Effect of the Sputtering Power on the Structure, Morphology and Magnetic Properties of Fe Films

Abstract

1. Introduction

2. Experimental Methods

3. Results and Discussion

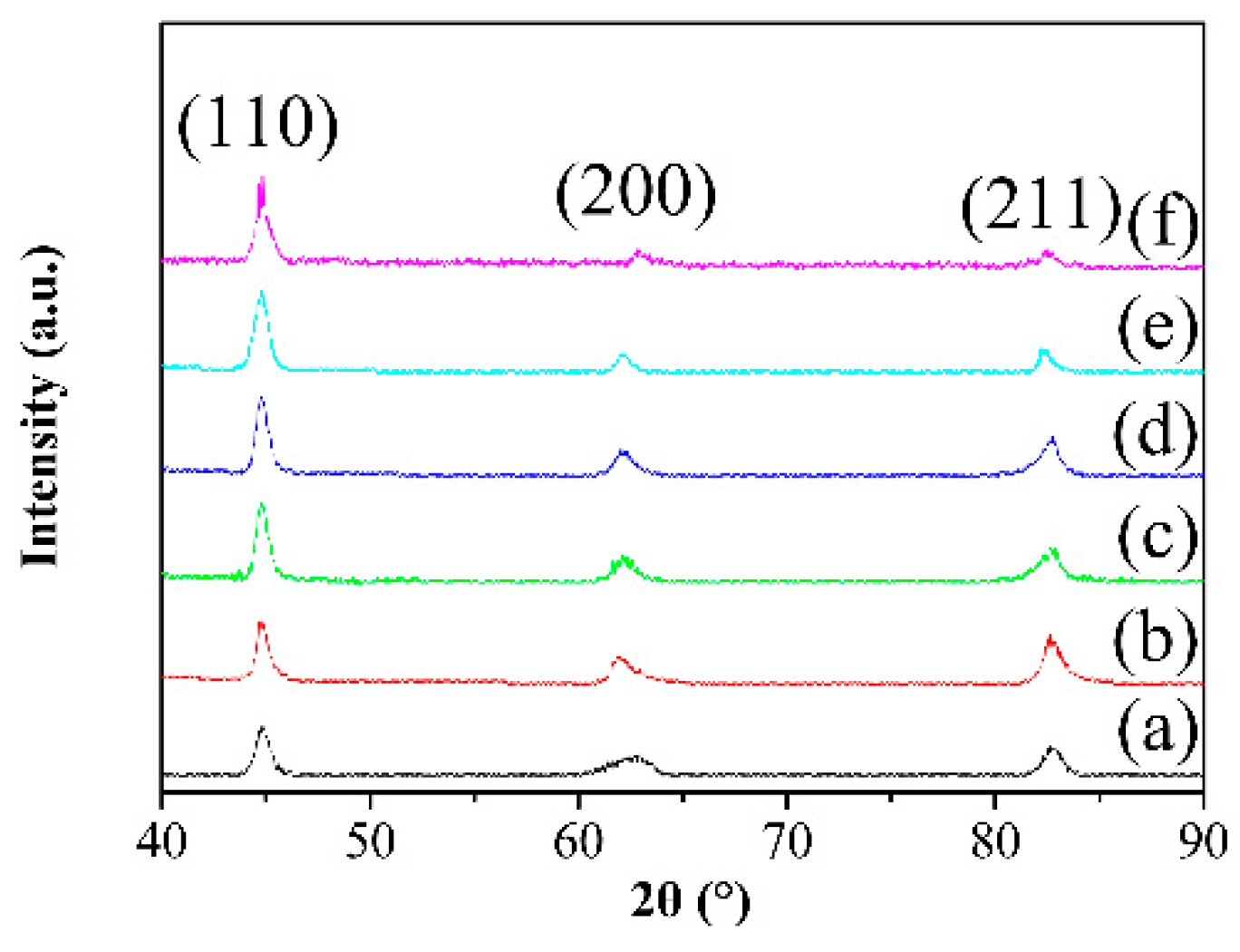

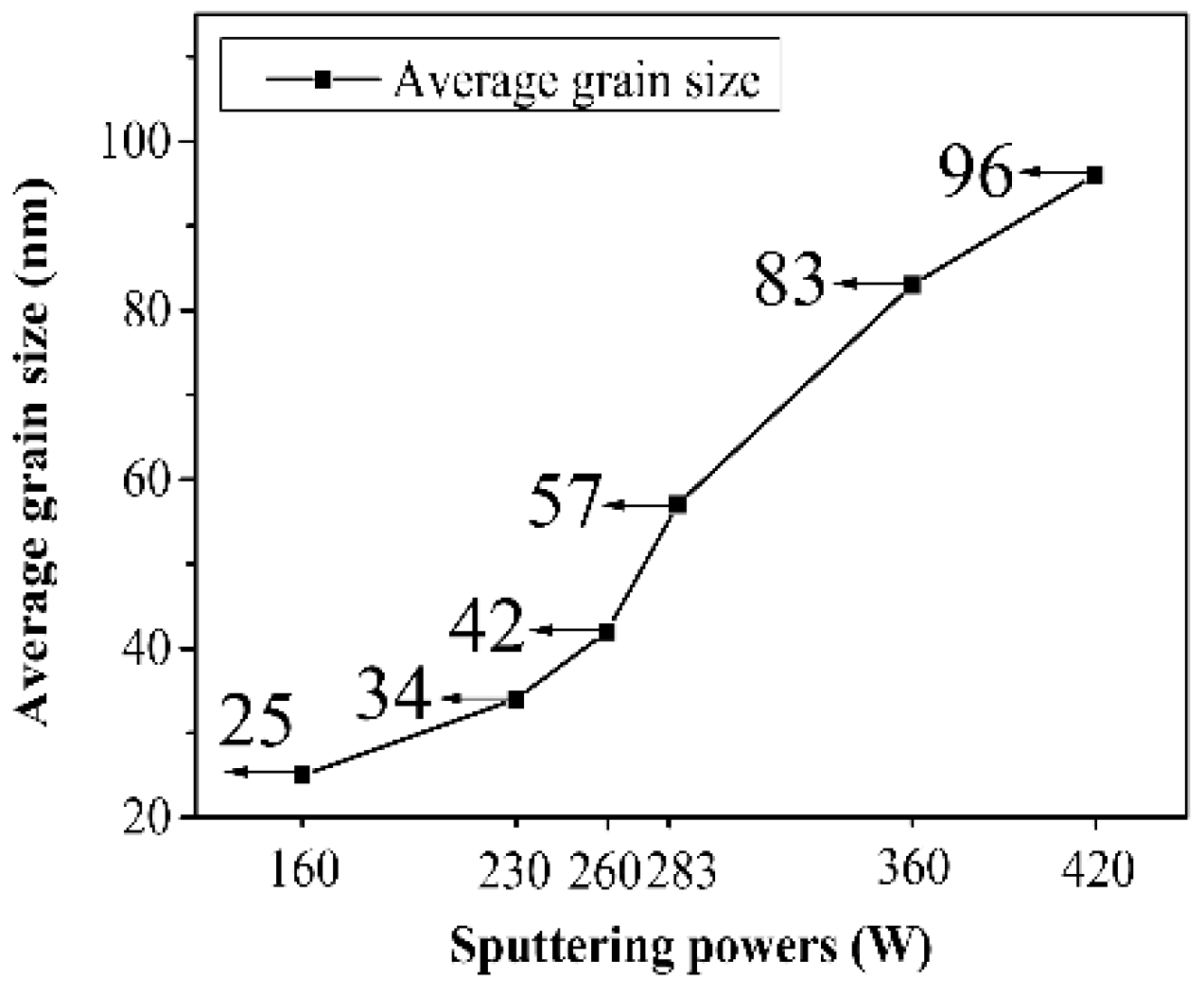

3.1. Crystal Structure

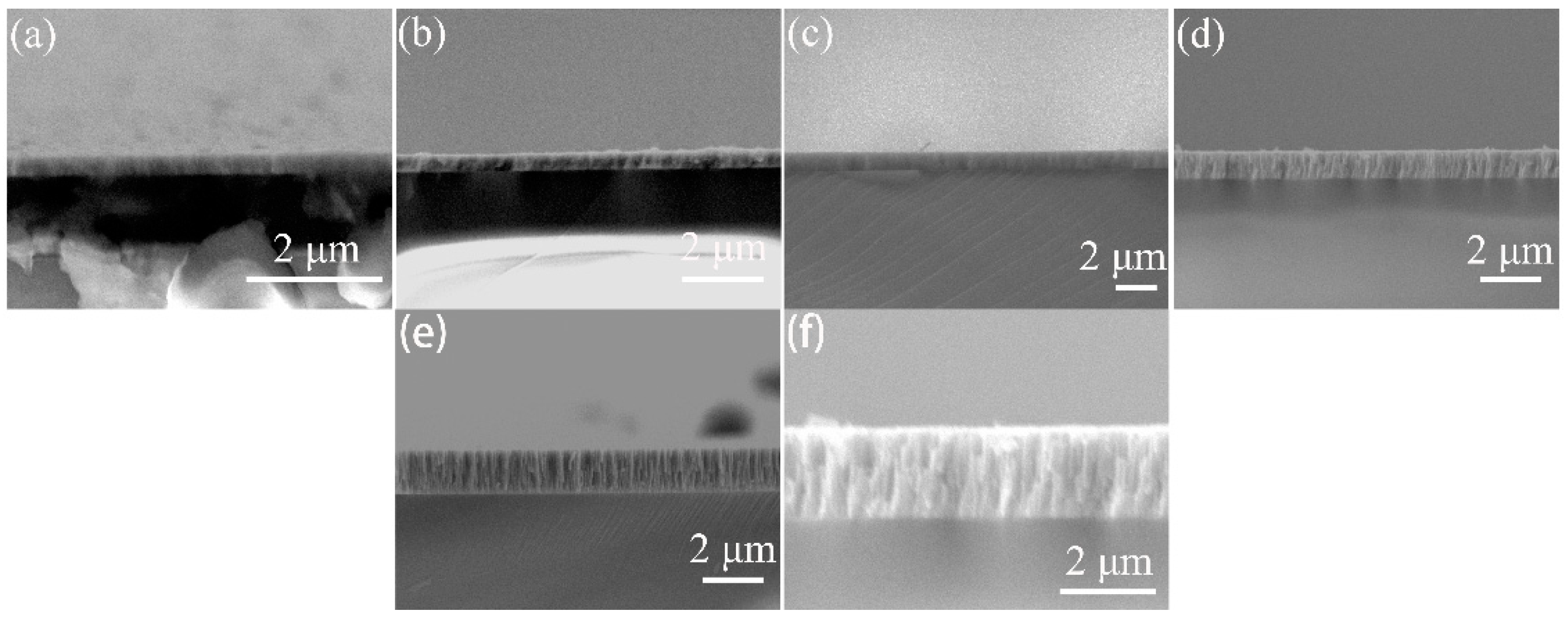

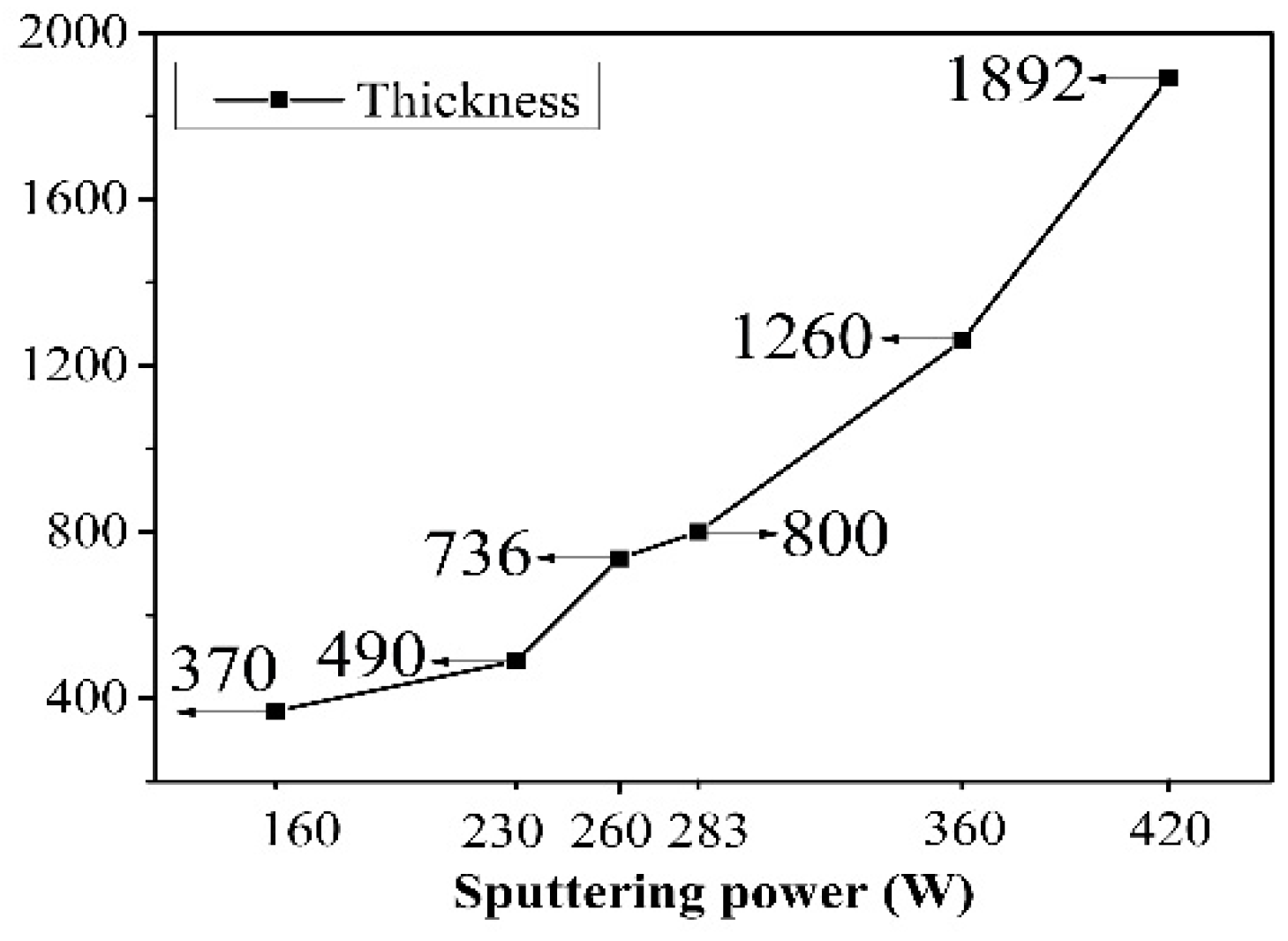

3.2. Cross-Sectional Morphology

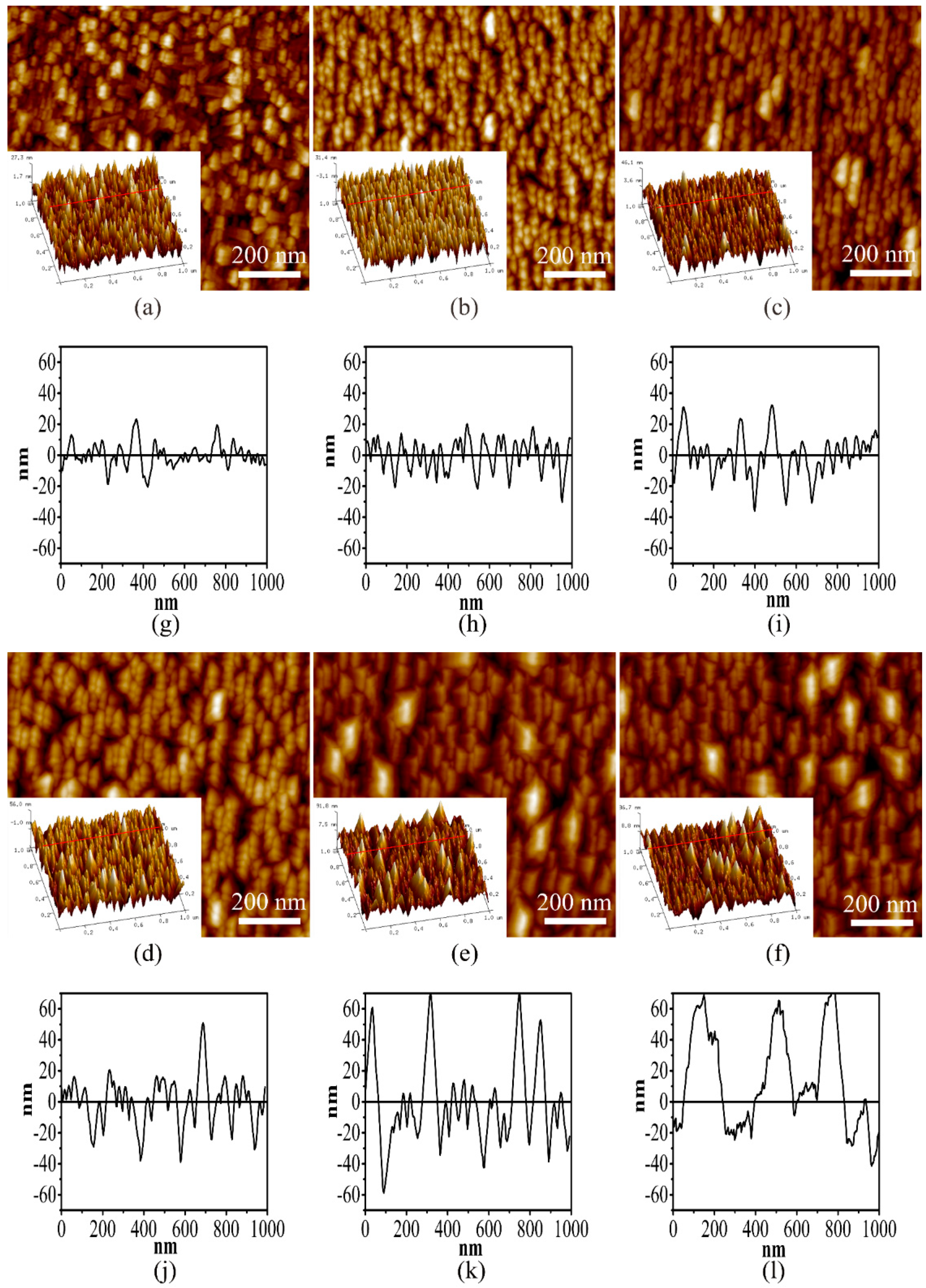

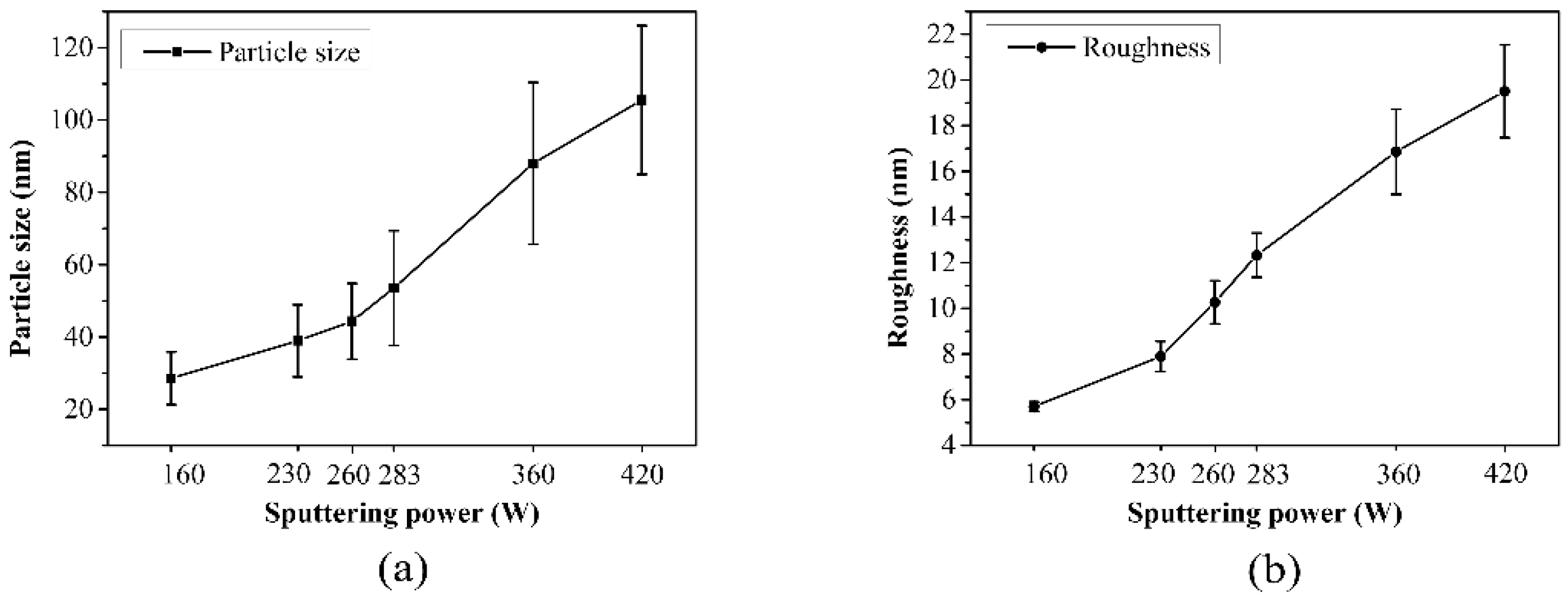

3.3. Surface Morphology

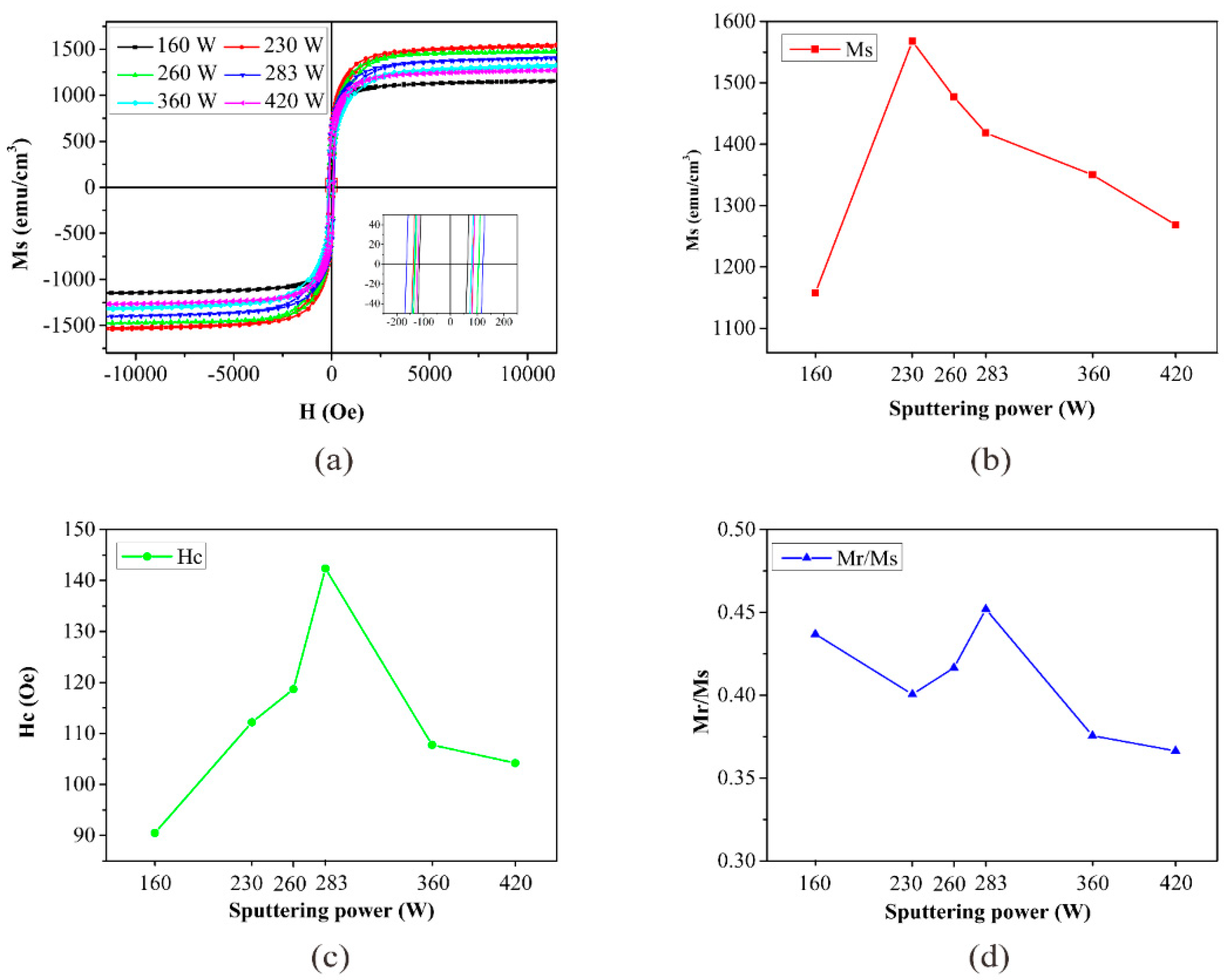

3.4. Magnetic Properties

4. Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Brajpuriya, R.; Tripathi, S.; Sharma, A.; Shripathi, T.; Chaudhari, S.M. Thickness dependent structural and magnetic properties of ultra-thin Fe/Al structures. Eur. Phys. J. B 2006, 51, 131–136. [Google Scholar] [CrossRef]

- Du, J.; Li, G.; Liu, S.; Liu, T.; Wu, C.; Wang, Q. Enhancement of magnetic properties by adjusted structure in Fe nanocrystalline films via annealing and applying high magnetic field at different film-formation stages. J. Magn. Magn. Mater. 2020, 495, 165857. [Google Scholar] [CrossRef]

- Feng, C.; Yin, J.; Niu, J.-G.; Zhang, Q.; Gu, L.; Yang, F.; Tang, X.; Xu, L.; Gong, K.; Cao, Y.; et al. Construction of FeN alloy films with ultra-strong magnetism and tunable magnetic anisotropy for spintronic application. J. Alloys Compd. 2017, 725, 32–40. [Google Scholar] [CrossRef]

- Zaman, S.S.; Dvořák, P.; Ritter, R.; Buchsbaum, A.; Stickler, D.; Oepen, H.P.; Schmid, M.; Varga, P. In-situ magnetic nano-patterning of Fe films grown on Cu(100). J. Appl. Phys. 2011, 110, 024309. [Google Scholar] [CrossRef]

- Muraca, D.; Cremaschi, V.; Moya, J.; Sirkin, H. FINEMET type alloy without Si: Structural and magnetic properties. J. Magn. Magn. Mater. 2008, 320, 1639–1644. [Google Scholar] [CrossRef]

- Liu, S.; Ma, Y.; Chang, L.; Li, G.; Wang, J.; Wang, Q. Effect of doping SiO2 and applying high magnetic field during the film growth on structure and magnetic properties of evaporated Fe films. Thin Solid Films 2018, 651, 1–6. [Google Scholar] [CrossRef]

- Du, J.; Li, G.; Wang, Q.; Ma, Y.; Cao, Y.; He, J. Microstructural evolution and magnetic properties of nanocrystalline Fe films prepared in a high magnetic field. Vacuum 2015, 121, 88–95. [Google Scholar] [CrossRef]

- Park, S.J.; Liu, C.-H.; Kim, H.S.; Park, N.J.; Jin, S.; Han, J.H. Texture and magnetic properties of Fe thin films fabricated by field-sputtering vs field-annealing. Thin Solid Films 2015, 594, 178–183. [Google Scholar] [CrossRef]

- Fan, J.; Sun, J.; Yang, Y.; Liang, R.; Jiang, Y.; Zhang, J.; Xu, X. Effect of nitrogen and cobalt additions on surface morphology and magnetic properties of Fe thin films. J. Alloys Compd. 2016, 662, 541–545. [Google Scholar] [CrossRef]

- Ahmad, S.S.; He, W.; Zhang, Y.-S.; Tang, J.; Li, Y.; Gul, Q.; Zhang, X.-Q.; Cheng, Z.-H. Effect of Ar+ beam sputtering on the magnetic anisotropy of Fe thin films deposited on the MgO(0 0 1) substrate. Results. Phys. 2017, 7, 1531–1535. [Google Scholar] [CrossRef]

- Papamihail, K.; Mergia, K.; Ott, F.; Serruys, Y.; Speliotis, T.; Apostolopoulos, G.; Messoloras, S. Fe+ ion irradiation induced changes in structural and magnetic properties of iron films. Nucl. Mater. Energy 2016, 9, 459–464. [Google Scholar] [CrossRef]

- He, S.H.; Zha, C.L.; Ma, B.; Zhang, Z.Z.; Jin, Q.Y. Formation of (002) texture in Fe films prepared by thermal treatment. J. Magn. Magn. Mater. 2007, 310, 2656–2658. [Google Scholar] [CrossRef]

- Sandu, S.G.; Palade, P.; Schinteie, G.; Birsan, A.; Trupina, L.; Kuncser, V. Tuning structural and magnetic properties of Fe films on Si substrates by hydrogenation processing. Mater. Sci. Eng. B 2014, 181, 24–32. [Google Scholar] [CrossRef]

- Serizawa, K.; Ohtake, M.; Kawai, T.; Futamoto, M.; Kirino, F.; Inaba, N. Influence of crystal orientation on the magnetostriction behavior of Fe films formed on MgO single-crystal substrates. J. Magn. Magn. Mater. 2019, 477, 420–426. [Google Scholar] [CrossRef]

- Gao, C.; Brandt, O.; Lähnemann, J.; Herfort, J.; Schönherr, H.-P.; Jahn, U.; Jenichen, B. Effect of growth temperature on the structural, morphological and magnetic properties of Fe films on GaN(0001). J. Cryst. Growth 2011, 323, 359–362. [Google Scholar] [CrossRef]

- Zhang, Y.-S.; He, W.; Ye, J.; Hu, B.; Tang, J.; Zhang, X.-Q.; Cheng, Z.-H. Temperature dependence of magnetic anisotropies in ultrathin Fe film on vicinal Si(111). Phys. B Condens. Matter 2017, 512, 32–38. [Google Scholar] [CrossRef]

- Javed, A.; Morley, N.A.; Gibbs, M.R.J. Effect of growth parameters on the structure and magnetic properties of thin polycrystalline Fe films fabricated on Si<100> substrates. Appl. Surf. Sci. 2011, 257, 5586–5590. [Google Scholar] [CrossRef]

- Getman, A.; Sivov, A.; Perov, N.S.; Iakubov, I.T.; Rozanov, K.N.; Ryzhikov, I.A.; Starostenko, S.N. Static and dynamic magnetic properties of Fe films. J. Magn. Magn. Mater. 2004, 272–276, E909–E910. [Google Scholar] [CrossRef]

- Bensehil, I.; Kharmouche, A.; Bourzami, A. Synthesis, Structural, and Magnetic Properties of Fe Thin Films. J. Supercond. Nov. Magn. 2016, 30, 795–799. [Google Scholar] [CrossRef]

- Sharma, A.; Tripathi, J.; Tripathi, S.; Ugochukwu, K.C. Investigation of magnetic and structural properties of Au capped Fe thin films. Phys. B Condens. Matter 2019, 560, 81–84. [Google Scholar] [CrossRef]

- Balashev, V.V.; Ermakov, K.S.; Chebotkevich, L.A.; Korobtsov, V.V. Electrical and Magnetic Properties of Ultrathin Polycrystalline Fe Films Grown on SiO2/Si(001). Tech. Phys. Lett. 2018, 44, 595–598. [Google Scholar] [CrossRef]

- Niu, Y.R.; Man, K.L.; Pavlovska, A.; Bauer, E.; Altman, M.S. Fe on W(001) from continuous films to nanoparticles: Growth and magnetic domain structure. Phy. Rev. B 2017, 95. [Google Scholar] [CrossRef]

- Gouralnik, A.S.; Galkin, N.G.; Ivanov, V.A.; Cherednichenko, A.I.; Plotnikov, V.S.; Pustovalov, E.V. Effect of deposition rate and a-Si precursor or cap layer on structure and magnetic properties of iron films on silicon substrates. Thin Solid Films 2011, 519, 8520–8523. [Google Scholar] [CrossRef]

- Kim, T.C.; Lee, S.H.; Jung, H.K.; Kim, Y.E.; Choi, J.W.; Yang, D.; Kim, D.H. Effect of sputtering conditions on the structure and magnetic properties of self-assembled BiFeO3-CoFe2O4 nanocomposite thin films. J. Magn. Magn. Mater. 2019, 471, 116–123. [Google Scholar] [CrossRef]

- Saravanan, L.; Raja, M.M.; Prabhu, D.; Therese, H.A. Influence of sputtering power on structural and magnetic properties of as-deposited, annealed and ERTA Co2FeSi films: A comparative study. Phys. B Condens. Matter 2018, 531, 180–184. [Google Scholar] [CrossRef]

- Wang, K.; Huang, Y.; Xu, Z.; Dong, S.; Chen, R. Effect of sputtering power on the magnetic properties of amorphous perpendicular TbFeCo films. J. Magn. Magn. Mater. 2017, 424, 89–92. [Google Scholar] [CrossRef]

- Basumatary, H.; Arout Chelvane, J.; Sridhara Rao, D.V.; Kamat, S.V.; Ranjan, R. Effect of sputtering parameters on the structure, microstructure and magnetic properties of Tb-Fe films. Thin Solid Films 2015, 583, 1–6. [Google Scholar] [CrossRef]

- Srinivas, K.; Manivel Raja, M.; Sridhara Rao, D.V.; Kamat, S.V. Effect of sputtering pressure and power on composition, surface roughness, microstructure and magnetic properties of as-deposited Co2FeSi thin films. Thin Solid Films 2014, 558, 349–355. [Google Scholar] [CrossRef]

- Chen, G.-J.; Jian, S.-R.; Jang, J.S.-C.; Shih, Y.-H.; Chen, Y.-T.; Jen, S.-U.; Juang, J.-Y. The effects of annealing temperature and sputtering power on the structure and magnetic properties of the Co-Fe-Zr-B thin films. Intermetallics 2012, 30, 127–131. [Google Scholar] [CrossRef]

- Meng, X.; Du, Y.; Gao, X. Face–centered cubic p–type NiO films room–temperature prepared via direct-current reactive magnetron sputtering–Influence of sputtering power on microstructure, optical and electrical behaviors. Phys. B Condens. Matter 2020, 579, 411897. [Google Scholar] [CrossRef]

- Lee, M.; Park, Y.; Kim, K.; Hong, J. Influence of sputtering conditions on the properties of aluminum-doped zinc oxide thin film fabricated using a facing target sputtering system. Thin Solid Films 2020, 703, 137980. [Google Scholar] [CrossRef]

- Simanjuntak, F.M.; Ohno, T.; Samukawa, S. Influence of rf sputter power on ZnO film characteristics for transparent memristor devices. AIP Adv. 2019, 9, 105216. [Google Scholar] [CrossRef]

- Ferdaous, M.T.; Shahahmadi, S.A.; Sapeli, M.M.I.; Chelvanathan, P.; Akhtaruzzaman, M.; Tiong, S.K.; Amin, N. Interplay between variable direct current sputtering deposition process parameters and properties of ZnO:Ga thin films. Thin Solid Films 2018, 660, 538–545. [Google Scholar] [CrossRef]

- Sakthivel, P.; Murugan, R.; Asaithambi, S.; Karuppaiah, M.; Vijayaprasath, G.; Rajendran, S.; Hayakawa, Y.; Ravi, G. Radio frequency power induced changes of structural, morphological, optical and electrical properties of sputtered cadmium oxide thin films. Thin Solid Films 2018, 654, 85–92. [Google Scholar] [CrossRef]

- Azevedo Neto, N.F.; Leite, D.M.G.; Lisboa-Filho, P.N.; da Silva, J.H.D. Role of the reactive sputtering deposition power in the phase control of cobalt oxide films. J. Vac. Sci. Technol. A 2018, 36, 061512. [Google Scholar] [CrossRef]

- Chelvanathan, P.; Shahahmadi, S.A.; Arith, F.; Sobayel, K.; Aktharuzzaman, M.; Sopian, K.; Alharbi, F.H.; Tabet, N.; Amin, N. Effects of RF magnetron sputtering deposition process parameters on the properties of molybdenum thin films. Thin Solid Films 2017, 638, 213–219. [Google Scholar] [CrossRef]

- Jen, S.U.; Tsai, T.L. Optimization of sputter deposition parameters for magnetostrictive Fe62Co19Ga19/Si(100) films. J. Appl. Phys. 2012, 111, 07A939. [Google Scholar] [CrossRef]

- Atkins, E. Elements of X-ray Diffraction. Phys. Today 1978, 10, 50. [Google Scholar] [CrossRef]

- Jhanwar, P.; Kumar, A.; Verma, S.; Rangra, K.J. Effect of Sputtering Power on the Growth of Ru films Deposited by Magnetron Sputtering. AIP Conf. Proc. 2016, 020073, 1–5. [Google Scholar] [CrossRef]

- De, R.; Haque, S.M.; Tripathi, S.; Prathap, C.; Rao, K.D.; Sahoo, N.K. Effect of sputtering power on MgF2 thin films deposited by sputtering technique under fluorine trapping. AIP Conf. Proc. 2016, 080078, 1–3. [Google Scholar] [CrossRef]

- Xiao, W.; Deng, H.; Zou, S.; Ren, Y.; Tang, D.; Lei, M.; Xiao, C.; Zhou, X.; Chen, Y. Effect of roughness of substrate and sputtering power on the properties of TiN coatings deposited by magnetron sputtering for ATF. J. Nucl. Mater. 2018, 509, 542–549. [Google Scholar] [CrossRef]

- Gao, C.; Brandt, O.; Schönherr, H.-P.; Jahn, U.; Herfort, J.; Jenichen, B. Thermal stability of epitaxial Fe films on GaN(0001). Appl. Phys. Lett. 2009, 111906, 1–3. [Google Scholar] [CrossRef]

- Kodam, U.; K.B., A.B.; Markandeyulu, G. In house designed magnetron sputtering source: Effect of power and annealing on structural, optical and magnetic properties of NiFe2−xLuxO4 (x = 0, 0.075) thin films. Thin Solid Films 2018, 662, 180–186. [Google Scholar] [CrossRef]

| Samples | Methods | Ms (emu/cm3) | Hc (Oe) | Mr/Ms | References |

|---|---|---|---|---|---|

| 160 W | RF magnetron sputtering | 1157 | 90 | 0.437 | This research |

| 230 W | 1566 | 112 | 0.401 | ||

| 260 W | 1477 | 119 | 0.417 | ||

| 283 W | 1418 | 142 | 0.446 | ||

| 360 W | 1350 | 108 | 0.376 | ||

| 420 W | 1268 | 104 | 0.363 | ||

| RT 0 T | Thermal evaporation | 1213 | 58 | - | Ref [7] |

| 0 T | Molecular beam vapor deposition | 1491 | - | 0.54 | Ref [2] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, C.; Li, T.; Wei, X.; Yan, B. Effect of the Sputtering Power on the Structure, Morphology and Magnetic Properties of Fe Films. Metals 2020, 10, 896. https://doi.org/10.3390/met10070896

Zhou C, Li T, Wei X, Yan B. Effect of the Sputtering Power on the Structure, Morphology and Magnetic Properties of Fe Films. Metals. 2020; 10(7):896. https://doi.org/10.3390/met10070896

Chicago/Turabian StyleZhou, Chunxia, Tongkui Li, Xianshun Wei, and Biao Yan. 2020. "Effect of the Sputtering Power on the Structure, Morphology and Magnetic Properties of Fe Films" Metals 10, no. 7: 896. https://doi.org/10.3390/met10070896

APA StyleZhou, C., Li, T., Wei, X., & Yan, B. (2020). Effect of the Sputtering Power on the Structure, Morphology and Magnetic Properties of Fe Films. Metals, 10(7), 896. https://doi.org/10.3390/met10070896