Influence of LPBF-Surface Characteristics on Fatigue Properties of Scalmalloy®

Abstract

:1. Introduction

2. Materials and Methods

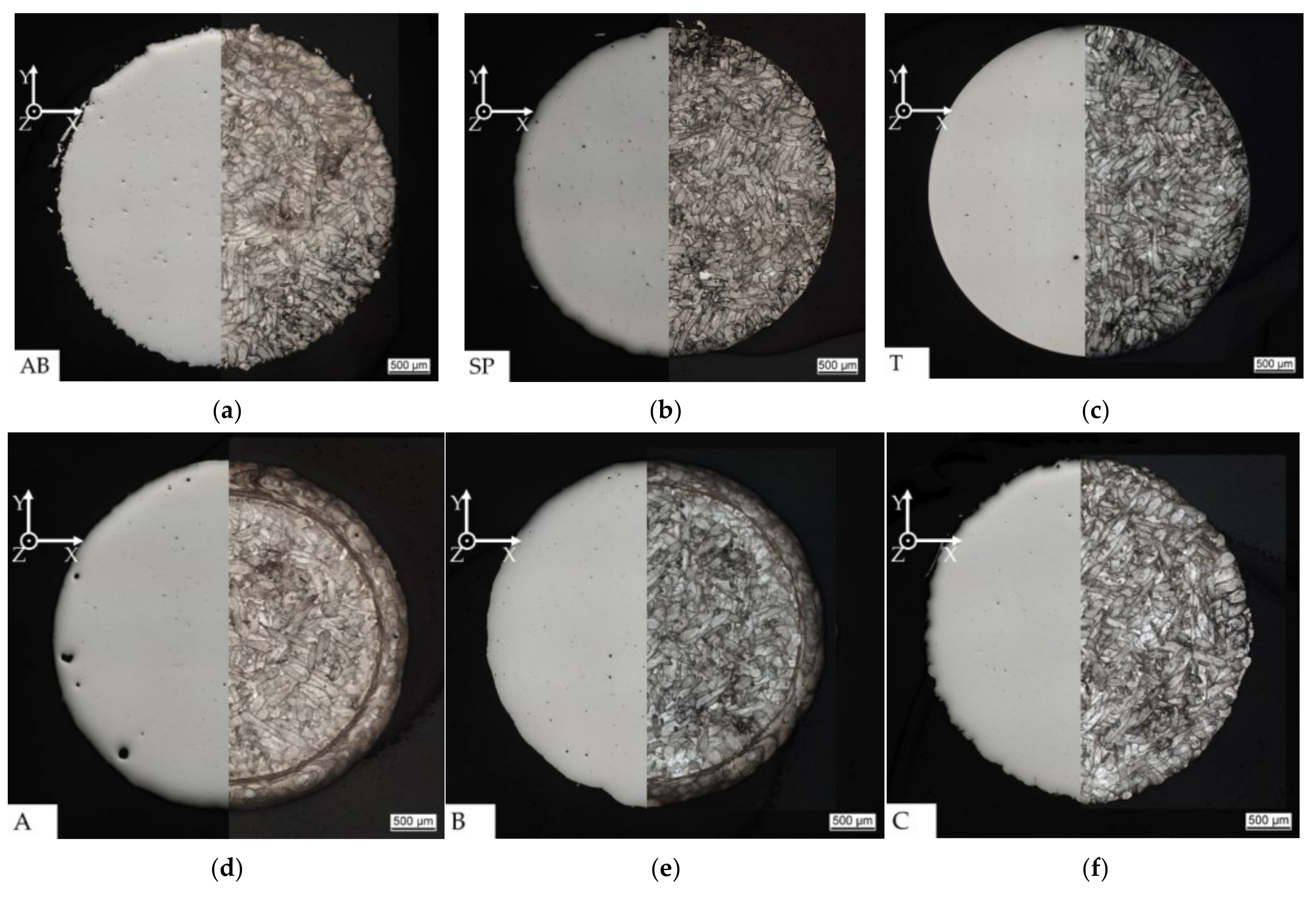

- Contour A: the lowest overall roughness of Ra < 7 μm (Rz < 55 μm) can be attained by applying a post-contour with a high line energy in the range of EL = 0.9 J/mm. The high line energy has a negative effect on the formation of keyhole pores, which start to form in the EL-range between 0.6 J/mm and 0.75 J/mm. For contour A, a second contour scan with a lower line energy of EL = 0.55 J/mm2 was applied with an offset to the first contour of 120%, which means a shift towards the inside of the sample.

- Contour B: the lowest roughness of Ra < 9.8 μm (Rz = 65.2 μm) utilizing a contour parameter set with no significant increase in contour porosity is achieved when using a pre-contour with EL = 0.6 J/mm and oci = 50%. Isolated larger pores can be detected in the area of the vertical specimen edge.

- Contour C: A reduction of roughness in the range of low line energies EL < 0.14 J/mm can be achieved by using a pre-contour. The lowest roughness Ra = 12.3 µm (Rz = 78.4 µm) is obtained at EL = 0.07 J/mm in combination with oci = 50%.

3. Results

3.1. Quasistatic Tests

3.2. Metallographic and Porosity Analysis

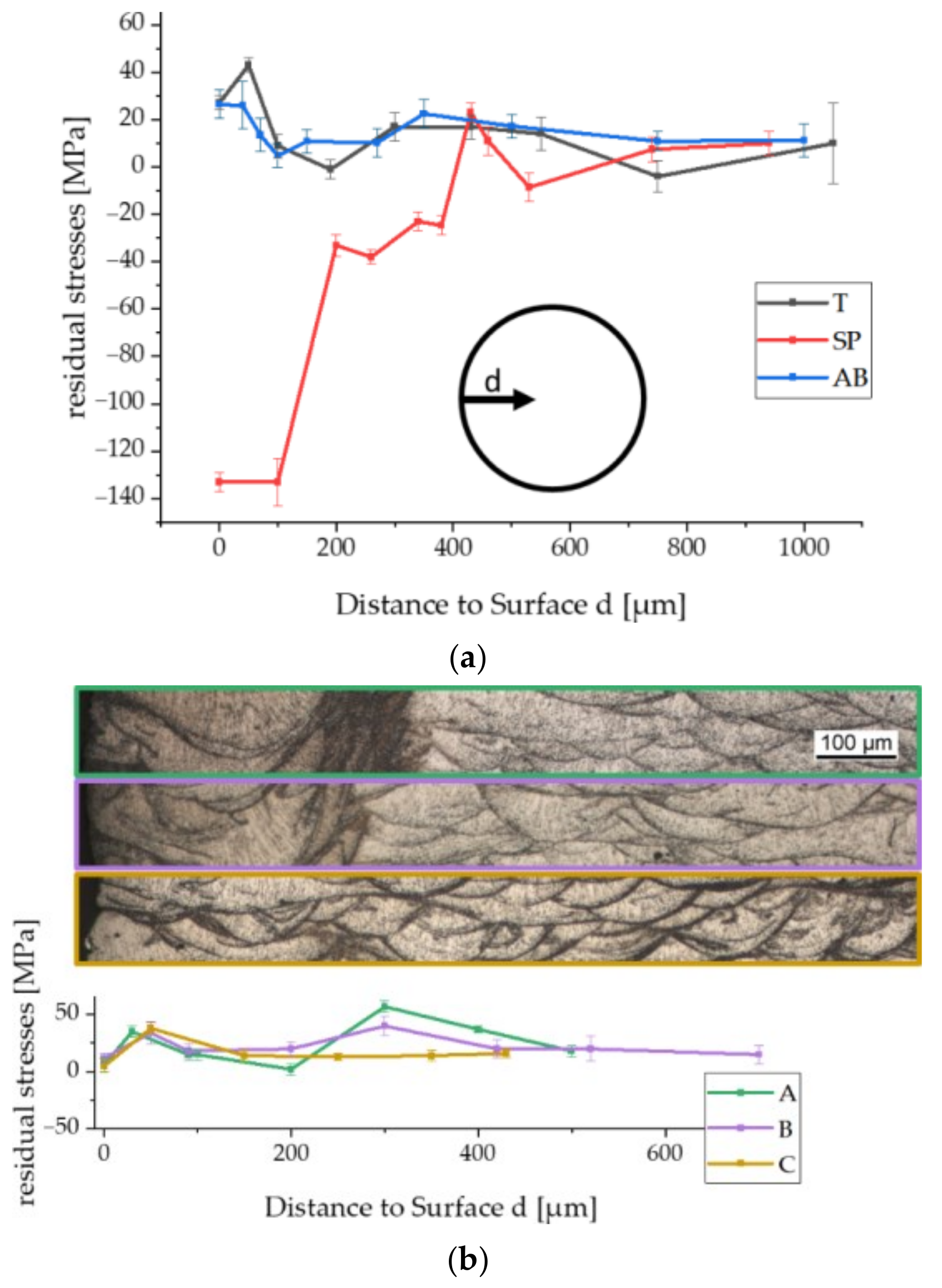

3.3. Residual Stress Analysis

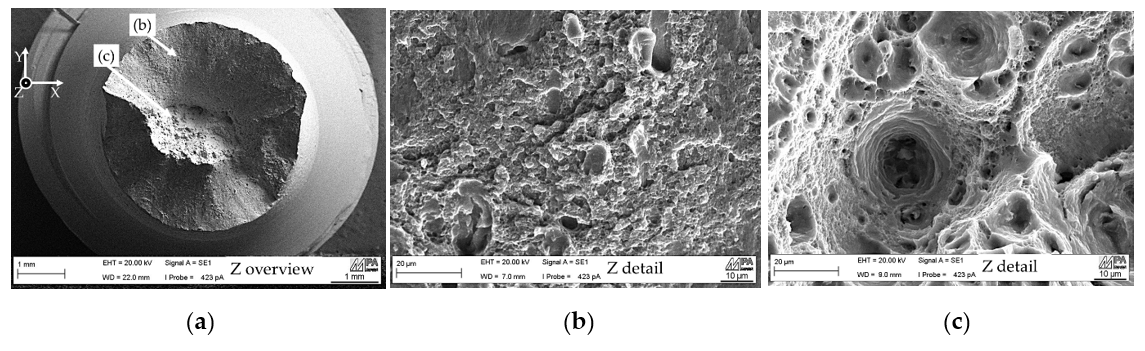

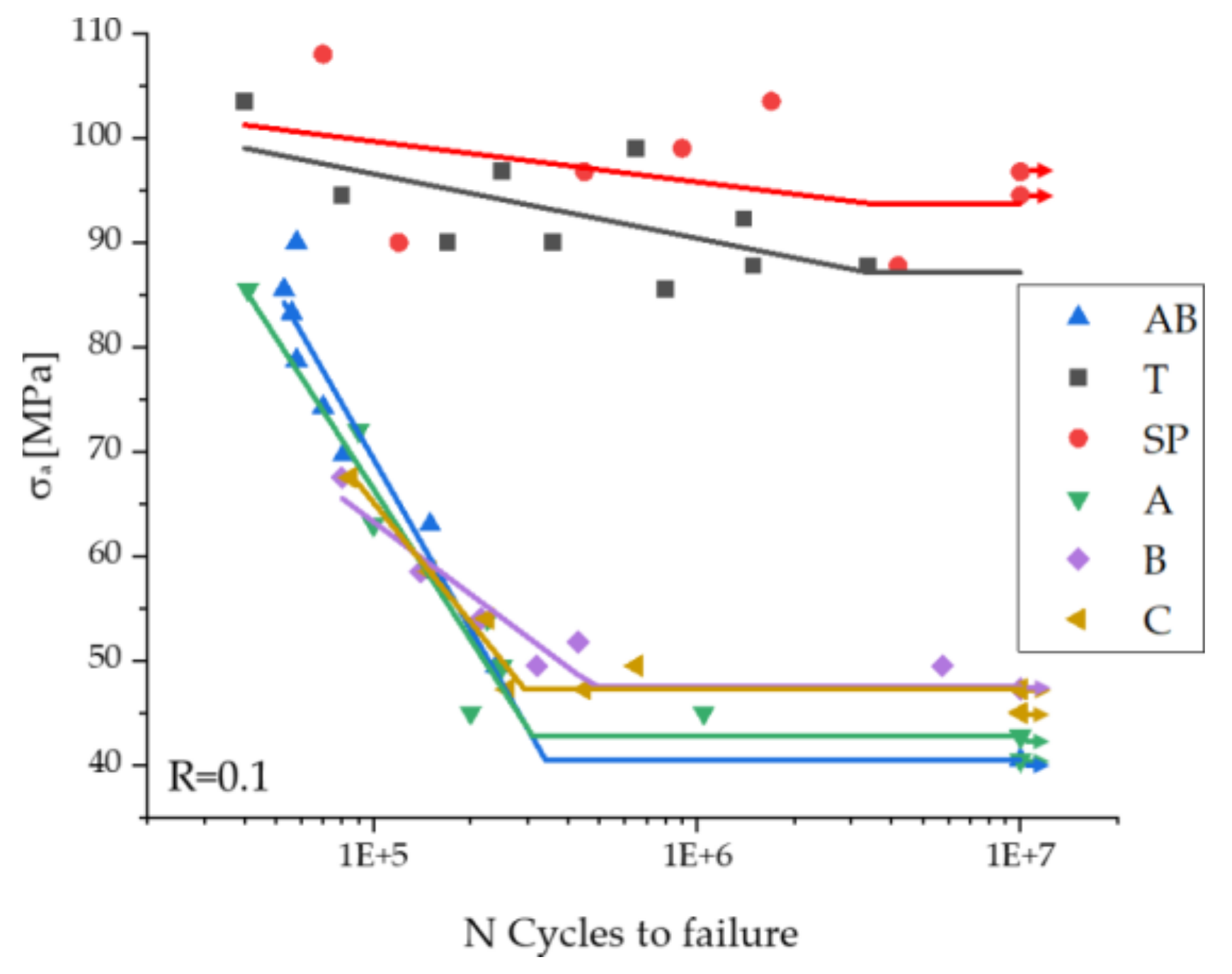

3.4. Fatigue Investigations

4. Conclusions

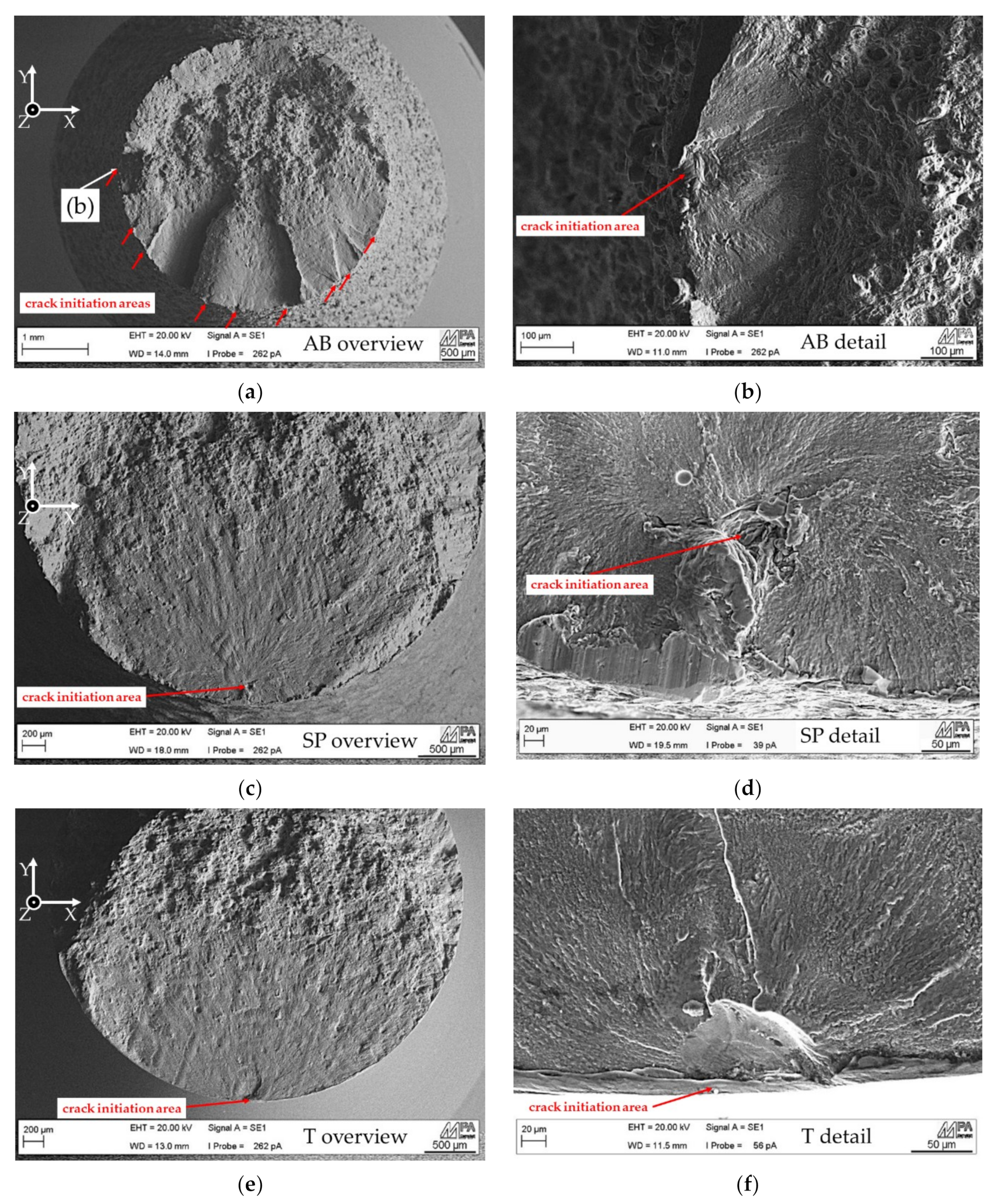

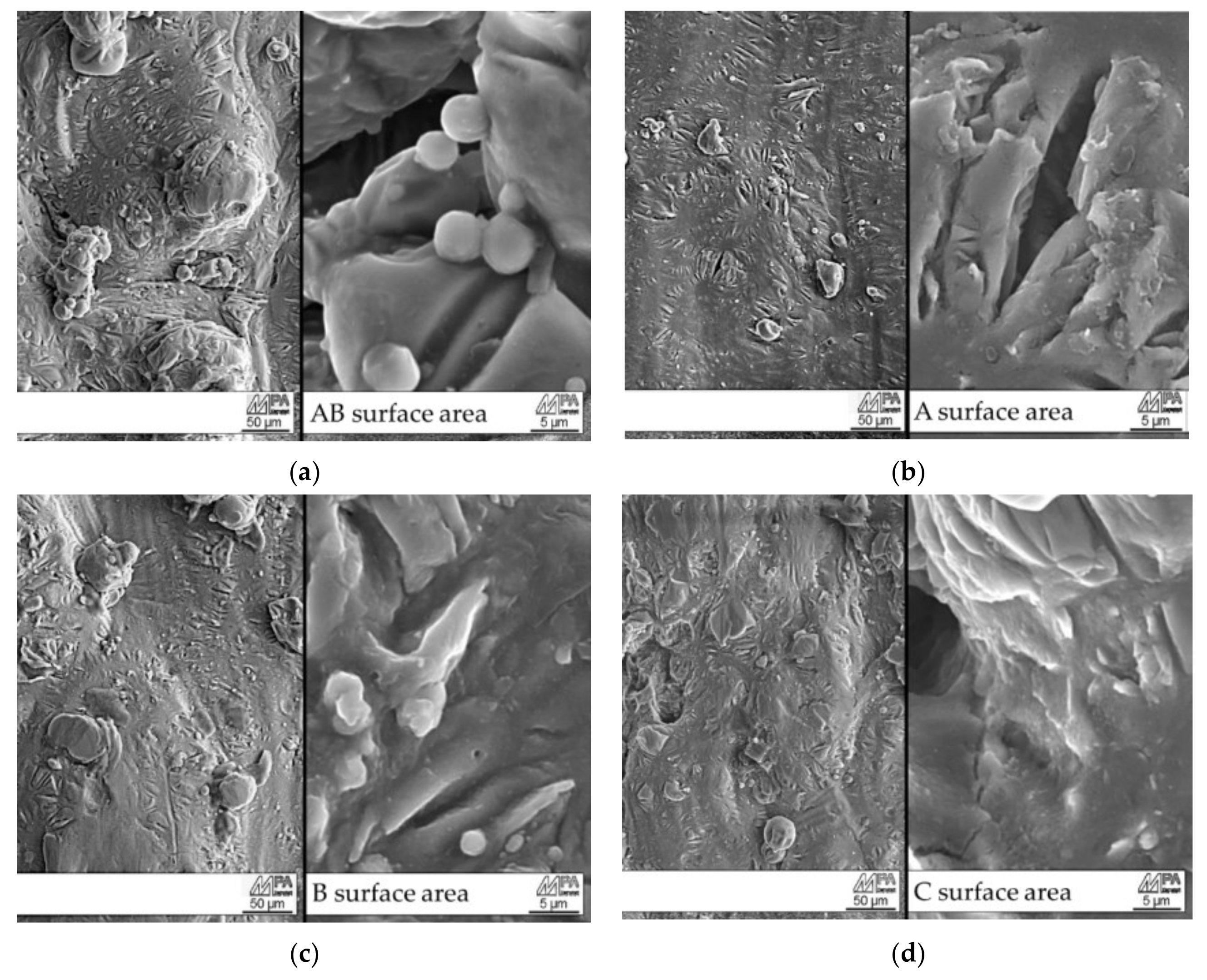

- Compared to the as-built surface state that only had infill parameters, the post processing steps using shot peening and turning increases the fatigue strength by a factor >2. In contrast, the use of contour parameters improves fatigue properties by only around 10 to 20% in comparison to the as-built state.

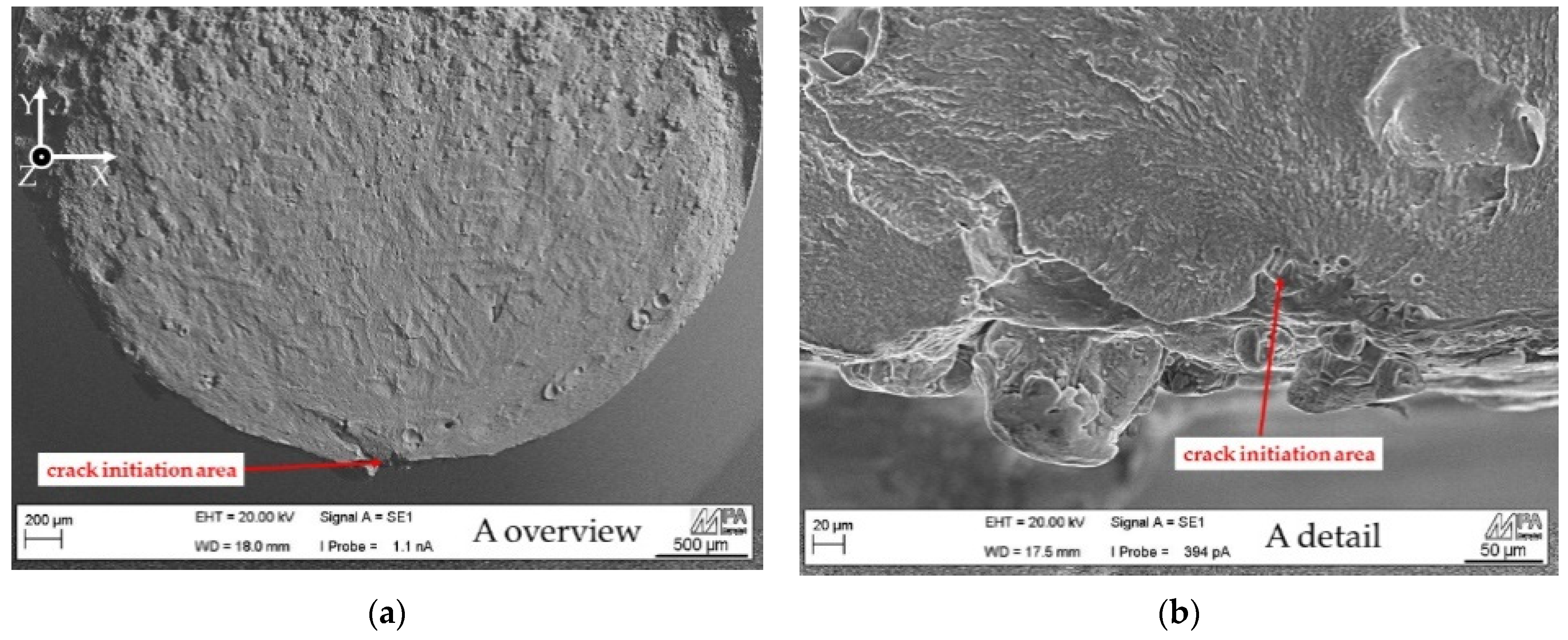

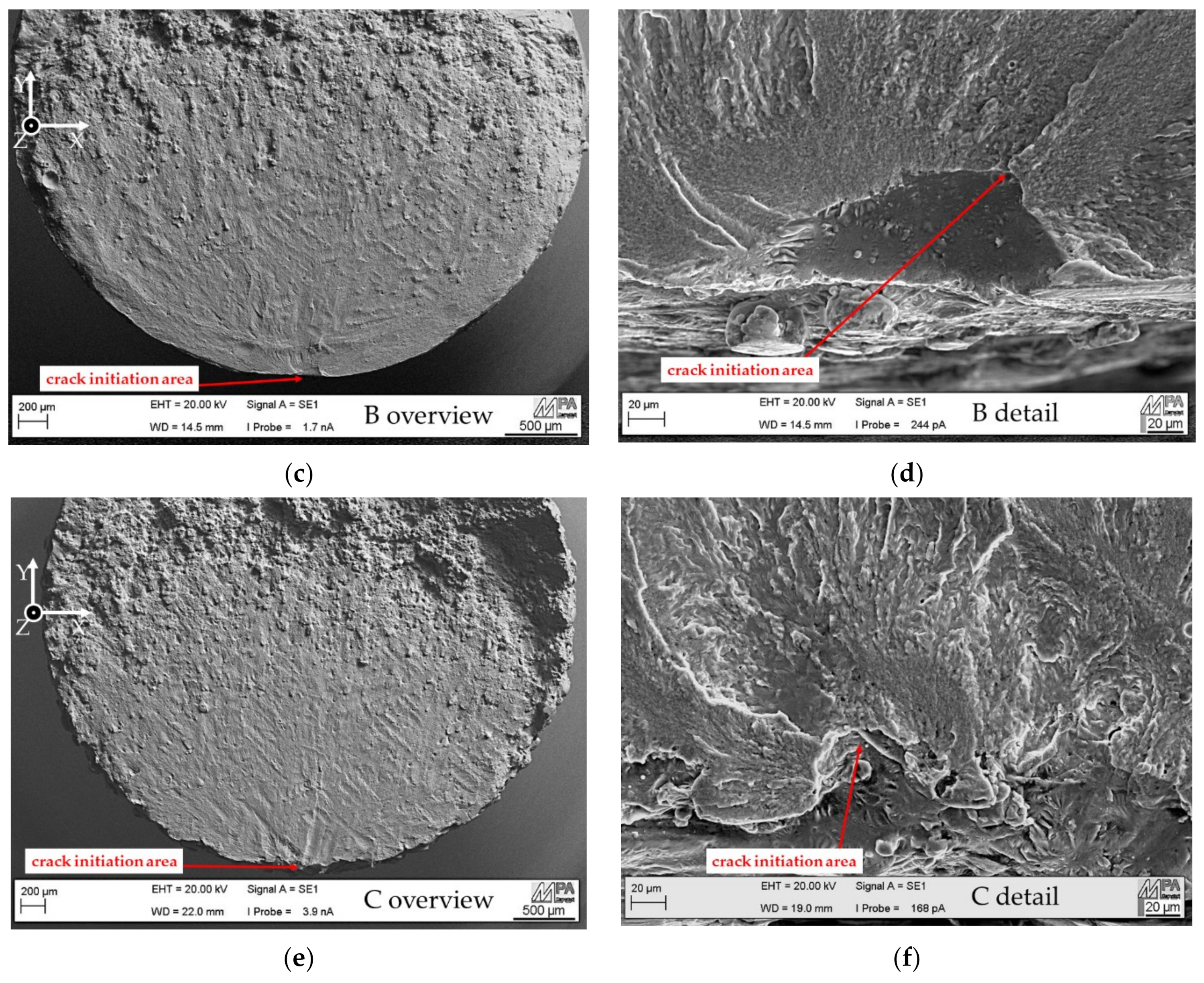

- Crack initiation on contour-parameter specimens occur on sharp, microscopic notches at the surface together with high tensile residual stresses. Even subsurface pores induced by a contour scan in keyhole-welding-mode do not change the crack initiation area at the surface.

- A contour scan with low line energy results in the same fatigue strength as a contour scan with medium line energy, despite the higher roughness, because the overall porosity, even in the surface area, is lowest, which results in less supporting crack initiation areas in combination with the sharp notches.

- Shot peened and turned specimens show comparable fatigue behaviours, despite the higher roughness of shot peened specimens: This disadvantage is compensated by the induced compressive residual stresses at the surface, which lowers the tendency for crack initiation at the surface and shifts the crack initiation area into the specimen.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gebhardt, A. Additive Fertigungsverfahren: Additive Manufacturing und 3D-Drucken für Prototyping—Tooling—Produktion, 5th ed.; Hanser: München, Germany, 2016; ISBN 9783446445390. [Google Scholar]

- Richard, H.A.; Schramm, B.; Zipsner, T. Additive Fertigung von Bauteilen und Strukturen; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2017. [Google Scholar]

- Zhai, Y.; Lados, D.A.; LaGoy, J.L. Additive Manufacturing: Making Imagination the Major Limitation. JOM 2014, 66, 808–816. [Google Scholar] [CrossRef] [Green Version]

- Wits, W.W.; Weitkamp, S.J.; van Es, J. Metal Additive Manufacturing of a High-pressure Micro-pump. Procedia CIRP 2013, 7, 252–257. [Google Scholar] [CrossRef] [Green Version]

- Meyer, J. Scalmalloy® is too expensive and design optimisation only makes sense in aerospace. True or false? Metal AM 2019, 5, 127–135. [Google Scholar]

- Ding, Y.; Muñiz-Lerma, J.A.; Trask, M.; Chou, S.; Walker, A.; Brochu, M. Microstructure and mechanical property considerations in additive manufacturing of aluminum alloys. MRS Bull. 2016, 41, 745–751. [Google Scholar] [CrossRef]

- Community Research and Development Information Service. research*eu: Selective Laser Melting for Aluminium Alloys, 57th ed.; Community Research and Development Information Service, Ed.; CORDIS: Luxembourg, 2016; ISBN 1977-4028. [Google Scholar]

- Palm, F.; Leuschner, R.; Schubert, T.; Kieback, B. Scalmalloy® = A Unique High Strength AlMgSc Type Material Concept Processed by Innovative Technologies for Aerospace Applications. In Proceedings of the World Powder Metallurgy Congress and Exhibition, World PM 2010, Florence, Italy, 10–14 October 2010. [Google Scholar]

- Koutny, D.; Skulina, D.; Pantělejev, L.; Paloušek, D.; Lenczowski, B.; Palm, F.; Nick, A. Processing of Al-Sc aluminum alloy using SLM technology. Procedia CIRP 2018, 74, 44–48. [Google Scholar] [CrossRef]

- Spierings, A.B.; Dawson, K.; Heeling, T.; Uggowitzer, P.J.; Schäublin, R.; Palm, F.; Wegener, K. Microstructural features of Sc- and Zr-modified Al-Mg alloys processed by selective laser melting. Mater. Des. 2017, 115, 52–63. [Google Scholar] [CrossRef]

- Schmidtke, K.; Palm, F.; Hawkins, A.; Emmelmann, C. Process and Mechanical Properties: Applicability of a Scandium modified Al-alloy for Laser Additive Manufacturing. Phys. Procedia 2011, 12, 369–374. [Google Scholar] [CrossRef] [Green Version]

- Rometsch, P.; Jia, Q.; Yang, K.; Wu, X. Aluminum alloys for selective laser melting—towards improved performance. In Additive Manufacturing for the Aerospace Industry; Froes, F.H., Boyer, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 301–325. ISBN 9780128140628. [Google Scholar]

- Davydov, V.G.; Elagin, V.I.; Rostova, T.D. Alloying aluminum alloys with scandium and zirconium additives. Nonferrous Met. Alloys 1996, 38, 347–352. [Google Scholar] [CrossRef]

- Zakharov, V.V. Effect of Scandium on the Structure and Properties of Aluminum Alloys. Met. Sci. Heat Treat. 2003, 45, 246–253. [Google Scholar] [CrossRef]

- Dahle, A.K.; Lee, Y.C.; Nave, M.D.; Schaffer, P.L.; StJohn, D.H. Development of the as-cast microstructure in magnesium-aluminium alloys. J. Light Met. 2001, 1, 61–72. [Google Scholar] [CrossRef]

- Schmidtke, K. Qualification of SLM: Additive Manufacturing for Aluminium; TUHH Universitätsbibliothek: Hamburg, Germany, 2020. [Google Scholar]

- Awd, M.; Tenkamp, J.; Hirtler, M.; Siddique, S.; Bambach, M.; Walther, F. Comparison of Microstructure and Mechanical Properties of Scalmalloy® Produced by Selective Laser Melting and Laser Metal Deposition. Materials 2017, 11, 17. [Google Scholar] [CrossRef] [Green Version]

- Spierings, A.B. Powder Spreadability and Characterization of Sc- and Zr-Modified Aluminium Alloys Processed by Selective Laser Melting: Quality Management System for Additive Manufacturing; ETH Zurich: Zurich, Switzerland, 2018. [Google Scholar]

- Shi, Y.; Rometsch, P.; Yang, K.; Palm, F.; Wu, X. Characterisation of a novel Sc and Zr modified Al–Mg alloy fabricated by selective laser melting. Mater. Lett. 2017, 196, 347–350. [Google Scholar] [CrossRef]

- Hamidi Nasab, M.; Giussani, A.; Gastaldi, D.; Tirelli, V.; Vedani, M. Effect of Surface and Subsurface Defects on Fatigue Behavior of AlSi10Mg Alloy Processed by Laser Powder Bed Fusion (L-PBF). Metals 2019, 9, 1063. [Google Scholar] [CrossRef] [Green Version]

- Thijs, L.; Kempen, K.; Kruth, J.-P.; van Humbeeck, J. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef] [Green Version]

- Yang, K.V.; Rometsch, P.; Jarvis, T.; Rao, J.; Cao, S.; Davies, C.; Wu, X. Porosity formation mechanisms and fatigue response in Al-Si-Mg alloys made by selective laser melting. Mater. Sci. Eng. A 2018, 712, 166–174. [Google Scholar] [CrossRef]

- Yang, T.; Liu, T.; Liao, W.; MacDonald, E.; Wei, H.; Chen, X.; Jiang, L. The influence of process parameters on vertical surface roughness of the AlSi10Mg parts fabricated by selective laser melting. J. Mater. Process. Technol. 2019, 266, 26–36. [Google Scholar] [CrossRef]

- Maamoun, A.H.; Xue, Y.F.; Elbestawi, M.A.; Veldhuis, S.C. Effect of Selective Laser Melting Process Parameters on the Quality of Al Alloy Parts: Powder Characterization, Density, Surface Roughness, and Dimensional Accuracy. Materials 2018, 11, 2343. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, T.; Liu, T.; Liao, W.; Wei, H.; Zhang, C.; Chen, X.; Zhang, K. Effect of processing parameters on overhanging surface roughness during laser powder bed fusion of AlSi10Mg. J. Manuf. Process. 2021, 61, 440–453. [Google Scholar] [CrossRef]

- Chen, Z.; Cao, S.; Wu, X.; Davies, C.H.J. Surface roughness and fatigue properties of selective laser melted Ti–6Al–4V alloy. In Additive Manufacturing for the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2019; pp. 283–299. [Google Scholar] [CrossRef]

- Beretta, S.; Gargourimotlagh, M.; Foletti, S.; Du Plessis, A.; Riccio, M. Fatigue strength assessment of “as built” AlSi10Mg manufactured by SLM with different build orientations. Int. J. Fatigue 2020, 139, 105737. [Google Scholar] [CrossRef]

- Kruth, J.P.; Froyen, L.; van Vaerenbergh, J.; Mercelis, P.; Rombouts, M.; Lauwers, B. Selective laser melting of iron-based powder. J. Mater. Process. Technol. 2004, 149, 616–622. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Bertrand, P.; Smurov, I. Parametric analysis of the selective laser melting process. Appl. Surf. Sci. 2007, 253, 8064–8069. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Gusarov, A.; Yadroitsava, I.; Smurov, I. Single track formation in selective laser melting of metal powders. J. Mater. Process. Technol. 2010, 210, 1624–1631. [Google Scholar] [CrossRef]

- Gouveia, R.M.; Silva, F.J.G.; Atzeni, E.; Sormaz, D.; Alves, J.L.; Pereira, A.B. Effect of Scan Strategies and Use of Support Structures on Surface Quality and Hardness of L-PBF AlSi10Mg Parts. Materials 2020, 13, 2248. [Google Scholar] [CrossRef]

- Fiegl, T.; Franke, M.; Körner, C. Impact of build envelope on the properties of additive manufactured parts from AlSi10Mg. Opt. Laser Technol. 2019, 111, 51–57. [Google Scholar] [CrossRef]

- Strano, G.; Hao, L.; Everson, R.M.; Evans, K.E. Surface roughness analysis, modelling and prediction in selective laser melting. J. Mater. Process. Technol. 2013, 213, 589–597. [Google Scholar] [CrossRef]

- Murakami, Y.; Masuo, H.; Tanaka, Y.; Nakatani, M. Defect Analysis for Additively Manufactured Materials in Fatigue from the Viewpoint of Quality Control and Statistics of Extremes. Procedia Struct. Integr. 2019, 19, 113–122. [Google Scholar] [CrossRef]

- Wagener, R.; Scurria, M.; Kaufmann, H.; Melz, T. Influence on the fatigue behavior of additively manufactured aluminum structures. Procedia Struct. Integr. 2019, 19, 380–387. [Google Scholar] [CrossRef]

- Murakami, Y. Metal Fatigue: Effects of Small Defects and Nonmetallic Inclusions; Elsevier: Amsterdam, The Netherlands, 2002; ISBN 9780080496566. [Google Scholar]

- Beretta, S.; Romano, S. A comparison of fatigue strength sensitivity to defects for materials manufactured by AM or traditional processes. Int. J. Fatigue 2017, 94, 178–191. [Google Scholar] [CrossRef]

- Smith, T.R.; Sugar, J.D.; Schoenung, J.M.; San Marchi, C. Relationship between manufacturing defects and fatigue properties of additive manufactured austenitic stainless steel. Mater. Sci. Eng. A 2019, 765, 138268. [Google Scholar] [CrossRef]

- Maskery, I.; Aboulkhair, N.T.; Corfield, M.R.; Tuck, C.; Clare, A.T.; Leach, R.K.; Wildman, R.D.; Ashcroft, I.A.; Hague, R.J.M. Quantification and characterisation of porosity in selectively laser melted Al–Si10–Mg using X-ray computed tomography. Mater. Charact. 2016, 111, 193–204. [Google Scholar] [CrossRef] [Green Version]

- Uzan, N.E.; Ramati, S.; Shneck, R.; Frage, N.; Yeheskel, O. On the effect of shot-peening on fatigue resistance of AlSi10Mg specimens fabricated by additive manufacturing using selective laser melting (AM-SLM). Addit. Manuf. 2018, 21, 458–464. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Maskery, I.; Tuck, C.; Ashcroft, I.; Everitt, N.M. Improving the fatigue behaviour of a selectively laser melted aluminium alloy: Influence of heat treatment and surface quality. Mater. Des. 2016, 104, 174–182. [Google Scholar] [CrossRef]

- Brandão, A.D.; Gumpinger, J.; Gschweitl, M.; Seyfert, C.; Hofbauer, P.; Ghidini, T. Fatigue Properties of Additively Manufactured AlSi10Mg—Surface Treatment Effect. Procedia Struct. Integr. 2017, 7, 58–66. [Google Scholar] [CrossRef]

- Bayat, M.; Thanki, A.; Mohanty, S.; Witvrouw, A.; Yang, S.; Thorborg, J.; Tiedje, N.S.; Hattel, J.H. Keyhole-induced porosities in Laser-based Powder Bed Fusion (L-PBF) of Ti6Al4V: High-fidelity modelling and experimental validation. Addit. Manuf. 2019, 30, 100835. [Google Scholar] [CrossRef]

- Reiber, T.; Rüdesheim, J.; Weigold, M.; Abele, E.; Musekamp, J.; Oechsner, M. Influence of contour scans on surface roughness and pore formation using Scalmalloy® manufactured by laser powder bed fusion (PBF—LB). Materialwiss. Werkstofftech. 2021, 52, 468–481. [Google Scholar] [CrossRef]

- Edelhäuser, S.; Hümmeler, L.; Hofbauer, P.; Schmitt, C. Homogenization of the Energy Input. U.S. Patent 701, 24 April 2018. [Google Scholar]

- Spierings, A.B.; Dawson, K.; Kern, K.; Palm, F.; Wegener, K. SLM-processed Sc- and Zr- modified Al-Mg alloy: Mechanical properties and microstructural effects of heat treatment. Mater. Sci. Eng. A 2017, 701, 264–273. [Google Scholar] [CrossRef]

- Deutsches Institut für Normung, e.V. ICS 77.040.10 (50125). Testing of Metallic Materials—Tensile Test Pieces; Beuth Standards Collection: Berlin, Germany, 2016. [Google Scholar]

- Deutsches Institut für Normung e.V. Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature (ISO 6892-1:2009), 1st ed.; Beuth Standards Collection: Berlin, Germany, 2009. [Google Scholar]

- Deutsches Institut für Normung e.V. Geometrical Product Specifications (GPS)—Surface Texture; Profile Method—Rules and Procedures for the Assessment of Surface Texture; Beuth Standards Collection: Berlin, Germany, 1997. [Google Scholar]

- Deutsches Institut für Normung e.V. Non-Destructive Testing—Test Method for Residual Stress Analysis by X-Ray Diffraction; Beuth Standards Collection: Berlin, Germany, 2009. [Google Scholar]

- Musekamp, J.; Reiber, T.; Hoche, H.; Oechsner, M.; Weigold, M. Charakterisierung und Analyseansätze mittels LPBF hergestellter Proben der Aluminumlegierung Scalmalloy. Additiv Gefertigte Bauteile und Strukturen 2019, 2019, 23–34. [Google Scholar]

- Schumann, H. Metallographie, 14. Berarb. u. Erw. Aufl; John Wiley & Sons: Hoboken, NJ, USA, 2004; ISBN 3-527-30679-X. [Google Scholar]

- Deutsches Institut für Normung e.V. Load Controlled Fatigue Testing—Execution and Evaluation of Cyclic Tests at Constant Load Amplitudes on Metallic Specimens and Components; Beuth Standards Collection: Berlin, Germany, 2016. [Google Scholar]

- Spierings, A.B.; Dawson, K.; Voegtlin, M.; Palm, F.; Uggowitzer, P.J. Microstructure and mechanical properties of as-processed scandium-modified aluminium using selective laser melting. CIRP Ann. 2016, 65, 213–216. [Google Scholar] [CrossRef]

- Ni, M.; Chen, C.; Wang, X.; Wang, P.; Li, R.; Zhang, X.; Zhou, K. Anisotropic tensile behavior of in situ precipitation strengthened Inconel 718 fabricated by additive manufacturing. Mater. Sci. Eng. A 2017, 701, 344–351. [Google Scholar] [CrossRef]

- Verein Deutscher Ingenieure. Failures Caused by Mechanical Working Conditions; Beuth Standards Collection: Berlin, Germany, 2008; Part 2. [Google Scholar]

- Denlinger, E.R.; Gouge, M.; Irwin, J.; Michaleris, P. Thermomechanical model development and in situ experimental validation of the Laser Powder-Bed Fusion process. Addit. Manuf. 2017, 16, 73–80. [Google Scholar] [CrossRef]

- Salvati, E.; Lunt, A.J.G.; Heason, C.P.; Baxter, G.J.; Korsunsky, A.M. An analysis of fatigue failure mechanisms in an additively manufactured and shot peened IN 718 nickel superalloy. Mater. Des. 2020, 191, 108605. [Google Scholar] [CrossRef]

- Neuber, H. Kerbspannungslehre: Theorie der Spannungskonzentration; Genaue Berechnung der Festigkeit, 4th ed.; Springer: Berlin/Heidelberg, Germany, 2001; ISBN 3540676570. [Google Scholar]

| - | Si | Fe | Mn | Mg | Zn | Ti | V | Sc | Al | |

|---|---|---|---|---|---|---|---|---|---|---|

| Nominal | Min. | 0 | 0 | 0.3 | 4 | 0 | 0 | 0 | 0.6 | Cal. |

| Max. | 0.4 | 0.4 | 0.8 | 4.9 | 0.25 | 0.15 | 0.05 | 0.8 | ||

| data | data | data | ||||||||

| Measured | 0.04 ± 0.01 | 0.1 ± 0.004 | 0.5 ± 0.003 | 3.95 ± 0.05 | <0.01 | 0.08 ± 0.003 | 0.02 ± 0.001 | 0.65 ± 0.05 | ||

| Volume energy, EV [J/mm3] | 110 |

| Line energy, EL [J/mm] | 0.23 |

| Laser power, P [W] | 370 |

| Scan speed, v [mm/s] | 1600 |

| Hatch distance, h [mm] | 0.07 |

| Layer height, lz [mm] | 0.03 |

| Exposure pattern | Stripes |

| Stripe width [mm] | 7 |

| Layer rotation | 67° |

| - | Type | EL [J/mm] | P [W] | v [mm/s] | oci [%] |

|---|---|---|---|---|---|

| Contour A | Post-cont. | 0.9 | 370 | 411 | 50 |

| Contour B | Pre-cont. | 0.6 | 370 | 600 | 50 |

| Contour C | Pre-cont. | 0.07 | 230 | 3286 | 50 |

| Name | Surface | Heat Treatment | Building Direction |

|---|---|---|---|

| AB | As-built | 325 °C, 4 h | Z |

| T | Turned | ||

| SP | Shot peened | ||

| A | Contour A | ||

| B | Contour B | ||

| C | Contour C |

| Orientation | Heat Treatment | Rm [MPa] | Rp0,2 [MPa] | A5 [%] | E [GPa] |

|---|---|---|---|---|---|

| X | As-built | 352 ± 1 | 290 ± 3 | 24.5 ± 1 | 70 ± 2 |

| Z | As-built | 349 ± 2 | 269 ± 1 | 22 ± 2 | 70 ± 1 |

| X | 325 °C, 4 h | 520 ± 2 | 490 ± 2 | 11.5 ± 1 | 71 ± 1 |

| Z | 325 °C, 4 h | 510 ± 2 | 476 ± 2 | 14 ± 1 | 71 ± 1 |

| Name | Ra [µm] | Rz [µm] | Overall Porosity (CT) [%] | Largest Pore [mm3] | Distance of Largest Pore to Surface [mm] |

|---|---|---|---|---|---|

| AB | 17 ± 2 | 101 ± 7 | 0.007 ± 0.004 | 0.0012 | 0.174 |

| T | 1 ± 0.2 | 5 ± 0,8 | 0.005 ± 0.003 | 0.0007 | 0.160 |

| SP | 8 ± 2 | 43 ± 11 | 0.003 ± 0.001 | 0.00151 | 0.164 |

| A | 5 ± 2.5 | 23 ± 11 | 0.252 ± 0.05 | 0.00302 | 0.112 |

| B | 6 ± 0.3 | 30 ± 7 | 0.019 ± 0.001 | 0.00133 | 0.096 |

| C | 11 ± 0.1 | 63 ± 4 | 0.012 ± 0.003 | 0.00184 | 1.498 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Musekamp, J.; Reiber, T.; Hoche, H.C.; Oechsner, M.; Weigold, M.; Abele, E. Influence of LPBF-Surface Characteristics on Fatigue Properties of Scalmalloy®. Metals 2021, 11, 1961. https://doi.org/10.3390/met11121961

Musekamp J, Reiber T, Hoche HC, Oechsner M, Weigold M, Abele E. Influence of LPBF-Surface Characteristics on Fatigue Properties of Scalmalloy®. Metals. 2021; 11(12):1961. https://doi.org/10.3390/met11121961

Chicago/Turabian StyleMusekamp, Jens, Thorsten Reiber, Holger Claus Hoche, Matthias Oechsner, Matthias Weigold, and Eberhard Abele. 2021. "Influence of LPBF-Surface Characteristics on Fatigue Properties of Scalmalloy®" Metals 11, no. 12: 1961. https://doi.org/10.3390/met11121961

APA StyleMusekamp, J., Reiber, T., Hoche, H. C., Oechsner, M., Weigold, M., & Abele, E. (2021). Influence of LPBF-Surface Characteristics on Fatigue Properties of Scalmalloy®. Metals, 11(12), 1961. https://doi.org/10.3390/met11121961