Nowadays, companies from the modern manufacturing industry face the challenges to reduce costs, increase productivity, and quality of products and minimize the environmental issues, in order to remain competitive in a global and dynamic market [

1]. The high quality requirements, the continuously demand for high productivity, the global competition, and the trend toward a cleaner production, push the manufacturers to continuously develop innovative strategies in machining, improve the production processes, take advantage from economic opportunities, and create a greener workplace and eco-friendly machining [

2]. To enhance these aspects, the machining process should be as economic as possible, providing a high material removal rate, high quality, reliability, and flexibility. Traditionally, grinding is the conventional method or the dominant process in the finishing of high hardened parts. However, the innovations from the last two decades in terms of machine-tools rigidity and accuracy and cutting inserts manufacturing, materials, grades, geometries, and coatings has led to an increase in the use of hard turning (HT) instead grinding [

3]. HT became a widely spread cutting technology for both roughing and finishing of revolution parts made by hardened steel with a hardness higher than 55 HRC, in many industries, e.g., automotive, bearings, dies, gears, and shafts, due to the numerous advantages it takes compared to grinding from an economic, technological, and environmental point of view. Viewed as a sustainable and attractive alternative to grinding, more environmentally and human-friendly manufacturing processes such as precision hard turning are able to yield a high quality machined surface and offer many benefits to manufactures in the context of higher flexibility, material removal rate, lower setup and cycle time, and lower costs [

4]. Surface quality in finishing operation is recognized as main indicator for accepting parts; therefore, reducing values of roughness in an economic way is an important task [

5,

6]. In order to have stability and efficiency in a hard turning process, special cutting inserts are used. Therefore, the materials meeting the tough requirements of hard turning are ceramics and cubic boron nitride (CBN) [

7]. Ceramics, having the major advantage against CBN in terms of cost, are known for they high hardness, high wear resistance, high hot hardness, excellent chemical stability, and low mechanical shock resistance [

8]. To increase their fracture toughness, other materials, e.g., titanium nitride (TiN), titanium carbide (TiC), or titanium carbonitride (TiCN), are added in their composition, resulting in mixed ceramics [

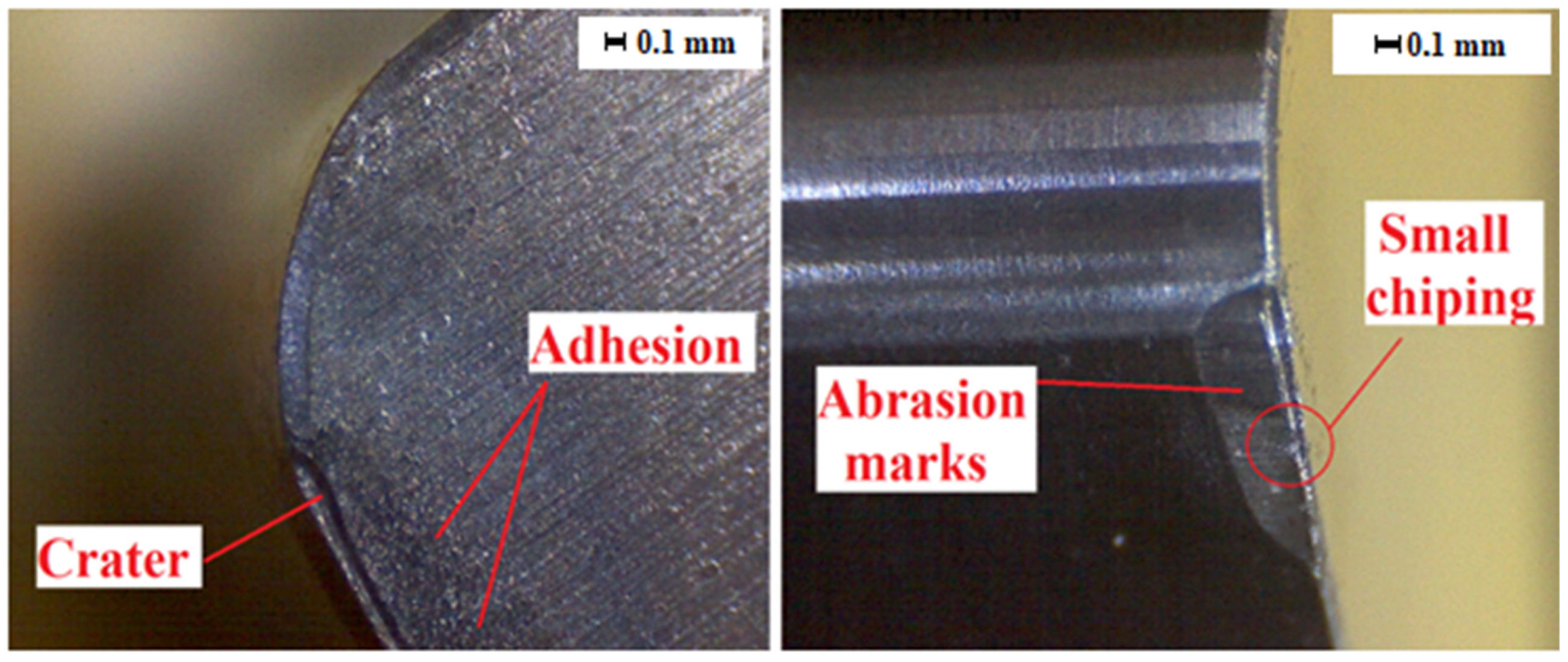

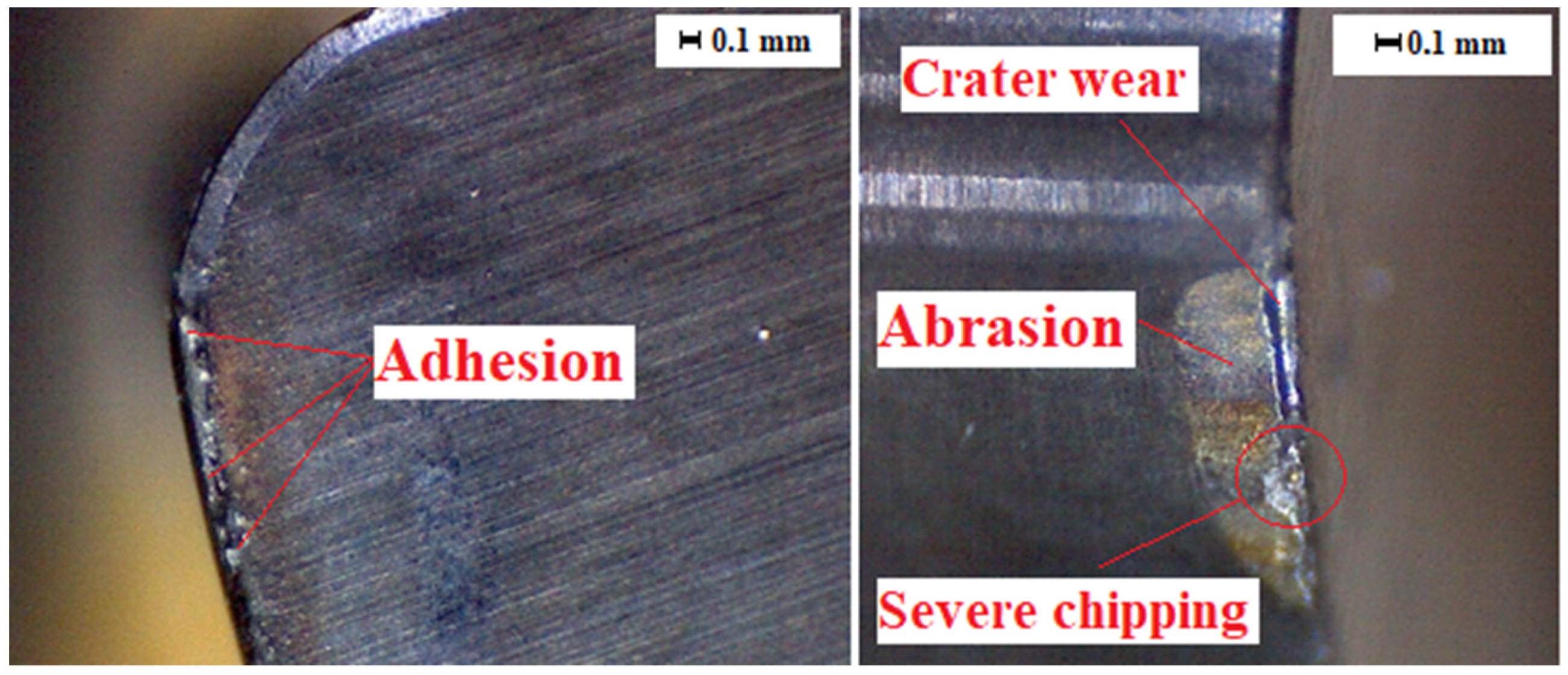

9]. Since the economical aspect of the manufacturing cannot be ignored, the tool cost is of high interest. Therefore, tool life in terms of tool wear must be regarded [

10]. The strength of the parts, heat generated in cutting zone, high cutting forces, and low thermal conductivity causes difficulties in machinability and lead to severe wear and surface integrity issues [

11]. Severe tool wear leads to low quality, failure, scrap, and breakdown and therefore should be controlled and reduced in order to maintain a stable and reliable process and enhance productivity [

12]. The control of wear, the reduction of friction, of temperature in the cutting zone and cutting forces is achieved through cutting fluids (CFs) [

13]. Doubtless, the CFs are improving tool life and surface quality [

14]. However, CFs, also known metal working fluids (MWFs), represent over 10% of production costs [

15,

16]. Being an essential constituent for improving machinability, CFs ensure cooling, lubrications, and process stability and provide lower tool wear, better surface integrity, and higher accuracy [

17,

18]. However, even if the MWFs are necessary and indispensable in many machining sectors, the environmental, costs, and health concerns will restrict this method in the future by regulations and laws [

19,

20]. Since the early 1990s, considerable efforts have been made to completely eliminate MWFs and many green cutting lubrication techniques have been proposed, e.g., dry cutting, self-lubricating tools, or MQL [

20,

21]. The MQL technique is a cooling and lubricating technique which consists of spraying a small amount of oil directly in the cutting zone at a flow rate between 10 and 200 milliliter/hour (mL/h) [

17,

21]. Practically, it uses atomized micro-droplets that can penetrate the cutting zone more effectively to achieve lubrication [

20,

22]. The technique merges the sustainability with productivity growth and was proposed as a viable alternative to flood cooling, as a solution to environment issues and professional risks, and has shown over time many advantages, e.g., lower costs with CFs, energy, tools, and equipment, flexibility in machine relocation, a healthier workplace, higher quality of products, and productivity growth [

10,

23]. Meanwhile, MQL gained more and more attention and quickly became a global sustainable solution. Nevertheless, conventional CFs are mineral oil based and the substitution is mandatory. Having better biodegradable and toxicity properties than petroleum or chemical-based oils which cause severe pollution, the vegetable oils gained popularity and have vast potential for many application as green cutting fluid (GCF) [

24,

25]. Vegetable oils are a feasible and promising alternative to mineral, synthetic, and semi-synthetic oils based on MWF, which are harmful for both worker and environment. Vegetable oils, due to their environmental friendly characteristics, e.g., low toxicity, biodegradability, and renewability, and proprieties useful in cutting, e.g., high flash point and viscosity, excellent lubrication capacity, low volatility, relatively low cost, have ecologic and economic benefits and cleaner and sustainable manufacturing. In addition, vegetable oils create a thick strong film which cools the machining zone, reduce friction coefficient, cutting forces, tool wear, and heat generation [

26,

27]. Since many differences in physicochemical properties of different vegetable oils exist [

20], the state of the art present a variety of research involving vegetable oils in machining, e.g., cotton seed [

25,

28,

29], coconut [

30,

31,

32,

33,

34,

35,

36,

37], soybean [

31,

33,

38,

39], canola [

31,

36,

37,

40], castor [

41,

42,

43,

44], palm [

43,

45,

46,

47], groundnut oil [

33,

43], and sunflower [

39,

42,

44].

1.2. Brief Review Regarding Use of Vegetable Oils in Machining

The state of the art in MQL-assisted hard turning presents few researches regarding usage of vegetable oils as cutting fluids. Chinchanikar et al. [

30] investigated the effect of cooling medium on surface roughness in hard turning of AISI 52100 (60–62 HRC) with water-based and coconut oil-based CFs. They used a coated carbide inserts and found that coconut oil produced lowers value of arithmetical mean roughness (Ra) specially at a cutting speed (Vc) between 160 and 200 m/min and depth of cut greater than 0.3 mm. At cutting speed lower than 160 m/min, dry turning was superior and the best surface roughness (Ra ≈ 0.5 μm) achieved also in dry. Gunjal and Patil [

31] experimentally studied the hard turning of AISI4340 (52–54 HRC) using vegetable oil-based CF under MQL, with coated carbide inserts. Canola oil, coconut oil, and soybean oil were used in experiments at an air pressure of 6 bar and fluid flow rate of 50 mL/h and the results showed that canola oil provided best results in terms of tool wear and tool life at cutting speed of 200 and 220 m/min, while at 240 m/min all three oils led to same tool life. However, the tools life was rather small (3–9 min). Xavior and Adithan [

32] analyzed the influence of coconut oil, on surface roughness and tool wear when turning AISI 304 steel with carbide insert, compared with soluble an straight oil and noticed that the coconut oil led to lower values of both. Feed was found to be most influencing factor on surface roughness with about 64% contribution followed by type of fluid and depth of cut with about 14%. Ghuge and Mahalle [

33] investigated the MQL (50 mL/h) turning of AISI 4130 with carbide insert, many types of vegetable, i.e., soybean, sunflower, coconut, and groundnut, dry and flood cooling, and reported that vegetable oil-assisted MQL provides lower cutting temperature and better surface roughness compared with dry and flood cooling. The best performance was achieved with soybean oil. Ananda Ghatge et al. [

35] studied the performance of coconut and neem oils in comparison with mineral oil in turning of AISI 2205 duplex stainless steels (32 HRC) at different cutting parameters and found that both vegetable oil-based cutting fluids are superior to mineral cutting fluid in terms of surface roughness an temperature. Padmini et al. [

36] compared under MQL condition the canola and coconut oil, pure and with nanoparticles, with dry and conventional cutting fluid in turning of AISI 1040 steel (30 HRC). Main cutting force, cutting temperature, tool wear and surface roughness were improved in MQL with vegetable oil; the coconut oil was found superior to canola oil. Padmini et al. [

37] investigated the machining performance of pure coconut, sesame oil, and canola oil compared with dry, conventional cutting fluid and nanofluids (fluid with inclusion of nanoparticle, e.g., molybdenum di sulphide, copper, alumina-oxide, or graphene added in a certain percentage), in turning of AISI 1040. The performance of pure oils was lower compared with nanofluids; however, in terms of cutting temperature and main cutting force, better results were obtained when vegetable oils were used compared to dry cutting or with conventional fluid. Raj et al. [

38] found that the soybean oil lead to lower cutting forces in MQL turning of AISI 4340 (45 HRC) compare with flood cooling even is vegetable or mineral oil flood cooling. Ghuge and Mahalle [

39] analyzed the MQL (50 mL/h) turning of 4130 with uncoated brazed carbide tool and with soybean oil, sunflower oil, and mineral-based cutting fluid and found that the use of vegetable oils have led to lower cutting force and power consumption with 7–9%. Belluco and De Chiffre [

40] analyzed the influence of rapeseed oil in drilling austenitic stainless steel 316L compared with commercial mineral oil-based under flood conditions. They used also some formulated oils containing rapeseed oil, ester oil, and meadow foam oil with sulphur and phosphor additives and found that all formulated oils and the simple rapeseed oil produced better results than the mineral reference oil in terms of tool life, thrust force, corner wear, and chip tangling around the tool. Elmunafi et al. [

41] conducted experiments to establish the influence of castor oil on surface roughness, forces and tool wear compared with dry turning of AISI 420 stainless steel (46–48 HRC) and shown that working under MQL with 50 mL/h flow rate, 5 bar air pressure and vegetable oil, the values obtained were improved. The Ra values obtained are in range 0.3–0.4 μm. Pereira et al. [

42] tried many types of oils, e.g., high-oleic sunflower, sunflower, castor, and recycled oil, in milling of Inconel 718. From a technical point of view, the high-oleic sun flower oil performed better than canola and simple sunflower oils, under MQL conditions. Suresh et al. [

43] performed desirability function analysis (DFA) and technique for order preference by similarity to an ideal solution (TOPSIS) to find the best the optimal process parameter setting. They turned under MQL condition AIDI D3 steel using three types of insert, three levels of cutting speed, feed, depth of cut, and cutting fluid (i.e., castor, palm and groundnut), and response variables measured were surface roughness, material removal rate, and specific energy. The authors found that by DFA the best CF is the groundnut oil and by TOPSIS the best CF is the castor oil. Cutting speed was the most significant parameter (≈46% contribution) followed by feed (≈32% contribution) and depth of cut, while cutting fluid and insert style were almost negligible. Khunt et al. [

44] analyzed the drilling of Aluminum-6063 alloy under dry, flood cooling and MQL conditions with castor and sunflower oil. They found that thrust force, torque and surface roughness are improved in MQL compared with the other two methods. Mahadi et al. [

45] reported that the boric acid aided in palm oil improve the surface roughness compared with conventional lubricant in MQL-assisted turning of AISI 431 (30 HRC) stainless steel. Rahim and Sasahara [

46] experimented the drilling of Inconel 718 with solid carbide drill under flood and MQL conditions, using water soluble CF, synthetic ester and palm oil for MQL. The palm oil it proved to be the best choice in this application since the lower temperature, thrust force, and torque were obtained under MQL with this oil. Same Rahim and Sasahara [

47] furthermore investigated the drilling of Ti–6Al–4V in same cooling conditions. Likewise, previous research of palm oil led to the best results, measuring the same characteristics. Last but not least, Gajrani et al. [

60] compared under MQL (0.5 MPa air pressure and oil flow rate of 35 mL/h) and flood cooling, a mineral oil and a vegetable oil-based CF in hard turning of AISI H13 (56 HRC) with tungsten carbide cutting insert. They reported that the vegetable oil-based eco-friendly bio-CF provide better results and significantly reduce cutting and feed force, friction coefficient, and surface roughness.

Most of the literature focuses on the study of machining soft materials with different types of vegetable oil. The existing literature slightly analyzed MQL-assisted hard turning of high hardness steels (hardness greater than 50 HRC) with commercial available (additive free) vegetable oil, while the corn oil and ceramic wiper inserts lack from researches. To fill this gap further research should be undergo and this paper aims to investigate these aspects with regard to surface roughness and tool wear and to contribute to the field.