A Review of Factors Affecting the Mechanical Properties of Maraging Steel 300 Fabricated via Laser Powder Bed Fusion

Abstract

:1. Introduction

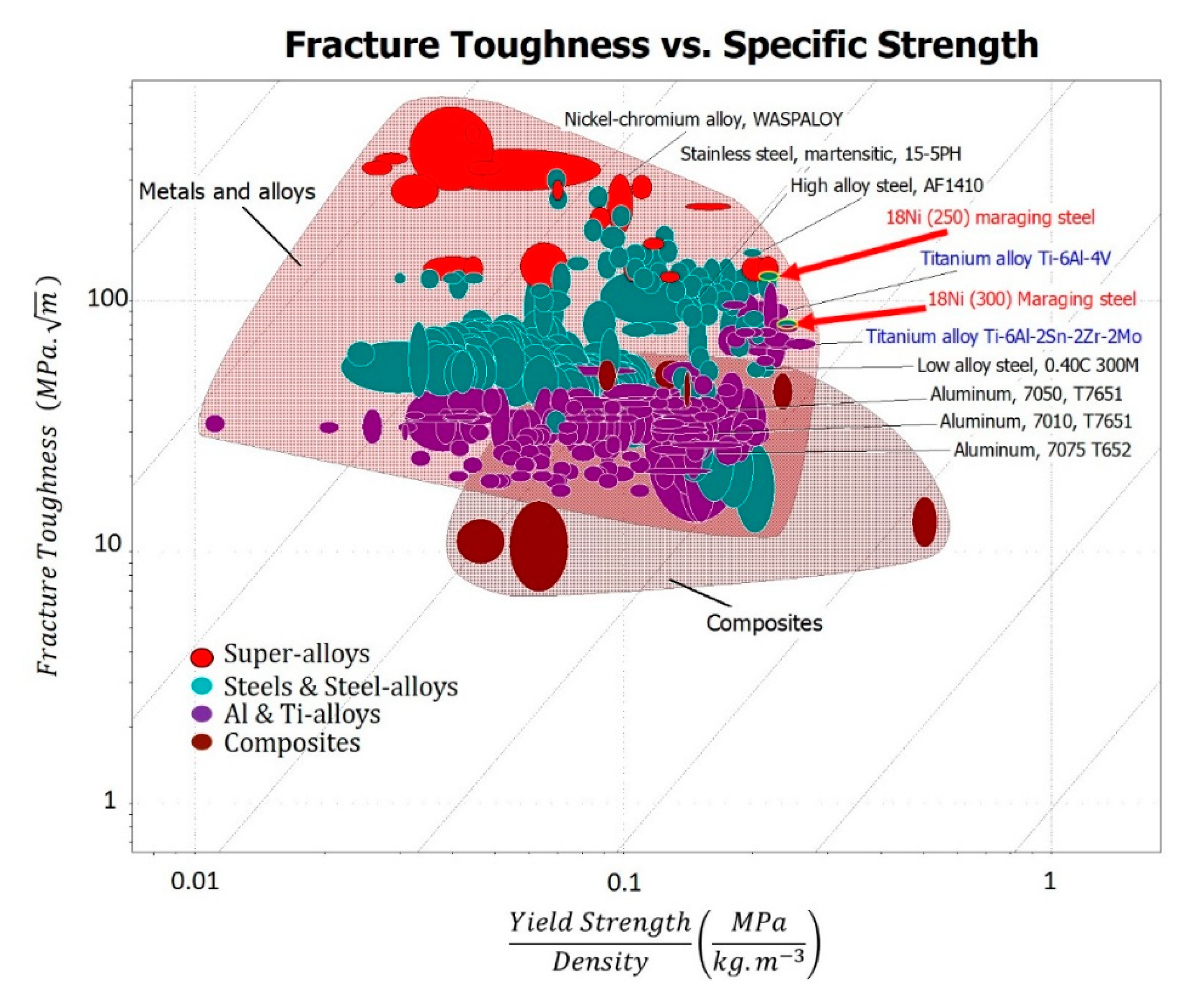

2. Conventionally Manufactured Maraging Steel

2.1. Characteristics

2.2. Heat Treatment

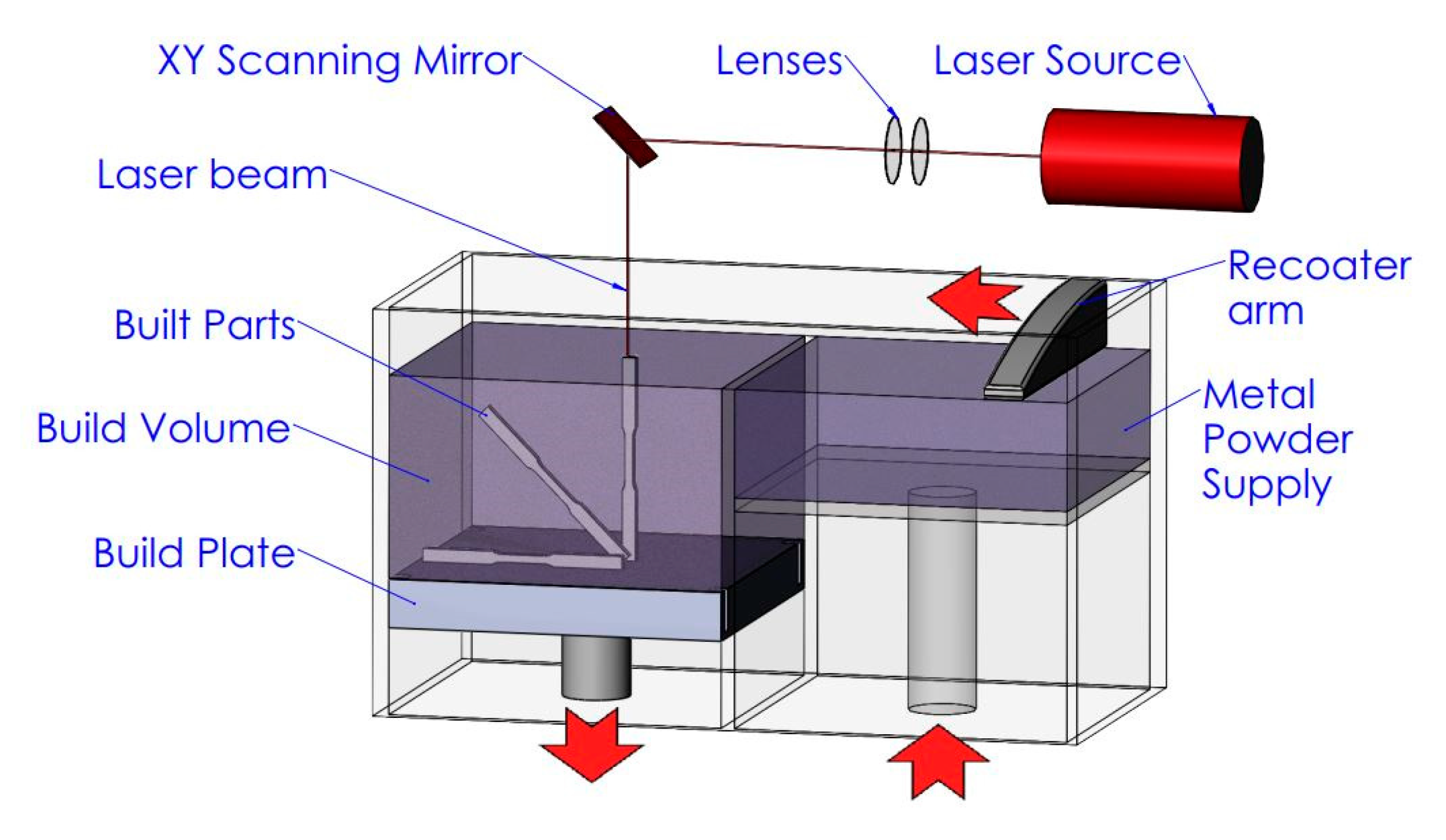

3. Factors Affecting Laser Powder Bed Fusion Built Part Properties

3.1. The Anisotropic Character of the Laser Powder Bed Fusion Process and Impact on Microstructure

3.2. Impact on Built Part Properties

4. The Laser Powder Bed Fusion Maraging Steel

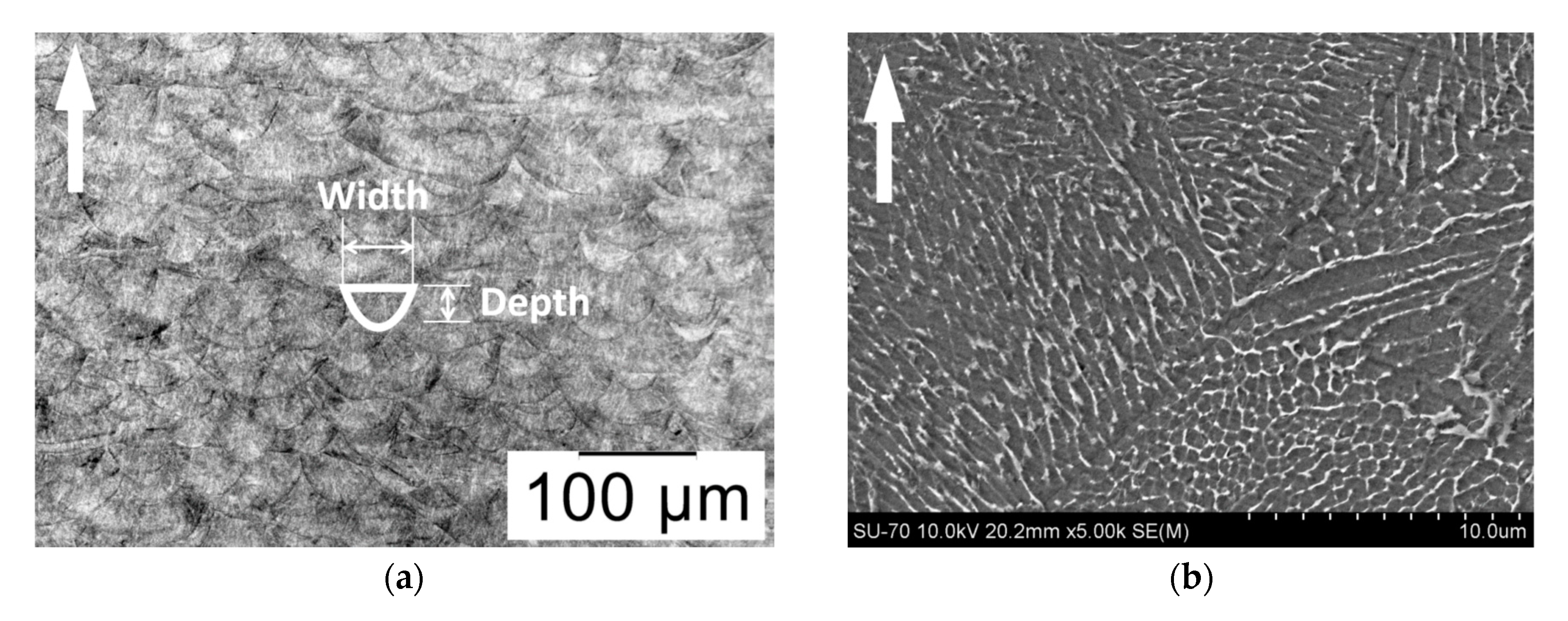

4.1. Microstructure

4.2. Factors Affecting Material Properties

4.2.1. Powder

4.2.2. Processing Parameters

4.2.3. Laser Scan Strategy

4.2.4. Build Orientation and Heat Treatment

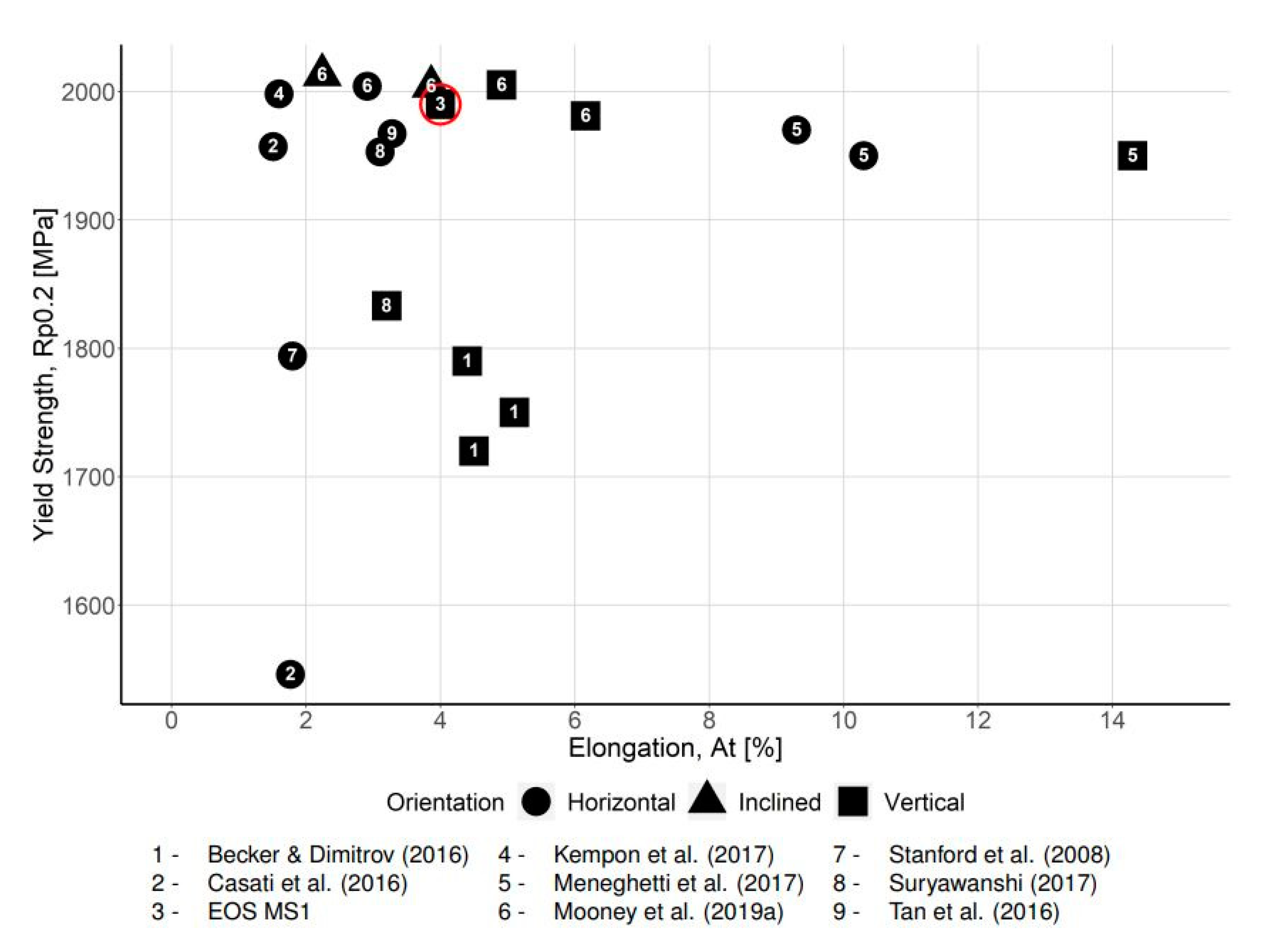

4.3. Mechanical Properties

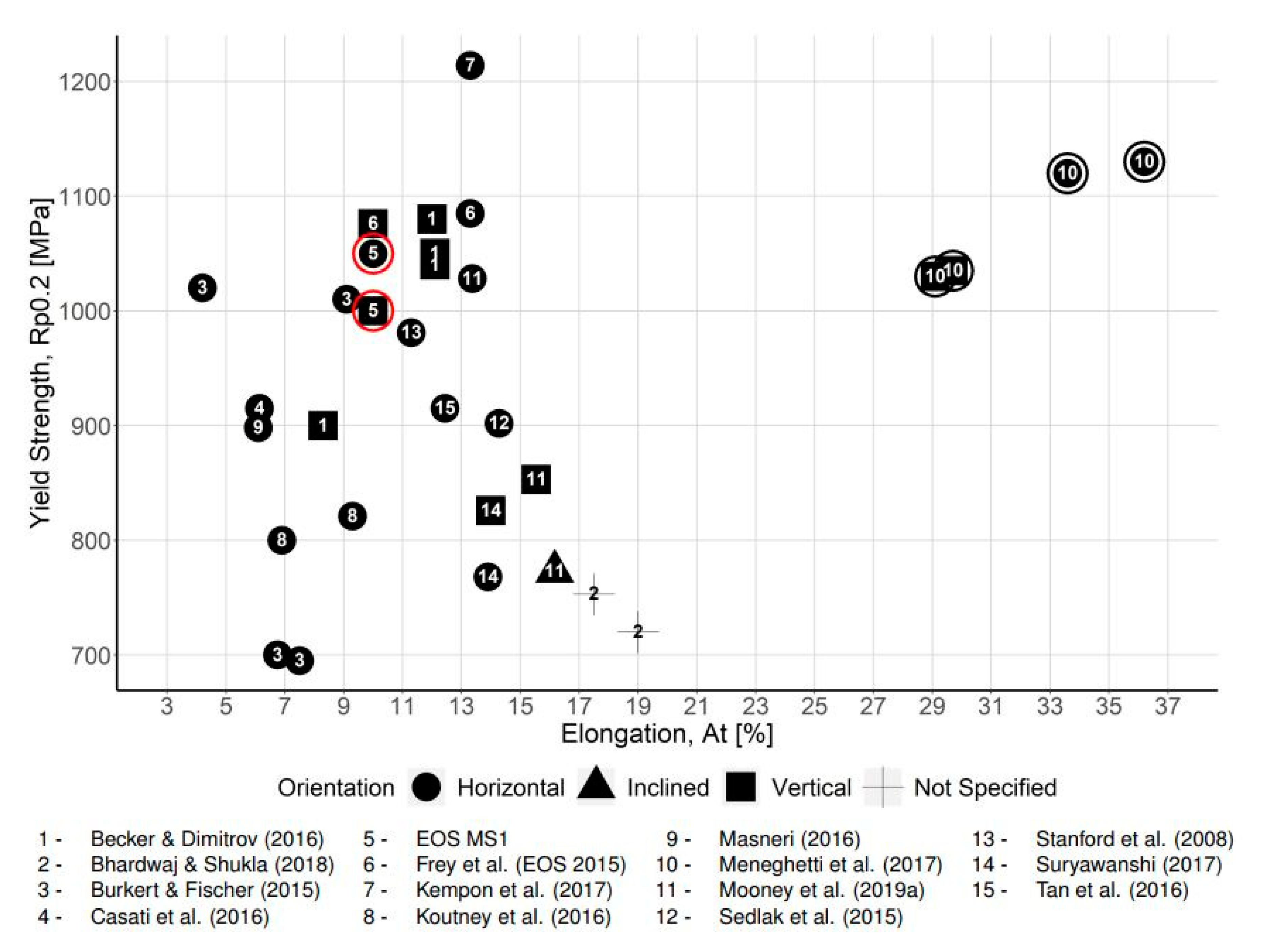

4.3.1. As-built Material

4.3.2. Heat-Treated (Aged) Material

5. Conclusions

- Not only the quality of the powder but also its morphology can play an important role in achieving higher relative density and optimising mechanical properties.

- Processing parameters directly influence the material microstructure, which in turn has an impact on the mechanical properties and anisotropic characteristics of the material. Moreover, in an effort to control density and porosity levels when manipulating processing parameters, adverse results may be obtained in terms of anisotropy.

- Laser scan strategy is a complex problem for material properties’ optimisation, yet it offers an opportunity for further research on how alternate strategies may offer not improved anisotropy.

- The build orientation influence on the mechanical performance of the material is best to be examined in conjunction with heat treatment plans. Anisotropy can be drastically reduced via an appropriate choice of such plans, which are generally easy to implement for this material. In addition, the growing body of research in this field is expected to inform changes in the way heat treatments are selected relative to the sought mechanical properties.

Author Contributions

Funding

Conflicts of Interest

References

- EOS. Materials for Metal Additive Manufacturing. EN. Electro Optical Systems. 2017. Available online: https://www.eos.info/en/additive-manufacturing/3d-printing-metal/dmls-metal-materials (accessed on 14 June 2020).

- Wohlers, T.; Gornet, T. History of Additive Manufacturing. White Paper. Wohlers Associates. 2014, p. 34. Available online: http://wohlersassociates.com/history2014.pdf (accessed on 2 November 2017).

- Carter, L.N.; Martin, C.; Withers, P.J.; Attallah, M.M. The influence of the laser scan strategy on grain structure and cracking behaviour in SLM powder-bed fabricated nickel superalloy. J. Alloys Compd. 2014, 615 (Suppl. C), 338–347. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117 (Suppl. C), 371–392. [Google Scholar] [CrossRef]

- Ahuja, B.; Schaub, A.; Junker, D.; Karg, M.; Tenner, F.; Plettke, R.; Merklein, M.; Schmidt, M. A round robin study for leaser beam melting in a metal powder bed. S. Afr. J. Ind. Eng. 2016, 27, 30–42, ISSN 1012-277X. [Google Scholar] [CrossRef] [Green Version]

- Bassoli, E.; Gatto, A.; Sewell, N.T.; Johns, D. On the effects of build orientation in powder-fed Additive Layer Manufacture of steel 316L. In Innovative Developments in Design and Manufacturing. Advanced Research in Virtual and Rapid Prototyping. 4th International Conference on Advanced Research and Rapid Prototyping. (Liberia, Portugal); CRC Press: Rotterdam, The Netherlands, 2010; pp. 263–268. ISBN 9781439859216. [Google Scholar]

- Appleyard, D. Powering up on powder technology. Met. Powder Rep. 2015, 70, 285–289, ISSN 0026-0657. Available online: http://www.sciencedirect.com/science/article/pii/S0026065715005184 (accessed on 6 October 2017). [CrossRef]

- Scott, D. Add It up: 5 Industrial Additive Manufacturing Trends for 2017. Autodesk. 2017. Available online: https://www.autodesk.com/redshift/industrialadditive-manufacturing-trends/ (accessed on 5 October 2017).

- Singh, S.; Ramakrishna, S.; Singh, R. Material issues in additive manufacturing: A review. J. Manuf. Process. 2017, 25 (Suppl. C), 185–200. [Google Scholar] [CrossRef]

- Grand-View-Research. 3D Metal Printing Market Analysis By Product (Titanium, Nickel, Steel, Aluminum), By Application (Aerospace and Defense, Automotive, Medical and Dental), By Form (Powder, Filament), By Region, By Country, And Segment Forecasts, 2014–2025. Annual Report 4312495. Research and Markets. May 2017, p. 90. Available online: https://www.researchandmarkets.com/research/j37c7h/3d_metal_printing (accessed on 5 October 2017).

- Davis, J.R. (Ed.) Alloying: Understanding the Basics; ASM International: Materials Park, OH, USA, 2001; ISBN 978-0-87170-744-4. [Google Scholar]

- Hall, A.M.; Slunder, C.J. The Metallurgy, Behaviour, and Application of the 18-Percent Nickel Maraging Steels. Survey 20000828 057. SP-5051. NASA. 1968. Available online: http://www.dtic.mil/dtic/tr/fulltext/u2/a382105.pdf (accessed on 14 June 2020).

- Stanford, M.; Kibble, K.; Lindop, M.; Mynors, D.; Durnall, C. An investigation into fully melting a maraging steel using Direct Metal Laser Sintering (DMLS). In Proceedings of the Special Edition Metal Forming Conference, Krakow, Poland, 21–24 September 2008; Volume 2, pp. 847–852. [Google Scholar]

- Sha, W.; Guo, Z. Maraging Steels, Modelling of Microstructure, Properties and Applications; Woodhead Publishing: Cambridge, UK, 2009; ISBN 978-1-84569-686-3. [Google Scholar]

- ASM International. ASM Handbook Volume 4: Heat Treating; ASM International: Materials Park, OH, USA, 1991; Volume 4. [Google Scholar]

- Jägle, E.A.; Sheng, Z.; Wu, L.; Lu, L.; Risse, J.; Weisheit, A.; Raabe, D. Precipitation reactions in age-hardenable alloys during laser additive manufacturing. JOM 2016, 68, 943–949. [Google Scholar] [CrossRef] [Green Version]

- Casati, R.; Lemke, J.N.; Tuissi, A.; Vedani, M. Aging behaviour and mechanical performance of 18-Ni 300 steel processed by selective laser melting. Metals 2016, 6, 218. [Google Scholar] [CrossRef]

- Lang, F.H.; Kenyon, N. WRC Bulletin: Welding of Maraging Steels; Technical Report 159; Welding Research Council: New York, NY, USA, 1971. [Google Scholar]

- Sercombe, T.B. Sintering of freeformed maraging steel with boron additions. Mater. Sci. Eng. A 2003, 363, 242–252. [Google Scholar] [CrossRef]

- Casavola, C.; Campanelli, S.L.; Pappalettere, C. Experimental Analysis of Residual Stresses in the Selective Laser Melting Process. In Proceedings of the XIth International Congress and Exposition; Society for Experimental Mechanics Inc.: Orlando, FL, USA, 2008. [Google Scholar]

- Renishaw. Digging Deep with Wassara; Case Study H-5800-4015-01; Renishaw: Wotton-under-Edge, UK, 2018; Available online: http://www.renishaw.com/en/digging-deep-withwassara--43252 (accessed on 10 July 2020).

- Tariq, F.; Naz, N.; Rasheed, A.B. Effect of cyclic aging on mechanical properties and microstructure of maraging steel 250. J. Mater. Eng. Perform. 2010, 19, 1005–1014. [Google Scholar] [CrossRef]

- Kleiner, L.M.; Simonov, Y.N. Structure and properties of low-carbon martensitic steels. Met. Sci. Heat Treat. 1999, 41, 366–368. [Google Scholar] [CrossRef]

- Inco. 18 per Cent Maraging Steels; Engineering Properties. Tech. Rep. 4419; International Nickel Company, Inco Euro Limited: Brussels, Belgium, 1976; p. 30. [Google Scholar]

- Davis, J.R. (Ed.) ASM Specialty Handbook: Tool Materials; ASM International: Materials Park, OH, USA, 2005; ISBN 9780871705457. [Google Scholar]

- Abrahamson, E.P. Processing and Properties on 18Ni Maraging Steel by Powder Metallurgy; Tech. Rep. AD 758439. AMMRC TR 73-4.; Army Materials and Mechanics Research Center: Watertown, MA, USA, 1973. [Google Scholar]

- Shekhter, A.; Aaronson, H.I.; Miller, M.R.; Ringer, S.P.; Pereloma, E.V. Effect of aging and deformation on the microstructure and properties of Fe- Ni-Ti maraging steel. Metall. Mater. Trans. A 2004, 35, 973–983. [Google Scholar] [CrossRef]

- Casati, R.; Lemke, J.; Vedani, M. Microstructural and Mechanical Properties of as Built, Solution Treated and Aged 18 Ni (300 grade) Maraging Steel Produced by Selective Laser Melting. La Metall. Ital. 2017, 11–20. Available online: http://www.aimnet.it/la_metallurgia_italiana/2017/gennaio/Casati.pdf (accessed on 14 June 2020).

- Jägle, E.A.; Choi, P.P.; van Humbeeck, J.; Raabe, D. Precipitation and austenite reversion behavior of a maraging steel produced by selective laser melting. J. Mater. Res. 2014, 29, 2072–2079. [Google Scholar] [CrossRef] [Green Version]

- Viswanathan, U.K.; Dey, G.K.; Sethumadhavan, V. Effects of austenite reversion during overageing on the mechanical properties of 18 Ni (350) maraging steel. Mater. Sci. Eng. A 2005, 398, 367–372. [Google Scholar] [CrossRef]

- Niendorf, T.; Leuders, S.; Riemer, A.; Richard, H.A.; Tröster, T.; Schwarze, D. Highly Anisotropic Steel Processed by Selective Laser Melting. Metall. Mater. Trans. B 2013, 44, 794–796, ISSN 1543-1916. [Google Scholar] [CrossRef] [Green Version]

- Kunze, K.; Etter, T.; Grässlin, J.; Shklover, V. Texture, anisotropy in microstructure and mechanical properties of IN738LC alloy processed by selective laser melting (SLM). Mater. Sci. Eng. A 2015, 620 (Suppl. C), 213–222. [Google Scholar] [CrossRef]

- Brown, C.U.; Donmez, A. NIST Advanced Manufacturing Series. In Microstructure Analysis for Additive Manufacturing: A Review of Existing Standards; Report 100-3; NIST: Gaithersburg, MD, USA, 2016; p. 27. [Google Scholar] [CrossRef]

- Etter, T.; Kunze, K.; Geiger, F.; Meidani, H. Reduction in mechanical anisotropy through high temperature heat treatment of Hastelloy X processed by Selective Laser Melting (SLM). IOP Conf. Ser. Mater. Sci. Eng. 2015, 82, 012097. [Google Scholar] [CrossRef]

- Dieter, G.E. Mechanical Metallurgy; McGraw-Hill: New York, NY, USA, 1961. [Google Scholar]

- Thijs, L.; Kempen, K.; Kruth, J.; van Humbeeck, J. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef] [Green Version]

- AlMangour, B.; Grzesiak, D.; Yang, J.M. Rapid fabrication of bulk-form TiB2/316L stainless steel nanocomposites with novel reinforcement architecture and improved performance by selective laser melting. J. Alloys Compd. 2016, 680, 480–493. [Google Scholar] [CrossRef]

- Bhardwaj, T.; Shukla, M. Effect of laser scanning strategies on texture, physical and mechanical properties of laser sintered maraging steel. Mater. Sci. Eng. A 2018, 734, 102–109, ISSN 0921-5093. [Google Scholar] [CrossRef]

- Becker, T.H.; Dimitrov, D. The achievable mechanical properties of SLM produced Maraging Steel 300 components. Rapid Prototyp. J. 2016, 22, 487–494. [Google Scholar] [CrossRef]

- Bai, Y.; Yang, Y.; Wang, D.; Zhang, M. Influence mechanism of parameters process and mechanical properties evolution mechanism of maraging steel 300 by selective laser melting. Mater. Sci. Eng. A 2017, 703 (Suppl. C), 116–123. [Google Scholar] [CrossRef]

- Yasa, E.; Deckers, J.; Kruth, J.P.; Rombouts, M.; Luyten, J. Experimental investigation of Charpy impact tests on metallic SLM parts. In Innovative Developments in Design and Manufacturing Advanced Research in Virtual and Rapid Prototyping; CRC Press-Taylor Francis Group: Leiria, Portugal, 2009; pp. 214–217. Available online: https://lirias.kuleuven.be/bitstream/123456789/224820/2/Yasa_VRAP_2009_submitted.pdf (accessed on 24 November 2017).

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Glaser, R.; Goel, R.; Hewitt, M.; Meng, F.; Wang, P.; Yan, R. 3D Printing Alloys; Report; Northwestern University: Evanston, IL, USA, 2015; Available online: https://canvas.northwestern.edu/files/2229202/download?download_frd=1&verifier=N8bi8oUaRn08EPsKLapRweNJAdhdKg2PH0jtJdIJ (accessed on 28 October 2017).

- Campanelli, S.L.; Contuzzi, N.; Angelastro, A.; Ludovico, A.D. NewTrends in Technologies: Devices, Computer, Communication and Industrial Systems; IntechOpen: London, UK, 2010; Chapter 13, Capabilities and Performances of the Selective Laser Melting Process; pp. 233–252. [Google Scholar]

- Tan, C.; Zhou, K.; Tong, X.; Huang, Y.; Jing, J.; Ma, W.; Li, F.; Kuang, T. Microstructure and Mechanical Properties of 18Ni-300 Maraging Steel Fabricated by Selective Laser Melting. In Proceedings of the 6th International Conference on Advanced Design and Manufacturing Engineering (ICADME 2016); Atlantis Press: Amsterdam, The Netherlands, 2016; pp. 404–410. [Google Scholar] [CrossRef] [Green Version]

- Suryawanshi, J.; Prashanth, K.G.; Ramamurty, U. Tensile, fracture, and fatigue crack growth properties of a 3D printed maraging steel through selective laser melting. J. Alloys Compd. 2017, 725 (Suppl. C), 355–364. [Google Scholar] [CrossRef]

- Bourdil, D. (Ed.) Microstructure and Mechanical Properties of Maraging Steel 300 after Selective Laser Melting. Solid Freeform Fabrication Symposium. (Texas, Aug. 12, 2010). USA. August 2010, pp. 383–396. Available online: https://sffsymposium.engr.utexas.edu/Manuscripts/2010/2010-32-Yasa.pdf (accessed on 8 August 2017).

- Tan, C.; Zhou, K.; Ma, W.; Zhang, P.; Liu, M.; Kuang, T. Microstructural evolution, nanoprecipitation behavior and mechanical properties of selective laser melted high-performance grade 300 maraging steel. Mater. Des. 2017, 134, 23–34. [Google Scholar] [CrossRef]

- Mutua, J.; Nakata, S.; Onda, T.; Chen, Z.C. Optimization of selective laser melting parameters and influence of post heat treatment on microstructure and mechanical properties of maraging steel. Mater. Des. 2018, 139, 486–497. [Google Scholar] [CrossRef]

- Morito, S.; Tanaka, H.; Konishi, R.; Furuhara, T.; Maki, T. The morphology and crystallography of lath martensite in Fe-C alloys. Acta Mater. 2003, 51, 1789–1799. [Google Scholar] [CrossRef]

- Kempen, K.; Yasa, E.; Thijs, L.; Kruth, J.-P.; van Humbeeck, J. Microstructure and mechanical properties of Selective Laser Melted 18Ni-300 steel. Lasers in Manufacturing 2011; In Proceedings of the Sixth International WLT Conference on Lasers in Manufacturing. Phys. Procedia 2011, 12, 255–263, ISSN 1875-3892. [Google Scholar] [CrossRef] [Green Version]

- Jägle, E.A.; Sheng, Z.; Kurnsteiner, P.; Ocylok, S.; Weisheit, A.; Raabe, D. Comparison of Maraging Steel Micro- and Nanostructure Produced Conventionally and by Laser Additive Manufacturing. Materials 2017, 10, 8. [Google Scholar] [CrossRef] [Green Version]

- Shamantha, C.R.; Narayanan, R.; Iyer, K.J.L.; Radhakrishnan, V.M.; Seshadri, S.K.; Sundararajan, S.; Sundaresan, S. Microstructural changes during welding and subsequent heat treatment of 18Ni (250-grade) maraging steel. Mater. Sci. Eng. A 2000, 287, 43–51. [Google Scholar] [CrossRef]

- Yin, S.; Chen, C.; Yan, X.; Feng, X.; Jenkins, R.; O’Reilly, P.; Liu, M.; Li, H.; Lupoi, R. The influence of aging temperature and aging time on the mechanical and tribological properties of selective laser melted maraging 18Ni-300 steel. Addit. Manuf. 2018, 22, 592–600. [Google Scholar] [CrossRef]

- EOS. EOS MaragingSteel MS1; Material data sheet EOSINT M280 EOSINT M270; EOS GmbH: Munich, Germany, 2011; p. 6. Available online: http://ip-saas-eos-cms.s3.amazonaws.com/public/1af123af9a636e61/042696652ecc69142c8518dc772dc113/EOS_MaragingSteel_MS1_en.pdf (accessed on 14 June 2020).

- Renishaw. Maraging Steel M300 Powder for Additive Manufacturing; Data sheet; Renishaw: New Mills, UK, 2017; p. 2. Available online: http://resources.renishaw.com/en/download/data-sheet-maraging-steel-m300-for-200-w-powder-for-additive-manufacturing--96325 (accessed on 14 June 2020).

- Concept Laser. CL 50WS Hot Work Steel 1.2709 Powder. Material Data Sheet; Concept Laser: Lichtenfels, Germany, 2016; p. 2. Available online: https://www.concept-laser.de/fileadmin//user_upload/Datasheet_CL_50WS.pdf (accessed on 15 August 2018).

- 3D Systems. LaserForm Maraging Steel (B) for ProX DMP 200 and 300 Direct Metal Printers; Material Product Data Sheet; 3D Systems: Rock Hill, SC, USA, 2017; p. 1. Available online: https://www.3dsystems.com/materials/maraging-steel (accessed on 19 September 2017).

- Oerlikon. Maraging Steel (C300) Type Powder for Additive Manufacturing; Material Product Data Sheet; Oerlikon AG: Pfäffikon, Switzerland, 2017; p. 1. Available online: https://www.oerlikon.com/metco/en/ (accessed on 19 September 2017).

- LPW. Powder Range. Metal Powders from LPW. Material Data Sheet; LPW Technologies: Widnes, UK, 2016; p. 12. Available online: http://www.lpwtechnology.com/wp-content/uploads/2016/11/LPW_Powders_Brochure.pdf (accessed on 19 September 2017).

- 3TRPD. Maraging Steel 1.2709 (Source EOS). Material Specification; 3TRPD: 3T Additive Manufacturing: Fulton Court, UK, 2012; p. 1. Available online: http://www.3trpd.co.uk/wp-content/uploads/2013/03/maraging-steel-1-2709-2012.pdf (accessed on 19 September 2017).

- Sandvik Materials Technology. Sandvik Osprey Metal Powders; Tech. Rep.; Sandvik Materials Technology Ltd.: Halesowen, UK, 2010; Available online: https://www.materials.sandvik/globalassets/global/downloads/products_downloads/metal_powders/s-po009-ps-eng-09.2010.pdf (accessed on 10 July 2020).

- LPW Technology. Case Study: Maraging Steel—The Effects of Alloy Chemistry on Processability. Case Study. LPW. August 2017. Available online: https://www.lpwtechnology.com/wp-content/uploads/2017/08/Case-Study-M300.pdf (accessed on 10 July 2020).

- LPW Technology. Case Study: The Impact of Powder Variability on Additive Manufacturing Build Quality. Case Study. LPW. May 2018. Available online: https://www.lpwtechnology.com/wp-content/uploads/2018/05/Case-Study-12-ALSi10Mg-Final.pdf (accessed on 10 July 2020).

- Sutton, A.T.; Kriewall, C.S.; Leu, M.C.; Newkirk, J.W. Powders for Additive Manufacturing Processes: Characterization Techniques and Effects on Part Properties. In Proceedings of the 26th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 8–10 August 2016. [Google Scholar]

- Burkert, T.; Fischer, A. The Effects of Heat Balance on the Void Formation within Marage 300 Processed by Selective Laser Melting. In International Solid Freeform Fabrication Symposium; University of Texas: Austin, TX, USA, 2015; pp. 745–757. Available online: http://sffsymposium.engr.utexas.edu/sites/default/files/2015/2015-61-Burkert.pdf (accessed on 14 June 2020).

- Koutney, D.; Panteljev, L.; Tomes, J.; Palousek, D. Comparison of selective laser melting of 18NI maraging steel by PXL and M2 cusing. Mod. Mach. Sci. J. 2016, 180, 1590–1596. [Google Scholar] [CrossRef]

- Kempen, K. Expanding the Materials Palette for Selective Laser Melting of Metals. In Dissertation. KU Leuven—Faculty of Engineering Science; Katholieke Universiteit Leuven: Leuven, Belgium, 2015. [Google Scholar]

- Masneri, C. Microstructural and Mechanical Properties of Maraging Steel Parts Produced by Selective Laser Melting. Master’s Thesis, Politecnico Milano, Milan, Italy, 2016. [Google Scholar]

- Renishaw. Investigating the Effects of Multiple Re-Use of Ti6Al4V Powder in Additive Manufacturing (AM). White Paper. Renishaw. 2016. Available online: http://resources.renishaw.com/en/details/white-paper-investigatingthe-effects-of-multiple-powder-re-use-in-am--83164 (accessed on 10 July 2020).

- Quinn, P.T.; O’Halloran, S.M.; Lawlor, J.; Raghavendra, R. Characterization of Recycled Powders and Resulting Properties Derived From Additive Manufacturing. In Proceedings of the Preliminary Proceedings: 35th International Manufacturing Conference (IMC35), 20 June 2018; Dublin Institute of Technology: Dublin, Ireland, 2018; pp. 8–11. [Google Scholar]

- Hoeges, S.; Schade, C.T.; Causton, R. Development of a Maraging Steel Powder for Additive Manufacturing. In Proceedings of the MPIF World Congress on Powder Metallurgy and Particulate Materials, San Diego, CA, USA, 17–28 May 2015; pp. 17–28. [Google Scholar]

- Montazeri, M.; Yavari, R.; Rao, P.; Boulware, P. In-Process Monitoring of Material Cross-Contamination Defects in Laser Powder Bed Fusion. ASME. J. Manuf. Sci. Eng. 2018, 140, 111001. [Google Scholar] [CrossRef]

- Mahmoudi, M.; Ezzat, A.A.; Elwany, A. Layerwise Anomaly Detection in Laser Powder-Bed Fusion Metal Additive Manufacturing. ASME. J. Manuf. Sci. Eng. 2019, 141, 031002. [Google Scholar] [CrossRef]

- Polozov, I.; Sufiiarov, V.; Kantyukov, A.; Razumov, N.; Goncharov, I.; Makhmutov, T.; Silin, A.; Kim, A.; Starikov, K.; Shamshurin, A.; et al. Microstructure, densification, and mechanical properties of titanium intermetallic alloy manufactured by laser powder bed fusion additive manufacturing with high-temperature preheating using gas atomized and mechanically alloyed plasma spheroidized powders. Addit. Manuf. 2020, 34, 101374. [Google Scholar] [CrossRef]

- Tolosa, I.; Garciandía, F.; Zubiri, F.; Zapirain, F.; Esnaola, A. Study of mechanical properties of AISI 316 stainless steel processed by “selective laser melting”, following different manufacturing strategies. Int. J. Adv. Manuf. Technol. 2010, 51, 639–647. [Google Scholar] [CrossRef]

- Casalino, G.; Campanelli, S.L.; Contuzzi, N.; Ludovico, A.D. Experimental investigation and statistical optimisation of the selective laser melting process of a maraging steel. Opt. Laser Technol. 2015, 65, 151–158. [Google Scholar] [CrossRef]

- Campanelli, S.L.; Contuzzi, N.; Ludovico, A.D. Manufacturing of 18 Ni Marage 300 Steel Samples by Selective Laser Melting. In Advances in Materials and Processing Technologies; Advanced Materials Research; Trans Tech Publications: Baech, Switzerland, 2010; Volume 83, pp. 850–857. [Google Scholar] [CrossRef]

- Casavola, C.; Campanelli, S.L.; Pappalettere, C. Preliminary investigation on distribution of residual stress generated by the selective laser melting process. J. Strain Anal. Eng. Des. 2009, 44, 93–104. [Google Scholar] [CrossRef]

- Frey, M.; Shellabear, M.; Thersson, L. Mechanical Testing of DMLS Parts. White Paper. EOS GmbH. 2015. Available online: https://gpiprototype.com/pdf/mechanical-testing-of-dmls-parts.pdf (accessed on 14 June 2020).

- Monkova, K.; Zetkova, I.; Kucerová, L.; Zetek, M.; Monka, P.; Dana, M. Study of 3D printing direction and effects of heat treatment on mechanical properties of MS1 maraging steel. Arch. Appl. Mech. 2018, 1–14. [Google Scholar] [CrossRef]

- Croccolo, D.; De Agostinis, M.; Fini, S.; Olmi, G.; Vranic, A.; Ciric-Kostic, S. Influence of the build orientation on the fatigue strength of EOS maraging steel produced by additive metal machine. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 637–647. [Google Scholar] [CrossRef]

- Contuzzi, N.; Campanelli, S.; Casalino, G.; Ludovico, A. Effect of Heat Treatment on Selective Laser Melted Steel Parts. In Annals of DAAAM for 2010 & Proceedings of the 21st International DAAAM Symposium; Katalinic, B., Ed.; DAAAM International: Vienna, Austria, 2010; pp. 1–2. Available online: https://www.daaam.info/Downloads/Pdfs/proceedings/proceedings_2010/24802_Symp_1_head.pdf (accessed on 14 June 2020).

- Mooney, B.; Kourousis, K.I.; Raghavendra, R. Plastic anisotropy of additively manufactured maraging steel: Influence of the build orientation and heat treatments. Addit. Manuf. 2019, 25, 19–31. [Google Scholar] [CrossRef] [Green Version]

- Mooney, B.; Kourousis, K.I.; Raghavendra, R.; Agius, D. Process phenomena influencing the tensile and anisotropic characteristics of additively manufactured maraging steel. Mater. Sci. Eng. A 2019, 745, 115–125. [Google Scholar] [CrossRef]

- Sedlak, J.; Rican, D.; Piska, M.; Rozkosny, L. Study of Materials Produced by Powder Metallurgy Using Classical and Modern Additive Laser Technology. Procedia Eng. 2015, 100, 1232–1241, Part of Special issue 25th DAAAM International Symposium on Intelligent Manufacturing and Automation, 2014. [Google Scholar] [CrossRef] [Green Version]

- Meneghetti, G.; Rigon, D.; Cozzi, D.; Waldhauser, W.; Dabala, M. Influence of Build Orientation on Static and Axial Fatigue Properties of Maraging Steel Specimens Produced by Additive Manufacturing. Procedia Structural Integrity 7 (2017). In Proceedings of the 3rd International Symposium on Fatigue Design and Material Defects, FDMD 2017, Lecco, Italy, 19–22 September 2017; pp. 149–157, ISSN 2452-3216. Available online: http://www.sciencedirect.com/science/article/pii/S2452321617304262 (accessed on 10 July 2020). [CrossRef]

- Campanelli, S.L.; Contuzzi, N.; Posa, P.; Angelastro, A. Study of the aging treatment on selective laser melted maraging 300 steel. Mater. Res. Express 2019, 6, 066580. [Google Scholar] [CrossRef]

- EOS. Machine and Software Parameters EOSINT M 280. EN. ParameterSheet. Made Available to EOSINT M280 Machine Owners by Request to EOS (not Published); EOS GmbH: Munich, Germany, 2015. [Google Scholar]

- Mercelis, P.; Kruth, J. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

- Edwards, P.; Ramulu, M. Fatigue performance evaluation of selective laser melted Ti-6Al-4V. Mater. Sci. Eng. A 2014, 598, 327–337. [Google Scholar] [CrossRef]

| Alloy Designation | Ni | Mo | Co | Ti | Al | Rp0.2 (MPa) |

|---|---|---|---|---|---|---|

| 18Ni (200) | 18 | 3.3 | 8.5 | 0.2 | 0.1 | 1400 |

| 18Ni (250) | 18 | 5.0 | 8.5 | 0.4 | 0.1 | 1700 |

| 18Ni (300) | 18 | 5.0 | 9.0 | 0.7 | 0.1 | 2000 |

| 18Ni (350) | 18 | 4.2 | 12.5 | 1.6 | 0.1 | 2400 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mooney, B.; Kourousis, K.I. A Review of Factors Affecting the Mechanical Properties of Maraging Steel 300 Fabricated via Laser Powder Bed Fusion. Metals 2020, 10, 1273. https://doi.org/10.3390/met10091273

Mooney B, Kourousis KI. A Review of Factors Affecting the Mechanical Properties of Maraging Steel 300 Fabricated via Laser Powder Bed Fusion. Metals. 2020; 10(9):1273. https://doi.org/10.3390/met10091273

Chicago/Turabian StyleMooney, Barry, and Kyriakos I. Kourousis. 2020. "A Review of Factors Affecting the Mechanical Properties of Maraging Steel 300 Fabricated via Laser Powder Bed Fusion" Metals 10, no. 9: 1273. https://doi.org/10.3390/met10091273

APA StyleMooney, B., & Kourousis, K. I. (2020). A Review of Factors Affecting the Mechanical Properties of Maraging Steel 300 Fabricated via Laser Powder Bed Fusion. Metals, 10(9), 1273. https://doi.org/10.3390/met10091273