Correlations and Scalability of Mechanical Properties on the Micro, Meso and Macro Scale of Precipitation-Hardenable Aluminium Alloy EN AW-6082

Abstract

1. Introduction

2. Materials and Methods

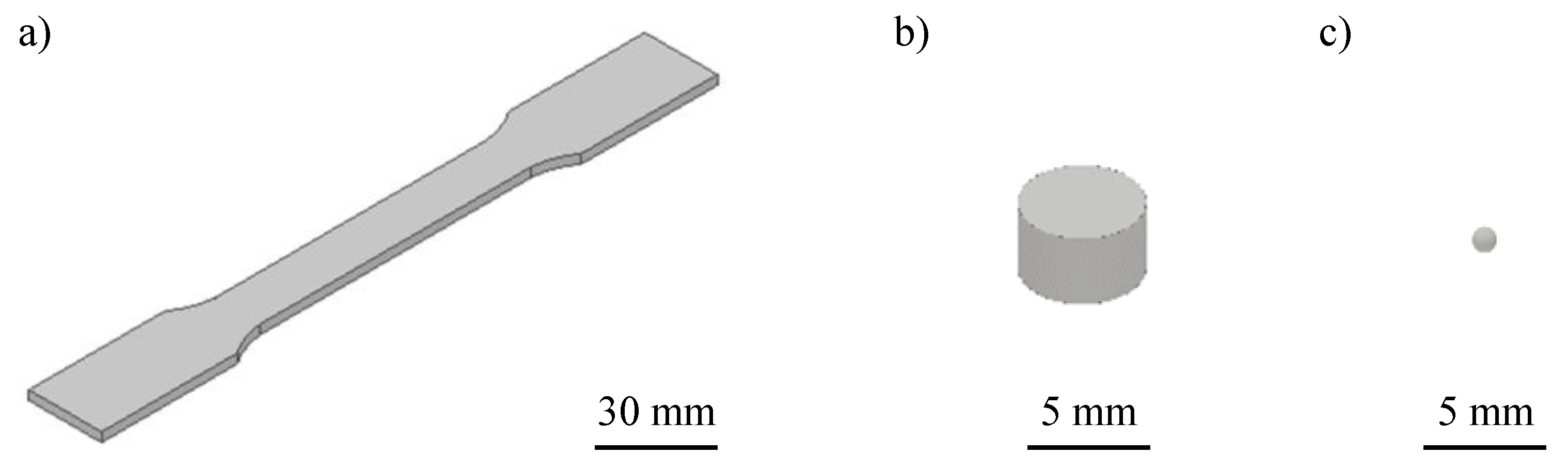

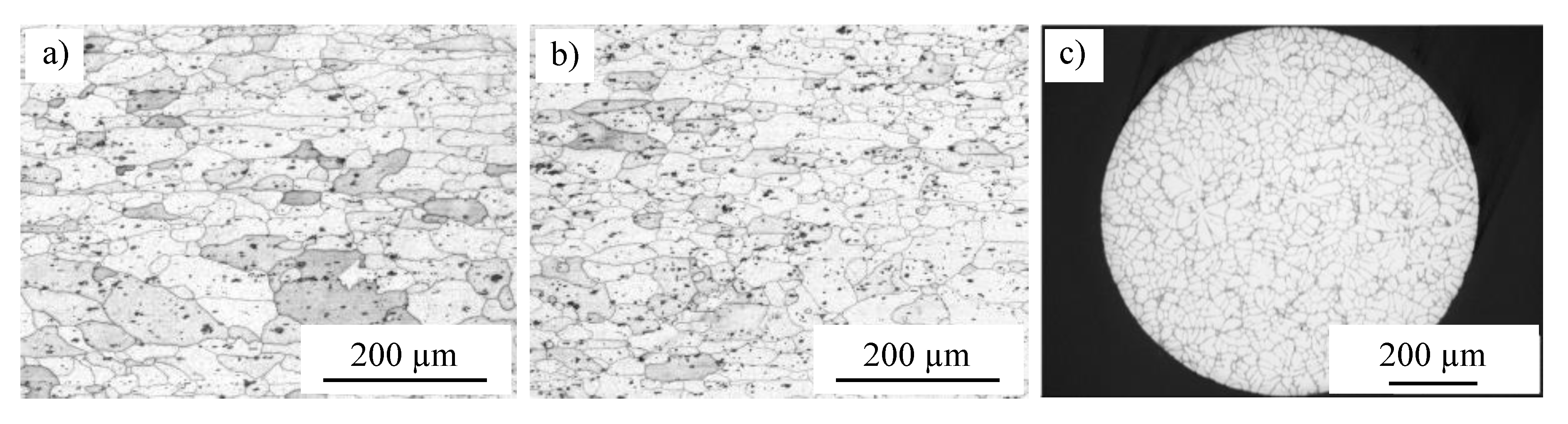

2.1. Material and Sample Geometry

2.2. Heat Treatment

2.3. Experimental Testing

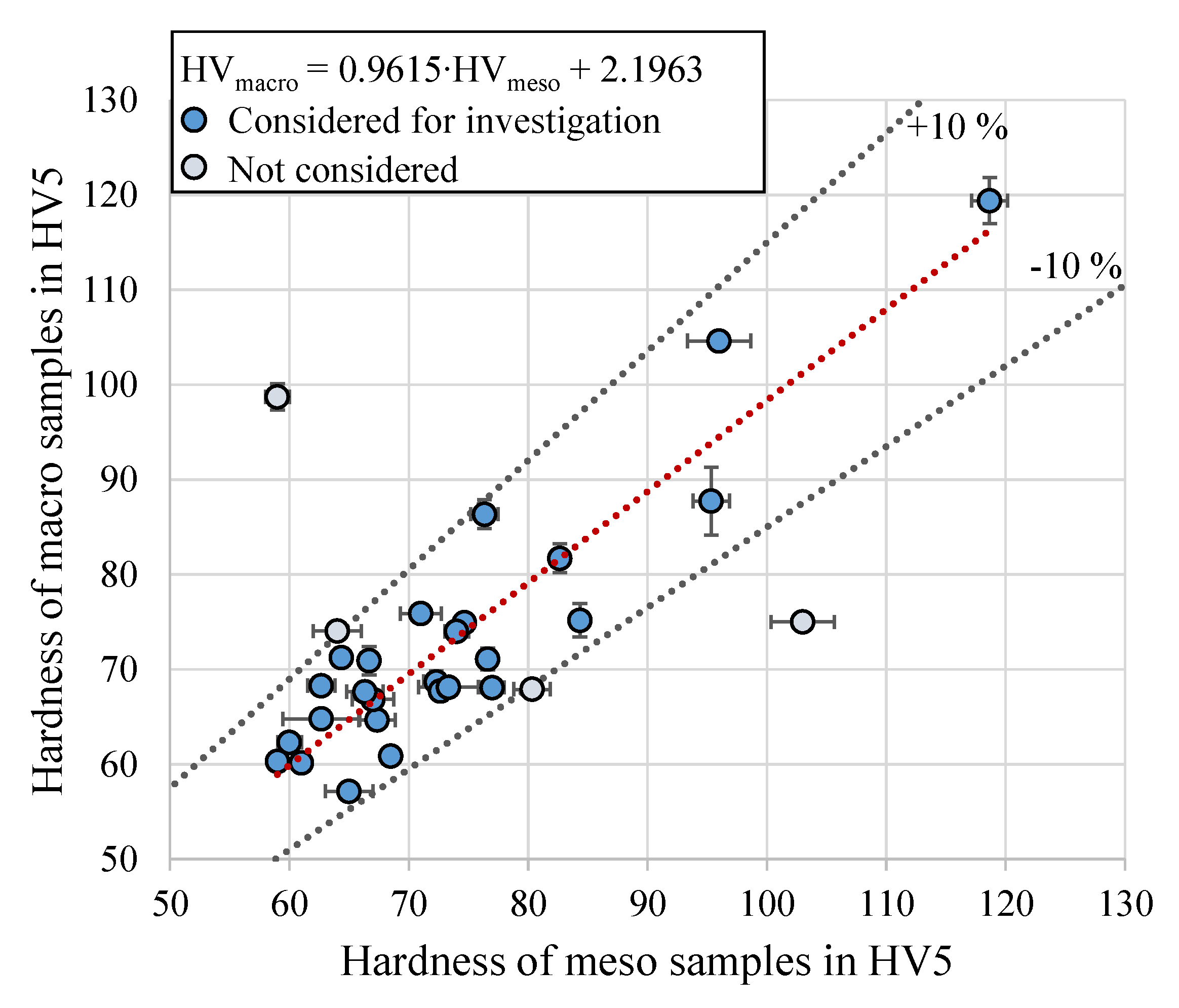

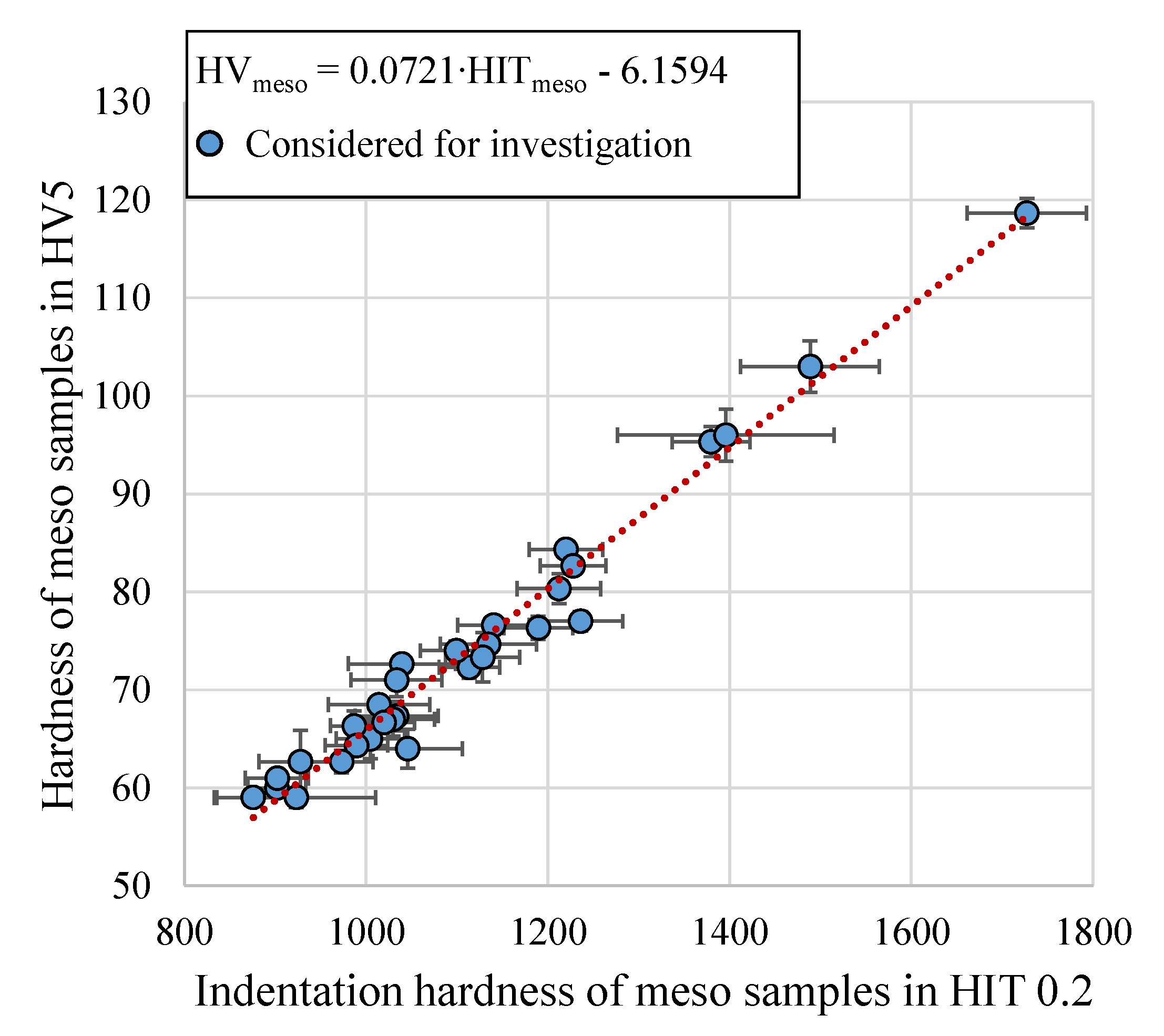

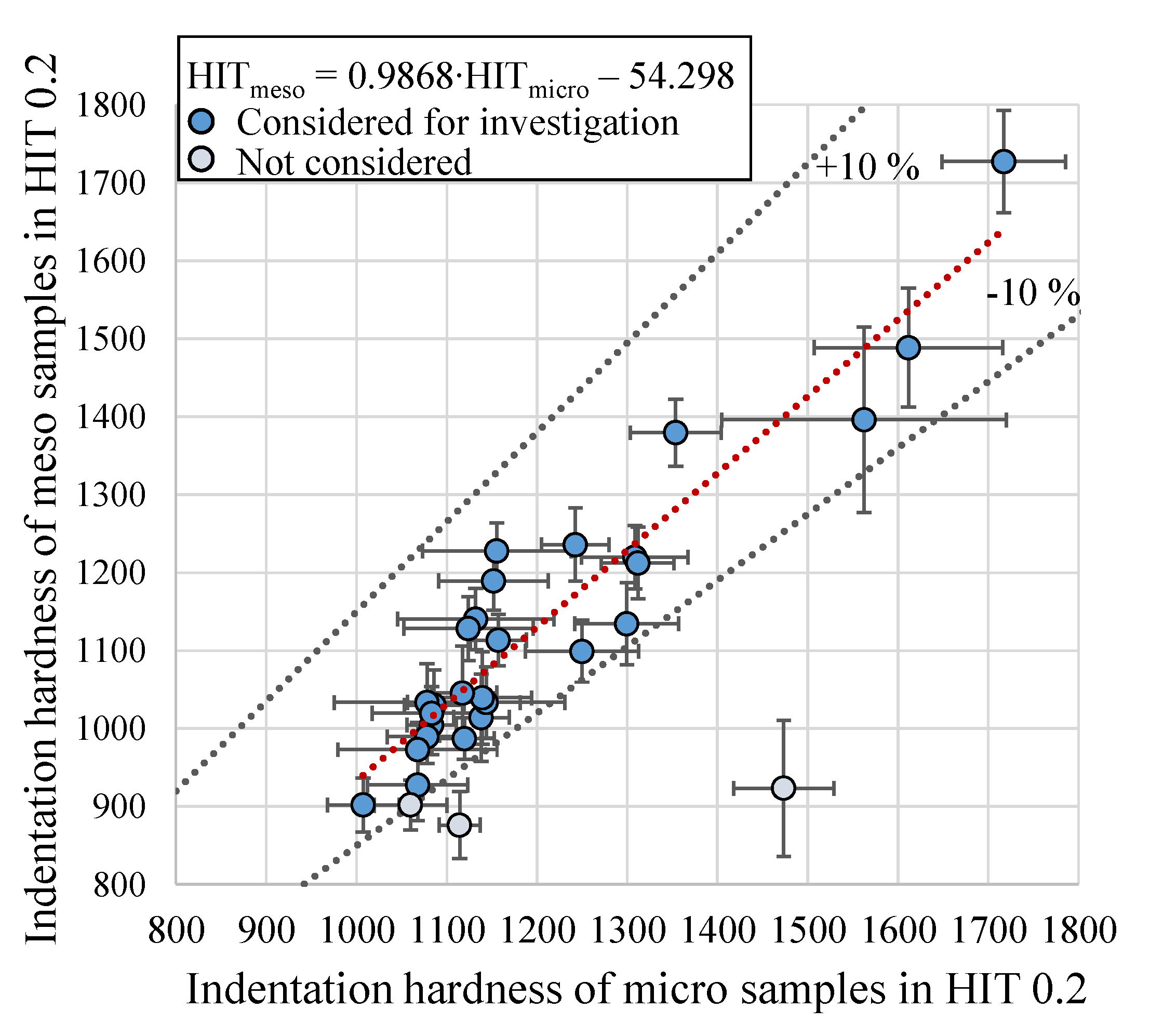

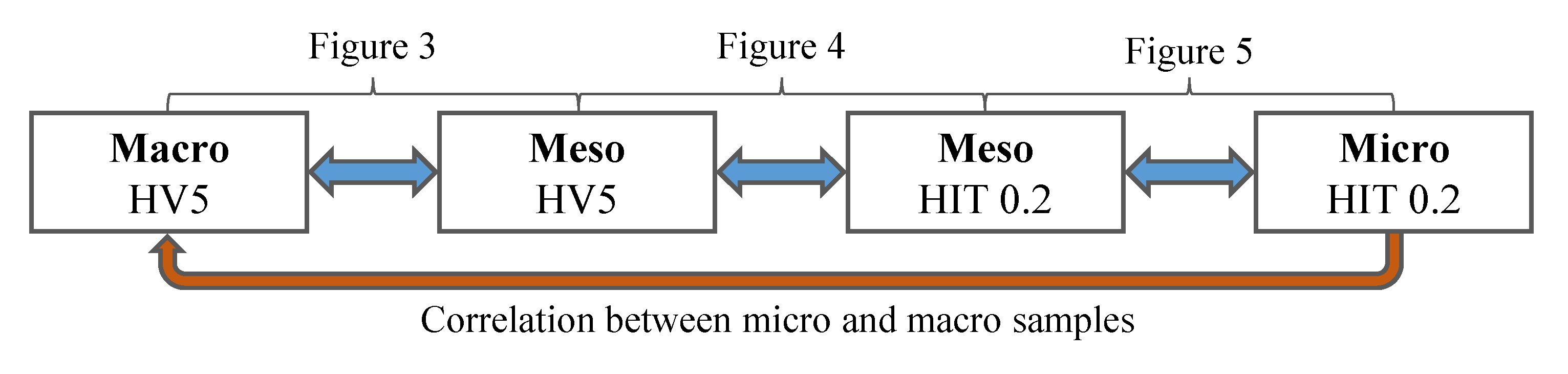

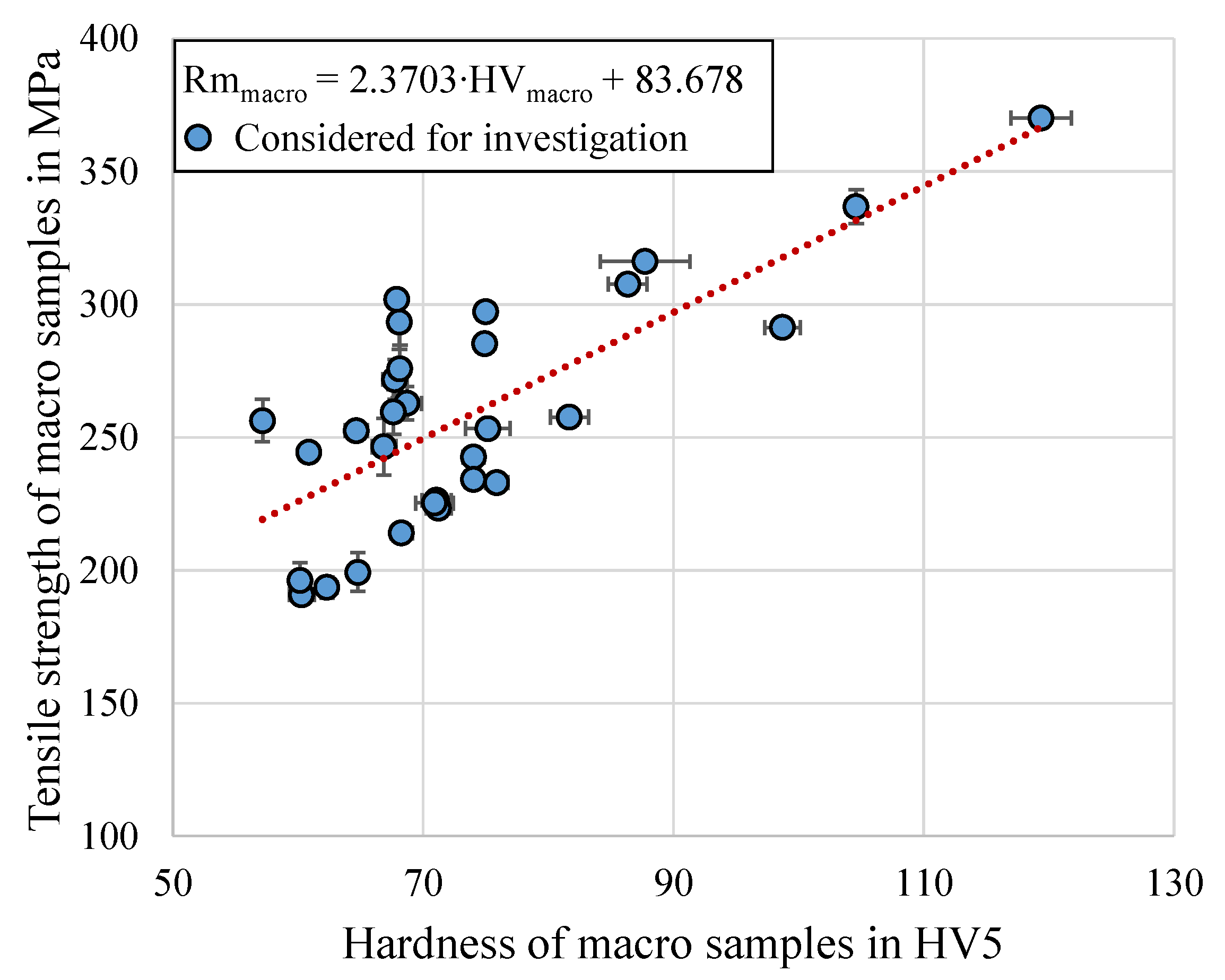

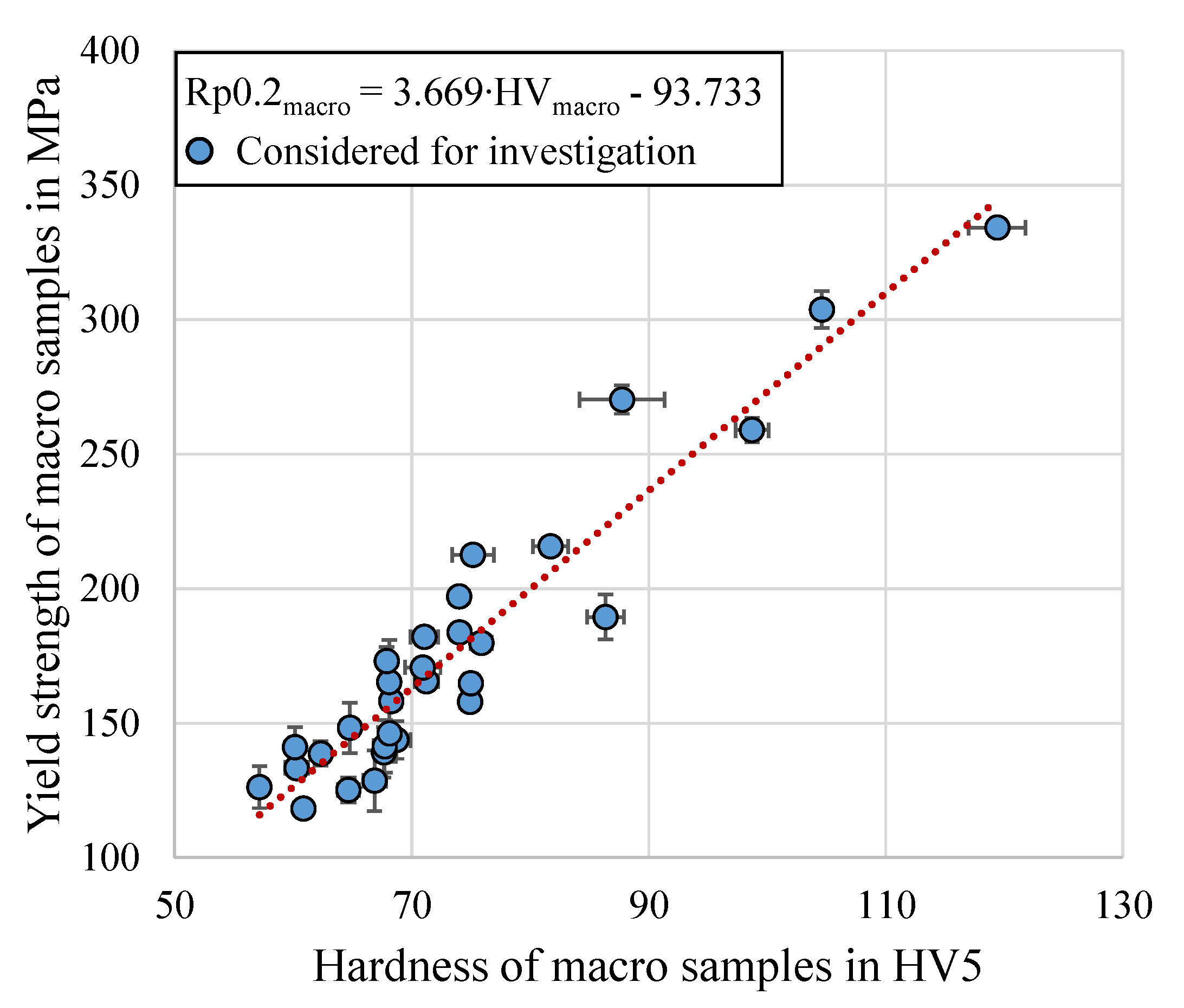

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nicolas, M.; Deschamps, A. Characterisation and modelling of precipitate evolution in an Al-Zn-Mg alloy during non-isothermal heat treatments. Acta Mater. 2003, 51, 6077–6094. [Google Scholar] [CrossRef]

- Werenskiold, J.C.; Deschamps, A.; Brechet, Y. Characterization and modeling of precipitation kinetics in an Al-Zn-Mg alloy. Mater. Sci. Eng. 2000, A293, 267–274. [Google Scholar] [CrossRef]

- Bardel, D.; Perez, M.; Nelias, D.; Deschamps, A.; Hutchinson, C.R.; Maisonnette, D.; Chaise, T.; Garnier, J.; Bourlier, F. Coupled precipitation and yield strength modelling for non-isothermal treatments of a 6061 aluminium alloy. Acta Mater. 2014, 62, 129–140. [Google Scholar] [CrossRef]

- Esmaeili, S.; Lloyd, D.J. Modeling of precipitation hardening in pre-aged AlMgSi(Cu) alloys. Acta Mater. 2005, 53, 5257–5271. [Google Scholar] [CrossRef]

- Khan, I.N.; Starink, M.J.; Yan, J.L. A model for precipitation kinetics and strengthening in Al-Cu-Mg alloys. Mater. Sci. Eng. 2008, A472, 66–74. [Google Scholar] [CrossRef]

- Österreicher, J.A.; Papenberg, N.P.; Kumar, M.; Ma, D.; Schwarz, S.; Schlögl, C.M. Quantitative prediction of the mechanical properties of precipitation-hardened alloys with special application to Al-Mg-Si. Mater. Sci. Eng. A 2017, 703, 380–385. [Google Scholar] [CrossRef]

- Sepehrband, P.; Esmaeili, S. Application of recently developed approaches to microstructural characterization and yield strength modeling of aluminum alloy AA7030. Mater. Sci. Eng. A 2008, 487, 309–315. [Google Scholar] [CrossRef]

- Esmaeili, S.; Lloyd, D.J.; Poole, W.J. A yield strength model for the Al-Mg-Si-Cu alloy AA6111. Acta Mater. 2003, 51, 2243–2257. [Google Scholar] [CrossRef]

- Zander, J.; Sandström, R. One parameter model for strength properties of hardenable aluminium alloys. Mater. Des. 2008, 29, 1540–1548. [Google Scholar] [CrossRef]

- Toenjes, A. Empirische Methode zur schnellen Charakterisierung von Wärmebehandlungszuständen hochfester Aluminiumlegierungen. Ph.D. Thesis, Universität Bremen, Bremen, Germany, 2019. [Google Scholar]

- Springer, H.; Raabe, D. Rapid alloy prototyping: Compositional and thermo-mechanical high throughput bulk combinatorial design of structural materials based on the example of 30Mn-1.2C-xAl triplex steels. Acta Mater. 2012, 60, 4950–4959. [Google Scholar] [CrossRef]

- Potyrailo, R.; Rajan, K.; Stoewe, K.; Takeuchi, I.; Chisholm, B.; Lam, H. Combinatorial and high-throughput screening of materials libraries: Review of state of the art. ACS Combinatorial Sci. 2011, 13, 579–633. [Google Scholar] [CrossRef] [PubMed]

- Ellendt, N.; Mädler, L. High-Throughput Exploration of Evolutionary Structural Materials. HTM J. Heat Treat. Mater. 2018, 73, 3–12. [Google Scholar] [CrossRef]

- Moqadam, S.I.; Madler, L.; Ellendt, N. Microstructure Adjustment of Spherical Micro-samples for High-Throughput Analysis Using a Drop-on-Demand Droplet Generator. Materials 2019, 12, 3769. [Google Scholar] [CrossRef] [PubMed]

- Steinbacher, M.; Alexe, G.; Baune, M.; Bobrov, I.; Bösing, I.; Clausen, B.; Czotscher, T.; Riemer, O.; Sonnenberg, H.; Thomann, A.; et al. Descriptors for High Throughput in Structural Materials Development. High-throughput 2019, 8, 22. [Google Scholar] [CrossRef] [PubMed]

- Sonnenberg, H.; Clausen, B. Short-Term Characterization of Spherical 100Cr6 Steel Samples Using Micro Compression Test. Materials 2020, 13, 733. [Google Scholar] [CrossRef] [PubMed]

- Box, G.E.P.; Lucas, H.L. Design of experiments in nonlinear situations. Biometrika 1959, 46, 77–90. [Google Scholar] [CrossRef]

- Sarmiento, G.; Bronzini, C.; Canale, A.; Canale, L.; Totten, G. Water and Polymer Quenching of Aluminum Alloys: A Review of the Effect of Surface Condition, Water Temperature, and Polymer Quenchant Concentration on the Yield Strength of 7075-T6 Aluminum Plate. J. ASTM Int. 2008, 6, 1–18. [Google Scholar]

| Material | Chemical Composition in wt.% | |||||||

|---|---|---|---|---|---|---|---|---|

| Al | Si | Mg | Mn | Fe | Cu | Others | ||

| Samples alloy | bal. | 0.916 | 0.727 | 0.437 | 0.381 | 0.086 | <0.05 | |

| DIN EN 573-3:2013-12 | min. | bal. | 0.7 | 0.6 | 0.40 | - | - | - |

| max. | 1.3 | 1.2 | 1.0 | 0.50 | 0.10 | 0.15 | ||

| No. | Ts (°C) | ts (h) | QM | Ta (°C) | ta (h) |

|---|---|---|---|---|---|

| 1 | 500 | 0.25 | Water | 100 | 20 |

| 2 | 500 | 0.25 | Water | 240 | 2 |

| 3 | 500 | 0.25 | Gas | 100 | 2 |

| 4 | 500 | 0.25 | Gas | 170 | 11 |

| 5 | 500 | 0.25 | Gas | 240 | 20 |

| 6 | 500 | 0.25 | Polymer | 240 | 20 |

| 7 | 500 | 2.13 | Polymer | 100 | 2 |

| 8 | 500 | 4 | Water | 100 | 2 |

| 9 | 500 | 4 | Water | 240 | 20 |

| 10 | 500 | 4 | Gas | 100 | 20 |

| 11 | 500 | 4 | Gas | 240 | 2 |

| 12 | 500 | 4 | Polymer | 100 | 20 |

| 13 | 500 | 4 | Polymer | 170 | 2 |

| 14 | 530 | 0.25 | Polymer | 100 | 11 |

| 15 | 530 | 2.13 | Gas | 170 | 20 |

| 16 | 530 | 4 | Gas | 100 | 2 |

| 17 | 530 | 4 | Polymer | 240 | 2 |

| 18 | 560 | 0.25 | Water | 100 | 2 |

| 19 | 560 | 0.25 | Water | 240 | 20 |

| 20 | 560 | 0.25 | Gas | 100 | 20 |

| 21 | 560 | 0.25 | Gas | 240 | 2 |

| 22 | 560 | 0.25 | Polymer | 170 | 20 |

| 23 | 560 | 0.25 | Polymer | 240 | 11 |

| 24 | 560 | 2.13 | Polymer | 240 | 11 |

| 25 | 560 | 4 | Water | 100 | 20 |

| 26 | 560 | 4 | Water | 240 | 2 |

| 27 | 560 | 4 | Gas | 100 | 11 |

| 28 | 560 | 4 | Gas | 240 | 20 |

| 29 | 560 | 4 | Polymer | 100 | 2 |

| 30 | 560 | 4 | Polymer | 240 | 20 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toenjes, A.; Sonnenberg, H.; von Hehl, A. Correlations and Scalability of Mechanical Properties on the Micro, Meso and Macro Scale of Precipitation-Hardenable Aluminium Alloy EN AW-6082. Metals 2020, 10, 608. https://doi.org/10.3390/met10050608

Toenjes A, Sonnenberg H, von Hehl A. Correlations and Scalability of Mechanical Properties on the Micro, Meso and Macro Scale of Precipitation-Hardenable Aluminium Alloy EN AW-6082. Metals. 2020; 10(5):608. https://doi.org/10.3390/met10050608

Chicago/Turabian StyleToenjes, Anastasiya, Heike Sonnenberg, and Axel von Hehl. 2020. "Correlations and Scalability of Mechanical Properties on the Micro, Meso and Macro Scale of Precipitation-Hardenable Aluminium Alloy EN AW-6082" Metals 10, no. 5: 608. https://doi.org/10.3390/met10050608

APA StyleToenjes, A., Sonnenberg, H., & von Hehl, A. (2020). Correlations and Scalability of Mechanical Properties on the Micro, Meso and Macro Scale of Precipitation-Hardenable Aluminium Alloy EN AW-6082. Metals, 10(5), 608. https://doi.org/10.3390/met10050608