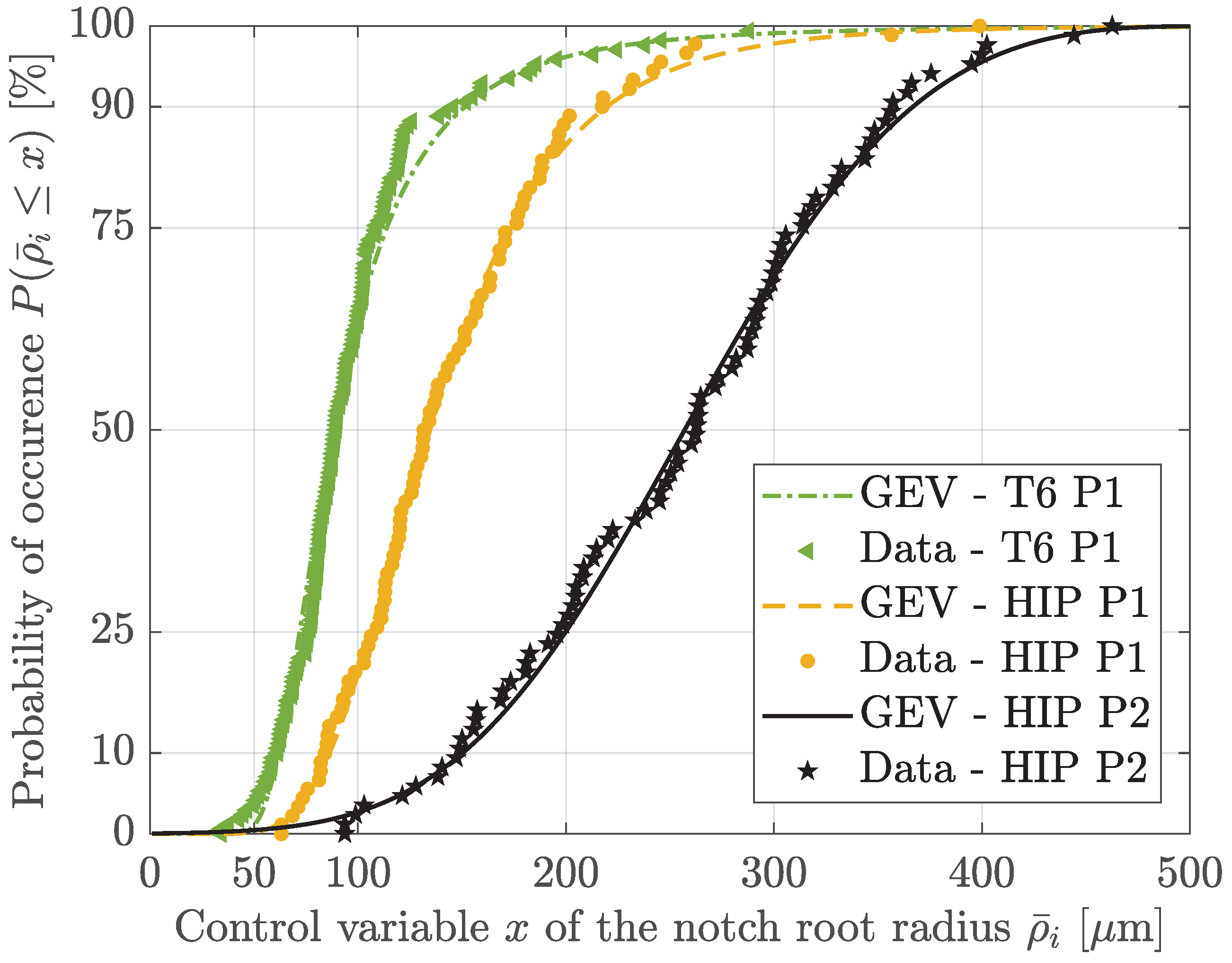

Within this work, fatigue tests were performed on HIP sand cast surfaces at sampling positions P1 and P2. Although three test series have been experimentally investigated (HIP P1, HIP P1(2), HIP P2), only two of them (HIP P1 and HIP P2) will be presented in detail to enhance clarity. However, fatigue test results such as S/N-parameters are evaluated and tabulated for all three investigated series.

All testing series possess cast surfaces and the fatigue tests were performed identically to the procedure described in [

36] utilising a Rumul Cracktronic

®. Due to the load stress ratio of R = 0 under bending load the highly tensile-stressed region of the specimen is set to the cast surface layer. The S/N-curves are statistically evaluated following the procedure applied in [

36].

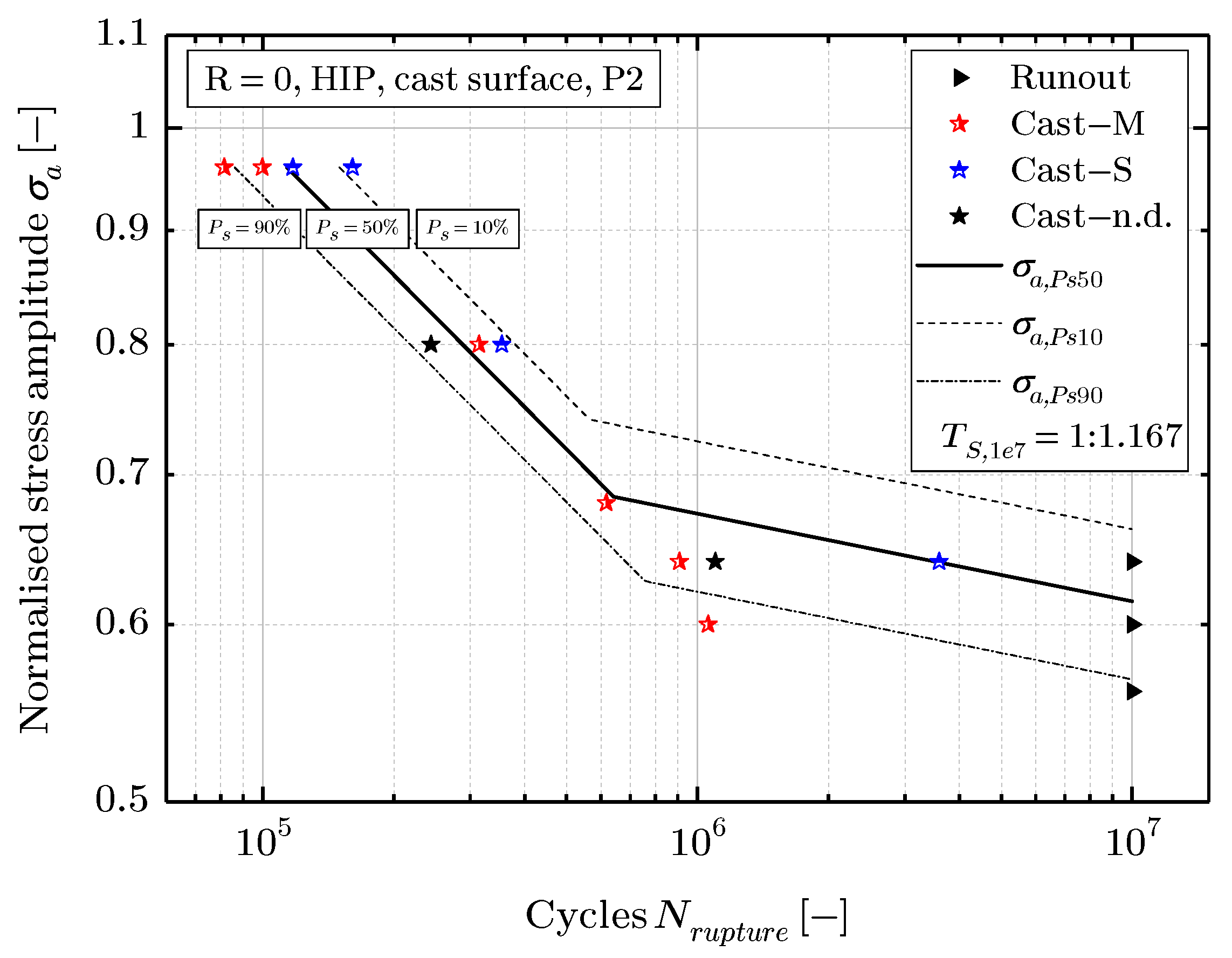

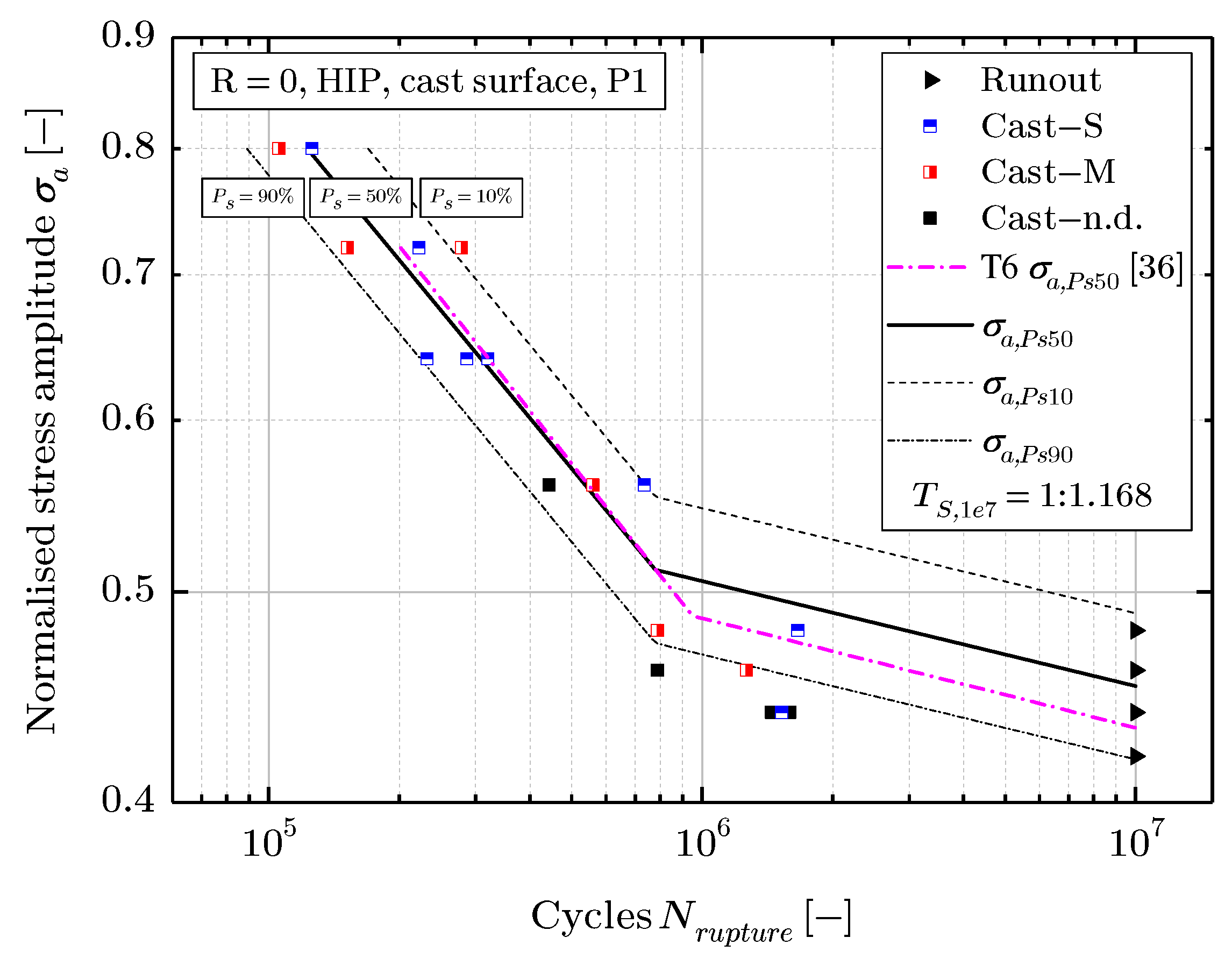

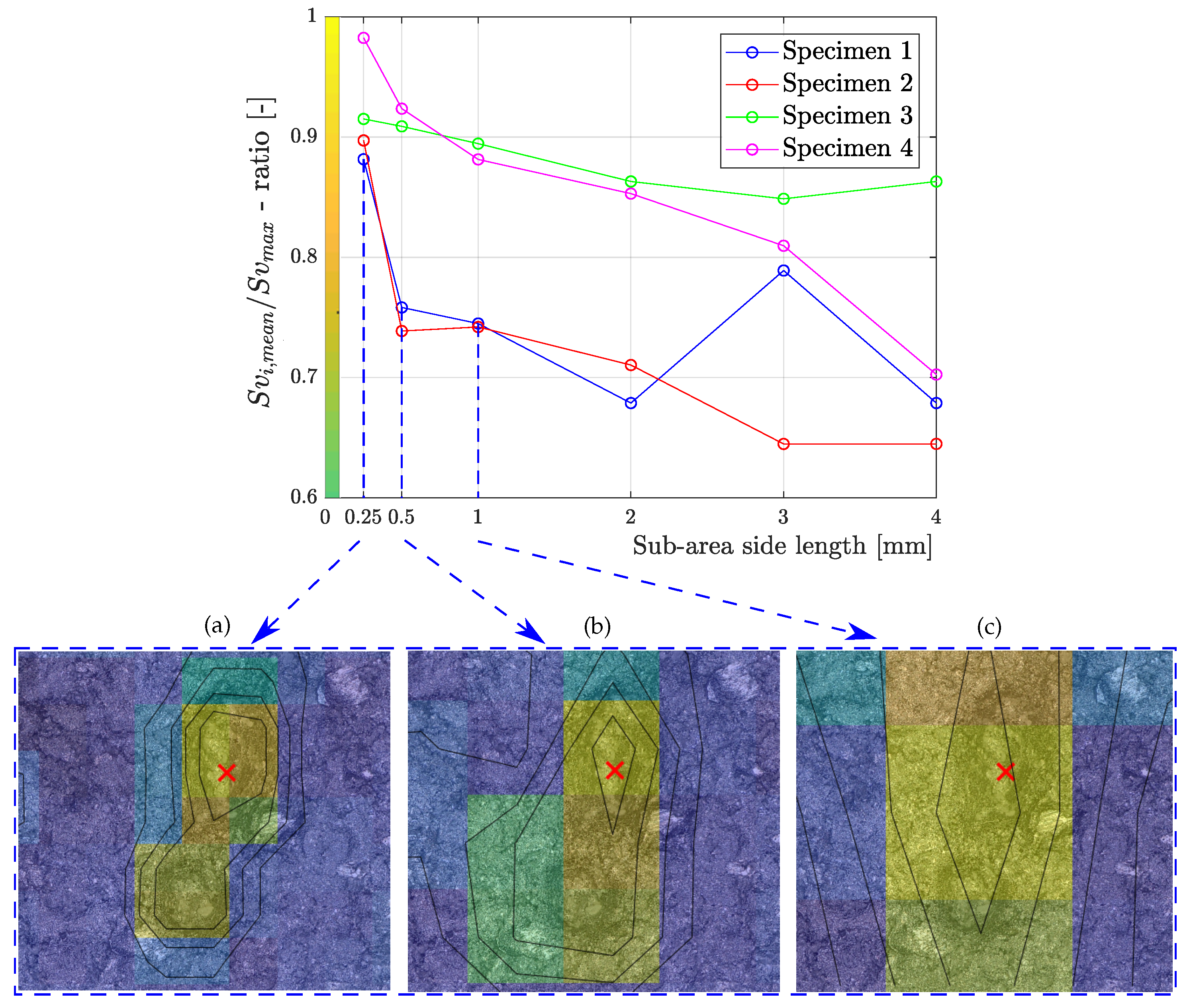

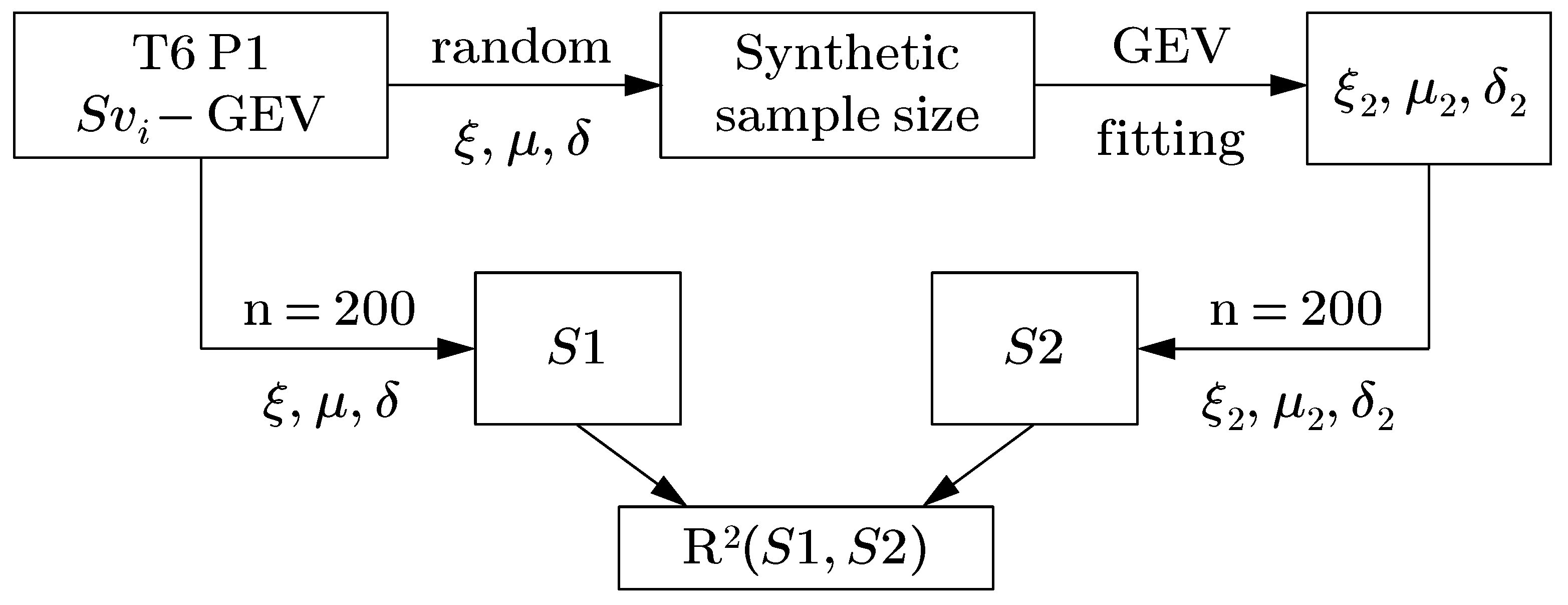

Figure 3 depicts the nominal bending S/N-curve of the HIP test series at the new sampling position P2, possessing a significantly reduced surface roughness, as discussed in

Section 5. Within all S/N-figures, the stress amplitude

is normalised to the material‘s near defect-free long life fatigue strength

. As stated in [

36], the value of

was experimentally evaluated by means of HIP specimens with machined and subsequently polished surface condition. Thus, the observed fatigue strength is unaffected both from porosity effect and surface roughness effect.

The crack initiation cause is marked red if the crack initiated at a combination of a surface pit and a micropore located directly within the surrounding area (Cast-M), and blue if only the cast surface texture (Cast-S), that is, surface roughness, caused technical crack initiation.

Figure 4 exemplary depicts the fractographically evaluated crack initiating defects of Cast-S and Cast-M specimens of the HIP P1 and HIP P2 testing series by means of scanning electron microscopy (SEM). Fractographic images of HIP P1 are also representative for the T6 P1 testing series of [

36]. For almost all Cast-M specimens shrinkage porosity was observed to participate in crack initiation. Only few cases revealed gas pores, bifilms or intermetallic phases to be critical. In contrast with the locations of the pores of Cast-M P1 specimens, those of Cast-M P2 rarely have been broached, but were found to be located about 10 µm to 30 µm beneath the surface. This may be caused by the elevated solidification rate within the surface layer at this sampling position. For Cast-n.d. specimens, no distinct crack initiation cause could be clearly determined by fracture surface analysis, which is why they are not subsequently taken into account for validation.

The S/N-curves (

Figure 3 and

Figure 5) are given with their 90% and 10% probability of survival and the stress scatter index

is calculated according to [

52] by means of Equation (

2) at ten million load cycles. The evaluated S/N-curve provides in

Table 4 the value of the inverse slopes

and

, which is five times

[

53], the transition knee point

and the normalised long life fatigue strength

as well as the stress scatter index

.

Figure 5 depicts the evaluated S/N-curve of the HIP specimen series at sampling position P1, which is similar to the original sampling position presented in [

36]. The coloration of the markers is the same as in

Figure 3. The accompanying fracture surface analysis revealed great similarity to those samples of the T6 P1 testing series in [

36]. As the evaluation of the long life fatigue strength of the HIP P1 specimen series by means of the arcsin

method [

54] would lead to a smaller scatter within the long life region compared to the finite life region, the normalisation process of S/N-curves was applied as proposed in [

52,

55], and also accordingly executed in [

36]. The evaluated S/N-curve results are listed in

Table 4 as well. Additionally, within

Figure 5 the evaluated long life fatigue strength

of the T6 testing series with cast surface, as sketched in [

36], is highlighted by the purple dash-dotted line for comparison.

At this point, it must be stated that the fact that Cast-M specimen fatigue results are similar to Cast-S specimens does not imply that surface layer porosity can be neglected. Both surface layer porosity and the cast surface texture showed similar fatigue results if the are evaluated independently. Thus, they both affect the fatigue strength in a comparable manner. However, if the cracks initiate combinatorial, as observed in Cast-M specimens, see

Figure 4a,c, they lead to similar fatigue test results even if the defects are smaller. Summing up, smaller surface layer inhomogeneities and less detrimental surface texture combinatorial considered may be more crucial than a single, distinct surface pit. Therefore, they may be treated in a combined manner. For more information regarding the combinatorial failure mechanism see the work in [

36].

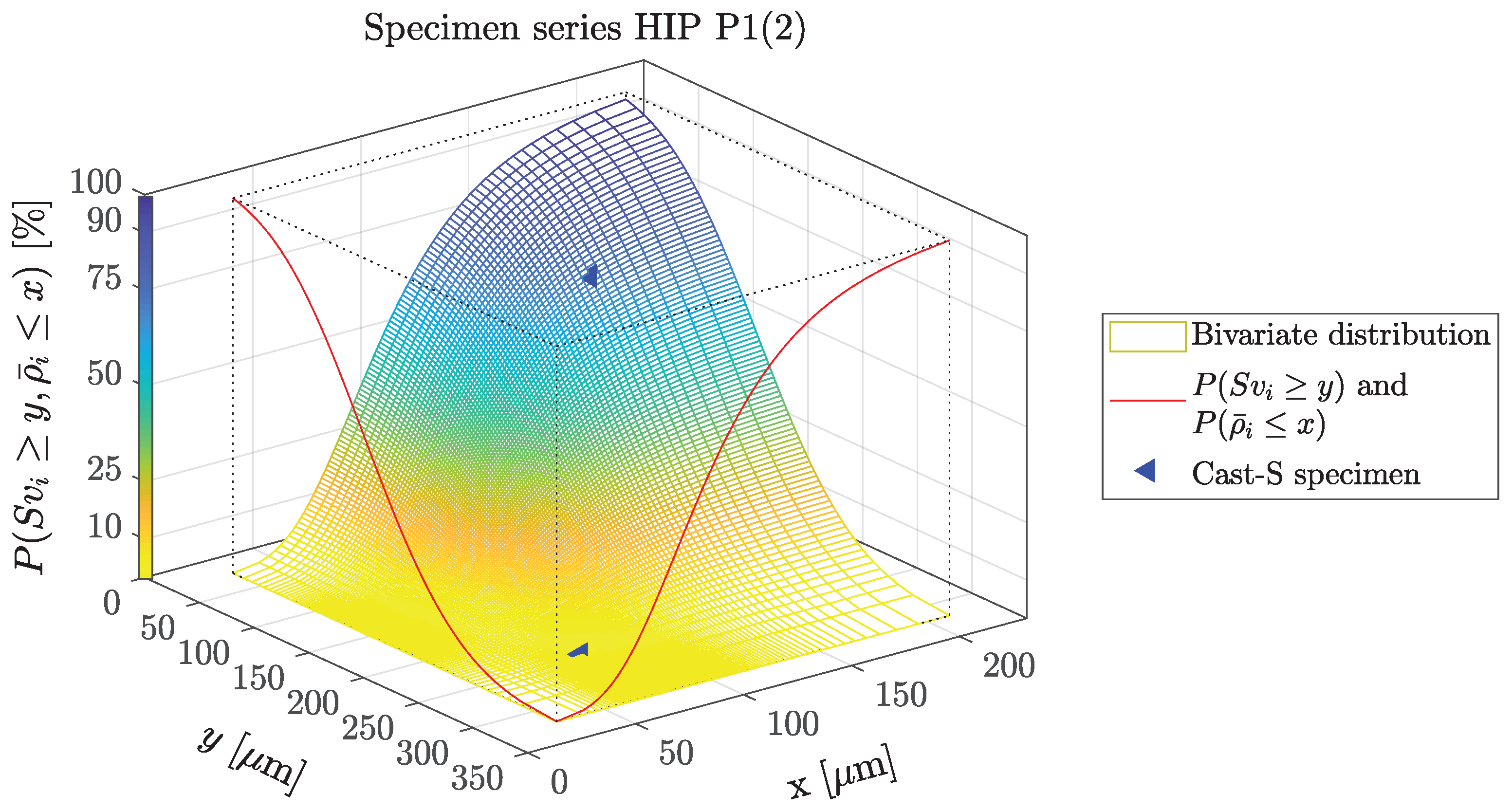

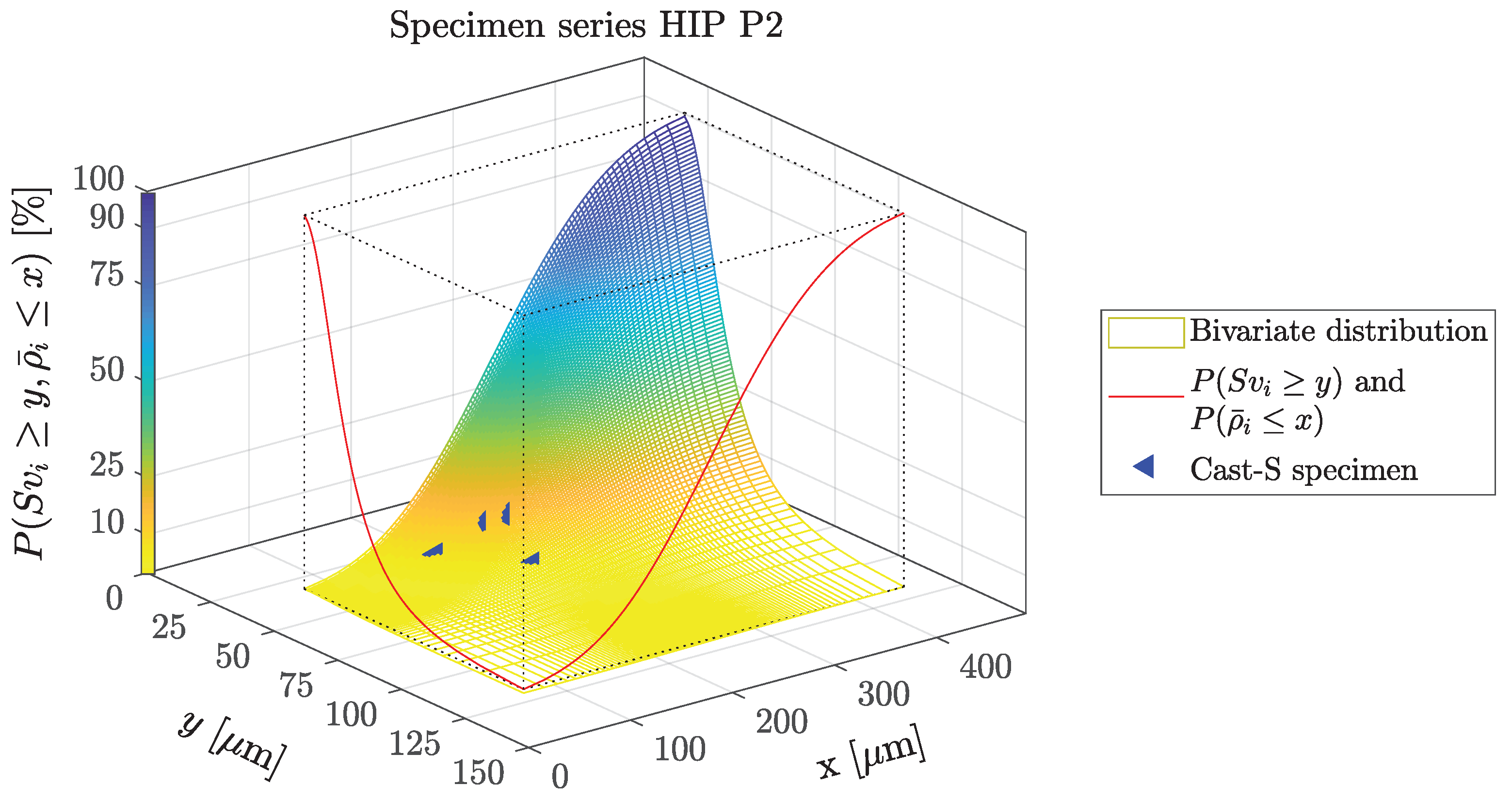

HIP Effect on the Cast Surface Layer

While the HIP process leads to significantly enhanced fatigue strength results in terms of bulk material testing [

45,

50,

56,

57,

58,

59], this effect was not present for any of the investigated HIP cast surface series. While for one HIP P1 testing series the evaluated long life fatigue strength

was above the T6 value (as presented in

Figure 5), the other HIP P1(2) testing series the

was slightly lowered, but both within the 90% and 10% stress scatter band of HIPped samples. In terms of Cast-S specimens, it was found that the evaluated surface roughness values, and therefore the estimated fatigue strength by means of the introduced fatigue assessment model, was comparable to those of the cast T6 P1 series. Therefore, it is reasonable that the Cast-S points of the HIP P1 specimens in

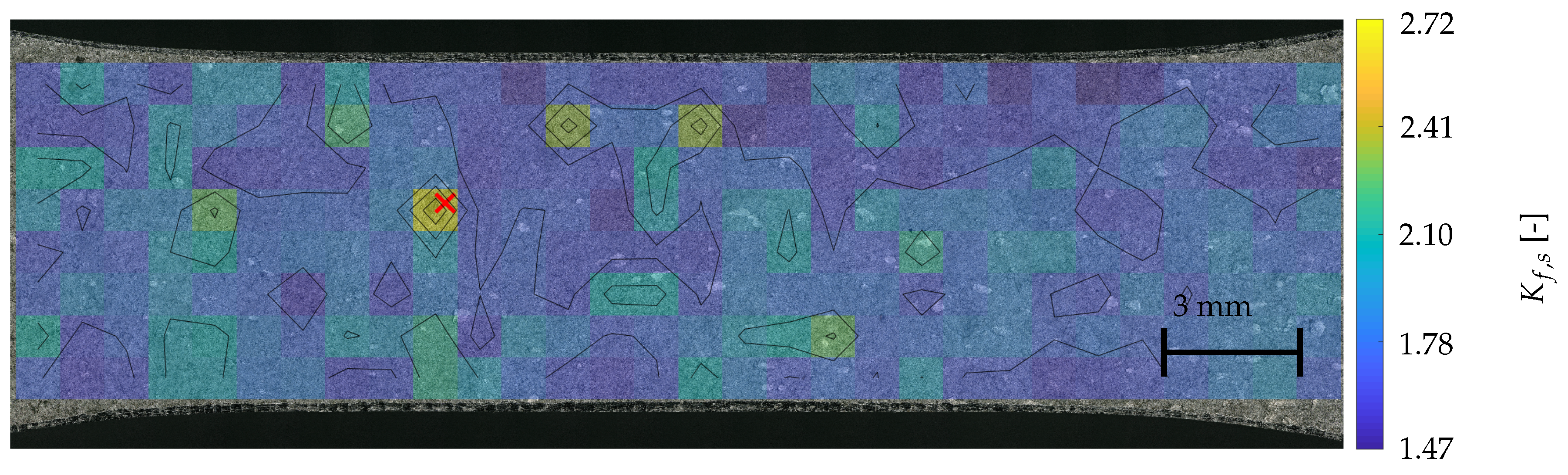

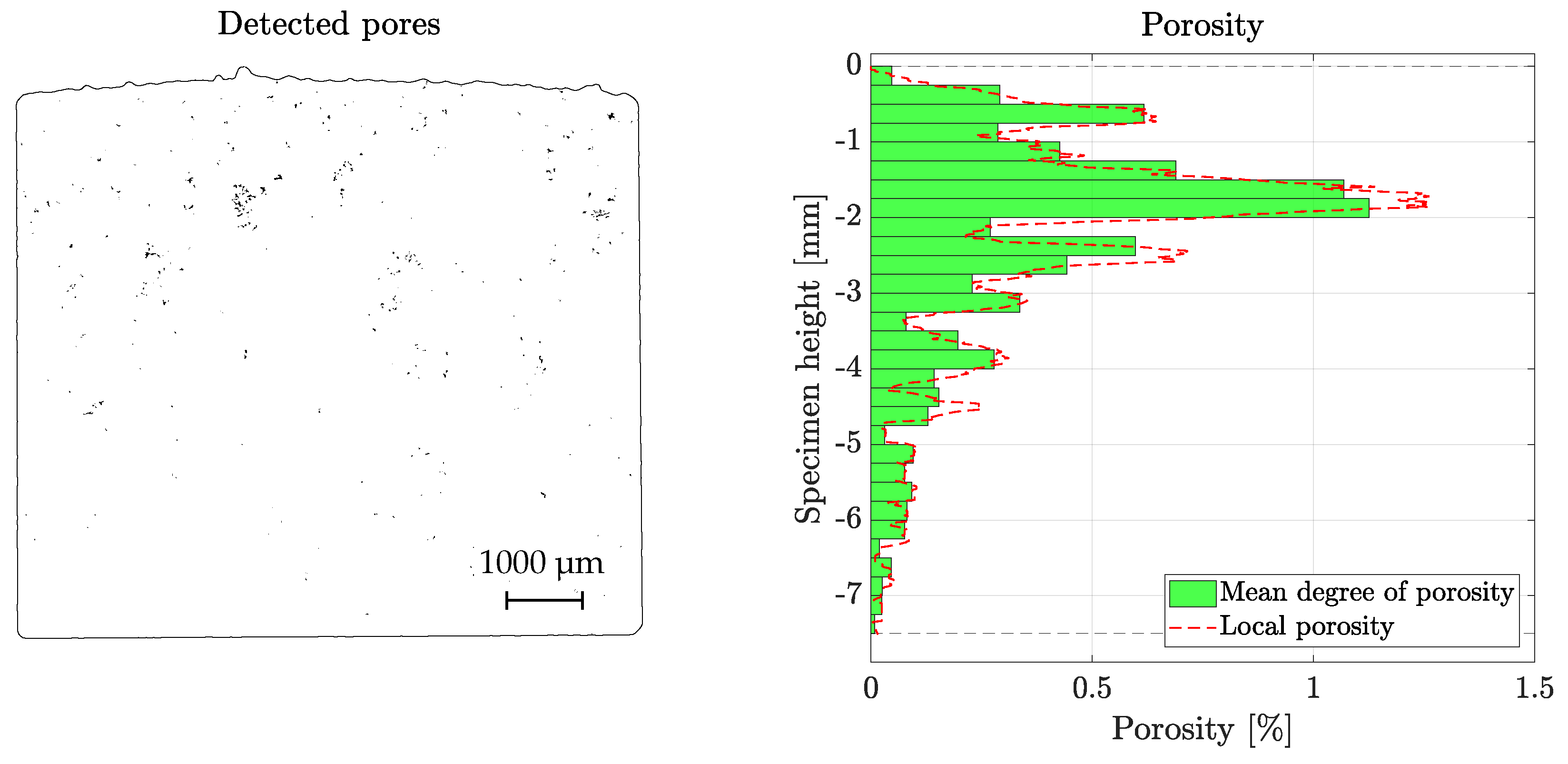

Figure 5 fit to the cast T6 P1 S/N-curve. However, regarding the Cast-M specimens, one may expect a significantly higher fatigue strength due to closed shrinkage porosity. Investigations on metallographic T6 specimens revealed a higher porosity within the surface layer, especially up to a certain depth, see

Figure 6. Almost without exception these were shrinkage pores evolving during the solidification process. The left sub-figure shows the detected micropores, while on the right diagram the evaluated degree of porosity is plotted. By means of a user defined routine, pores are detected on a metallographic specimen, which have been captured by means of a digital optical microscope. The degree of porosity was then evaluated by counting the black pixels of the picture, which have been determined as pores, in relation to the white pixels within the same horizontal line. Subsequently, mean values of the degree of porosity have been calculated within a vertical range of 250 µm. It is clearly recognisable that the highest degree of porosity occurs in about 1 mm to 2 mm depth measured from the cast surface. To achieve information about the spatial distribution of the micropores, the metallographic specimen was subsequently grinded, thereby removing about 100 µm, and subsequently evaluated again. This methodology hast been carried out several times for four T6 specimens, resulting in 140 metallographic analysis in total. It emerged that the trend of degree of porosity, as depicted in

Figure 6, is representative for the T6 P1 specimens series. An increased degree of porosity near the cast surface of AlSi castings was also stated by Leitner et al. [

60]. This increased porosity formation may be reasoned by the oxide entrainment mechanism as a result of turbulent mould filling, see [

61,

62,

63]. However, a comprehensive insight in the degree of porosity can be more properly evaluated by means of XCT-scans [

21,

60].

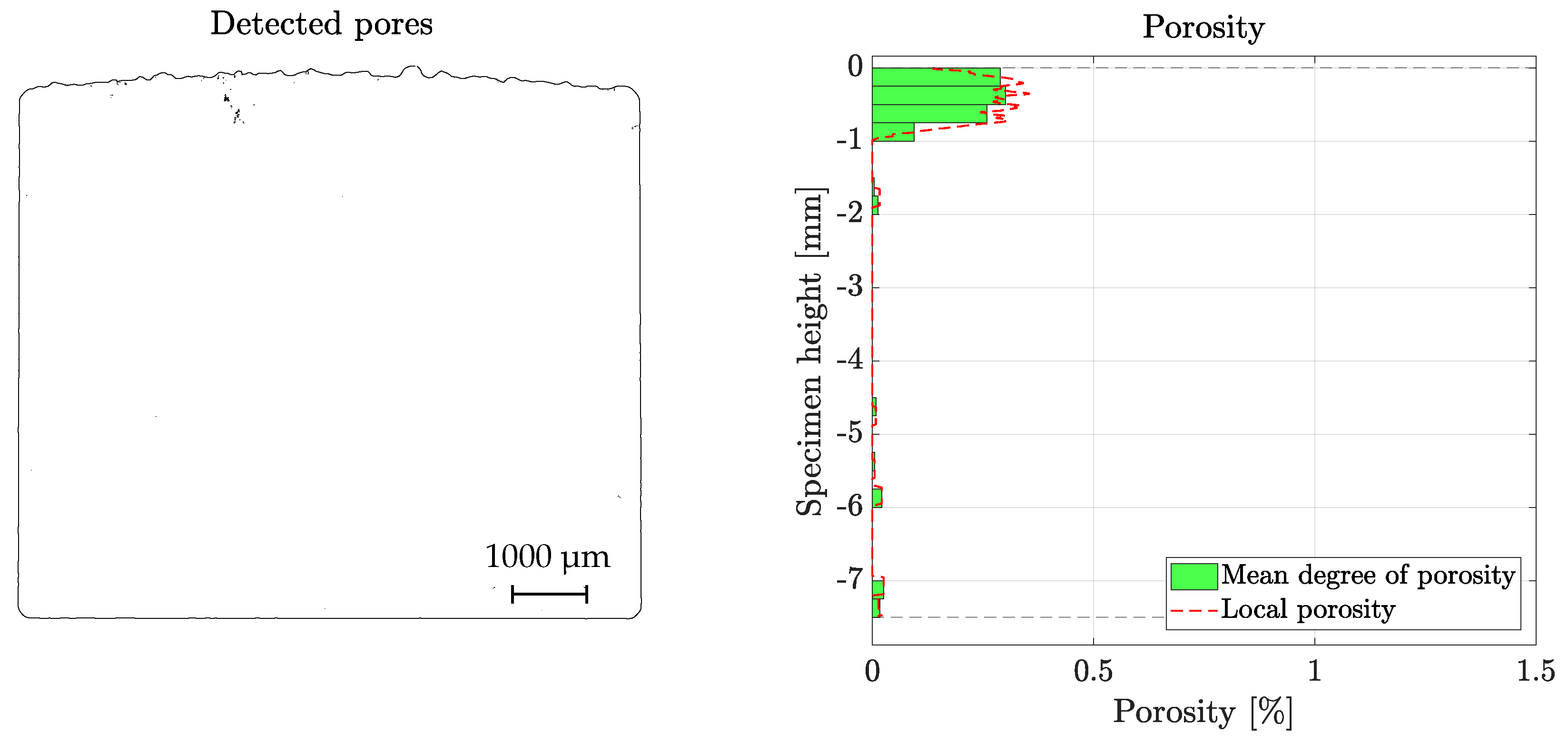

The same investigations and evaluation procedure have been conducted for four HIP specimens, again resulting in 140 metallographic analysis slices. A representative result is depicted in

Figure 7. It is clearly recognisable, that the HIP process lead to significantly reduced, or even partially completely suppressed porosity within the bulk material. Only within the first mm in depth, porosity was still observable whereat the HIP process did not close these micropores. As this is within the highly stressed region of the specimen, crack initiation is still caused by those surface roughness and microporosity mixed cases (Cast-M), thus resulting in similar long life fatigue strength values as previously discussed.

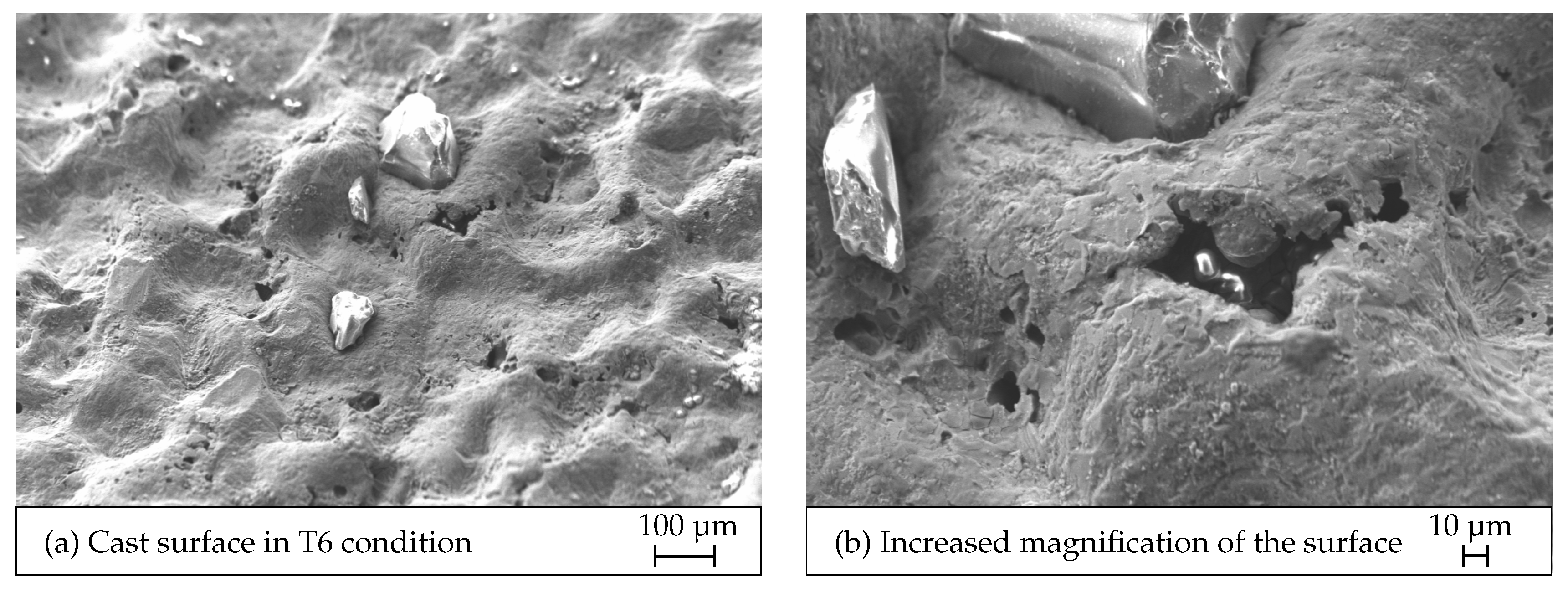

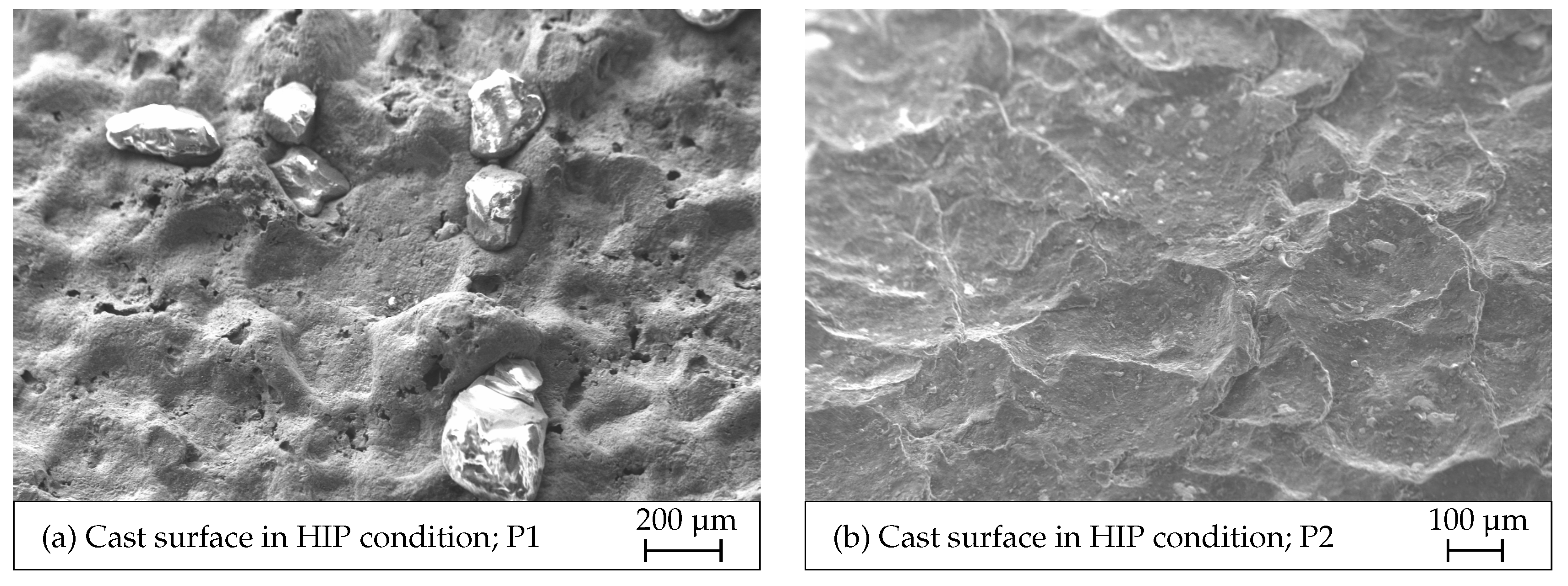

The comparably high possibility of observing a mixed (Cast-M) defect case becomes visible by a comparison of the cast surfaces in T6 and HIP condition by means of SEM.

Figure 8a,b depicts SEM images of the cast T6 surface at sampling position P1. Both sub-figures show that the cast surface is frequently broached by cavities, or shrinkage pores. Those cavities can be found both within surface pits as well as at surface peaks. In

Figure 8b, even the dendritic structure of the

-phase is observable. Thus, a relatively high chance of crack initiation occurring at a combination of both surface pits due to the surface roughness and surface layer porosity is present.

In

Figure 9, the SEM images of the investigated cast surfaces in HIP condition are illustrated for both sampling position P1 and P2. For cast surface texture comparison purpose,

Table 5 lists the mean values

of the global

roughness parameter of all specimens, in respect to the sampling position. Additionally, the 10–90% scatter values are given. The cast surface of P1 (

Figure 9a) is basically identical to the cast surface in T6 heat treatment condition presented in

Figure 8a. Especially broached pores are again observable in a similar amount. Those cavities and dendritic canals, created by the solidification process, can reach down to about 1 mm in depth in some cases, as those micropores can not be closed by the HIP process. This matches the statement of Atkinson [

56] on surface connected porosity. Thus, it can be stated that if, subsequently to the casting process, the machined surface finish is conducted with the aim of removal of surface near porosity, the process has to cover a certain depth. For the exemplified case of

Figure 7, removing only 0.5 mm of the cast surface would lead to a broached pore. As broached pores essentially decrease the local fatigue strength as well, such a machining process would not have the intended favourable fatigue effect and lead to similar fatigue strength results as those including cast surface, as presented in [

36]. For the cast surface in HIP condition at sampling position P2, see

Figure 9b, no broached pores were recognisable on the surface. This matches the results of the HIP P2 fracture surface analysis, where predominantly surface layer pores have been observed which are not broaching the cast surface, but are located about 10 µm to 30 µm beneath. As already mentioned, this might be caused by the significantly increased solidification rate at this sampling position P2 compared to P1.