Low-Cycle Fatigue and Fracture Behavior of Aluminized Stainless Steel AISI 321 for Solar Thermal Power Generation Systems

Abstract

1. Introduction

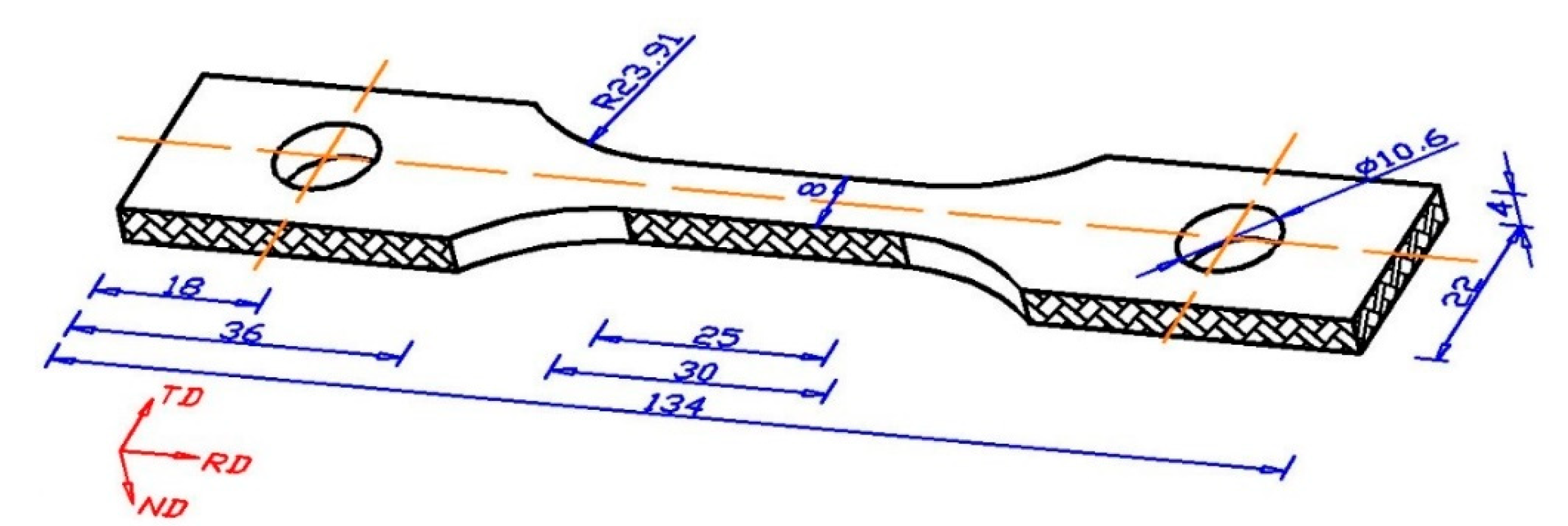

2. Materials and Methods

3. Results

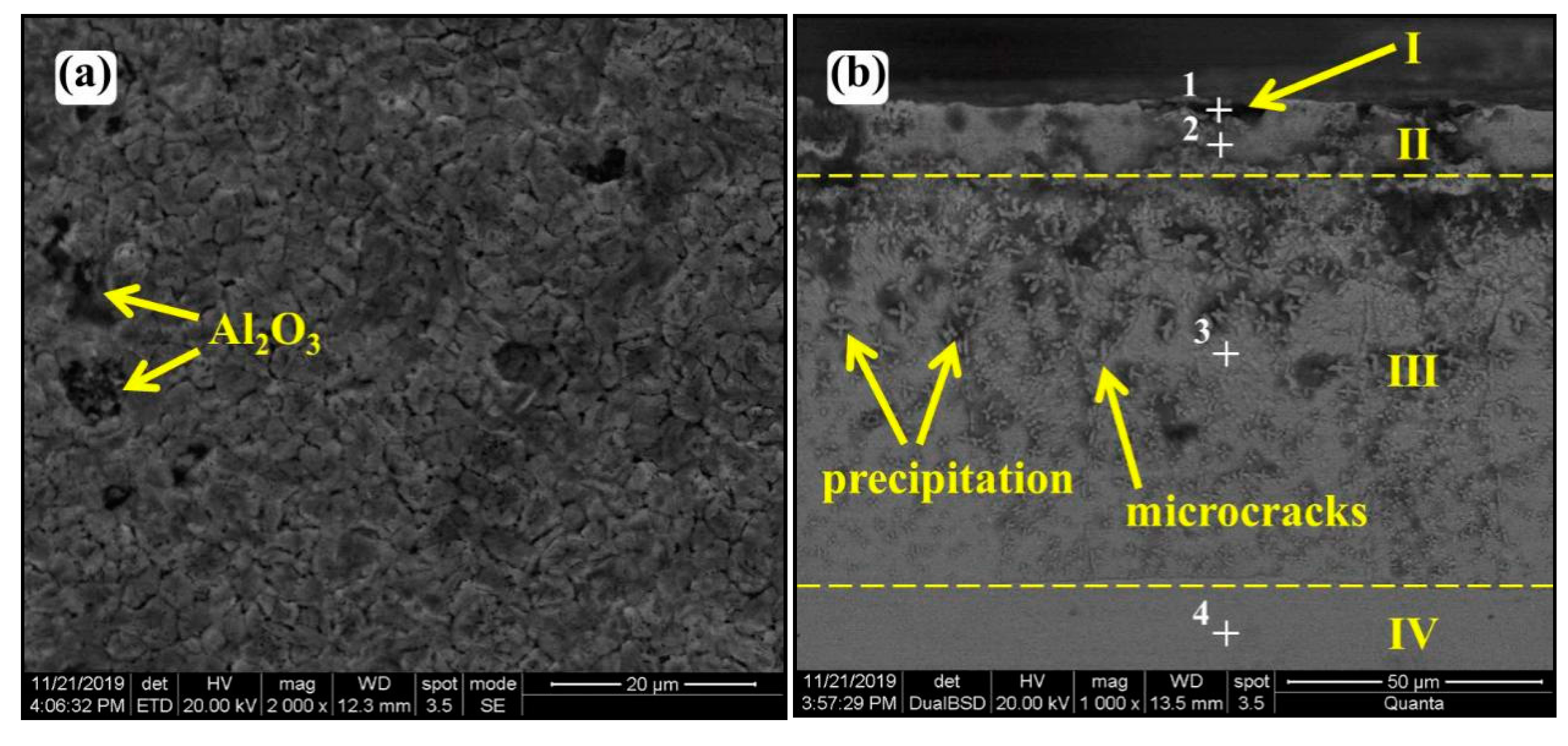

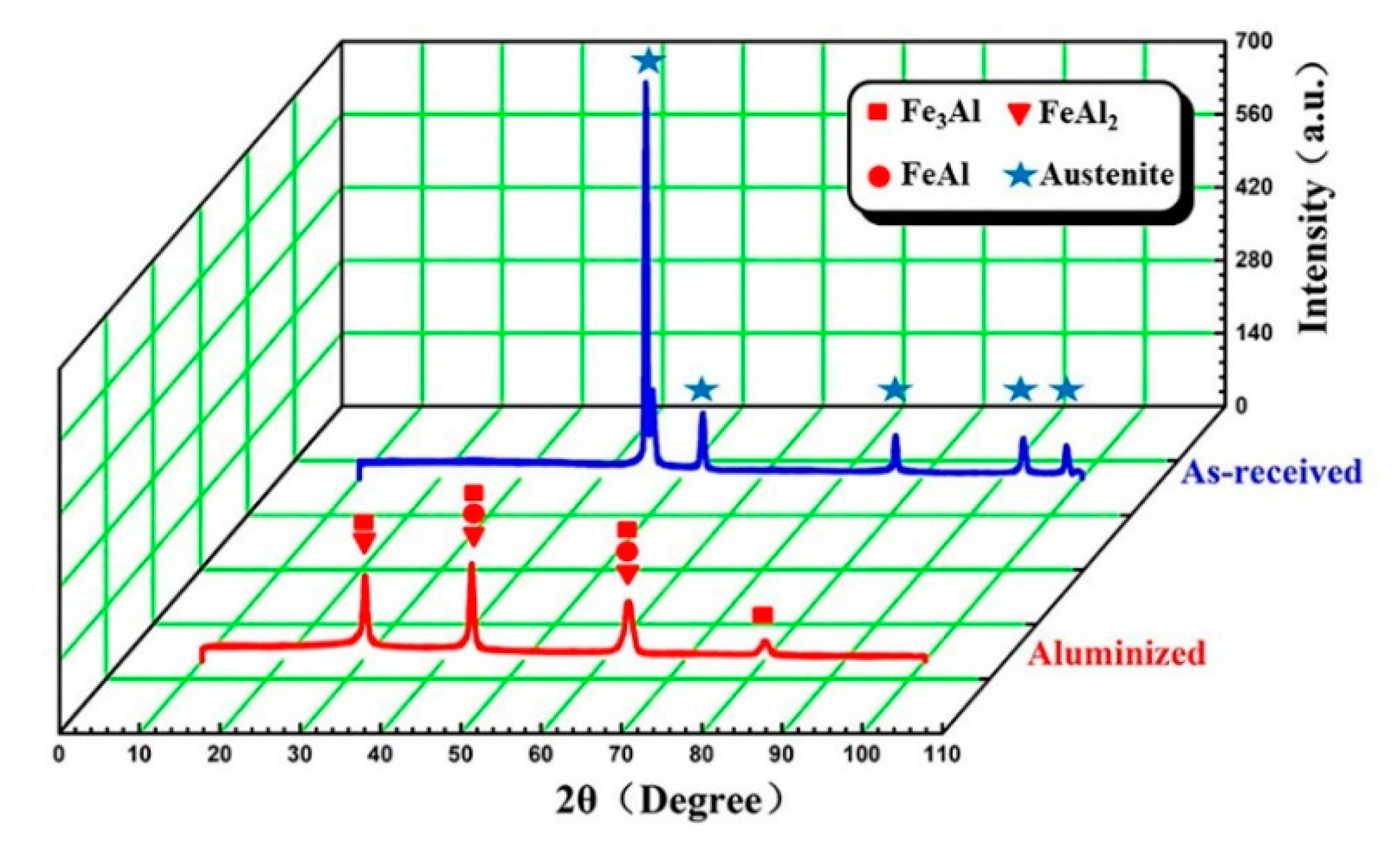

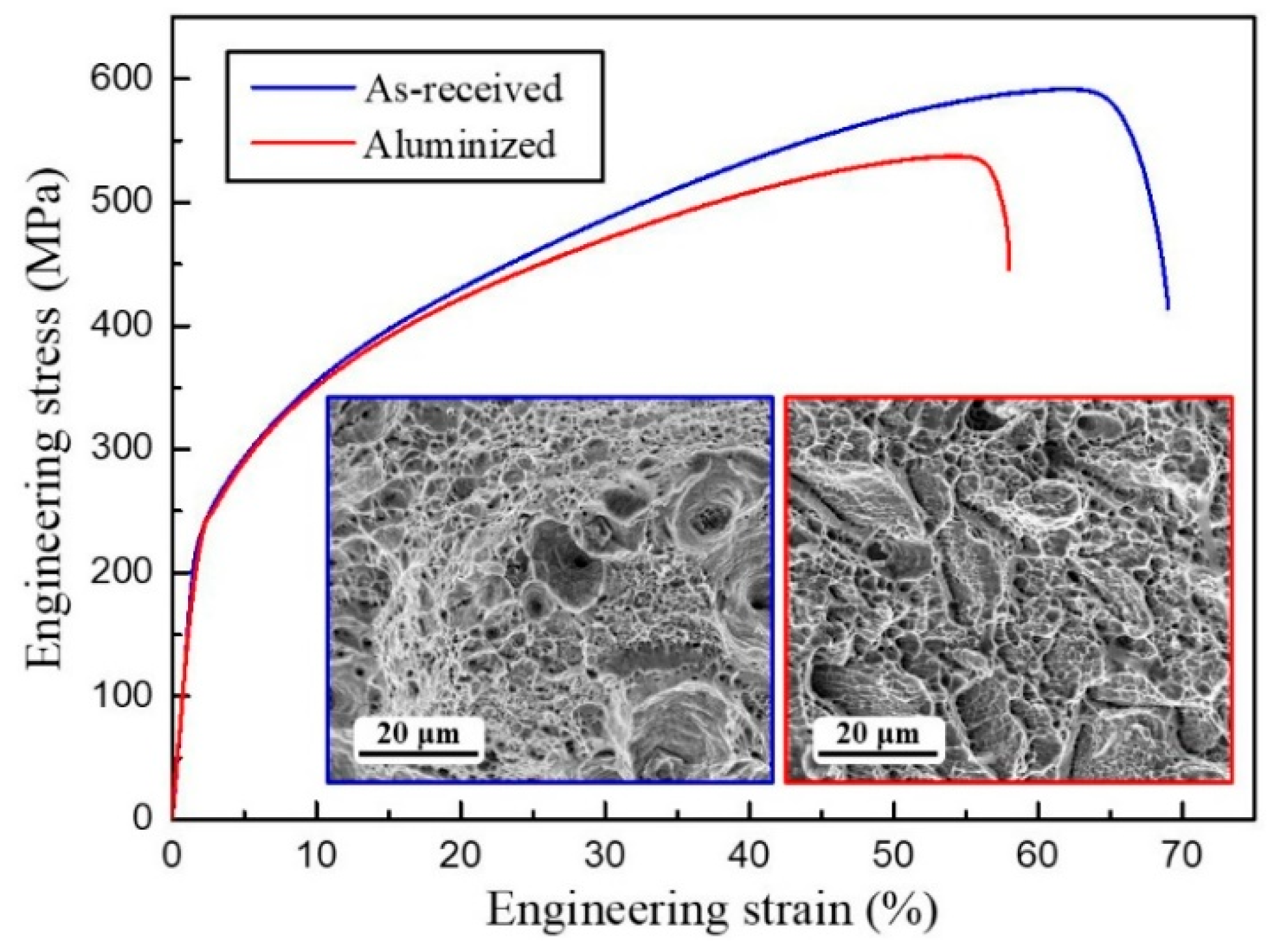

3.1. Microstructure Characterization and Tensile Property

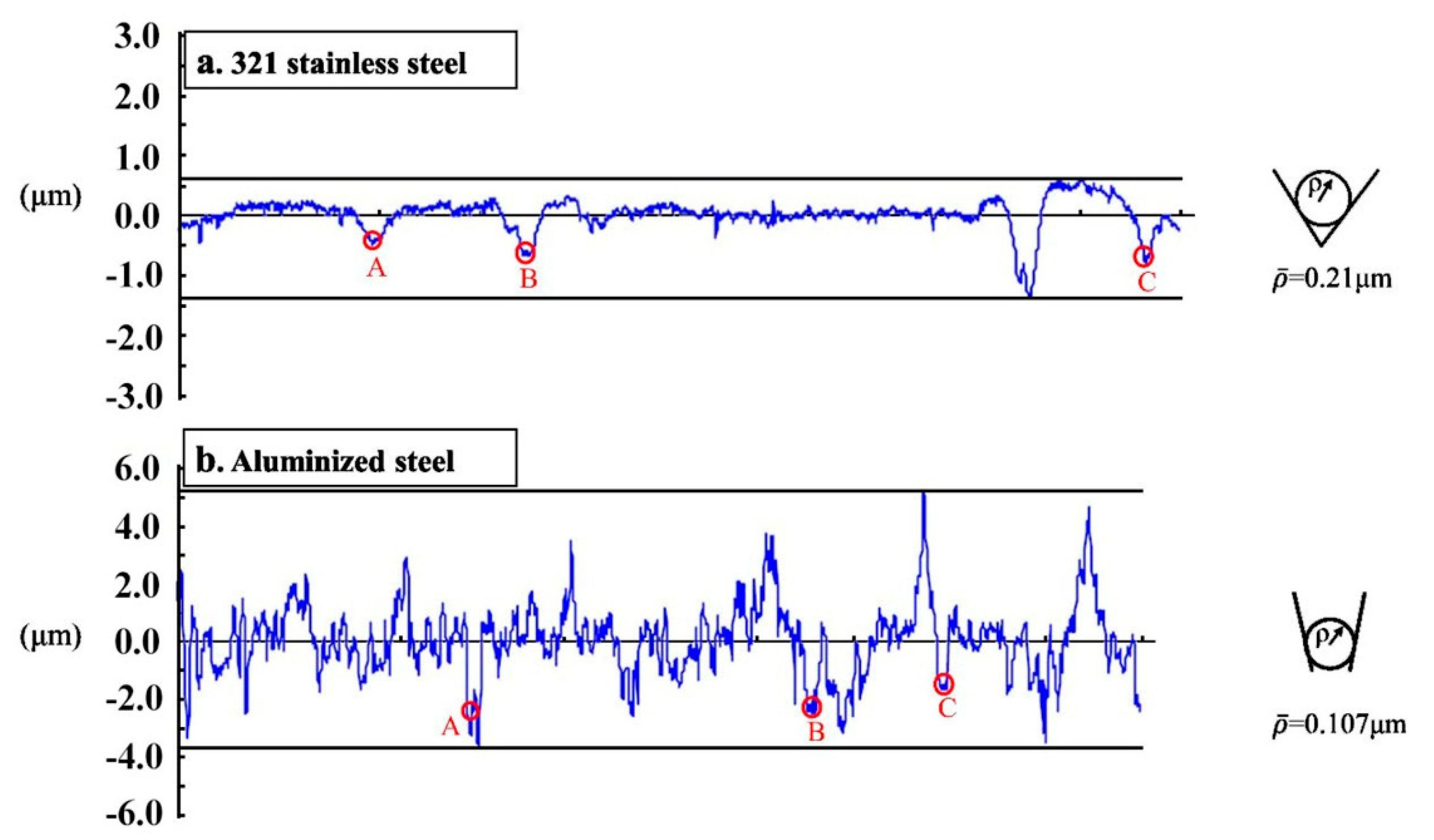

3.2. Surface Integrity

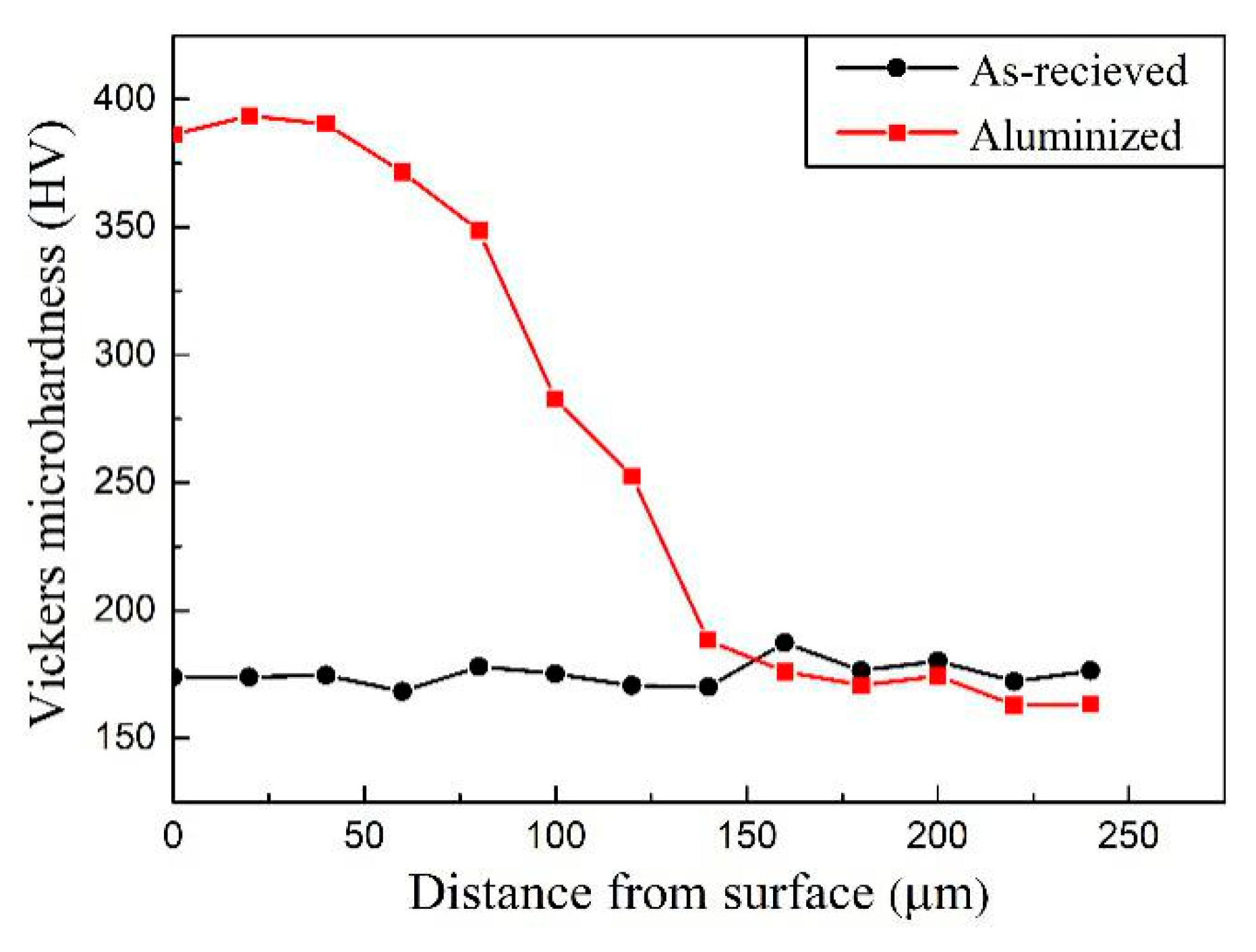

3.2.1. Microhardness

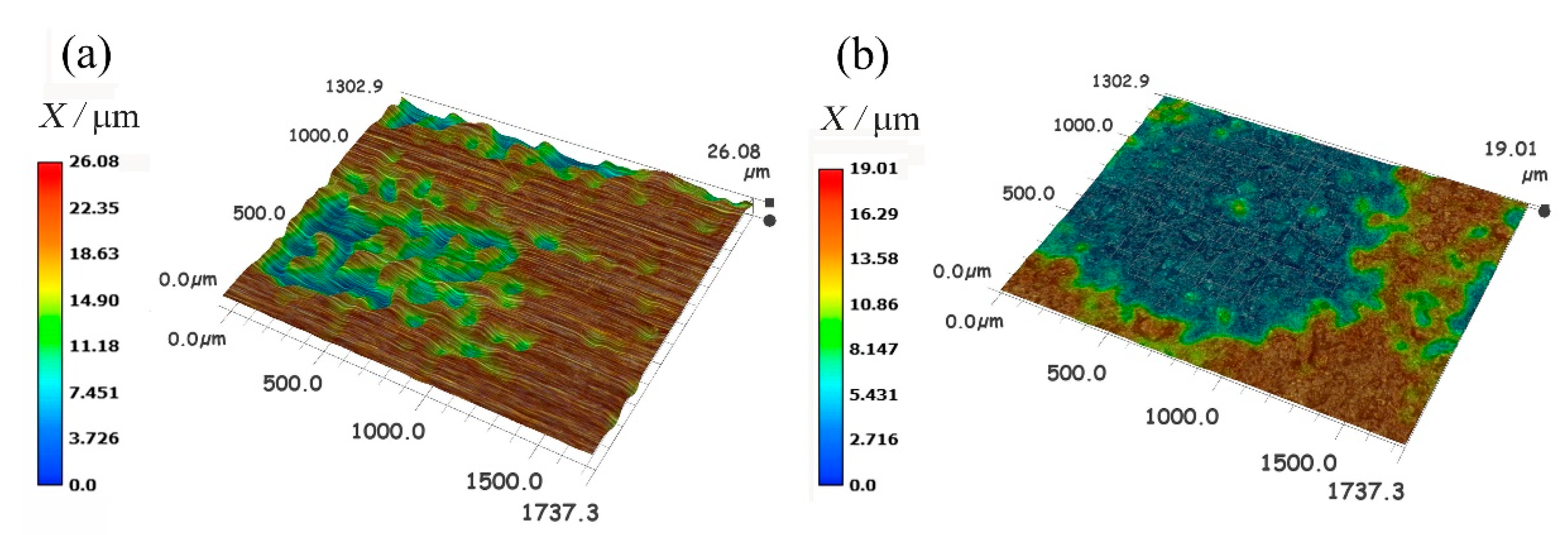

3.2.2. Surface Roughness

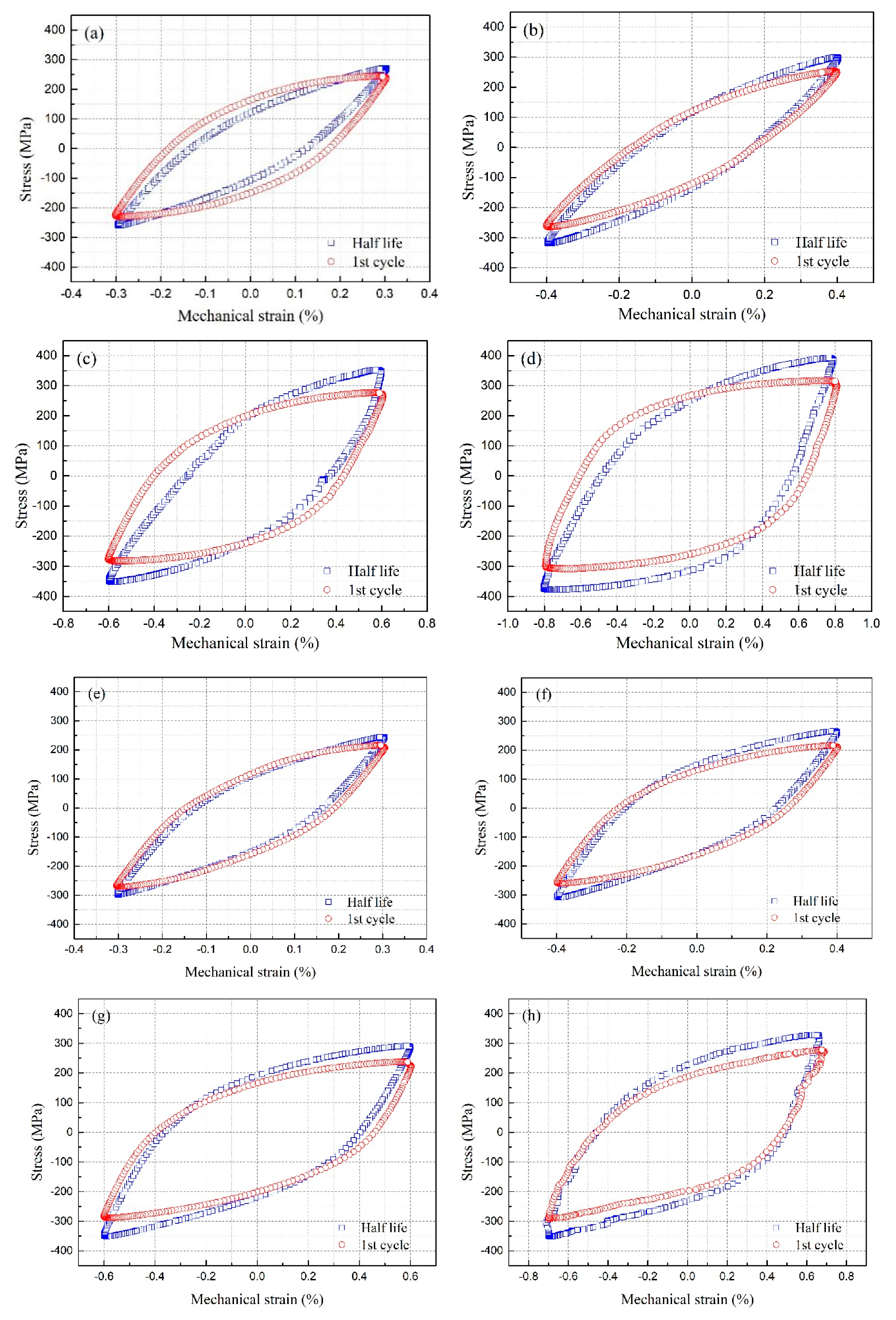

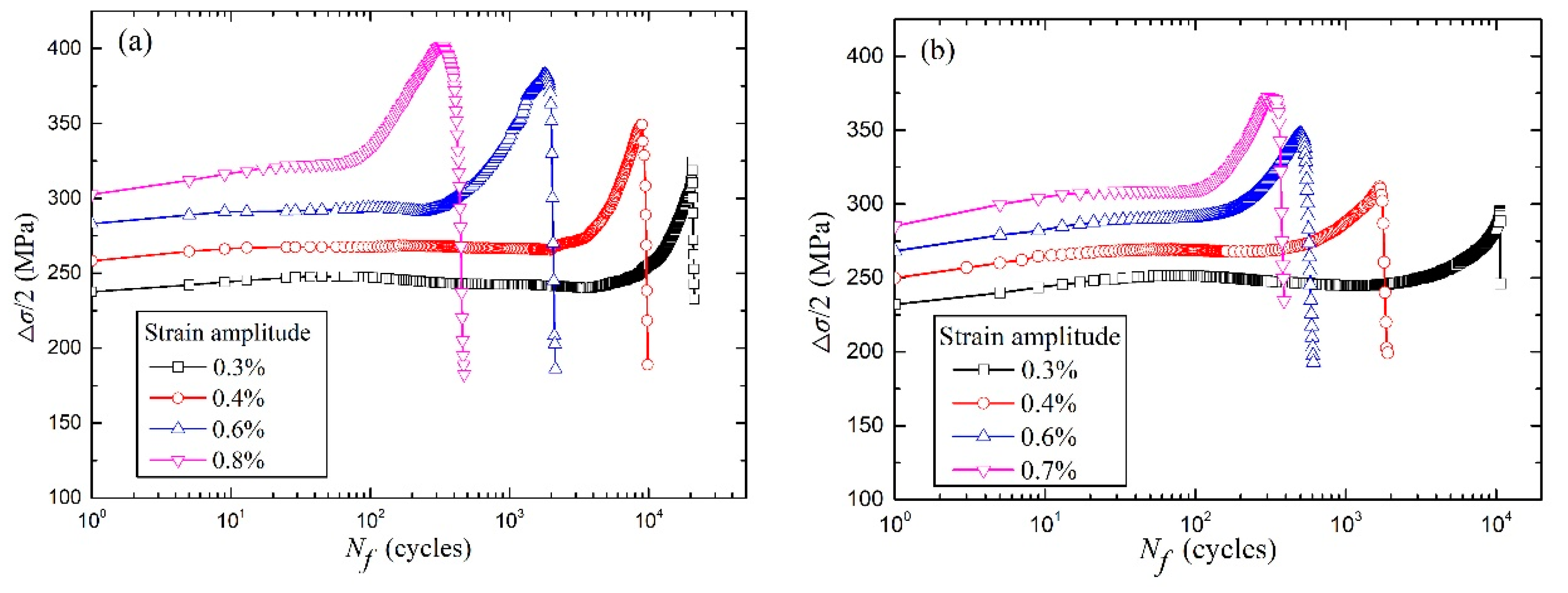

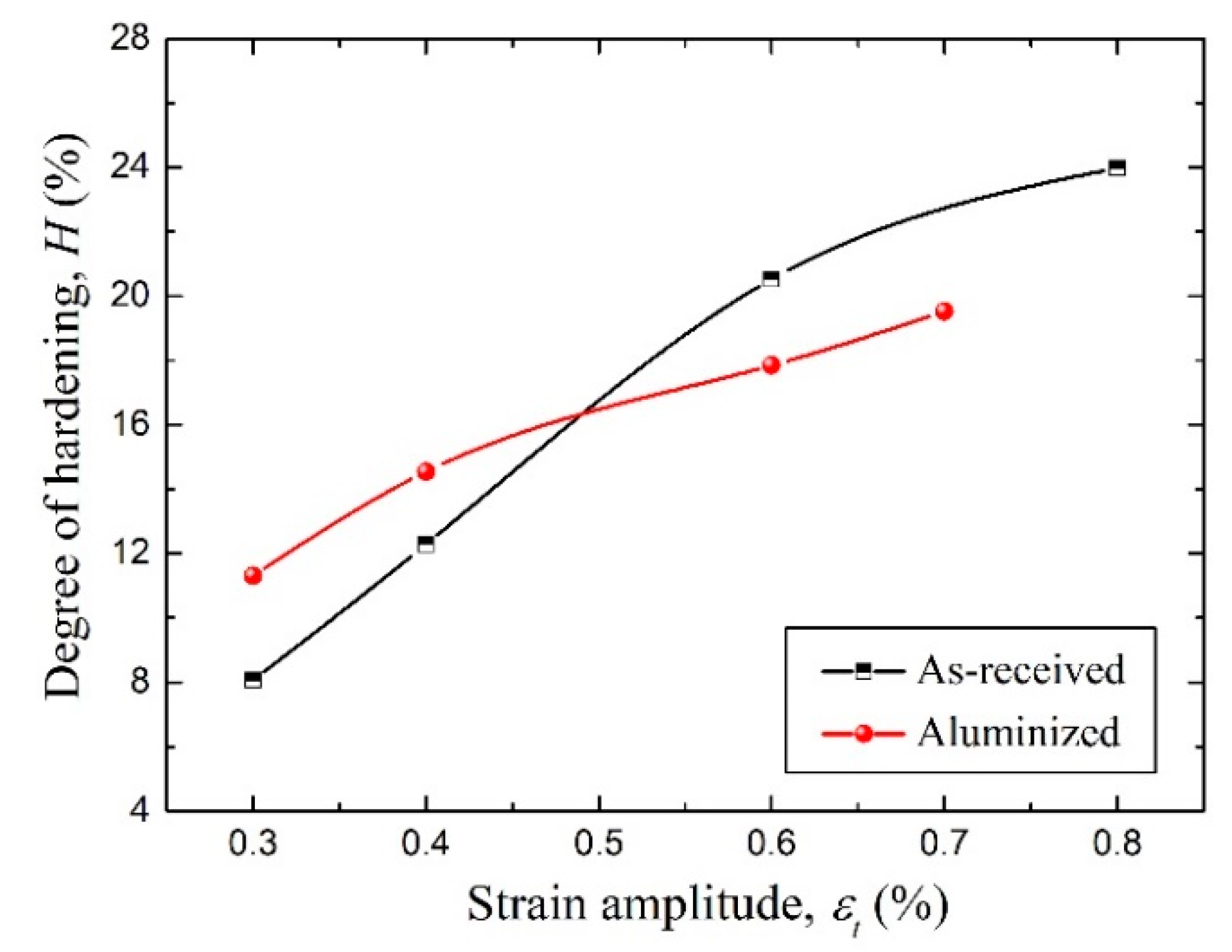

3.3. Hysteresis Loops and Cyclic Stress Response

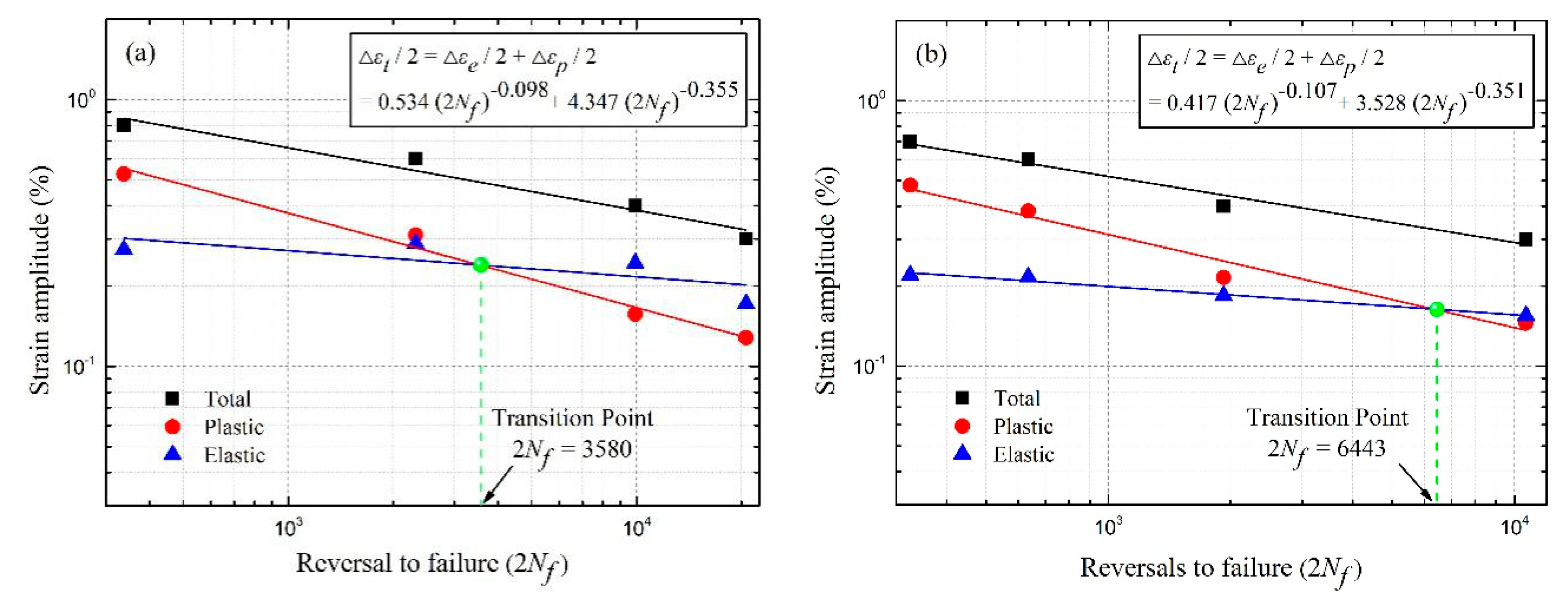

3.4. Low-Cycle Fatigue Life

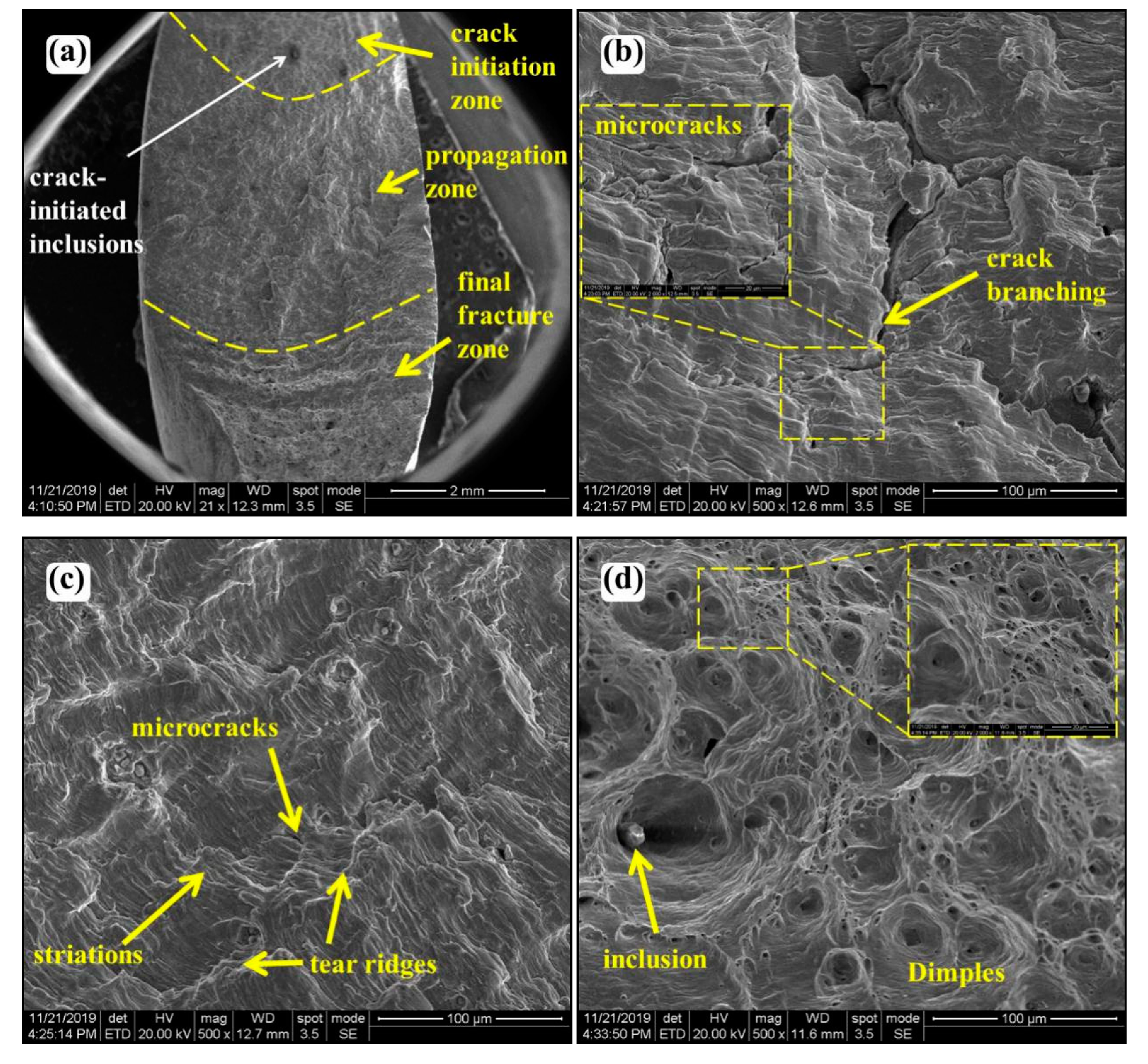

3.5. Fracture Behavior

4. Discussion

4.1. Microstructure Evolution

4.2. Surface Integrity

4.3. Cyclic Stress Response

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Regin, A.F.; Solanki, S.C.; Saini, J.S. Heat transfer characteristics of thermal energy storage system using PCM capsules: A review. Renew. Sustain. Energy Rev. 2008, 12, 2438–2458. [Google Scholar] [CrossRef]

- Xu, B.; Li, P.; Chan, C. Application of phase change materials for thermal energy storage in concentrated solar thermal power plants: A review to recent developments. Appl. Energy 2015, 160, 286–307. [Google Scholar] [CrossRef]

- Py, X.; Azoumah, Y.; Olives, R. Concentrated solar power: Current technologies, major innovative issues and applicability to West African countries. Renew. Sustain. Energy Rev. 2013, 18, 306–315. [Google Scholar] [CrossRef]

- Wang, Z. Prospectives for China’s solar thermal power technology development. Energy 2010, 35, 4417–4420. [Google Scholar] [CrossRef]

- Christopher, C.; Benjamin, K.S. Miracle or mirage? The promise and peril of desert energy part 1. Renew. Energy 2013, 50, 628–636. [Google Scholar]

- Vignarooban, K.; Xu, X.; Arvay, A.; Hsu, K.; Kannan, A.M. Heat transfer fluids for concentrating solar power systems—A review. Appl. Energy 2015, 146, 383–396. [Google Scholar] [CrossRef]

- Junping, J.; Hua, T.; Peng, J. Economic potential to develop concentrating solar power in China: A provincial assessment. Renew. Sustain. Energy Rev. 2019, 114, 109279. [Google Scholar]

- Xiao, H.; Xie, P.; Cheng, M.; Song, L. Enhancing mechanical properties of quasi-continuous-wave laser additive manufactured Inconel 718 through controlling the niobium-rich precipitates. Addit. Manuf. 2020, 34, 101278. [Google Scholar]

- Stéphanie, G.; Abdessamad, F.; Aydar, R.; Julien, L.; Emmanuel, V.; Patrick, E.; Catherine, B.; Nicolas, C.; Py, X. Corrosion effects between molten salts and thermal storage material for concentrated solar power plants. Appl. Energy 2012, 94, 174–181. [Google Scholar]

- Smola, B. Precipitation and hardening mechanisms in the AISI 321 steel. Acta Univ. Carolinae. Math. Phys. 1990, 31, 27–46. [Google Scholar]

- Prasad Reddy, G.V.; Dinesh, P.M.; Sandhya, R.; Laha, K.; Jayakumar, T. Behavior of 321 stainless steel under engineering stress and strain controlled fatigue. Int. J. Fatigue 2016, 92, 272–280. [Google Scholar] [CrossRef]

- Xiao, H.; Cheng, M.; Song, L. Direct fabrication of single-crystal-like structure using quasi-continuous-wave laser additive manufacturing. J. Mater. Sci. Technol. 2021, 60, 216–221. [Google Scholar] [CrossRef]

- Ferré, F.G.; Ormellese, M.; Fonzo, F.D.; Beghi, M.G. Advanced Al2O3 coatings for high temperature operation of steels in heavy liquid metals: A preliminary study. Corros. Sci. 2013, 77, 375–378. [Google Scholar] [CrossRef]

- Xu, Z.; Dai, J.; Niu, J.; He, L.; Mu, R.; Wang, Z. Isothermal oxidation and hot corrosion behaviors of diffusion aluminide coatings deposited by chemical vapor deposition. J. Alloys Compd. 2015, 637, 343–349. [Google Scholar] [CrossRef]

- Singh, K.; Fernandes, A.; Paul, B.; Gonal, M.R.; Abraham, G.; Krishnamurthy, N. Preparation and investigation of aluminized coating and subsequent heat treatment on 9Cr–1Mo Grade 91 steel. Fusion. Eng. Des. 2014, 89, 2534–2544. [Google Scholar] [CrossRef]

- Ravi, V.A.; Nguyen, T.K.; Nava, J.C. Thermochemical Surface Engineering of Steels; Woodhead Publishing: Sawston, Cambridge, UK, 2015; pp. 751–767. [Google Scholar]

- Majumdar, S.; Paul, B.; Kain, V.; Dey, G.K. Formation of Al2O3/Fe-Al layers on SS 316 surface by pack aluminizing and heat treatment. Mater. Chem. Phys. 2017, 190, 31–37. [Google Scholar] [CrossRef]

- Mušálek, R.; Kovářík, O.; Skiba, T.; Haušild, P.; Karlík, M.; Colmenares-Angulo, J. Fatigue properties of Fe–Al intermetallic coatings prepared by plasma spraying. Intermetallics 2010, 18, 1415–1418. [Google Scholar] [CrossRef]

- Manesh, H.D.; Taheri, A.K. Bond strength and formability of an aluminum-clad steel sheet. J. Alloys Compd. 2003, 361, 138–143. [Google Scholar] [CrossRef]

- Peng, L.M.; Li, H.; Wang, J.H.; Gong, M. High strength and high fracture toughness ceramic-iron aluminide (Fe3Al) composites. Mater. Lett. 2006, 60, 883–887. [Google Scholar] [CrossRef]

- Guu, Y.H.; Hocheng, H. Improvement of fatigue life of electrical discharge machined AISI D2 tool steel by TiN coating. Mater. Sci. Eng. A 2001, 318, 155–162. [Google Scholar] [CrossRef]

- Poursaiedi, E.; Salarvand, A. Effect of coating surface finishing on fatigue behavior of C450 steel CAPVD coated with (Ti,Cr)N. J. Mater. Eng. Perform. 2016, 25, 3448–3455. [Google Scholar] [CrossRef]

- Mordyuk, B.N.; Milman, Y.V.; Iefimov, M.O.; Prokopenko, G.I.; Silberschmidt, V.V.; Danylenko, M.I.; Kotko, A.V. Characterization of ultrasonically peened and laser-shock peened surface layers of AISI 321 stainless steel. Surf. Coat. Technol. 2008, 202, 4875–4883. [Google Scholar] [CrossRef]

- Sealy, M.P.; Guo, Y.B.; Caslaru, R.C.; Sharkins, J.; Feldman, D. Fatigue performance of biodegradable magnesium–calcium alloy processed by laser shock peening for orthopedic implants. Int. J. Fatigue 2016, 82, 428–436. [Google Scholar] [CrossRef]

- Webster, G.A.; Ezeilo, A.N. Residual stress distributions and their influence on fatigue lifetimes. Int. J. Fatigue 2001, 23, 375–383. [Google Scholar] [CrossRef]

- Sharafi, S.; Farhang, M.R. Effect of aluminizing on surface microstructure of an HH309 stainless steel. Surf. Coat. Technol. 2006, 200, 5048–5051. [Google Scholar] [CrossRef]

- Lopez, C.; Kvryan, A.; Kasnakjian, S.; Coronado, A.; Sujittosakul, S.; Villalpando, O.; Ravi, V.A. Effect of austenite stability on pack aluminizing of austenitic stainless steels. JOM 2015, 67, 61–67. [Google Scholar] [CrossRef]

- Arola, D.; Williams, C.L. Estimating the fatigue stress concentration factor of machined surfaces. Int. J. Fatigue 2002, 24, 923–930. [Google Scholar] [CrossRef]

- Grosse, M.; Kalkhof, D.; Keller, L.; Schell, N. Influence parameters of martensitic transformation during low cycle fatigue for steel AISI 321. Phys. B 2004, 350, 102–106. [Google Scholar] [CrossRef]

- Prasad Reddy, G.V.; Sandhya, R.; Sankaran, S.; Mathew, M.D. Low cycle fatigue behavior of 316LN stainless steel alloyed with varying nitrogen content. Part I: Cyclic deformation behavior. Metall. Mater. Trans. A 2014, 45, 5044–5056. [Google Scholar] [CrossRef]

- Song, W.; Liu, X.; Berto, F.; Razavi, S.M.J. Low-cycle fatigue of 10CrNi3MoV high strength steel and its undermatched welds. Materials 2018, 11, 661. [Google Scholar] [CrossRef]

- Ye, D.; Matsuoka, S.; Nagashima, N.; Suzuki, N. The low-cycle fatigue, deformation and final fracture behaviour of an austenitic stainless steel. Mater. Sci. Eng. A 2006, 415, 104–117. [Google Scholar] [CrossRef]

- Branco, R.; Costa, J.D.; Antunes, F.V. Low-cycle fatigue behaviour of 34CrNiMo6 high strength steel. Theor. Appl. Fract. Mech. 2012, 58, 28–34. [Google Scholar] [CrossRef]

- Stoloff, N.S. Iron aluminides: Present status and future prospects. Mater. Sci. Eng. A 1998, 258, 1–14. [Google Scholar] [CrossRef]

- Kim, J.K.; Kim, Y.H.; Kim, K.Y. Influence of Cr, C and Ni on intergranular segregation and precipitation in Ti-stabilized stainless steels. Scr. Mater. 2010, 63, 449–451. [Google Scholar] [CrossRef]

- Schwind, M.; Källqvist, J.; Nilsson, J.O. σ-phase precipitation in stabilization austenitic stainless steels. Acta Mater. 2000, 48, 2473–2481. [Google Scholar] [CrossRef]

- Kobayashi, S.; Yakou, T. Control of intermetallic compound layers at interface between steel and aluminum by diffusion-treatment. Mater. Sci. Eng. A 2002, 338, 44–53. [Google Scholar] [CrossRef]

- Peterson, R.E.; Plunkett, R. Stress concentration factors. Nav. Eng. J. 1955, 67, 697–708. [Google Scholar] [CrossRef]

- Neuber, H. On the Effect of Stress Concentration in Cosserat Continua; Springer: Berlin, Germany, 1968; pp. 109–113. [Google Scholar]

- Varma, V.K.; Kamat, S.V.; Mahajan, Y.R.; Kutumbarao, V.V. Cyclic stress response of Al-Cu-Mg alloy matrix composites with SiCp of varying sizes. Scr. Mater. 1998, 38, 1571–1575. [Google Scholar] [CrossRef]

- Kim, K.Y.; Jung, H.G.; Seong, B.G.; Hwang, S.Y. Improvement of cyclic high-temperature corrosion resistance of pack-aluminized heat-resistant stainless steels. Oxid. Met. 1994, 41, 11–35. [Google Scholar] [CrossRef]

- Lo, K.H.; Shek, C.H.; Lai, J.K.L. Recent developments in stainless steels. Mater. Sci. Eng. R 2009, 65, 39–104. [Google Scholar] [CrossRef]

- Nam, S.W.; Yoon, Y.C.; Choi, B.G.; Lee, J.M.; Hong, J.W. The normalized Coffin-Manson plot in terms of a new damage function based on grain boundary cavitation under creep-fatigue condition. Metall. Mater. Trans. A 1996, 27, 1273. [Google Scholar] [CrossRef]

- Tanaka, M.; Miyagawa, O.; Sakaki, T.; Lizuka, H.; Ashihara, F.; Fujishiro, D. Creep rupture strength and grain-boundary sliding in austenitic 21 Cr-4Ni-9Mn steels with serrated grain boundaries. J. Mater. Sci. 1988, 23, 621–628. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | P | S | Cr | Ni | N | Ti |

|---|---|---|---|---|---|---|---|---|---|

| wt. % | 0.035 | 0.38 | 1.08 | 0.028 | 0.003 | 17.02 | 9.06 | 0.045 | 0.22 |

| Point | Fe | Al | O | Cr |

|---|---|---|---|---|

| 1 (external layer) | 0.44 | 32.45 | 59.89 | 4.72 |

| 2 | 30.68 | 43.98 | 15.21 | 7.01 |

| 3 | 50.01 | 23.54 | 3.33 | 9.38 |

| 4 | 76.62 | 1.40 | 0 | 17.49 |

| Samples | 0.2% Yield Strength (σys) (MPa) | Ultimate Tensile Strength (σb) (MPa) | Elongation (A) (%) |

|---|---|---|---|

| As-received | 260 | 608 | 69 |

| Aluminized | 232 | 518 | 58 |

| Sample | Ra (μm) | Rz (μm) | Ry (μm) |

|---|---|---|---|

| As-received | 0.168 | 0.962 | 1.97 |

| Aluminized | 0.952 | 7.174 | 9.473 |

| Sample | Δεt/2 (%) | Δεp/2 (%) | Δεe/2 (%) | Nf |

|---|---|---|---|---|

| As-received | 0.3 | 0.12822 | 0.17178 | 20632 |

| As-received | 0.4 | 0.15674 | 0.24326 | 9918 |

| As-received | 0.6 | 0.31116 | 0.28884 | 2324 |

| As-received | 0.8 | 0.52592 | 0.27408 | 338 |

| Aluminized | 0.3 | 0.14535 | 0.15465 | 10685 |

| Aluminized | 0.4 | 0.21578 | 0.18422 | 1923 |

| Aluminized | 0.6 | 0.38358 | 0.21642 | 635 |

| Aluminized | 0.7 | 0.48018 | 0.21982 | 325 |

| Sample | σb (MPa) | (μm) | γ (mm) | q | ||

|---|---|---|---|---|---|---|

| As-received | 608 | 0.210 | 0.227 | 0.000925 | 4.286 | 1.003 |

| Aluminized | 518 | 0.107 | 0.303 | 0.000353 | 24.497 | 1.008 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Yang, L.; Li, C.; Chen, H.; Zuo, L.; Li, Y.; Chen, J.; He, J.; Zhang, S.-d. Low-Cycle Fatigue and Fracture Behavior of Aluminized Stainless Steel AISI 321 for Solar Thermal Power Generation Systems. Metals 2020, 10, 1089. https://doi.org/10.3390/met10081089

Li W, Yang L, Li C, Chen H, Zuo L, Li Y, Chen J, He J, Zhang S-d. Low-Cycle Fatigue and Fracture Behavior of Aluminized Stainless Steel AISI 321 for Solar Thermal Power Generation Systems. Metals. 2020; 10(8):1089. https://doi.org/10.3390/met10081089

Chicago/Turabian StyleLi, Wei, Lei Yang, Cong Li, Huitao Chen, Lu Zuo, Yide Li, Jian Chen, Jianjun He, and Sheng-de Zhang. 2020. "Low-Cycle Fatigue and Fracture Behavior of Aluminized Stainless Steel AISI 321 for Solar Thermal Power Generation Systems" Metals 10, no. 8: 1089. https://doi.org/10.3390/met10081089

APA StyleLi, W., Yang, L., Li, C., Chen, H., Zuo, L., Li, Y., Chen, J., He, J., & Zhang, S.-d. (2020). Low-Cycle Fatigue and Fracture Behavior of Aluminized Stainless Steel AISI 321 for Solar Thermal Power Generation Systems. Metals, 10(8), 1089. https://doi.org/10.3390/met10081089