Determination of Constitutive Equation and Thermo–Mechanical Processing Map for Pure Iridium

Abstract

1. Introduction

2. Materials and Methods

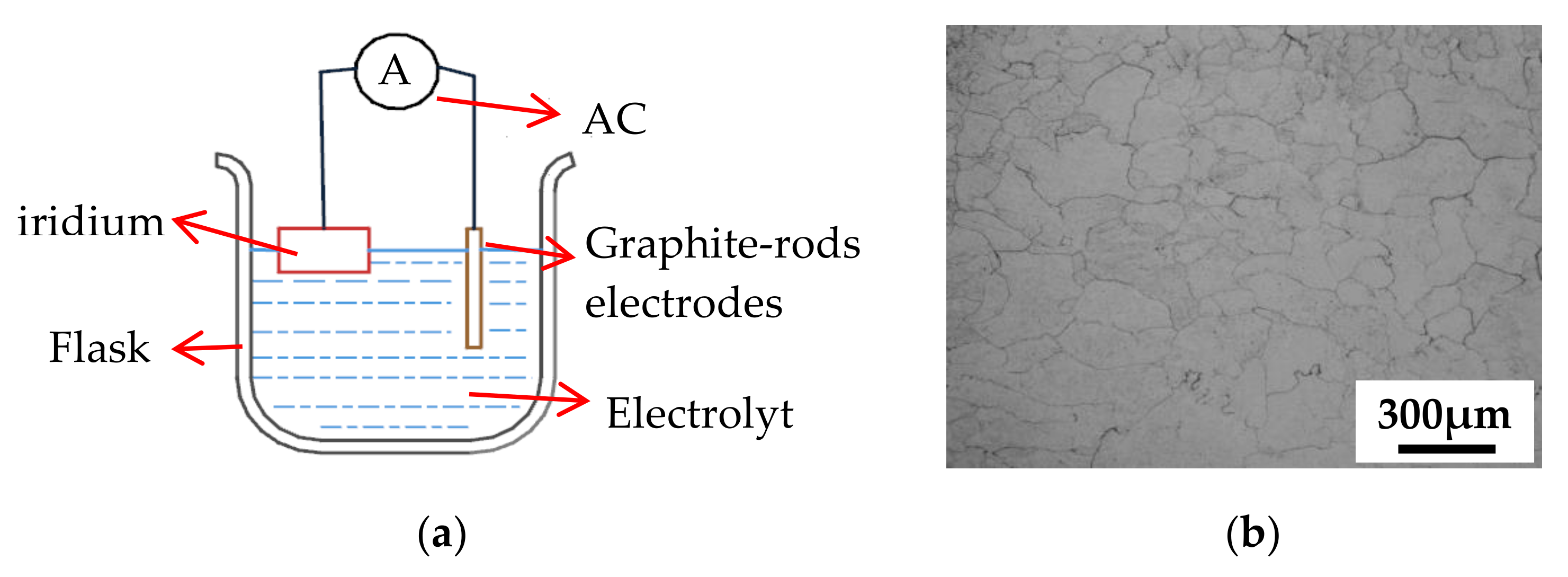

2.1. Preparation of Compression Specimen

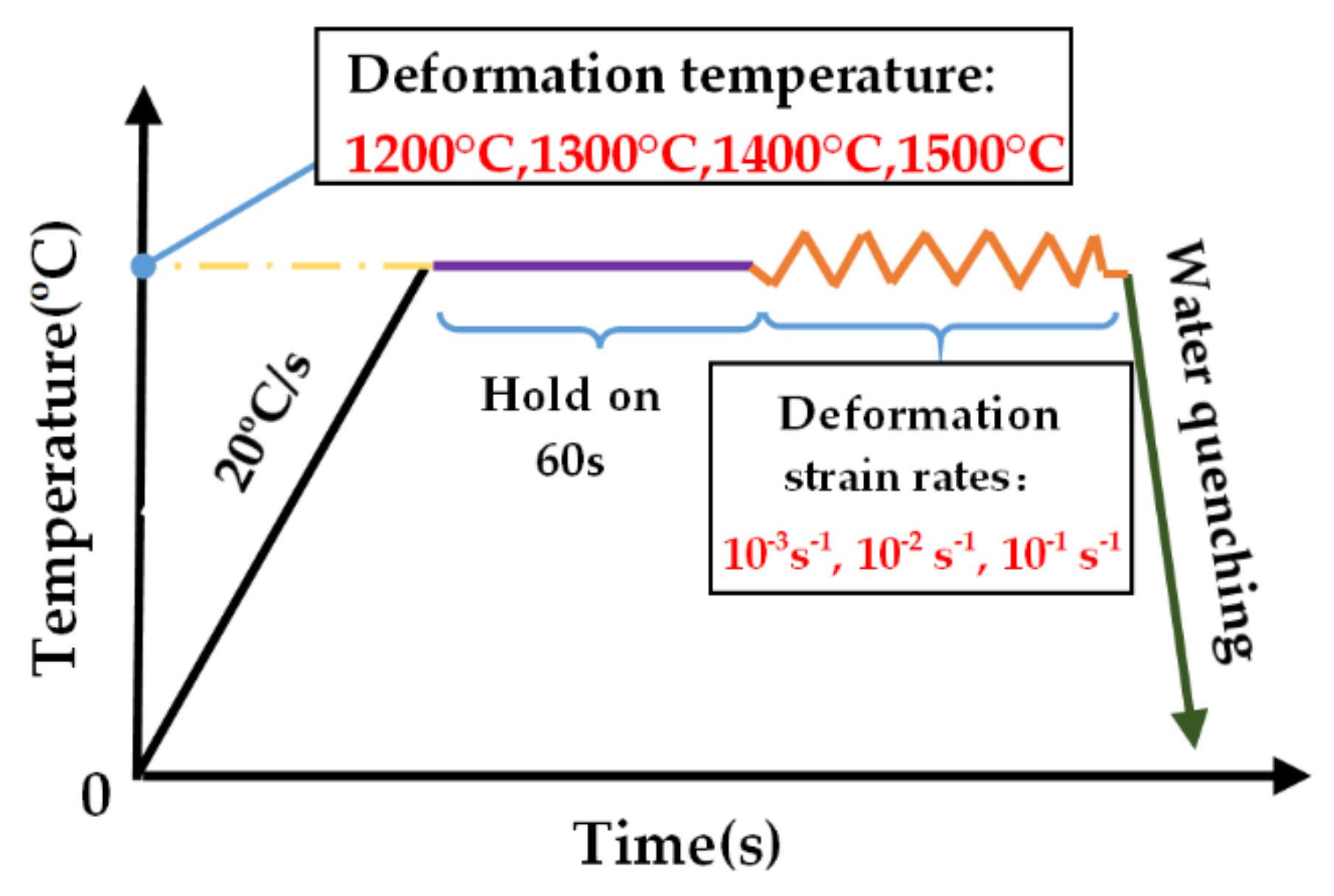

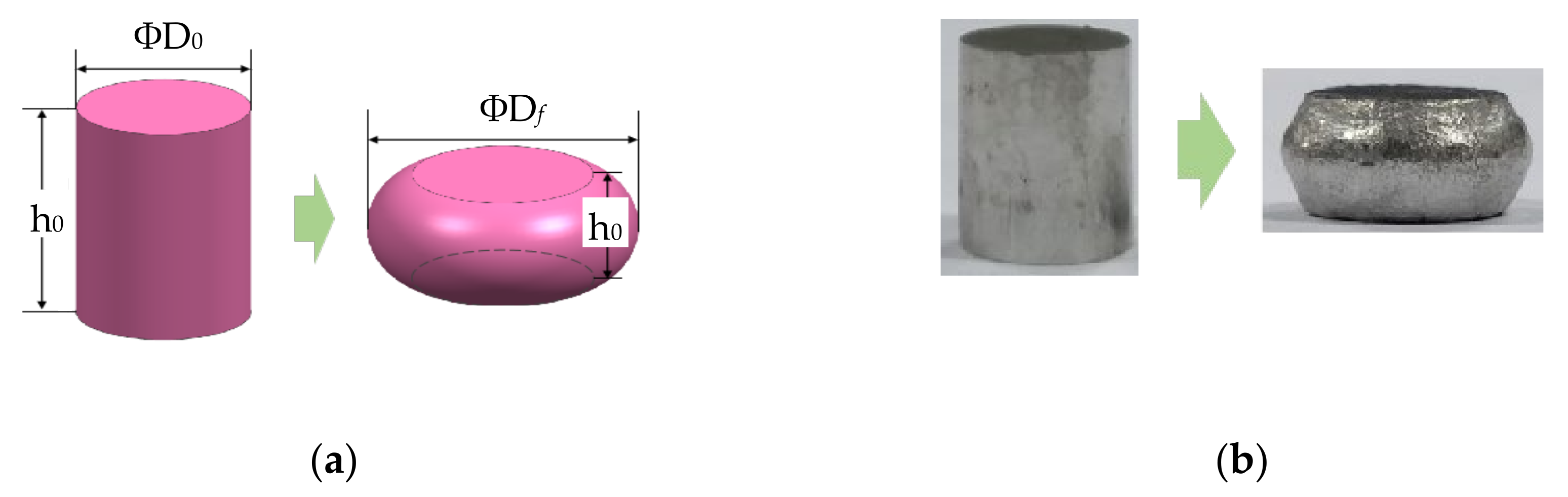

2.2. Hot Compression Test

2.3. Microstructure Characterization

3. Results and Discussion

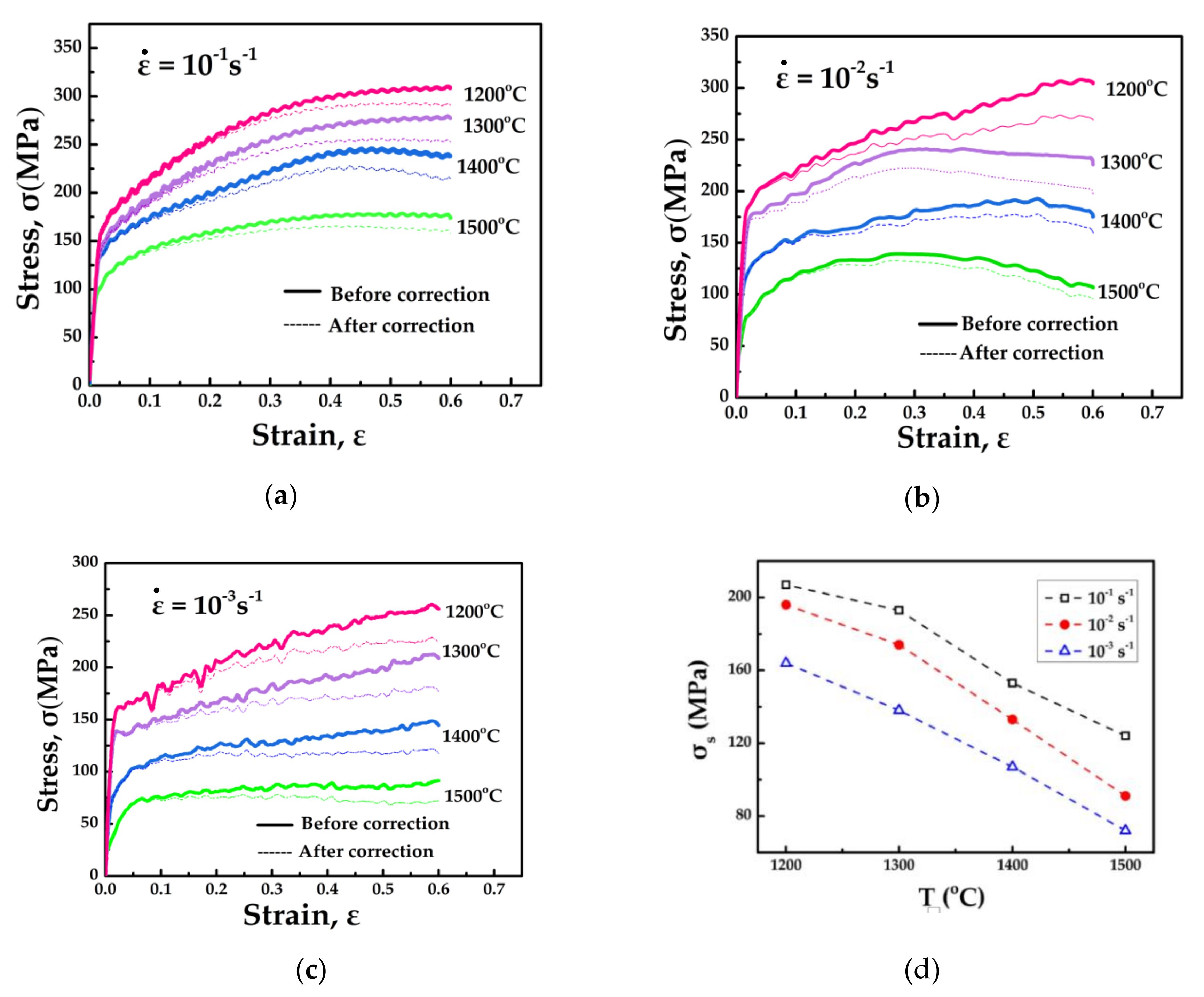

3.1. Modification of Flow Stress Curves

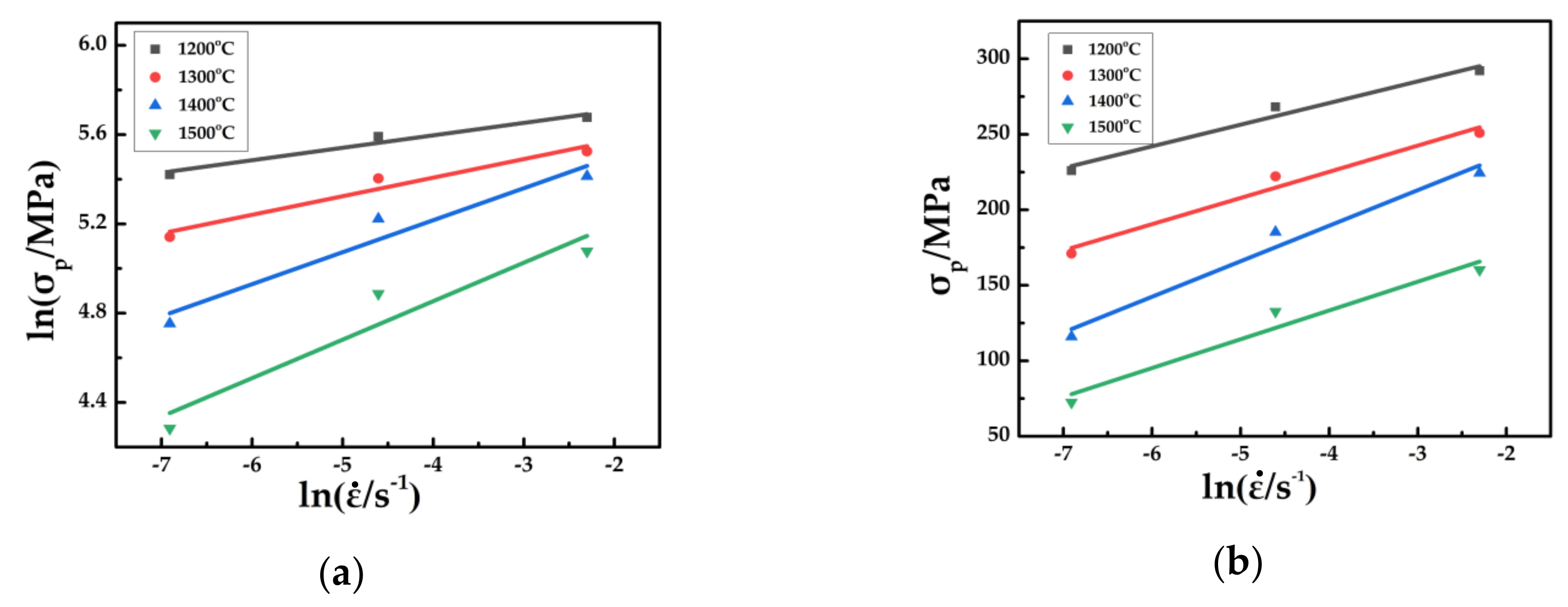

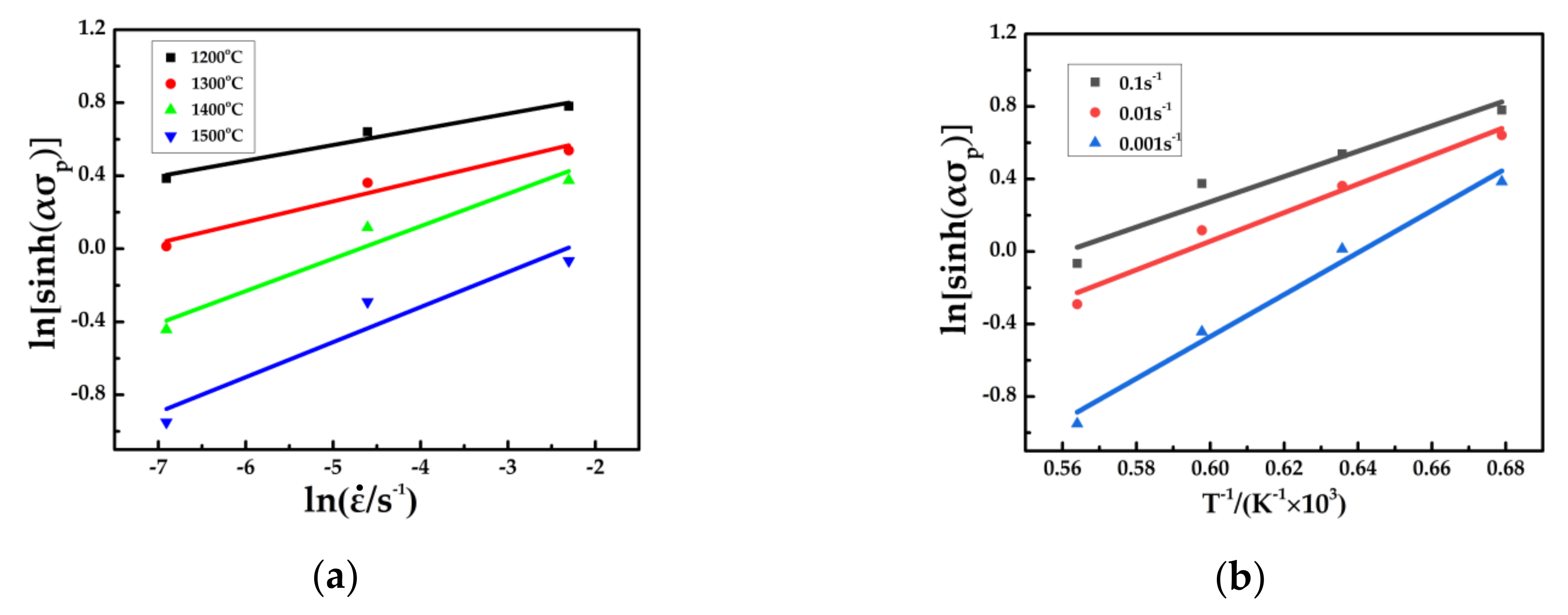

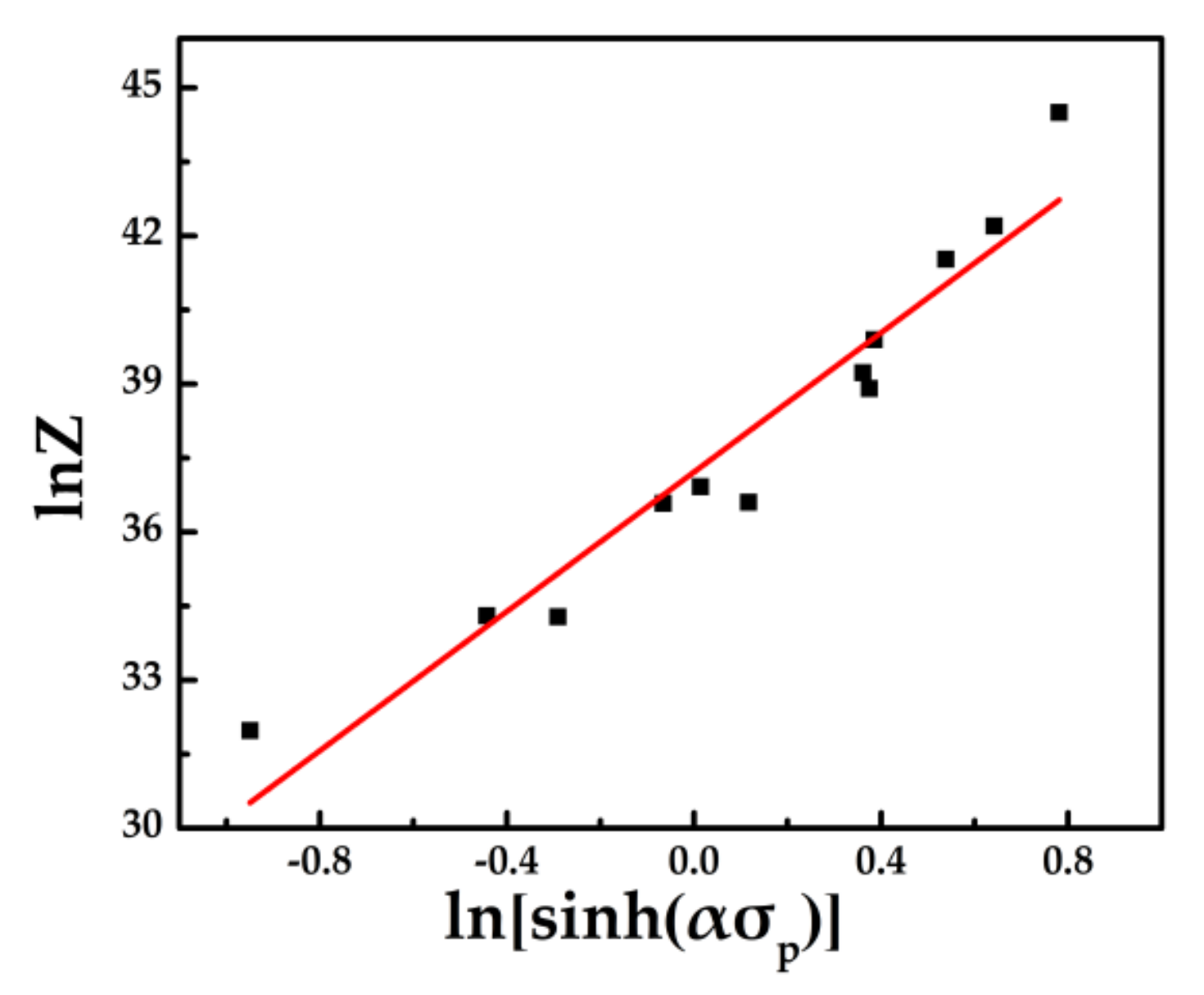

3.2. Constitutive Equations of Flow Stress for Pure Iridium

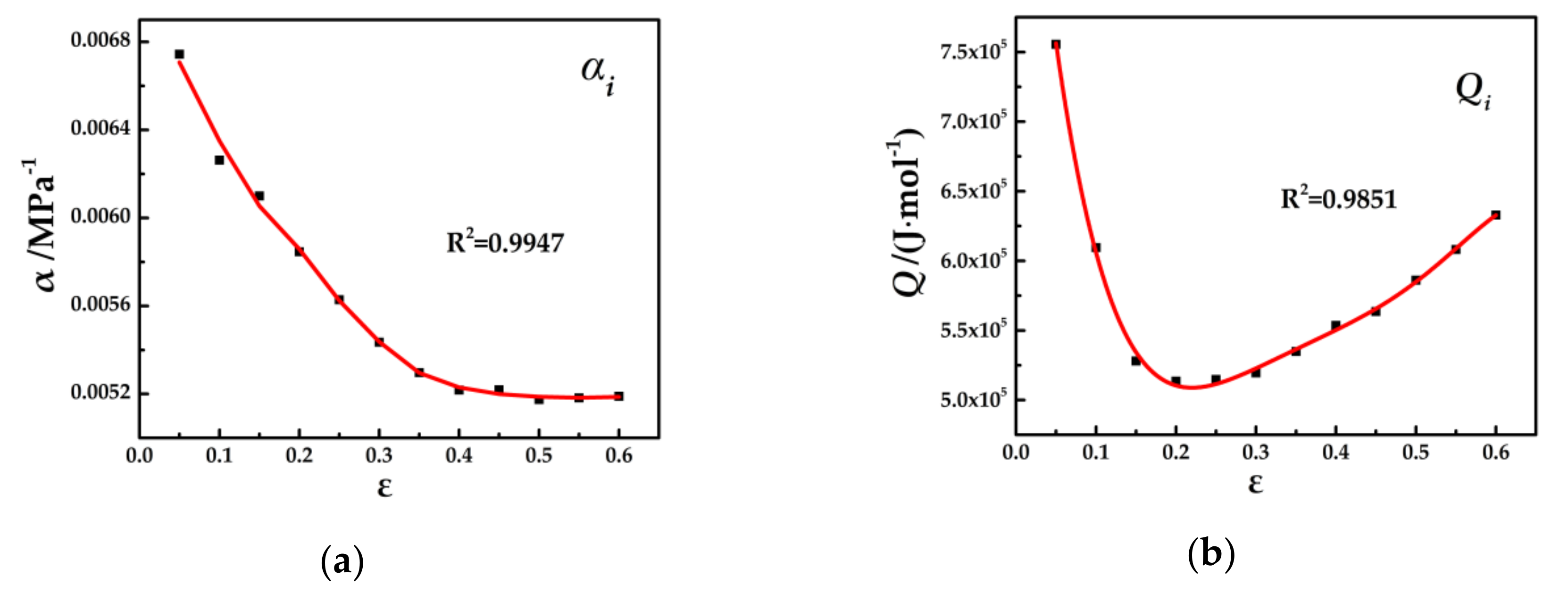

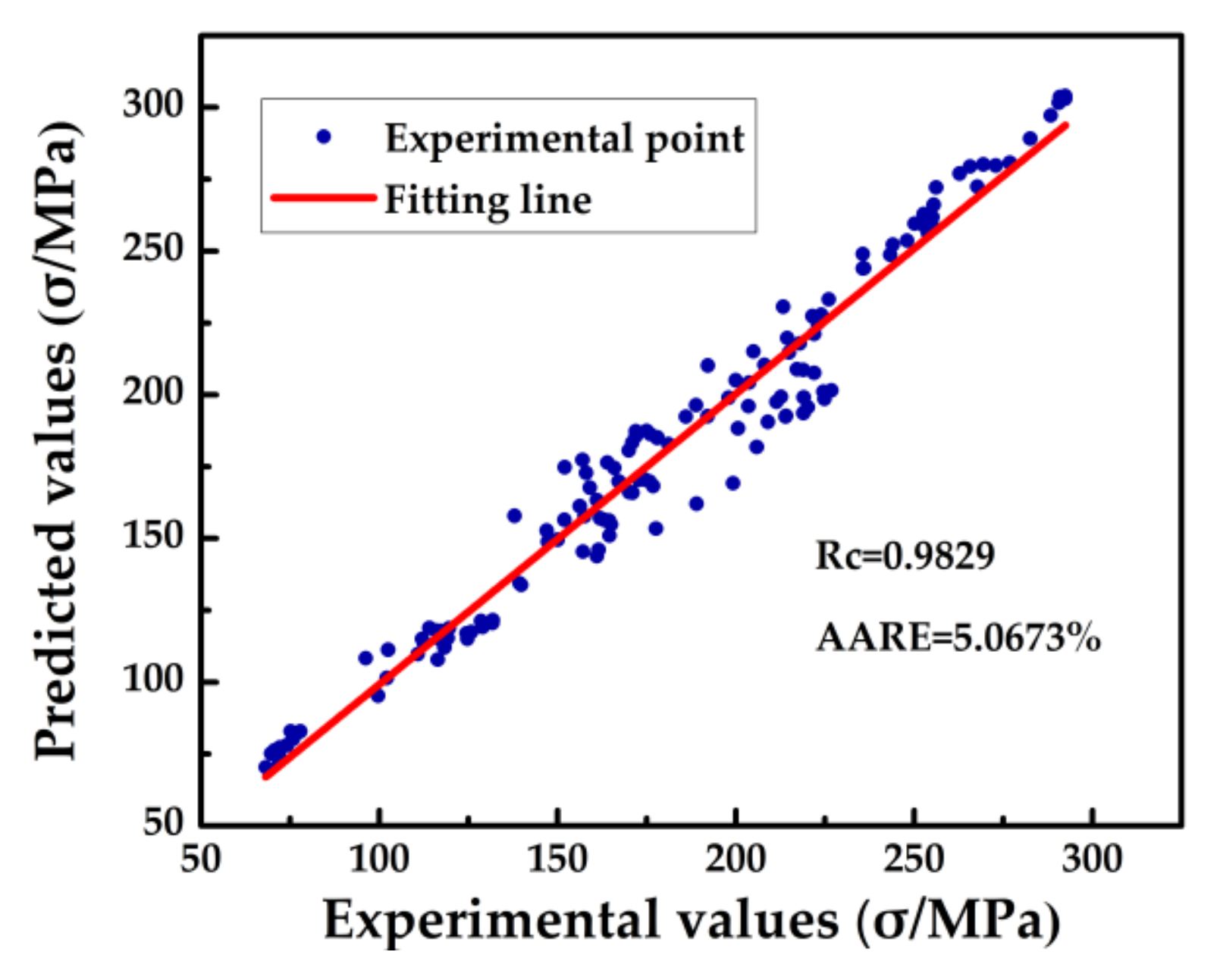

3.3. Constitutive Equations with Compensation for Strain

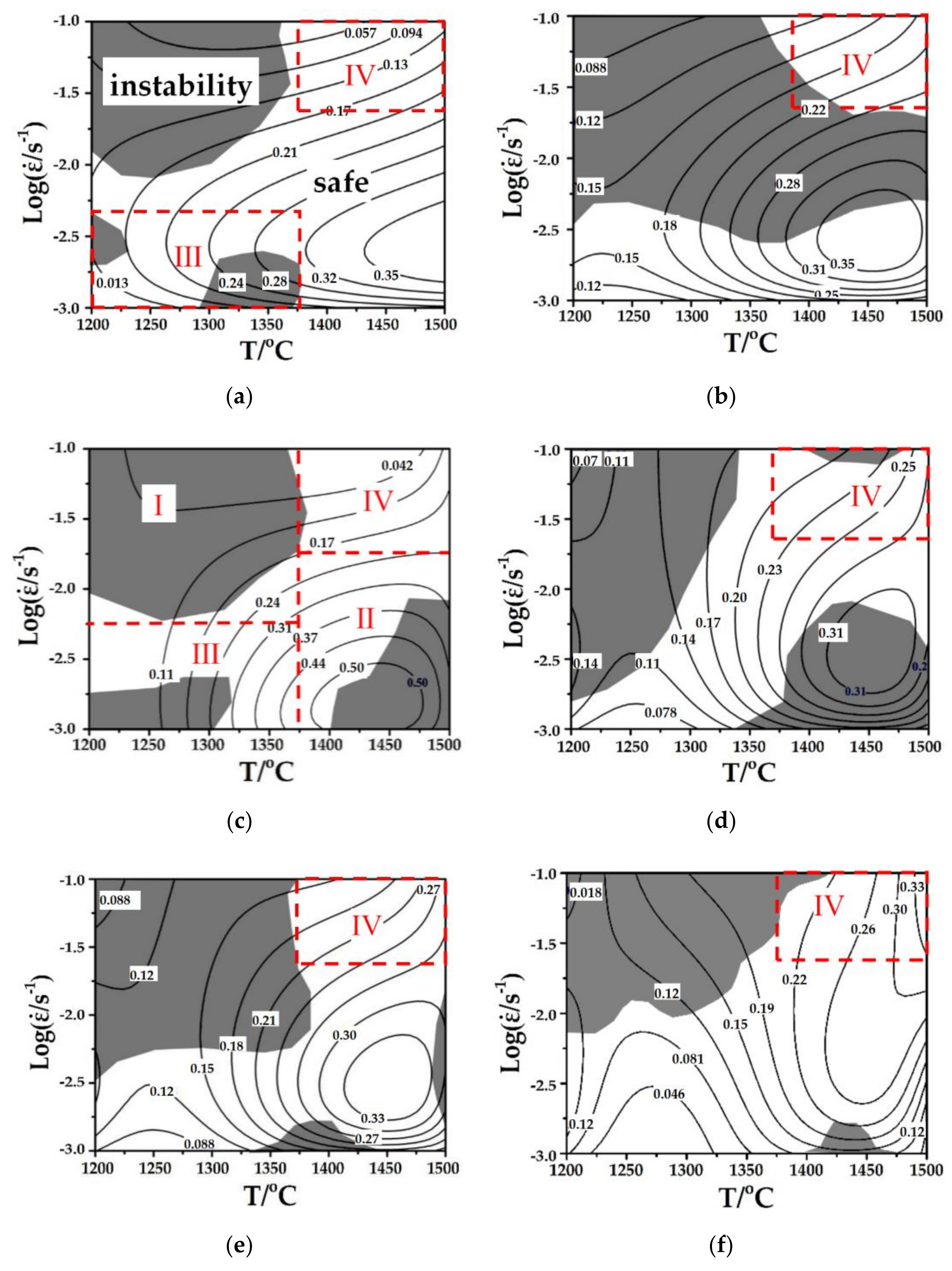

3.4. Establishment and Analysis of Processing Map

3.4.1. The Theory of Processing Map

3.4.2. Analysis of Processing Map

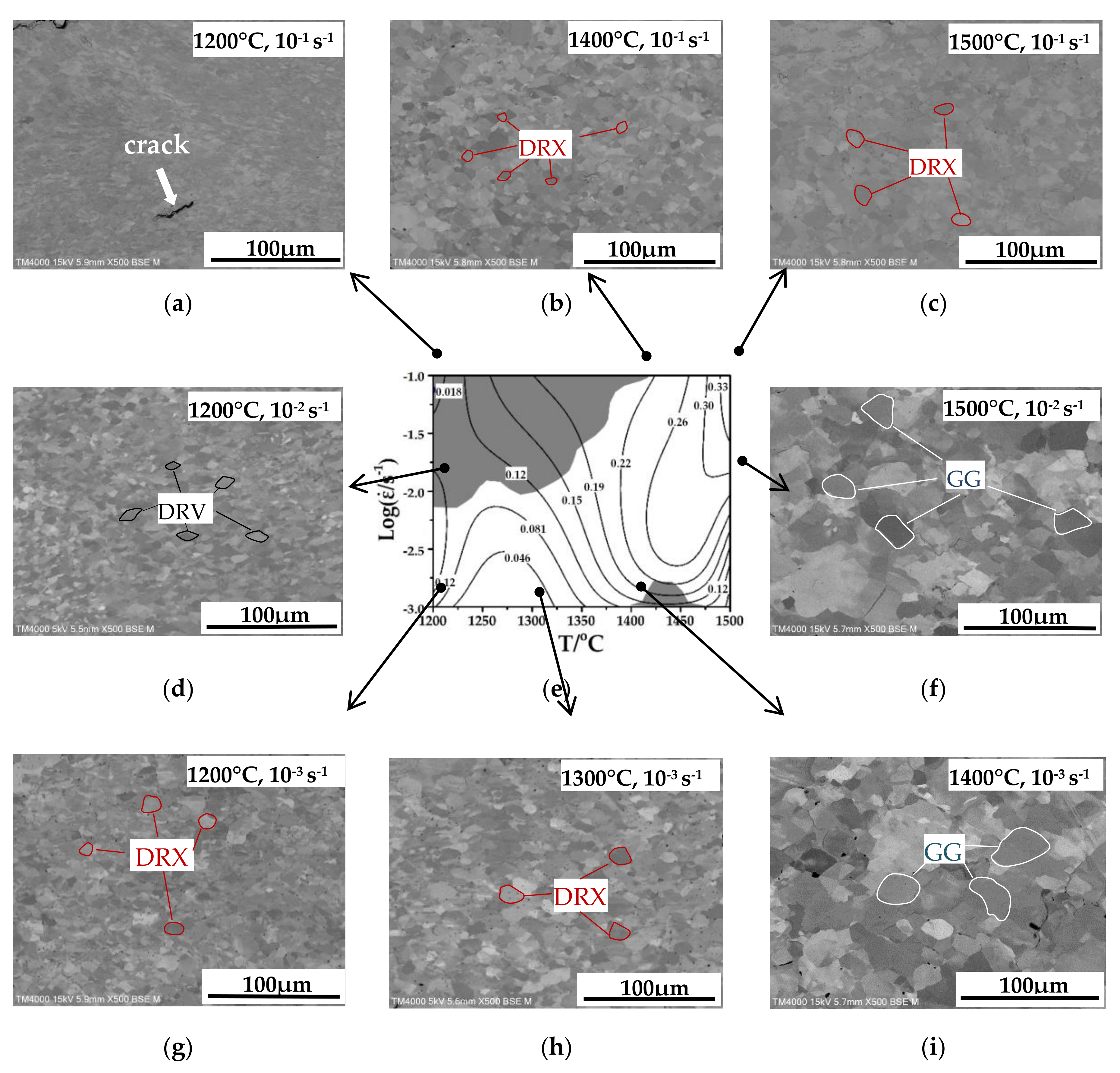

3.5. Microstructure Evolution of Pure Iridium

4. Conclusions

- The compressive stress is greatly influenced by deformation temperature and strain rate during hot compression. The compression yield strength of pure iridium is sharply decreased from 208.6 MPa (1200 °C, 10−1 s−1) to 72.1 MPa (1500 °C, 10−3 s−1) with the temperature increasing and strain rate reducing during hot compression.

- The deformation mechanisms of pure iridium are dependent upon temperature as well as strain rate and it varies from the dynamic recovery at temperature range of 1200 °C~1300 °C and 10−1 s−1~10−2 s−1 to the dynamic recrystallization as the temperature increases and strain rate reduces, then to the abnormal grain grown at elevated temperature-low strain rate (1400 °C~1500 °C and 10−2 s−1~10−3 s−1).

- In view of the hyperbolic sine constitutive equation and multinomial fitting model, the relations between forming temperature, strain rate, strain and flow stress have been established to predict the deformation behavior of pure iridium. The average absolute relative error of equation, as little as 5.067%, suggests a high accuracy in predicting flow stresses. A very high value of activation energy for iridium, 573 KJ/mol, clearly indicates that it is very hard to deform this material.

- The processing maps under various strains of pure iridium were established to identify ideal conditions for processing. The suitable processing window for hot forming of pure iridium is 1400 °C~1500 °C and 0.1 s−1~0.05 s−1, obtained through processing maps and microstructure analysis.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Weiland, R.; Lupton, D.F.; Fischer, B.; Merker, J.; Scheckenbach, C. High-temperature mechanical properties of the platinum group metals. Platin. Met. Rev. 2006, 50, 158–170. [Google Scholar] [CrossRef]

- Yang, J.R.; Wang, H.; Wang, B.Q.; Hu, R.; Liu, Y.; Luo, X.M. Numerical and experimental study of electron beam floating zone melting of iridium single crystal. J. Mater. Process. Technol. 2017, 250, 239–246. [Google Scholar] [CrossRef]

- Liu, C.T.; Inouye, H.; Schaffhauser, A.C. Effect of Thorium Additions on Metallurgical and Mechanical Properties of Ir-0.3pct W Alloys. Metall. Trans. A 1981, 12, 993–1002. [Google Scholar] [CrossRef]

- Loginova, Y.N.; Gladkovskiib, S.V.; Potapovb, A.I.; Fomina, A.A.; Salikhyanova, D.R. Investigation into the deformation resistance of polycrystalline iridium. Phys. Metall. Hard Treat. 2015, 56, 532–539. [Google Scholar]

- Cawkwell, M.J. Origin of brittle cleavage in iridium. Science 2005, 309, 1059–1062. [Google Scholar] [CrossRef]

- Panfilov, P.; Novgorodov, V.; Yermakov, A. Fracture behaviour of polycrystalline iridium under tension in the temperature range 20–1500 °C. J. Mater. Sci. Lett. 1994, 13, 137–141. [Google Scholar] [CrossRef]

- Merker, J.; Koch, M. Metals for high temperature applications under extreme conditions development and testing. Mater. Sci. Forum 2014, 783, 1165–1170. [Google Scholar]

- Prasad, Y.V.R.K.; Ravichandran, N. Effect of stacking fault energy on the dynamic recrystallization during hot working of FCC metals: A study using processing maps. Bull. Mater. Sci. 1991, 14, 1241–1248. [Google Scholar] [CrossRef]

- Ding, X.F.; Zhao, F.Q.; Shuang, Y.H.; Ma, L.F.; Chu, Z.B.; Zhao, C.J. Characterization of hot deformation behavior of as-extruded AZ31 alloy through kinetic analysis and processing maps. J. Mater. Process. Technol. 2020, 276, 116325. [Google Scholar] [CrossRef]

- Wang, B.Q.; Li, S.M.; Wang, Y.M.; Zhong, H.; Hu, R.; Liu, Y.; Luo, X.M. Single-crystal growth of iridium with [100] and [110] orientations by electron beam zone melting. Vacuum 2018, 154, 141–147. [Google Scholar] [CrossRef]

- Venugopal, S.; Srinivasan, G.; Venkadesan, S.; Seetharaman, V. A note on the determination of the friction factor by means of the reduction-capacity test. J. Mech. Work. Technol. 1989, 19, 261–266. [Google Scholar] [CrossRef]

- Shen, G.; Vedhanayagam, A.; Kropp, E.; Altan, T. A method for evaluating friction using a backward extrusion-type forging. J. Mater. Process. Technol. 1992, 33, 109–123. [Google Scholar] [CrossRef]

- Roebuck, B.; Lord, J.D.; Brooks, M.; Loveday, C.M.; Sellars, C.M.; Evans, R.W. Measurement of flow stress in hot axisymmetric compression tests. Mater. High Temp. 2006, 23, 59–83. [Google Scholar] [CrossRef]

- Mcqueen, H.J. Development of dynamic recrystallization theory. Mater. Sci. Eng. A 2004, 387, 203–208. [Google Scholar] [CrossRef]

- Sellars, C.; Whiteman, J. Recrystallization and grain growth in hot rolling. Met. Sci. 1979, 13, 187–194. [Google Scholar] [CrossRef]

- Chen, Z.Y.; Tong, R.; Dong, Z.C. Plastic flow characteristics of an extruded Mg-Li-Zn-RE alloy. Rare Met. Mater. Eng. 2013, 42, 1779–1784. [Google Scholar]

- Xu, T.C.; Peng, X.D.; Qin, J.; Chen, Y.F.; Yang, Y.; Wei, G.B. Dynamic recrystallization behavior of Mg-Li-Al-Nd duplex alloy during hot compression. J. Alloys Compd. 2015, 639, 79–88. [Google Scholar] [CrossRef]

- Liu, J.W.; Zhao, Z.G.; Lu, S.Q. Microstructure evolution and constitutive equation for the hot deformation of LZ91 Mg alloy. Catal. Today 2018, 318, 119–125. [Google Scholar]

- Chaudhuri, A.; Sarkar, A.; Suwas, S. Investigation of stress-strain response, microstructure and texture of hot deformed pure molybdenum. Int. J. Refract. Met. Hard Mater. 2018, 73, 168–182. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, R.; Li, J.S.; Kou, H.C.; Li, H.W.; Chang, H.; Fu, H.Z. Deformation characteristics of as-received Haynes230 nickel base superalloy. Mater. Sci. Eng. A 2008, 497, 283–289. [Google Scholar] [CrossRef]

- Zener, C.; Hollomon, J.H. Effect of strain rate upon the plastic flow of steel. J. Appl. Phys. 1944, 15, 22–32. [Google Scholar] [CrossRef]

- Sui, F.L.; Xu, L.X.; Chen, L.Q.; Liu, X.H. Processing map for hot working of Inconel 718 alloy. J. Mater. Process. Technol. 2011, 211, 433–440. [Google Scholar] [CrossRef]

- Meng, Q.G.; Bai, C.G.; Xu, D.S. Flow behavior and processing map for hot deformation of ATI425 titanium alloy. J. Mater. Process. Technol. 2018, 34, 105–114. [Google Scholar] [CrossRef]

- Li, Z.; Chen, Y.B.; Wei, S.Z.; Xiao, F.N.; Sajid, H.S.; Xu, L.J. Flow behavior and processing map for hot deformation of W-1.5ZrO2 alloy. J. Alloys Compd. 2019, 802, 118–128. [Google Scholar] [CrossRef]

- Montheillet, F.; Jonas, J.J.; Neale, K.W. Modeling of dynamic material behavior: A critical evaluation of the dissipator power co-content approach. Metall. Mater. Trans. A 1996, 27, 232–235. [Google Scholar] [CrossRef]

- Murty, S.V.S.N.; Rao, B.N. On the development of instability criteria during hotworking with reference to IN 718. Mater. Sci. Eng. A 1998, 254, 76–82. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Seshacharyulu, T. Processing maps for hot working of titanium alloys. Mater. Sci. Eng. A 1998, 243, 82–88. [Google Scholar] [CrossRef]

- Zhang, J.; Di, H.; Wang, H.T.; Mao, K.; Ma, T.J.; Cao, Y. Hot deformation behavior of Ti-15-3 titanium alloy: A study using processing maps, activation energy map and Zener-Hollomon parameter map. J. Mater. Sci. 2012, 47, 4000–4011. [Google Scholar] [CrossRef]

- Wu, H.Y.; Wu, C.T.; Yang, J.C.; Lin, M.J. Hot workability analysis of AZ61-Mg alloys with processing maps. Mater. Sci. Eng. A 2014, 607, 261–268. [Google Scholar] [CrossRef]

- Sakai, T.; Jonas, J. Dynamic recrystallization-Mechanical and microstructural considerations. Acta Metall. 1984, 32, 189–209. [Google Scholar] [CrossRef]

- Huang, K.; Logé, R.E. A review of dynamic recrystallization phenomena in metallic materials. Mater. Des. 2016, 111, 548–574. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

| Ir ≥ wt.% | Impurity Elements (ppm) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 99.95 | Pt | Ru | Rh | Pd | Au | Ag | Cu | Fe | Ni | Si | |

| 30 | 30 | 10 | 10 | <10 | <10 | <10 | 10 | 10 | 10 | ||

| T/°C | /s−1 | Df/mm | hf/mm | B |

|---|---|---|---|---|

| 1200 | 10−3 | 8.83 | 4.90 | 1.18 |

| 10−2 | 8.90 | 5.00 | 1.22 | |

| 10−1 | 8.89 | 5.10 | 1.24 | |

| 1300 | 10−3 | 8.78 | 4.87 | 1.25 |

| 10−2 | 8.91 | 5.03 | 1.22 | |

| 10−1 | 8.83 | 5.20 | 1.24 | |

| 1400 | 10−3 | 9.10 | 5.02 | 1.21 |

| 10−2 | 8.79 | 4.80 | 1.25 | |

| 10−1 | 8.75 | 5.04 | 1.25 | |

| 1500 | 10−3 | 8.82 | 4.95 | 1.29 |

| 10−2 | 9.05 | 4.92 | 1.25 | |

| 10−1 | 8.81 | 5.10 | 1.19 |

| i | αi/(MPa−1) | Qi/(J·mol−1) | ni | ln(Ai/s−1) |

|---|---|---|---|---|

| 0 | 7.86 × 10−3 | 9.46 × 105 | 12.6 | 68.0 |

| 1 | −3.68 × 10−2 | −3.84 × 106 | −43.1 | −4.00 × 102 |

| 2 | 0.358 | −6.29 × 106 | 3.20 | 9.30 × 102 |

| 3 | −1.99 | 1.65 × 108 | 9.76 × 102 | 3.86 × 103 |

| 4 | 5.37 | −6.44 × 108 | −3.80 × 103 | −2.12 × 104 |

| 5 | −7.00 | 1.02 × 109 | 5.73 × 103 | 3.48 × 104 |

| 6 | 3.51 | −5.86 × 108 | −3.09 × 103 | −1.95 × 104 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, M.; Hu, R.; Yang, J.; Wang, C.; Wen, M. Determination of Constitutive Equation and Thermo–Mechanical Processing Map for Pure Iridium. Metals 2020, 10, 1087. https://doi.org/10.3390/met10081087

Zhou M, Hu R, Yang J, Wang C, Wen M. Determination of Constitutive Equation and Thermo–Mechanical Processing Map for Pure Iridium. Metals. 2020; 10(8):1087. https://doi.org/10.3390/met10081087

Chicago/Turabian StyleZhou, Mi, Rui Hu, Jieren Yang, Chuanjun Wang, and Ming Wen. 2020. "Determination of Constitutive Equation and Thermo–Mechanical Processing Map for Pure Iridium" Metals 10, no. 8: 1087. https://doi.org/10.3390/met10081087

APA StyleZhou, M., Hu, R., Yang, J., Wang, C., & Wen, M. (2020). Determination of Constitutive Equation and Thermo–Mechanical Processing Map for Pure Iridium. Metals, 10(8), 1087. https://doi.org/10.3390/met10081087