Evaluating Microstructure, Wear Resistance and Tensile Properties of Al-Bi(-Cu, -Zn) Alloys for Lightweight Sliding Bearings

Abstract

1. Introduction

2. Materials and Methods

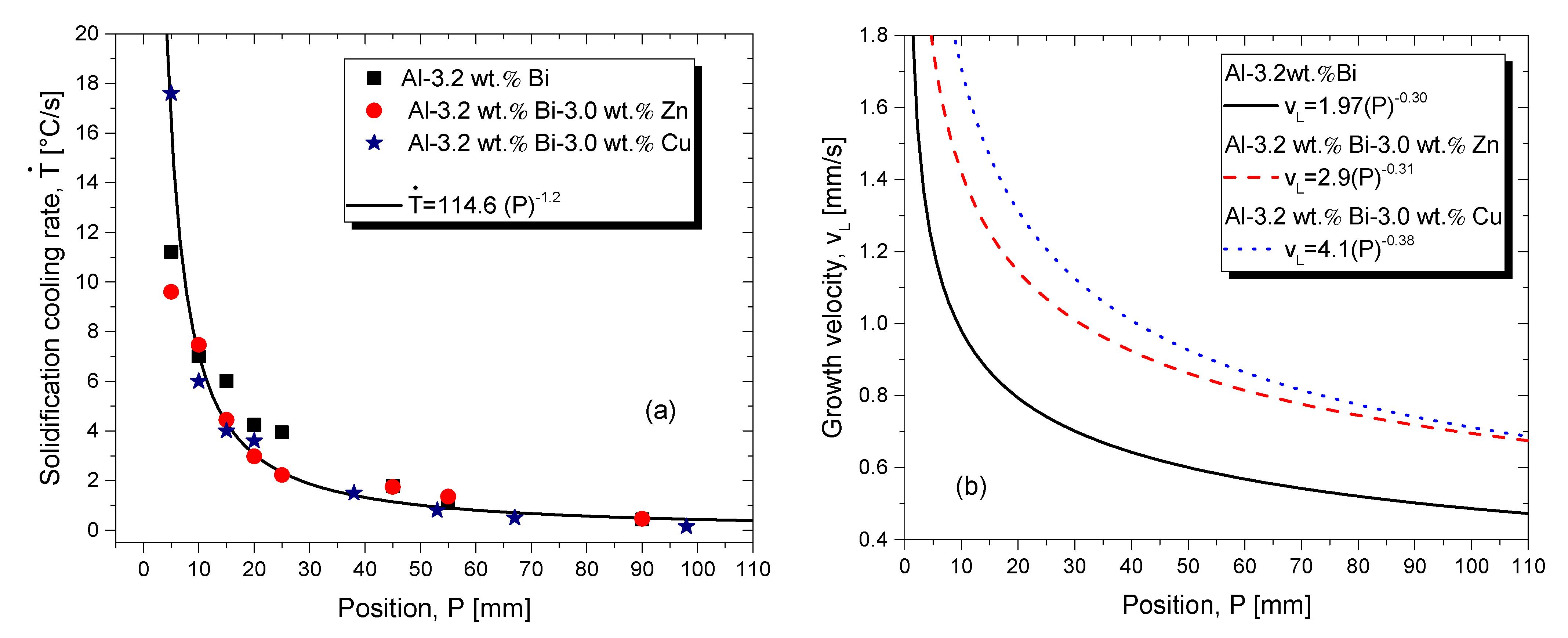

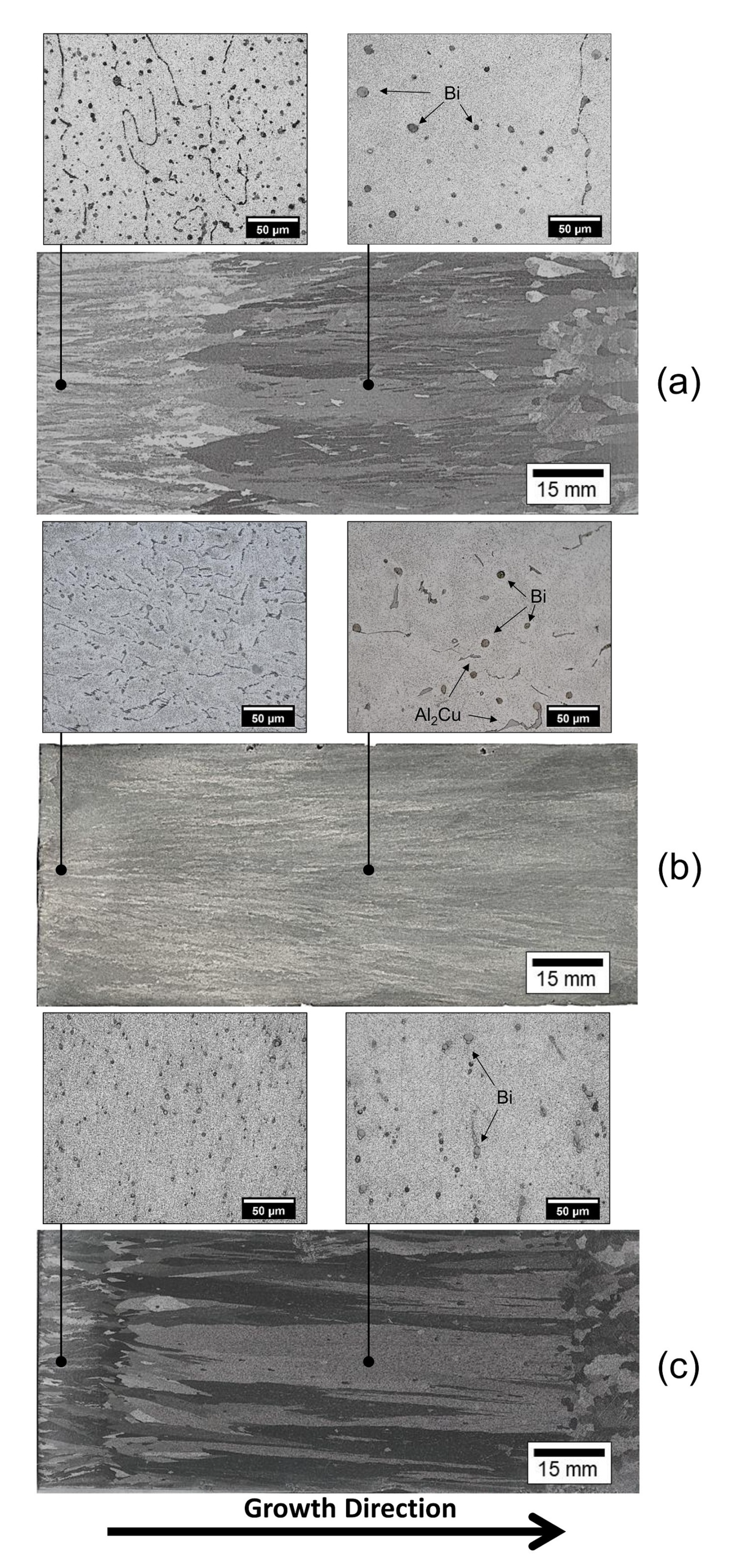

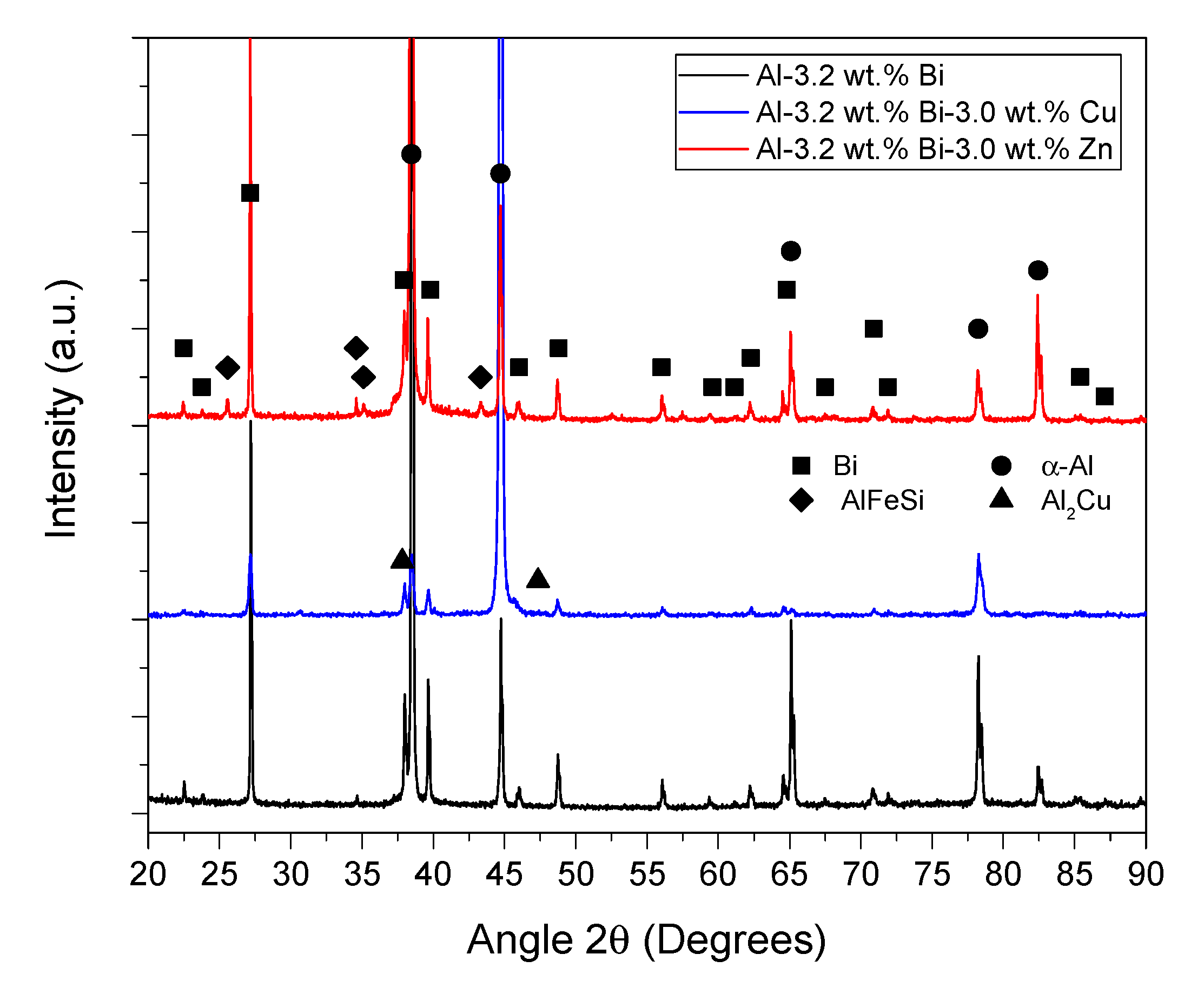

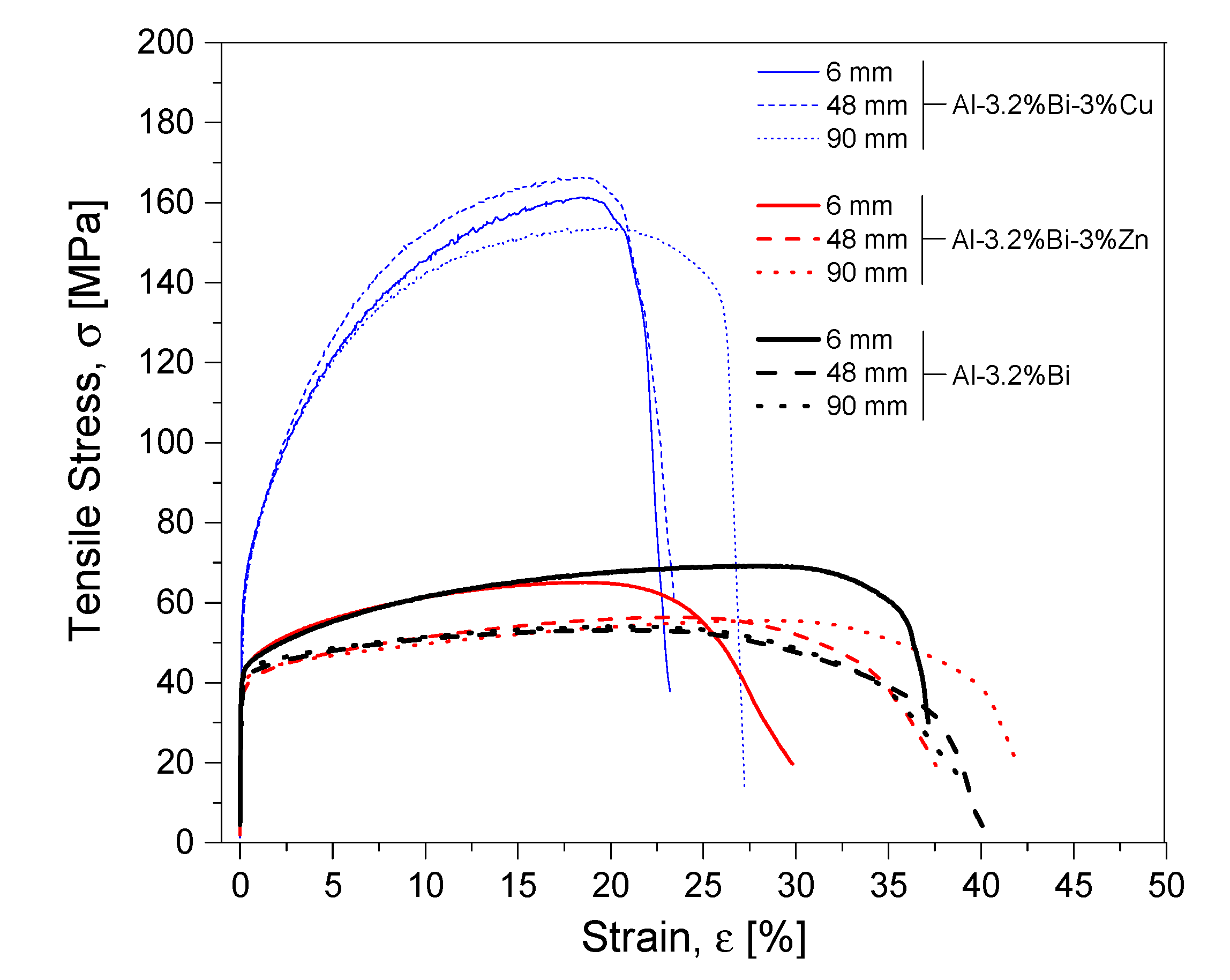

3. Results and Discussion

4. Conclusions

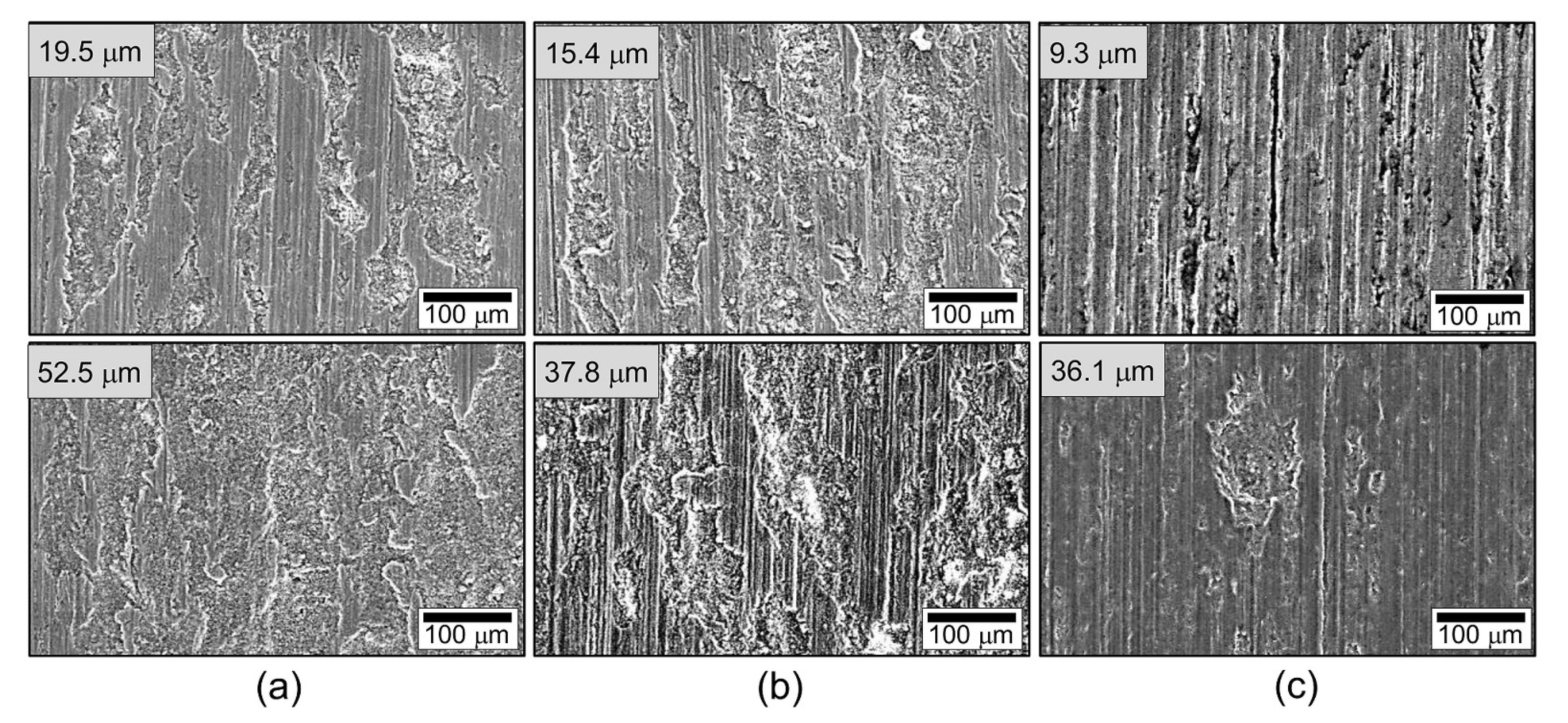

- The solidification microstructures of the DS Al-3.2wt.% Bi- (3.0 wt.%Zn/3.0 wt.% Cu) alloys castings were shown to be formed essentially by a α-Al-rich matrix and Bi particles. For the Zn containing alloy, Zn phases could not be distinguished, since Zn is possibly in solid solution in Al due to the experimental non-equilibrium solidification conditions. For the Cu containing alloy, Cu is both in solid solution in Al and as in Al2Cu. The spacing between Bi particles (λBi) and Bi diameter (dBi), representing the length scale of the microstructure, have been correlated with the solidification cooling rate (ṪL) for any examined alloy. For lower cooling rates (<6.0 K/s), the additions of both Cu and Zn were shown to result in a positive microstructural refining effect, reducing λBi and dBi.

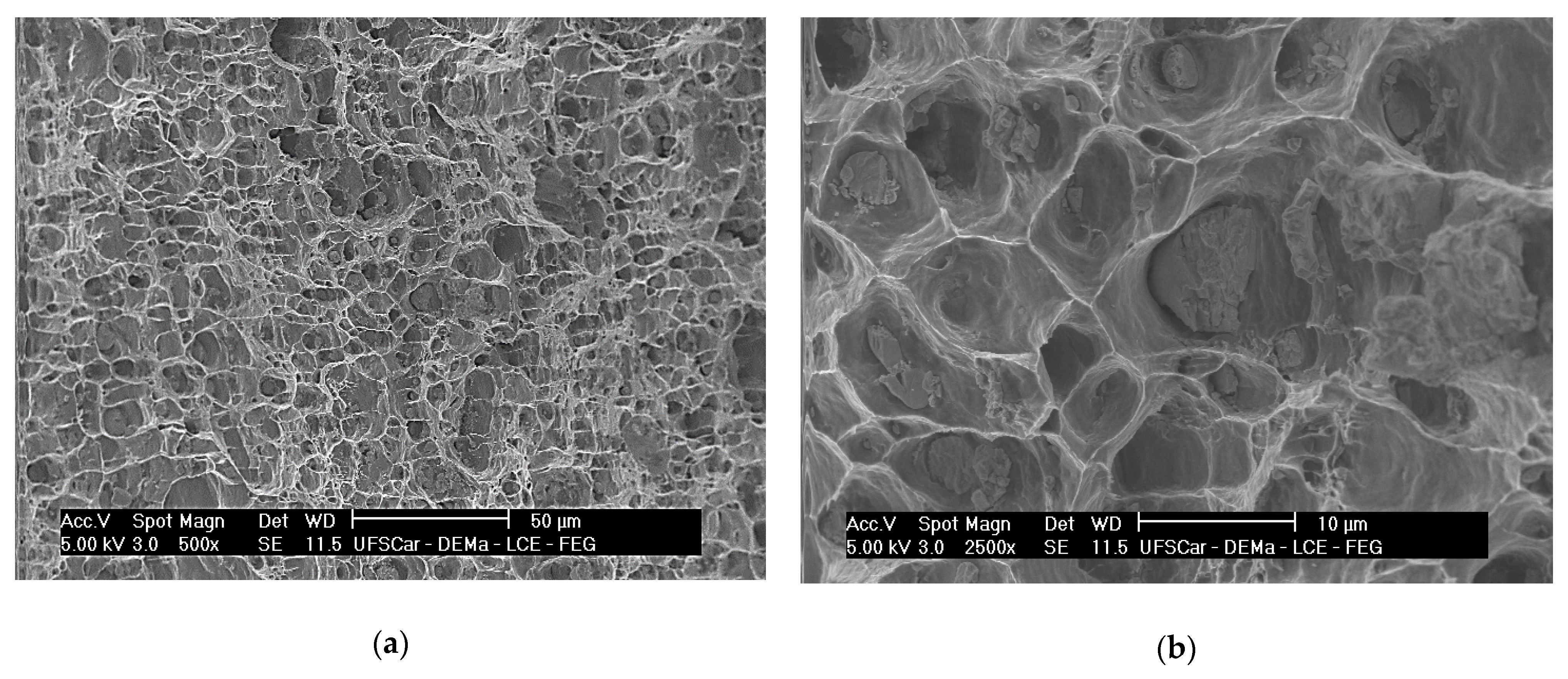

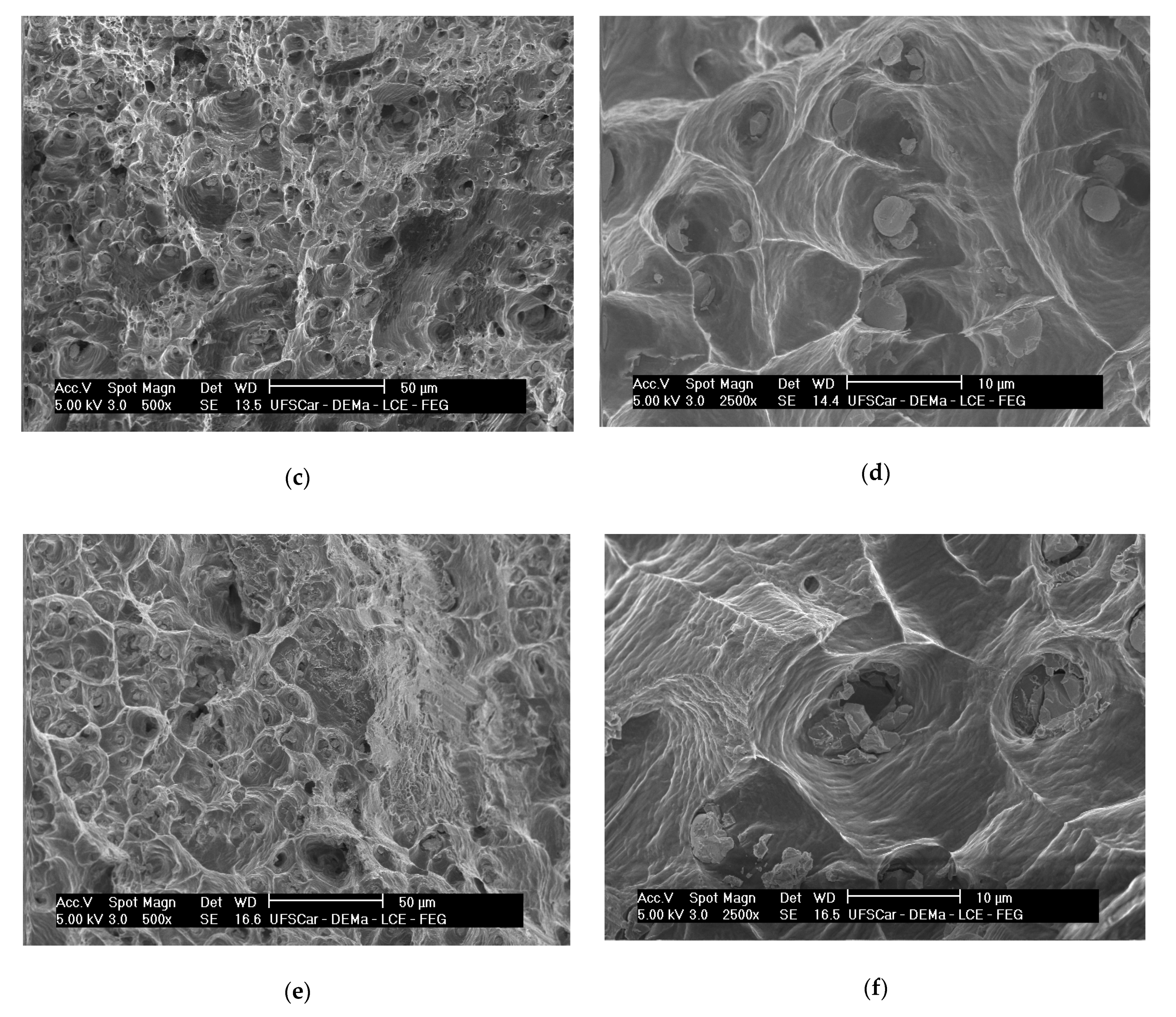

- The tensile properties, i.e., ultimate (σu) and yield (σy) strengths and elongation at fracture (δ), were experimentally examined with respect to λBi by analyzing samples of each alloy casting representing conditions of fast, intermediate, and slow solidification inside an experimental range of cooling rates from 0.5 to 15 K/s. Hall-Petch-type relationships relating σu, σy, and δ to λBi−1/2 have been derived. Only the addition of Cu was shown to be effective in terms of improving the tensile strength, whereas the additions of Zn and Cu reduced the elongation, even for the highest cooling rates that resulted in better distribution of Bi.

- The wear resistance (WR) of the studied alloys has been experimentally examined as a function of λBi. It was shown that WR of the alloy containing Cu is nearly double that of the other two alloys, since a finer distribution of the Bi minority phase promotes a better self-lubricating effect, thus reducing wear damage.

- The area under the tensile stress-strain curve to the point of fracture, was also measured for the Al-3.2 wt.% Bi-3.0 wt.% Cu alloy, with a view to permitting the toughness, U, to be determined. A joint plot of the application properties, i.e., (συ and WR) vs. λBi−1/2 and (U and WR) vs. λBi−1/2 demonstrated that the reduction in U in the range in which it occurred for this alloy samples, does not decisively affect the improvement of wear resistance, which depends largely on the tensile strength.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Bi | Bismuth |

| Zn | Zinc |

| Cu | Copper |

| Al | Aluminum |

| wt.% | Weight % |

| vL | Growth rate or growth velocity |

| Si | Silicon |

| DS | Directionally Solidified |

| SAE | Society of Automotive Engineering |

| λBi | Bi spacing |

| dBi | Bi diameter |

| HF | Hydrofluoric acid |

| AISI | American Iron and Steel Institute |

| V | Volume |

| N | Newton |

| rpm | Rotation per minute |

| FEG | Field Emission Gun |

| SEM | Scanning Electron Microscopy |

| EDS | Energy Dispersive X-Ray Spectroscopy |

| ASTM | American Society for Testing and Materials |

| P | Position from the metal-mold interface |

| t | time of passage of the liquidus solidification front |

| ṪL | Solidification cooling rate |

| XRD | X-ray diffraction |

| Fe | Iron |

| L | Liquid |

| a.u. | Arbitrary unit |

| σ | Tensile stress |

| ε | Strain |

| WR | Wear resistance |

| σu | Ultimate tensile strength |

| σy | Yield tensile strength |

| δ | Elongation-to-fracture |

| U | Toughness |

References

- Schaffer, P.L.; Mathiesen, R.H.; Arnberg, L.; Di Sabatino, M.; Snigirev, A. In situ investigation of spinodal decomposition in hypermonotectic Al-Bi and Al-Bi-Zn alloys. New J. Phys. 2008, 10, 053001. [Google Scholar] [CrossRef]

- Schaffer, P.L.; Mathiesen, R.H.; Arnberg, L. L2 droplet interaction with α-Al during solidification of hypermonotectic Al-8 wt.% Bi alloys. Acta Mater. 2009, 57, 2887–2895. [Google Scholar] [CrossRef]

- Ran, G.; Zhou, J.E.; Xi, S.; Li, P. Microstructure and morphology of Al-Pb bearing alloy synthesized by mechanical alloying and hot extrusion. J. Alloys Compd. 2006, 419, 66–70. [Google Scholar] [CrossRef]

- Gröbner, J.; Schmid-Fetzer, R. Phase transformations in ternary monotectic aluminum alloys. JOM 2005, 57, 19–23. [Google Scholar] [CrossRef]

- Wang, N.; Wei, B. Phase separation and structural evolution of undercooled Fe-Sn monotectic alloy. Mater. Sci. Eng. A 2003, 345, 145–154. [Google Scholar] [CrossRef]

- Freitas, E.S.; Spinelli, J.E.; Casteletti, L.C.; Garcia, A. Microstructure-wear behavior correlation on a directionally solidified Al-In monotectic alloy. Tribol. Int. 2013, 66, 182–186. [Google Scholar] [CrossRef]

- Phanikumar, G.; Dutta, P.; Galun, R.; Chattopadhyay, K. Microstructural evolution during remelting of laser surface alloyed hyper-monotectic Al-Bi alloy. Mater. Sci. Eng. A 2004, 371, 91–102. [Google Scholar] [CrossRef]

- Kumar Sharma, D.; Filipponi, M.; Di Schino, A.; Rossi, F.; Castaldi, J. Corrosion behaviour of high temperature fuel cells: Issues for materials selection. Metalurgija 2019, 58, 347–351. [Google Scholar]

- Silva, A.P.; Spinelli, J.E.; Garcia, A. Thermal parameters and microstructure during transient directional solidification of a monotectic Al-Bi alloy. J. Alloys Compd. 2009, 475, 347–351. [Google Scholar] [CrossRef]

- Majumdar, B.; Chattopadhyay, K. Aligned monotectic growth in unidirectionally solidified Zn-Bi alloys. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2000, 31, 1833–1842. [Google Scholar] [CrossRef]

- Battezzati, L.; Curiotto, S.; Johnson, E.; Pryds, N.H. Undercooling and demixing in rapidly solidified Cu-Co alloys. Mater. Sci. Eng. A 2007, 449–451, 7–11. [Google Scholar] [CrossRef]

- Wang, J.; Ding, F.; Shen, W.; Li, T.; Wang, G.; Zhao, J. Thermal behavior of Cu-Co bimetallic clusters. Solid State Commun. 2001, 119, 13–18. [Google Scholar] [CrossRef]

- Jiang, H.X.; Zhao, J.Z. Solidification of Immiscible Alloys Under the Effect of Electric and Magnetic Fields. Acta Metall. Sin. Lett. 2018, 31, 1240–1248. [Google Scholar] [CrossRef]

- Zheng, T.X.; Zhong, Y.B.; Lei, Z.S.; Ren, W.L.; Ren, Z.M.; Debray, F.; Beaugnon, E.; Fautrelle, Y. Effects of high static magnetic field on distribution of solid particles in BiZn immiscible alloys with metastable miscibility gap. J. Alloys Compd. 2015, 623, 36–41. [Google Scholar] [CrossRef]

- Silva, A.P.; Garcia, A.; Spinelli, J.E. Microstructure morphologies during the transient solidification of hypomonotectic and monotectic Al-Pb alloys. J. Alloys Compd. 2011, 509, 10098–10104. [Google Scholar] [CrossRef]

- MAHLE GmbH. Bearings. In Cylinder Components Properties, Applications, Materials; Vieweg+Teubner: Wiesbaden, Germany, 2010; pp. 49–68. [Google Scholar] [CrossRef]

- Ratke, L.; Diefenbach, S.; Drees, S.; Alkemper, J.; Prinz, B.; Romero, A.; Ahlborn, H. Multi-droplet Marangoni motion in immiscible AlSiBi alloys—Results of a D-2 experiment. Adv. Space Res. 1995, 16, 185–190. [Google Scholar] [CrossRef]

- Ratke, L. Theoretical considerations and experiments on microstructural stability regimes in monotectic alloys. Mater. Sci. Eng. A 2005, 413–414, 504–508. [Google Scholar] [CrossRef]

- Lamrous, D.; Debili, M.Y.; Boehm-Courjault, E. Microstructure and phase composition of Al-Zn alloys. J. Adv. Microsc. Res. 2013, 8, 266–269. [Google Scholar] [CrossRef]

- Maki, K.; Ito, Y.; Matsunaga, H.; Mori, H. Solid-solution copper alloys with high strength and high electrical conductivity. Scr. Mater. 2013, 68, 777–780. [Google Scholar] [CrossRef]

- Kumar, J.; Singh, D.; Kalsi, N.S.; Sharma, S.; Pruncu, C.I.; Pimenov, D.Y.; Rao, K.V.; Kapłonek, W. Comparative study on the mechanical, tribological, morphological and structural properties of vortex casting processed, Al–SiC–Cr hybrid metal matrix composites for high strength wear-resistant applications: Fabrication and characterizations. J. Mater. Res. Technol. 2020, 9, 13607–13615. [Google Scholar] [CrossRef]

- Man, T.; Zhang, L.; Xu, N.; Wang, W.; Xiang, Z.; Wang, E. Effect of Rare-Earth ce on macrosegregation in Al-Bi immiscible alloys. Metals 2016, 6, 177. [Google Scholar] [CrossRef]

- Jia, P.; Zhang, J.; Geng, H.; Teng, X.; Zhao, D.; Yang, Z.; Wang, Y.; Hu, S.; Xiang, J.; Hu, X. High-Efficiency Inhibition of Gravity Segregation in Al–Bi Immiscible Alloys by Adding Lanthanum. Met. Mater. Int. 2018, 24, 1262–1274. [Google Scholar] [CrossRef]

- Man, T.; Zhang, L.; Xiang, Z.; Wang, W.; Huang, M.; Wang, E. Improvement of Microstructure and Wear Property of Al–Bi Alloys by Nd Addition. JOM 2018, 70, 1344–1348. [Google Scholar] [CrossRef]

- Yang, Q.; Sun, Z.; Wang, Z. Effects of Sn, Si, and Cu addition on the microstructure and properties of hypermonotectic Al 92 Bi 8 alloy. Mater. Sci. Eng. A 2019, 756, 71–81. [Google Scholar] [CrossRef]

- Pereira, C.L.; Gomes, L.F.; Spinelli, J.E. Effects of Bi addition on Si features, tensile properties and wear resistance of hypereutectic Al-15Si alloy. IOP Conf. Ser. Mater. Sci. Eng. 2020, 861. [Google Scholar] [CrossRef]

- Oliveira, R.; Kakitani, R.; Ramos, L.R.; Gonçalves, D.L.; Garcia, A.; Cheung, N. The Roles of Mn and Ni Additions to Fe-Contaminated Al in Neutralizing Fe and Stabilizing the Cellular α-Al Microstructure. J. Sustain. Metall. 2019, 5, 561–580. [Google Scholar] [CrossRef]

- Mandolfo, L.F. Aluminum Alloys: Structure and Properties, 1st ed.; Butterworth: Oxford, UK, 1976. [Google Scholar]

- Mirković, D.; Gröbner, J.; Kaban, I.; Hoyer, W.; Schmid-Fetzer, R. Integrated approach to thermodynamics, phase relations, liquid densities and solidification microstructures in the Al–Bi–Cu system. Int. J. Mater. Res. 2009, 100. [Google Scholar] [CrossRef]

- Kattner, U.R.; Burton, B.P. The Al-Bi-Cu System. J. Phase Equilibria 1992, 13, 629–635. [Google Scholar] [CrossRef]

- Shabestari, S.G.; Moemeni, H. Effect of copper and solidification conditions on the microstructure and mechanical properties of Al–Si–Mg alloys. J. Mater. Process. Technol. 2004, 153–154, 193–198. [Google Scholar] [CrossRef]

- Bertelli, F.; Freitas, E.S.; Cheung, N.; Arenas, M.A.; Conde, A.; de Damborenea, J.; Garcia, A. Microstructure, tensile properties and wear resistance correlations on directionally solidified Al-Sn-(Cu; Si) alloys. J. Alloys Compd. 2017, 695, 3621–3631. [Google Scholar] [CrossRef]

| Elements (wt.%) | Al | Zn | Bi | Cu | Fe | Si | Sn | Cd | Pb | As | Sb |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | 99.85 | 0.01 | - | - | 0.09 | 0.05 | - | - | - | - | - |

| Zn | 0.0001 | 99.997 | - | 0.0002 | 0.0001 | - | 0.0001 | 0.0006 | - | - | - |

| Bi | - | 0.0005 | 99.99 | 0.0005 | 0.001 | - | 0.001 | 0.0005 | 0.001 | 0.001 | 0.0005 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valenzuela Reyes, R.A.; Garcia, A.; Spinelli, J.E. Evaluating Microstructure, Wear Resistance and Tensile Properties of Al-Bi(-Cu, -Zn) Alloys for Lightweight Sliding Bearings. Metals 2021, 11, 153. https://doi.org/10.3390/met11010153

Valenzuela Reyes RA, Garcia A, Spinelli JE. Evaluating Microstructure, Wear Resistance and Tensile Properties of Al-Bi(-Cu, -Zn) Alloys for Lightweight Sliding Bearings. Metals. 2021; 11(1):153. https://doi.org/10.3390/met11010153

Chicago/Turabian StyleValenzuela Reyes, Rodrigo André, Amauri Garcia, and José Eduardo Spinelli. 2021. "Evaluating Microstructure, Wear Resistance and Tensile Properties of Al-Bi(-Cu, -Zn) Alloys for Lightweight Sliding Bearings" Metals 11, no. 1: 153. https://doi.org/10.3390/met11010153

APA StyleValenzuela Reyes, R. A., Garcia, A., & Spinelli, J. E. (2021). Evaluating Microstructure, Wear Resistance and Tensile Properties of Al-Bi(-Cu, -Zn) Alloys for Lightweight Sliding Bearings. Metals, 11(1), 153. https://doi.org/10.3390/met11010153