Micro-/Nano-Texturing of Aluminum by Precise Coining for Functional Surface Decoration

Abstract

1. Introduction

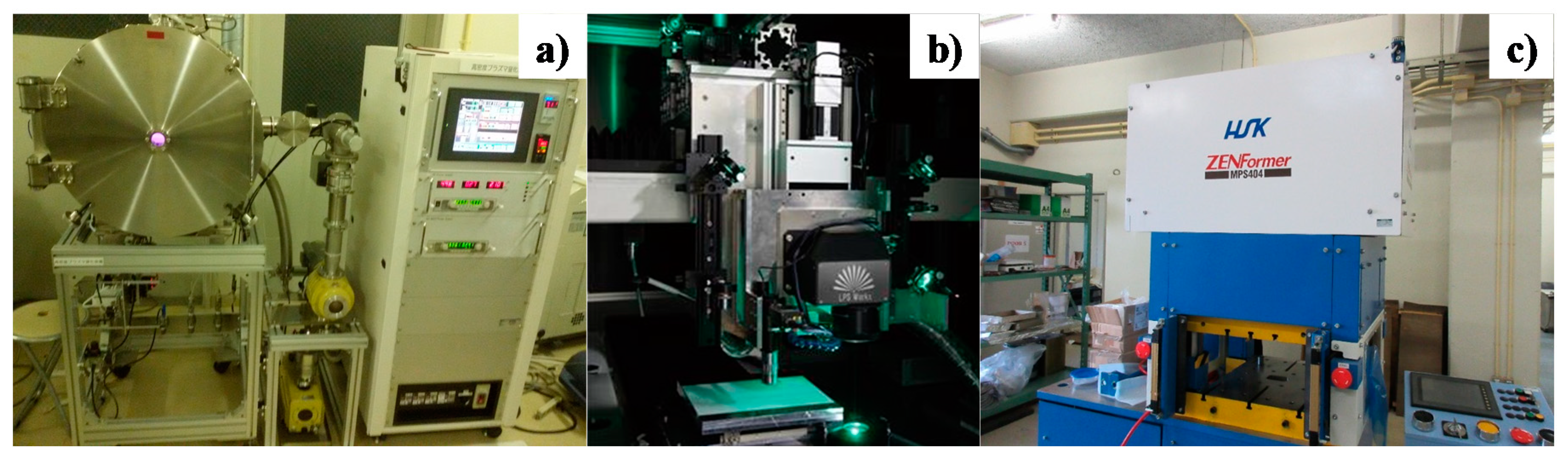

2. Experimental Procedure

3. Experimental Results

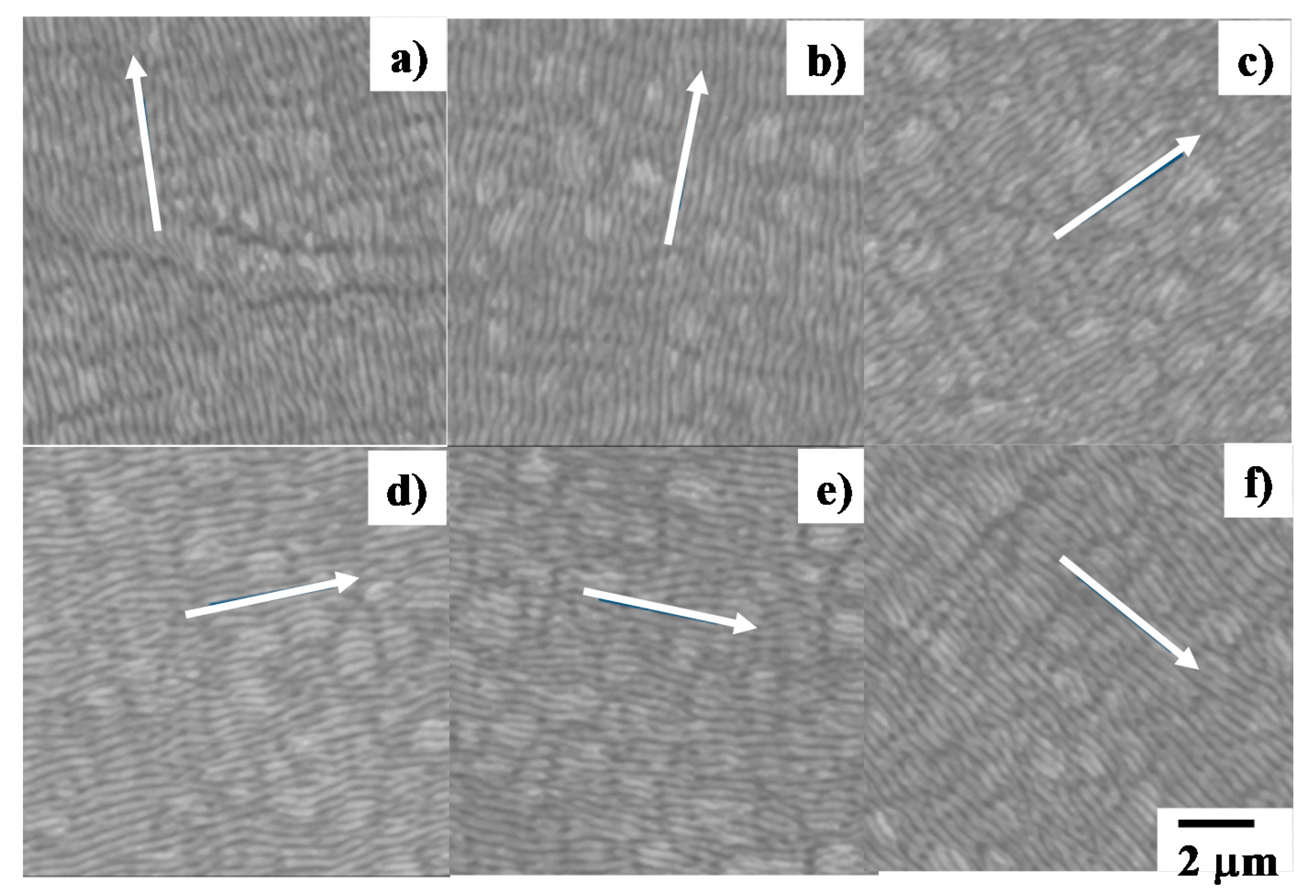

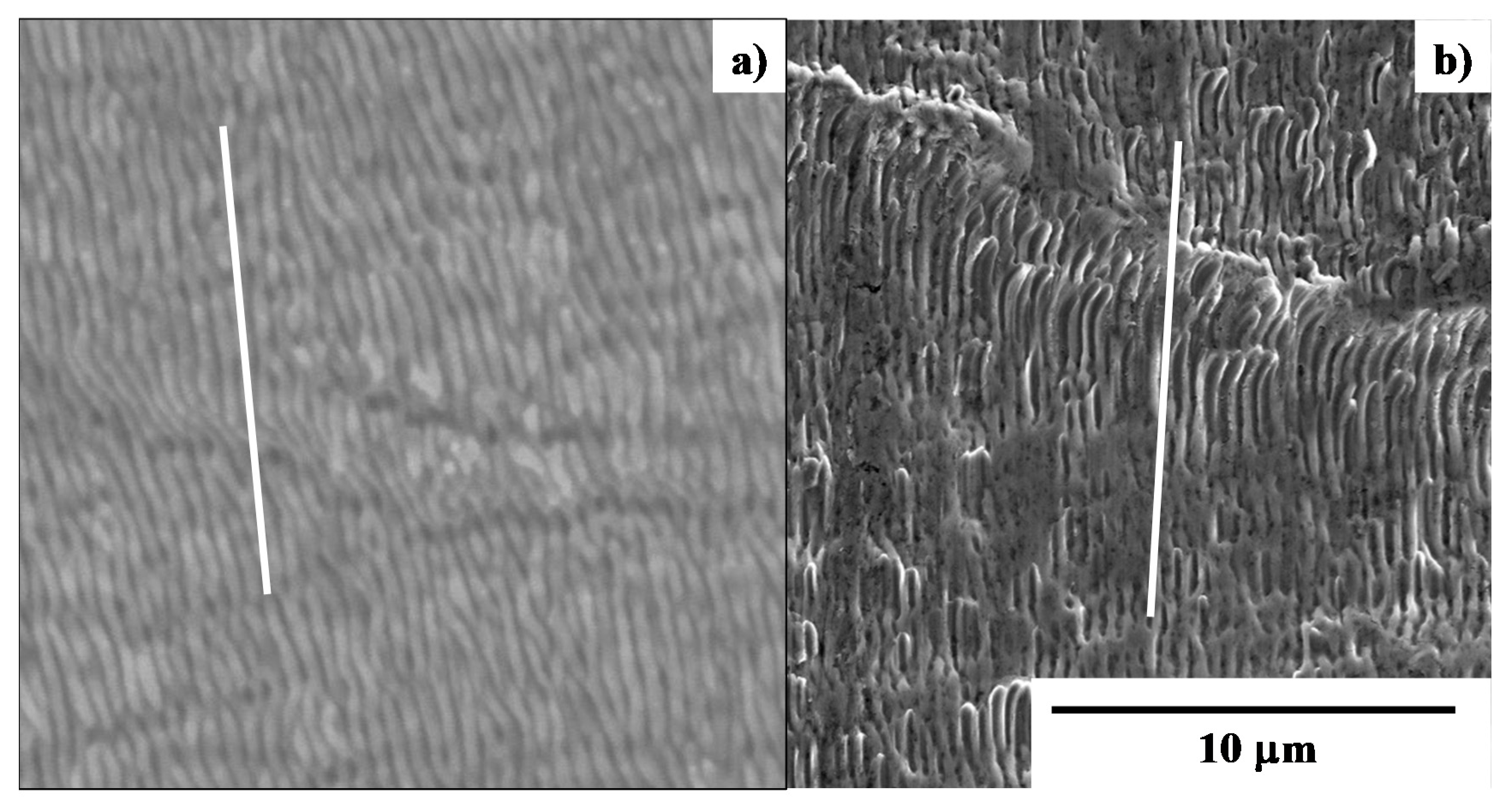

3.1. Formation of Unidirectional Nanotextures onto Stainless Steels

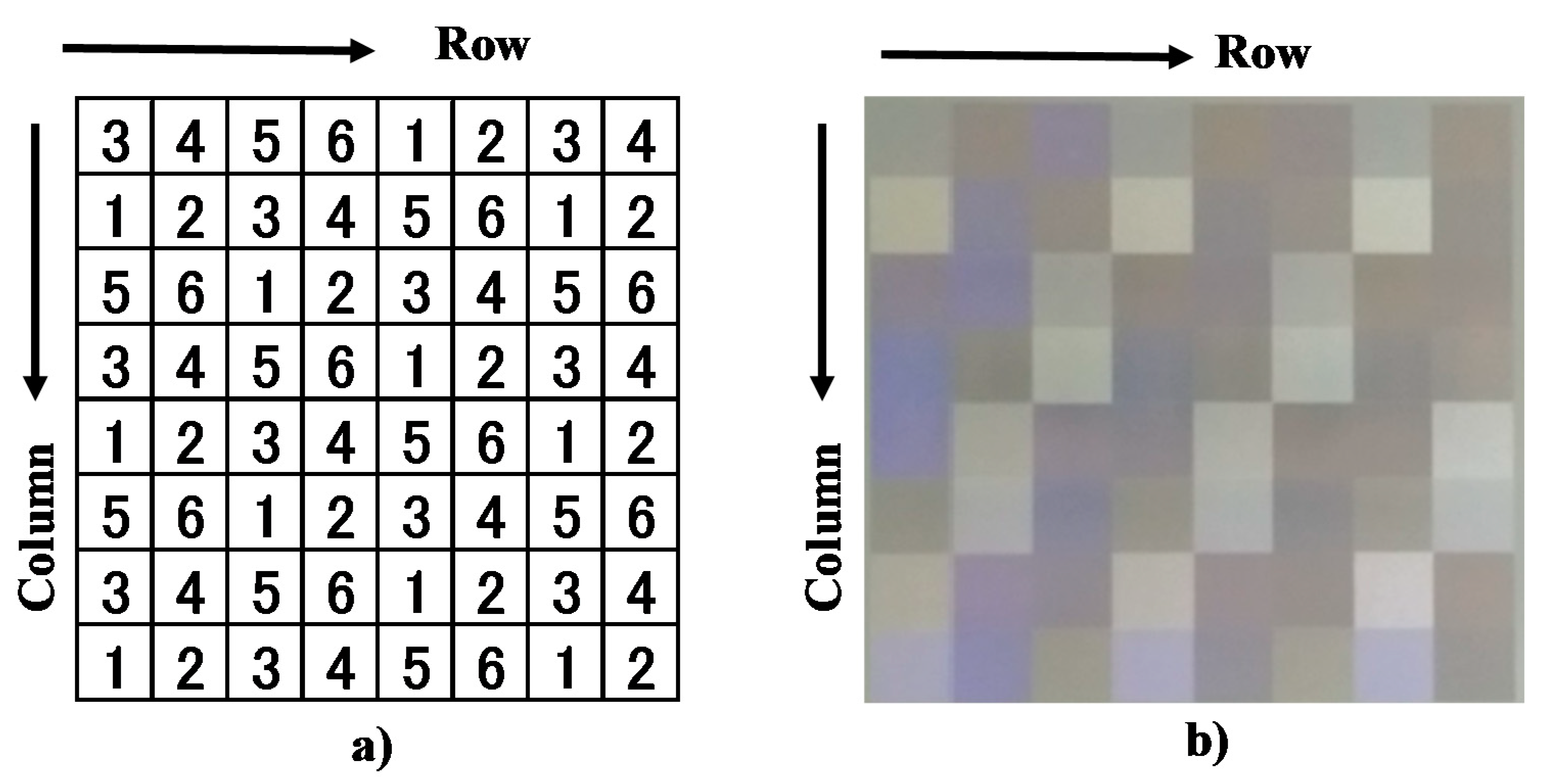

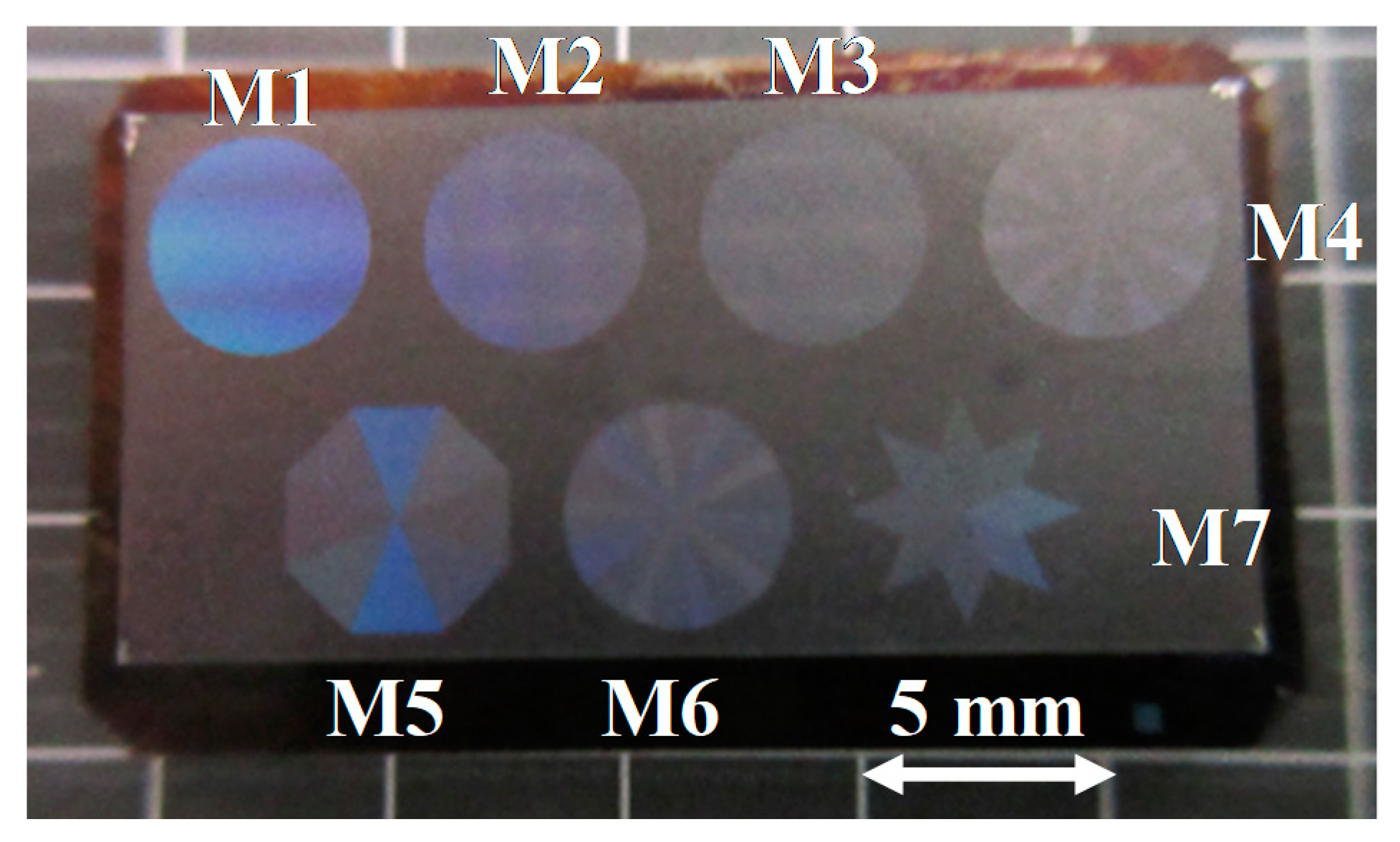

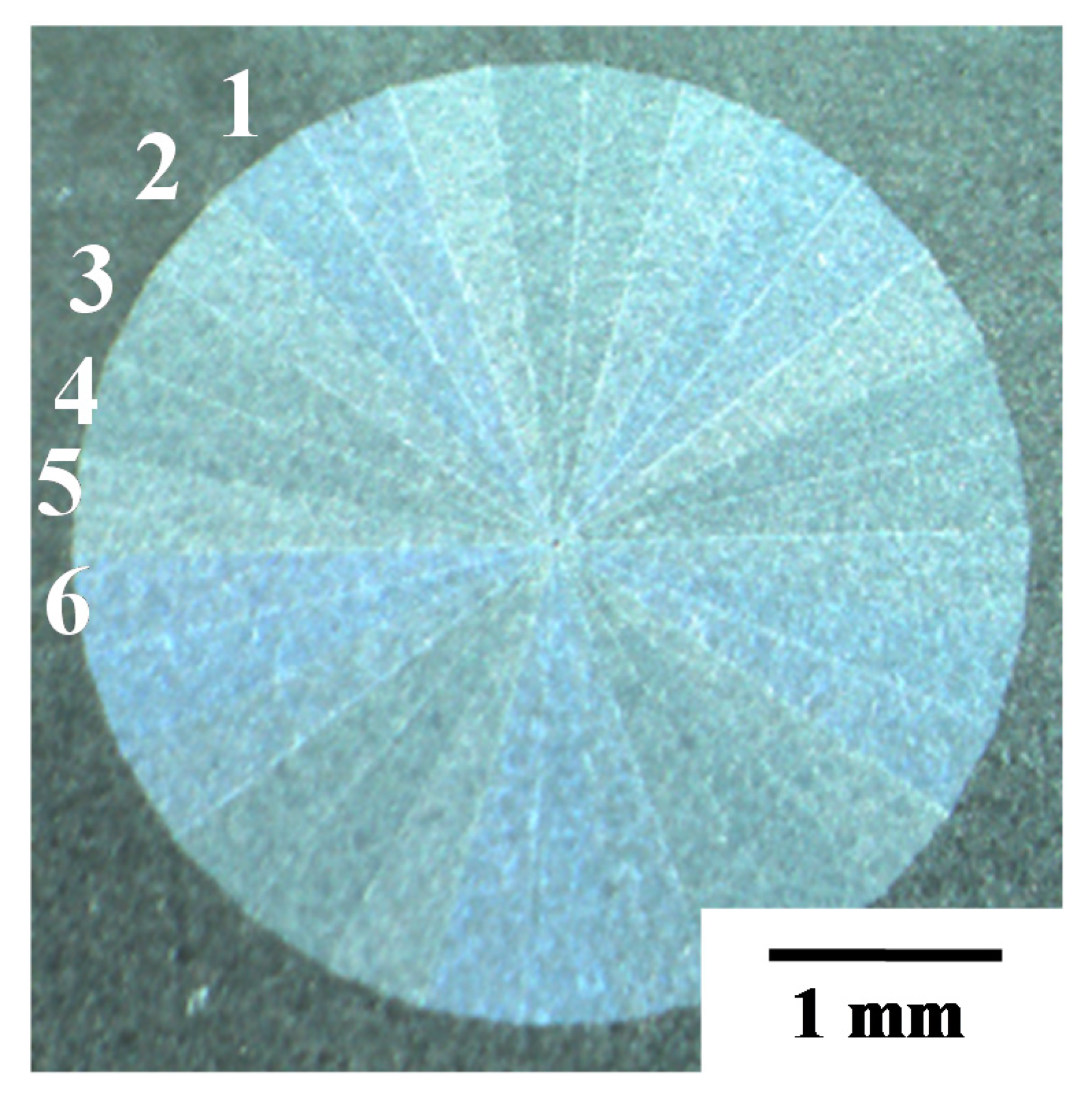

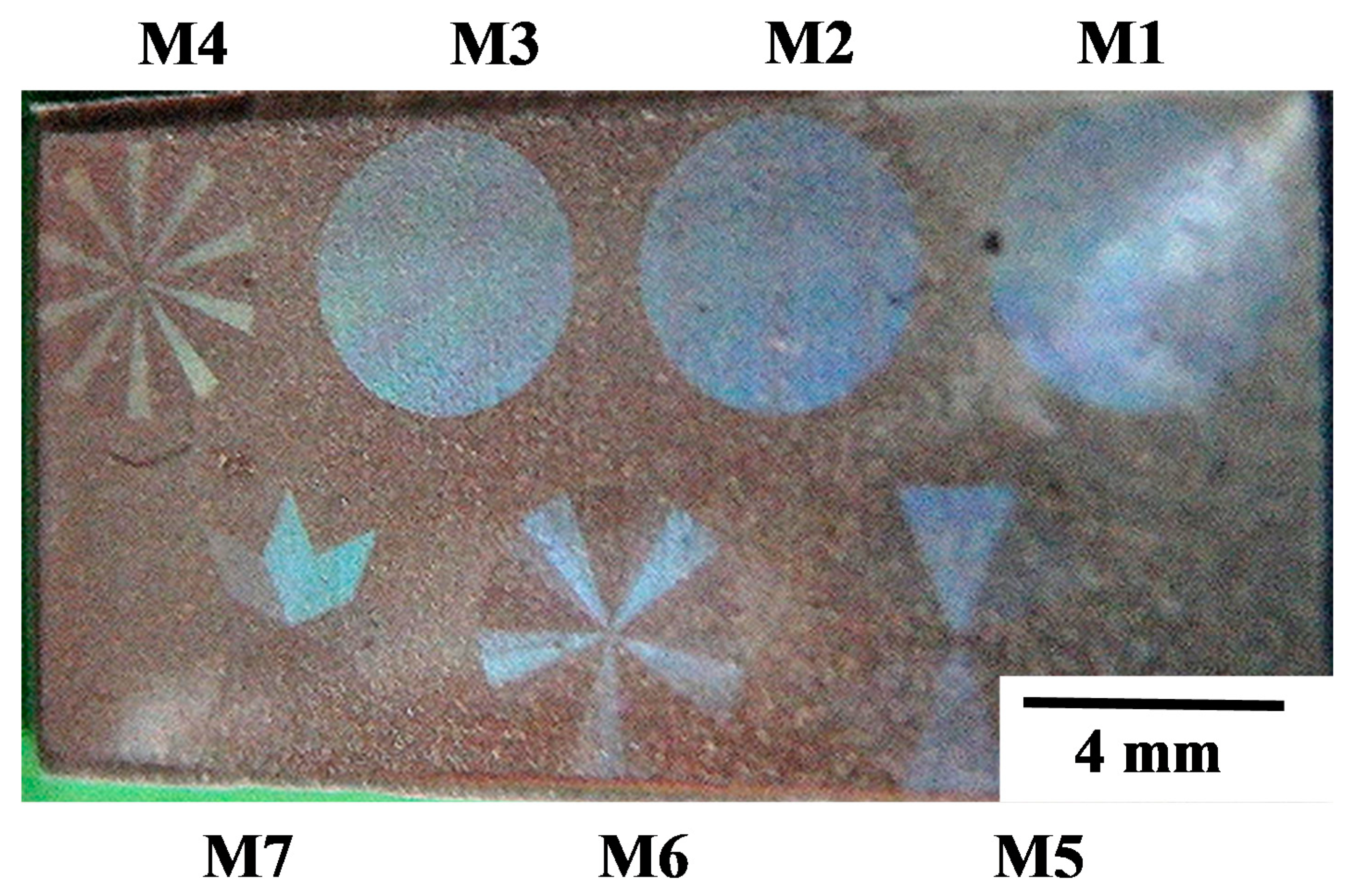

3.2. Fabrication of AISI316 Micro-/Nano-Textured Punch

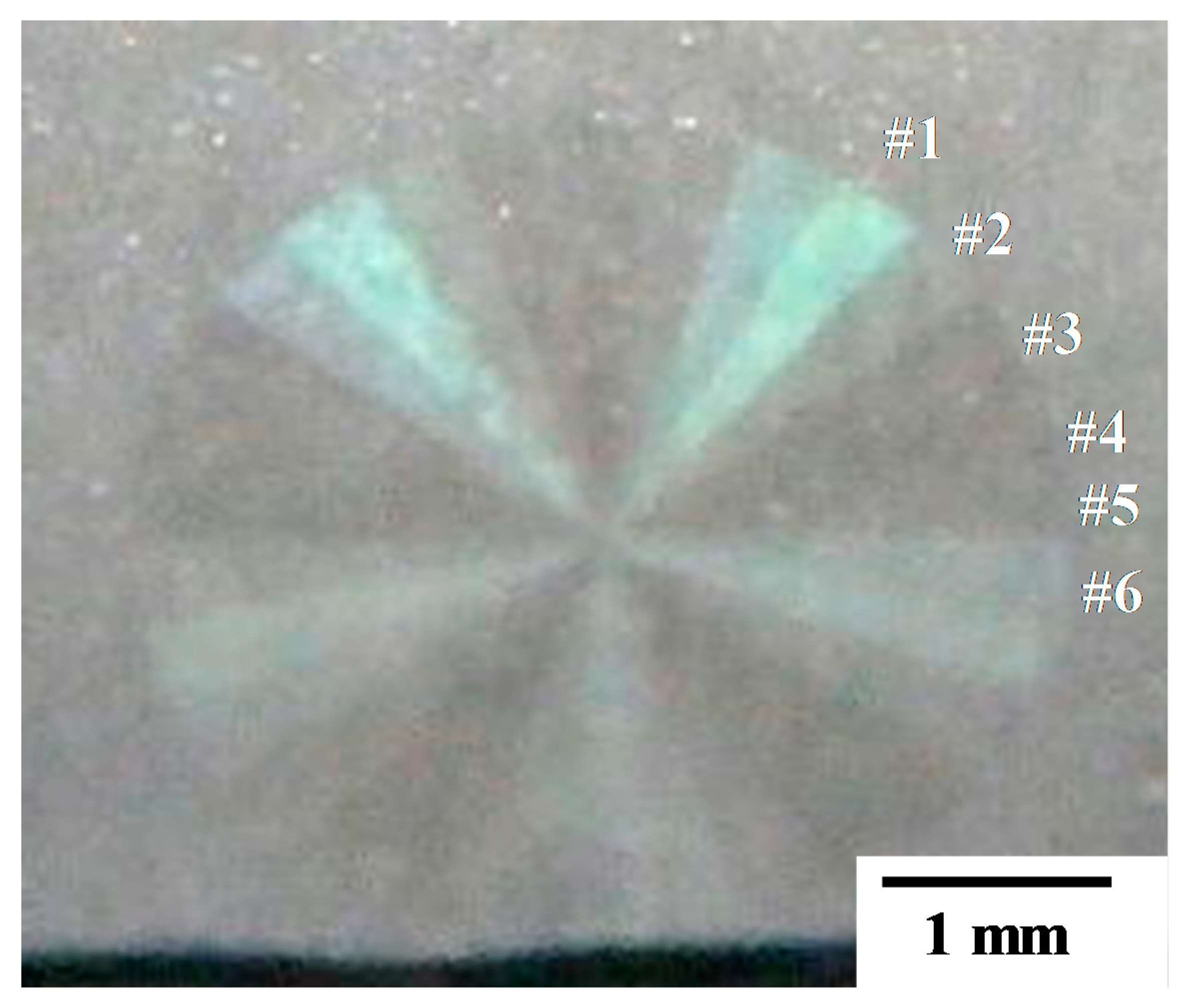

3.3. Coining of Micro-/Nano-Textures onto AA1060 Aluminum Plates

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- GF Laser Texturing Revolution Dans la Decoration Horlogere. Available online: https://www.swissphotonics.net/libraries.files/nicolet.pdf (accessed on 8 July 2020).

- Yang, Y.; Pan, Y.; Guo, P. Structural coloration of metallic surfaces with micro/nano-structures induced by elliptical vibration texturing. Appl. Surf. Sci. 2017, 402, 400–409. [Google Scholar] [CrossRef]

- Aizawa, T.; Hasegawa, T.; Inohara, T. Surface geometry control of stainless steels by femtosecond laser nano-/micro-texturing toward super-hydrophilicity and super-hydrophobicity. In Proceedings of the 12th AFGS, Kunming, China, 12 August 2019; pp. 71–78. [Google Scholar]

- Aizawa, T.; Inohara, T.; Wasa, K. Femtosecond laser micro/nano-texturing of stainless steels for surface property control. Micromachines 2019, 10, 512. [Google Scholar] [CrossRef] [PubMed]

- Aizawa, T.; Inohara, T.; Wasa, K. Fabrication of hydrophobic stainless steel nozzle by femtosecond laser micro-/nan-texturing. Int. J. Automot. Technol. 2020, 14, 159–166. [Google Scholar] [CrossRef]

- Gong, L.; Zhao, J.; Huang, S. Numerical study on layout of micro-channel heat sink for thermal management of electric devices. Appl. Therm. Eng. 2015, 88, 480–490. [Google Scholar] [CrossRef]

- Aizawa, T.; Shiratori, T.; Wasa, K. Plasma-printed AISI316L multi-punch array for fabrication of aluminum heatsink with micro-pillar fines. In Proceedings of the 3rd WCMNM International Conference, Raleigh, NC, USA, 10–12 September 2019; pp. 220–223. [Google Scholar]

- Jung, S.M.; Preston, D.J.; Jung, H.Y.; Deng, Z.; Wang, E.N.; Kong, J. Porous Cu nanowire aerosponges from one-step assembly and their applications in heat dissipation. Adv. Mater. 2016, 28, 1413–1419. [Google Scholar] [CrossRef] [PubMed]

- Aizawa, T.; Wasa, K.; Tamagaki, H. A DLC-punch array to fabricate the micro-textured aluminum sheet for boiling heat transfer control. Micromechanics 2018, 9, 147. [Google Scholar] [CrossRef] [PubMed]

- Aizawa, T.; Ono, N. Boiling heat transfer control by micro-/nano-texturing of metallic heat-spreading devices. In Proceedings of the 4th WCMNM International Conference, Mumbai, India, 14 March 2021. In press. [Google Scholar]

- Misun, P.M.; Hierlemann, A.; Frey, O. Miniature fluidic microtissue culturing device for rapid biological detection. In Miniature Fluidic Devices for Rapid Biological Detection; Springer: New York, NY, USA, 2018; pp. 207–225. [Google Scholar]

- Browne, D.J.; Karakozian, S.; Chen, X. Cell Culturing Device. U.S. Patent US2015.0072377 A1, 12 March 2015. [Google Scholar]

- Su, Y.; Luo, C.; Zhang, Z.; Hermawan, H.; Zhu, S.; Huang, J.; Liang, Y.; Li, G.; Ren, L. Bioinspired surface functionalization of metallic biomaterials. J. Mech. Behav. Biomed. Mater. 2018, 77, 90–105. [Google Scholar] [CrossRef] [PubMed]

- Davim, P. Nontraditional Machining Processes: Research Advances; Springer: New York, NY, USA, 2013. [Google Scholar]

- Aizawa, T.; Inohara, T. Pico- and femtosecond laser micromachining for surface texturing. In Micromachining; InTech-Open: London, UK, 2019; pp. 1–24. [Google Scholar]

- Aizawa, T.; Shiratori, T.; Kira, Y.; Inohara, T. Simultaneous nano-texturing onto a CVD-diamond coated piercing punch with femtosecond laser trimming. Appl. Sci. 2020, 10, 2674. [Google Scholar] [CrossRef]

- Derrien, T.J.-Y.; Koter, R.; Kueger, J.; Hoem, S.; Rosenfeld, A.; Bonse, J. Plasmonic formation mechanism of periodic 100nm-structures in femtosecond laser irradiation of silicon in water. J. Appl. Phys. 2014, 116, 074902. [Google Scholar] [CrossRef]

- Hasegawa, T.; Aizawa, T.; Inohara, T.; Wasa, K.; Anzai, M. Hot mold stamping of optical plastics and glasses with transcription of super-hydrophobic surfaces. Procedia Manuf. 2019, 15, 1437–1444. [Google Scholar] [CrossRef]

- Hasegawa, T.; Aizawa, T.; Inohara, T.; Yoshihara, S.-I. Mold-stamping of optical glasses by micro/ nano-textured die to transcript the hydrophobicity. J. JSTP 2019, 60, 23–27. [Google Scholar] [CrossRef]

- Aizawa, T.; Inohara, T.; Wasa, K. Nano-texturing onto tool-surface by the femtosecond laser processing. In Proceedings of the 4th WCMNM 2020, Mumbai, India, 13 March 2021. In press. [Google Scholar]

- Vorobyev, A.Y.; Guo, C. Thermal response and optical absorptance of metals under femtosecond laser irradiation. Nat. Sci. 2011, 4, 488–495. [Google Scholar] [CrossRef][Green Version]

- Shulka, P.; Waugh, D.G.; Lawrence, J.; Vilar, R. Laser surface structuring of ceramics, metals and polymers for biomedical applications: A review. In Laser Surface Modification of Biomaterials; Woodhead Publishing: Cambridge, UK, 2016; pp. 281–299. [Google Scholar]

- van Driel, H.M.; Sipe, J.E.; Young, J.F. Laser-induced periodic surface structure on solids: A universal phenomenon. Phys. Rev. Lett. 1982, 49, 1955–1958. [Google Scholar] [CrossRef]

- Jang, Y.; Choi, W.T.; Johnson, C.T.; Garcia, A.J.; Singh, P.M.; Breedveld, V.; Hess, D.W.; Champion, J.A. Inhibition of bacterial adhesion on nanotextured stainless steel 316L by electrochemical etching. ACS Biomater. Sci. Eng. 2018, 4, 90–97. [Google Scholar] [CrossRef]

- Ferraris, S.; Cochis, A.; Cazzola, M.; Tortello, M.; Scalia, A.; Spriano, S.; Rimondini, L. Cytocompatible and anti-bacterial adhesion nanotextured titanium oxide layer on titanium surfaces for dental and orthopedic implants. Front. Bioeng. Biotechnol. 2019, 9, 103–110. [Google Scholar] [CrossRef] [PubMed]

- Ferraris, S.; Vemturello Miola, M.; Cochis, A.; Rimondini, L.; Spriano, S. Antibacterial and bioactive nanostructure titanium surfaces for bone integration. Appl. Surf. Sci. 2014, 311, 279–291. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aizawa, T.; Yoshino, T.; Inohara, T. Micro-/Nano-Texturing of Aluminum by Precise Coining for Functional Surface Decoration. Metals 2020, 10, 1044. https://doi.org/10.3390/met10081044

Aizawa T, Yoshino T, Inohara T. Micro-/Nano-Texturing of Aluminum by Precise Coining for Functional Surface Decoration. Metals. 2020; 10(8):1044. https://doi.org/10.3390/met10081044

Chicago/Turabian StyleAizawa, Tatsuhiko, Tomoaki Yoshino, and Tadahiko Inohara. 2020. "Micro-/Nano-Texturing of Aluminum by Precise Coining for Functional Surface Decoration" Metals 10, no. 8: 1044. https://doi.org/10.3390/met10081044

APA StyleAizawa, T., Yoshino, T., & Inohara, T. (2020). Micro-/Nano-Texturing of Aluminum by Precise Coining for Functional Surface Decoration. Metals, 10(8), 1044. https://doi.org/10.3390/met10081044