Effect of Severe Shot Peening on the Very-High Cycle Notch Fatigue of an AW 7075 Alloy

Abstract

1. Introduction

2. Experimental Material and Methodology

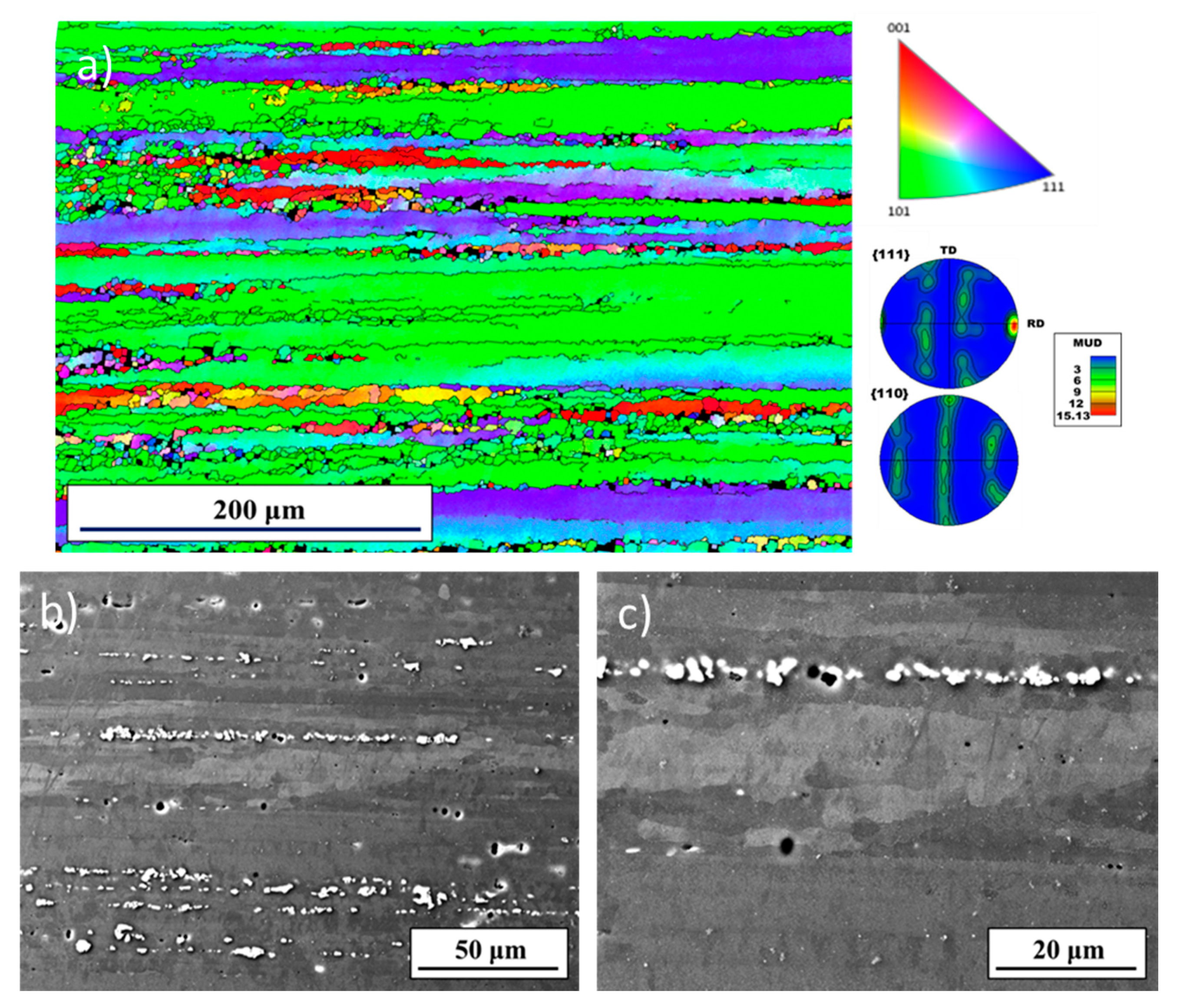

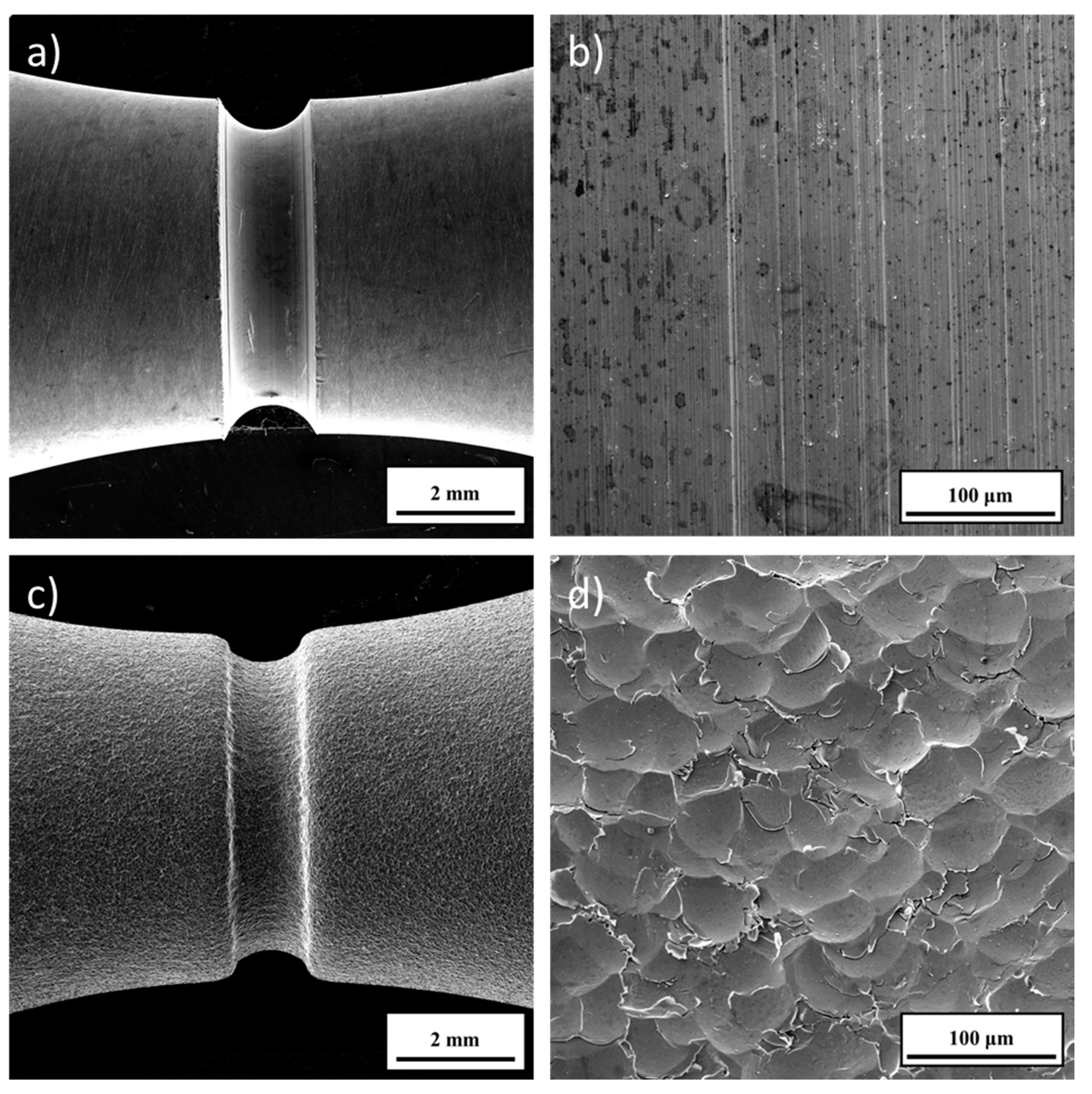

2.1. Material and Specimens

2.2. Surface Treatment

2.3. Fatigue Life Analysis

3. Results

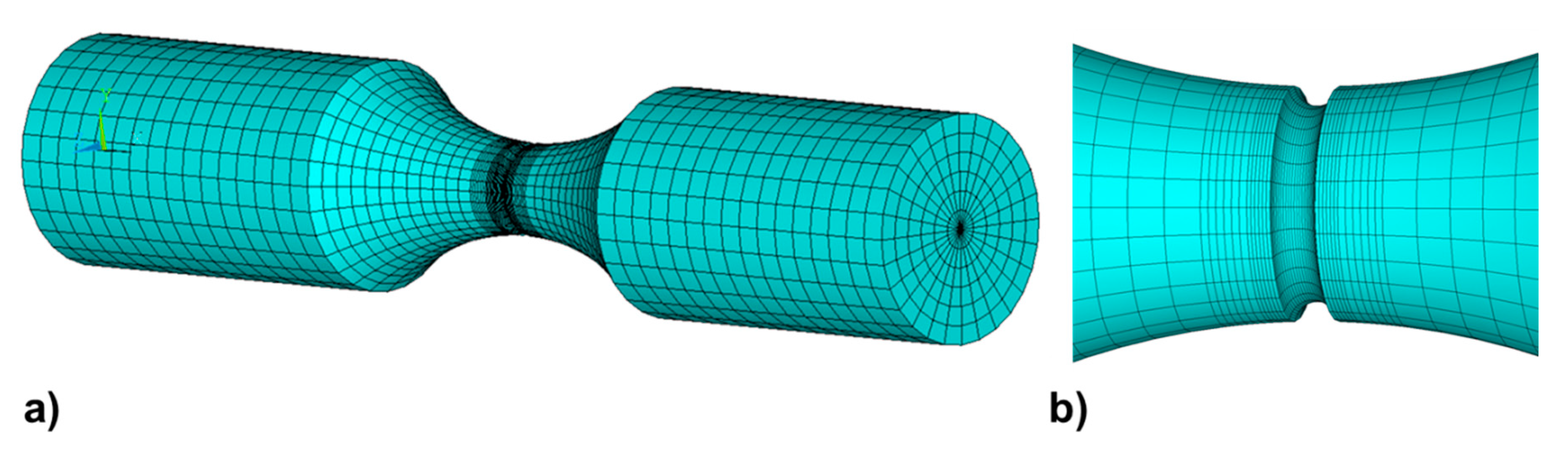

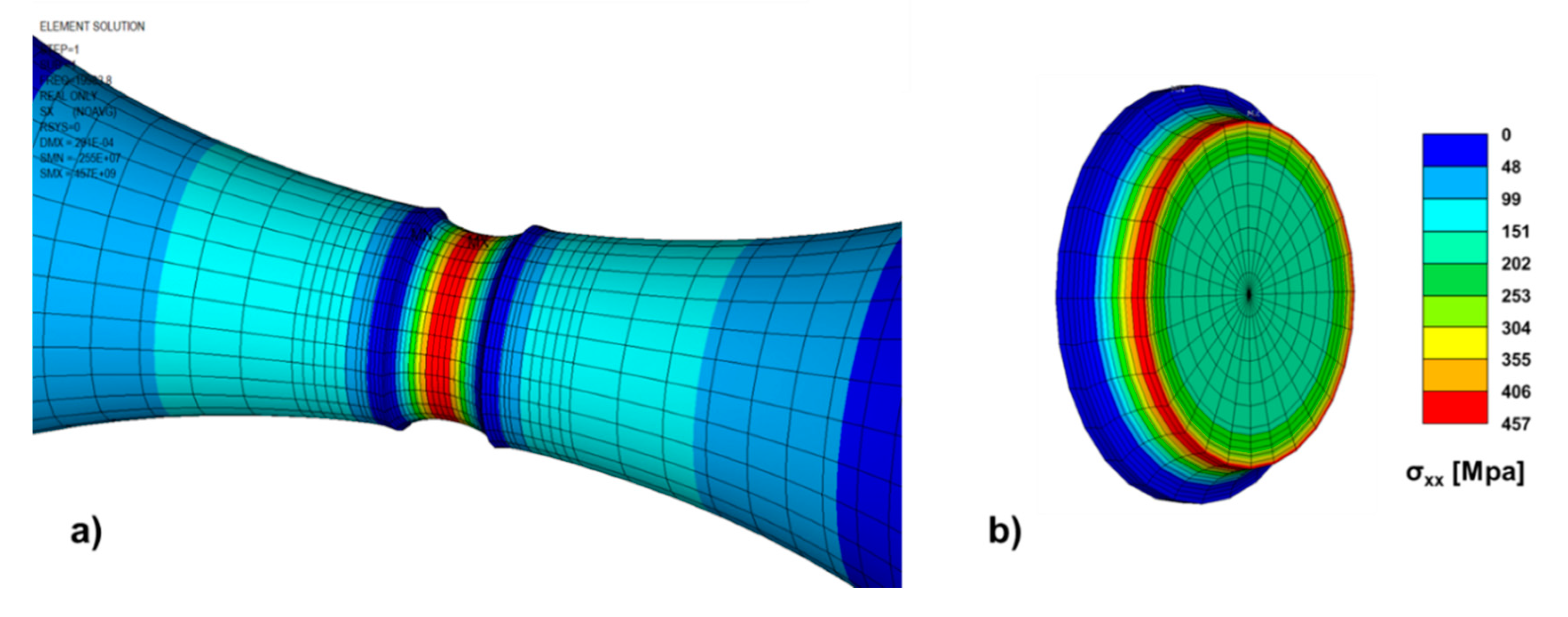

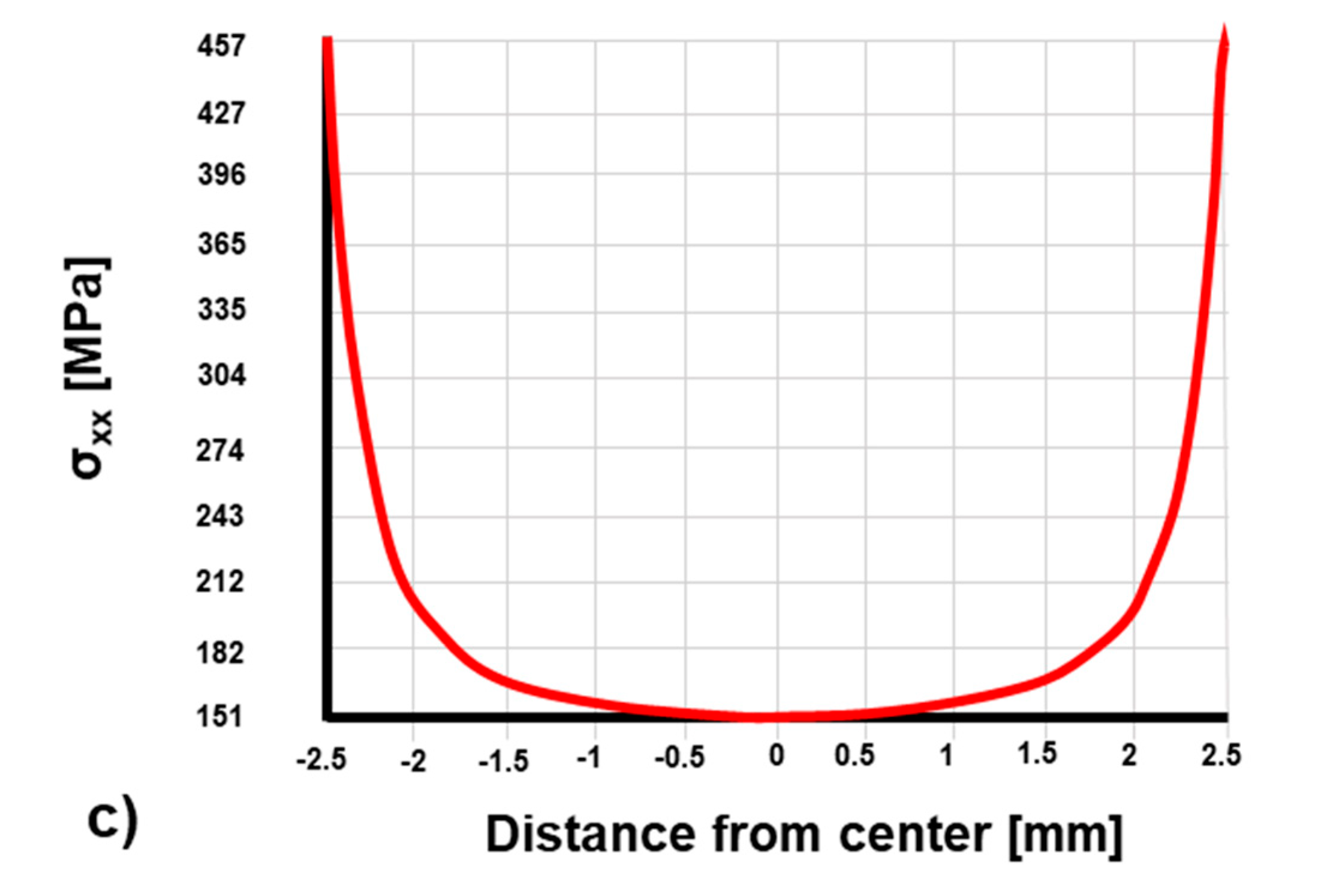

3.1. Stress Analysis in the Notch

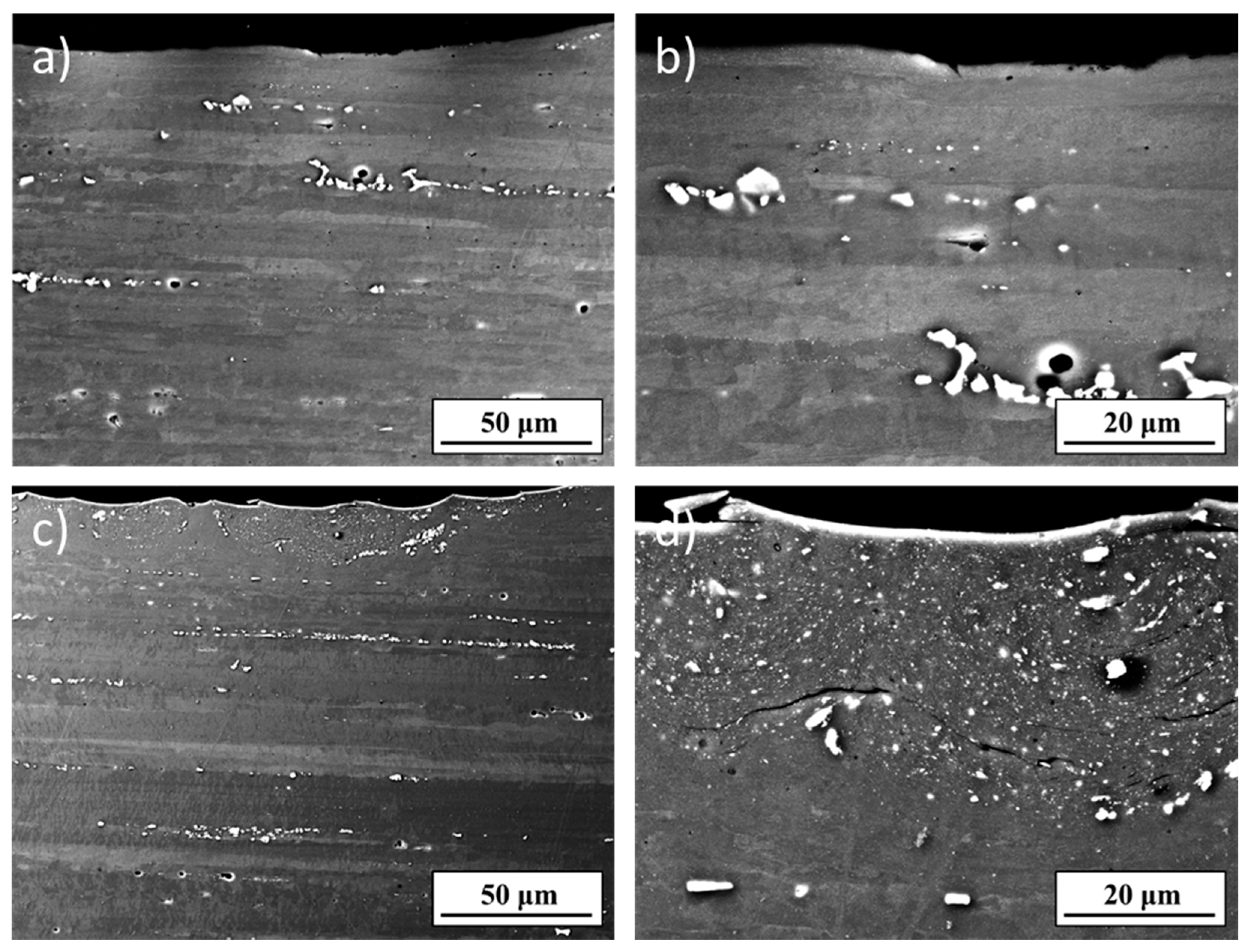

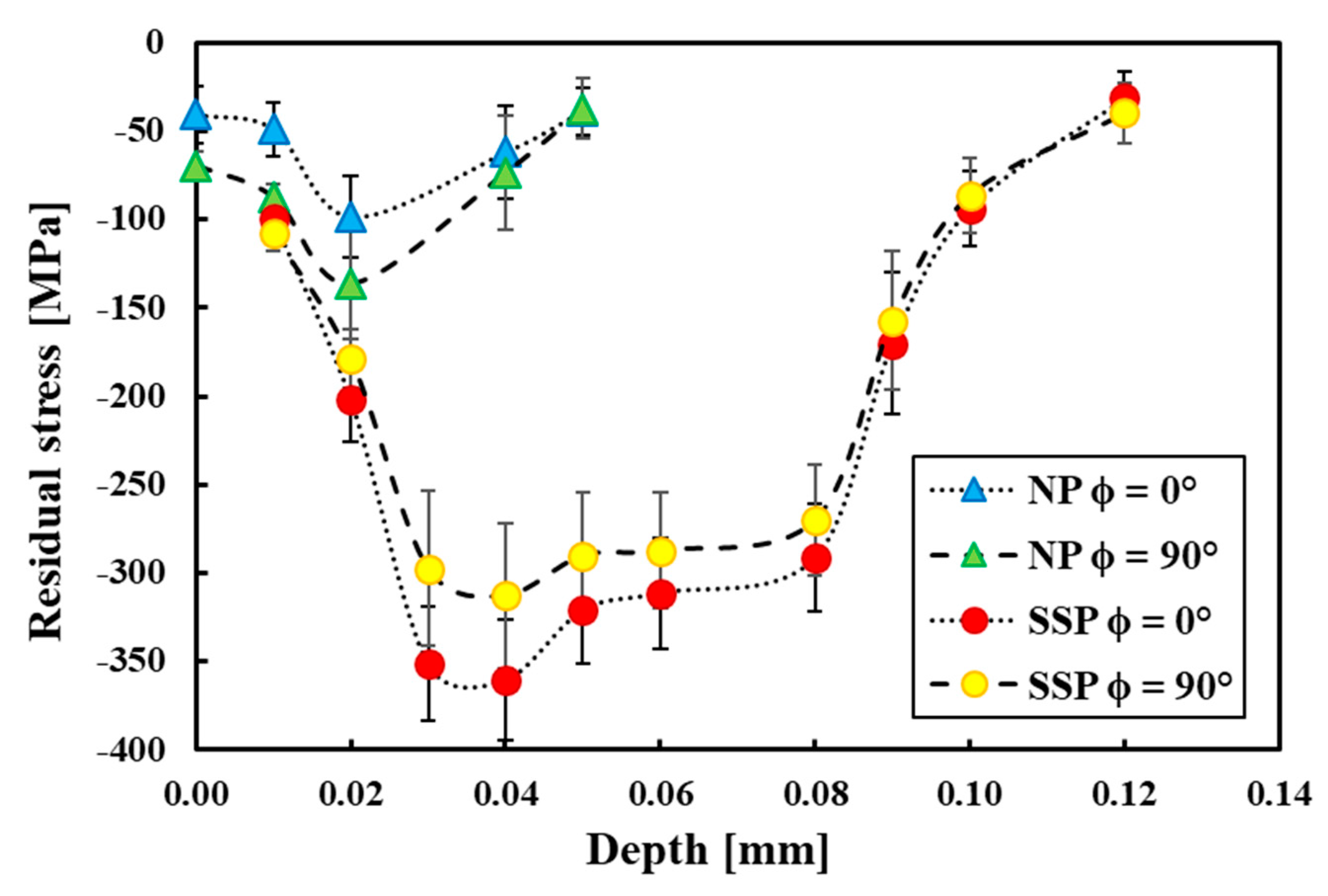

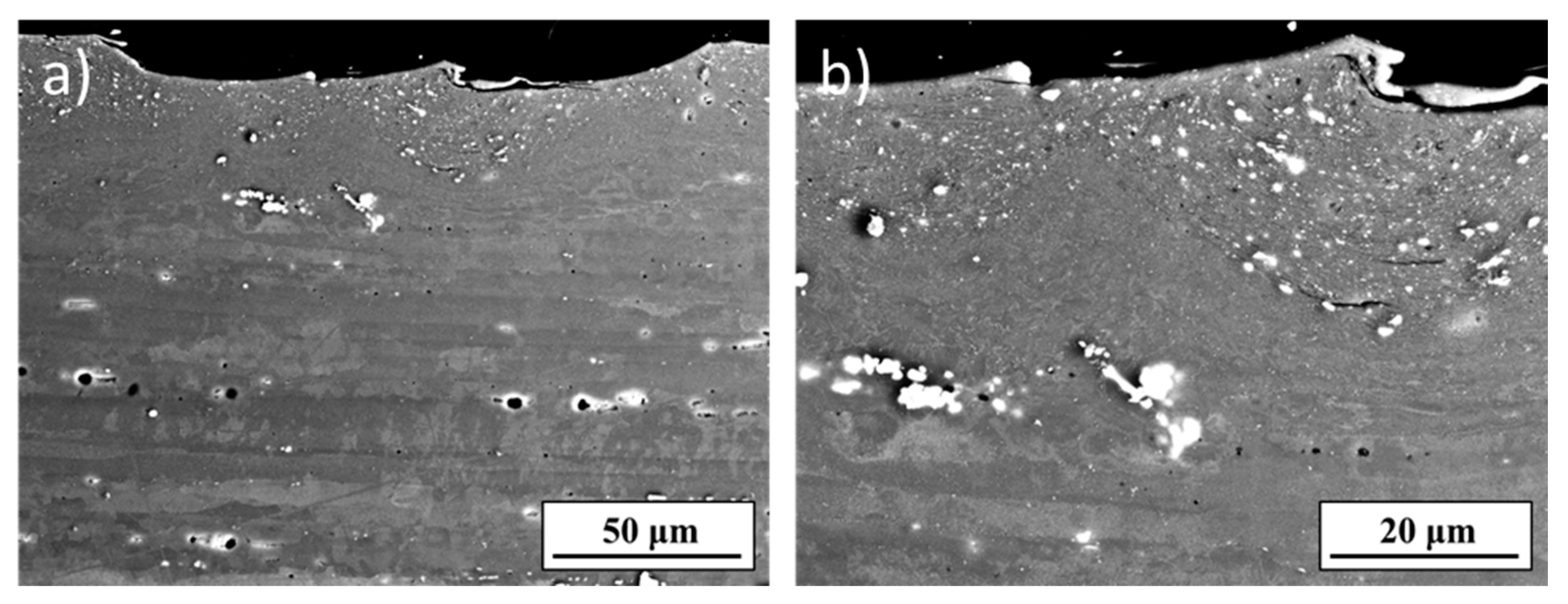

3.2. Effect of Shot Peening on the Surface State

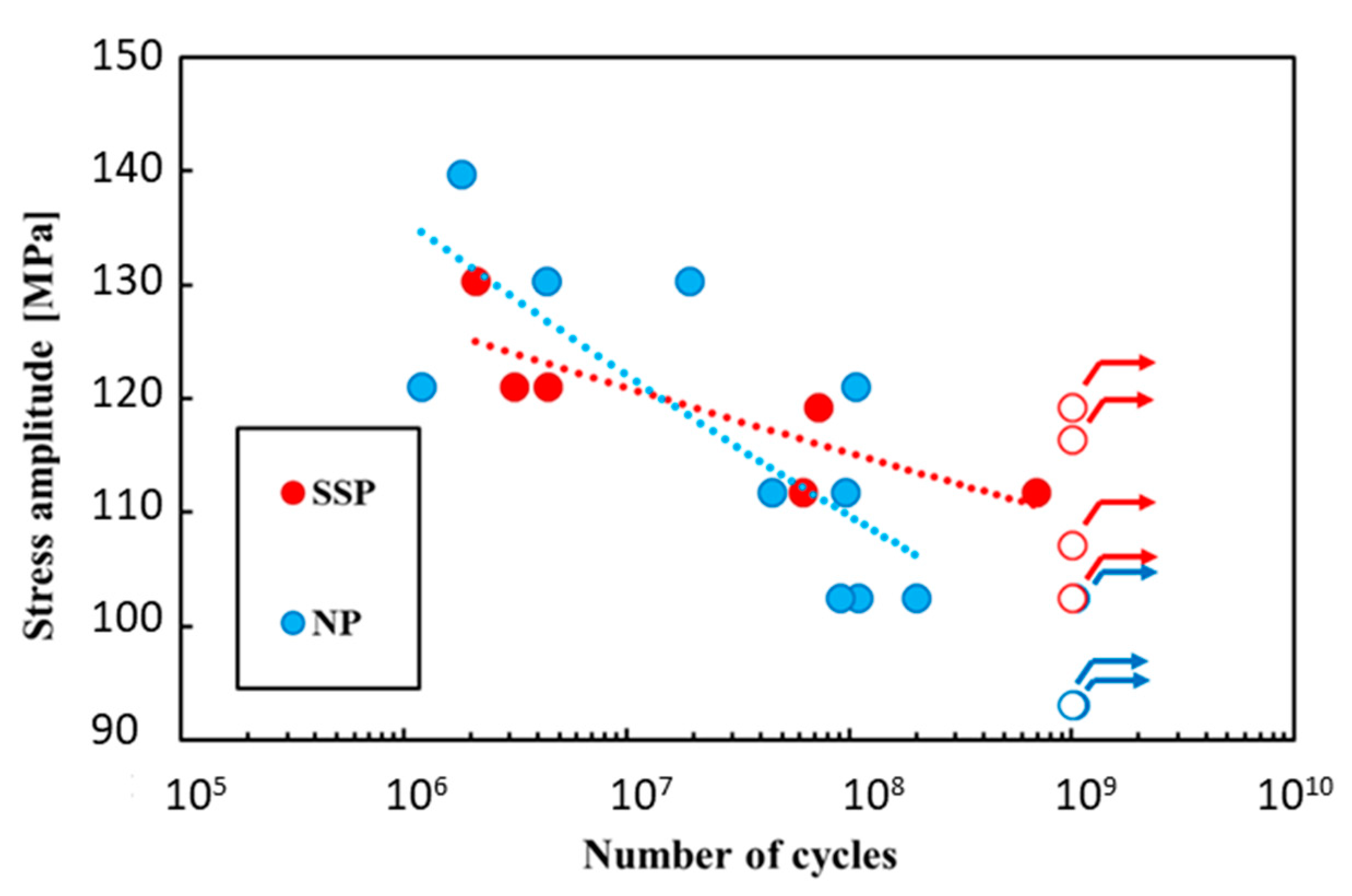

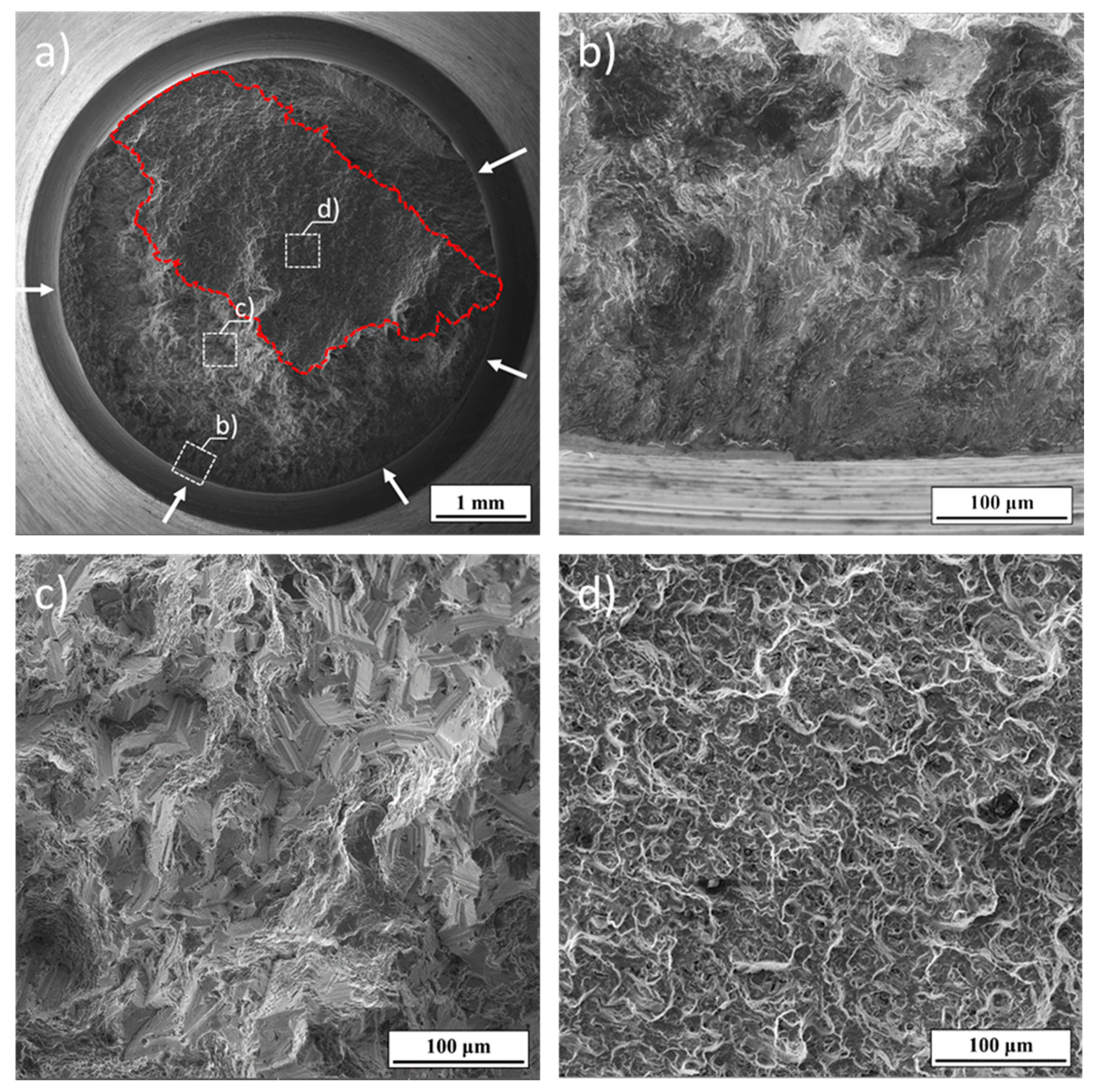

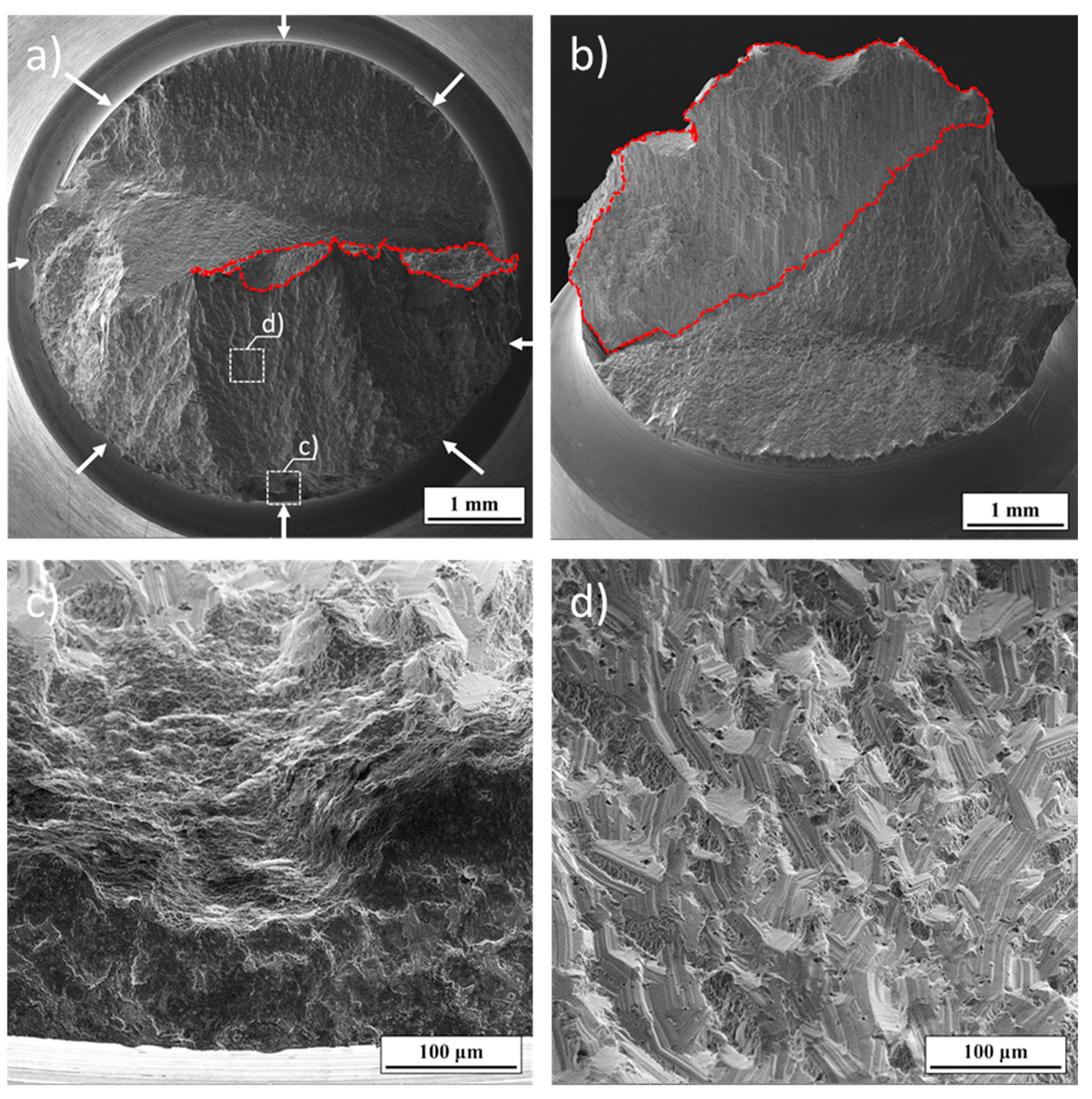

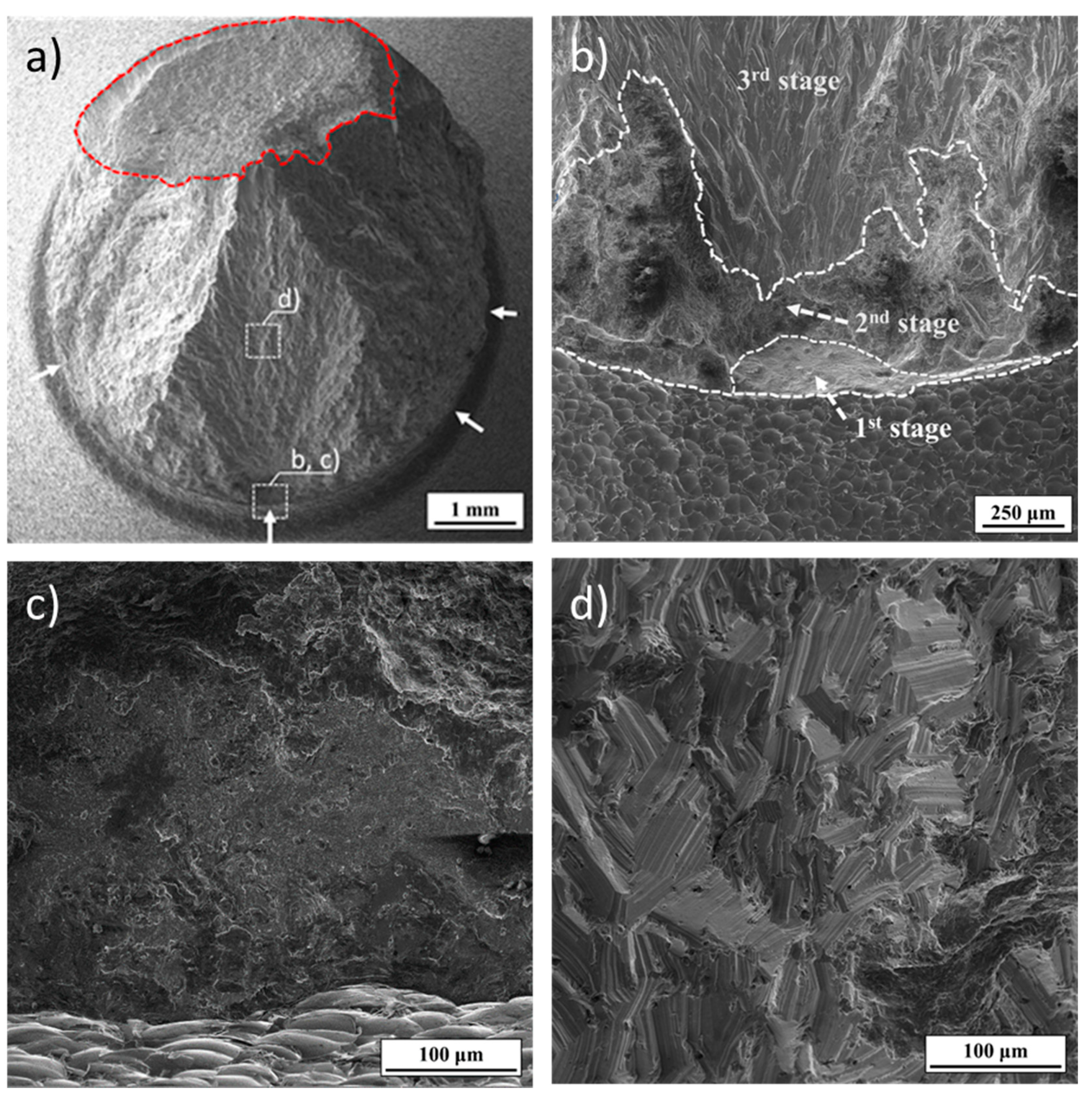

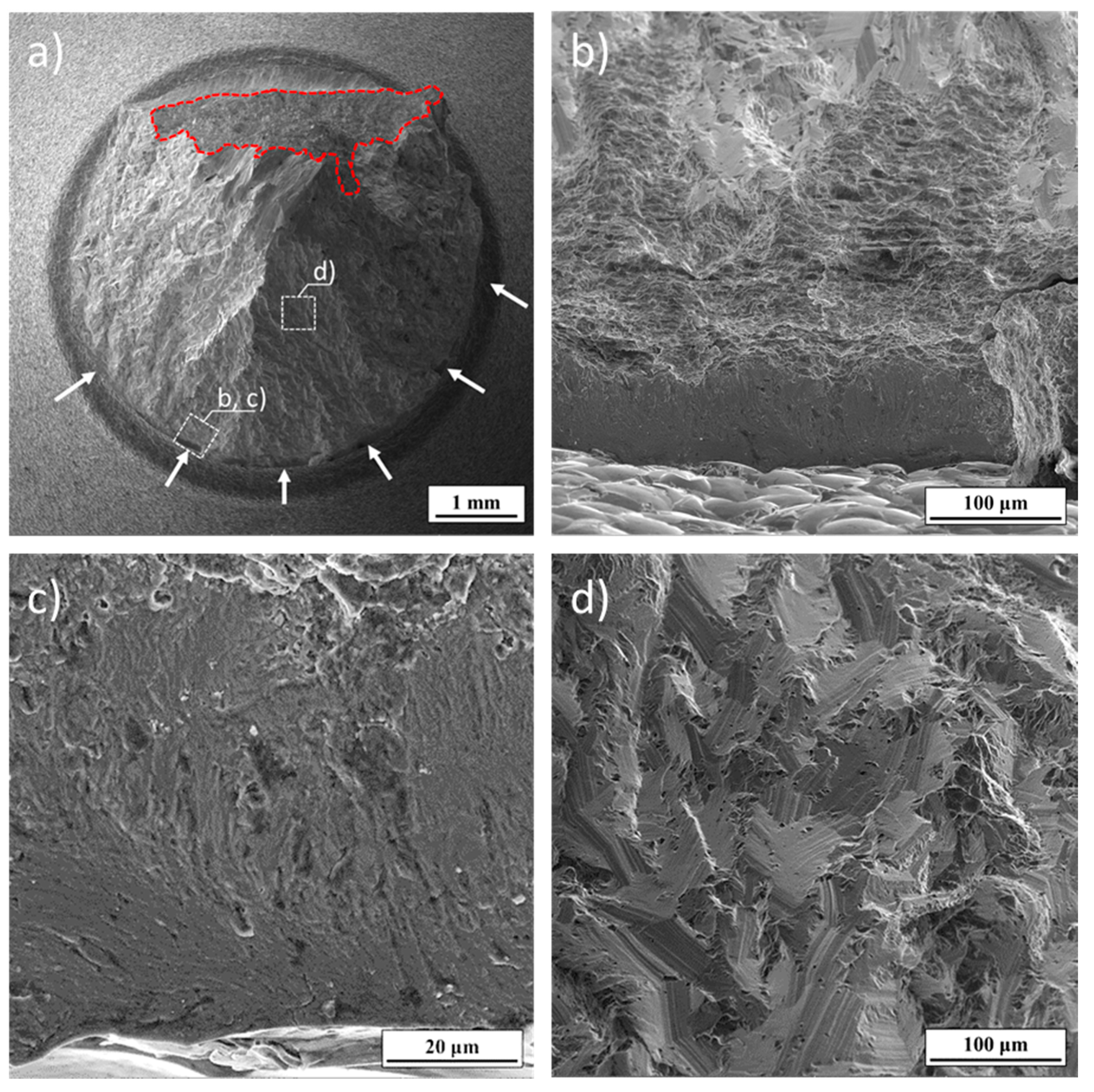

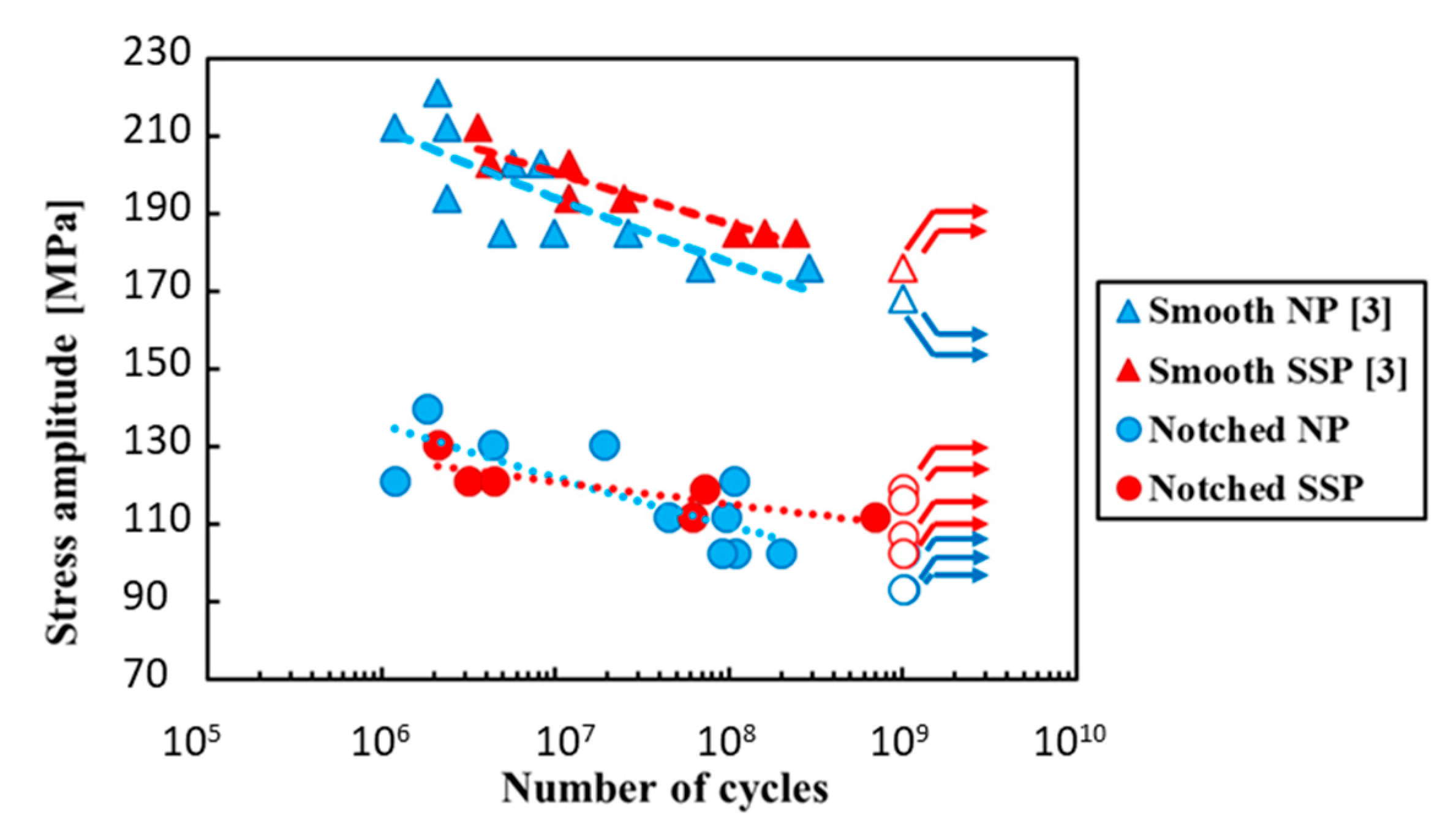

3.3. Fatigue Test Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Benedetti, M.; Fontanari, V.; Bandini, M. Very high-cycle fatigue resistance of shot peened high-strength Aluminium alloys. In Experimental and Applied Mechanics; Springer: New York, NY, USA, 2012; Volume 4, pp. 203–211. [Google Scholar]

- Han, W.Z.; Chen, Y.; Vinogradov, A.; Hutchinson, C.R. Dynamic precipitation during cyclic deformation of an underaged Al-Cu alloy. Mater. Sci. Eng. A 2011, 528, 7410. [Google Scholar] [CrossRef]

- Trško, L.; Guagliano, M.; Bokůvka, O.; Nový, F.; Jambor, M.; Florková, Z. Influence of severe shot peening on the surface state and ultra-high-cycle fatigue behavior of an AW 7075 Aluminum alloy. J. Mater. Eng. Perform. 2017, 26, 2784–2797. [Google Scholar] [CrossRef]

- Luong, H.; Hill, M.R. The effect of laser peening and shot peening on high cycle fatigue in 7050-T7451 aluminum alloy. Mater. Sci. Eng. A 2010, 527, 699–707. [Google Scholar] [CrossRef]

- Lago, J.; Trško, L.; Jambor, M.; Nový, F.; Bokůvka, O.; Mičian, M.; Pastorek, F. Fatigue life improvement of the high strength steel welded joints by ultrasonic impact peening. Metals 2019, 9, 619. [Google Scholar] [CrossRef]

- Ramulu, M.; Kunaporn, S.; Jenkins, M.; Hashish, M.; Hopkins, J. Fatigue Performance of high-pressure waterjet-peened aluminum alloy. J. Press. Vessel Technol. 2002, 124, 118–123. [Google Scholar] [CrossRef]

- Trško, L.; Fintová, S.; Nový, F.; Bokůvka, O.; Jambor, M.; Pastorek, F.; Florková, Z.; Oravcová, M. Study of relation between shot peening parameters and fatigue fracture surface character of an AW 7075 Aluminum alloy. Metals 2018, 8, 111. [Google Scholar] [CrossRef]

- Bagherifard, S.; Beretta, N.; Monti, S.; Riccio, M.; Bandini, M.; Guagliano, M. On the fatigue strength enhancement of additive manufactured AlSi10Mg parts by mechanical and thermal post-processing. Mater. Des. 2018, 145, 28–41. [Google Scholar] [CrossRef]

- Hadzima, B.; Nový, F.; Trško, L.; Pastorek, F.; Jambor, M.; Fintová, S. Shot peening as a pre-treatment to anodic oxidation coating process of AW 6082 aluminum for fatigue life improvement. Int. J. Adv. Manuf. Technol. 2017, 93, 3315–3323. [Google Scholar] [CrossRef]

- Gao, Y.K.; Wu, X.R. Experimental investigation and fatigue life prediction for 7435-T7351 aluminum alloy with and without shot peening-induced residual stresses. Acta Mater. 2011, 59, 3737–3747. [Google Scholar] [CrossRef]

- Benedetti, M.; Fontanari, V.; Bandini, M.; Taylor, D. Multiaxial fatigue resistance of shot peened high-strength aluminum alloys. Int. J. Fatigue 2014, 61, 271–282. [Google Scholar] [CrossRef]

- Benedetti, M.; Fontanari, V.; Winiarski, B.; Withers, P.J.; Allahkarami, M.; Hanan, J.C. Fatigue behavior of shot peened notched specimens: Effect of the residual stress field ahead of the notch root. Procedia Eng. 2015, 109, 80–88. [Google Scholar] [CrossRef]

- González, J.; Bagherifard, S.; Guagliano, M.; Pariente, I.F. Influence of different shot peening treatments on surface state and fatigue behavior of Al 6063 alloy. Eng. Fract. Mech. 2017, 185, 72–81. [Google Scholar] [CrossRef]

- Pandey, V.; Chattopadhyay, K.; Srinivas, N.S.; Singh, V. Role of ultrasonic shot peening on low cycle fatigue behavior of 7075 Aluminium alloy. Int. J. Fatigue 2017, 103, 426–435. [Google Scholar] [CrossRef]

- Oguri, K. Fatigue life enhancement of aluminum alloy for aircraft by Fine Particles Shot Peening (FPSP). J. Mater. Process. Technol. 2011, 211, 1395–1399. [Google Scholar] [CrossRef]

- Benedetti, M.; Fontanari, V.; Bandini, M.; Savio, E. High and very high-cycle plain fatigue resistance of shot peened high-strength aluminum alloys: The role of surface morphology. Int. J. Fatigue 2015, 70, 451–462. [Google Scholar] [CrossRef]

- Berge, C.; Pytell, B.; Trosmann, T. Very high cycle fatigue tests with smooth and notched specimens and screws made of light metal alloys. Int. J. Fatigue 2006, 28, 1640–1646. [Google Scholar] [CrossRef]

- Wang, Q.Y.; Kawagoishi, N.; Chen, Q. Fatigue and fracture behavior of structural Al-alloys up to very long life regimes. Int. J. Fatigue 2006, 28, 1572–1576. [Google Scholar] [CrossRef]

- Benedetti, M.; Fontanari, V.; Scardi, P.; Ricardo, C.A.; Bandini, M. Reverse bending fatigue of shot-peened 7075-T651 aluminium alloys: The role of residual stress relaxation. Int. J. Fatigue 2009, 31, 1225–1236. [Google Scholar] [CrossRef]

- Benedetti, M.; Fontanari, V.; Bandini, M. A simplified and fast method to predict plain and notch fatigue of shot peened high-strength Aluminium alloys under reverse bending. Surf. Coat. Technol. 2014, 243, 2–9. [Google Scholar] [CrossRef]

- Zhao, X.; Sun, Z.; Xu, D.; Liu, Y. Local fatigue strength evaluation of shot peened 40Cr notched steel. Metals 2018, 8, 681. [Google Scholar] [CrossRef]

- Miková, K.; Bagherifard, S.; Bokuvka, O.; Guagliano, M.; Trško, L. Fatigue behavior of X70 microalloyed steel after severe shot peening. Int. J. Fatigue 2013, 55, 33–42. [Google Scholar] [CrossRef]

- Polmear, I. Light Alloys-From Traditional Alloys to Nanocrystals; Butterworth-Heinemann: Oxford, UK, 2006; p. 416. [Google Scholar]

- Chen, L.; Chen, G.; Tang, J.; Zhao, G.; Zhang, C. Evolution of grain structure, micro-texture and second phase during porthole die extrusion of Al-Zn-Mg alloy. Mater. Charact. 2019, 158, 109953. [Google Scholar] [CrossRef]

- Ayer, R.; Koo, J.Y.; Steeds, J.W.; Park, B.K. Microanalytical Study of the Heterogeneous Phases in Commercial Al-Zn-Mg-Cu Alloys. Metall. Trans. A 1985, 16A, 1925–1936. [Google Scholar] [CrossRef]

- Löffler, H.; Kovács, I.; Lendvai, J. Review: Decomposition processes in Al-Zn-Mg alloys. J. Mater. Sci. 1983, 18, 2215–2240. [Google Scholar] [CrossRef]

- Park, J.K.; Ardell, A.J. Precipitate microstructure of peak-aged 7075 Al. Scr. Metall. 1988, 22, 1115–1119. [Google Scholar] [CrossRef]

- Li, J.F.; Peng, Z.W.; Li, C.X.; Jia, Z.Q.; Chen, W.J.; Zheng, Z.Q. Mechanical properties, corrosion behavior and microstructure of 7075 aluminum alloy with various aging treatments. Trans. Nonferrous Met. Soc. China 2008, 18, 755–762. [Google Scholar] [CrossRef]

- Trško, L.; Nový, F.; Bokůvka, O.; Jambor, M. Ultrasonic Fatigue Testing in the Tension-Compression Mode. J. Vis. Exp. 2018, 133, e57007. [Google Scholar] [CrossRef] [PubMed]

- Bokůvka, O.; Jambor, M.; Hrček, S.; Šteininger, J.; Trško, L. Design of Shaft Respecting the Fatigue Limit for Ultra-High Number of Cycles. Period. Polytech. Trasp. Eng. 2018, 47, 6–12. [Google Scholar] [CrossRef]

- Bathias, C.; Paris, P.C. Gigacycle Fatigue in Mechanical Practice; CRC Press: Boca Raton, FL, USA, 2004; ISBN 978-0203020-609. [Google Scholar]

- Murakami, Y. Theory of Elasticity and Stress Concentration; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2017; ISBN 9781119274094. [Google Scholar]

- Trško, L.; Bokůvka, O.; Nový, F.; Guagliano, M. Effect of severe shot peening on ultra-high-cycle fatigue of a low-alloy steel. Mater. Des. 2014, 57, 103–113. [Google Scholar] [CrossRef]

- Trško, L.; Guagliano, M.; Lukáč, P.; Bokůvka, O.; Nový, F. Effects of severe shot peening on the surface state of AW 7075 Al alloy. Kov. Mater. Met. Mater. 2015, 53, 239–243. [Google Scholar]

- Whaley, R.E. Fatigue and static strength of notched and unnotched aluminum-alloy and steel specimens. Exp. Mech. 1962, 2, 329–334. [Google Scholar] [CrossRef]

- Fathallah, R.; Laamouri, A.; Sidhom, H.; Braham, C. High cycle fatigue behavior prediction of shot-peened parts. Int. J. Fatigue 2004, 26, 1053–1067. [Google Scholar] [CrossRef]

| Al | Zn | Mg | Cu | Cr | Fe |

|---|---|---|---|---|---|

| 87.1–91.4 | 5.1–6.1 | 2.1–2.9 | 1.2–2 | 0.18–0.28 | max. 0.5 |

| Mn | Si | Ti | Ti + Zr | Other-each | Other-total |

| max. 0.3 | max. 0.4 | max. 0.2 | max. 0.25 | max. 0.05 | max. 0.15 |

| UTS (MPa) | Elongation (%) | Reduction of area (%) | Hardness (HV10) |

|---|---|---|---|

| 631 | 4.9 | 15.7 | 175 |

| Regression Coefficients | Fatigue Strengths Calculated Based on the Regression Coefficient | |||||

|---|---|---|---|---|---|---|

| Specimen | Coefficient of Fatigue Toughness σF (MPa) | Exponent of Fatigue Life Curve b | Number of Cycles | NP | SSP | Difference (SSP vs. NP) (%) |

| (MPa) | ||||||

| NP | 257.9 | −0.046 | 106 | 136 | 127 | −6.62 |

| 107 | 123 | 121 | −1.63 | |||

| SSP | 170.15 | −0.021 | 108 | 111 | 116 | +4.50 |

| 109 | 99 | 110 | +11.11 | |||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jambor, M.; Trško, L.; Klusák, J.; Fintová, S.; Kajánek, D.; Nový, F.; Bokůvka, O. Effect of Severe Shot Peening on the Very-High Cycle Notch Fatigue of an AW 7075 Alloy. Metals 2020, 10, 1262. https://doi.org/10.3390/met10091262

Jambor M, Trško L, Klusák J, Fintová S, Kajánek D, Nový F, Bokůvka O. Effect of Severe Shot Peening on the Very-High Cycle Notch Fatigue of an AW 7075 Alloy. Metals. 2020; 10(9):1262. https://doi.org/10.3390/met10091262

Chicago/Turabian StyleJambor, Michal, Libor Trško, Jan Klusák, Stanislava Fintová, Daniel Kajánek, František Nový, and Otakar Bokůvka. 2020. "Effect of Severe Shot Peening on the Very-High Cycle Notch Fatigue of an AW 7075 Alloy" Metals 10, no. 9: 1262. https://doi.org/10.3390/met10091262

APA StyleJambor, M., Trško, L., Klusák, J., Fintová, S., Kajánek, D., Nový, F., & Bokůvka, O. (2020). Effect of Severe Shot Peening on the Very-High Cycle Notch Fatigue of an AW 7075 Alloy. Metals, 10(9), 1262. https://doi.org/10.3390/met10091262