3. Results and Discussion

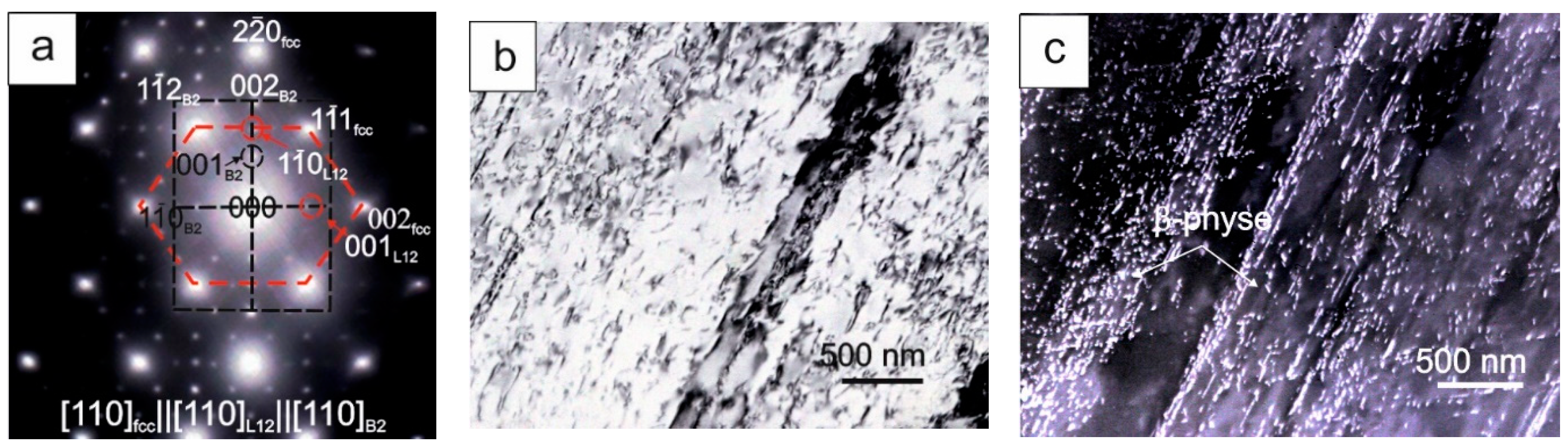

TEM investigations have shown that a planar dislocation structure, with dislocation pile ups, developed in the quenched Al

0.3CoCrFeNi HEA single crystals after undergoing strain at 77 K [

5]. In the [001]-oriented crystals, after undergoing strain of 20%, a high density of dislocations and multipoles was observed, but there were no twins. Thin twins with a thickness of 15–25 nm were found in the

-oriented crystals after undergoing strain of 50% at 77 K, simultaneously with a high density of dislocations and multipoles.

Figure 1 and

Figure 2 display the dislocation structures after ageing at 893 K for 50 h of the deformed [001]- and

-oriented crystals of the Al

0.3CoCrFeNi HEA, having undergone up to 20% and 50% strain, respectively, at 77 K.

During the ageing of the deformed crystals at 893 K for 50 h, recrystallization did not occur, grain boundaries were not detected and, therefore, the single-crystalline matrix was retained, as in samples deformed at 77 K (

Figure 1 and

Figure 2). In the deformed

- and [001]-oriented crystals, ageing at 893 K for 50 h led to the precipitation of coherent L1

2 and non-coherent B2 particles [

15,

17]. In the diffraction pattern, clear super-structural reflections from L1

2 and B

2 particles were detected (

Figure 1a and

Figure 2c). The particles differed in size

d (L1

2 with

d = 5–7 nm [

17] and B2 with

d = 30–40 nm (

Figure 1c and

Figure 2b). The simultaneous precipitation of L1

2 and B2 particles in the matrix apparently suppressed the formation of the nuclei of grain boundaries, and the recrystallization process did not occur during this ageing, which requires further research and is not discussed in this paper. In polycrystalline Al

0.3CoCrFeNi HEA, particles were precipitated in the grain body, L1

2, and at the grain boundaries, B2 [

15]. In the initial quenched Al

0.3CoCrFeNi HEA single crystals, when aged for 50 h at 893 K, only L1

2 particles with the same size were precipitated, while B

2 particles were not precipitated, due to the very high nucleation barrier, as a result of the need to generate large elastic and fcc/B2 interphase energies [

17,

18]. In the deformed

- and [001]-oriented crystals during ageing at 893 K for 50 h, L1

2 particles were distributed uniformly in the matrix, as was shown earlier in [

17]. The precipitation of B2 particles occurred along the boundaries of multipoles and at dislocations, as well as near the twin boundaries in the deformed

-oriented crystals (

Figure 1 and

Figure 2). Therefore, we can infer that not only grain boundaries in polycrystals, but also dislocations, multipoles and twins in deformed crystals facilitate the nucleation of B2 particles in an imperfect structure.

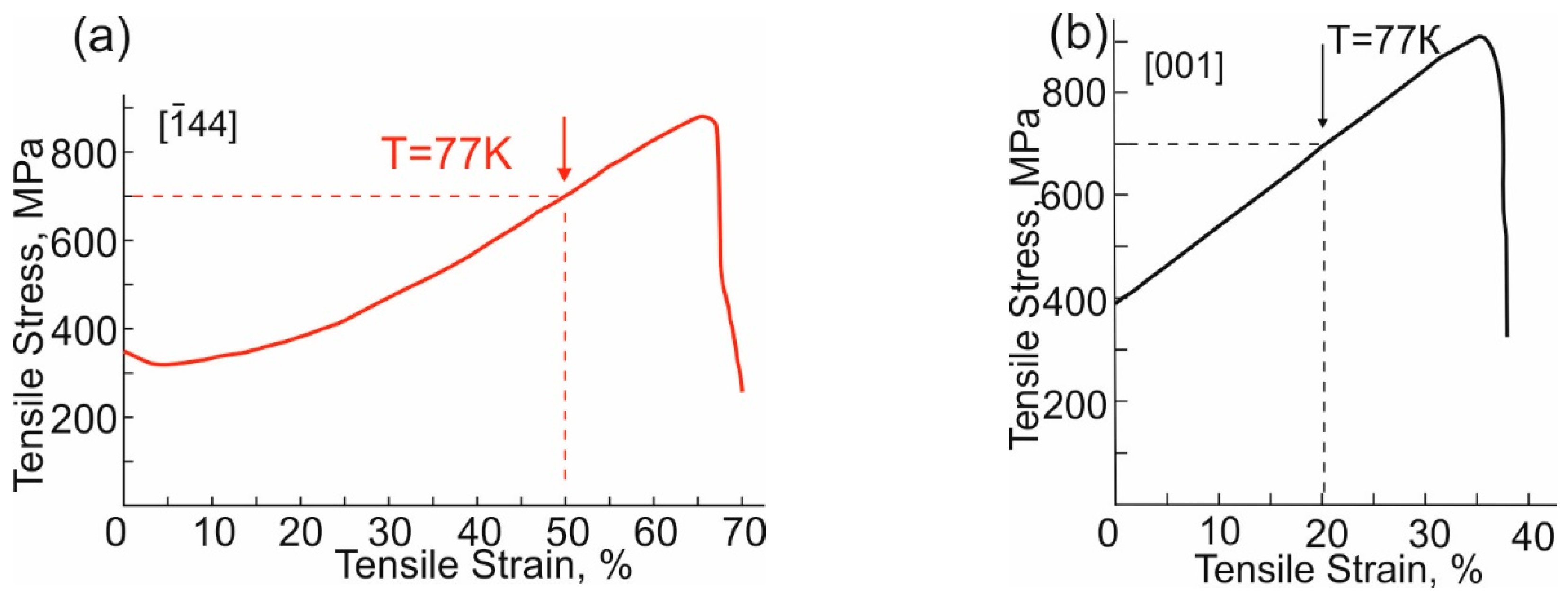

Figure 3 shows the “stress–strain” (

σ(

ε)) curves at 77 K for the

- and [001]-oriented crystals, and indicates the level of strain at which the stress of 700 MPa was achieved during deformation.

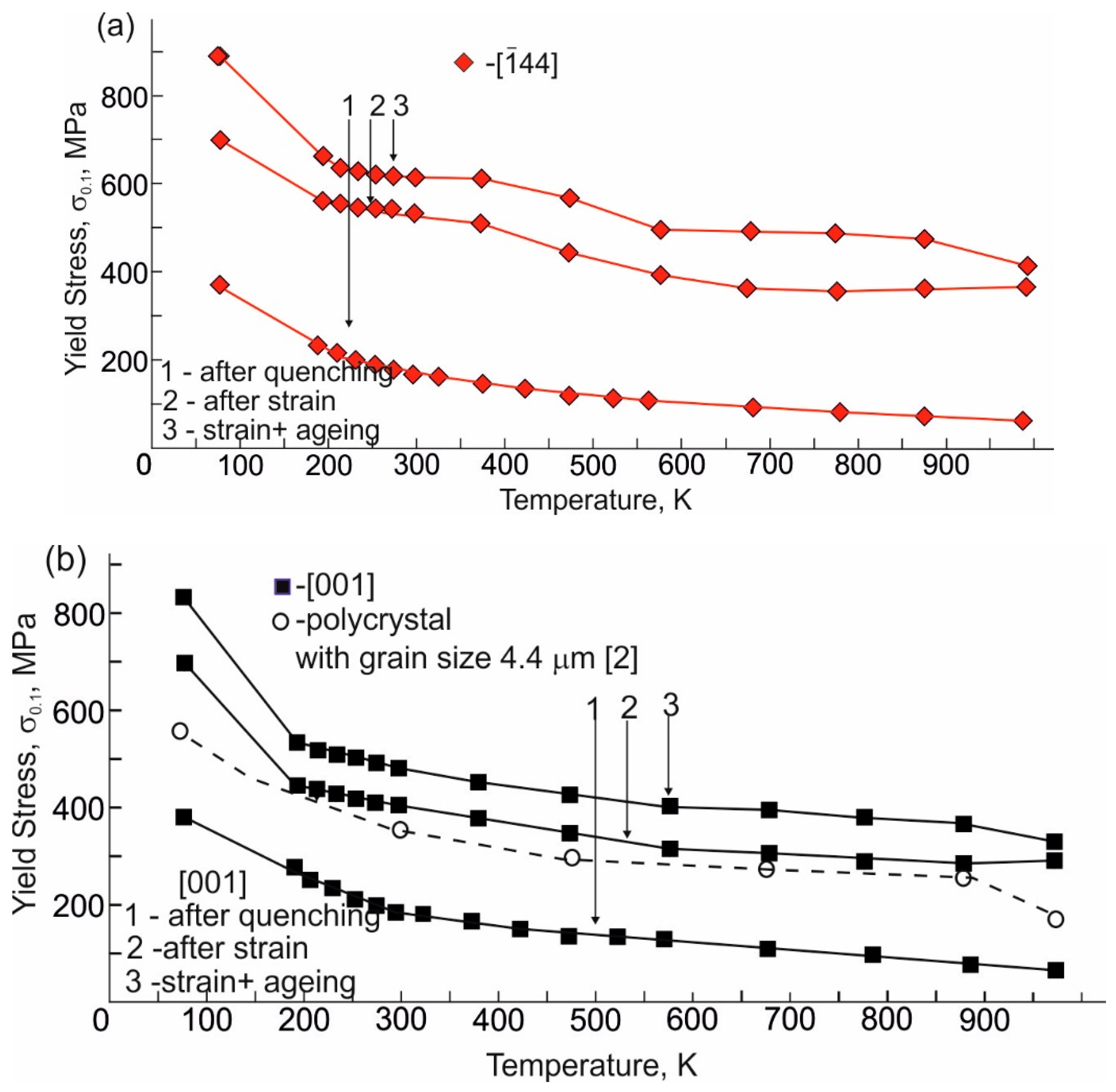

Figure 4 displays the temperature dependence of the yield point

σ0.1(T) and CRSS

τcr(T) for three states (quenched, deformed and deformed + aged) of the

- and [001]-oriented crystals of Al

0.3CoCrFeNi HEA, under tensile strain and within the wide temperature range T = 77–973 K.

It can be seen that after low-temperature deformation at 77 K, the

σ0.1 of the

- and [001]-oriented crystals increased relative to the initial crystals in the studied temperature range; by 320 MPa at 77 K and 200–330 MPa at T ≥ 296 K. The precipitation of L1

2 and B2 particles additionally increased

σ0.1 by 130 and 200 MPa at 77 K, and by 80–130 MPa at T ≥ 296 K, relative to the deformed [001]- and

-oriented crystals, respectively (

Figure 4a,b). As a result, in the

- and [001]-oriented crystals,

σ0.1 ≈ G/100–G/160 within a temperature range of 77–973 K, due to joint hardening with a dislocation structure and ordered particles (

Figure 4a,b). Thus, Al

0.3CoCrFeNi HEA single crystals became high-strength at T < 296 K, and close to high-strength at T ≥ 296 K. In this state, as shown in

Figure 5, Al

0.3CoCrFeNi HEA single crystals remained plastic.

In the initial quenched

- and [001]-oriented crystals of the Al

0.3CoCrFeNi HEA, the

τcr values were found to be independent of the crystal orientation within the studied temperature range, and the Schmid law was satisfied (

Figure 4c, curve 1) [

5,

17]. The temperature dependence of the

τcr(T) of both orientations consists of two sections, characteristic of the slip deformation of fcc substitution alloys [

5,

23]. At T < 373 K, there is a strong temperature dependence of

τcr(T) (the thermally activated

τS component of

τcr), associated with the thermally-activated interaction of dislocations with substitution atoms. At T > 373 K,

τcr(T) is weakly dependent on temperature as G(T), and the athermal

τG component of

τcr is observed. The ratio

τcr(77 K)/

τcr(300 K) = 2.1. Consequently, the behavior of the initial Al

0.3CoCrFeNi HEA single crystals is typical of low-strength fcc alloys [

23].

Upon reaching a high-strength state at the yield point

σ0.1, Al

0.3CoCrFeNi HEA single crystals showed features of mechanical behavior that had not previously been manifested in the quenched HEA single crystals. Firstly, in the deformed

- and [001]-oriented crystals of the Al

0.3CoCrFeNi HEA, the

τcr were found to be independent of the crystal orientation at 77 K only, since at the low-temperature deformation, the same stress level of 700 MPa was artificially given, and

msl ≈

msl[001] [

19,

20]. At T ≥ 200 K,

τcr became dependent on the crystal orientation, and

τcr >

τcr[001] (

Figure 4c).

According to the known models of hardening under the assumption of the additivity of the contributions to

τcr [

16,

24], the effect of hardening from a defect structure (dislocations, multipoles, twins), L1

2 and B2 particles can be determined in the

-oriented crystals,

and in the [001]-oriented crystals,

Here,

are the critical shear stresses of the quenched undeformed crystals, which do not depend on the crystal orientation [

5,

25];

= α

Gbρ1/2 is the hardening caused by dislocations (α is the constant [

3], G = 80 GPa [

7] is the shear modulus of HEA,

b = 0.25 nm is the Burgers vector of the perfect dislocation,

ρ is the dislocation density);

= δ

nGbx−1 is the contribution to hardening from twins (

δ is a constant,

n = 5–7 is the number of dislocations in a pile up at a tensile strain of 5%,

x is the average distance between twin boundaries [

26]); and

and

are the contribution to hardening from L1

2 and B2 particles, respectively.

L1

2 particles are coherent [

15,

16,

17], and their effect of hardening is determined by the contribution of the elastic stress fields due to the mismatch between the lattices of the particle and matrix E, and the long-range order in Ni

3Al particles:

where

is the contribution of elastic stress fields from the L1

2 particles [

24],

and

is the stress due to ordering in the L1

2 particles [

16,

24],

Here, E = Δ

a/

am is the lattice mismatch parameter of the initial matrix,

am, and L1

2 particles,

ap (Δ

a =

am −

ap),

r is the particle radius in the slip plane,

f is the volume fraction of particles estimated by TEM,

b = 0.25 nm is the modulus of the Burgers vector of the a/2 <110> dislocation,

μ is the antiphase boundary energy,

k is the number of dislocations in the complex and

B = (

Gb2)/2 is the line tension. The contribution to hardening from L1

2 particles, estimated earlier for single crystals of the studied HEA according to Equations (3)–(5), was 18 MPa [

17]. Moreover, the

turned out to be the same for crystals of all orientations, since after the precipitation of L1

2 particles, the orientation dependence of CRSS was not observed, and the Schmid law was fulfilled [

17].

B2 particles are non-coherent [

15,

27], and their contribution to hardening, according to [

24], can be estimated by the Orowan equation:

Here,

L = 250 nm is the average distance between B2 particles. The contribution to hardening from B2 particles, with an average distance between them of

L = 250 nm, was 80 MPa according to Equation (6), and turned out to be close to the experimentally obtained data, whereby

= 60–80 MPa in crystals of both orientations at 77 K. In both orientations, the contribution to the hardening from B2 particles was the same, and remained within the temperature range when studying the temperature dependence of

τcr(T) (

Figure 4c). This correlated with the close volume fraction of B2 particles in the crystals of the studied orientations, which was ~20%. The volume fraction of particles was determined from dark-field images, and 10 pictures from different places on thin foils were used to estimate it. At 77 K in the studied orientations, after ageing, the

τcr values turned out to be close (

Figure 4c). In addition, in the Al

0.3CoCrFeNi HEA single crystals after ageing at 973 K at 50 h, when only B2 particles were precipitated, the

τcr values were not dependent on the crystal orientation in a wide temperature range, as was shown earlier in [

27]. All this qualitatively indicates a similar volume fraction of the precipitated B2 particles in the deformed

- and [001]-oriented crystals. Consequently, in the deformed

- and [001]-oriented crystals of the Al

0.3CoCrFeNi HEA, the contribution to the CRSS value from B2 particles, as well as from L1

2 particles, does not depend on the crystal orientation.

Thus, the analysis of Equations (1) and (2) and the experimental data presented in

Figure 4c shows that the

,

and

in the deformed and aged Al

0.3CoCrFeNi HEA single crystals are independent of the crystal orientation. Consequently, the orientation dependence of

τcr in the deformed and aged Al

0.3CoCrFeNi HEA single crystals is due to the orientation dependence of the dislocation structure and, in this case, the dislocation structure with twins makes the largest contribution to the hardening at the yield point, as compared to that without twins. So,

(

) =

([001]) = 70 MPa at 296 K. At 296 K, after low-temperature deformation at 77 K in the [001]-oriented crystals, where there was no twinning, the contribution to hardening at the yield point from the defect structure relative to quenched crystals was Δ

τcr =

–

= 160 MPa − 70 MPa = 90 MPa, and in the

-oriented crystals with twins in the dislocation structure, Δ

τcr =

−

= 215 MPa − 70 MPa = 145 MPa. In the

-oriented crystals at 296 K, the contribution to hardening at the yield point from the defect structure was 55 MPa greater than in the [001]-oriented crystals (

Figure 4c). If we assume that when the stress level of 700 MPa was reached during the low-temperature deformation at 77 K, the contribution of

= α

Gbρ1/2 to the

- and [001]-oriented crystals was similar, then the difference in the stresses Δ

τcr in the deformed crystals can be seen to be due to twinning at 296 K. The estimate of the contribution from twins

=

δnGbx−1 to hardening at the yield point—at an average value of

x = 500 nm, as determined from TEM data,

δ = 0.5 and

n = 5—was 100 MPa, which correlates quite well with the experimental data.

Moreover, the orientation dependence of the

τcr value of high-strength crystals within a wide temperature range is associated with the different temperature dependence of

τcr(T). In the deformed

-oriented crystals with twins in the dislocation structure, the

τS and the temperature dependence of

τcr(T) were weakened (

τcr(77 K)/

τcr(300 K) = 1.3), and

τcr(T) was determined by the temperature dependence of the shear modulus G(T) for the HEAs [

7]. In the deformed [001]-oriented crystals without twins in the dislocation structure, as in the initial crystals, the strong temperature dependence of

τcr(T) was preserved (

τcr(77 K)/

τcr(300 K) = 1.7). If, when hardened by plastic deformation, the

σ0.1 in the

- and [001]-oriented crystals was governed by slip, then the temperature dependence of

τcr(T) should have the same dependence as the initial crystals, and

τcr should not depend on orientation. A weak temperature dependence of

τcr(T), like G(T), was characteristic of twinning from the yield point and its safekeeping over a wide temperature range [

28]. A qualitative confirmation of the development of twinning in the deformed

-oriented crystals from the onset of deformation at T > 200 K is the fact that within a temperature range of 200 to 473 K, the

τcr is close in magnitude to the CRSS for twinning,

= 200MPa, obtained with the [011]-oriented crystals of the Al

0.3CoCrFeNi HEA, with a Schmid factor for twinning,

mtw, close to that of

-orientation (

mtw = 0.47 in [011]-crystals and

mtw = 0.5 in

-orientation) [

5].

Secondly, the precipitation of L1

2 and B2 particles preserves the orientation dependence of

τcr, induced by low-temperature deformation at 77 K. However, in the deformed

-crystals after ageing,

τS and

τcr(T) were again increased. The ratio

τcr(77 K)/

τcr(300 K) = 1.5, and this has been revealed to be close in magnitude to the deformed [001]-crystals, with particles in which the onset of plastic flow was associated with slip and

τcr(77 K)/

τcr(300 K) = 1.7. TEM investigations of the dislocation structure, after strain of 5% at 296 K in the aged

-crystals, showed that the onset of plastic flow in these crystals was also associated with slip, rather than twinning. Ordered coherent L1

2 particles, as was shown earlier in [

17], suppress the development of twinning in the Al

0.3CoCrFeNi HEA single crystals.

Thirdly, in the strain-hardened

-and [001]-oriented crystals,

σ0.1 and

τcr were found to change only slightly within a temperature range of 573 to 973 K (

Figure 4). In polycrystalline CoCrFeMnNi HEA with a grain size of 4.4 μm,

σ0.1 decreased by 1.4 times with an increase in temperature from 673 K to 973 K, due to the GBS, which usually occurs in polycrystals at T > T

cr (T

cr = 0.5T

m is the critical temperature above which GBS occurs in polycrystals; T

m—melting temperature) (

Figure 4b). In strain-hardened

- and [001]-oriented crystals, there were no grain boundaries, but there were twins and multipoles. Twins are athermal obstacles to moving dislocations, and there is no sliding on them. Multipoles, like twins, are also obstacles to moving dislocations [

5]. Both twins and multipoles provide a high stress level at the yield point

σ0.1, and its weak dependence at T ≥ 573 K. However, the contribution to

σ0.1 from multipoles is smaller than that from twins at T ≥ 573 K (

Figure 4). In the hardened

- and [001]-oriented crystals with L1

2 and B2 particles, the

τcr values change slightly within a temperature range of 573 to 873 K. At T > 873 K,

τcr decreases, which can be associated with an increase in the size of B2 particles, and with the partial dissolution of L1

2 particles during heating and testing, since the temperature of 873 K is higher than the ageing temperature [

15,

16,

17], and this requires additional study.

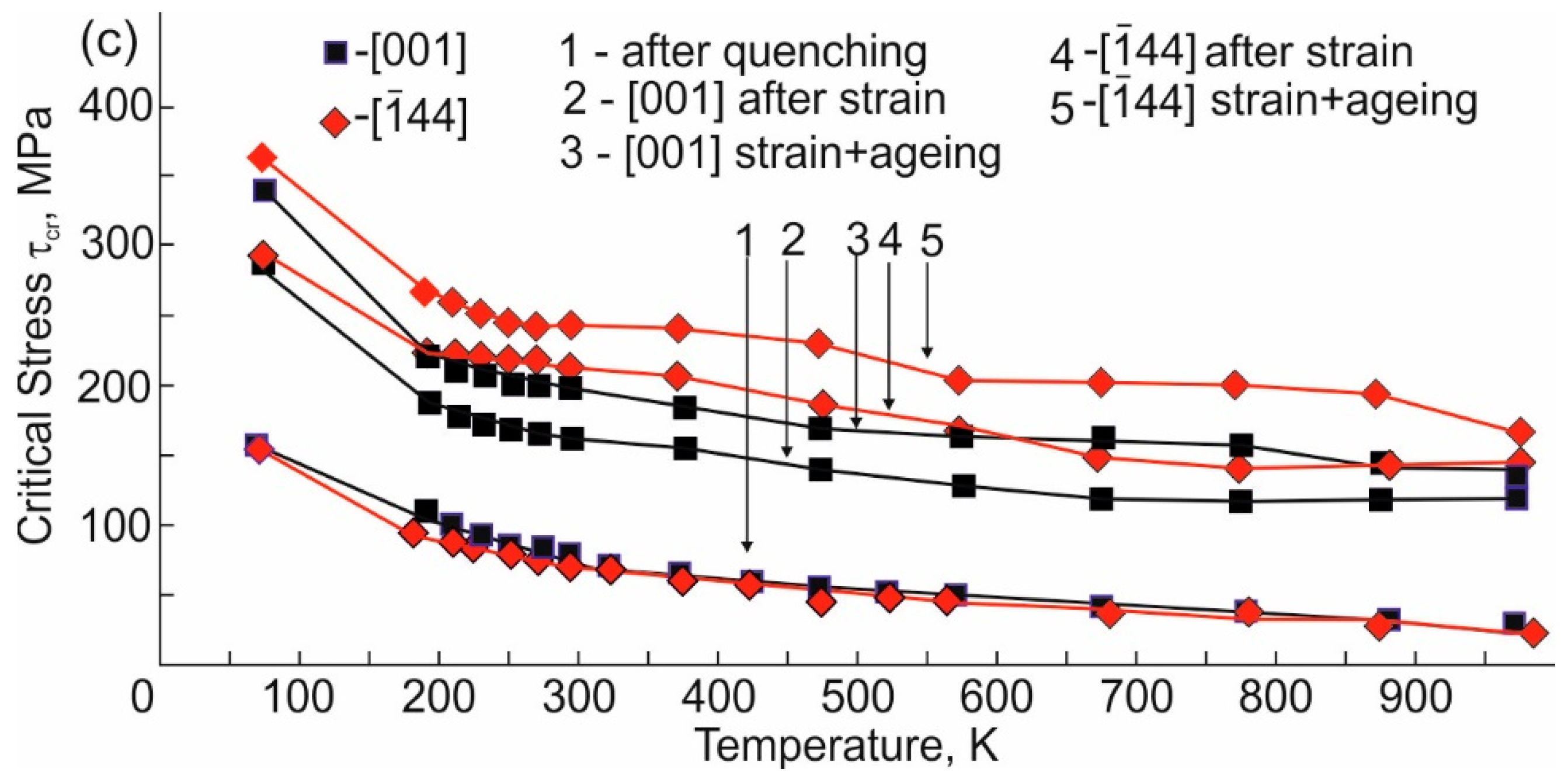

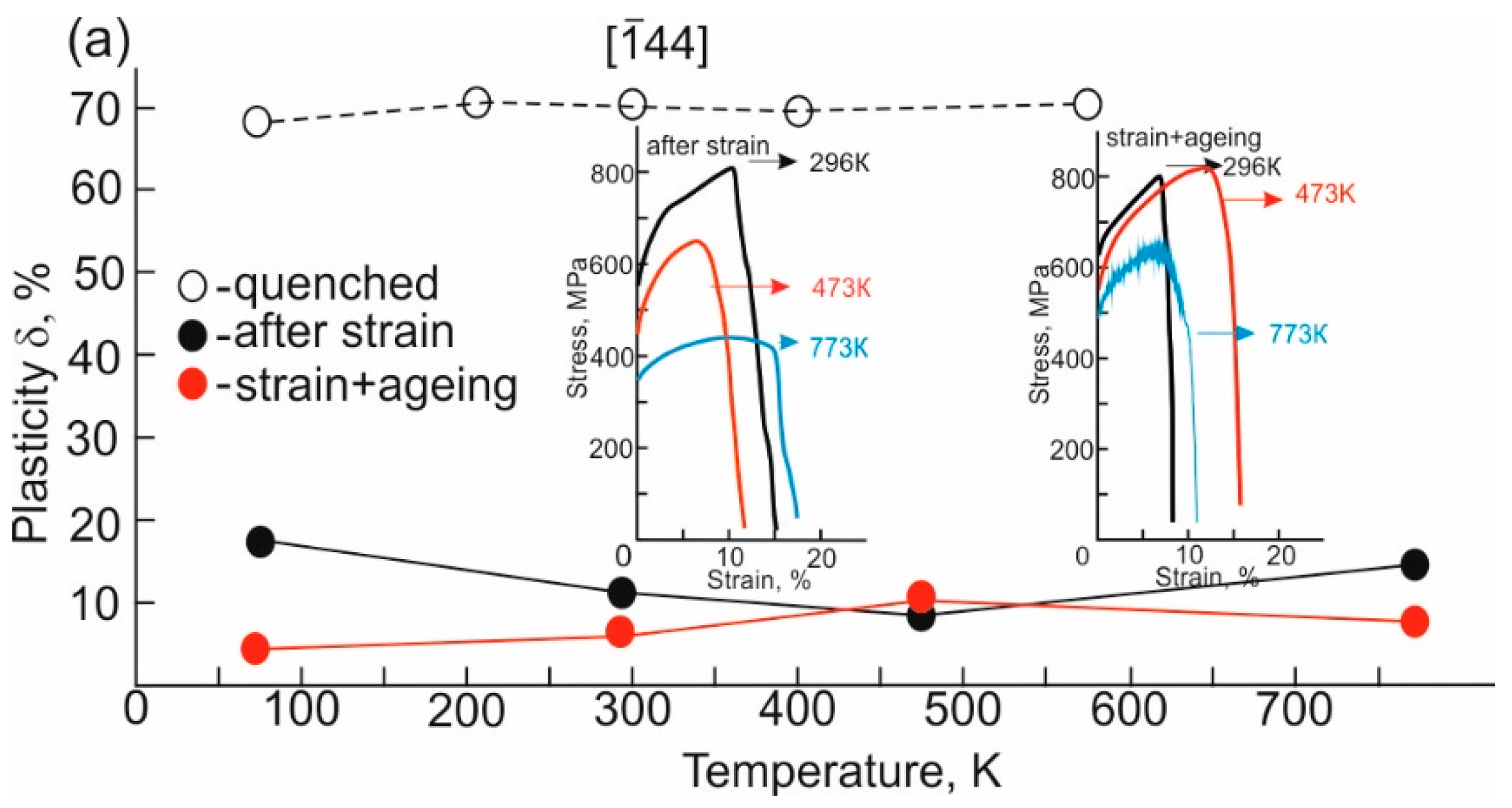

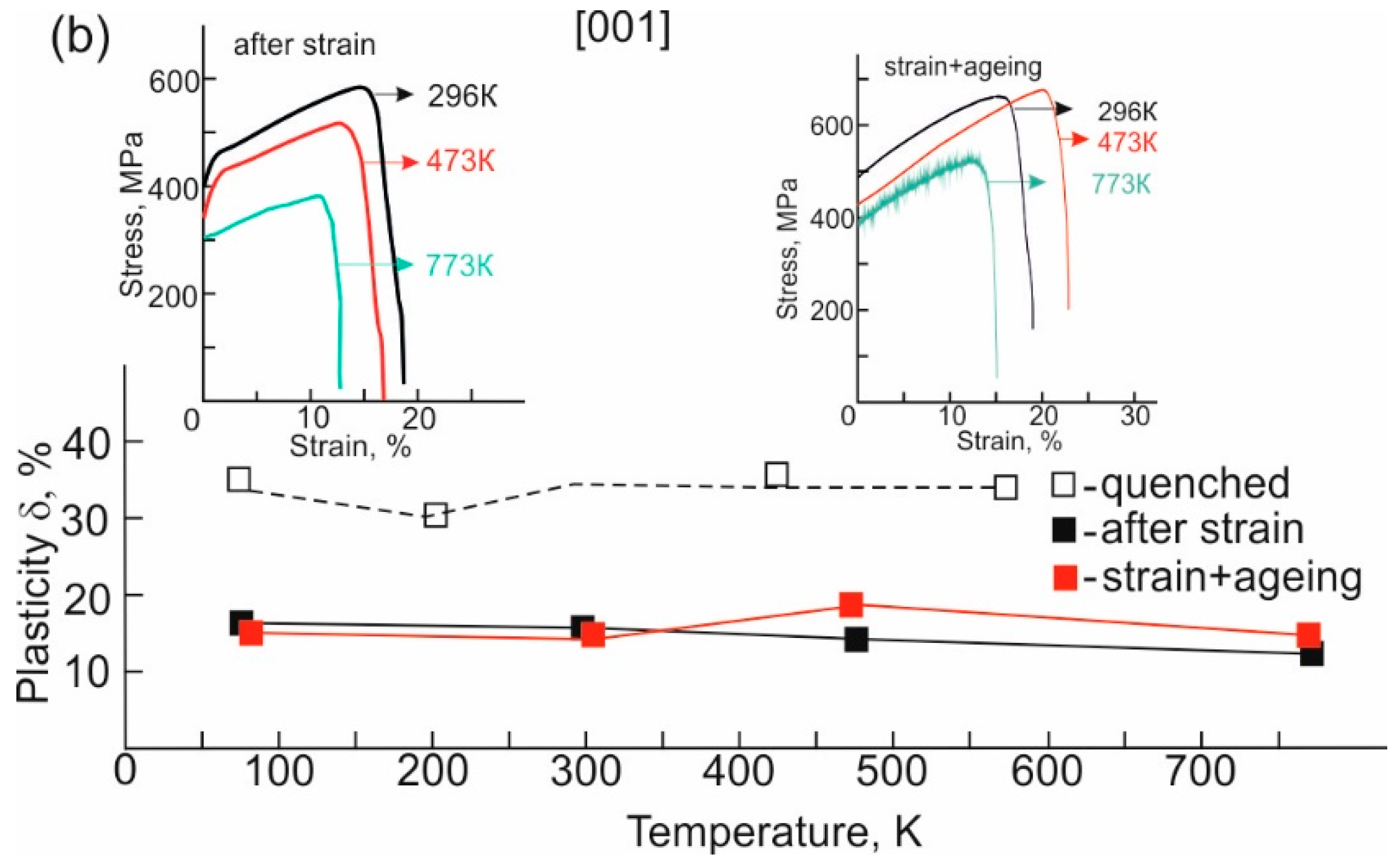

Finally, achieving a high-strength state at the yield point

σ0.1 in the Al

0.3CoCrFeNi HEA single crystals via deformation and subsequent ageing was accompanied by a decrease in plasticity (3.5–13 times in

-crystals and 2.3 times in [001]-crystals) (

Figure 5), but at the same time, the samples retained their ductile fracture qualities. With an increase in the stress level at the yield point

σ0.1, achieved via the dislocation structure during low-temperature deformation, the uniform strain in the crystals decreased. In the

-orientation with twins in the dislocation structure,

σ0.1 increased 3–5.5-fold, and the plasticity decreased to 7–13% compared to the initial crystals within a temperature range of 296 to 973 K. In the [001]-oriented crystals without twins in the dislocation structure,

σ0.1 increased 2–4-fold compared to the initial crystals of this orientation, but the plasticity remained equal to 15–20% (

Figure 4 and

Figure 5).

It should be noted that in the high-strength

- and [001]- oriented crystals of the Al

0.3CoCrFeNi HEA under tension at a test temperature of 773 K, a serrated flow was observed on the

σ(

ε) curves, as in the quenched crystals of this alloy under tension and compression [

8,

17]. Consequently, in high-strength single crystals of the Al

0.3CoCrFeNi HEA upon tensile strain at 773 K, dynamic strain ageing was observed, associated with the formation of Cottrell atmospheres by mobile Al atoms near a moving dislocation core [

8]. Dynamic strain ageing qualitatively confirms that during the precipitation of particles, some of the Al atoms are in a solid solution and lead to the blocking of moving dislocations. The locking and rapid unlocking of dislocations from the atmosphere of Al atoms leads to a serrated flow on the

σ(

ε) curves [

8,

17].

Thus, the achievement of a high-strength state at the yield point σ0.1 of the Al0.3CoCrFeNi HEA single crystals via low-temperature straining and subsequent ageing provides, on the one hand, a high stress level of σ0.1 at T > 296 K and a weak temperature dependence σ0.1(T) at high temperatures T ≥ 573 K, which is determined by the absence of GBS yet, while on the other hand retaining plasticity.