4383. [Google Scholar] [CrossRef]

- Galiyev, A.; Kaibyshev, R.; Gottstein, G. Correlation of plastic deformation and dynamic recrystallization in magnesium alloy zk60. Acta Mater. 2001, 49, 1199–1207. [Google Scholar] [CrossRef]

- Sitdikov, O.; Kaibyshev, R. Dynamic recrystallization in pure magnesium. Mater Trans. 2005, 42, 1928–1937. [Google Scholar] [CrossRef]

- Dai, Q.; Deng, Y.; Tang, J.; Wang, Y. Deformation characteristics and strain-compensated constitutive equation for aa5083 aluminum alloy under hot compression. Trans. Nonferrous Metals Soc. China 2019, 29, 2252–2261. [Google Scholar] [CrossRef]

- Beer, A.G.; Barnett, M.R. Microstructural Development during Hot Working of Mg-3Al-1Zn. Metall. Mater.Trans. 2007, 38, 1856–1867. [Google Scholar] [CrossRef]

| Mg | Si | Fe | Cu | Mn | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| 4.30 | 0.118 | 0.188 | 0.022 | 0.03 | 0.01 | 0.03 | 0.031 | Bal. |

| True Strain | A/s−1 | α/MPa−1 | n | Q/kJ/mol |

|---|---|---|---|---|

| 0.69 | 1.55×109 | 1.45×10−2 | 3.83588 | 140.300 |

| 0.92 | 8.37×108 | 1.44×10−2 | 3.70879 | 136.350 |

| 1.20 | 1.13×108 | 1.39×10−2 | 3.77810 | 124.079 |

| 1.38 | 1.70×107 | 1.27×10−2 | 4.03817 | 112.744 |

| True Strain | Q/kJ/mol | R* | AARE(%) |

|---|---|---|---|

| 0.69 | 140.300 | 0.9962 | 2.77% |

| 0.92 | 136.350 | 0.9974 | 2.28% |

| 1.20 | 124.079 | 0.9963 | 4.29% |

| 1.38 | 112.744 | 0.9883 | 5.96% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Ding, H.; Cao, Y.; Chen, P.; Hu, Z.; Zhang, J.; Li, L. Hot Processing Map of an Al–4.30 Mg Alloy under High One-Pass Deformation. Metals 2021, 11, 347. https://doi.org/10.3390/met11020347

Zhao Y, Ding H, Cao Y, Chen P, Hu Z, Zhang J, Li L. Hot Processing Map of an Al–4.30 Mg Alloy under High One-Pass Deformation. Metals. 2021; 11(2):347. https://doi.org/10.3390/met11020347

Chicago/Turabian StyleZhao, Yanjun, Haochen Ding, Yunfei Cao, Peilin Chen, Zhiliu Hu, Jingrui Zhang, and Lingxiao Li. 2021. "Hot Processing Map of an Al–4.30 Mg Alloy under High One-Pass Deformation" Metals 11, no. 2: 347. https://doi.org/10.3390/met11020347

APA StyleZhao, Y., Ding, H., Cao, Y., Chen, P., Hu, Z., Zhang, J., & Li, L. (2021). Hot Processing Map of an Al–4.30 Mg Alloy under High One-Pass Deformation. Metals, 11(2), 347. https://doi.org/10.3390/met11020347