Abstract

Direct laser deposition (DLD) is a promising additive technology that allows for the rapid and cheap production of metal parts of complex geometry in various sectors of mechanical engineering. Thick-walled metal structures occupy a significant part in mechanical engineering. The purpose of this study was to develop and test an algorithm for predicting the geometry of deposited multi-pass walls. To achieve this goal, the main interrelated processes involved in the formation of a multi-pass wall were described—the process of laser radiation propagation, the process of heat transfer and the process of bead formation. To construct the calculation algorithm, five characteristic types of beads are identified. For these five types, the features of the bead formation and the features of the laser radiation intensity distribution are described. The calculated data were verified. A good match of the calculated data with the geometry of the deposited walls from AISI321 steel, Inconel718 and Ti-6Al-4V alloys was obtained.

1. Introduction

The process of direct laser deposition is one of the types of additive manufacturing technologies that allows for the production parts of complex geometric shape [1] from various materials [2,3,4], due to melting and crystallization of the filler material under the action of laser radiation directly in the processing zone, in situ. The deposited parts can be divided into three groups: thin-walled parts [5] deposited in one pass, thick-walled parts [6] with a width of several passes and parts manufactured in a combined way. The presented work is devoted to the problem of deposition walls with a thickness of several passes.

Research in the field of modeling the shape of the deposited layers, in most cases, is devoted to a detailed description of the process of forming one bead, since the quality of subsequent beads depends on the optimization of the surfacing process of the first bead. Less often, there are works devoted to simulation of thin and thick walls.

A number of factors influence the formation of the deposited beads, which are caused by the presence of several interrelated processes: heat transfer in the deposition zone, hydrodynamics of the melt pool, gas dynamics of the gas-powder jet and shielding gas, melting and transfer of the filler material, etc.

In this paper, we consider only thermal processes during heating of the substrate, defined as a multi-pass wall. The type of material supplied, powder or wire, is not taken into account in this work, but the average amount of added material is determined.

The heating process of the base and filler material is initiated by laser radiation, usually defocused. Most often, a Gaussian beam model is used to describe the laser radiation intensity distribution [7,8,9,10,11,12,13,14]. There are variants of representing the beam as a sum of Gaussian beams of various modes [15]. Gaussian beam models are used not only to simulate the process of direct laser deposition; in Reference [16], such a model was used to simulate the SLM process.

The form of the laser radiation intensity distribution may have a different representation [9,10,11,12,13,17], and it may change depending on the slope of the surface [8], or the addition of coefficients characterizing the parameters of the material. In Reference [14], the intensity distribution of the laser beam was measured experimentally. Analysis of the variants of the equations for the laser radiation intensity distribution from various sources has shown that they are all mathematically similar, based on the law of two-dimensional normal distribution, but differ from each other by coefficients. In general, it can be written as follows:

where is the correlation coefficient, are mathematical expectations and are dispersion.

From analyzing modern methods and approaches to the calculation of temperature fields and the shape of the deposited beads, we can say that a significant part of the calculations is based on the use of mesh methods [10,11,12,13,14,15,16,17,18,19]. Mesh methods are often used for the joint solution of thermal and hydrodynamic problems. This approach has been applied in References [11,14,16,19]. In some works [7,8,9,20,21], analytical methods were used to calculate the temperature field and the shape of the cross-section of the deposited bead. For example, in Reference [8], an analytical formula was used to find the width of the melt pool; it includes the process parameters and the value of the physical properties of the material. As a rule, the shape of the bead is approximated by parabolic, ellipsoidal or sinusoidal curves. It is worth noting that studies using the same methodology may use different calculation schemes.

There are also other approaches; for example, the capillary theory was used to calculate the profile of the deposited bead in the study [9], artificial neural network technologies were used in the work [22] and the authors of Reference [13] used regression analysis for the same purpose.

2. Materials and Methods

2.1. Bead Formation Description

Since the formation of a massive element or a thick wall consists of a repetitive process of surfacing one layer, and the mechanism of formation of a single layer, in turn, consists of a repetitive process of surfacing one bead, then you should start building a model with the formation of a single bead.

The molten metal falling on the substrate surface is an axisymmetric meniscus of infinite length. Then, taking into account the capillary effects, in order to find the cross-sectional shape of the surface, it is necessary to solve the equation of the liquid phase equilibrium in the gravity field, linking the curvature of the bead profile and surface tension with hydrostatic pressure. We then use the approach used by the authors [23,24]:

where is the surface tension, is the melt density, is the acceleration of gravity, is the radius of the surface curvature at the calculation point and is the radius of the surface curvature at the origin. We then look for the solution of Equation (1) in dimensionless coordinates:

where is the capillary constant. By expressing the surface curvature of the bead profile at the calculation point through the derivatives of the function and using the Laplace capillary equation, we obtain the following:

The solution of Equation (1), according to Reference [24], has the following form:

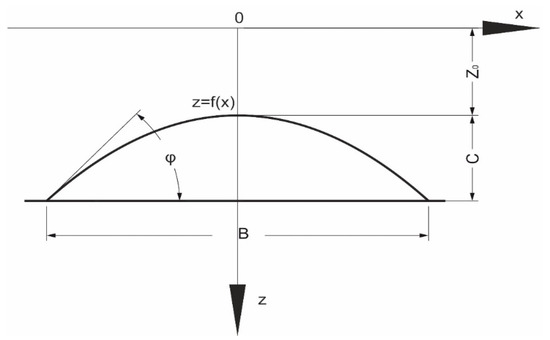

where is the distance from the top of the bead to the origin, and is the angle between the axis and the normal to the curve (Figure 1).

Figure 1.

Scheme for calculating the shape of the cross-section in case of deposition a single bead.

To determine the calculated parameters of the curve, we use a system of equations:

where is the height of the deposited bead, is the dimensionless width of the deposited bead, is the dimensionless cross-sectional area of the deposited bead and is the contact angle of wetting. and are, accordingly, the width and cross-sectional area of the bead. For the case of deposition on a flat surface and for subsequent cases, the cross-sectional area of the deposited bead, , can be easily calculated by knowing the velocity of the process and the feed rate of filler material. The width of the bead, , is determined by the solution of the heat transfer equation.

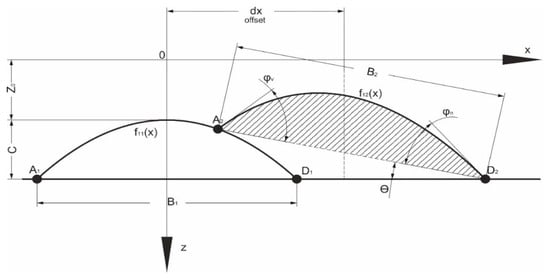

Let us now consider the case of deposition for a single layer. We will assume that, in the process of deposition, the layer is carried out sequentially—the beads are deposited one after the other. The general scheme of the deposition of the beads in the first layer is shown in Figure 2.

Figure 2.

Scheme for calculating the shape of the cross-section in the case of deposition subsequent beads in the first layer.

The area of the curved triangle AD1D2 is filled with molten metal and does not participate in the calculation, and the shape of the deposited roller is obtained from solving the problem of deposition on an inclined surface. Then, for the entire volume of molten metal per unit length of the bead, it can be determined as follows:

where is the volume of material involved in the formation of a bead on an inclined surface AD2, is the volume of whole molten material and is the volume of the material filling the curved triangle AD1D2.

According to References [25,26], the shape of the deposited bead on an inclined surface can be determined by Formula (4); however, the system of Equation (5) for determining the calculated parameters should take into account the angle of inclination of the surface A2D2 to the X-axis and transform to the following:

where is the angle between the straight line A2D2 and the X-axis, is the out-leakage angle and is the in-leakage angle (Figure 2).

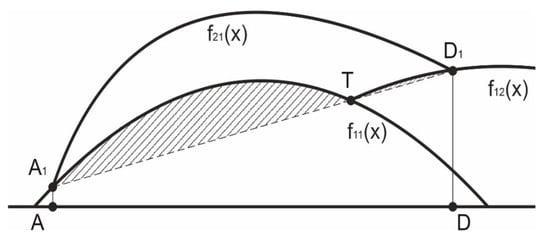

Consider the formation of subsequent layers. The process of forming subsequent layers is also cyclical and can be divided into three repeating parts—the deposition of the first bead, middle and last beads. Consider the first bead (Figure 3).

Figure 3.

The scheme of deposition of the first beads in subsequent layers.

The scheme of deposition on an inclined surface described above is used for calculating the shape of the first bead in case of deposition subsequent layers. However, in this case, in contrast to the case of surfacing in the first layer, the area marked in Figure 3 by hatching is taken into account in Expression (6) with the opposite sign. To find the hatched area, functions and are integrated in the range from A to T and from T to D, respectively. Knowing the coordinates of the deposited bead from the Expression (4), it is possible to construct a polynomial approximation of the order determined by the required accuracy. Then the area of the shaded zone Fadd from the Expression (6) can be determined as follows:

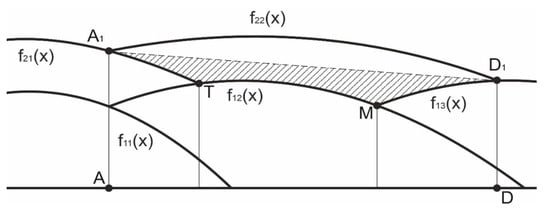

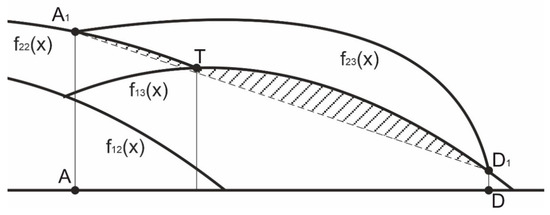

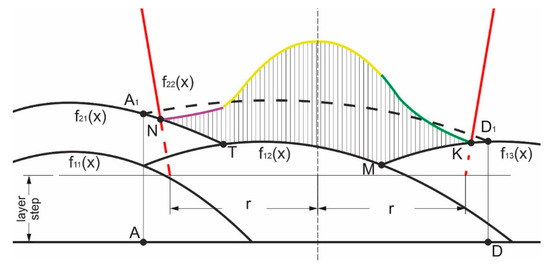

The calculation of the profile of the middle beads during the deposition in the second and subsequent layers occurs according to the scheme shown in Figure 4.

Figure 4.

Scheme of deposition of the middle beads in subsequent layers.

The calculation is again performed using the algorithm of deposition on an inclined surface, in case of deposition of the middle beads in the second and subsequent layers. In addition, during the calculation, the value of the cross-sectional area of the deposited bead is corrected—it is reduced by the amount of the hatched area. The hatched area is defined as the difference between the areas of the trapezoid AA1D1D and the sum of the integrals of functions , and in the range from A1 to T, from T to M and from M to D1.

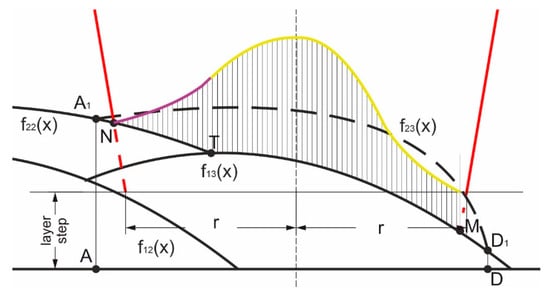

A general view of the scheme for calculating the shape of the last bead in deposition in the second and subsequent layers is shown in Figure 5.

Figure 5.

Scheme of deposition of the last beads in subsequent layers.

In deposition the last bead, the hatched area should be added to the already calculated cross-sectional area of the bead. The calculation should be made by the method for the shape of the bead on an inclined surface. The hatched area can be found as the difference of integrals of functions и in the range from A1 to T and from T to D1 and trapezoid AA1D1D.

2.2. Heat Transfer Model

The boundaries of the molten area of the substrate, which is involved in the formation of the beads, are determined from the solution of the thermal problem. At that, heat source is a laser beam for which the intensity distribution is approximated by the Gaussian beam model. According to Reference [27], the beam width at a distance z from the focus point is given as follows:

where is the wavelength, and is the beam waist.

The radiation intensity in the cross-section is described by the following expression:

where is the radius vector lying in a plane perpendicular to the axis of radiation propagation, and is the coordinate on the axis of radiation propagation with the origin in the waist of the beam.

Thus, by setting the distance between the focal plane and the spot position on the substrate, it is possible to obtain the size of the working spot and the corresponding shape of the laser radiation intensity distribution.

It is also worth considering that the laser energy is spent on heating the substrate, Esub and heating the filler material, Efiller:

The energy required to heat the filler material can be calculated by knowing the specific enthalpy of melting:

where is the specific enthalpy of melting of the filler material, and is the volume of material deposited per unit of time.

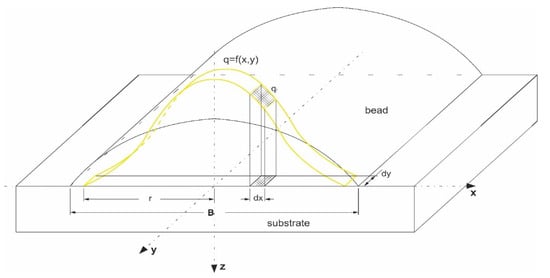

We divide the laser beam spot coverage on the substrate into elementary areas with a length and width of dx and dy, respectively. A point heat source, qi, operates on each elementary area. Then the total effect of the entire distributed source can be determined by integrating over the surface of the substrate within the spot (Figure 6).

Figure 6.

Heating scheme of deposition a single bead on a horizontal surface. —beam spot radius, —bead width.

Thus, in the first approximation, we do not take into account the dependence of the thermophysical coefficients on temperature, thus greatly simplify the calculation of the integral:

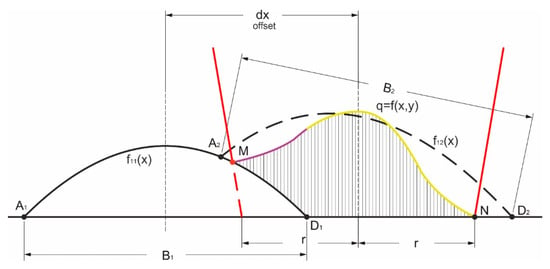

In the case of the deposition of the subsequent beads in the first layer, the shape of the surface on which the laser radiation falls (Figure 7) changes, and the formula for calculating the temperature field also changes.

Figure 7.

Heating scheme of deposition of subsequent beads in the first layer.

The red dotted lines show a change in the position of the extreme points of the incident laser radiation. The power, qi, per elementary area, dxdy, is determined in accordance with Expression (9). If you replace the z coordinate with the function f11(x) on the section A2D1, then integration over z is not required. Then Expression (12) is transformed into the following:

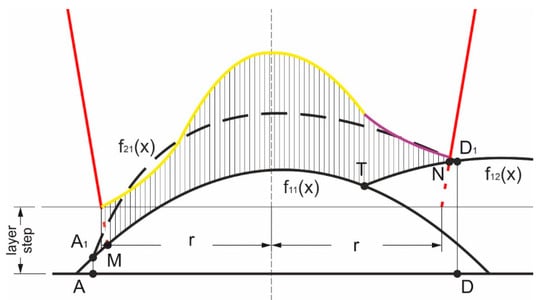

The next step is a bead-formation process in the second and subsequent layers. In these cases, a similar scheme for calculating the temperature field at individual sites is applied, followed by their combination. In this case, it is taken into account that the focal plane of the laser beam rises to the height specified by the technological parameter and is at some distance above the substrate (Figure 8). In forming the following layers, starting from the second, two options are possible for the position of the outer anchor points M of the edge beads to be determined: on the surface of the bead of the previous layer or beside it. The position of the point M is determined by the ratio between the size of the bead from the previous layer and the position of the laser spot on the surface under consideration.

Figure 8.

Heating scheme of deposition of the first bead on the second and subsequent layers.

The following expressions are used to calculate the temperature:

In the case of deposition of middle beads in the second and subsequent layers, the distribution of laser radiation intensity for surfacing is schematically shown in Figure 9.

Figure 9.

Heating scheme of deposition of middle beads on the second and subsequent layers.

In this case, the following formulas should be used to calculate temperatures:

The last case is the laser radiation intensity distribution during the deposition of the last beads in the second and subsequent layers (Figure 10).

Figure 10.

Heating scheme of deposition the last beads on the second and subsequent layers.

The following formulas should be used to calculate the temperature field:

2.3. Experiment Details

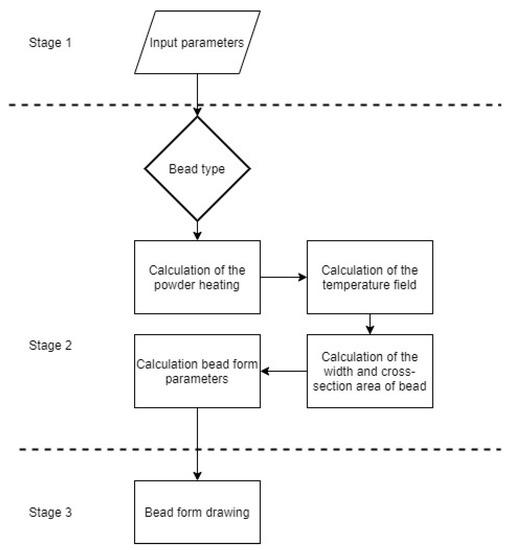

Thus, the above reasoning can be combined into a single algorithm, the flowchart of which is shown in Figure 11. It is worth noting that the procedure for calculating the shape of the bead in any of the cases considered has a repetitive character; the differences can be formalized through the parameters of the calculation functions.

Figure 11.

Flowchart of the algorithm for calculating one bead.

To verify the developed algorithm for calculating the deposited layers geometry during direct laser deposition of multi-passed walls, we used the results of the experiments on depositing model samples from various materials. The deposition parameters of the experiment are shown in Table 1. For all experiments, the layer step was 0.8 mm, the hatch spacing was 1.67 mm and the deposition strategy was unidirectional. The values of thermophysical and thermodynamic properties [28,29,30,31,32] of metals used for calculations are shown in Table 2.

Table 1.

Deposition parameters.

Table 2.

Material properties [28,29,30,31,32].

3. Results

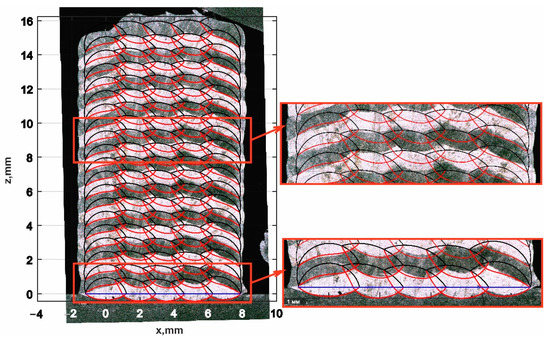

An example of a comparison of experimental and calculated data is shown in Figure 12. In Figure 12, black curves show the shapes of deposited beads, and red curves show the fusion zones. The experimental sample shown in Figure 12 is made of two different titanium alloys. Alternating layers of different titanium alloys give a contrasting image, which is very convenient for comparing calculations and experiments. As can be seen from Figure 12, the height of the calculated and experimental walls coincides. The exact coincidence of the melting zones was obtained on the first layer and on the extreme beads in subsequent layers. Although an error begins to accumulate from some layer, the overall calculation accuracy remains high. The difference in the width of the deposited and calculated wall is 5.57%, and in the height, it is 3.55%. The properties of Ti-6Al-4V alloy were used for the calculation. The properties of Ti-6Al-4V and CP alloys differ only at room temperature. When heated, the values of the thermophysical properties are equalized.

Figure 12.

Comparison of experimental and calculated data for Ti-6Al-4V/CP material. Velocity—20 mm/s, laser power—1900 W, bead diameter—2.5 mm, hatch spacing—1.67 mm, layer step 0.8 mm, deposition strategy—unidirectional, beads count—5 and layers count—20.

The results of comparing the calculated and experimental measured parameters of the walls—height and width—are summarized in Table 3. Axalit software (v3.5.1.b, Axalit, Moscow, Russia) was used for microstructural analysis.

Table 3.

Comparison of experimental and calculated data of beads.

The experimental mode shown in Figure 12 is excluded from the general comparison, due to differences in the material and the deposition mode (20 layers). However, the accuracy of the calculation for this sample coincides with the accuracy of the calculation of other samples.

4. Discussion

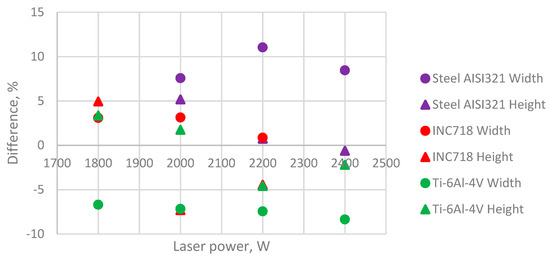

For a more convenient analysis of the results, the dependence of the measured values from the power of laser radiation was plotted. Generally, the difference between experimental and calculated data does not exceed 10% for all materials (Figure 13), indicating that the model parameters and calculation algorithms were correctly selected.

Figure 13.

Difference of calculated and experimental data at different laser powers.

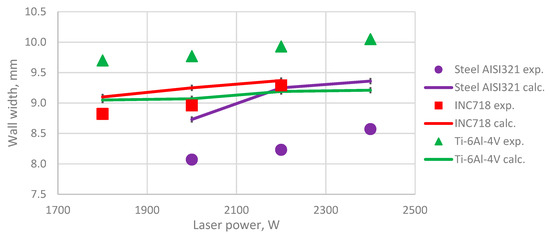

A comparison of the experimental and calculated values of the wall width (Figure 14) shows a slight difference between them, not more than 10 percent. The smallest deviation of the results is obtained for a nickel alloy. The calculation of the wall width for AISI 321 steel gives an overestimated result, and for Ti-6Al-4V titanium alloy, it is underestimated. Perhaps this is the result of varying degrees of dependence of the surface tension coefficient on temperature, which is not taken into account in the proposed model. The influence of the surface tension coefficient is especially strong when deposition titanium alloys. Due to the low surface tension coefficient of titanium, the outside beads drain and become distinctly wider (Figure 12).

Figure 14.

Width of the deposited and calculated walls at different laser powers.

The width of the deposited wall depends on the distribution of the intensity of laser radiation and the degree of its absorption by the material. Such a characteristic as the absorption coefficient of laser radiation varies depending on the temperature and composition of the atmosphere above the melt pool. With intense heating due to the evaporation of metal from the surface, the composition of the atmosphere changes, and this naturally also affects the transmission of laser radiation. Taking into account the influence of the evaporation process and the interaction of laser radiation with metal vapors is not part of the task of our study, but this could affect the accuracy of the calculation results. It is logical that the absorption capacity of metal vapors depends on the absorption coefficient of laser radiation by this metal. The higher the absorption coefficient of laser radiation, the greater the power loss when radiation passes through metal vapors. This can also explain the underestimated results of the calculation of the wall width for titanium and the overestimated results of the calculation for steel.

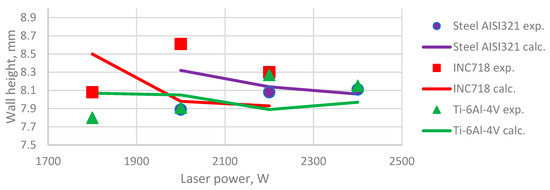

An even more accurate match was obtained when comparing the heights of the experimental and calculated walls for all materials (Figure 15). The calculation algorithm does not take into account the change in the material capture coefficient during the calculation. The addition of such an option helps to increase the accuracy of the calculation.

Figure 15.

Height of the deposited and calculated walls at different laser powers.

Despite the lack of consideration of the temperature dependence of the thermophysical and thermodynamic properties of materials, the calculation results based on the constructed model have high accuracy and make it possible to predict the geometry of the deposited walls. The change in the model material also does not affect the convergence of the calculation process. The constructed calculation algorithm is stable and can be used for various materials.

5. Conclusions

In this paper, a numerical estimation of the geometry of the deposited beads in multi-pass walls is presented. The Gaussian beam model was used as a model of laser radiation propagation. As in most studies, the chosen model provided a good match between the calculated and experimental data, despite the fact that, during the process, the real distribution may change under the influence of random external factors. To calculate the temperature fields, an analytical solution of the heat equation in a quasi-stationary formulation (in the form of Green’s functions) was used. The shape of the deposited beads was described by using the capillary theory. Five repetitive types of beads used in wall deposition are identified.

Experimental verification of the presented model was carried out on samples deposited from various materials. A good agreement of the calculation results with the experimental data was obtained. The algorithm takes into account the physical features of the DLD process, can predict the geometry of multi-pass walls with high accuracy (difference no more than 10%) and can serve as a tool when choosing technological parameters of deposition.

Author Contributions

Conceptualization, E.V.; methodology, I.U. and E.V.; software, I.U. and E.V.; validation, N.K. and I.U.; formal analysis, E.V.; investigation, E.V., N.K. and I.U.; resources, I.U.; data curation, N.K. and I.U.; writing—original draft preparation, I.U. and E.V.; writing—review and editing, I.U. and E.V.; visualization N.K. and I.U.; supervision, E.V.; project administration E.V.; funding acquisition, E.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ministry of Science and Higher Education of the Russian Federation as part of the World-Class Research Center Program: Advanced Digital Technologies (Contract No. 075-15-2020-903, dated 16 November 2020).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Turichin, G.A.; Klimova, G.; Zemlyakov, V.; Babkin, K.D.; Kolodyazhnyy, D.Y.; Shamray, A.; Travyanov, A.Y.; Petrovskiy, P.V. Technological aspects of high speed direct laser deposition based on heterophase powder metallurgy. Phys. Procedia 2015, 78, 397–406. [Google Scholar] [CrossRef] [Green Version]

- Mendagaliyev, R.; Turichin, G.A.; Klimova-Korsmika, O.G.; Zotov, O.G.; Eremeeva, A.D. Microstructure and mechanical properties of laser metal deposited cold-resistant steel for arctic application. Procedia Manuf. 2019, 36, 249–255. [Google Scholar] [CrossRef]

- Magerramova, L.A.; Turichin, G.A.; Nozhnitsky, Y.A.; Klimova-Korsmik, O.G.; Vasiliev, B.E.; Volkov, M.E.; Salnikov, A.V. Peculiarities of additive technologies application in the production of gas turbine engine parts. In Proceedings of the 9th International Conference on Beam Technologies and Laser Application, Saint Petersburg, Russia, 17–19 September 2018. [Google Scholar]

- Rashkovets, M.; Nikulina, A.; Turichin, G.; Klimova-Korsmik, O.; Sklyar, M. Microstructure and phase composition of Ni-based alloy obtained by high-speed direct laser deposition. J. Mater. Eng. Perform. 2018, 27, 6398–6406. [Google Scholar] [CrossRef]

- Turichin, G.; Zemlyakov, E.; Babkin, K.; Ivanov, S.; Vildanov, A. Analysis of distortion during laser metal deposition of large parts. Procedia CIRP 2018, 74, 154–157. [Google Scholar] [CrossRef]

- Korsmik, R.; Tsybulskiy, I.; Rodionov, A.; Klimova-Korsmik, O.; Gogolukhina, M.; Ivanov, S.; Zadykyan, G.; Mendagaliev, R. The approaches to design and manufacturing of large-sized marine machinery parts by direct laser deposition. Procedia CIRP 2020, 94, 298–303. [Google Scholar] [CrossRef]

- Ansari, M.; Martinez-Marchese, A.; Huang, Y.; Toyserkani, E. A mathematical model of laser directed energy deposition for process mapping and geometry prediction of Ti-5553 single-tracks. Materialia 2020, 12, 100710. [Google Scholar] [CrossRef]

- Wang, D.; Li, T.; Shi, B.; Wang, H.; Xia, Z.; Cao, M.; Zhang, X. An analytical model of bead morphology on the inclined substrate in coaxial laser cladding. Surf. Coat. Technol. 2021, 410, 126944. [Google Scholar] [CrossRef]

- Li, J.; Li, H.N.; Liao, Z.; Axinte, D. Analytical modelling of full single-track profile in wire-fed laser cladding. J. Mater. Process. Technol. 2021, 290, 116978. [Google Scholar] [CrossRef]

- Knapp, G.L.; Mukherjee, T.; Zuback, J.S.; Wei, H.L.; Palmer, T.A.; De, A.; DebRoy, T. Building blocks for a digital twin of additive manufacturing. Acta Mater. 2017, 135, 390–399. [Google Scholar] [CrossRef]

- Chai, Q.; Fang, C.; Hu, J.; Xing, Y.; Huang, D. Cellular automaton model for the simulation of laser cladding profile of metal alloys. Mater. Des. 2020, 195, 109033. [Google Scholar] [CrossRef]

- Nie, Z.; Wang, G.; McGuffin-Cawley, J.D.; Narayanan, B.; Zhang, S.; Schwam, D.; Kottman, M.; Rong, Y.K. Experimental study and modeling of H13 steel deposition using laserhot-wire additive manufacturing. J. Mater. Process. Technol. 2016, 235, 171–186. [Google Scholar] [CrossRef]

- Caiazzo, F.; Alfieri, V. Simulation of laser-assisted directed energy deposition of aluminum powder: Prediction of geometry and temperature evolution. Materials 2019, 12, 2100. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhong, C.; Pirch, N.; Gasser, A.; Poprawe, R.; Schleifenbaum, J.H. The influence of the powder stream on high-deposition-rate laser metal deposition with inconel 718. Metals 2017, 7, 443. [Google Scholar] [CrossRef] [Green Version]

- Kovalev, O.; Bedenko, D.; Zaitsev, A. Development and application of laser cladding modeling technique: From coaxial powder feeding to surface deposition and bead formation. Appl. Math. Model. 2018, 57, 339–359. [Google Scholar] [CrossRef]

- Gu, H.; Wei, C.; Li, L.; Han, Q.; Setchi, R.; Ryan, M.; Li, Q. Multi-physics modelling of molten pool development and track formation in multi-track, multi-layer and multi-material selective laser melting. Int. J. Heat Mass Transf. 2020, 151, 119458. [Google Scholar] [CrossRef]

- Panda, B.K.; Sarkar, S.; Nath, A.K. 2D thermal model of laser cladding process of Inconel 718. Mater. Today Proc. 2021, 41, 286–291. [Google Scholar] [CrossRef]

- Wei, H.; Liu, F.; Liao, W.; Liu, T. Prediction of spatiotemporal variations of deposit profiles and inter-track voids during laser directed energy deposition. Addit. Manuf. 2020, 34, 101219. [Google Scholar] [CrossRef]

- Paes, L.E.D.S.; Ferreira, H.S.; Pereira, M.; Xavier, F.A.; Weingaertner, W.L.; Vilarinho, L.O. Modeling layer geometry in directed energy deposition with laser for additive manufacturing. Surf. Coat. Technol. 2021, 409, 126897. [Google Scholar] [CrossRef]

- Liu, J. Formation of cross-sectional profile of a clad bead in coaxial laser cladding. Opt. Laser Technol. 2007, 39, 1532–1536. [Google Scholar] [CrossRef]

- Liu, F.; Wei, L.; Shi, S.; Wei, H. On the varieties of build features during multi-layer laser directed energy deposition. Addit. Manuf. 2020, 36, 101491. [Google Scholar] [CrossRef]

- Karmuhilan, M.; Sood, A.K. Intelligent process model for bead geometry prediction in WAAM. Mater. Today Proc. 2018, 5, 24005–24013. [Google Scholar] [CrossRef]

- Berezovsky, B.M.; Stikhin, V.A. Influence of surface tension forces on the formation of weld reinforcement. Sverochnoe Proizvodstvo (Weld. Prod.) 1977, 1, 51–53. [Google Scholar]

- Matsunawa, A.; Ohji, T. Role of surface tension in fusion welding (Part 1). Trans. JWRI 1982, 11, 145–154. [Google Scholar]

- Berezovsky, B.M. Optimization of metal layer formation during arc surfacing. Weld. Prod. 1990, 6, 33–36. [Google Scholar]

- Berezovsky, B.M.; Stikhin, V.A. Mathematical modeling of the formation of horizontal seams on an inclined plane. Avtom. Svarka (Autom. Weld.) 1988, 1, 26–31. [Google Scholar]

- Korolenko, P.V. Coherent Radiation Optics; Lomonosov Moscow State University Faculty of Physics: Moscow, Russia, 1997. [Google Scholar]

- Li, Z.; Xu, R.; Zhang, Z.; Kucukkoc, I. The influence of scan length on fabricating thin-walled components in selective laser melting. Int. J. Mach. Tools Manuf. 2018, 126, 1–12. [Google Scholar] [CrossRef]

- Sainte-Catherine, C.; Jeandin, M.; Kechemair, D.; Ricaud, J.P.; Sabatier, L. Study of dynamic absorptivity at 10.6 μm (CO2) and 1.06 μm (Nd-YAG) wavelengths as a function of temperature. J. Phys. Proc. EDP Sci. 1991, 1, 151–157. [Google Scholar]

- Kim, S.S. Thermophysical Properties of Stainless Steels; Argonne National Laboratory: Lemont, IL, USA, 1976.

- Xie, J. Laser welding of thin sheet steel with surface oxidation. Weld. J. 1999, 78, 343. [Google Scholar]

- Valencia, J.J.; Quested, P.N. Thermophysical Properties ASM Handbook; Volume 15: Casting; ASM Press: Washington, DC, USA, 2008; pp. 468–481. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).