On the Influence of the Tool Path and Intrusion Depth on the Geometrical Accuracy in Incremental Sheet Forming

Abstract

:1. Introduction

- Does the tool path direction influence the final part geometry?

- Is there an influence of the intrusion depth on the resulting part geometry?

2. Materials and Methods

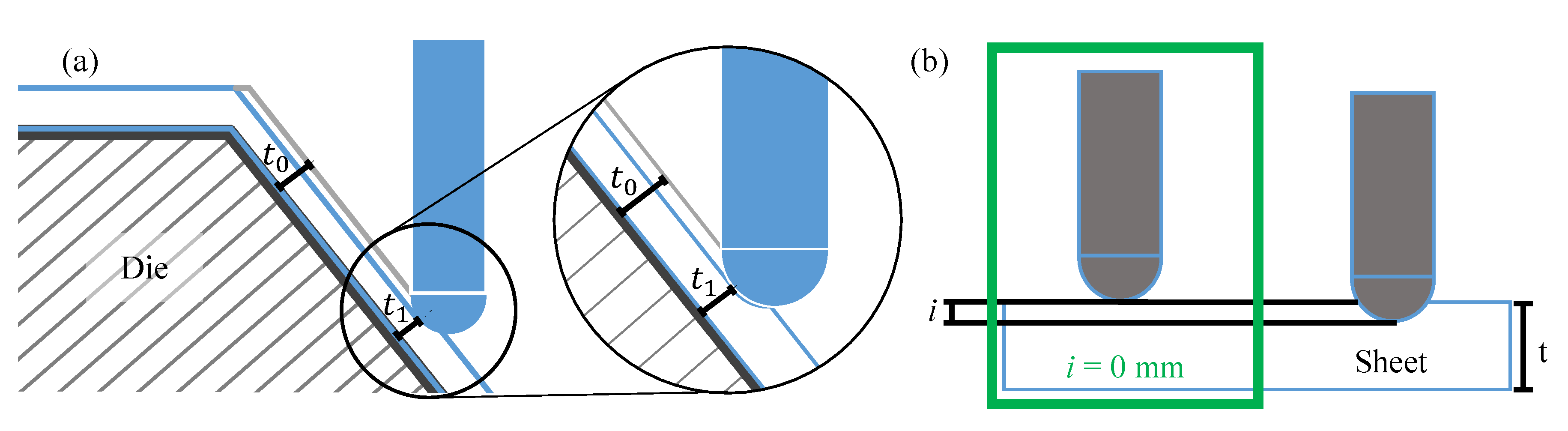

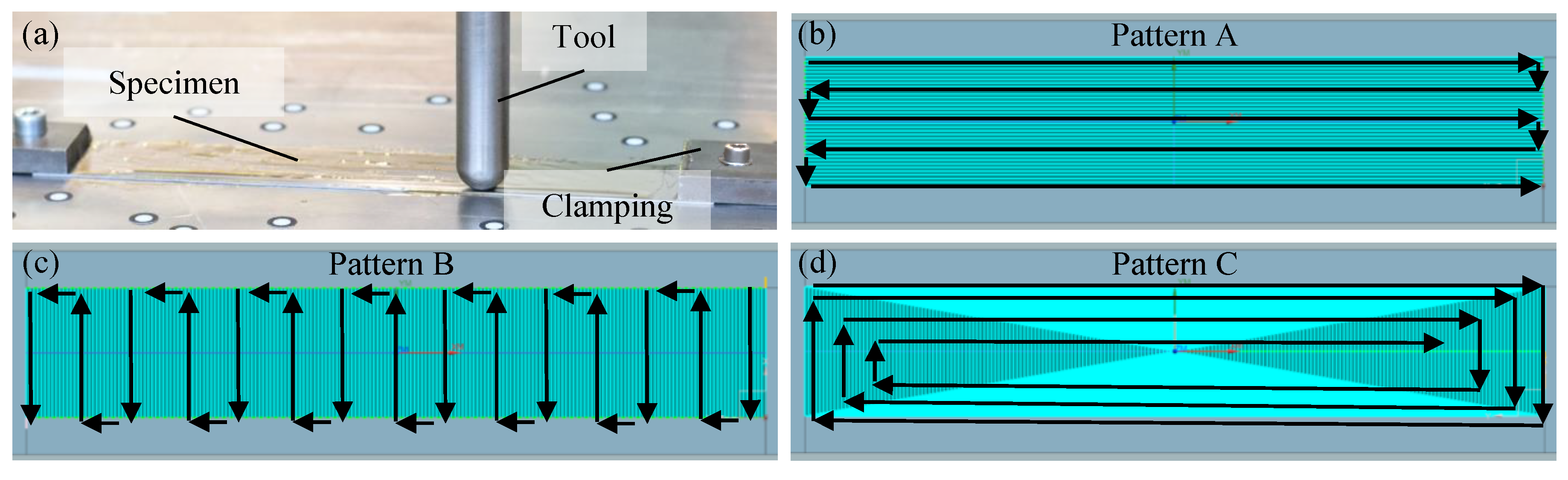

2.1. Experimental Setup for Pure ISF

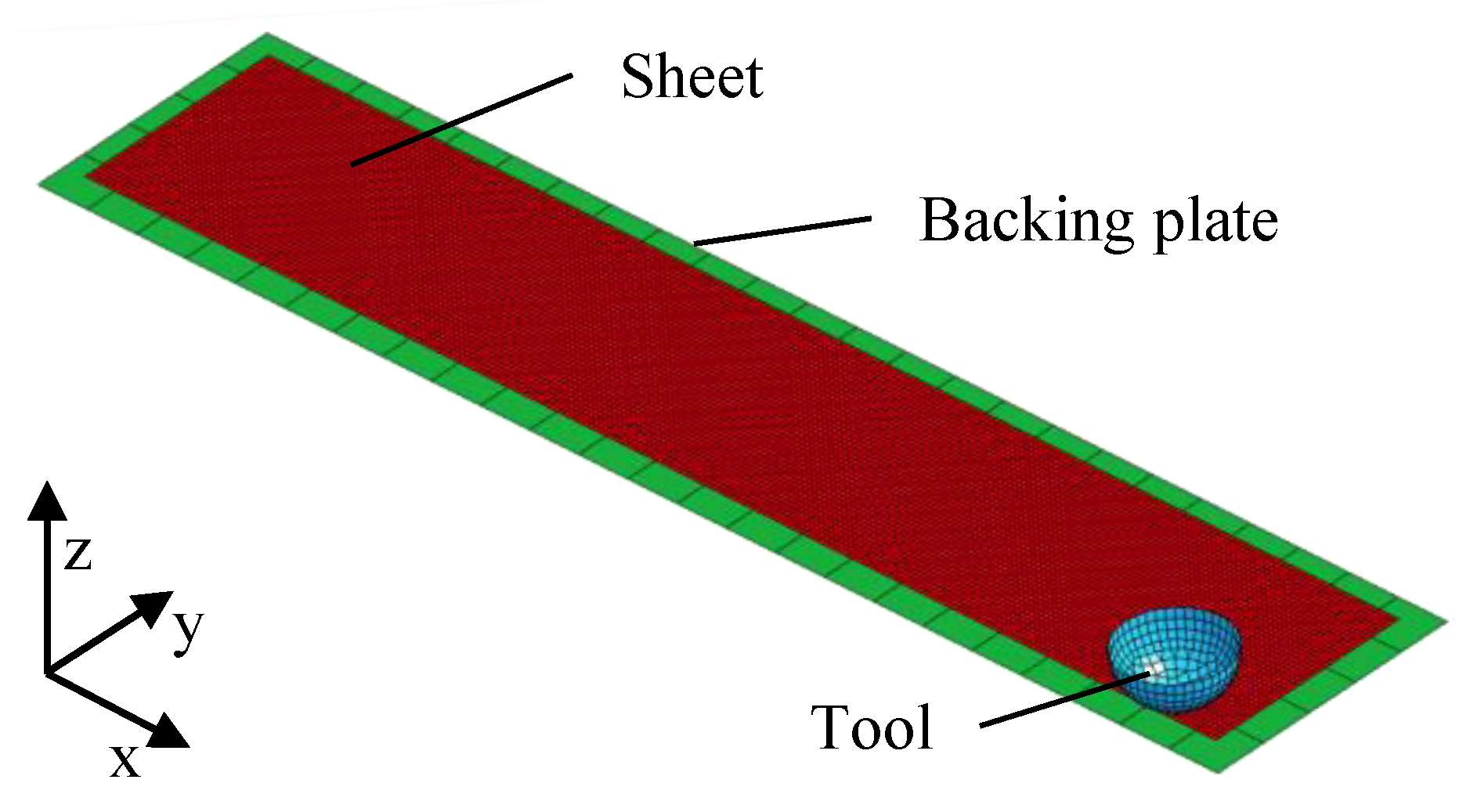

2.2. FE Model for Pure ISF

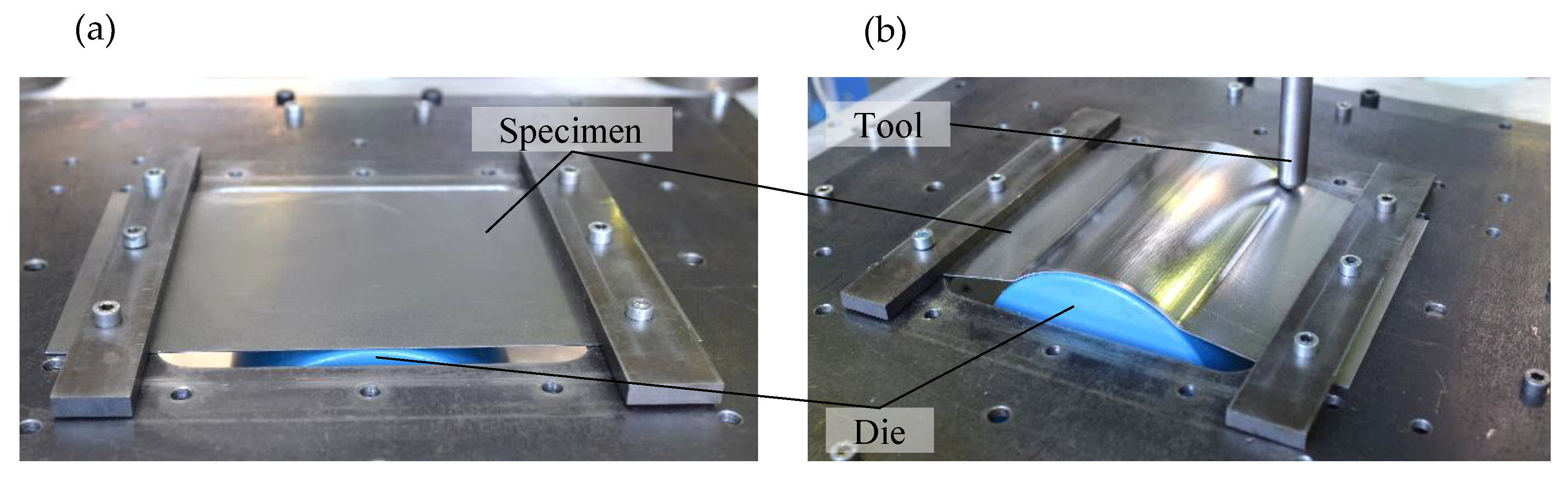

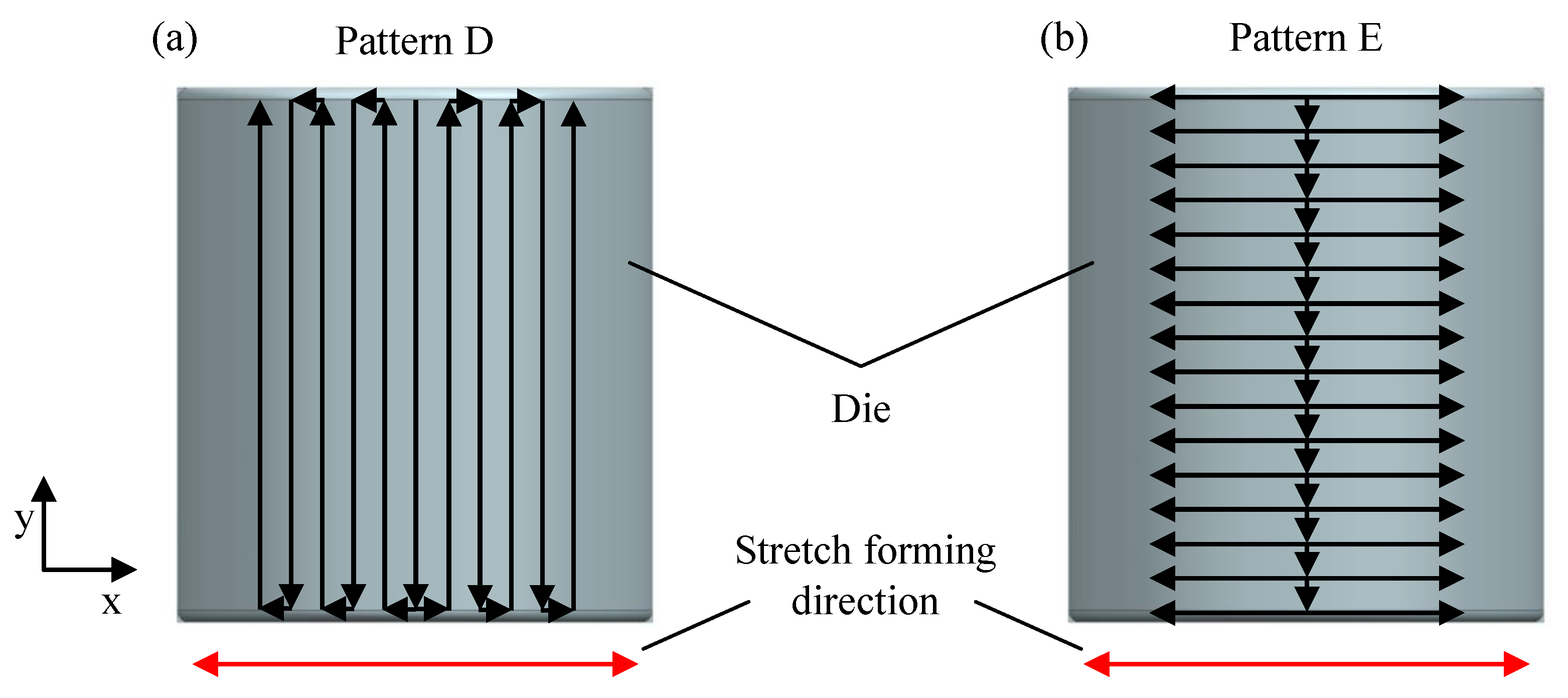

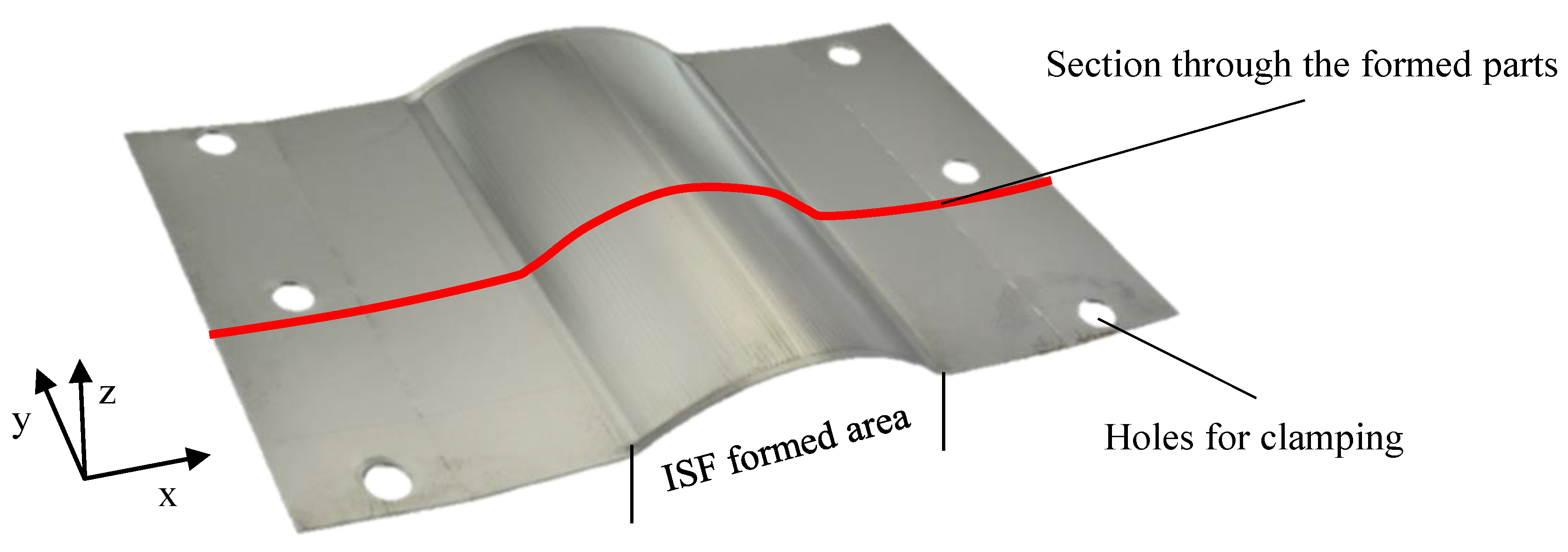

2.3. Experimental Setup for Stretch-formed Sheets

3. Results and Discussion

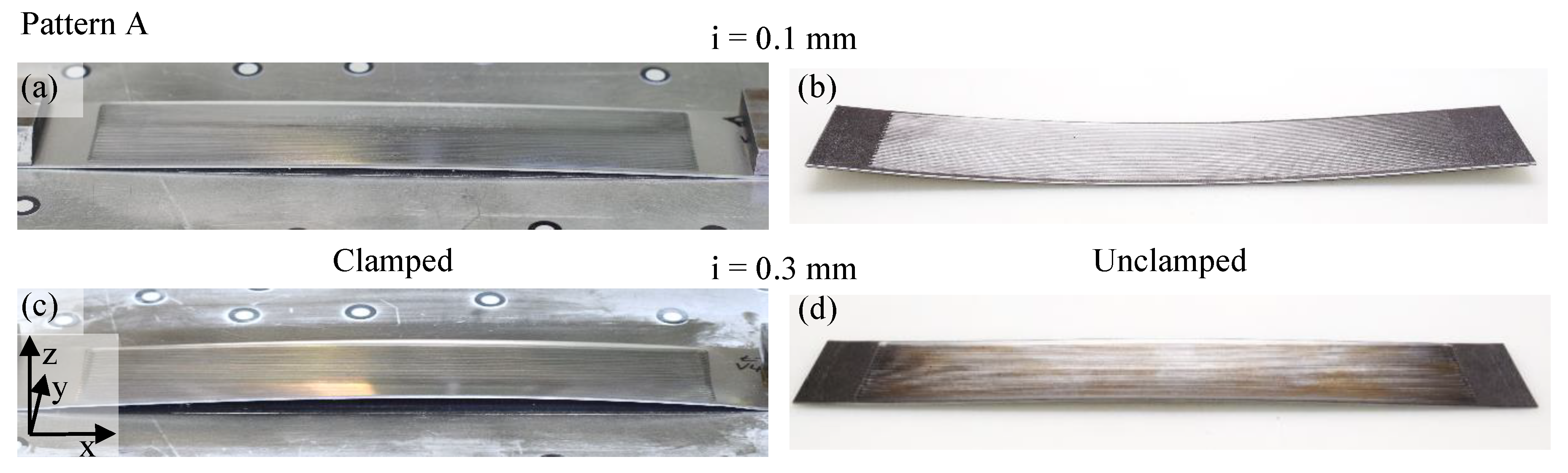

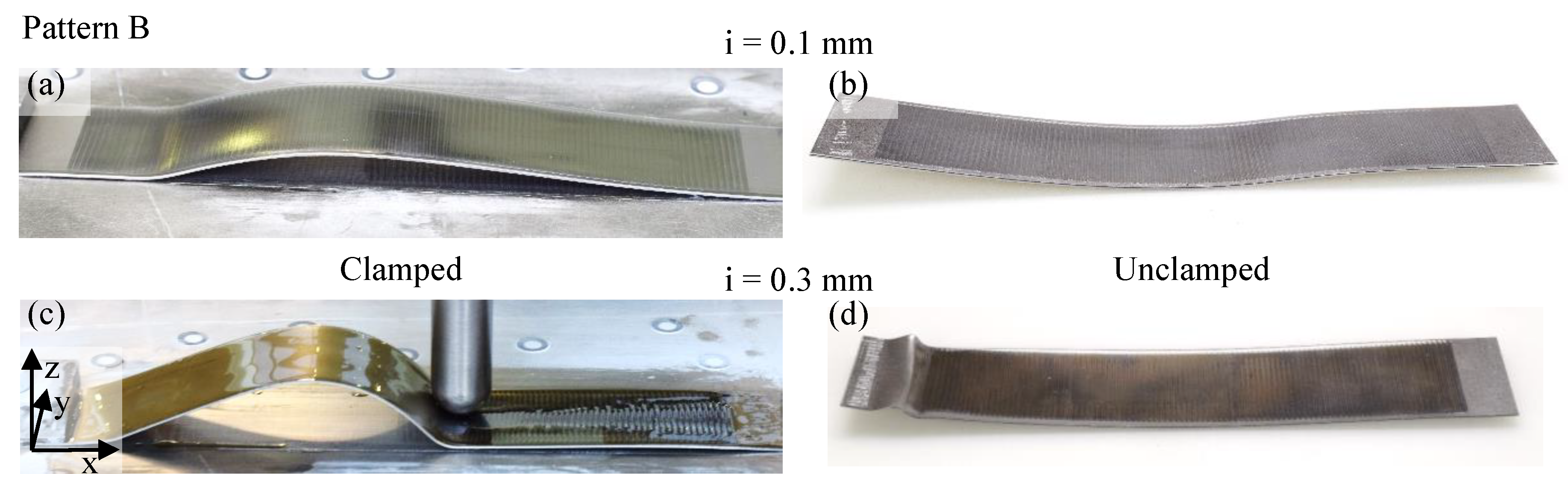

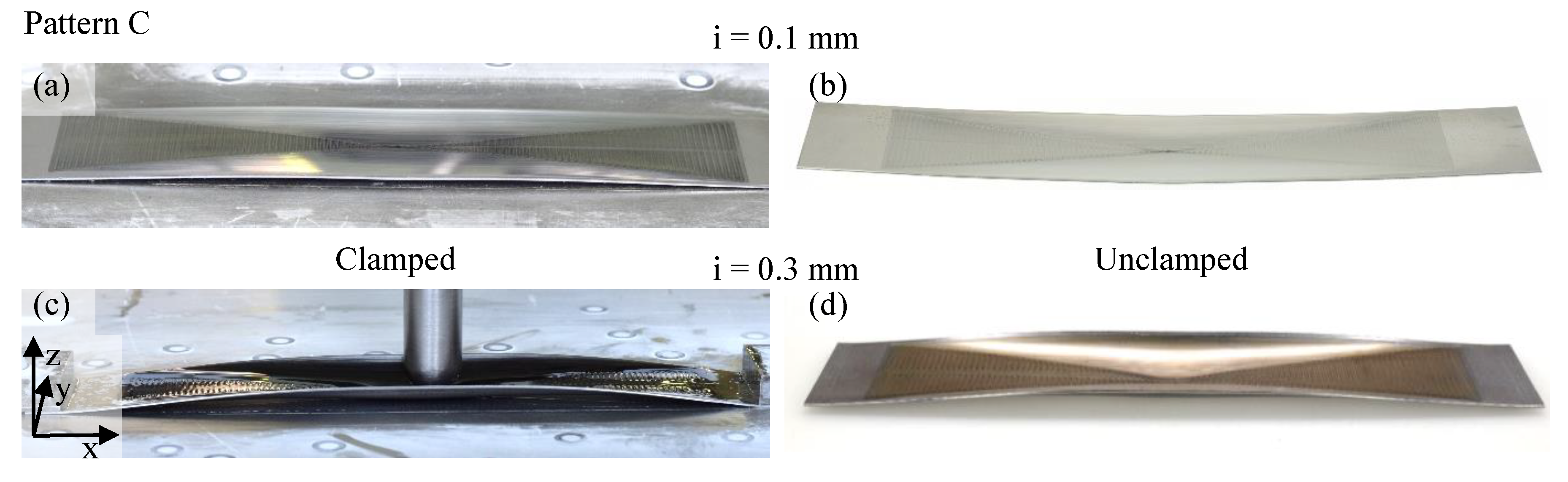

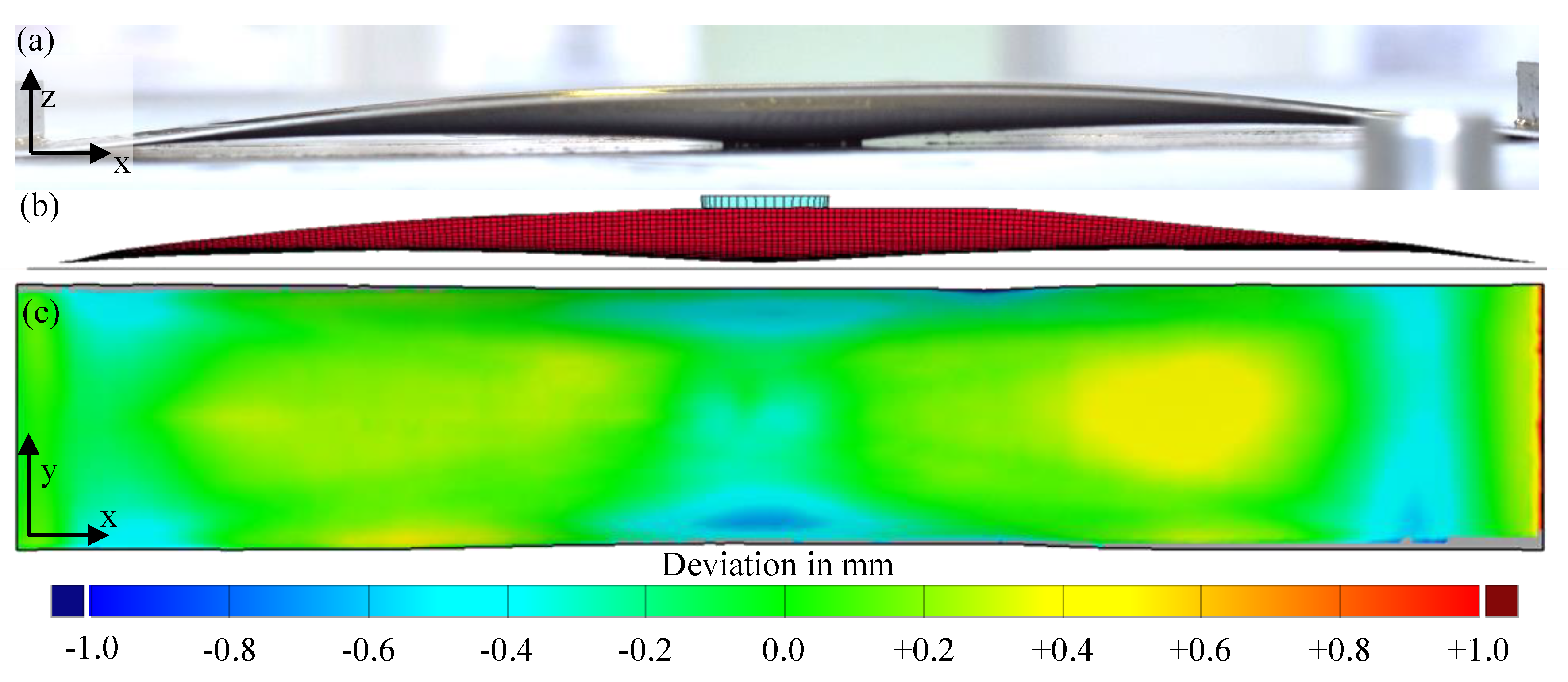

3.1. Experimental Results for Pure ISF

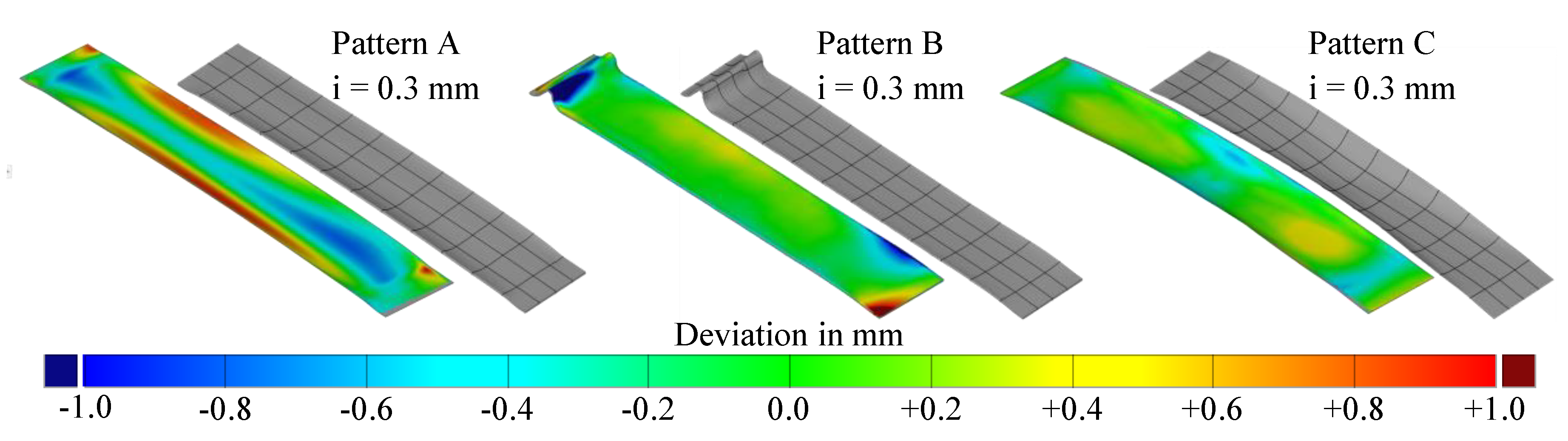

3.2. Numerical Results for Pure ISF

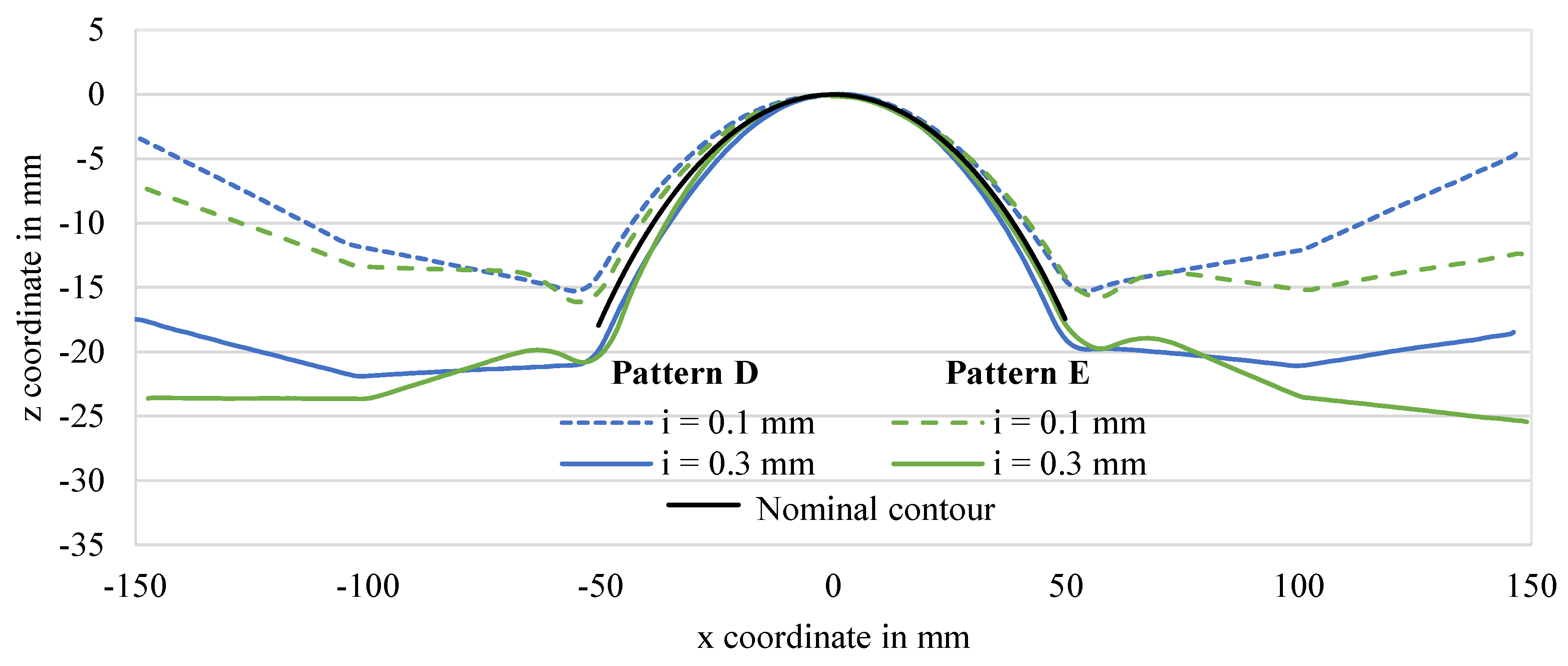

3.3. Experimental Results for Stretch-Formed Sheets

4. Conclusion

Author Contributions

Funding

Conflicts of Interest

References

- Jeswiet, J.; Micari, F.; Hirt, G.; Bramley, A.; Duflou, J.; Allwood, J.M. Asymmetric single point incremental forming of sheet metal. CIRP Ann. 2005, 54, 88–114. [Google Scholar] [CrossRef]

- Meier, H.; Buff, B.; Laurischkat, R.; Smukala, V. Increasing the part accuracy in dieless robot-based incremental sheet metal forming. CIRP Ann. 2009, 58, 233–238. [Google Scholar] [CrossRef]

- Meier, H.; Laurischkat, R.; Zhu, J.; Chinesta, F.; Chastel, Y.; El Mansori, M. A model based approach to increase the part accuracy in robot based incremental sheet metal forming. AIP Conf. Proc. 2011, 1315, 1407. [Google Scholar]

- Hirt, G.; Junk, S.; Witulski, N. Surface Quality, Geometric Precision and Sheet Thinning in Incremental Sheet Forming. In Proceedings of the Materials Week, Munich, Germany, 1–3 October 2001; pp. 1–8. [Google Scholar]

- Bambach, M.; Taleb, B.A.; Hirt, G. Strategies to improve the geometric accuracy in asymmetric single point incremental forming. Prod. Eng. 2009, 3, 145–156. [Google Scholar] [CrossRef]

- Hirt, G.; Ames, J.; Bambach, M.; Kopp, R. Forming strategies and process modelling for CNC incremental sheet forming. CIRP Ann. 2004, 53, 203–206. [Google Scholar] [CrossRef]

- Duflou, J.R.; Lauwers, B.; Verbert, J.; Tunckol, Y.; Baerdemaeker, H.D. Achievable Accuracy in Single Point Incremental Forming: Case Studies. In Proceedings of the 8th European Scientific Association for material Forming Conference on Material Forming (2005), Cluj-Napoca, Romania, 27–29 April 2005; pp. 675–678. [Google Scholar]

- Malhotra, R.; Bhattacharya, A.; Kumar, A.; Reddy, N.V.; Cao, J. A new methodology for multi-pass single point incremental forming with mixed toolpaths. CIRP Ann. 2011, 60, 323–326. [Google Scholar] [CrossRef]

- Wang, J.; Li, L.; Zhou, P.; Wang, X.; Sun, S. Improving formability of sheet metals in incremental forming by equal diameter spiral tool path. Int. J. Adv. Manuf. Technol. 2018, 101, 225–234. [Google Scholar] [CrossRef]

- Bambach, M.; Hirt, G.; Ames, J. Modeling of optimization strategies in the incremental CNC sheet metal forming process. AIP Conf. Proc. 2004, 712, 1969–1974. [Google Scholar]

- Bambach, M. Process Strategies and Modelling Approaches for Asymmetric Incremental Sheet Forming. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 12 December 2007. [Google Scholar]

- Lu, H.; Kearney, M.; Liu, S.; Daniel, W.J.; Meehan, P. Two-directional toolpath correction in single-point incremental forming using model predictive control. Int. J. Adv. Manuf. Technol. 2016, 91, 91–106. [Google Scholar] [CrossRef]

- Allwood, J.M.; Music, O.; Raithathna, A.; Duncan, S.R. Closed-loop feedback control of product properties in flexible metal forming processes with mobile tools. CIRP Ann. 2009, 58, 287–290. [Google Scholar] [CrossRef]

- Araghi, B.T.; Göttmann, A.; Bergweiler, G.; Saeed-Akbari, A.; Bültmann, J.; Zettler, J.; Bambach, M.; Hirt, G. Investigation on incremental sheet forming combined with laser heating and stretch forming for the production of lightweight structures. Key Eng. Mater. 2011, 473, 919–928. [Google Scholar] [CrossRef]

- Taleb, B.A.; Göttmann, A.; Bambach, M.; Hirt, G.; Bergweiler, G.; Diettrich, J.; Steiners, M.; Saeed-Akbari, A. Review on the development of a hybrid incremental sheet forming system for small batch sizes and individualized production. Prod. Eng. 2011, 5, 393–404. [Google Scholar] [CrossRef]

- Bambach, M. A geometrical model of the kinematics of incremental sheet forming for the prediction of membrane strains and sheet thickness. J. Mater. Process. Technol. 2010, 210, 1562–1573. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schmitz, R.U.C.; Bremen, T.; Bailly, D.B.; Hirt, G.K.P. On the Influence of the Tool Path and Intrusion Depth on the Geometrical Accuracy in Incremental Sheet Forming. Metals 2020, 10, 661. https://doi.org/10.3390/met10050661

Schmitz RUC, Bremen T, Bailly DB, Hirt GKP. On the Influence of the Tool Path and Intrusion Depth on the Geometrical Accuracy in Incremental Sheet Forming. Metals. 2020; 10(5):661. https://doi.org/10.3390/met10050661

Chicago/Turabian StyleSchmitz, Roman Ulrich Christopher, Thomas Bremen, David Benjamin Bailly, and Gerhard Kurt Peter Hirt. 2020. "On the Influence of the Tool Path and Intrusion Depth on the Geometrical Accuracy in Incremental Sheet Forming" Metals 10, no. 5: 661. https://doi.org/10.3390/met10050661

APA StyleSchmitz, R. U. C., Bremen, T., Bailly, D. B., & Hirt, G. K. P. (2020). On the Influence of the Tool Path and Intrusion Depth on the Geometrical Accuracy in Incremental Sheet Forming. Metals, 10(5), 661. https://doi.org/10.3390/met10050661