Investigation and Optimization of Load Distribution for Tandem Cold Steel Strip Rolling Process

Abstract

1. Introduction

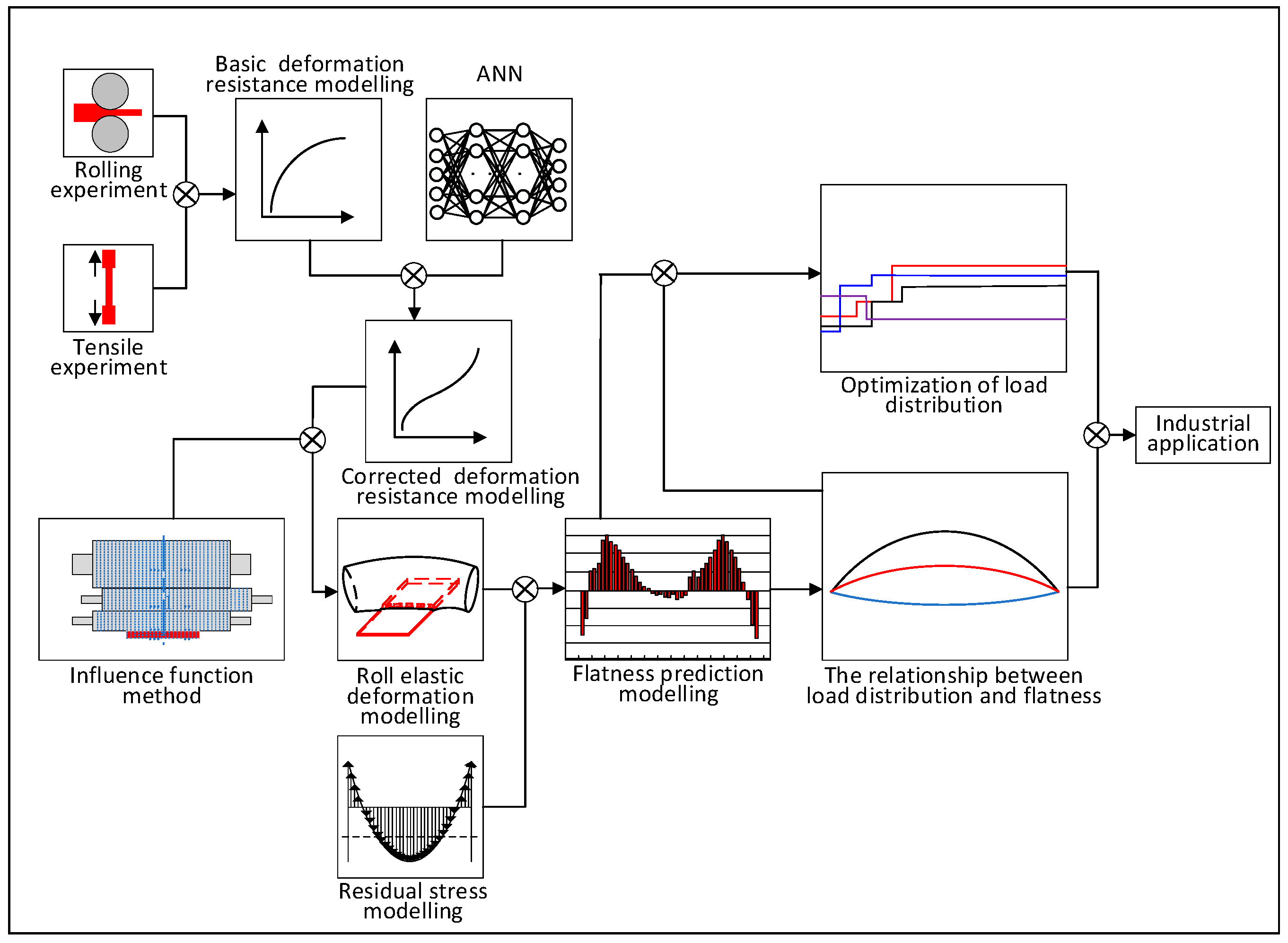

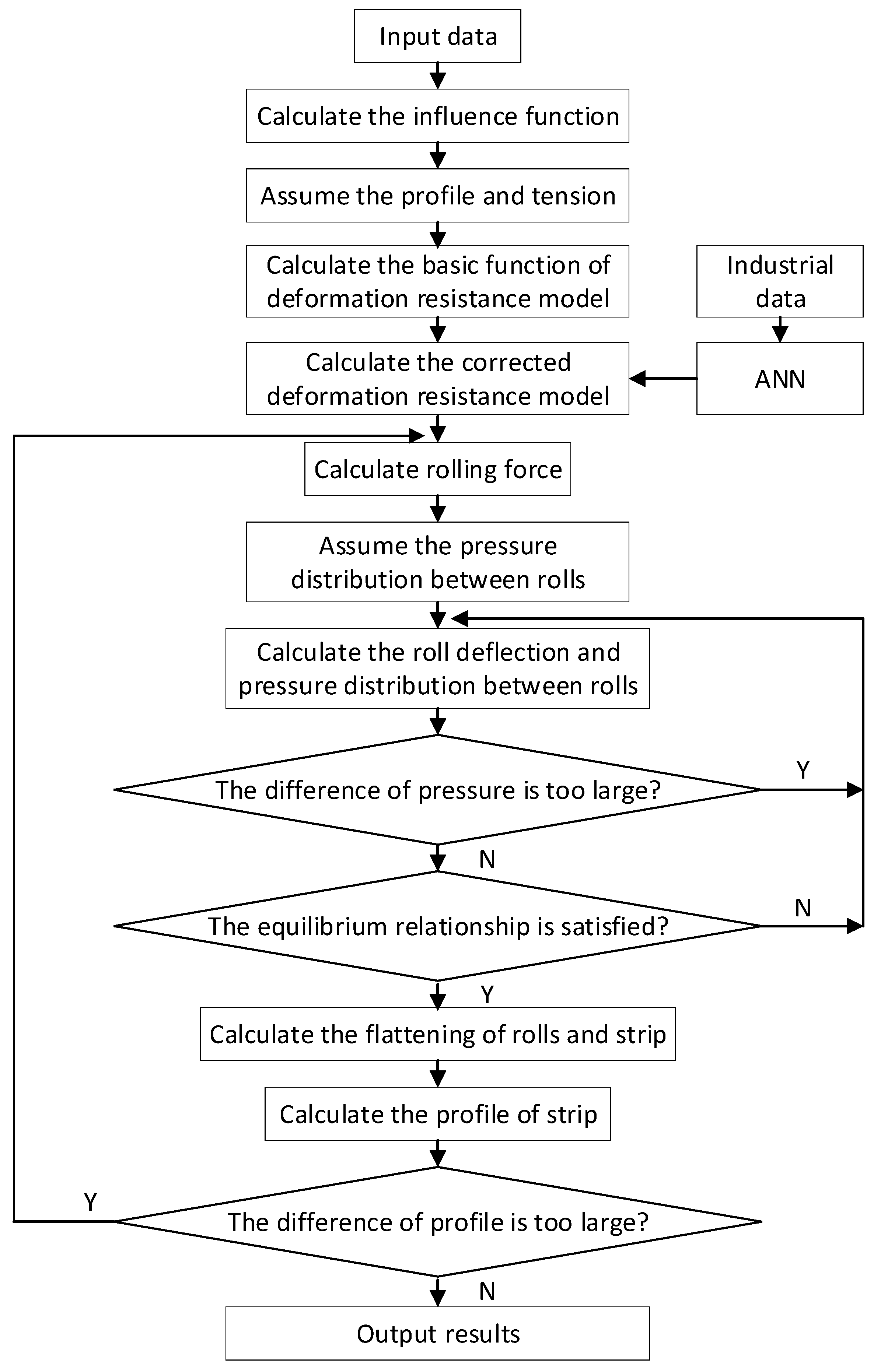

2. Modeling of Flatness Prediction for Tandem Cold Rolling

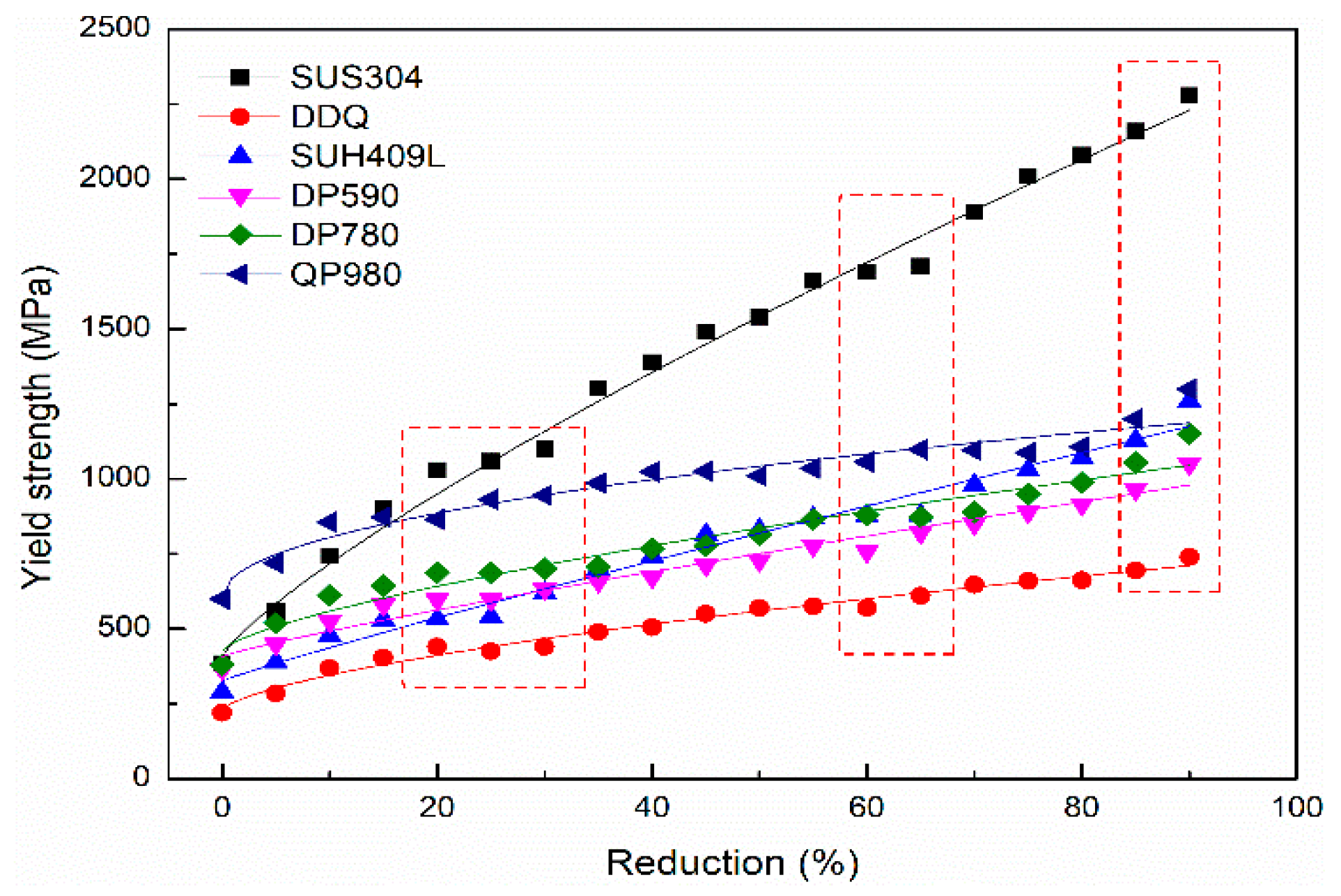

2.1. Modeling of Deformation Resistance of Cold-Rolled Steel

2.1.1. Basic Function of Deformation Resistance Model

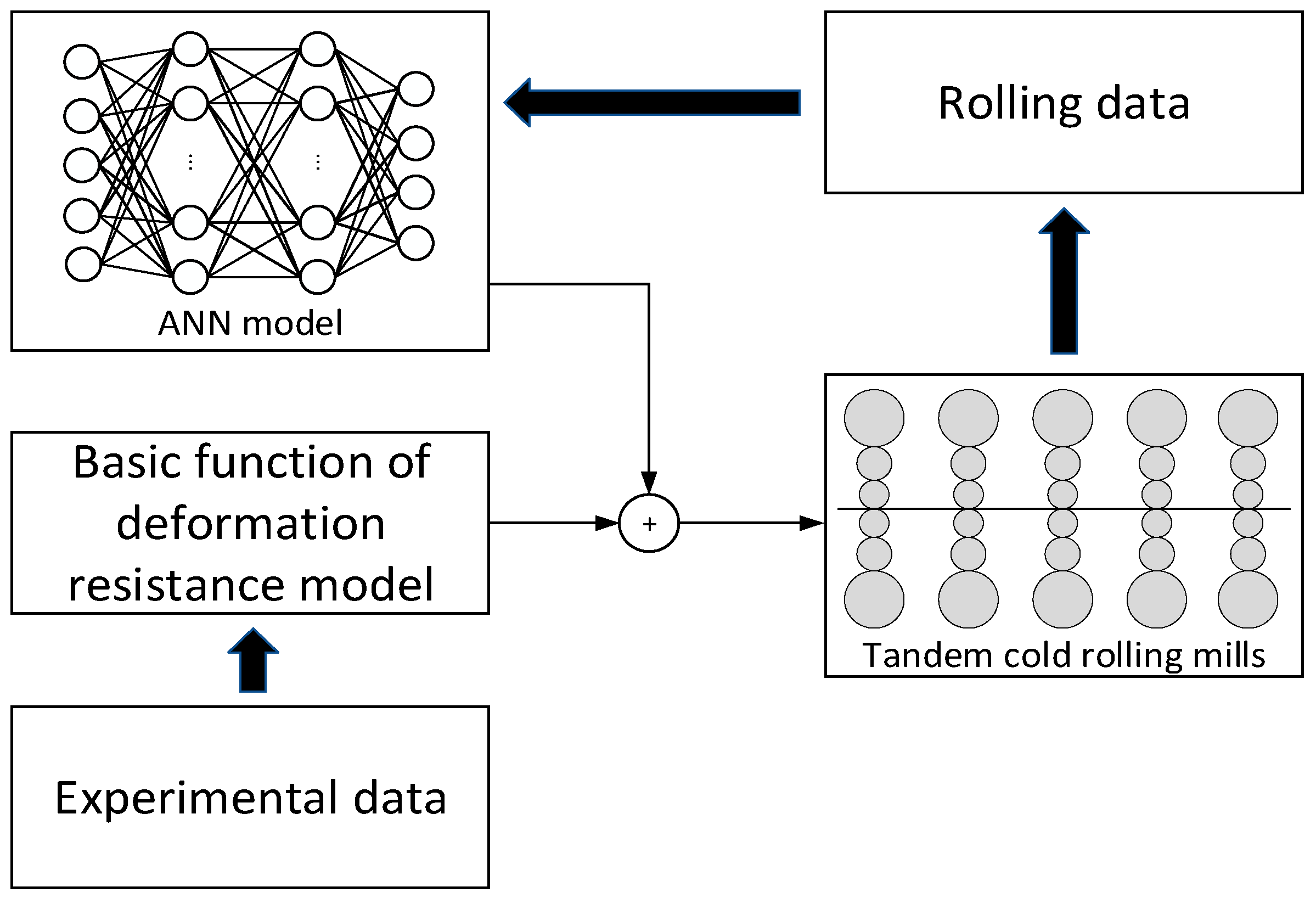

2.1.2. Correction of Deformation Resistance by Artificial Neural Network

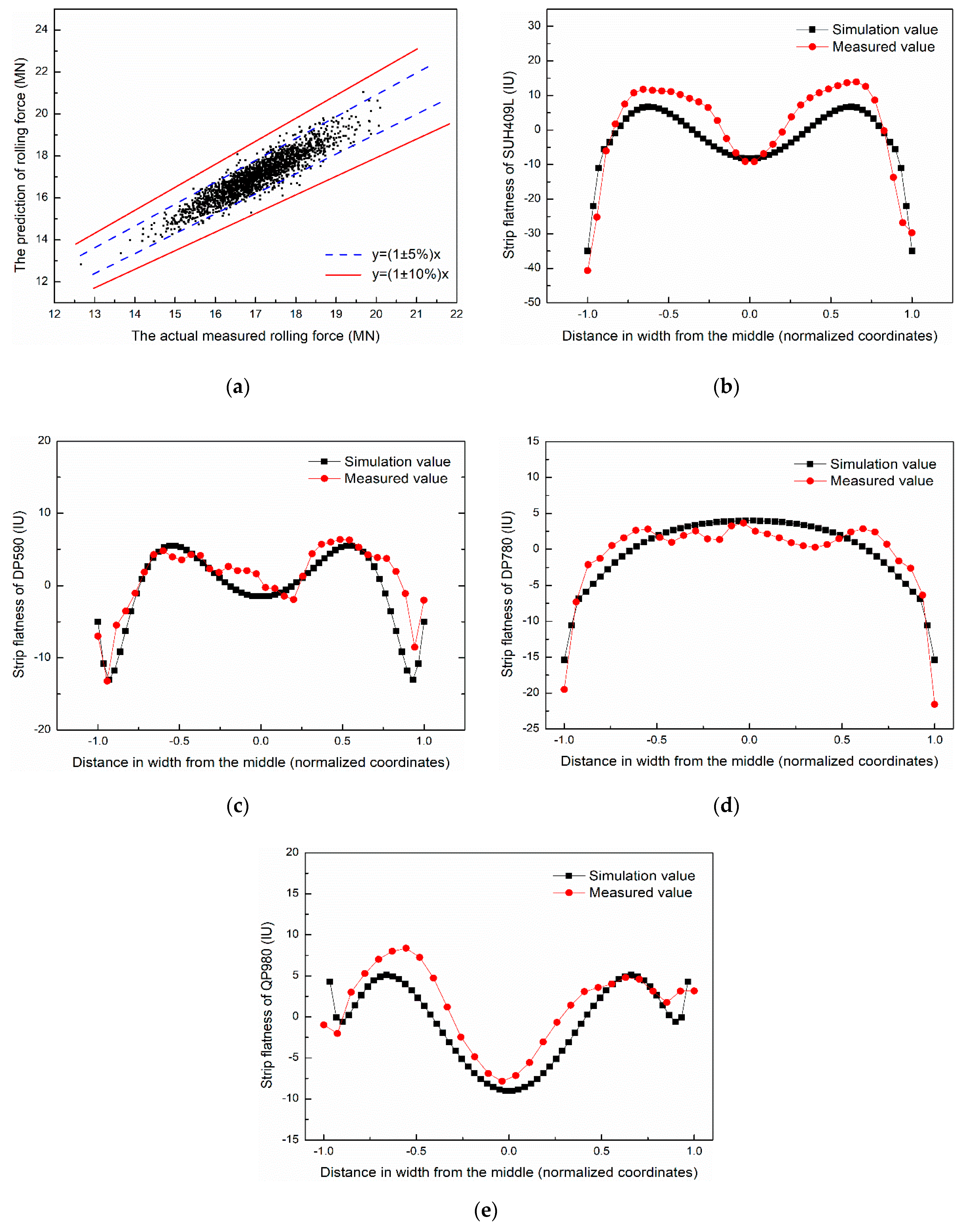

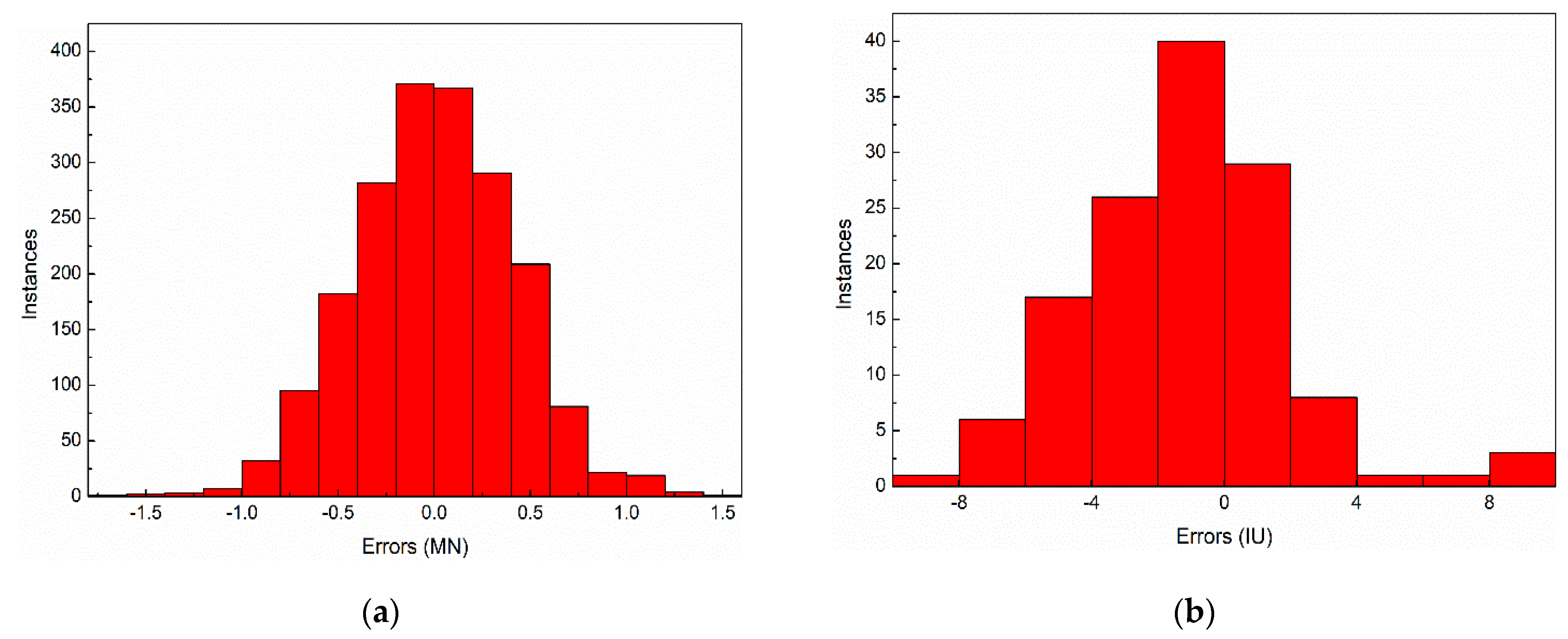

2.1.3. Evaluation of Proposed Deformation Resistance Model

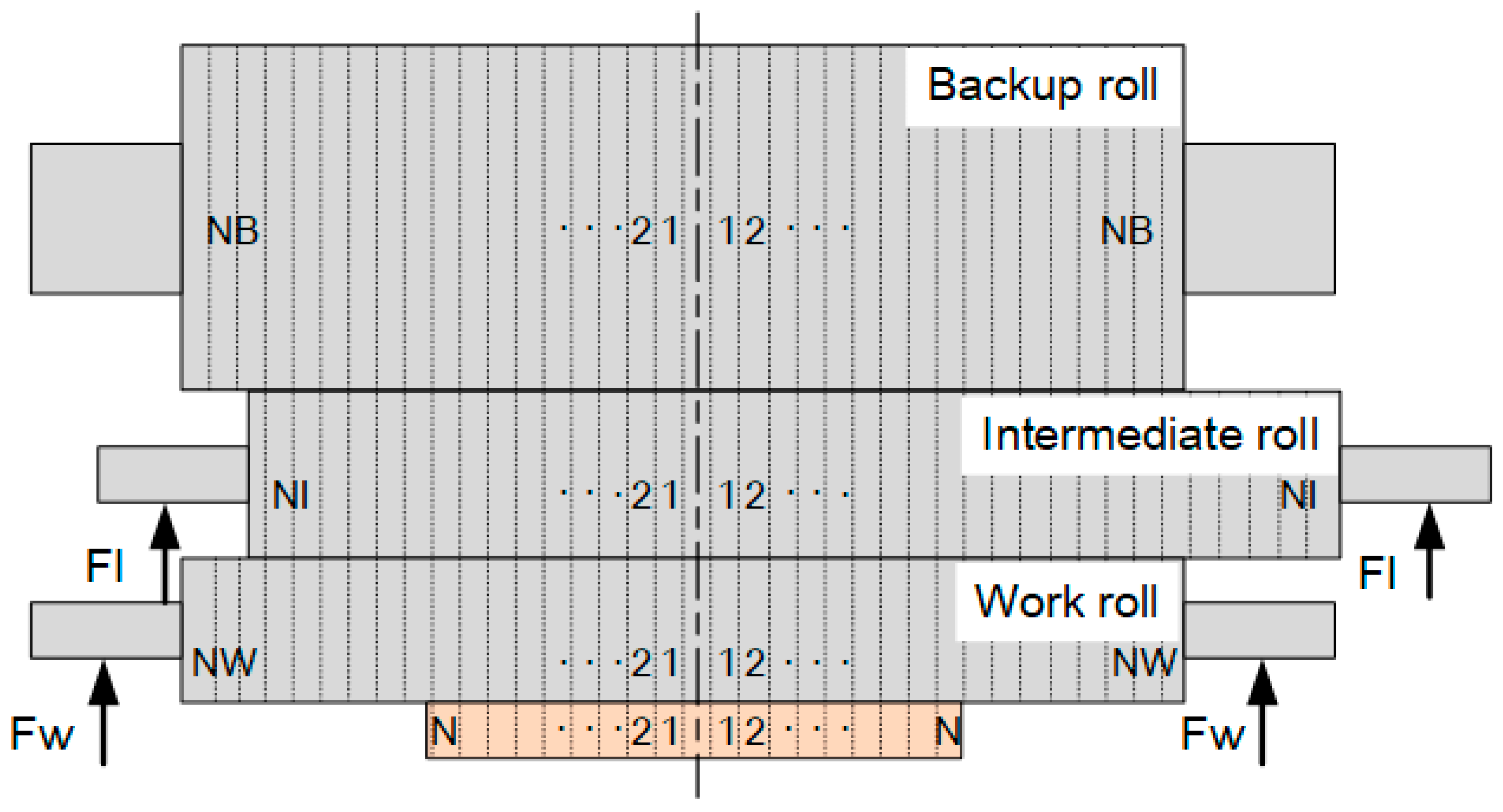

2.2. Modeling of Rolls Elastic Deformation

2.3. Modeling of Residual Stress of Strip after Rolling

2.4. Verification of the Flatness Prediction Model

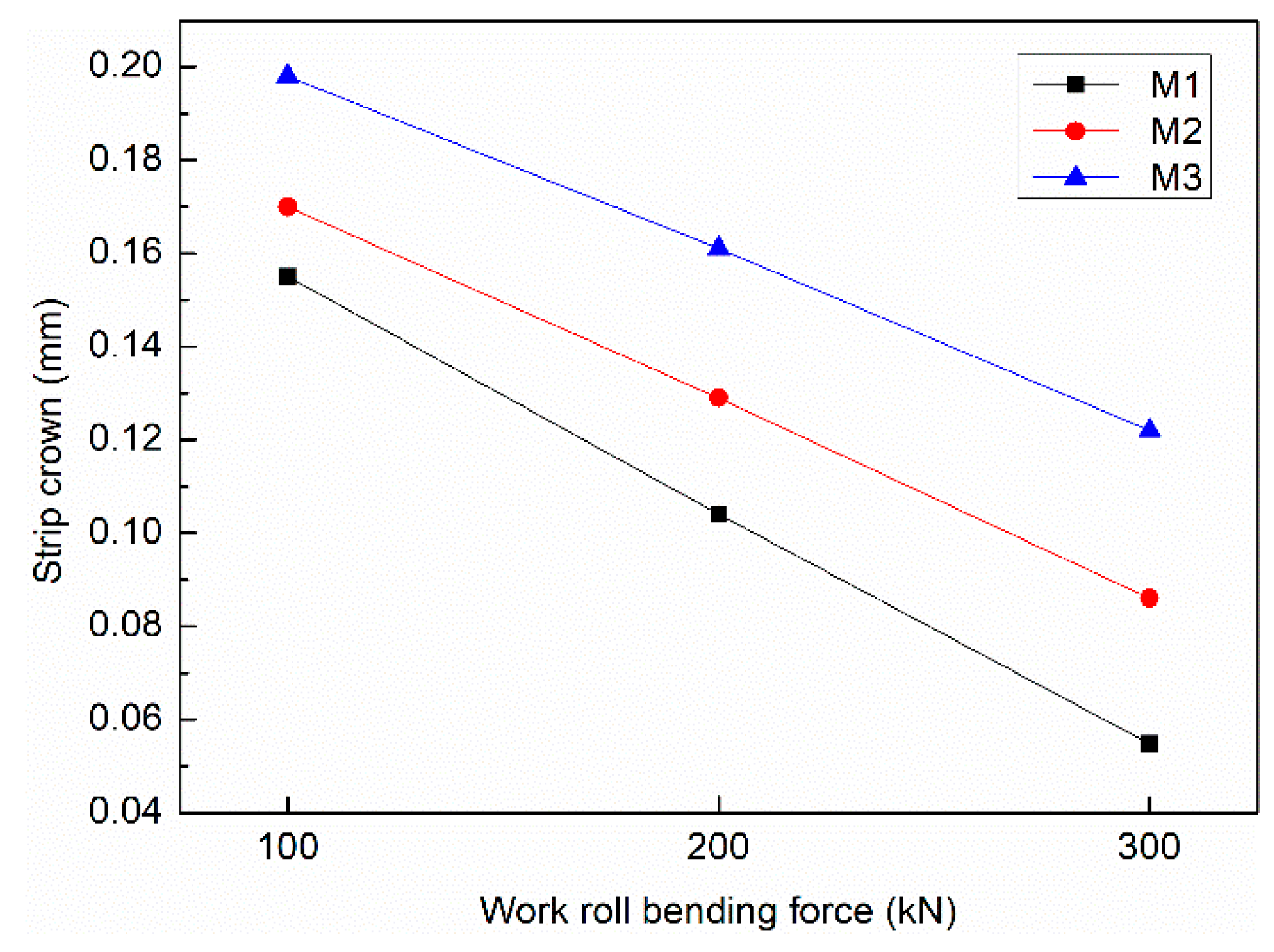

3. Influence of Load Distribution on Flatness

4. Optimization of Load Distribution by Genetic Algorithm

4.1. Fitness Function

4.2. Constraint Conditions

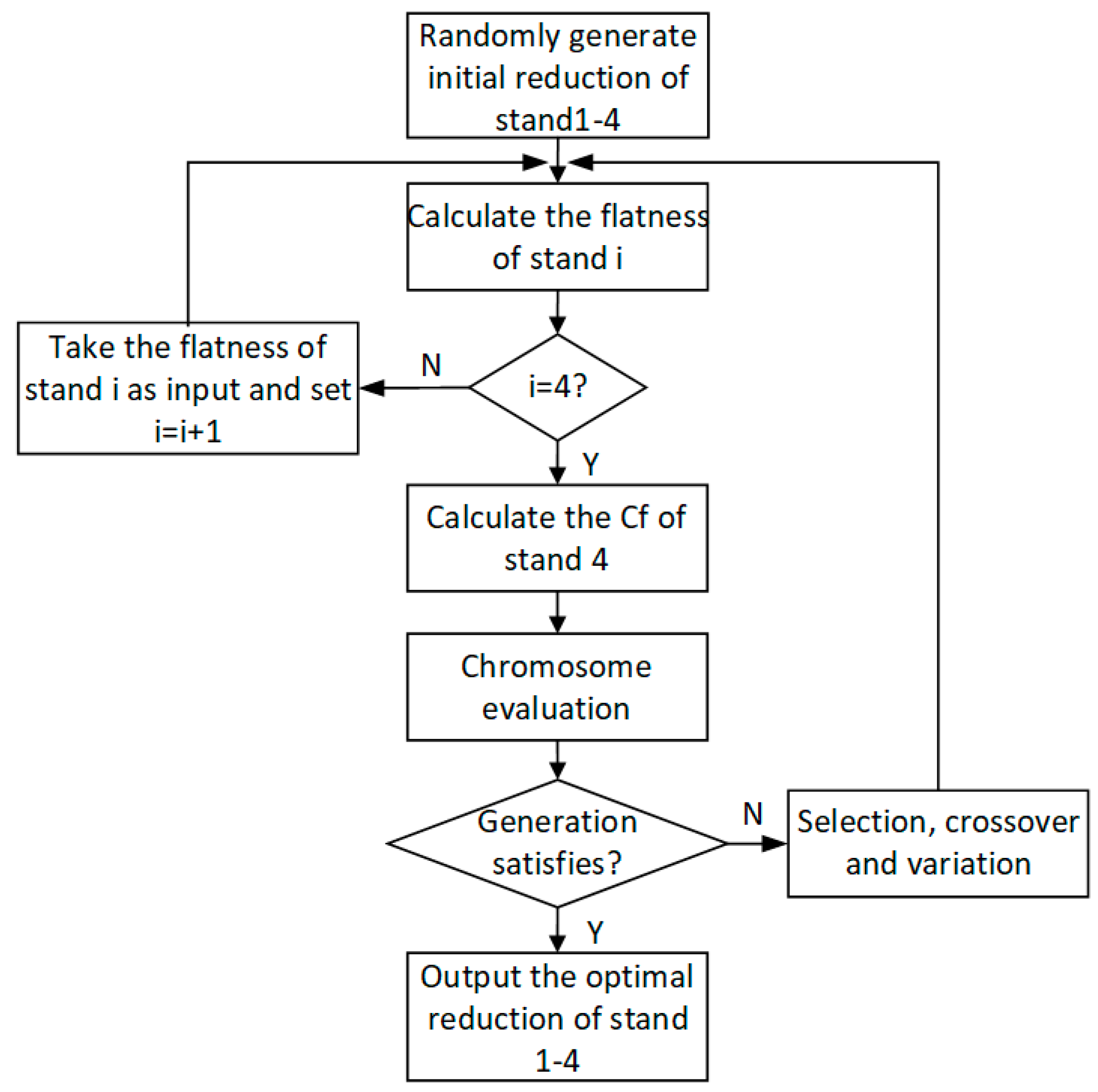

4.3. Load Distribution Optimization Procedure

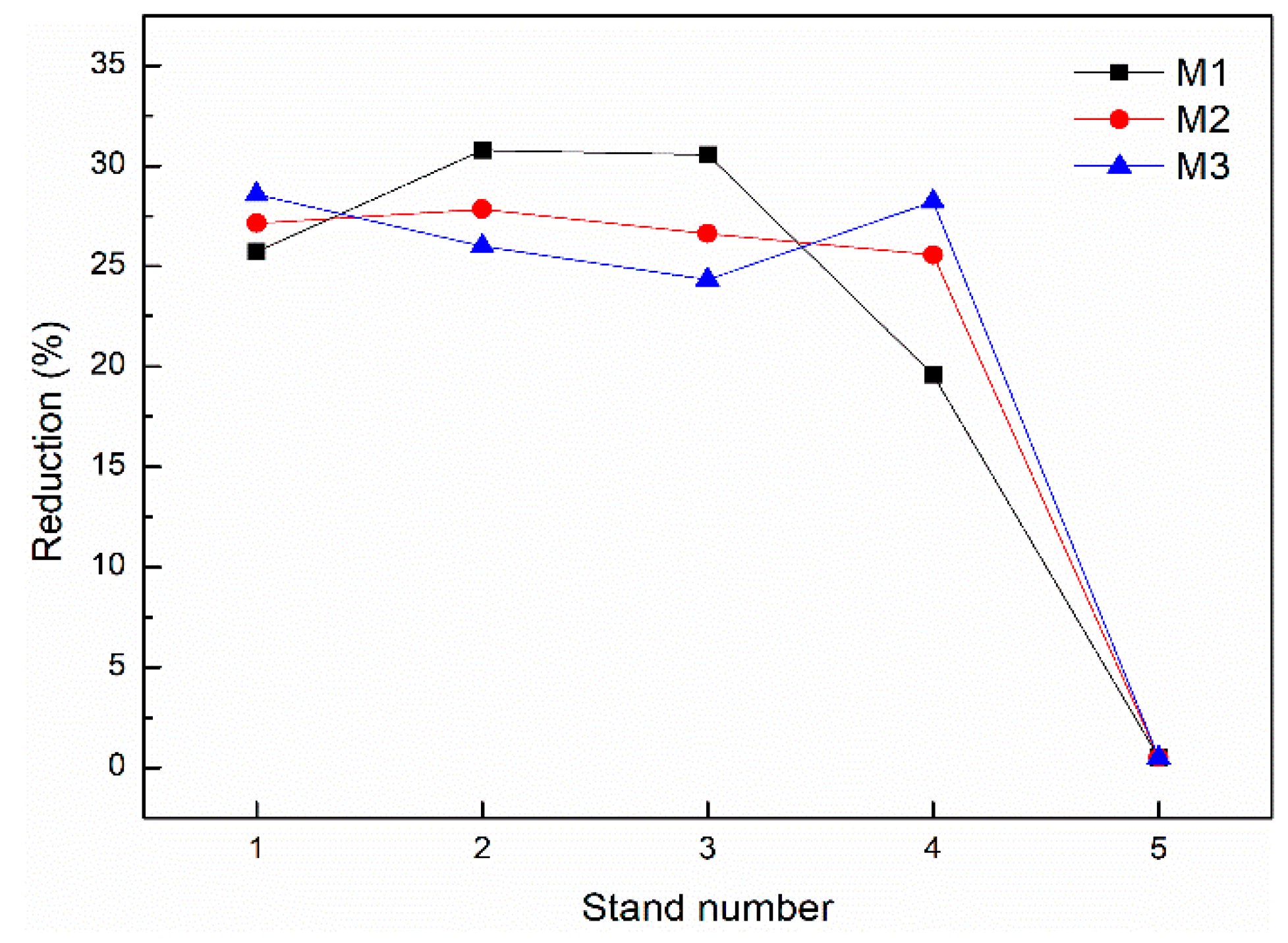

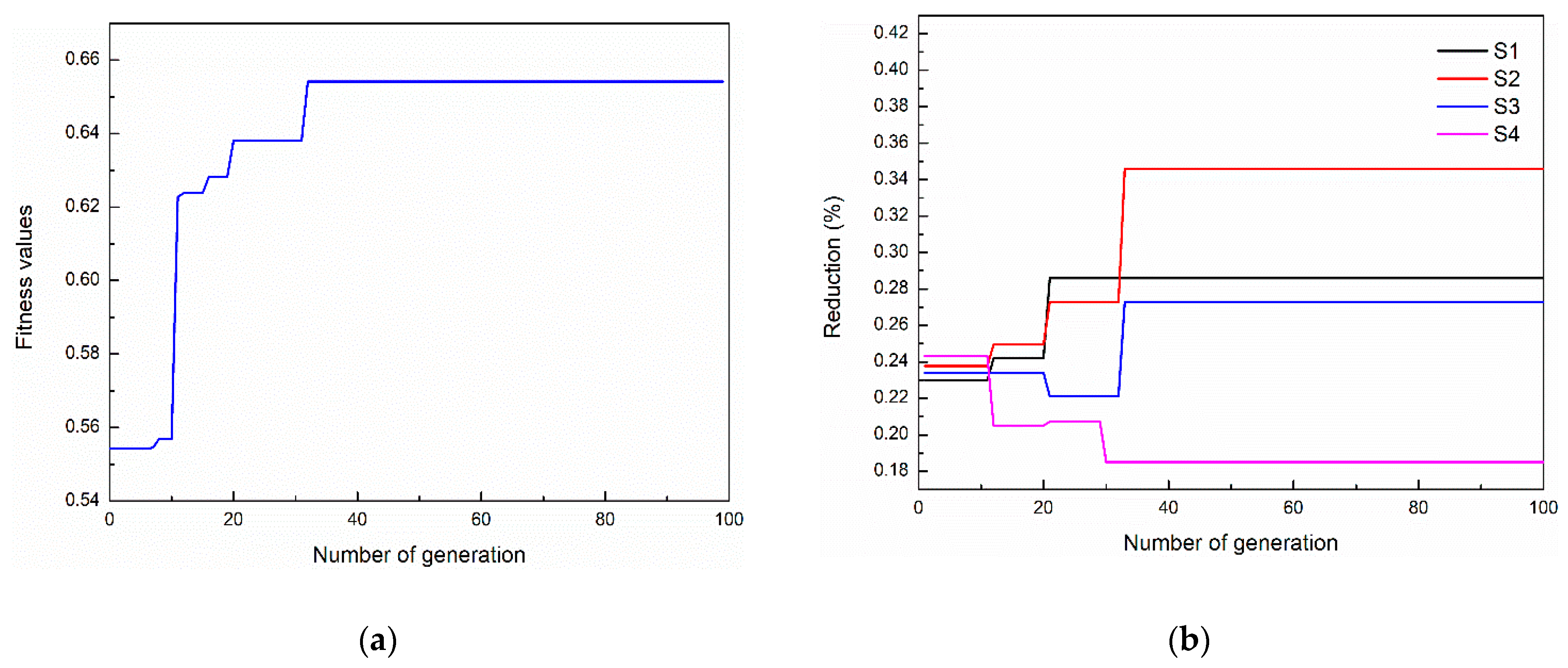

4.4. Optimization Results

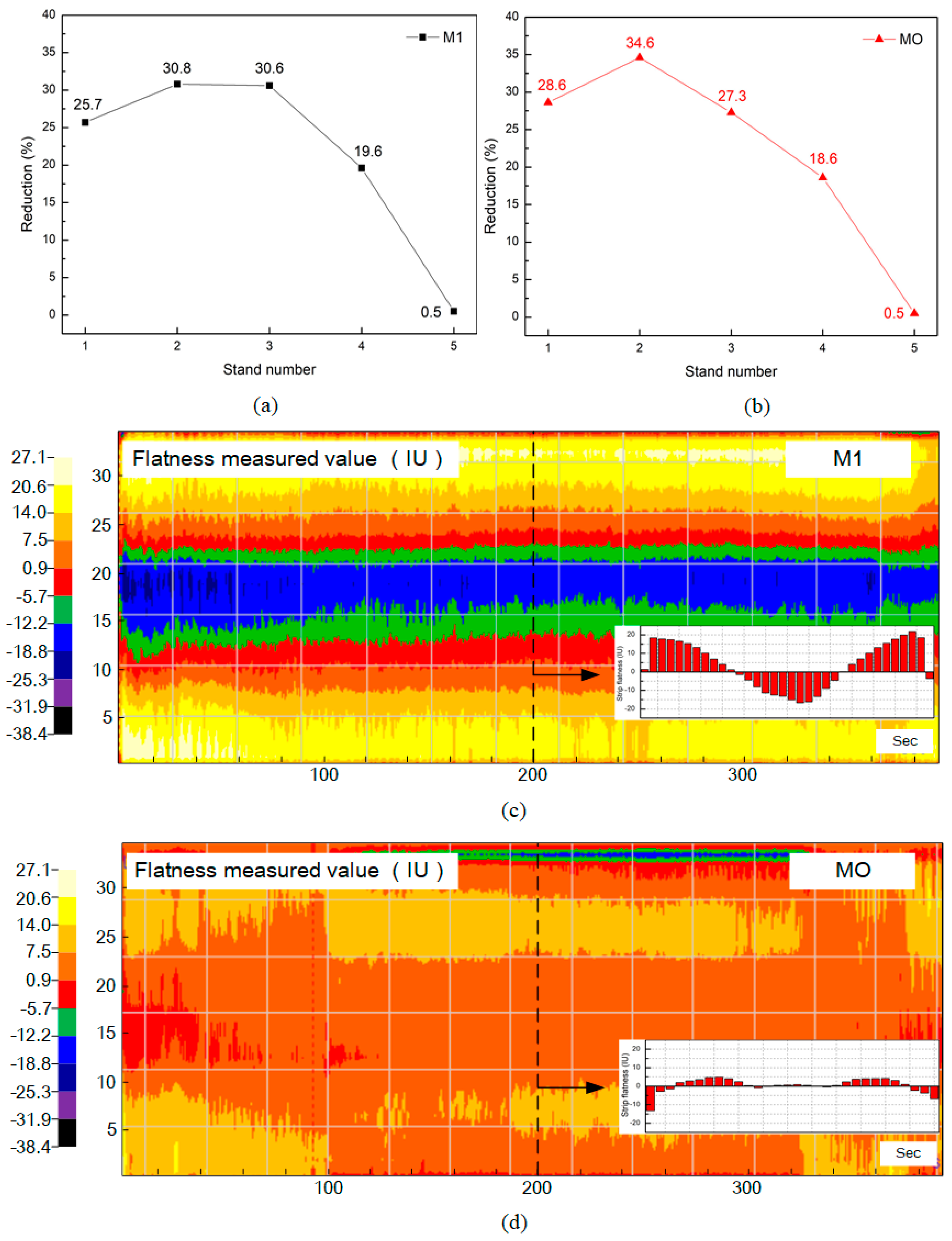

5. Industrial Application

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hu, Z.; Yang, J.; Zhao, Z.; Sun, H.; Che, H. Multi-objective optimization of rolling schedules on aluminum hot tandem rolling. Int. J. Adv. Manuf. Technol. 2016, 85, 85–97. [Google Scholar] [CrossRef]

- Pires, C.; Ferreira, H.; Sales, R.; Silva, M. Set-up optimization for tandem cold mills: A case study. J. Mater. Process. Technol. 2006, 173, 368–375. [Google Scholar] [CrossRef]

- Reddy, N.; Suryanarayana, G. A set-up model for tandem cold rolling mills. J. Mater. Process. Technol. 2001, 116, 269–277. [Google Scholar] [CrossRef]

- Cao, J.; Chai, X.; Li, Y.; Kong, N.; Jia, S.; Zeng, W. Integrated design of roll contours for strip edge drop and crown control in tandem cold rolling mills. J. Mater. Process. Technol. 2018, 252, 432–439. [Google Scholar] [CrossRef]

- Peng, P.; Yang, Q. Generalized shape and gauge decoupling load distribution optimization based on IGA for tandem cold mill. J. Iron Steel Res. Int. 2009, 16, 30–34. [Google Scholar] [CrossRef]

- Che, H.; Han, X.; Yang, J.; Li, L. Optimization of Schedule with Multi-Objective for Tandem Cold Rolling Mill Based on IAGA. In Proceedings of the 2010 International Conference on Mechanic Automation and Control Engineering, Wuhan, China, 26–28 June 2010. [Google Scholar]

- Jia, S.; Li, W.; Liu, X.; Du, B. Multi-objective load distribution optimization for hot strip mills. J. Iron Steel Res. Int. 2013, 20, 27–32. [Google Scholar] [CrossRef]

- Li, W.; Liu, X.; Guo, Z. Multi-objective optimization for draft scheduling of hot strip mill. J. Cent. South. Univ. 2012, 19, 3069–3078. [Google Scholar] [CrossRef]

- Li, Y.; Fang, L. Robust multi-objective optimization of rolling schedule for tandem cold rolling based on evolutionary direction differential evolution algorithm. J. Iron Steel Res. Int. 2017, 24, 795–802. [Google Scholar] [CrossRef]

- Dzubinsky, M.; Kovac, F.; Petercakova, A. New form of equation for deformation resistance prediction under hot rolling industrial conditions. Scri. Mater. 2002, 47, 119–124. [Google Scholar] [CrossRef][Green Version]

- Lee, S.; Lee, S.J.; Cooman, D.B.C. Work hardening behavior of ultrafine-grained Mn transformation-induced plasticity steel. Acta Mater. 2011, 59, 7546–7553. [Google Scholar] [CrossRef]

- Cai, M.; Shi, H.; Yu, T. A dislocation-based constitutive description of strain-rate effect on the deformation resistance of metals. J. Mater. Sci. 2011, 46, 1087–1094. [Google Scholar] [CrossRef]

- Eyckens, P.; Mulder, H.; Gawad, J.; Vegter, H.; Roose, D.; Van den Boogaard, T.; Van Beal, A.; Van Houtte, P. The prediction of differential hardening behaviour of steels by multi-scale crystal plasticity modelling. Int. J. Plast. 2015, 73, 119–141. [Google Scholar] [CrossRef]

- Rumelhart, D.; Hinton, G.; Williams, R. Learning representations by back-propagating errors. Nature 1986, 323, 533–536. [Google Scholar] [CrossRef]

- Peng, Y.; Liu, H.; Du, R. A neural network-based shape control system for cold rolling operations. J. Mater. Process. Technol. 2008, 202, 54–60. [Google Scholar] [CrossRef]

- Wang, Z.; Gong, D.; Li, X.; Li, G.; Zhang, D. Prediction of bending force in the hot strip rolling process using artificial neural network and genetic algorithm (ANN-GN). Int. J. Adv. Manuf. Technol. 2017, 93, 3325–3338. [Google Scholar] [CrossRef]

- Linghu, K.; Jiang, Z.; Zhao, J.; Li, F.; Wei, D.; Xu, J.; Zhang, X.; Zhao, X. 3D FEM analysis of strip shape during multi-pass rolling in a 6-high CVC cold rolling mill. Int. J. Adv. Manuf. Technol. 2014, 74, 1733–1745. [Google Scholar] [CrossRef]

- Wang, Q.; Li, X.; Hu, Y.; Sun, J.; Zhang, D. Numerical analysis of intermediate roll shifting-induced rigidity characteristics of UCM cold rolling mill. Steel Res. Int. 2018, 89, 1700454. [Google Scholar] [CrossRef]

- Wang, Q.; Sun, J.; Liu, Y.; Wang, P.; Zhang, D. Analysis of symmetrical flatness actuator efficiencies for UCM cold rolling mill by 3D elastic-plastic FEM. Int. J. Adv. Manuf. Technol. 2017, 92, 1371–1389. [Google Scholar] [CrossRef]

- Jin, X.; Li, C.; Wang, Y.; Li, X.; Gu, T.; Xiang, Y. Multi-objective optimization of intermediate roll profile for a 6-High cold rolling mill. Metals 2020, 10, 287. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Y. Stream surface strip element method for simulation of the three-dimensional deformations of plate and strip rolling. Int. J. Mech. Sci. 2003, 45, 1541–1561. [Google Scholar] [CrossRef]

- Son, J.; Lee, D.; Kim, I.; Choi, S. A study on genetic algorithm to select architecture of a optimal neural network in the hot rolling process. J. Mater. Process. Technol. 2004, 153–154, 643–648. [Google Scholar] [CrossRef]

- Kadkhodaei, M.; Salimi, M.; Poursina, M. Analysis of asymmetrical sheet rolling by a genetic algorithm. Int. J. Mech. Sci. 2007, 49, 622–634. [Google Scholar] [CrossRef]

- Cao, J.; Xu, X.; Zhang, J.; Song, M.; Gong, G.; Zeng, W. Preset model of bending force for 6-high reversing cold rolling mill based on genetic algorithm. J. Cent. South. Univ. Technol. 2011, 18, 1487–1492. [Google Scholar] [CrossRef]

| Error Index Type | Rolling Force | Strip Flatness |

|---|---|---|

| Correlation coefficient (R) | 0.9242 | 0.9278 |

| Mean absolute error (MAE) | 0.3269 | 2.5227 |

| Mean absolute percentage error (MAPE, %) | 1.9179 | - |

| Standard deviation (SD) | 0.2504 | 2.1944 |

| Maximum absolute error | 1.6031 | 9.1346 |

| Name | Value |

|---|---|

| Work roll diameter/length (mm) | 425/1740 |

| Intermediate roll diameter/length (mm) | 490/1990 |

| Backup roll diameter/length (mm) | 1300/1750 |

| Strip width (mm) | 1250 |

| Entry and exit thickness of the strip (mm) | 3.5/1 |

| Material | DP780 |

| Mode | Reduction % | ||||

|---|---|---|---|---|---|

| S1 | S2 | S3 | S4 | S5 | |

| M1 | 25.7 | 30.8 | 30.6 | 19.6 | 0.5 |

| M2 | 27.1 | 27.8 | 26.6 | 25.6 | 0.5 |

| M3 | 28.1 | 26.0 | 24.3 | 28.2 | 0.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, X.; Li, C.; Wang, Y.; Li, X.; Xiang, Y.; Gu, T. Investigation and Optimization of Load Distribution for Tandem Cold Steel Strip Rolling Process. Metals 2020, 10, 677. https://doi.org/10.3390/met10050677

Jin X, Li C, Wang Y, Li X, Xiang Y, Gu T. Investigation and Optimization of Load Distribution for Tandem Cold Steel Strip Rolling Process. Metals. 2020; 10(5):677. https://doi.org/10.3390/met10050677

Chicago/Turabian StyleJin, Xin, Changsheng Li, Yu Wang, Xiaogang Li, Yongguang Xiang, and Tian Gu. 2020. "Investigation and Optimization of Load Distribution for Tandem Cold Steel Strip Rolling Process" Metals 10, no. 5: 677. https://doi.org/10.3390/met10050677

APA StyleJin, X., Li, C., Wang, Y., Li, X., Xiang, Y., & Gu, T. (2020). Investigation and Optimization of Load Distribution for Tandem Cold Steel Strip Rolling Process. Metals, 10(5), 677. https://doi.org/10.3390/met10050677