Experimental Characterization and Deterministic Prediction of In-Plane Formability of 3rd Generation Advanced High Strength Steels

Abstract

1. Introduction

2. Constitutive Characterization

2.1. Characterization of Anisotropy

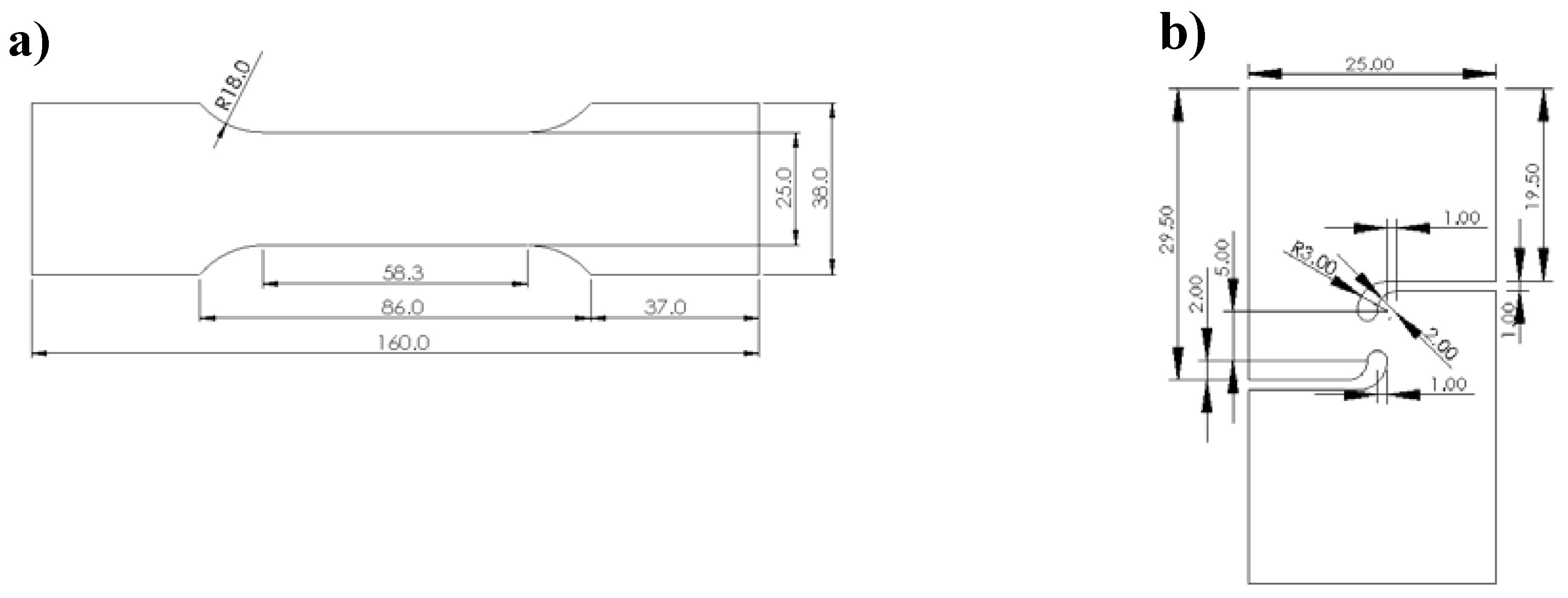

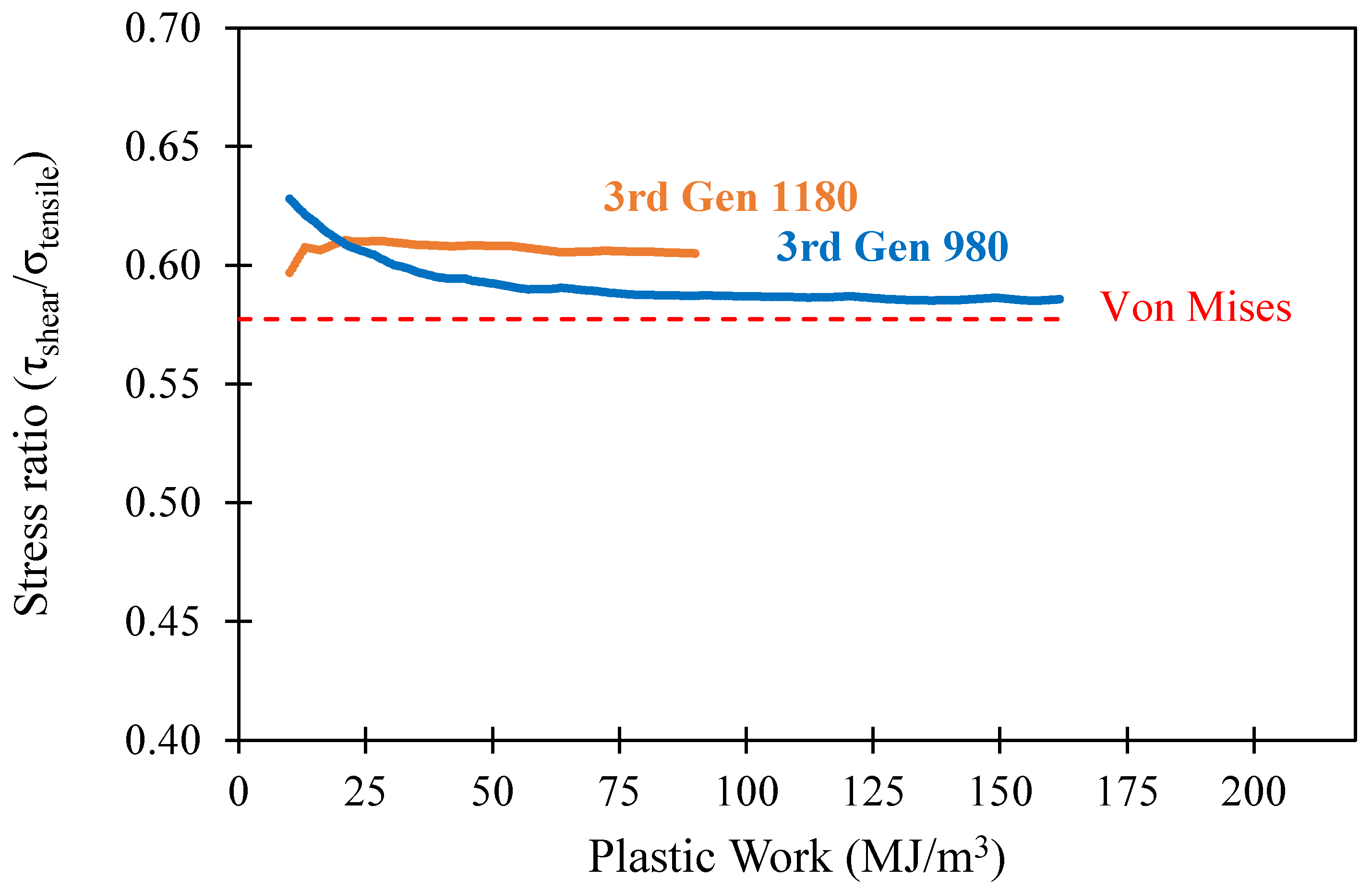

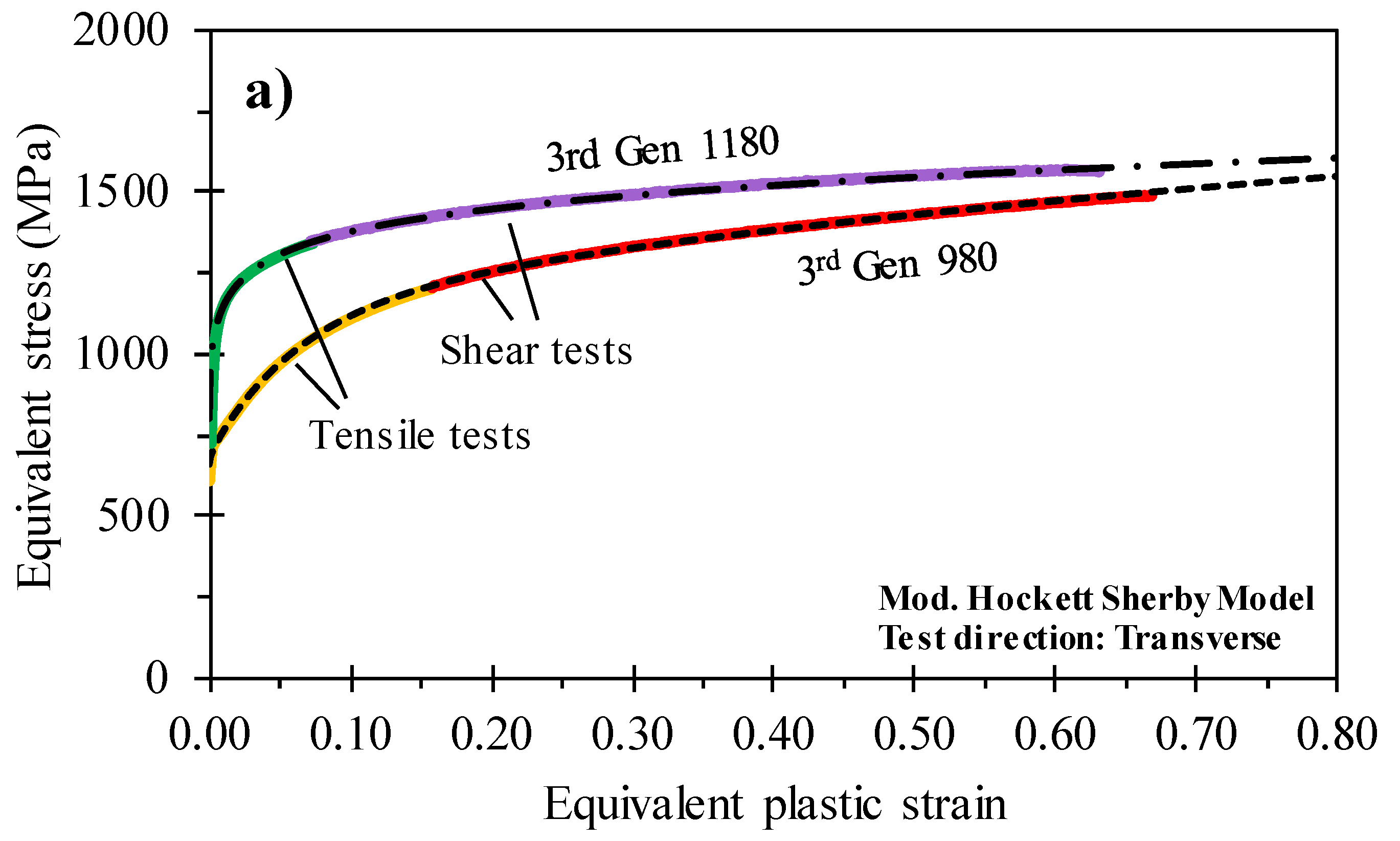

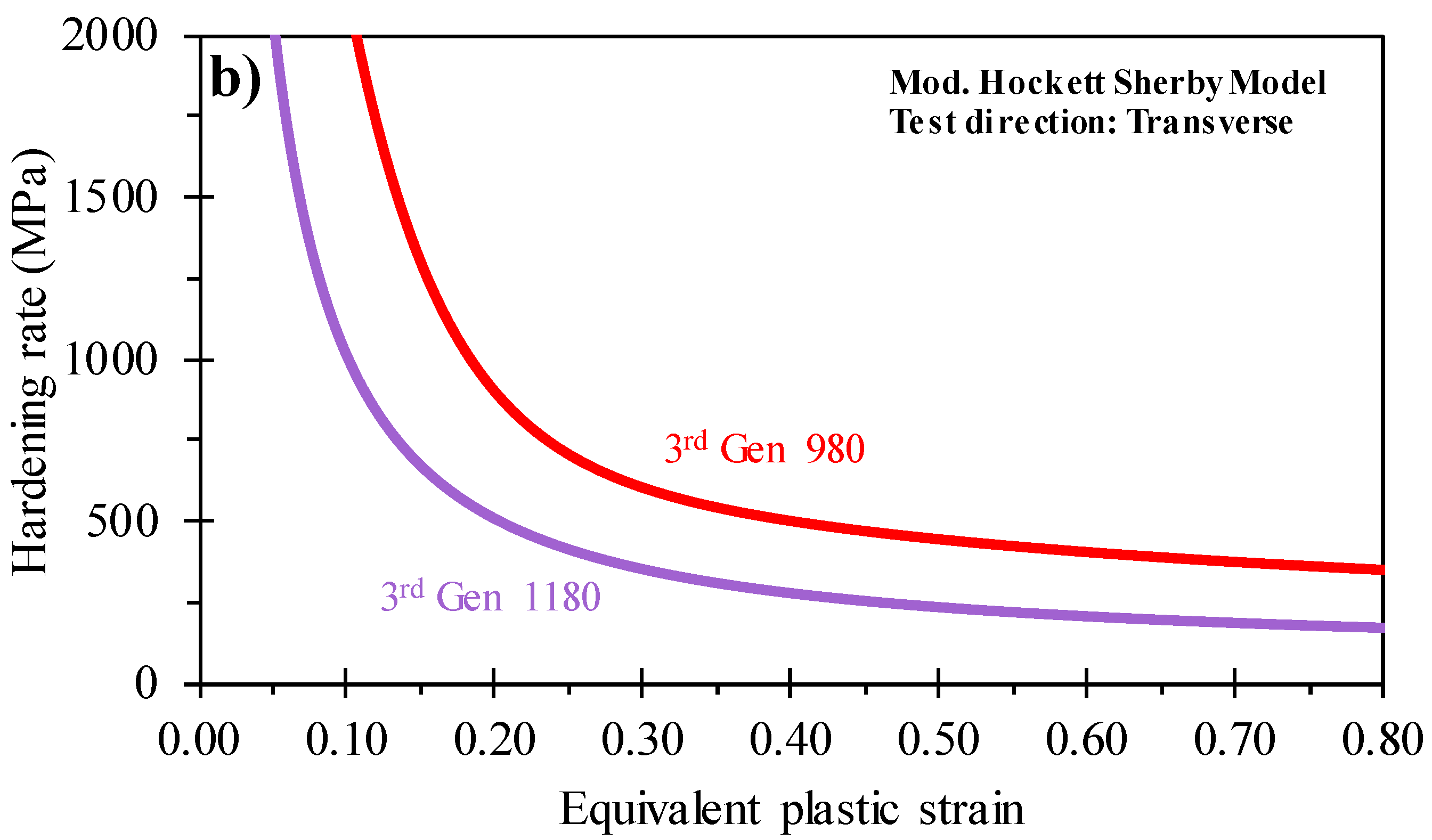

2.2. Determination and Calibration of the Isotropic Hardening Behavior up to Large Strains

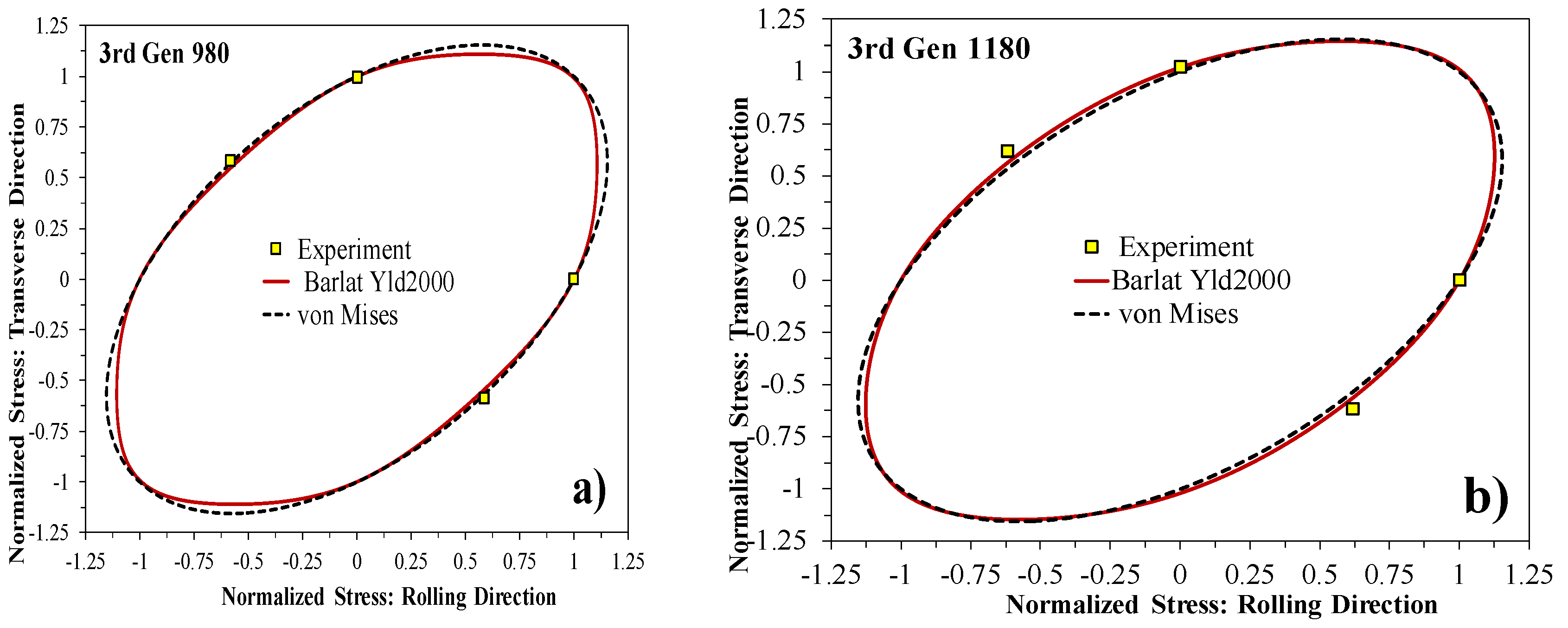

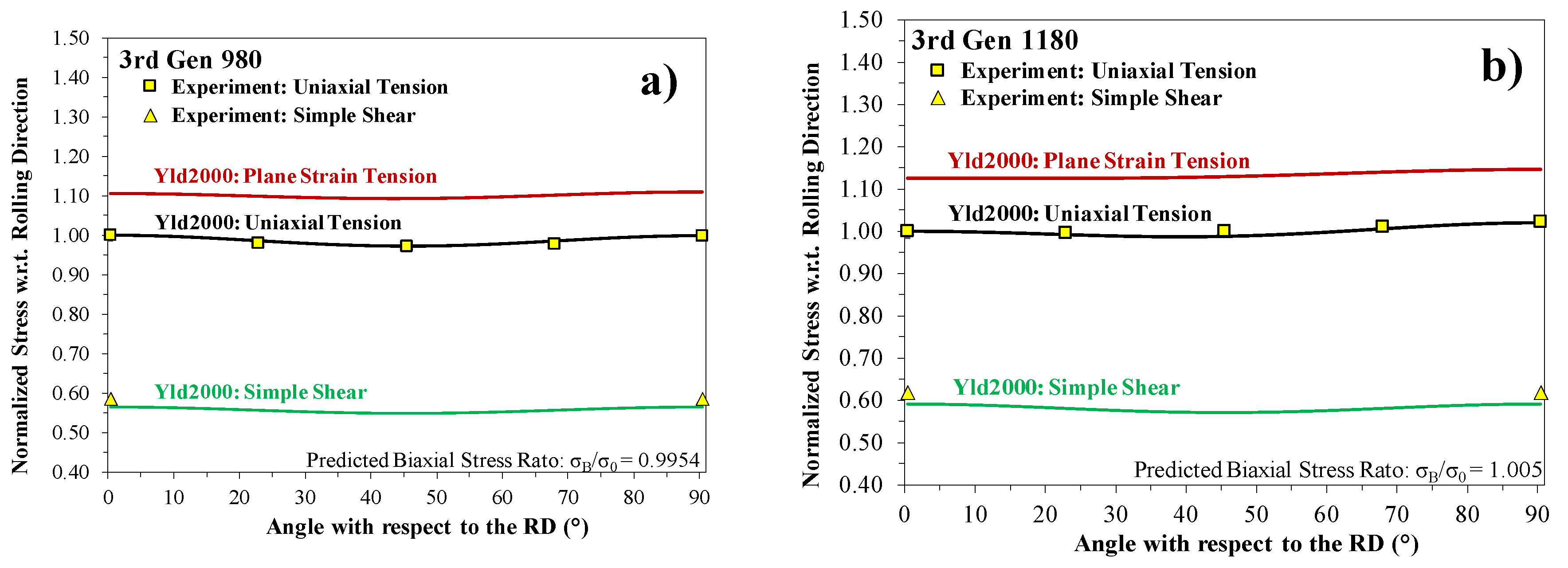

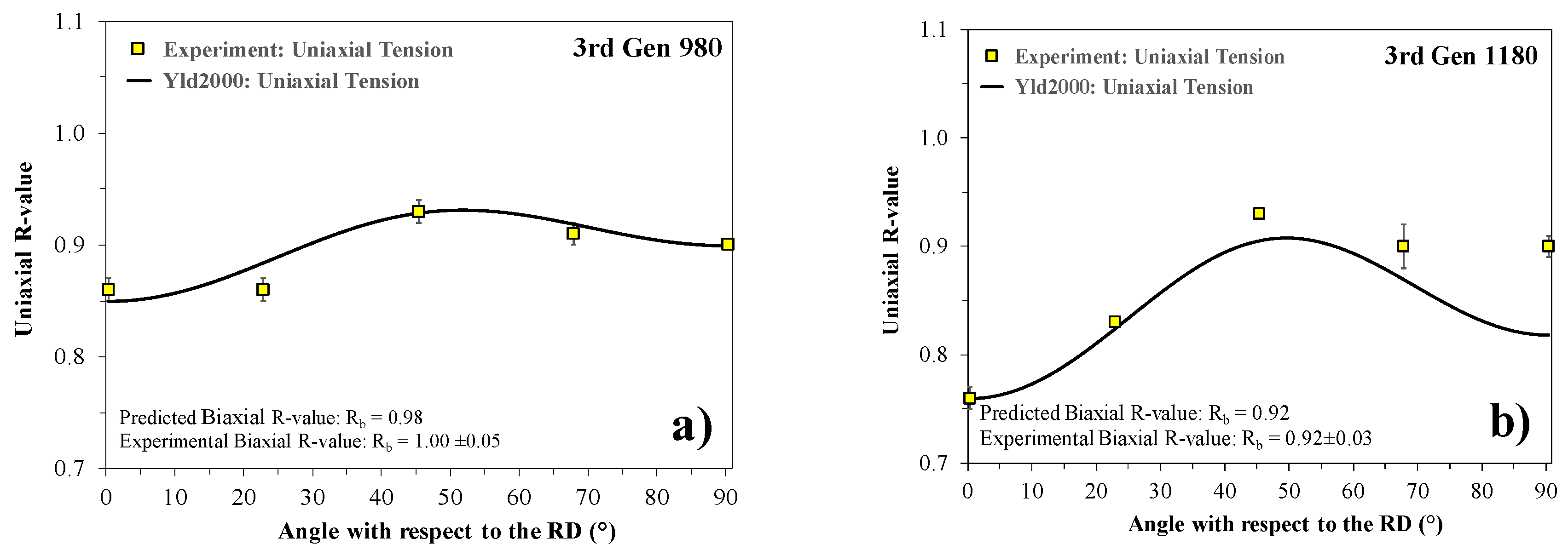

2.3. Calibration of the Yld2000 Anisotropic Yield Function

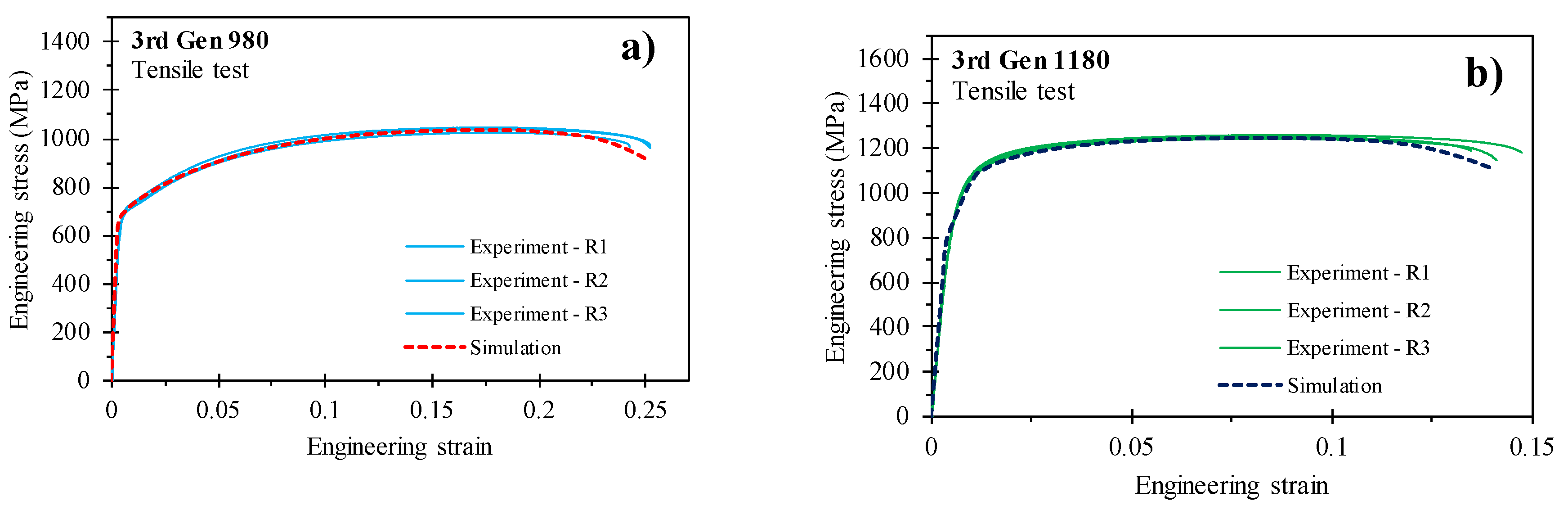

2.4. Validation of the Hardening Model in Tensile Simulations

3. Experimental Formability Characterization

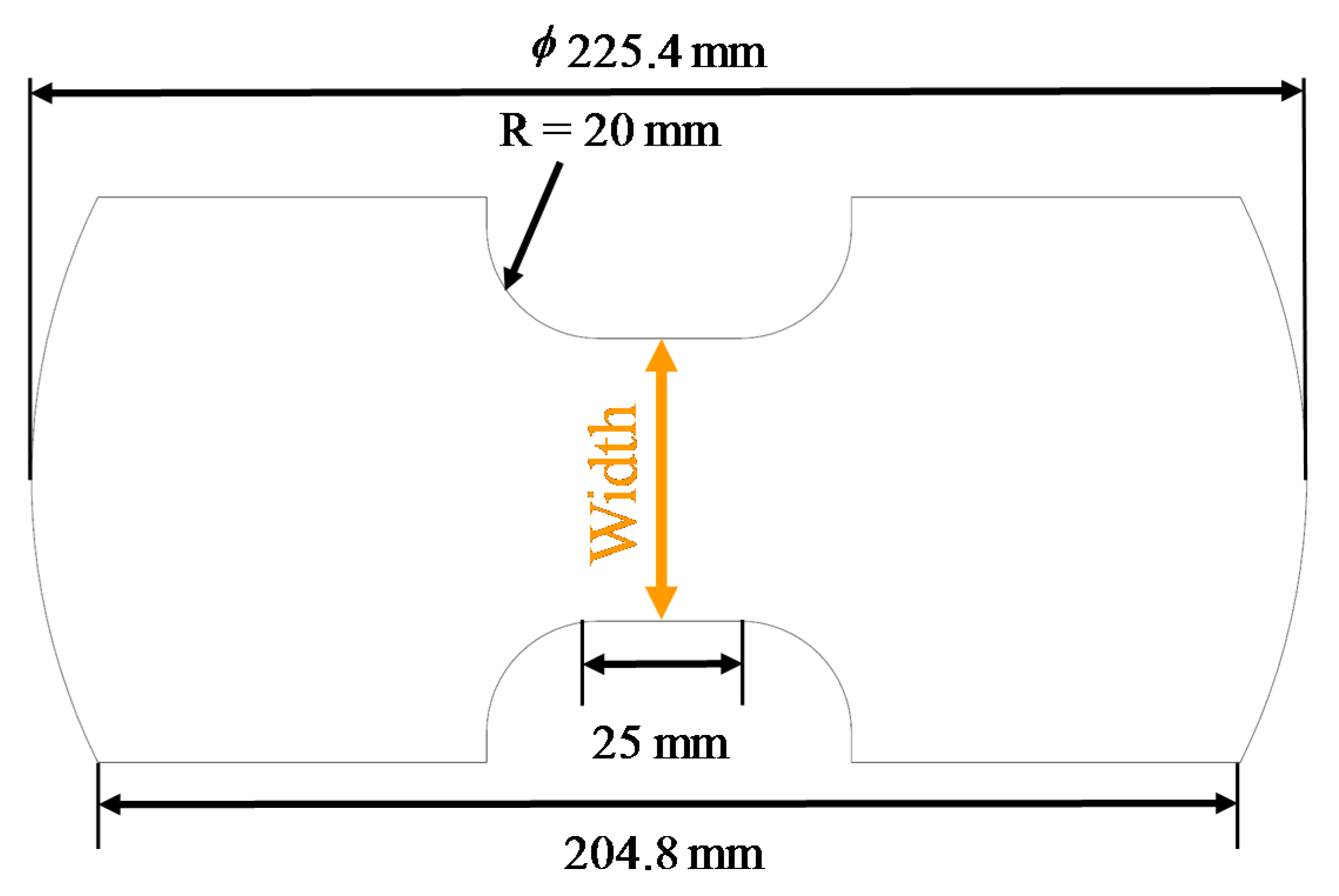

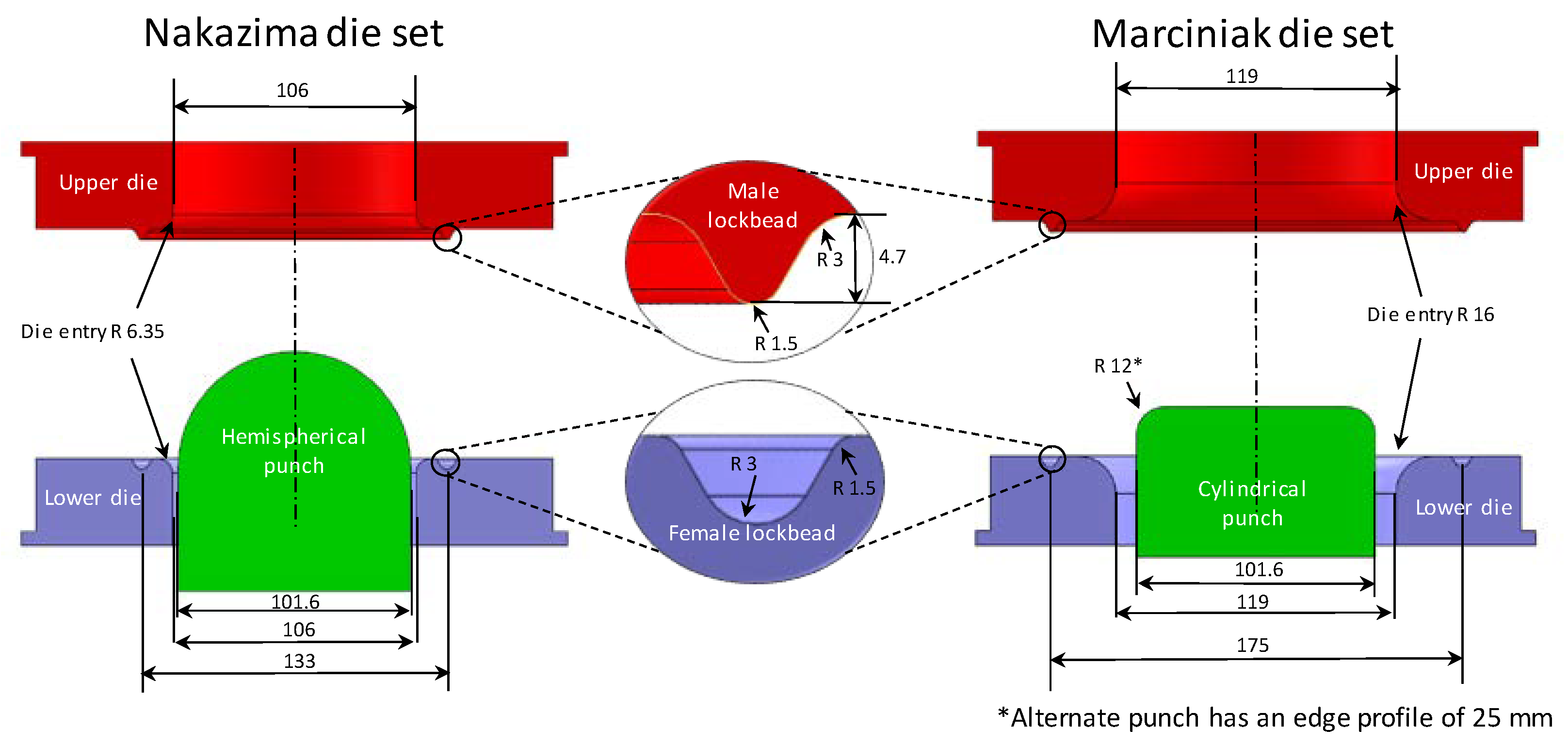

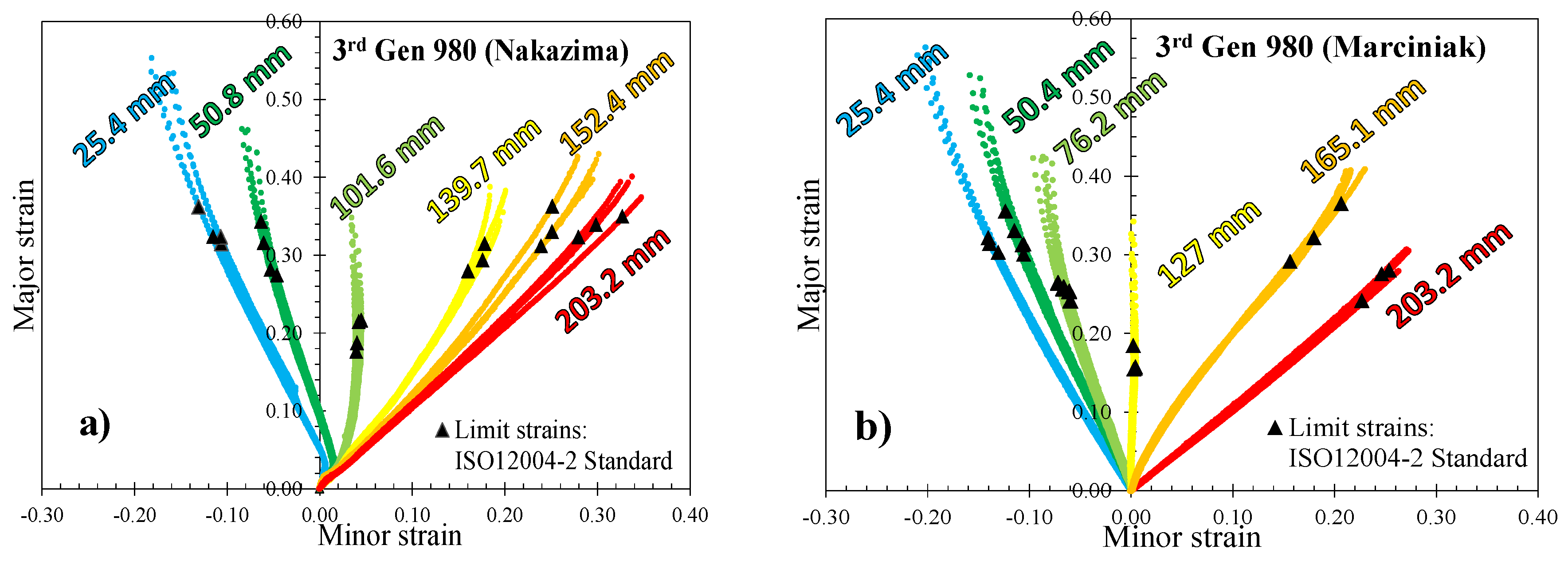

3.1. Marciniak and Nakazima Tests

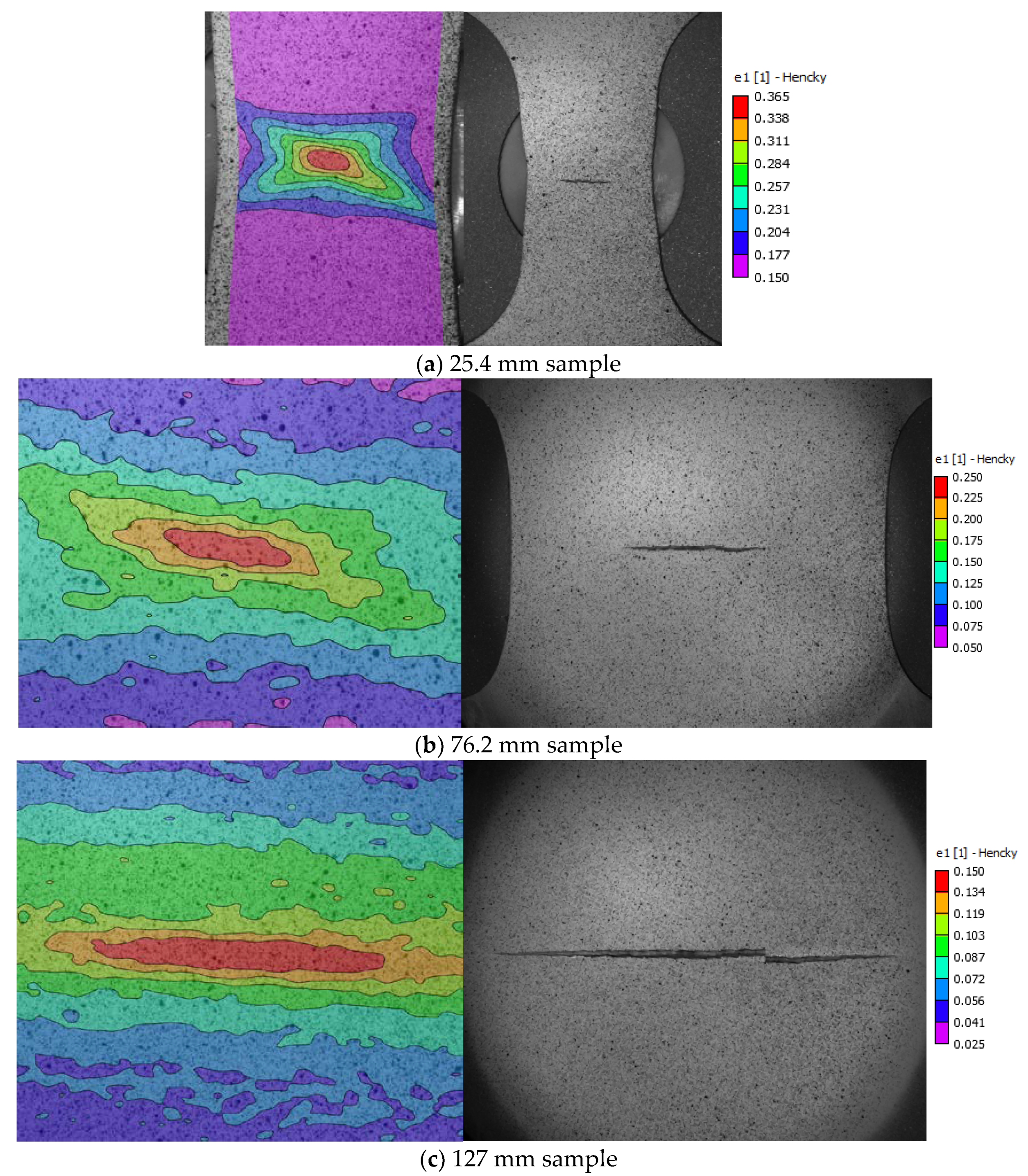

3.2. DIC Settings and Limiting Strain Methodology

Limit Strain Detection: ISO12004-2

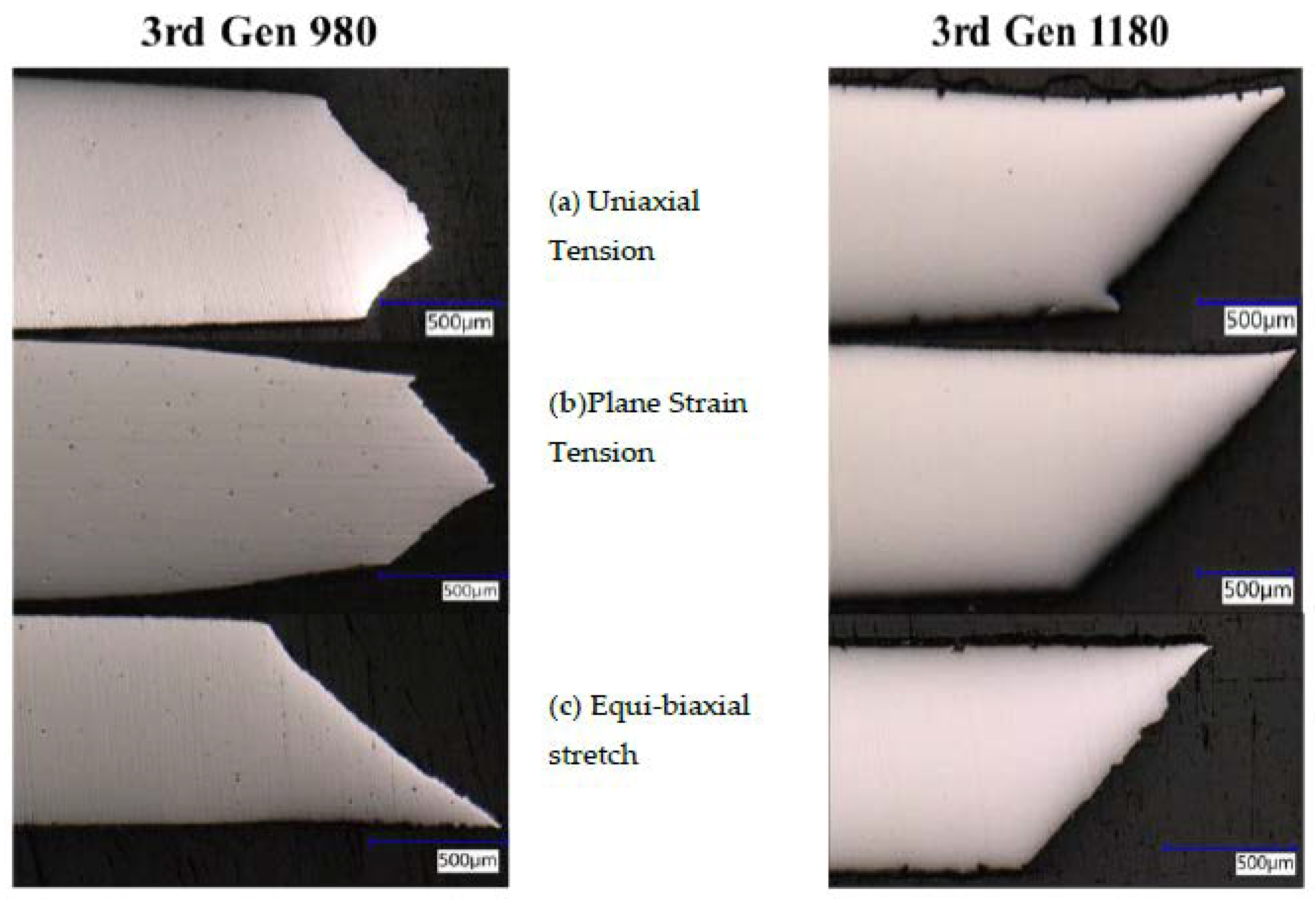

3.3. Fracture Modes

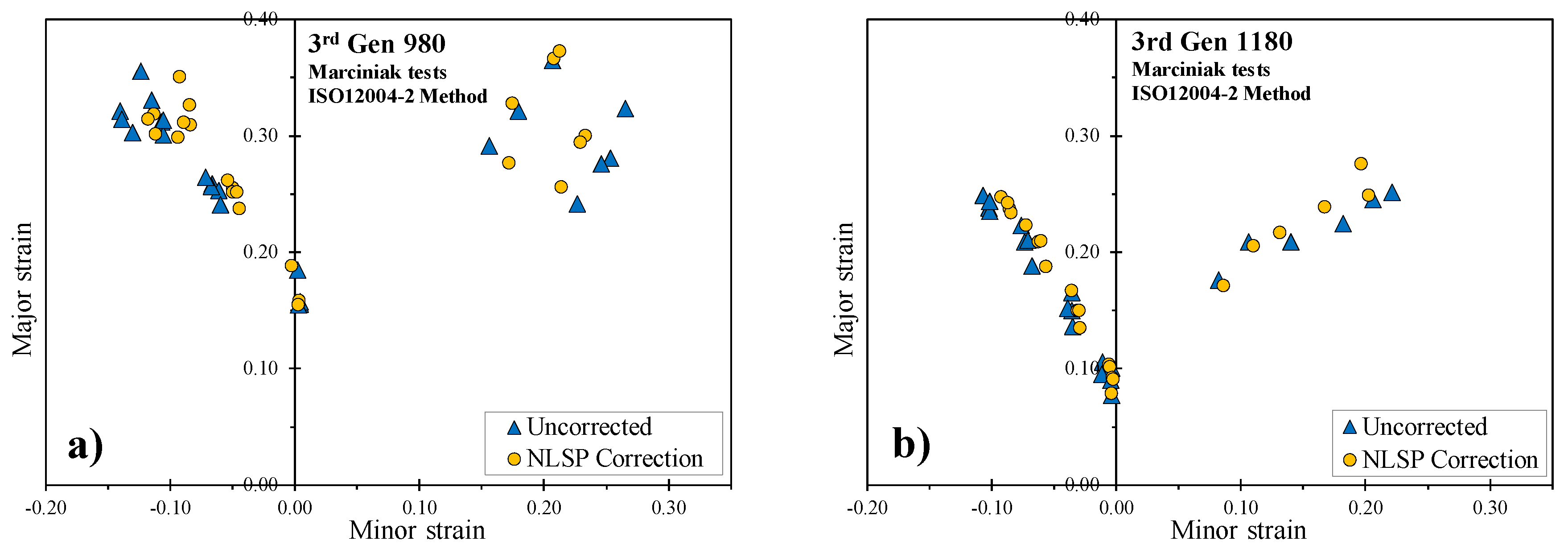

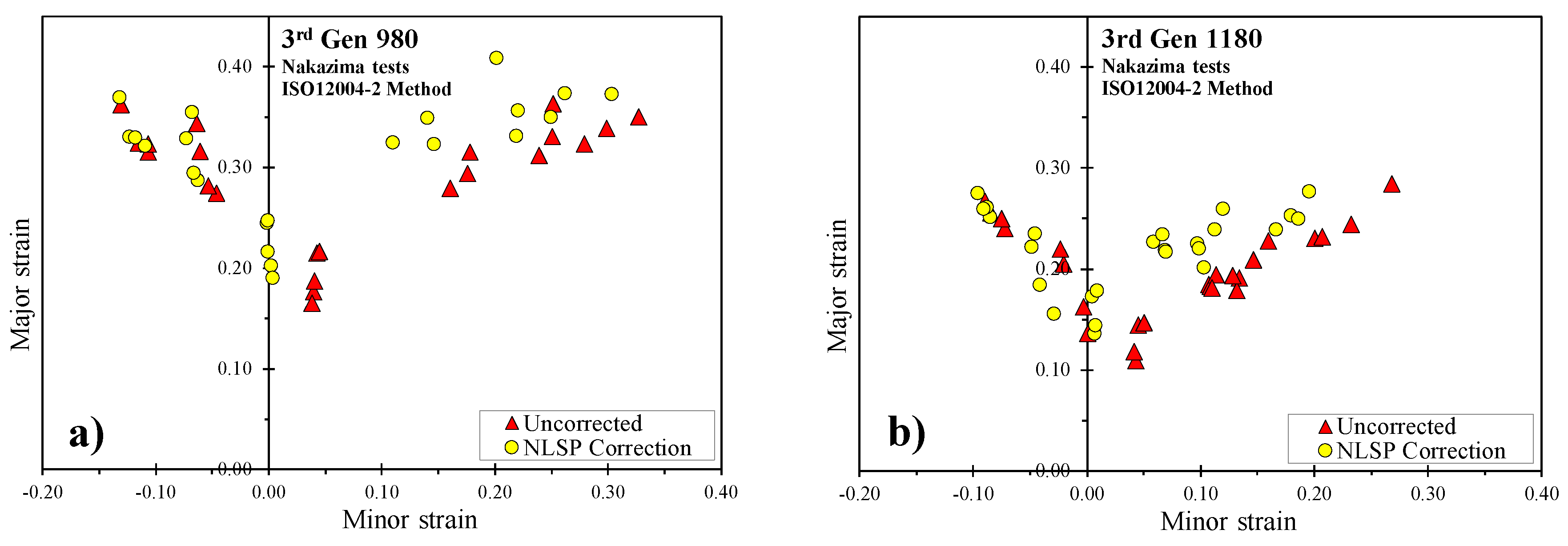

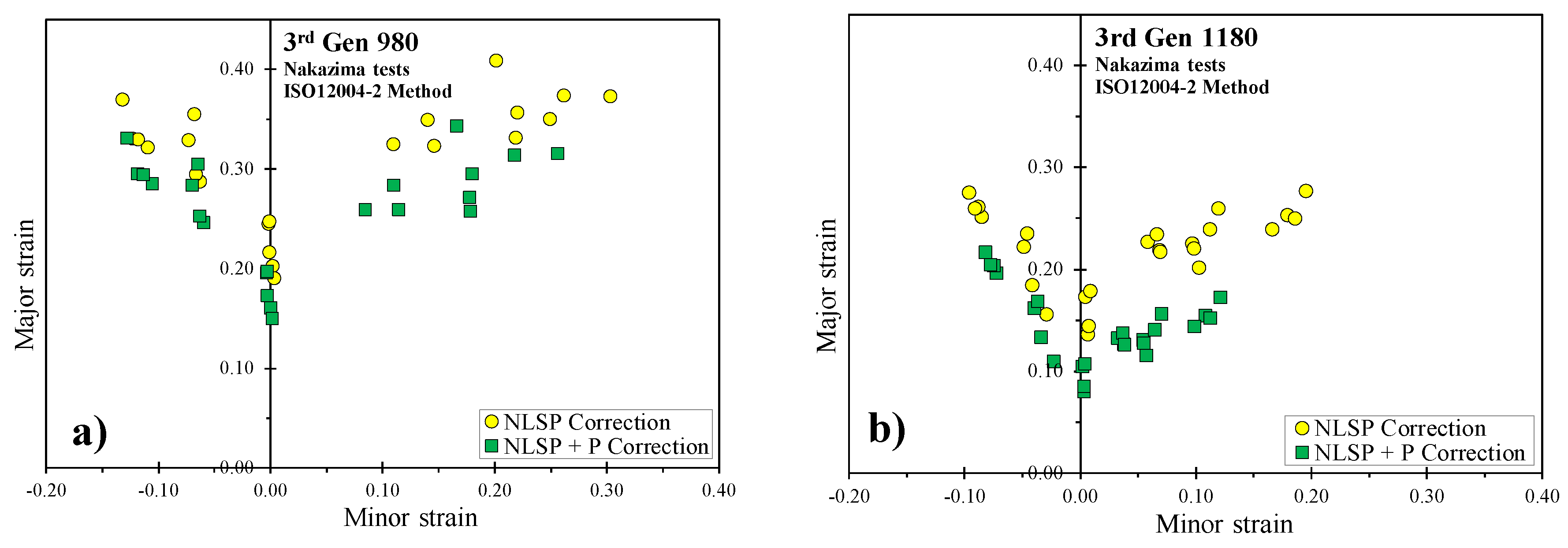

3.4. Process Corrections of the Limiting Strains

4. Analytical FLC Models

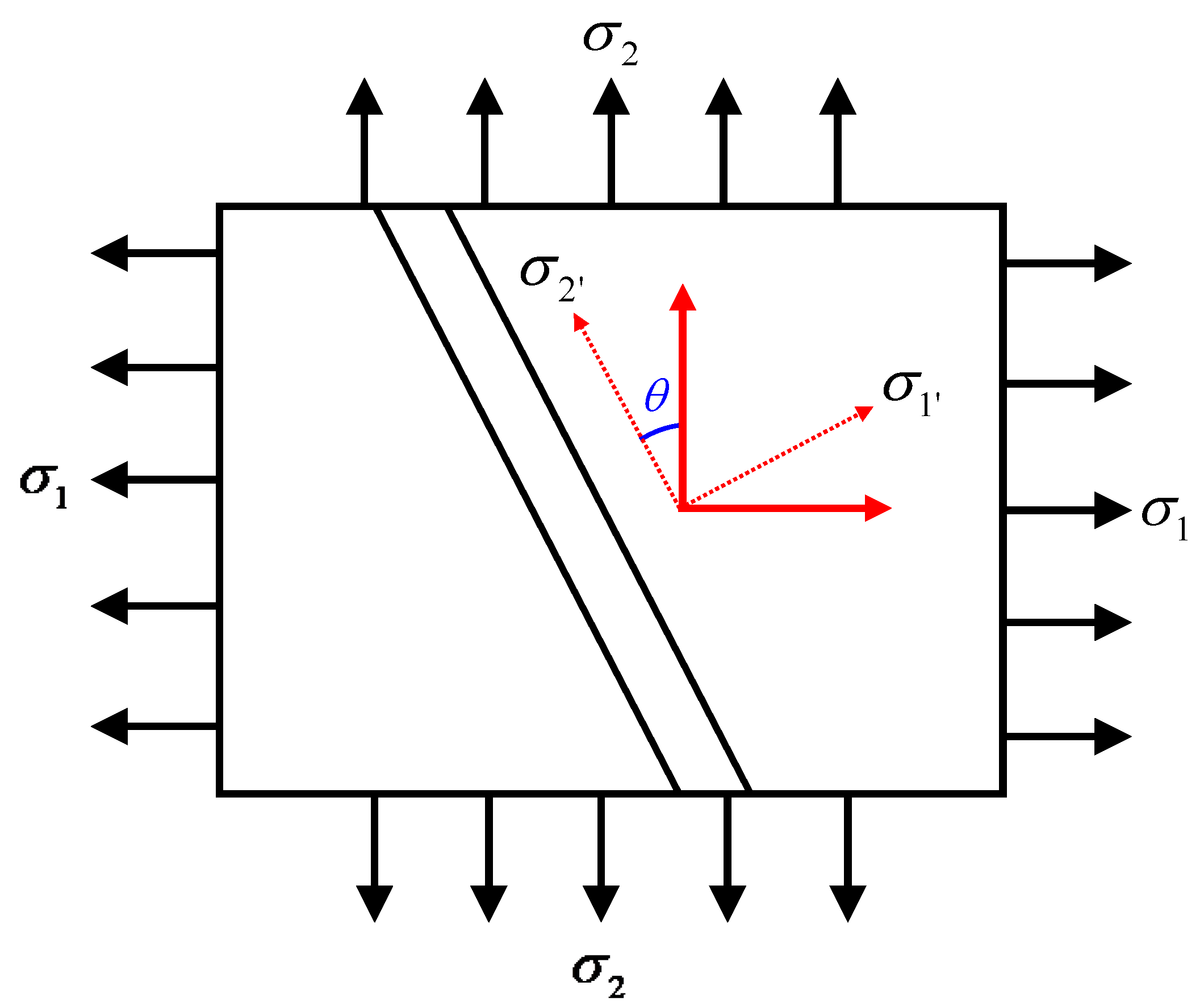

4.1. MK Model

4.2. MMFC Model

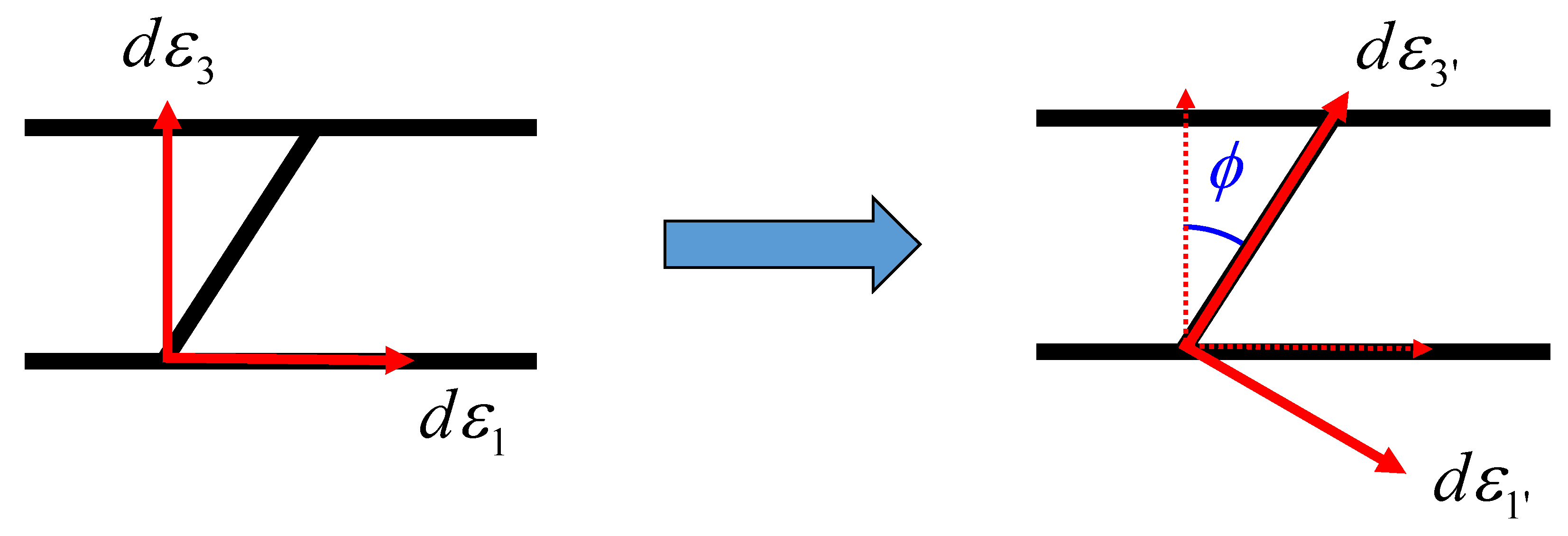

4.3. Bressan-Williams-Hill Model

BWx Model

5. Results

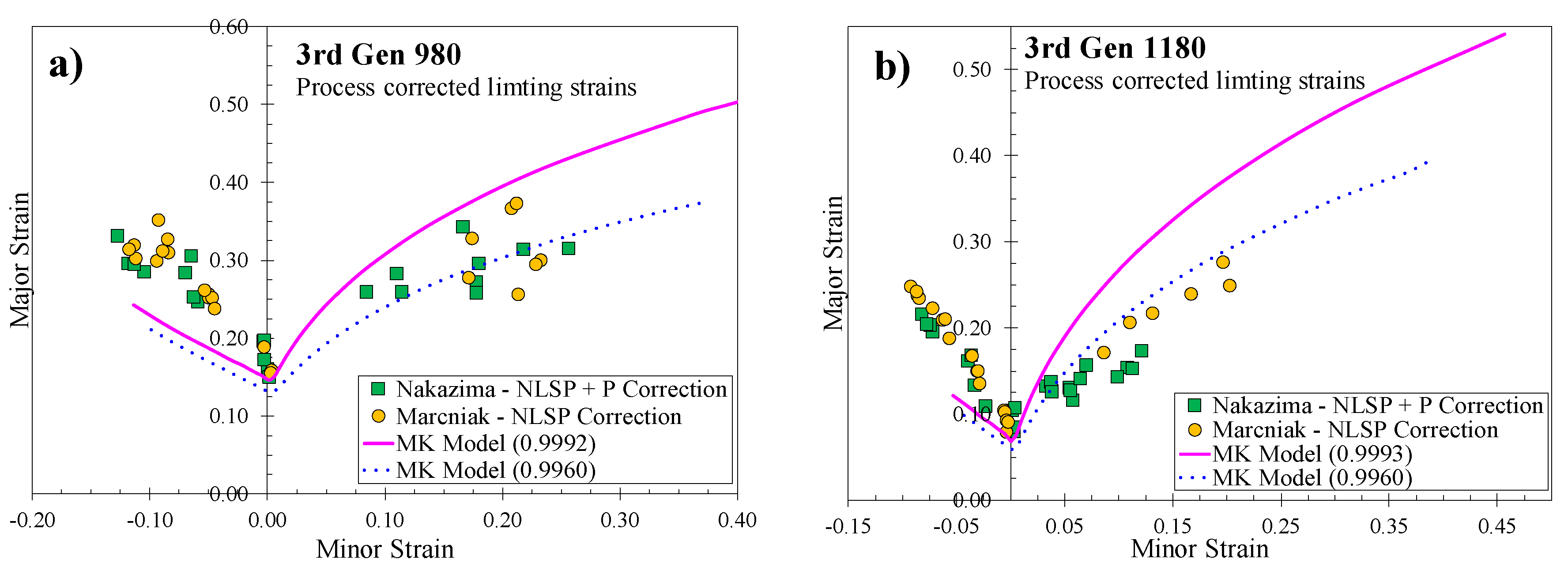

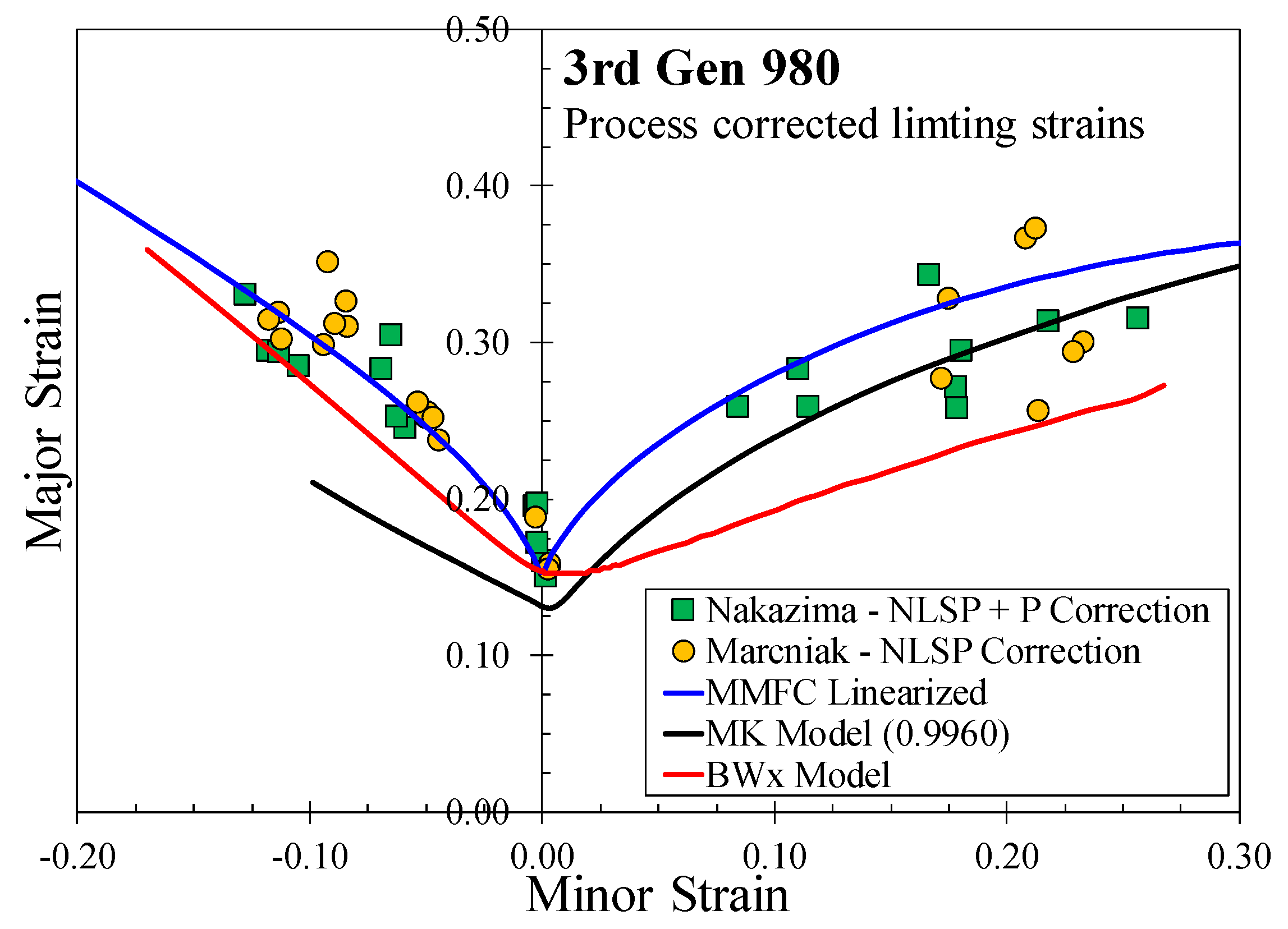

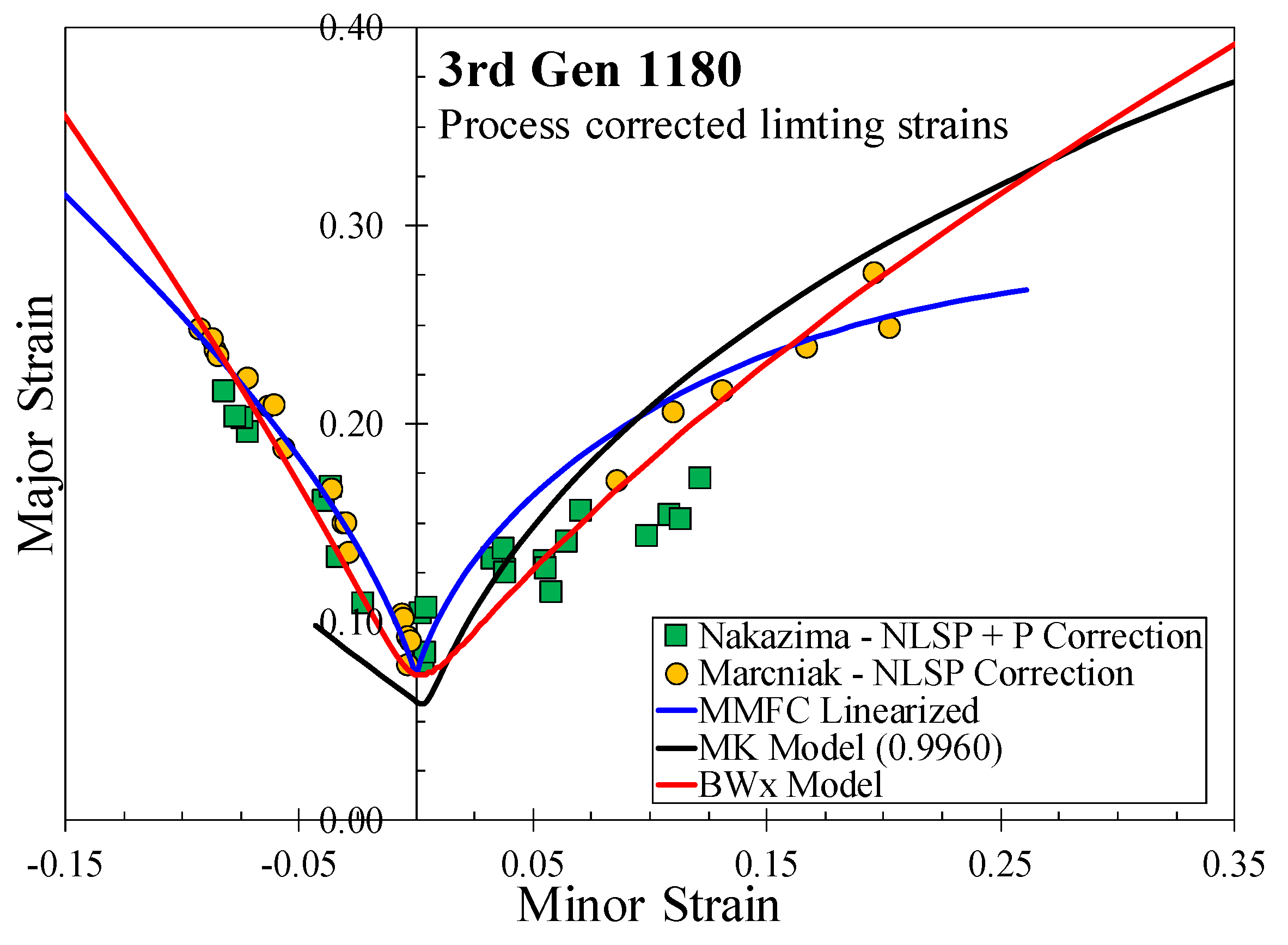

5.1. MK Model Predictions

5.2. MMFC Model Predictions

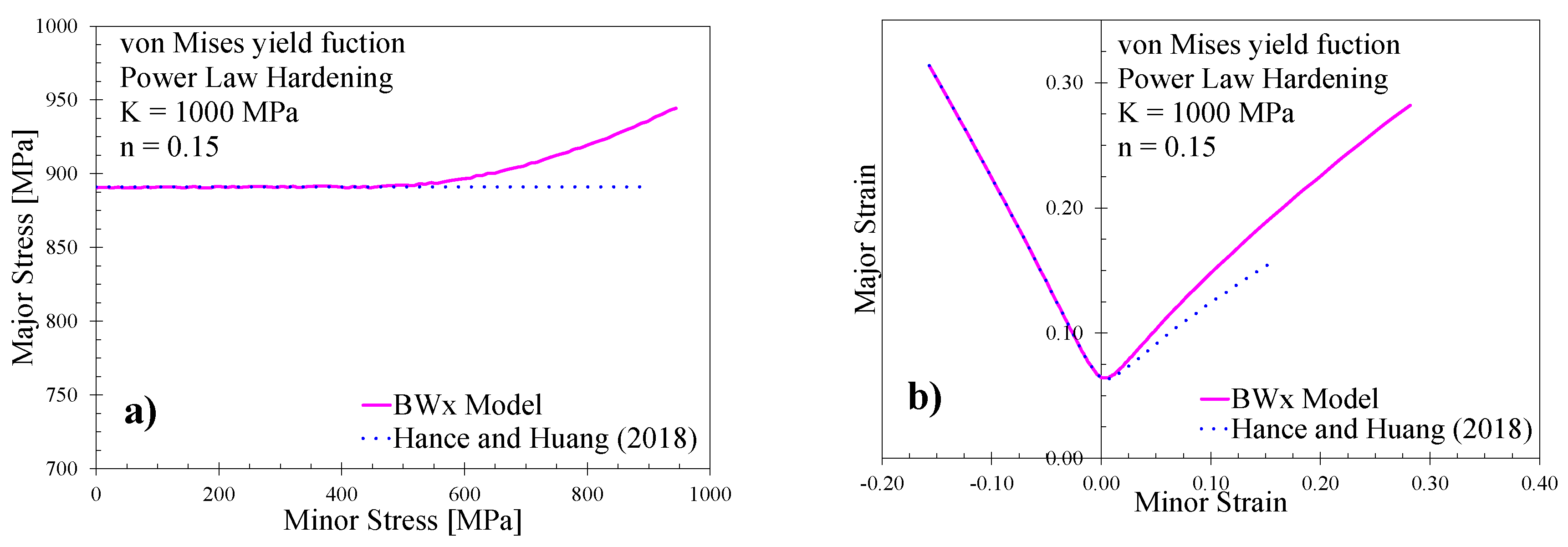

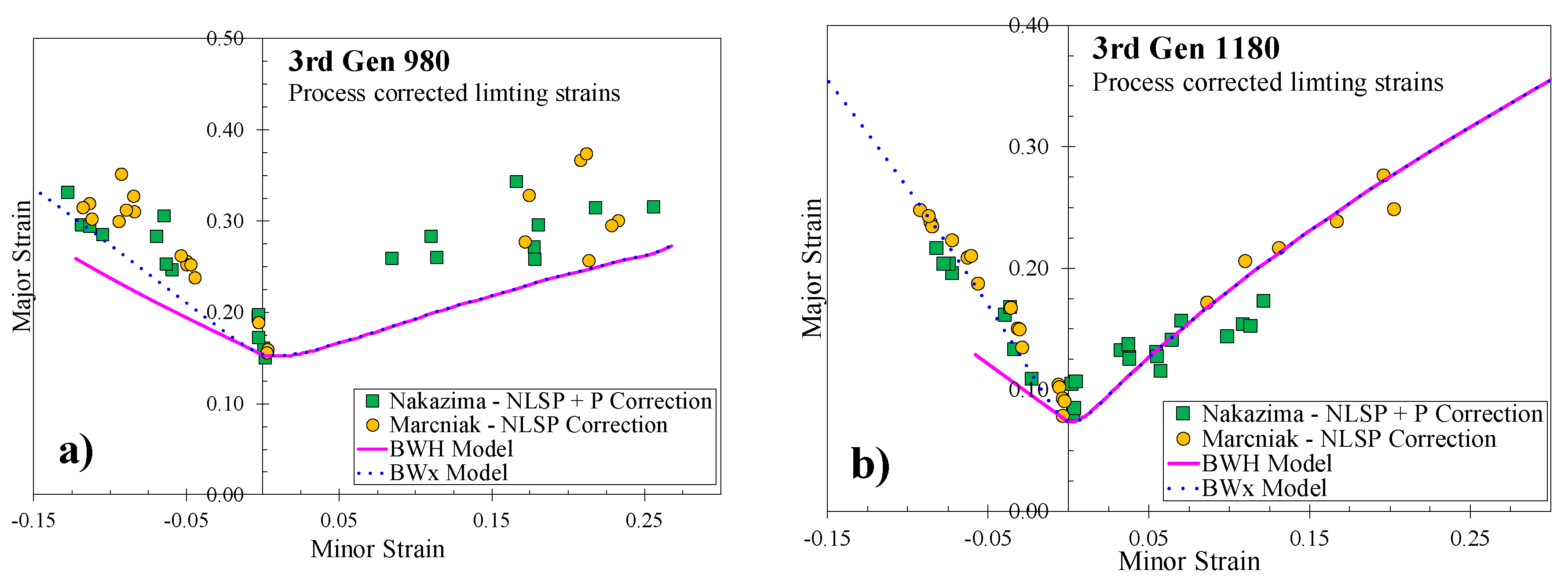

5.3. BWH and BWx Model Predictions

6. Discussion

6.1. Comparison of Analytical FLC Predictions for 3rd Gen AHSS

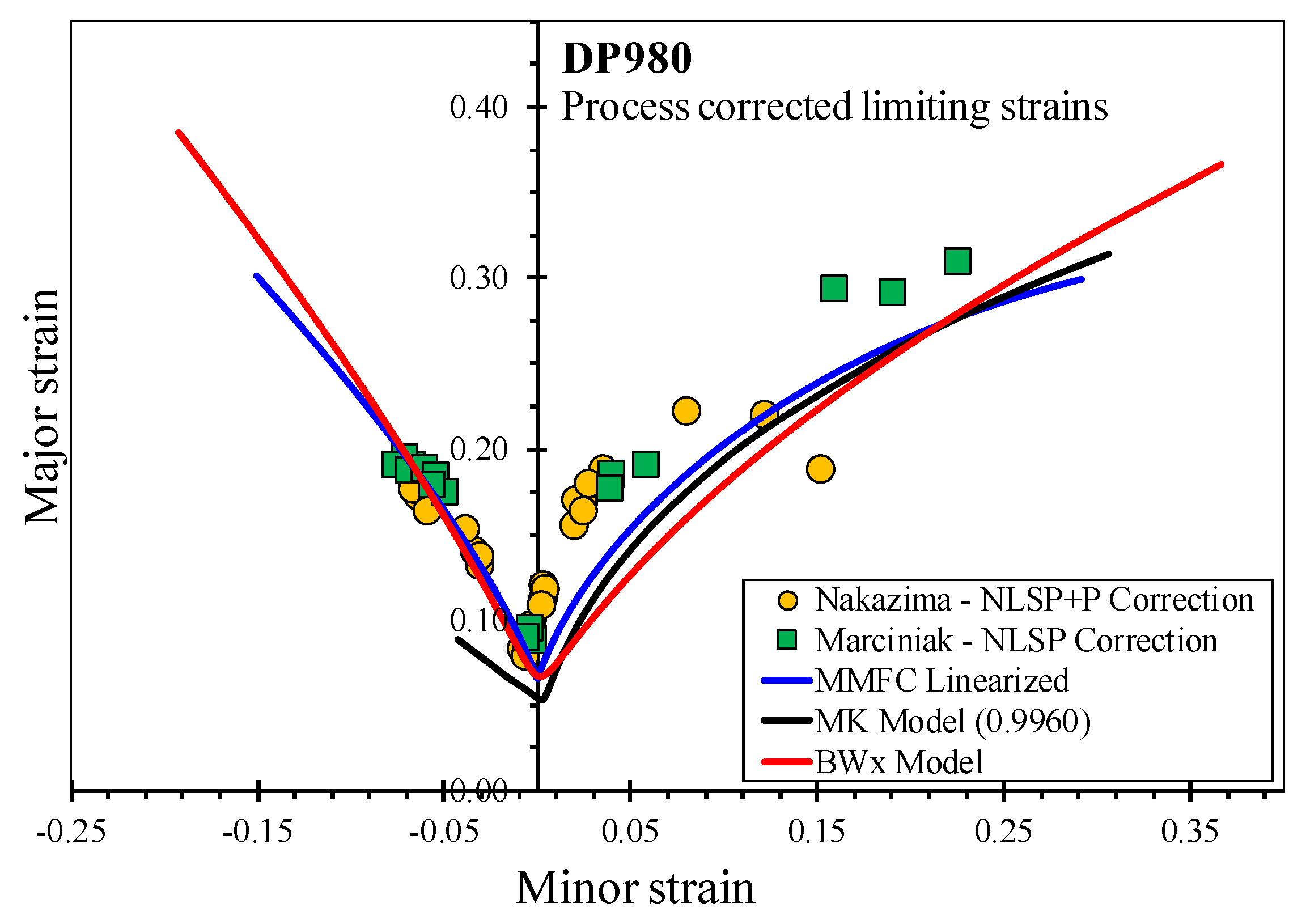

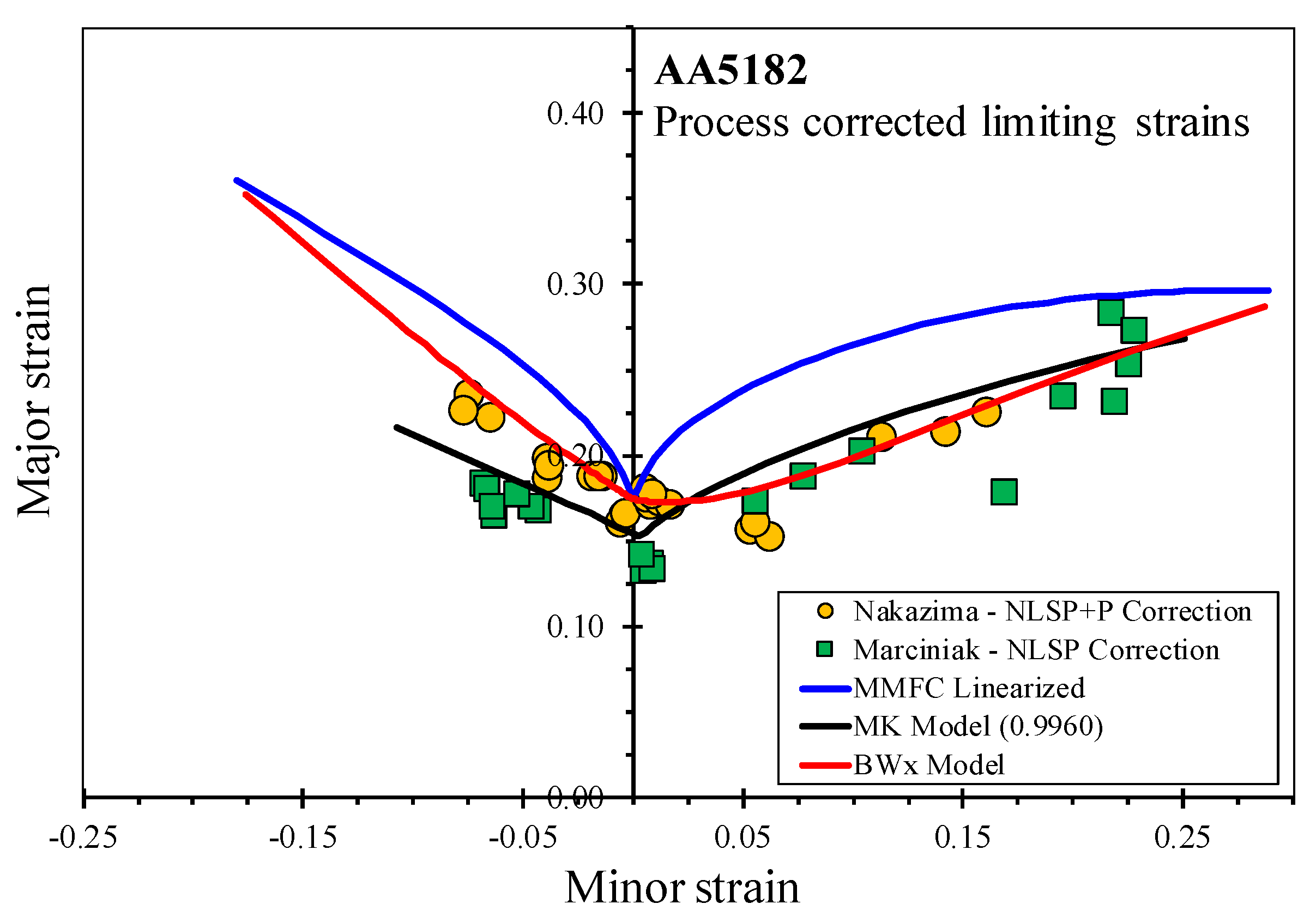

6.2. Application to DP980 and AA5182

7. Conclusions

- Finite element simulations of uniaxial tensile tests confirmed that the experimental shear conversion methodology proposed by Rahmaan et al. [20] provides a reliable technique to accurately obtain the material hardening response of AHSS to large strains that is suitable for formability prediction.

- Nakazima forming limit curves should be corrected for process effects associated with out-of-plane deformation to be consistent with analytical formability models for proportional plane stress loading.

- The MK model, when evaluated deterministically using an assumed imperfection factor of 0.996, predicted the biaxial limit strains to good agreement but were too conservative for the uniaxial tension of the three AHSS. The best performance of the MK model was found for the AA5182 aluminum.

- The BWH model was found to be unsatisfactory on the draw side of the FLC due to its reliance upon the Hill model. The proposed extension to the BW model to employ the maximum shear stress criterion on the draw side (BWx model) led to superior formability predictions without adding any new parameters. Aside from its simplicity, the BWx model is particularly attractive for materials sensitive to through-thickness shear such as the 3rd Gen 1180 and performed well for AA5182.

- Among the studied analytical models, the linearized MMFC [9] proposed in this study showed a superior correlation with experiments for the three AHSS but overestimated the formability of the AA5182. The predicted necking strain in the MMFC was linearized over the average strain path to be more consistent with the process-corrected forming limit strains for in-plane stretching.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Process Corrected Limiting Strains

| 25.4 mm Wide 3rd Gen 980 Samples | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| - | Nakazima | Marciniak | ||||||||

| Repeat | Limit Strains | After NLSP Correction | After Pressure Correction | Limit Strains | After NLSP Correction | |||||

| - | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 |

| R1 | 0.32 | −0.11 | 0.32 | −0.11 | 0.29 | −0.10 | 0.32 | −0.14 | 0.32 | −0.11 |

| R2 | 0.32 | −0.12 | 0.33 | −0.12 | 0.30 | −0.12 | 0.30 | −0.13 | 0.30 | −0.11 |

| R3 | 0.36 | −0.13 | 0.37 | −0.13 | 0.33 | −0.13 | 0.31 | −0.14 | 0.31 | −0.12 |

| R4 | 0.36 | −0.13 | 0.37 | −0.13 | 0.33 | −0.13 | X | X | X | X |

| R5 | 0.32 | −0.11 | 0.33 | −0.12 | 0.29 | −0.11 | X | X | X | X |

| Av | 0.33 | −0.11 | 0.34 | −0.12 | 0.30 | −0.12 | 0.31 | −0.14 | 0.31 | −0.11 |

| Std | 0.02 | 0.01 | 0.02 | 0.01 | 0.02 | 0.01 | 0.01 | 0.01 | 0.01 | 0.00 |

| 50.8 mm Wide 3rd Gen 980 Samples | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| - | Nakazima | Marciniak | ||||||||

| Repeat | Limit Strains | After NLSP Correction | After Pressure Correction | Limit Strains | After NLSP Correction | |||||

| - | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 |

| R1 | 0.27 | −0.05 | 0.29 | −0.06 | 0.25 | −0.06 | 0.31 | −0.11 | 0.31 | −0.08 |

| R2 | 0.34 | −0.06 | 0.35 | −0.07 | 0.30 | −0.06 | 0.30 | −0.11 | 0.30 | −0.09 |

| R3 | 0.32 | −0.06 | 0.33 | −0.07 | 0.28 | −0.07 | 0.31 | −0.11 | 0.31 | −0.09 |

| R4 | 0.28 | −0.05 | 0.29 | −0.07 | 0.25 | −0.06 | 0.33 | −0.11 | 0.33 | −0.08 |

| R5 | X | X | X | X | X | X | 0.36 | −0.12 | 0.35 | −0.09 |

| Av | 0.30 | −0.06 | 0.32 | −0.07 | 0.27 | −0.06 | 0.32 | −0.11 | 0.32 | −0.09 |

| Std | 0.03 | 0.01 | 0.03 | 0.00 | 0.03 | 0.00 | 0.02 | 0.01 | 0.02 | 0.00 |

| 76.2 mm Wide 3rd Gen 980 Samples | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| - | Nakazima | Marciniak | ||||||||

| Repeat | Limit Strains | After NLSP Correction | After Pressure Correction | Limit Strains | After NLSP Correction | |||||

| - | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 |

| R1 | X | X | X | X | X | X | 0.26 | −0.07 | 0.26 | −0.05 |

| R2 | X | X | X | X | X | X | 0.25 | −0.06 | 0.25 | −0.05 |

| R3 | X | X | X | X | X | X | 0.26 | −0.07 | 0.25 | −0.05 |

| R4 | X | X | X | X | X | X | 0.24 | −0.06 | 0.24 | −0.04 |

| R5 | X | X | X | X | X | X | 0.26 | −0.07 | 0.26 | −0.05 |

| Av | X | X | X | X | X | X | 0.25 | −0.07 | 0.25 | −0.05 |

| Std | X | X | X | X | X | X | 0.01 | 0.00 | 0.01 | 0.00 |

| 101.6 mm Wide 3rd Gen 980 Samples | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| - | Nakazima | Marciniak | ||||||||

| Repeat | Limit Strains | After NLSP Correction | After Pressure Correction | Limit Strains | After NLSP Correction | |||||

| - | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 |

| R1 | 0.21 | 0.04 | 0.24 | 0.00 | 0.20 | 0.00 | X | X | X | X |

| R2 | 0.22 | 0.04 | 0.25 | 0.00 | 0.20 | 0.00 | X | X | X | X |

| R3 | 0.18 | 0.04 | 0.20 | 0.00 | 0.16 | 0.00 | X | X | X | X |

| R4 | 0.19 | 0.04 | 0.22 | 0.00 | 0.17 | 0.00 | X | X | X | X |

| R5 | 0.17 | 0.04 | 0.19 | 0.00 | 0.15 | 0.00 | X | X | X | X |

| Av | 0.19 | 0.04 | 0.22 | 0.00 | 0.17 | 0.00 | X | X | X | X |

| Std | 0.02 | 0.00 | 0.03 | 0.00 | 0.02 | 0.00 | X | X | X | X |

| 127 mm Wide 3rd Gen 980 Samples | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| - | Nakazima | Marciniak | ||||||||

| Repeat | Limit Strains | After NLSP Correction | After Pressure Correction | Limit Strains | After NLSP Correction | |||||

| - | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 |

| R1 | X | X | X | X | X | X | 0.18 | 0.00 | 0.19 | 0.00 |

| R2 | X | X | X | X | X | X | 0.16 | 0.00 | 0.16 | 0.00 |

| R3 | X | X | X | X | X | X | 0.16 | 0.00 | 0.16 | 0.00 |

| R4 | X | X | X | X | X | X | 0.15 | 0.00 | 0.15 | 0.00 |

| Av | X | X | X | X | X | X | 0.16 | 0.00 | 0.16 | 0.00 |

| Std | X | X | X | X | X | X | 0.01 | 0.00 | 0.02 | 0.00 |

| 139.7 mm Wide 3rd Gen 980 Samples | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| - | Nakazima | Marciniak | ||||||||

| Repeat | Limit Strains | After NLSP Correction | After Pressure Correction | Limit Strains | After NLSP Correction | |||||

| - | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 |

| R1 | 0.31 | 0.18 | 0.35 | 0.14 | 0.28 | 0.11 | X | X | X | X |

| R2 | 0.29 | 0.18 | 0.32 | 0.15 | 0.26 | 0.11 | X | X | X | X |

| R3 | 0.28 | 0.16 | 0.32 | 0.11 | 0.26 | 0.10 | X | X | X | X |

| Av | 0.30 | 0.17 | 0.33 | 0.13 | 0.27 | 0.10 | X | X | X | X |

| Std | 0.02 | 0.01 | 0.01 | 0.02 | 0.01 | 0.02 | X | X | X | X |

| 152.4 mm Wide 3rd Gen 980 Samples | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| - | Nakazima | Marciniak | ||||||||

| Repeat | Limit Strains | After NLSP Correction | After Pressure Correction | Limit Strains | After NLSP Correction | |||||

| - | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 |

| R1 | 0.36 | 0.25 | 0.41 | 0.20 | 0.34 | 0.17 | X | X | X | X |

| R2 | 0.31 | 0.24 | 0.33 | 0.22 | 0.27 | 0.18 | X | X | X | X |

| R3 | 0.33 | 0.25 | 0.36 | 0.22 | 0.30 | 0.18 | X | X | X | X |

| Av | 0.34 | 0.25 | 0.36 | 0.21 | 0.30 | 0.17 | X | X | X | X |

| Std | 0.03 | 0.01 | 0.04 | 0.01 | 0.04 | 0.01 | X | X | X | X |

| 165.1 mm Wide 3rd Gen 980 Samples | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| - | Nakazima | Marciniak | ||||||||

| Repeat | Limit Strains | After NLSP Correction | After Pressure Correction | Limit Strains | After NLSP Correction | |||||

| - | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 |

| R1 | X | X | X | X | X | X | 0.29 | 0.16 | 0.28 | 0.17 |

| R2 | X | X | X | X | X | X | 0.37 | 0.21 | 0.37 | 0.21 |

| R3 | X | X | X | X | X | X | 0.32 | 0.18 | 0.33 | 0.17 |

| Av | X | X | X | X | X | X | 0.33 | 0.18 | 0.32 | 0.18 |

| Std | X | X | X | X | X | X | 0.04 | 0.03 | 0.04 | 0.02 |

| 203.2 mm Wide 3rd Gen 980 Samples | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| - | Nakazima | Marciniak | ||||||||

| Repeat | Limit Strains | After NLSP Correction | After Pressure Correction | Limit Strains | After NLSP Correction | |||||

| - | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 |

| R1 | 0.32 | 0.28 | 0.35 | 0.25 | 0.26 | 0.18 | 0.24 | 0.26 | 0.26 | 0.21 |

| R2 | 0.35 | 0.33 | 0.47 | 0.30 | 0.32 | 0.26 | 0.28 | 0.25 | 0.30 | 0.23 |

| R3 | 0.34 | 0.30 | 0.37 | 0.26 | 0.31 | 0.22 | 0.28 | 0.25 | 0.29 | 0.23 |

| Av | 0.34 | 0.30 | 0.36 | 0.27 | 0.30 | 0.22 | 0.28 | 0.25 | 0.31 | 0.22 |

| Std | 0.01 | 0.02 | 0.01 | 0.03 | 0.03 | 0.04 | 0.03 | 0.02 | 0.05 | 0.01 |

| 25.4 mm Wide 3rd Gen 1180 Samples | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| - | Nakazima | Marciniak | ||||||||

| Repeat | Limit Strains | After NLSP Correction | After Pressure Correction | Limit Strains | After NLSP Correction | |||||

| - | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 |

| R1 | 0.24 | −0.07 | 0.25 | −0.08 | 0.20 | −0.07 | 0.25 | −0.11 | 0.25 | −0.09 |

| R2 | 0.26 | −0.08 | 0.26 | −0.09 | 0.20 | −0.07 | 0.24 | −0.10 | 0.24 | −0.09 |

| R3 | 0.27 | −0.09 | 0.27 | −0.10 | 0.22 | −0.08 | 0.24 | −0.10 | 0.23 | −0.08 |

| R4 | 0.25 | −0.08 | 0.26 | −0.09 | 0.20 | −0.08 | 0.24 | −0.10 | 0.24 | −0.09 |

| Av | 0.25 | −0.08 | 0.26 | −0.09 | 0.20 | −0.08 | 0.24 | −0.10 | 0.24 | −0.09 |

| Std | 0.01 | −0.01 | 0.01 | 0.00 | 0.01 | 0.00 | 0.01 | 0.00 | 0.01 | 0.00 |

| 50.8 mm Wide 3rd Gen 1180 Samples | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| - | Nakazima | Marciniak | ||||||||

| Repeat | Limit Strains | After NLSP Correction | After Pressure Correction | Limit Strains | After NLSP Correction | |||||

| ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | |

| R1 | 0.20 | −0.02 | 0.22 | −0.05 | 0.16 | −0.04 | 0.21 | −0.07 | 0.21 | −0.06 |

| R2 | 0.14 | 0.00 | 0.15 | −0.03 | 0.11 | −0.02 | 0.22 | −0.08 | 0.22 | −0.07 |

| R3 | 0.16 | 0.00 | 0.18 | −0.04 | 0.13 | −0.03 | 0.19 | −0.07 | 0.19 | −0.06 |

| R4 | 0.22 | −0.02 | 0.23 | −0.04 | 0.17 | −0.04 | 0.21 | −0.07 | 0.21 | −0.06 |

| Av | 0.18 | −0.01 | 0.20 | −0.04 | 0.14 | −0.03 | 0.21 | −0.07 | 0.21 | −0.06 |

| Std | 0.04 | 0.01 | 0.04 | 0.01 | 0.03 | 0.01 | 0.01 | 0.00 | 0.01 | 0.01 |

| 76.2 mm Wide 3rd Gen 1180 Samples | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| - | Nakazima | Marciniak | ||||||||

| Repeat | Limit Strains | After NLSP Correction | After Pressure Correction | Limit Strains | After NLSP Correction | |||||

| - | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 |

| R1 | X | X | X | X | X | X | 0.17 | −0.04 | 0.17 | −0.04 |

| R2 | X | X | X | X | X | X | 0.14 | −0.04 | 0.13 | −0.03 |

| R3 | X | X | X | X | X | X | 0.15 | −0.04 | 0.15 | −0.03 |

| R4 | X | X | X | X | X | X | 0.15 | −0.04 | 0.15 | −0.03 |

| Av | X | X | X | X | X | X | 0.15 | −0.04 | 0.15 | −0.03 |

| Std | X | X | X | X | X | X | 0.01 | 0.00 | 0.01 | 0.00 |

| 101.6 mm Wide 3rd Gen 1180 Samples | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| - | Nakazima | Marciniak | ||||||||

| Repeat | Limit Strains | After NLSP Correction | After Pressure Correction | Limit Strains | After NLSP Correction | |||||

| - | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 |

| R1 | 0.11 | 0.04 | 0.14 | 0.01 | 0.08 | 0.00 | X | X | X | X |

| R2 | 0.14 | 0.05 | 0.17 | 0.01 | 0.10 | 0.00 | X | X | X | X |

| R3 | 0.15 | 0.05 | 0.18 | 0.01 | 0.11 | 0.00 | X | X | X | X |

| R4 | 0.12 | 0.04 | 0.14 | 0.01 | 0.08 | 0.00 | X | X | X | X |

| Av | 0.13 | 0.05 | 0.16 | 0.01 | 0.09 | 0.00 | X | X | X | X |

| Std | 0.02 | 0.00 | 0.02 | 0.00 | 0.01 | 0.00 | X | X | X | X |

| 127 mm Wide 3rd Gen 1180 Samples | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| - | Nakazima | Marciniak | ||||||||

| Repeat | Limit Strains | After NLSP Correction | After Pressure Correction | Limit Strains | After NLSP Correction | |||||

| - | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 |

| R1 | X | X | X | X | X | X | 0.11 | −0.01 | 0.10 | −0.01 |

| R2 | X | X | X | X | X | X | 0.10 | 0.00 | 0.10 | −0.01 |

| R3 | X | X | X | X | X | X | 0.10 | −0.01 | 0.09 | 0.00 |

| R4 | X | X | X | X | X | X | 0.08 | 0.00 | 0.08 | 0.00 |

| R5 | X | X | X | X | X | X | 0.09 | 0.00 | 0.09 | 0.00 |

| Av | X | X | X | X | X | X | 0.09 | −0.01 | 0.09 | 0.00 |

| Std | X | X | X | X | X | X | 0.01 | 0.00 | 0.01 | 0.00 |

| 139.7 mm Wide 3rd Gen 1180 Samples | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| - | Nakazima | Marciniak | ||||||||

| Repeat | Limit Strains | After NLSP Correction | After Pressure Correction | Limit Strains | After NLSP Correction | |||||

| - | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 |

| R1 | 0.18 | 0.11 | 0.22 | 0.07 | 0.13 | 0.04 | X | X | X | X |

| R2 | 0.18 | 0.11 | 0.23 | 0.06 | 0.13 | 0.03 | X | X | X | X |

| R3 | 0.19 | 0.11 | 0.23 | 0.07 | 0.14 | 0.04 | X | X | X | X |

| R4 | 0.18 | 0.11 | 0.22 | 0.07 | 0.13 | 0.04 | X | X | X | X |

| Av | 0.19 | 0.11 | 0.22 | 0.07 | 0.13 | 0.04 | X | X | X | X |

| Std | 0.01 | 0.00 | 0.01 | 0.00 | 0.01 | 0.00 | X | X | X | X |

| 152.4 mm Wide 3rd Gen 1180 Samples | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| - | Nakazima | Marciniak | ||||||||

| Repeat | Limit Strains | After NLSP Correction | After Pressure Correction | Limit Strains | After NLSP Correction | |||||

| - | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 |

| R1 | 0.19 | 0.13 | 0.22 | 0.10 | 0.13 | 0.05 | X | X | X | X |

| R2 | 0.18 | 0.13 | 0.20 | 0.10 | 0.12 | 0.06 | X | X | X | X |

| R3 | 0.23 | 0.16 | 0.26 | 0.12 | 0.16 | 0.07 | X | X | X | X |

| R4 | 0.19 | 0.13 | 0.22 | 0.10 | 0.13 | 0.06 | X | X | X | X |

| R5 | 0.21 | 0.15 | 0.24 | 0.11 | 0.14 | 0.06 | X | X | X | X |

| Av | 0.20 | 0.14 | 0.23 | 0.11 | 0.13 | 0.06 | X | X | X | X |

| Std | 0.02 | 0.01 | 0.02 | 0.01 | 0.02 | 0.01 | X | X | X | X |

| 165.1 mm Wide 3rd Gen 1180 Samples | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Nakazima | Marciniak | |||||||||

| Repeat | Limit Strains | After NLSP Correction | After Pressure Correction | Limit Strains | After NLSP Correction | |||||

| ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | |

| R1 | X | X | X | X | X | X | 0.21 | 0.11 | 0.21 | 0.11 |

| R2 | X | X | X | X | X | X | 0.18 | 0.08 | 0.17 | 0.09 |

| R3 | X | X | X | X | X | X | 0.21 | 0.14 | 0.22 | 0.13 |

| Av | X | X | X | X | X | X | 0.20 | 0.11 | 0.20 | 0.11 |

| Std | X | X | X | X | X | X | 0.02 | 0.03 | 0.02 | 0.02 |

| 203.2 mm Wide 3rd Gen 1180 Specimens | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| - | Nakazima | Marciniak | ||||||||

| Repeat | Limit Strains | After NLSP Correction | After Pressure Correction | Limit Strains | After NLSP Correction | |||||

| - | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 | ε1 | ε2 |

| R1 | 0.23 | 0.20 | 0.25 | 0.18 | 0.15 | 0.11 | 0.25 | 0.21 | 0.25 | 0.20 |

| R2 | 0.23 | 0.21 | 0.25 | 0.19 | 0.15 | 0.11 | 0.22 | 0.18 | 0.24 | 0.17 |

| R3 | 0.28 | 0.27 | 0.24 | 0.17 | 0.14 | 0.10 | 0.25 | 0.22 | 0.28 | 0.20 |

| R4 | 0.24 | 0.23 | 0.28 | 0.20 | 0.17 | 0.12 | X | X | X | X |

| Av | 0.25 | 0.23 | 0.25 | 0.18 | 0.16 | 0.11 | 0.24 | 0.20 | 0.25 | 0.19 |

| Std | 0.02 | 0.03 | 0.02 | 0.01 | 0.01 | 0.01 | 0.01 | 0.02 | 0.02 | 0.02 |

References

- Muttana, S.B.; Mubashir, S. Lightweighting of Passenger Cars: A Comparative Lifecycle Analysis of Energy Consumption and CO2 Emissions; SAE Technical Paper 2013-26-0072; The Automotive Research Association of India: Pune, India, 2013. [Google Scholar] [CrossRef]

- Billur, E.; Dykeman, J.; Altan, T. Three generations of advanced high-strength steels for automotive applications, Part II. Stamp. J. 2014, 12–13. Available online: https://ercnsm.osu.edu/sites/ercnsm.osu.edu/files/uploads/S_FormingAHSS/664-2.pdf (accessed on 29 June 2020).

- Matlock, D.K.; Speer, J.G. Third Generation of AHSS: Microstructure Design Concepts. In Microstructure and Texture in Steel and Other Materials; Springer: London, UK, 2008; pp. 185–203. [Google Scholar]

- Davenport, M.D. Third Generation Advanced High-Strength Steel Emerges. Stamp. J. 2017, 22–28. Available online: https://www.thefabricator.com/stampingjournal/article/stamping/third-generation-advanced-high-strength-steel-emerges (accessed on 29 June 2020).

- Billur, E.; Altan, T. Three generations of advanced high-strength steels for automotive applications, Part III. Stamp. J. 2014, 12–13. Available online: https://ercnsm.osu.edu/sites/ercnsm.osu.edu/files/uploads/S_FormingAHSS/664-3.pdf (accessed on 29 June 2020).

- Volk, W.; Gaber, C. Investigation and compensation of biaxial pre-strain during the standard Nakajima- and Marciniak test using generalized forming limit concept. Procedia Eng. 2017, 207, 568–573. [Google Scholar] [CrossRef]

- Min, J.; Stoughton, T.B.; Carsley, J.; Lin, J. Comparison of DIC Methods of Determining Forming Limit Strain. Procedia Manuf. 2017, 7, 668–674. [Google Scholar] [CrossRef]

- Maciniak, Z.; Kuczynski, K. Limit Strains in the Process of Stretch-Forming Sheet Metal. Int. J. Mech. Sci. 1967, 9, 609–620. [Google Scholar] [CrossRef]

- Hora, P.; Tong, L.; Berisha, B. Modified maximum force criterion, a model for the theoretical prediction of forming limit curves. Int. J. Mater. Form. 2013, 6, 267–279. [Google Scholar] [CrossRef]

- Soare, S. Theoretical considerations upon the MK model for limit strains prediction: The plane strain case, strain-rate effects, yield surface influence and material heterogeneity. Eur. J. Mech. Solids 2010, 29, 938–950. [Google Scholar] [CrossRef]

- Nakazima, K.; Kikuma, T. Forming limits under biaxial stretching of sheet metals. Tetsu-to Hagane 1967, 53, 455–458. [Google Scholar]

- Ghosh, A.; Hecker, S. Stretching Limits in Sheet Metals: In-Plane Versus Out-of-Plane Deformation. Metall. Trans. 1974, 5, 2161–2164. [Google Scholar] [CrossRef]

- Ghosh, A.; Hecker, S. Failure in Thin Sheets Stretched Over Rigid Punches. Metall. Trans. A 1975, 6, 1065–1074. [Google Scholar] [CrossRef]

- International Organization for Standardization. Metallic Materials Sheet and Strip—Determination of Forming Limit Curves—Part 2: Determination of Forming Limit Curves in the Laboratory; ISO/DIC 12004-2:2008; International Organization for Standardization: Geneva, Switzerland, 2008. [Google Scholar]

- Marciniak, Z.; Kuczynski, K.; Pokora, T. Influence of the plastic properties of a material on the forming limit diagram for sheet metals in tension. Int. J. Mech. Sci. 1973, 15, 789. [Google Scholar] [CrossRef]

- Min, J.; Stoughton, T.B.; Carsley, J.E.; Carlson, B.E.; Lin, J.; Gao, X. Accurate characterization of biaxial stress-strain response of sheet metal from bulge testing. Int. J. Plast. 2016, 94, 192–213. [Google Scholar] [CrossRef]

- Butcher, C.; Khameneh, F.; Abedini, A.; Connolly, D.; Kurukuri, S. On the Experimental Characterization of Sheet Metal Formability and the Consistent Calibration of the MK Model for Biaxial Stretching in Plane Stress. Int. J. Mater. Process. Technol. 2020. accepted. [Google Scholar]

- Noder, J.; Butcher, C. A Comparative Investigation into the Influence of the Constitutive Model on the Prediction of In-Plane Formability. Int. J. Mech. Sci. 2019, 163, 105138. [Google Scholar] [CrossRef]

- Min, J.; Stoughton, T.B.; Carsley, J.; Lin, J. Compensation for process-dependent effects in the determination of localized necking limits. Int. J. Mech. Sci. 2016, 117, 115–134. [Google Scholar] [CrossRef]

- Rahmaan, T.; Abedini, A.; Butcher, C.; Pathak, N.; Worswick, M.J. Investigation into the shear stress, localization and fracture behaviour of DP600 and AA5182-O shee metal alloys under elevated strain rates. Int. J. Impact Eng. 2017, 108, 303–332. [Google Scholar] [CrossRef]

- Bressan, J.D.; Williams, J.A. The use of a shear instability criterion to predict local necking in sheet metal deformation. Int. J. Mech. Sci. 1983, 5, 155–168. [Google Scholar] [CrossRef]

- Peirs, J.; Verleysen, P.; Degrieck, J. Novel Technique for Static and Dynamic Shear Testing of Ti6Al4V Sheet. Exp. Mech. 2012, 52, 729–741. [Google Scholar] [CrossRef]

- Tian, H.; Brownell, B.; Baral, M.; Korkolis, Y.P. Earing in cup-drawing of anisotropic Al-6022-T4 sheets. Int. J. Mater. Form. 2017, 10, 329–343. [Google Scholar] [CrossRef]

- Considère, A. Mémoire sur L’Emploi du Fer et de L’Acier dans les Constructions. In Annales de Ponts et Chaussées; Commission des Annales des Ponts: Paris, French, 1885; Volume 9, pp. 574–775. [Google Scholar]

- Mohammadi, M.; Brahme, A.P.; Mishra, R.K.; Inal, K. Effects of post-necking hardening behavior and equivalent stress-strain curves on the accuracy of M-K based forming limit diagrams. Comput. Mater. Sci. 2014, 85, 316–323. [Google Scholar] [CrossRef]

- Abedini, A.; Noder, J.; Kohar, C.; Butcher, C. Accounting for shear anisotropy and material frame rotation on the constitutive characterization of automotive alloys using simple shear tests. Mech. Mater. 2020, 148, 103419. [Google Scholar] [CrossRef]

- Barlat, F. Crystallographic Texture, Anisotropic Yield Surfaces and Forming Limits of Sheet Metals. Mater. Sci. Eng. 1987, 91, 55–72. [Google Scholar] [CrossRef]

- Lian, J.; Barlat, F.; Baudelet, B. Plastic behavior and stretchability of sheet metals. Part II: Effect of yield surface shape on sheet forming limit. Int. J. Plast. 1989, 5, 131–147. [Google Scholar] [CrossRef]

- Barlat, F.; Brem, J.C.; Yoon, J.W.; Chung, K.; Dick, R.E.; Lege, D.J.; Pourboghrat, F.; Choi, S.-H.; Chu, E. Plane stress yield function for aluminum alloy sheets—part 1: Theory. Int. J. Plast. 2003, 19, 1297–1319. [Google Scholar] [CrossRef]

- Kuwabara, T.; Nakajima, T. Material modeling of 980 MPa Dual Phase Steel Sheet Based on Biaxial Tensile Test and In-plane Stress Reversal Test. J. Solid Mech. Mater. Eng. 2011, 5, 709–720. [Google Scholar] [CrossRef]

- Yoshida, F.; Hamasaki, H.; Uemori, T. A user-friendly 3D yield function to describe anisotropy of steel sheets. Int. J. Plast. 2013, 45, 119–139. [Google Scholar] [CrossRef]

- Smith, L.M.; Averill, R.C.; Lucas, J.P.; Stoughton, T.B.; Matin, P.H. Influence of transverse normal stress on sheet metal formability. Int. J. Plast. 2003, 19, 1567–1583. [Google Scholar] [CrossRef]

- Matin, P.H.; Smith, L.M. Practial limitations to the influence of through-thickness normal stress on sheet metal formability. Int. J. Plast. 2005, 21, 671–690. [Google Scholar] [CrossRef]

- Butuc, M.C. Forming Limit Diagrams: Definition of Plastic Instability Criteria. Ph.D. Thesis, Engineering Faculty of Porto University, Porto, Portugal, March 2004. [Google Scholar]

- Ratchev, P.; Van Houtte, P.; Verlinden, B.; De Smet, P.; Neutjens, P.; Baartman, R.; Drent, P. Prediction of forming limit diagrams of Al-Mg rolled sheets taking texture into account. Textures Microstruct. 1994, 22, 219–231. [Google Scholar] [CrossRef]

- Barlat, F.; Jalinier, J.M. Formability of sheet metal with heterogeneous damage. J. Mater. Sci. 1985, 20, 3385–3399. [Google Scholar] [CrossRef]

- Swift, H.W. Plastic instability under plane stress. J. Mech. Phys. Solids 1952, 1, 1–18. [Google Scholar] [CrossRef]

- Hill, R. On discontinuous plastic states, with special reference to localized necking in thin sheets. J. Mech. Phys. Solids 1952, 1, 19–30. [Google Scholar] [CrossRef]

- Alsos, H.S.; Hopperstad, O.S.; Törnqvist, R.; Jørgen, A. Analyrical and numerical analysis of sheet metal instability using a stress based criterion. Int. J. Solids Struct. 2008, 45, 2042–2055. [Google Scholar] [CrossRef]

- Hance, B.M.; Huang, L. A simplified stress-based forming limit criterion for advanced high strength steel (AHSS). IOP Conf. Ser. Mater. Sci. Eng. 2018, 418, 012037. [Google Scholar] [CrossRef]

- Chan, K.S.; Koss, D.A.; Ghosh, A.K. Localized Necking of Sheet at Negative Minor Strains. Metall. Trans. A 1984, 15, 323–329. [Google Scholar]

- Hutchinson, J.W.; Neale, K.W. Sheet Necking-III. Strain-rate effects. In Mechanics of Sheet Metal Forming; Koisteinen, D.P., Wang, N.-M., Eds.; Springer: Boston, MA, USA, 1978. [Google Scholar]

- Zhang, C.; Leotoing, L.; Guines, D.; Ragneau, E. Theoretical and numerical study of strain rate influence on AA5083 formability. J. Mater. Process. Technol. 2009, 209, 3849–3858. [Google Scholar] [CrossRef]

- Volk, W.; Hora, P. New algorithm for a robust user-independent evaluation of beginning instability for the experimental FLC determination. Int. J. Mater. Form. 2011, 4, 339–346. [Google Scholar] [CrossRef]

- Rahmaan, T. Low to High Strain Rate Characterization of DP600, TRIP780, AA5182-O. Master’s Thesis, University of Waterloo, Waterloo, ON, Canada, 2015. [Google Scholar]

| Grade | Sheet Thickness (mm) | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Uniform Elongation UE (%) | Total Elongation TE (%) | Surface Roughness Ra (µm) |

|---|---|---|---|---|---|---|

| 3rd Gen 980 | 1.39 (±0.02) | 681 (±8) | 1034 (±10) | 18.0 (±0.5) | 24.9 (±0.6) | 1.07 (±0.07) |

| 3rd Gen 1180 | 1.43 (±0.02) | 950 (±12) | 1251 (±8) | 8.4 (±0.2) | 14.1 (±0.6) | 1.08 (±0.08) |

| 3rd Gen 980 | σ0/σ0 | σ22.5/σ0 | σ45/σ0 | σ67.5/σ0 | σ90/σ0 | τ0/σ0 |

| 1.000 (±0.013) | 0.981 (±0.001) | 0.971 (±0.006) | 0.979 (±0.003) | 0.998 (±0.008) | 0.585 | |

| R0 | R22.5 | R45 | R67.5 | R90 | RB | |

| 0.86 (±0.01) | 0.86 (±0.01) | 0.93 (±0.01) | 0.91 (±0.01) | 0.90 (±0.00) | 1.00 (±0.05) | |

| 3rd Gen 1180 | σ0/σ0 | σ22.5/σ0 | σ45/σ0 | σ67.5/σ0 | σ90/σ0 | τ0/σ0 |

| 1.000 (±0.015) | 0.996 (±0.010) | 1.001 (±0.004) | 1.010 (±0.007) | 1.022 (±0.006) | 0.618 | |

| R0 | R22.5 | R45 | R67.5 | R90 | RB | |

| 0.76 (±0.01) | 0.83 (±0.00) | 0.93 (±0.00) | 0.90 (±0.02) | 0.90 (±0.01) | 0.92 (±0.03) |

| Steel | Modified Hockett-Sherby Model Parameters | |||||

|---|---|---|---|---|---|---|

| Grade | C1 (MPa) | C2 (MPa) | C3 | C4 | C5 (MPa) | Plastic Strain at Uniform Elongation |

| 3rd Gen 1180 RD | 1323.56 | 785.18 | 5.29 | 0.395 | 281.46 | 0.075 |

| 3rd Gen 980 RD | 985.73 | 664.79 | 20.34 | 1.103 | 634.69 | 0.158 |

| Steel | Barlat Yld2000 Calibration Coefficients | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Grade | |||||||||

| 3rd Gen 980 | 0.970 | 1.005 | 1.001 | 1.007 | 1.011 | 0.992 | 1.015 | 1.079 | 6 |

| 3rd Gen 1180 | 0.969 | 0.946 | 0.978 | 0.998 | 1.016 | 0.964 | 0.993 | 1.066 | 4.7 |

| Test Methodology | Sample Width (mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Nakazima experiments | 25.4 | 50.8 | 101.6 | 139.7 | 152.4 | 203.2 | |||

| (FLC0) | |||||||||

| Marciniak experiments | 25.4 | 50.8 | 76.2 | 127 | 165.1 | 203.2 | |||

| (FLC0) | |||||||||

| Carrier Blank Material for 3rd Gen 980 | |||||||||

| Carrier Blank Material for 3rd Gen 1180 | MS | MS | MS | ||||||

| Alloy | B1 (MPa) | B2 (MPa) | B3 (MPa) | B4 |

|---|---|---|---|---|

| AA5182-O, 1.55 mm thickness | 134.73 | 182.76 | 144.09 | 16.25 |

| Grade | C1 (MPa) | C2 (MPa) | C3 | C4 | C5 (MPa) |

|---|---|---|---|---|---|

| DP980, 1.2 mm thickness | 615.99 | 1092.54 | 11.54 | 0.50 | 333.25 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gutierrez, J.E.; Noder, J.; Butcher, C. Experimental Characterization and Deterministic Prediction of In-Plane Formability of 3rd Generation Advanced High Strength Steels. Metals 2020, 10, 902. https://doi.org/10.3390/met10070902

Gutierrez JE, Noder J, Butcher C. Experimental Characterization and Deterministic Prediction of In-Plane Formability of 3rd Generation Advanced High Strength Steels. Metals. 2020; 10(7):902. https://doi.org/10.3390/met10070902

Chicago/Turabian StyleGutierrez, Jon Edward, Jacqueline Noder, and Clifford Butcher. 2020. "Experimental Characterization and Deterministic Prediction of In-Plane Formability of 3rd Generation Advanced High Strength Steels" Metals 10, no. 7: 902. https://doi.org/10.3390/met10070902

APA StyleGutierrez, J. E., Noder, J., & Butcher, C. (2020). Experimental Characterization and Deterministic Prediction of In-Plane Formability of 3rd Generation Advanced High Strength Steels. Metals, 10(7), 902. https://doi.org/10.3390/met10070902