Hot-Deformation Behavior and Processing Maps of a Low-Carbon Fe-2 wt% Nb Steel

Abstract

:1. Introduction

2. Experimental Materials and Procedure

3. Results and Discussion

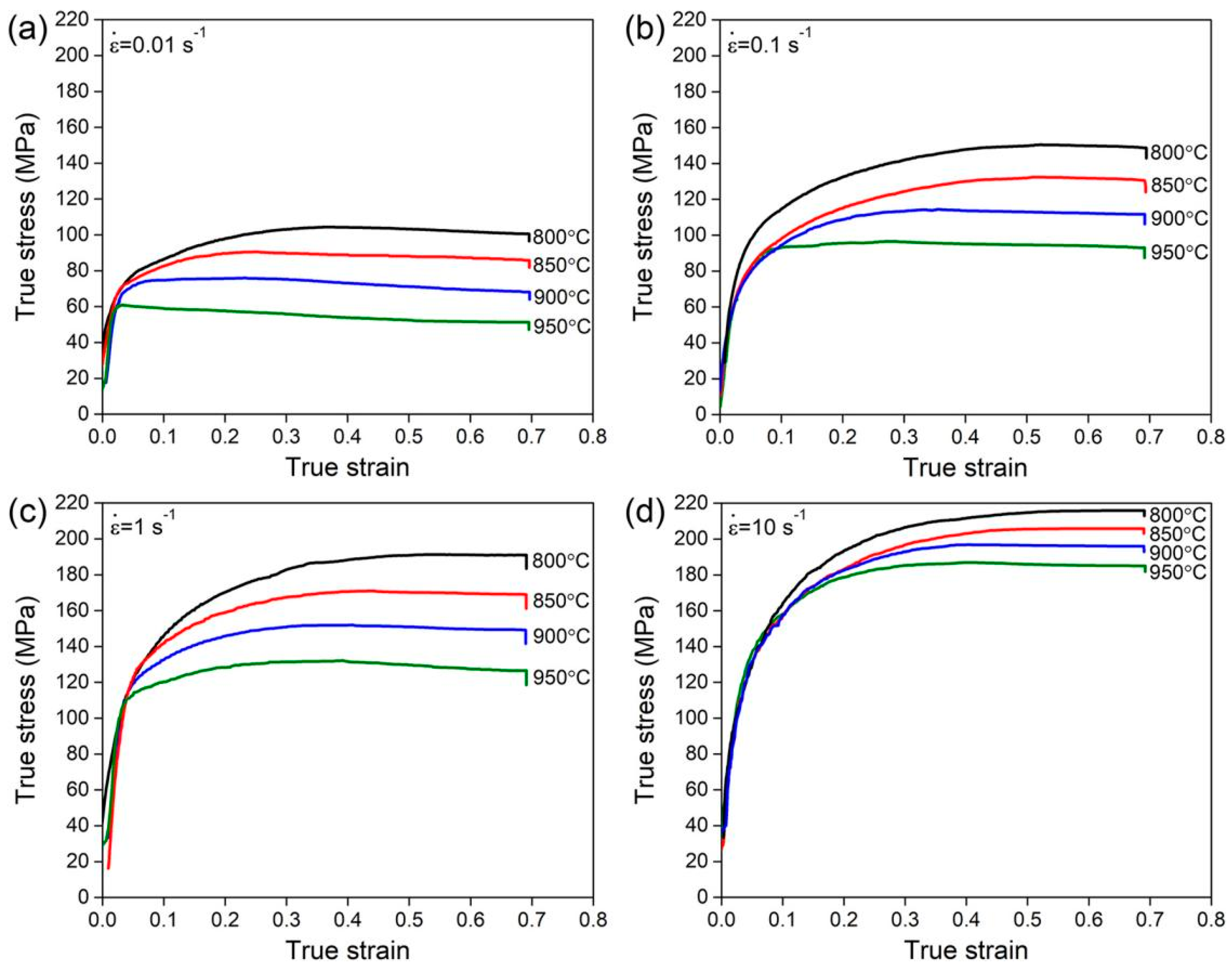

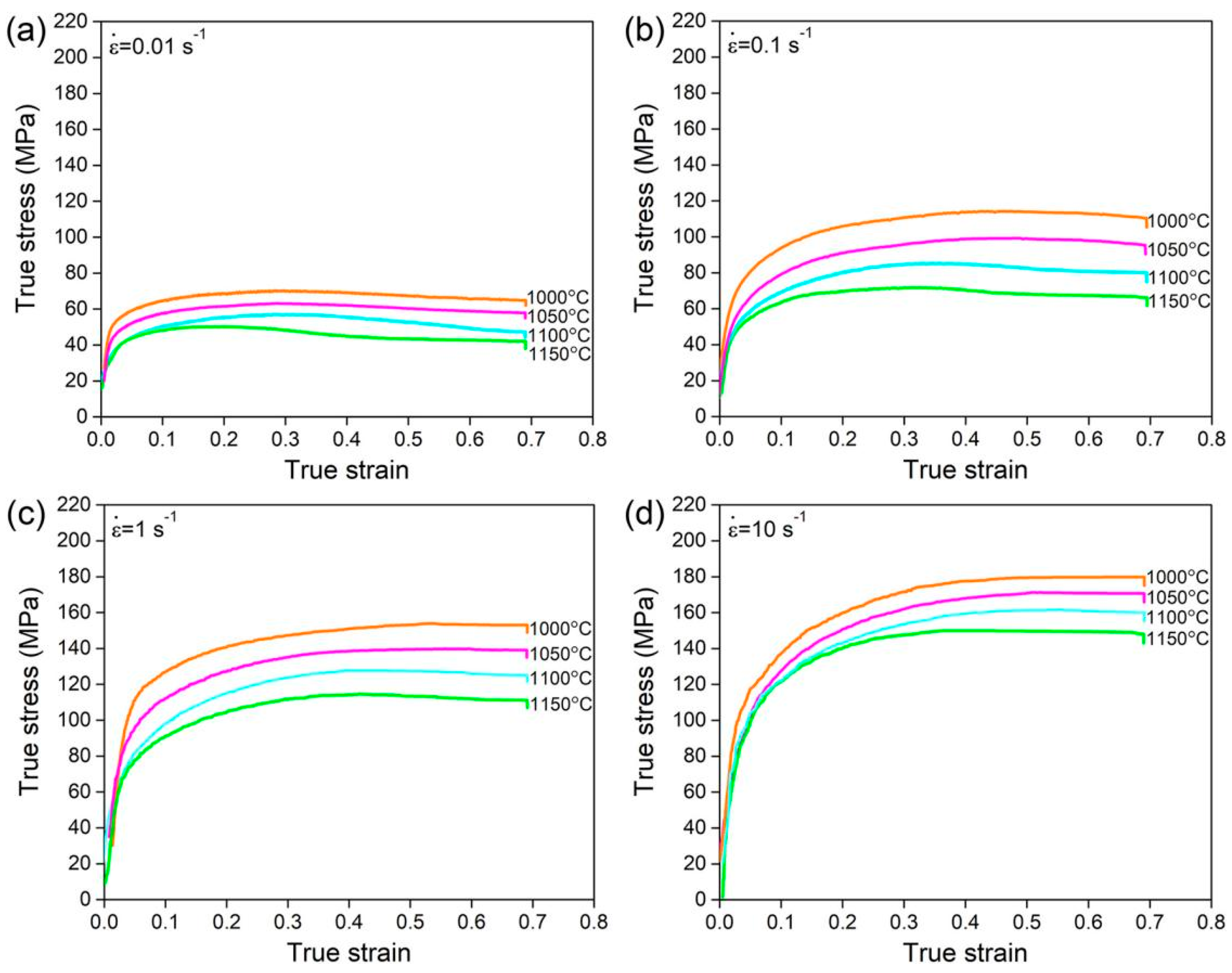

3.1. Hot-Compressive Stress–Strain Curves

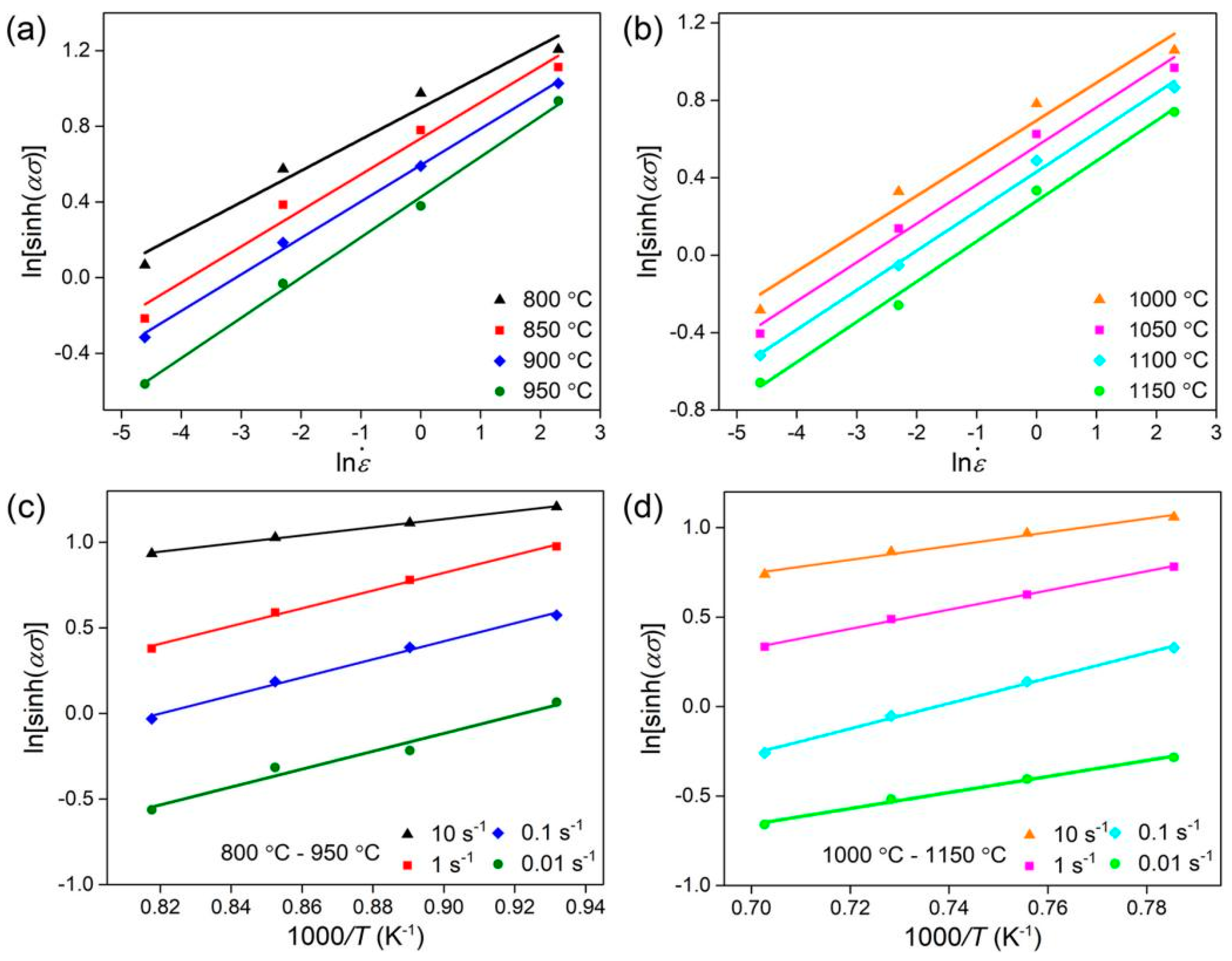

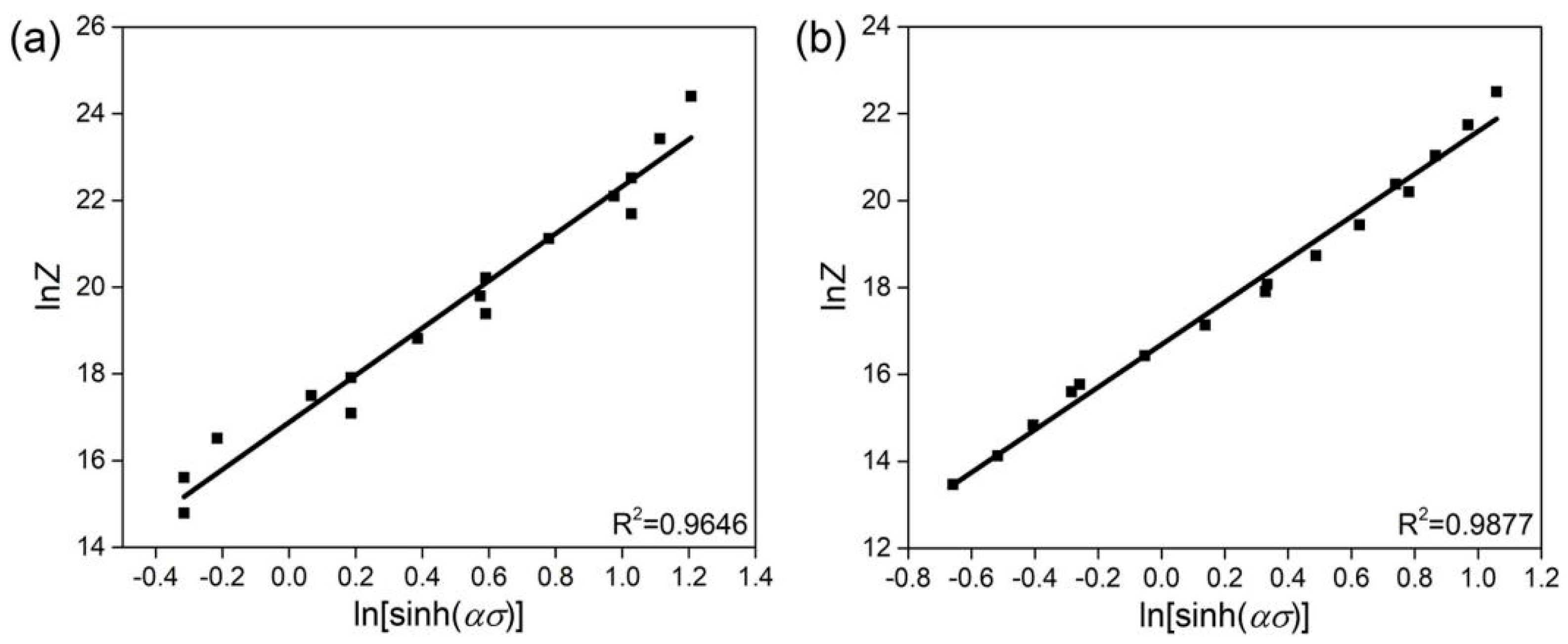

3.2. Hot-Compressive-Deformation Model

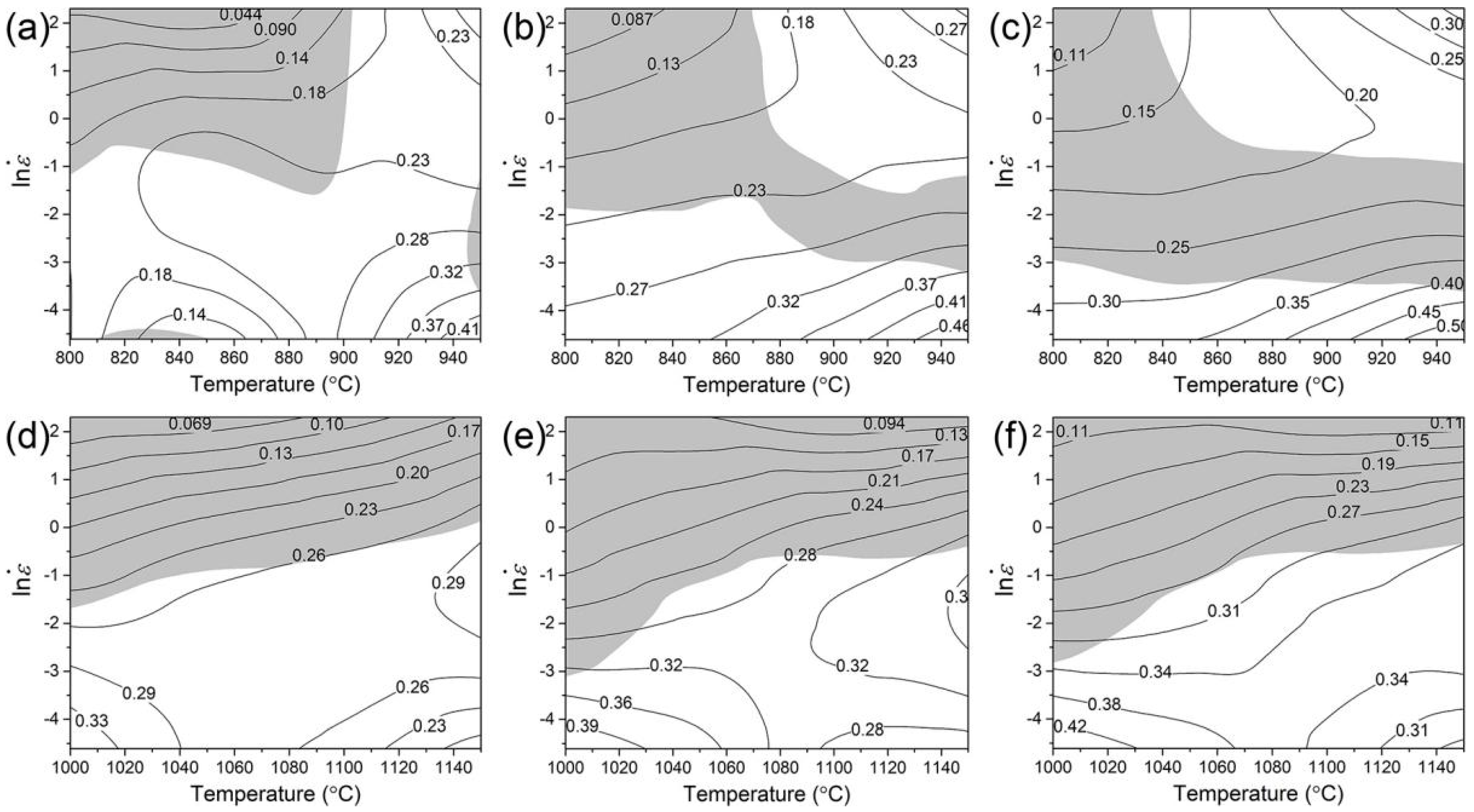

3.3. Hot-Processing Maps

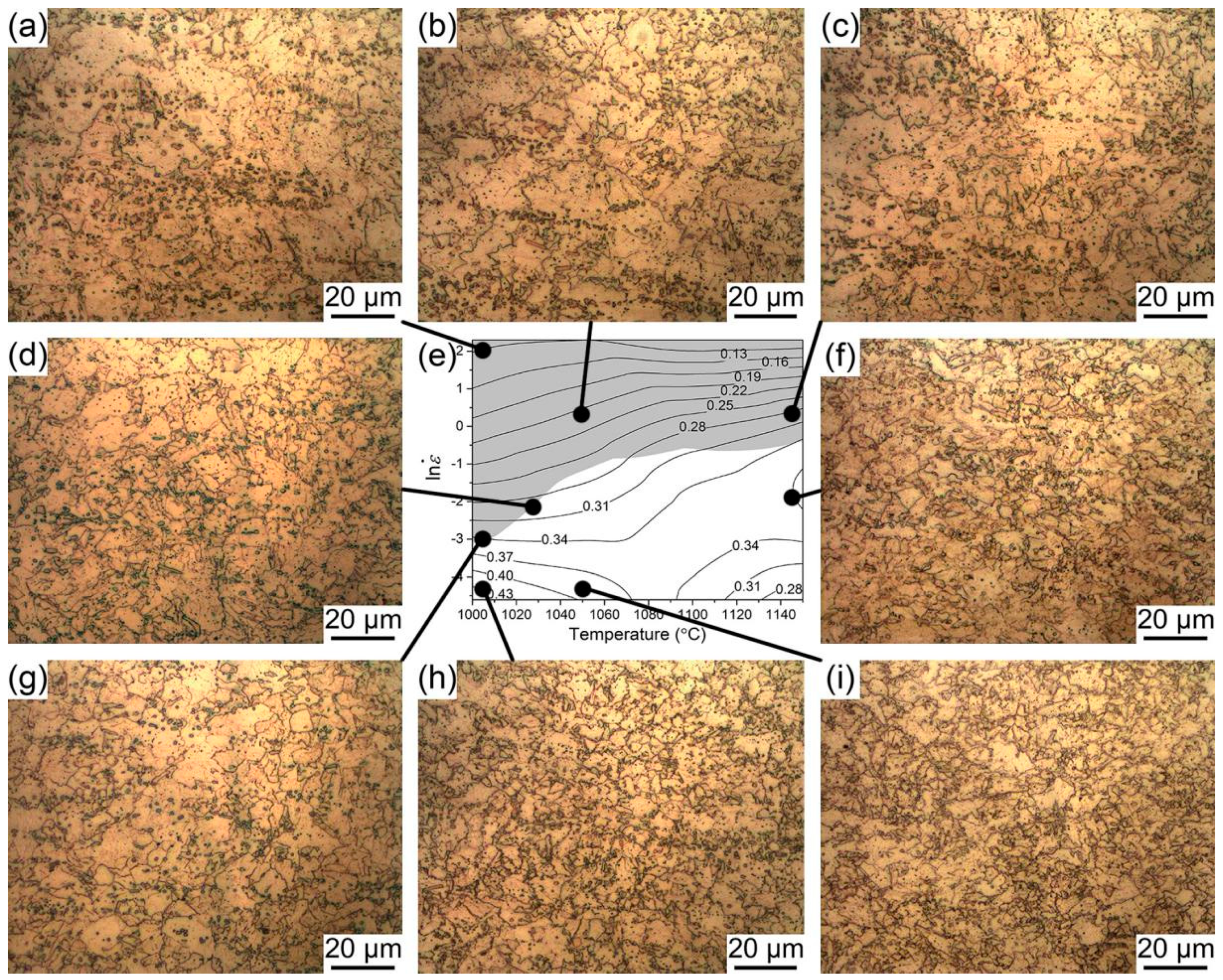

3.4. Microstructural Evolution

4. Conclusions

- The constitutive equations of hot deformation are as follows:for the bcc + fcc dual-phase microstructure andfor the fcc phase microstructure.

- Based on the experimental data, the processing maps were obtained. For the ferrite matrix condition, the feasible regions are in the 850–950 °C range with strain rates of 0.4–10 s−1 and 800–950 °C with strain rates of 0.01–0.03 s−1, respectively. For the austenite matrix, the feasible region ranges from 1000 °C to 1150 °C with strain rates of 0.01–0.05 s−1.

- In the safe domains, with an increase in , the grains are gradually refined, showing a typical recrystallization structure. However, in the instable domains, the grains are elongated and separated without recrystallization, showing typical rheological-instability characteristics.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Yamamoto, Y.; Brady, M.P.; Lu, Z.P.; Maziasz, P.J.; Liu, C.T.; Pint, B.A.; More, K.L.; Meyer, H.M.; Payzant, E.A. Creep-Resistant, Al2O3-Forming Austenitic Stainless Steels. Science 2007, 316, 433–436. [Google Scholar] [CrossRef] [PubMed]

- Kanno, N.; Yoshimura, K.; Takata, N.; Tarigan, I.; Takeyama, M. Mechanical properties of austenitic heat-resistant Fe-20Cr-30Ni-2Nb steel at ambient temperature. Mater. Sci. Eng. A 2016, 662, 551–563. [Google Scholar] [CrossRef] [Green Version]

- Matsunaga, T.; Hongo, H.; Tabuchi, M.; Souissi, M.; Sahara, R. Creep lifetime and microstructure evolution in boron-added 9Cr-1Mo heatresistant steel. Mater. Sci. Eng. A 2019, 760, 267–276. [Google Scholar] [CrossRef]

- Jung, S.; Jo, Y.H.; Jeon, C.; Choi, W.M.; Lee, B.J.; Oh, Y.J.; Kim, G.Y. Effects of Mn and Mo addition on high-temperature tensile properties in high-Ni-containing austenitic cast steels used for turbo-charger application. Mater. Sci. Eng. A 2017, 682, 147–155. [Google Scholar] [CrossRef]

- Loktionov, V.; Lyubashevskaya, I.; Sosnin, O.; Terentyev, E. Short-term strength properties and features of high-temperature deformation of VVER reactor pressure vessel steel 15Kh2NMFA-A within the temperature range 20—1200 °C. Nucl. Eng. Des. 2019, 352, 110188–110192. [Google Scholar] [CrossRef]

- Luo, W.T.; Wang, L.L.; Wang, Y.H.; Meng, L.; Yuan, Y.; Zhang, L.; Wu, G.L. Microstructure and mechanical properties of a 2 wt% Nb bearing low carbon steel. Mater. Sci. Eng. A 2021, 826, 141957. [Google Scholar] [CrossRef]

- Lakshmi, A.; SrinivasaRaob, C.; Gangadharc, J.; Srinivasud, C.; Singh, S.K. Review of Processing Maps and Development of Qualitative Processing Maps. Mater. Today Proc. 2017, 4, 946–956. [Google Scholar] [CrossRef]

- Liu, P.T.; Huang, Q.X.; Ma, L.F.; Wang, T. Characterization of hot deformation behavior of wear-resistant steel BTW1 using processing maps and constitutive equations. J. Iron Steel Res. Int. 2018, 25, 1054–1061. [Google Scholar] [CrossRef]

- Wang, H.; Liu, D.; Wang, J.G.; Wang, H.P.; Hu, Y.; Rao, H.D. Characterization of hot deformation behavior of 30Si2MnCrMoVE low-alloying ultra-high-strength steel by constitutive equations and processing maps. J. Iron Steel Res. Int. 2020, 27, 807–819. [Google Scholar] [CrossRef]

- Chen, X.M.; Lin, Y.C.; Wen, D.X.; Zhang, J.L.; He, M. Dynamic recrystallization behavior of a typical nickel-based superalloy during hot deformation. Mater. Des. 2014, 57, 568–577. [Google Scholar] [CrossRef]

- Wang, H.R.; Cai, C.Y.; Chen, D.N.; Ma, D.F. Dynamic compressive behavior of Pr-Nd alloy at high strain rates and temperatures. J. Appl. Phys. 2012, 112, 014903. [Google Scholar] [CrossRef]

- Liang, R.; Khan, A.S. A critical review of experimental results and constitutive models for BCC and FCC metals over a wide range of strain rates and temperatures. Int. J. Plast. 1999, 15, 963–980. [Google Scholar] [CrossRef]

- Sheikh, H.; Serajzadeh, S. Estimation of flow stress behavior of AA5083 using artificial neural networks with regard to dynamic strain ageing effect. J. Mater Process. Technol. 2008, 196, 115–119. [Google Scholar] [CrossRef]

- Sun, Y.; Zeng, W.D.; Zhao, Y.Q.; Qi, Y.L.; Ma, X.; Han, Y.F. Development of constitutive relationship model of Ti600 alloy using artificial neural network. Comp. Mater. Sci. 2010, 48, 686–691. [Google Scholar] [CrossRef]

- Cao, Y.; Di, H.H.; Misra, R.D.K.; Yi, X.; Zhang, J.; Ma, T.J. On the hot deformation behavior of AISI 420 stainless steel based on constitutive analysis and CSL model. Mater. Sci. Eng. A 2014, 593, 111–119. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, M.S.; Zhong, J. Constitutive modeling for elevated temperature flow behavior of 42CrMo steel. Comp. Mater. Sci. 2008, 42, 470–477. [Google Scholar] [CrossRef]

- Amiri, A.; Sadeghi, M.H.; Ebrahimi, G.R. Characterization of Hot Deformation Behavior of AMS 5708 Nickel-Based Superalloy Using Processing Map. J. Mater. Eng. Perform. 2013, 22, 3940–3945. [Google Scholar] [CrossRef]

- Zener, C.; Hollomon, J.H. Effect of Strain Rate Upon Plastic Flow of Steel. J. Appl. Phys. 1944, 15, 22–32. [Google Scholar] [CrossRef]

- Sellars, C.M.; Mctegart, W.J. On the mechanism of hot deformation. Acta Metall. 1966, 14, 1136–1138. [Google Scholar] [CrossRef]

- Rajput, S.K.; Chaudhari, G.P.; Nath, S.K. Characterization of hot deformation behavior of a low carbon steel using processing maps, constitutive equations and Zener-Hollomon parameter. J. Mater. Process. Technol. 2016, 237, 113–125. [Google Scholar] [CrossRef]

- Cao, Y.B.; Xiao, F.R.; Qiao, G.Y.; Huang, C.J.; Zhang, X.B.; Wu, Z.X.; Liao, B. Strain-induced precipitation and softening behaviors of high Nb microalloyed steels. Mater. Sci. Eng. A 2012, 552, 502–513. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Gegel, H.L.; Doraivelu, S.M.; Malas, J.C.; Morgan, J.T.; Lark, K.A.; Barker, D.R. Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242. Mater. Trans. A 1984, 15, 1883–1892. [Google Scholar] [CrossRef]

- Babu, K.A.; Mandal, S.; Kumar, A.; Athreya, C.N.; Boer, B. Characterization of hot deformation behavior of alloy 617 through kinetic analysis, dynamic material modeling and microstructural studies. Mater. Sci. Eng. A 2016, 664, 177–187. [Google Scholar] [CrossRef]

- Shi, Z.X.; Yan, X.F.; Duan, C.H. Characterization of hot deformation behavior of GH925 superalloy using constitutive equation, processing map and microstructure observation. J. Alloy. Compd. 2015, 652, 30–38. [Google Scholar] [CrossRef]

- Peng, X.N.; Guo, H.Z.; Shi, Z.F.; Qin, C.; Zhao, Z.L.; Yao, Z.K. Study on the hot deformation behavior of TC4-DT alloy with equiaxed α+β starting structure based on processing map. Mater. Sci. Eng. A 2014, 605, 80–88. [Google Scholar] [CrossRef]

- Beynon, J.H. Tribology of hot metal forming. Tribol. Inter. 1998, 31, 73–77. [Google Scholar] [CrossRef]

| Element | Nb | C | Cr | Ni | V | P | Fe |

|---|---|---|---|---|---|---|---|

| wt% | 2.110 | 0.198 | 0.026 | 0.017 | 0.013 | 0.010 | bal |

| T | n0 | β | α | n | A | Q (KJ/mol) |

|---|---|---|---|---|---|---|

| 800–950 °C | 6.77 | 0.061 | 0.0089 | 5.25 | 2.15 × 107 | 197.23 |

| 1000–1150 °C | 6.32 | 0.063 | 0.0099 | 4.96 | 1.77 × 107 | 213.86 |

| 800–1150 °C | 5.55 | 0.064 | 0.0115 | 4.21 | 3.88 × 107 | 266.59 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, W.; Cai, P.; Hou, Z.; Wang, Y.; Zhang, L.; Wu, G. Hot-Deformation Behavior and Processing Maps of a Low-Carbon Fe-2 wt% Nb Steel. Metals 2021, 11, 1939. https://doi.org/10.3390/met11121939

Luo W, Cai P, Hou Z, Wang Y, Zhang L, Wu G. Hot-Deformation Behavior and Processing Maps of a Low-Carbon Fe-2 wt% Nb Steel. Metals. 2021; 11(12):1939. https://doi.org/10.3390/met11121939

Chicago/Turabian StyleLuo, Wentao, Pengzhan Cai, Ziyong Hou, Yuhui Wang, Ling Zhang, and Guilin Wu. 2021. "Hot-Deformation Behavior and Processing Maps of a Low-Carbon Fe-2 wt% Nb Steel" Metals 11, no. 12: 1939. https://doi.org/10.3390/met11121939

APA StyleLuo, W., Cai, P., Hou, Z., Wang, Y., Zhang, L., & Wu, G. (2021). Hot-Deformation Behavior and Processing Maps of a Low-Carbon Fe-2 wt% Nb Steel. Metals, 11(12), 1939. https://doi.org/10.3390/met11121939