Application of the Cumulative Kinetic Model in the Comminution of Critical Metal Ores

Abstract

:1. Introduction

2. Theoretical Background

2.1. The Cumulative Based Kinetic Model

2.2. Determination of the CKM Parameters C and n

2.3. Simplified Procedure to Grinding Kinetic Parameters Determination

3. Methodology

3.1. Sample Preparation

3.2. Work Index Determination

3.3. Determination of the Kinetic Parameters

3.4. Simulation Based on the Cumulative Kinetic Model

4. Results

4.1. Simulation of the Work Index, Obtaining the Kinetic Parameters through the Conventional Procedure

4.2. Work Index Determination by Obtaining the Kinetic Parameters through the Simplified Procedure

5. Discussion

- (1)

- Feed preparation 100% passing a 3350 µm (6 mesh) sieve followed by gradual crushing to avoid the overproduction of fines.

- (2)

- PSD determination with sieves between 3350 and 37 µm, and determination of the feed characteristic particle size (F80).

- (3)

- Grinding of a quantity equivalent to 700 cm3 for 5 min.

- (4)

- PSD analysis to determine the product characteristic particle size (P80).

- (5)

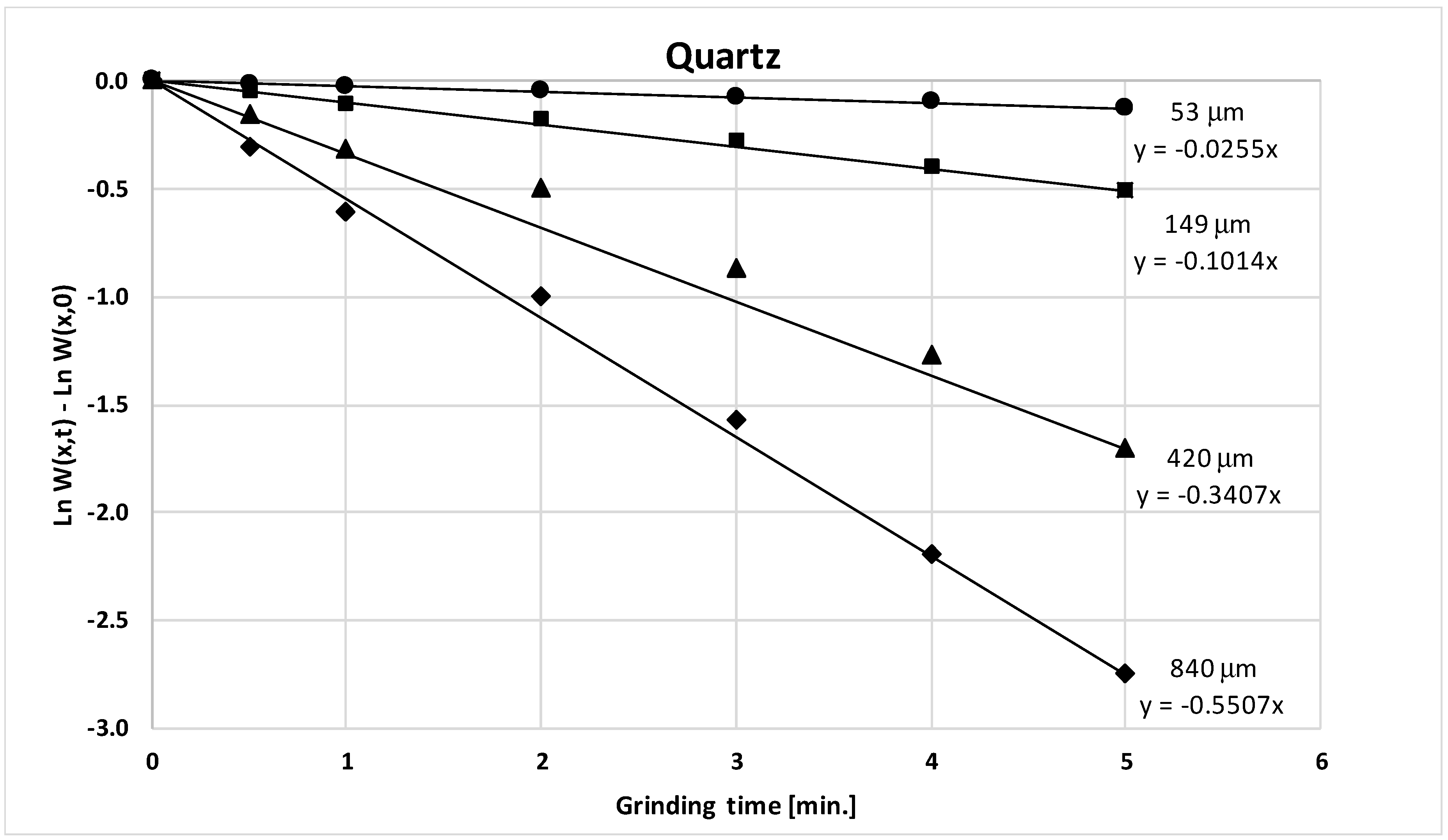

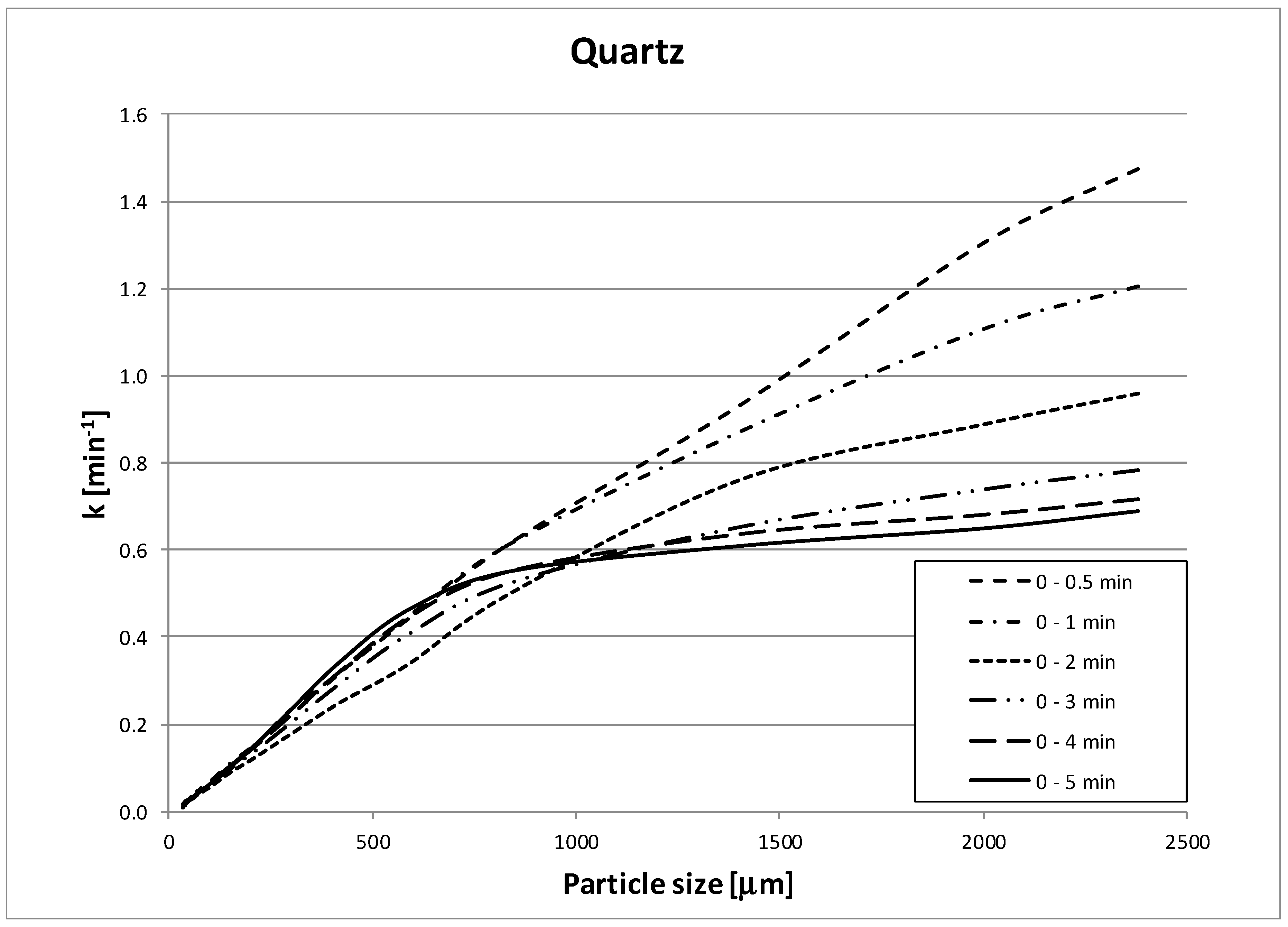

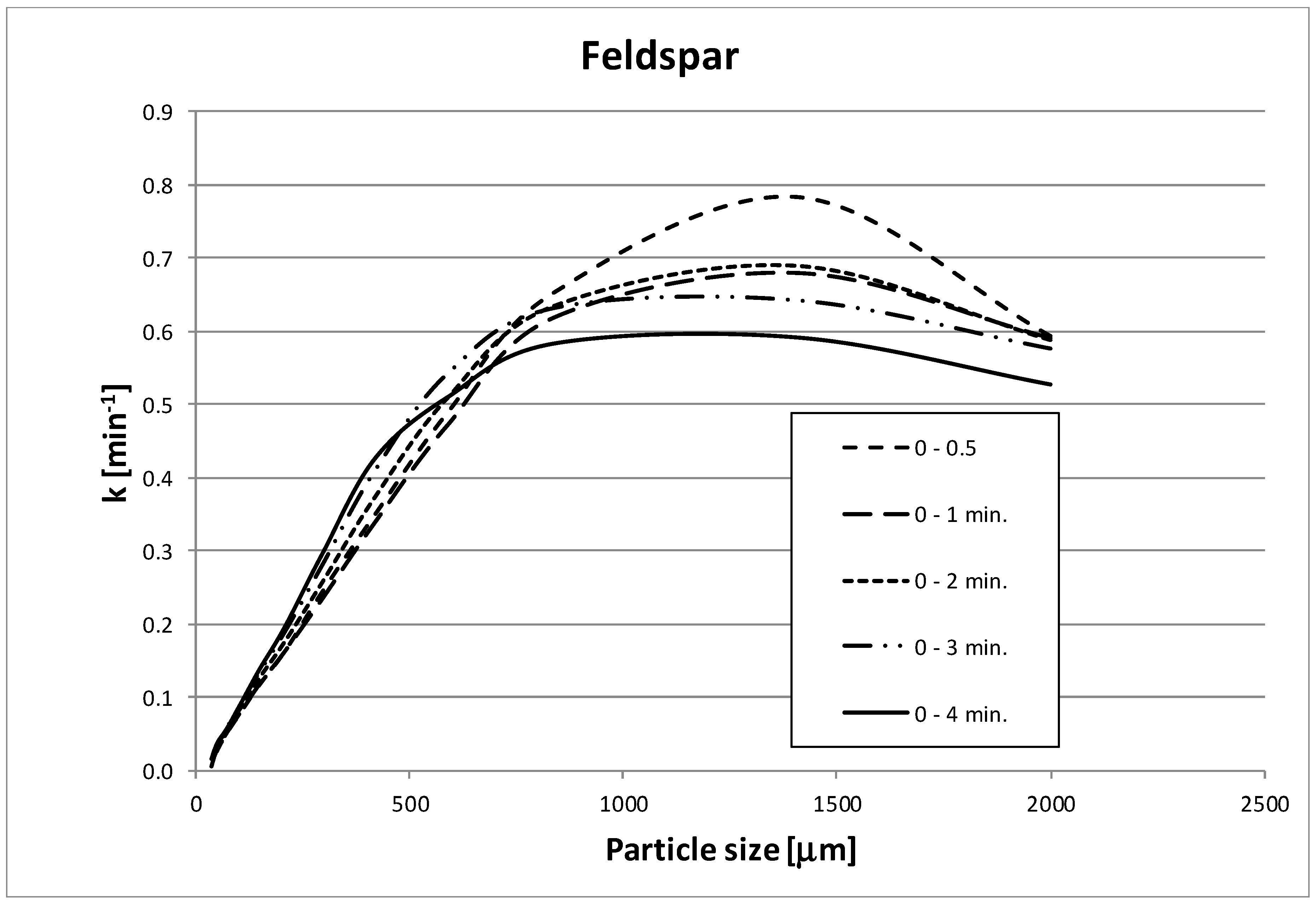

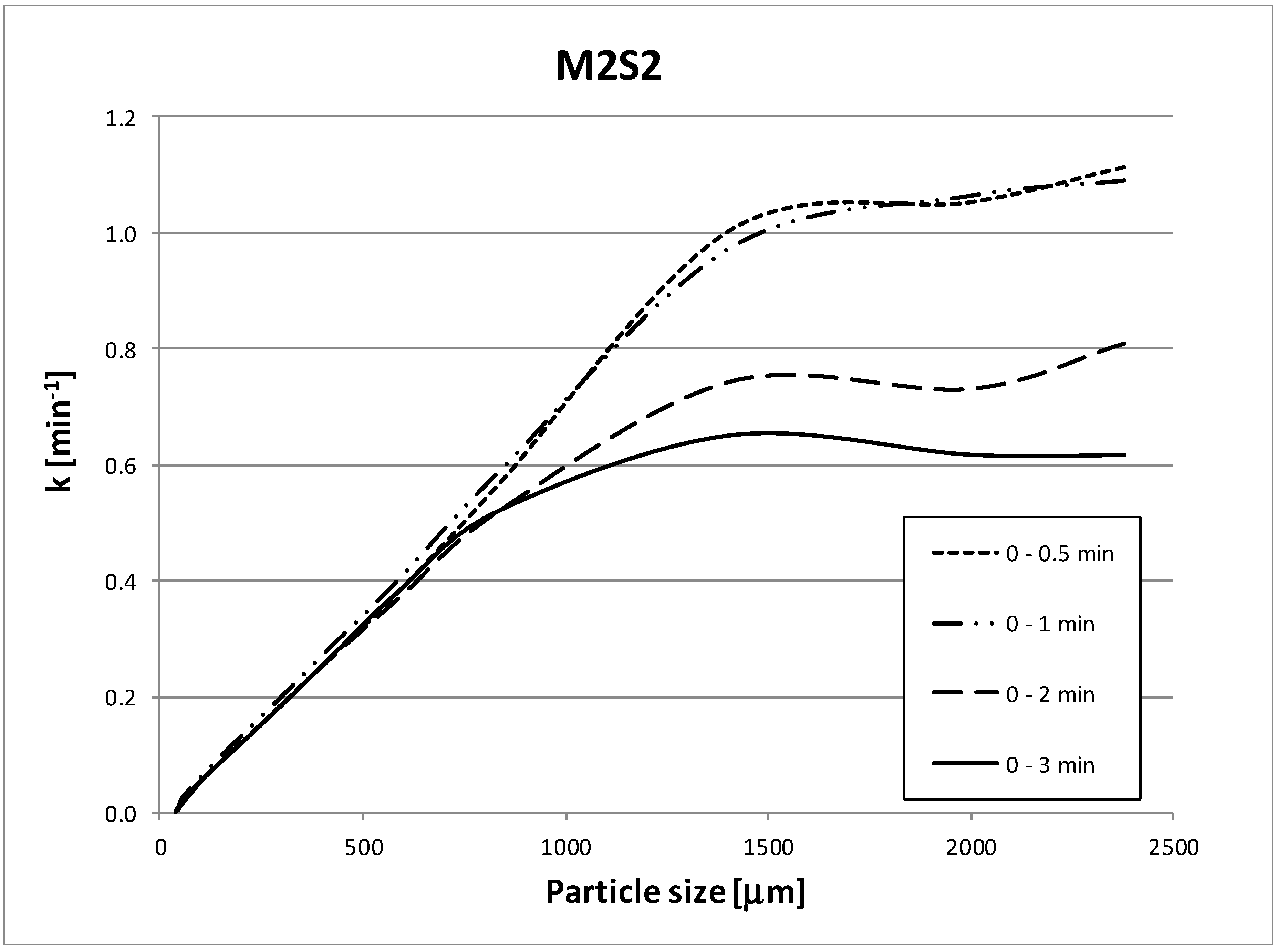

- Determination of k for each particle size class (slope from 0 to 5 min).

- (6)

- Determination of the slope (n) and the intercept on the y-axis (C) of the logarithmic-scale graph of k as a function of particle size (k vs. particle size).

6. Conclusions

- The conventional cumulative kinetic model (CKM) is a tool that allows determining the Work Index (wi) for ball mill grinding, simulating the standard procedure of F.C. Bond. The respective results provided, according to literature, differ from less than 7%.

- A simplified procedure has been proposed to obtain the CKM parameters. It is based on determining k with one grinding time since k variation with particle size is rather constant for times less than 5 min. This makes it valid for simulating batch grinding with residence times on the order specified.

- The proposed simplified procedure has been proven to be valid for using the CKM to simulate the F.C. Bond’s standard test. It permits to obtain the Work Index in ball mill grinding for a reference size range between 840 (20 mesh) and 53 µm (400 mesh), yielding results that differ by less than 10% with respect to real values. This considerably reduces the involved laboratory work, thus being enough with one grinding run and two PSD determinations.

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Rittinger von, P.R. Lehrbuch der Aufbereitungskunde; Ernst and Korn: Berlin, Germany, 1867. [Google Scholar]

- Kick, F. Das Gesetz der Proportionalen Widerstände und Seine Anwendungen; Arthur Felix: Leipzig, Germany, 1885. [Google Scholar]

- Bond, F.C. Third Theory of Comminution. Min. Eng. Trans. Aime 1952, 193, 484–494. [Google Scholar]

- Bond, F.C. Crushing and Grinding Calculations; Allis Chalmers Manufacturing Co.: Milmwaukee, WI, USA, 1961. [Google Scholar]

- Jankovic, A.; Dundar, H.; Mehta, R. Relationships between comminution energy and product size for a magnetite ore. J. South. Afr. Inst. Min. Metall. 2010, 110, 141–146. [Google Scholar]

- Sepúlveda, J.; Gutierrez, R. Dimensionamiento y Optimización de Plantas Concentradoras Mediante Técnicas de Modelación Matemática; CIMM: Santiago, Chile, 1986. [Google Scholar]

- Aksani, B.; Sönmez, B. Simulation of Bond Grindability Test by Using Cumulative Based Kinetic Model. Miner. Eng. 2000, 13, 673–677. [Google Scholar] [CrossRef]

- Coello Velázquez, A.L.; Menéndez-Aguado, J.M.; Brown, R.L. Grindability of lateritic nickel ores in Cuba. Powder Technol. 2008, 182, 113–115. [Google Scholar] [CrossRef]

- Berry, T.F.; Bruce, R.W. A simple method of determining the grindability of ores. Can. Min. J. 1966, 87, 63–65. [Google Scholar]

- Menéndez-Aguado, J.M.; Dzioba, B.R.; Coello-Velazquez, A.L. Determination of work index in a common laboratory mill. Miner. Metall. Process. 2005, 22, 173–176. [Google Scholar] [CrossRef]

- Bonoli, A.; Ciancabilla, F. The Ore Grindability Definition as an Energy Saving Tool in the Mineral Grinding Processes. In Proceedings of the 2nd International Congress “Energy, Environment and Technological Innovation”, Rome, Italy, 12–16 October 1992. [Google Scholar]

- Chakrabarti, D.M. Simple Approach to Estimation of Work Index. Trans. Instn. Min. Met. Sect. C Min. Proc. Ext. Met. 2000, 109, 83–89. [Google Scholar] [CrossRef]

- Napier- Munn, T.J.; Morrell, S.; Morrison, R.D.; Kojovic, T. Mineral Comminution Circuits: Their Operation and Optimization; JKMRC: Queensland, Australia, 1996. [Google Scholar]

- Prediction of Bond’s work index from measurable rock properties. Int. J. Miner. Process. 2016, 157, 134–144.

- Rodríguez, B.Á.; García, G.G.; Coello-Velázquez, A.L.; Menéndez-Aguado, J.M. Product size distribution function influence on interpolation calculations in the Bond ball mill grindability test. Int. J. Miner. Process. 2016, 157, 16–20. [Google Scholar] [CrossRef]

- Lewis, K.A.; Pearl, M.; Tucker, P. Computer Simulation of the Bond Grindability Test. Miner. Eng. 1990, 3, 199–206. [Google Scholar] [CrossRef]

- Silva, M.; Casali, A. Modelling SAG Milling Power and Specific Energy Consumption Including the Feed Percentage of Intermediate Size Particles. Miner. Eng. 2015, 70, 156–161. [Google Scholar] [CrossRef]

- Menéndez-Aguado, J.M.; Coello-Velázquez, A.L.; Dzioba, B.R.; Diaz, M.A.R. Process models for simulation of Bond tests. Trans. Inst. Min. Metall. Sect. C Miner. Process. Extr. Metall. 2006, 115, 85–90. [Google Scholar] [CrossRef]

- Lvov, V.V.; Chitalov, L.S. Comparison of the Different Ways of the Ball Bond Work Index Determining. Int. J. Mech. Eng. Technol. 2019, 10, 1180–1194. Available online: https://ssrn.com/abstract=3452642 (accessed on 5 June 2020).

- Gharehgheshlagh, H.H. Kinetic grinding test approach to estimate the ball mill work index. Physicochem. Probl. Miner. Process. 2016, 52, 342–352. [Google Scholar]

- Laplante, A.R.; Finch, J.A.; del Villar, R. Simplification of Grinding Equation for Plant Simulation. Trans. IMM Sec. C 1987, 96, C108–C112. [Google Scholar]

- Loveday, B.K. An analysis of comminution kinetics in terms of size distribution parameters. J. S. Afr. Inst. Min. Metall. 1967, 68, 111–131. [Google Scholar]

- Finch, J.A.; Ramirez-Castro, J. Modelling Mineral Size Reduction in Closed-Circuit Ball Mill at the Pine Point Mines Concentrator. Int. J. Min. Proc. 1981, 8, 67–78. [Google Scholar] [CrossRef]

- Ersayin, S.; Sönmez, B.; Ergün, L.; Akasani, B.; Erkal, F. Simulation of the grinding circuit at Gümüşköy Silver Plant, Turkey. Trans. IMM Sect. C 1993, 102, C32–C38. [Google Scholar]

- Ahmadi, R.; Shahsavari, S. Procedure for determination of ball Bond work index in the commercial operations. Miner. Eng. 2009, 22, 104–106. [Google Scholar] [CrossRef]

| Ore | Kinetic Parameters | R2 | wis (kWh/t) | wi (kWh/t) | Difference (%) | |

|---|---|---|---|---|---|---|

| C | n | |||||

| Feldspar @100 µm | 0.000586 | 1.07 | 0.98 | 11.67 | 12.41 | 6.0 |

| Limestone @100 µm | 0.001789 | 0.87 | 0.97 | 9.66 | 9.98 | 3.2 |

| Calcite @100 µm | 0.000973 | 1.09 | 0.95 | 6.41 | 6.30 | −1.7 |

| Quartz @100 µm | 0.000448 | 1.07 | 0.99 | 13.77 | 13.88 | 0.8 |

| Ore | Kinetic Parameters | R2 | wis (kWh/t) | wi (kWh/t) | Difference (%) | |

|---|---|---|---|---|---|---|

| C | n | |||||

| M1S1 @100 µm | 0.000792 | 0.89 | 0.99 | 19.56 | 19.25 | 1.6 |

| M2S1 @100 µm | 0.000451 | 1.03 | 0.98 | 15.55 | 14.83 | −4.9 |

| M2S2 @100 µm | 0.000486 | 1.03 | 0.98 | 16.61 | 15.98 | 3.8 |

| M2S3 @100 µm | 0.000303 | 1.10 | 0.99 | 17.06 | 17.35 | −1.7 |

| Ore | Kinetic Parameters | R2 | wis (kWh/t) | wi (kWh/t) | Difference (%) | |

|---|---|---|---|---|---|---|

| C | n | |||||

| Feldspar @150 µm | 0.000586 | 1.07 | 0.98 | 11.67 | 12.41 | 6.0 |

| Feldspar @100 µm | 14.19 | 14.69 | 3.4 | |||

| Quartz @150 µm | 0.000448 | 1.07 | 0.99 | 13.77 | 13.88 | 0.8 |

| Quartz @100 µm | 17.34 | 17.88 | 3.0 | |||

| Ore | Size Interval (µm) | Grinding Time (min) | wi (kWh/t) | Difference (%) | ||

|---|---|---|---|---|---|---|

| Minimum | Maximum | Real | Simulated | |||

| Feldspar @100 µm | 53 | 840 | 0–4 | 14.69 | 13.38 | 8.91 |

| Feldspar @150 µm | 53 | 840 | 0–4 | 12.41 | 11.20 | 9.76 |

| Quartz @100 µm | 53 | 840 | 0–5 | 17.88 | 17.82 | 0.33 |

| Quartz @150 µm | 53 | 840 | 0–5 | 13.88 | 14.63 | −5.37 |

| Limestone @100 µm | 53 | 840 | 0–4 | 9.98 | 9.41 | 5.72 |

| Calcite @100 µm | 53 | 840 | 0–4 | 6.30 | 6.24 | 0.96 |

| M1S1 @100 µm | 74 | 840 | 0–3 | 19.25 | 21.11 | −9.68 |

| M2S1 @100 µm | 53 | 840 | 0–3 | 14.83 | 15.40 | −3.85 |

| M2S2 @100 µm | 74 | 840 | 0–3 | 15.98 | 17.01 | −6.47 |

| M2S3 @ 100 µm | 53 | 840 | 0–3 | 17.35 | 16.79 | 3.21 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciribeni, V.; Bertero, R.; Tello, A.; Puerta, M.; Avellá, E.; Paez, M.; Menéndez Aguado, J.M. Application of the Cumulative Kinetic Model in the Comminution of Critical Metal Ores. Metals 2020, 10, 925. https://doi.org/10.3390/met10070925

Ciribeni V, Bertero R, Tello A, Puerta M, Avellá E, Paez M, Menéndez Aguado JM. Application of the Cumulative Kinetic Model in the Comminution of Critical Metal Ores. Metals. 2020; 10(7):925. https://doi.org/10.3390/met10070925

Chicago/Turabian StyleCiribeni, Victor, Regina Bertero, Andrea Tello, Matías Puerta, Enzo Avellá, Matías Paez, and Juan María Menéndez Aguado. 2020. "Application of the Cumulative Kinetic Model in the Comminution of Critical Metal Ores" Metals 10, no. 7: 925. https://doi.org/10.3390/met10070925

APA StyleCiribeni, V., Bertero, R., Tello, A., Puerta, M., Avellá, E., Paez, M., & Menéndez Aguado, J. M. (2020). Application of the Cumulative Kinetic Model in the Comminution of Critical Metal Ores. Metals, 10(7), 925. https://doi.org/10.3390/met10070925