Diagnosis Method for the Heat Balance State of an Aluminum Reduction Cell Based on Bayesian Network

Abstract

:1. Introduction

2. Bayesian Network

2.1. Selection of Network Node

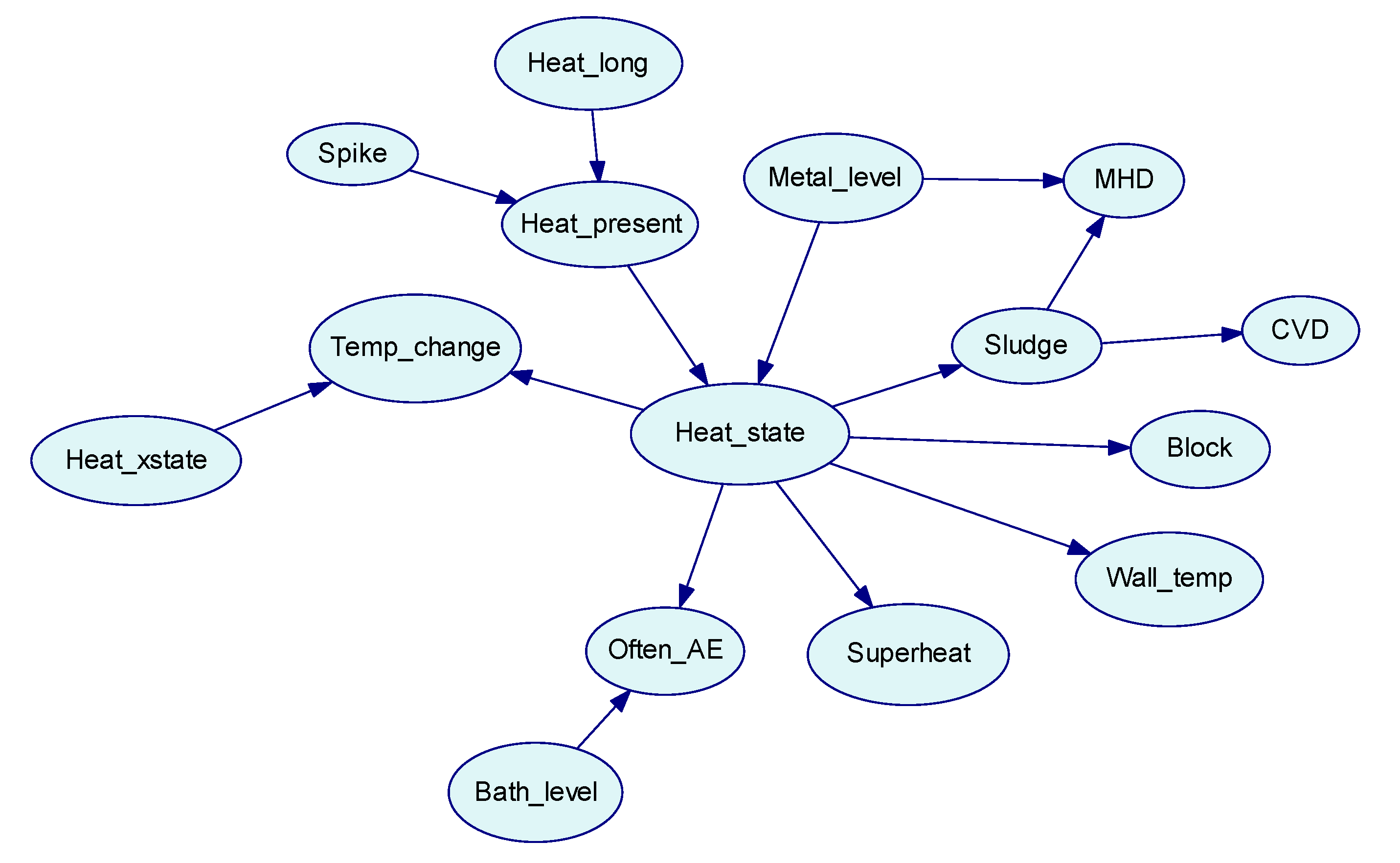

2.2. Analysis of Causality among Nodes

2.2.1. Variables Influencing “Heat_State”

2.2.2. Variables Affected by “Heat_State”

2.2.3. Influencing of Other Variables

2.3. Configuration of Bayesian Network

2.3.1. Structure of Bayesian Network

2.3.2. Conditional Probability Tables

3. Diagnosis and Analysis of Heat Balance

3.1. Inference and Calculation Method of Bayesian Network

3.2. Single Diagnosis

3.3. Continuous Diagnosis

3.4. Application Effect

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rye, K. Dynamic Ledge Response in Hall-Héroult Cells. In Proceedings of the TMS Light Metals, San Diego, CA, USA, 28 February–4 March 1999; The Minerals, Metals & Materials Society: Pittsburg, PA, USA, 1999; pp. 347–352. [Google Scholar]

- Romerio, M.V.; Flueck, M.; Rappaz, J. Determination and Influence of the Ledge Shape on Electrical Potential and Fluid Motions in a Smelter. In Proceedings of the TMS Light Metals, San Francisco, CA, USA, 13–17 February 2005; The Minerals, Metals & Materials Society: Pittsburg, PA, USA, 2005; pp. 461–468. [Google Scholar]

- Solheim, A. Towards a Proper Understanding of Sideledge Facing the Metal in Aluminium Cells. In Proceedings of the TMS Light Metals, San Antonio, TX, USA, 12–16 March 2006; The Minerals, Metals & Materials Society: Pittsburg, PA, USA, 2006; pp. 439–443. [Google Scholar]

- Solheim, A.; Gudbrandsen, H.; Rolseth, S. Sideledge in Aluminium Cells: The Trench at the Metal-Bath Boundary. In Proceedings of the TMS Light Metals, San Francisco, CA, USA, 15–19 February 2009; The Minerals, Metals & Materials Society: Pittsburg, PA, USA, 2009; pp. 411–416. [Google Scholar]

- Solheim, A. Some aspects of heat transfer between bath and sideledge in aluminium reduction cells. In Proceedings of the TMS Light Metals, San Diego, CA, USA, 27 February–3 March 2011; The Minerals, Metals & Materials Society: Pittsburg, PA, USA, 2011; pp. 381–386. [Google Scholar]

- Guo, Y.J.; Hu, F.; Yu, H.; Zhang, H. Prediction model of superheat in aluminum electrolysis based on time granularity. J. Nanjing Univ. 2019, 55, 624–632. [Google Scholar]

- Cao, D.Y.; Zeng, S.P.; Li, J.H. Research on prediction model of aluminium electrolyte superheat degree. Light Met. 2010, 10, 35–38. (In Chinese) [Google Scholar]

- Long, G.W. Heat balance control of aluminum reduction cell based on BP nerve networks. Light Met. 2006, 8, 47–50. (In Chinese) [Google Scholar]

- Ding, L. 350kA Aluminum Production Cell Fault Diagnosis System Research. Master’s Thesis, North China University of Technology, Beijing, China, 2006. [Google Scholar]

- Li, H.; Mei, Z.; Tang, Q. The Aluminum Production Cell Status Diagnosis on the Fuzzy Neural Network. J. Syst. Stimul. 2006, 18, 482–484. [Google Scholar]

- Boadu, K.D.; Omani, F.K. Adaptive control of feed in the Hall-Héroult cell using a neural network. JOM 2010, 62, 32–36. [Google Scholar] [CrossRef]

- Frost, F.; Karri, V. Productivity Improvements through Prediction of Electrolyte Temperature in Aluminium Reduction Cell Using BP Neural Network. In PRICAI 2000 Topics in Artificial Intelligence, Proceedings of the Pacific Rim International Conference on Artificial Intelligence, Melbourne, VIC, Australia, 28 August–1 September 2000; Mizoguchi, R., Slaney, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2000; pp. 490–499. [Google Scholar]

- Karri, V.; Frost, F. Need for Optimization Techniques to Select Neural Network Algorithms for Process Modelling of Reduction Cell. In PRICAI 2000 Topics in Artificial Intelligence, Proceedings of the Pacific Rim International Conference on Artificial Intelligence, Melbourne, VIC, Australia, 28 August–1 September 2000; Mizoguchi, R., Slaney, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2000; pp. 480–489. [Google Scholar]

- Zeng, S.; Wang, R.; Guo, Y. Research on Addition of Aluminum Fluoride for Aluminum Reduction Cell Based on the Neural Network. In Proceedings of the Advanced Research on Computer Education, Simulation and Modeling, Wuhan, China, 18–19 June 2011; Springer: Berlin/Heidelberg, Germany, 2011; pp. 200–206. [Google Scholar]

- Zeng, S.; Li, J.; Cui, L. Cell Status Diagnosis for the Aluminum Production on BP Neural Network with Genetic Algorithm. In Proceedings of the Advanced Research on Computer Education, Simulation and Modeling, Wuhan, China, 18–19 June 2011; Springer: Berlin/Heidelberg, Germany, 2011; pp. 146–152. [Google Scholar]

- Li, H.S.; Han, L.G. Diagnosis of working conditions of aluminum reduction cells based on wavelet-neutral network. J. Vib. Meas. Diagn. 2006, 4, 309–333. [Google Scholar]

- Li, H.S.; Mei, C.; Tang, Q. Diagnosis of working conditions of aluminum reduction cells based on fuzzy neural network. J. Syst. Simul. 2006, 18, 482–484. [Google Scholar] [CrossRef]

- Li, J.J.; Wu, C.D.; Li, Y. Application research on neural network predictive control technology in aluminum electrolysis process. Instrum. Tech. Sens. 2011, 8, 91–93. [Google Scholar] [CrossRef]

- Wang, S.C. Bayesian Network Learning Inference and Application; Lixin Accounting Press: Shanghai, China, 2010; pp. 45–50. [Google Scholar]

- Hong, B.; Tian, Q.H.; Chen, Z.Y.; Tan, X.; Yu, S. The Application of Intelligent Breaking and Feeding Technology for Aluminium Reduction Pot. In Proceedings of the TMS Light Metals, San Diego, CA, USA, 23–27 February 2020; The Minerals, Metals & Materials Society: Pittsburg, PA, USA, 2020; pp. 719–725. [Google Scholar]

- Solheim, A.; Rolseth, S.; Skybakmoen, E. Liquidus temperatures for primary crystallization of cryolite in molten salt systems of interest for aluminum electrolysis. Metall. Mater. Trans. B. 1996, 27, 739–744. [Google Scholar] [CrossRef]

- Liu, Y.X.; Li, J. Modern Aluminum Reduction; Metallurgical Industry Press: Beijing, China, 2008; pp. 121–124. [Google Scholar]

- Li, J.; Yang, S.; Zou, Z.; Zhang, H. Experiments on Measurement of Online Anode Currents at Anode Beam in Aluminum Reduction Cells. In Proceedings of the TMS Light Metals, Orlando, FA, USA, 15–19 March 2015; The Minerals, Metals & Materials Society: Pittsburg, PA, USA, 2015; pp. 741–745. [Google Scholar]

- Yang, S.; Zou, Z.; Li, J.; Zhang, H. Online anode current signal in aluminum reduction cells: Measurements and prospects. JOM 2016, 68, 623–634. [Google Scholar] [CrossRef]

- Lu, H.M.; Qiu, Z.X. Relationship curves of pseudo-resistance vs alumina concentration for low cryolite ratio aluminium electrolytes. Nonferr. Metals 1997, 49, 53–56. [Google Scholar]

| Node Name | State 1 | State 2 | State 3 |

|---|---|---|---|

| “Heat state” | Low: | Normal *: | High: |

| Superheat < 7 °C | Superheat 7–13 °C | Superheat > 13 °C | |

| “Often AE” | No *: | Medium: | High: |

| Zero times | Smaller or equal to two times | More than two times | |

| “Block” | Low *: | High: | |

| Smaller or equal to one time | More than one time | ||

| “Bath_level” | Low: | Normal *: | High: |

| <16 cm | 16–19 cm | >19 cm | |

| “Metal_level” | Low: | Normal *: | High: |

| <26 cm | 26~30 cm | >30 cm | |

| “Superheat” | Low: | Normal *: | High: |

| <7 °C | 7–13 °C | >13 °C | |

| “Heat_long” | Low: | Normal *: | High: |

| <1.91 V | 1.91–1.96 V | >1.96 V | |

| “MHD” | Low: | Medium *: | High: |

| <30 min | 30–60 min | >60 min | |

| “CVD” | Normal *: | High: | Very high: |

| <(V0 + 30) mV | (V0 + 30)–(V0 + 100) mV | >(V0 + 100) mV | |

| “Spike” | No *: | Yes: | |

| No spikes all the time | There are spikes | ||

| “Temp_change” | Decrease: | Stable *: | Increase: |

| T0 ≤ (T1 − 4) °C and T1 ≤ (T2 + 1) °C or T0 ≤ (T1 − 2) °C and T1 ≤ (T2 − 2) °C | Neither decrease nor increase | T0 ≥ (T1 + 4) °C and T1 ≥ (T2 − 1) °C or T0 ≥ (T1 + 2) °C and T1 ≥ (T2 + 2) °C | |

| “Heat_xstate” | Low: | Normal *: | High: |

| Superheat < 7 °C | Superheat 7–13 °C | Superheat > 13 °C | |

| “Wall_temp” | Normal*: | High: | Very high: |

| <350 °C | 350–400 °C | >450 °C | |

| “Sludge” | No *: | Yes: | |

| No hard sludge | Hard sludge | ||

| “Heat_present” | Low: | Normal *: | High: |

| <1.91 V | 1.91–1.96 V | >1.96 V |

| Heat_Present | Metal_Level | Heat_State (%) | ||

|---|---|---|---|---|

| Low | Normal | High | ||

| Low | Low | 10.3 | 84.5 | 5.2 |

| Low | Normal | 23.5 | 74.4 | 2.1 |

| Low | High | 58.8 | 40.3 | 0.9 |

| Normal | Low | 2.5 | 80.5 | 17.0 |

| Normal | Normal | 4.7 | 92.1 | 3.2 |

| Normal | High | 15.2 | 82.6 | 2.2 |

| High | Low | 1.2 | 52.4 | 46.4 |

| High | Normal | 5.7 | 74.1 | 20.2 |

| High | High | 7.0 | 80.4 | 12.6 |

| Evidence | “Heat_State” Results (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| Superheat | Often_AE | Temp_Change | CVD | Spike | Block | Low | Normal | High |

| Normal | No | Normal | No | No | 0.1 | 99.3 | 0.6 | |

| Low | No | Normal | No | No | 4.8 | 95.2 | 0.0 | |

| High | No | Normal | No | No | 0.0 | 68.9 | 31.1 | |

| Medium | Normal | No | No | 4.1 | 94.4 | 1.5 | ||

| High | Normal | No | No | 27.4 | 72.6 | 0.0 | ||

| No | Decrease | Normal | No | No | 4.4 | 95.2 | 0.4 | |

| No | Increase | Normal | No | No | 0.0 | 73.2 | 26.8 | |

| No | High | No | No | 2.6 | 93.5 | 3.9 | ||

| No | Very high | No | No | 7.8 | 89.8 | 2.4 | ||

| No | Normal | Yes | No | 0.5 | 77.2 | 22.3 | ||

| No | Normal | No | Yes | 1.1 | 98.2 | 0.7 | ||

| High | Normal | No | Yes | 45.2 | 54.8 | 0.0 | ||

| Day | Evidence | Results of “Heat_State” (%) | |||

|---|---|---|---|---|---|

| Superheat | Temp_Change | Low | Normal | High | |

| 1 | Normal | 0.1 | 99.3 | 0.6 | |

| 2 | Normal | 0.1 | 99.3 | 0.6 | |

| 3 | Stable | 0.1 | 99.1 | 0.8 | |

| 4 | Increase | 0.0 | 88.5 | 11.5 | |

| 5 | Increase | 0.0 | 31.7 | 68.3 | |

| 6 | Increase | 0.0 | 2.8 | 97.2 | |

| 7 | Increase | 0.0 | 0.3 | 99.7 | |

| Day | Evidence | Results of “Heat_State” (%) | |||

|---|---|---|---|---|---|

| Superheat | Temp_Change | Low | Normal | High | |

| 1 | Normal | 0.1 | 99.3 | 0.6 | |

| 2 | Normal | 0.1 | 99.3 | 0.6 | |

| 3 | Stable | 0.1 | 99.1 | 0.8 | |

| 4 | Decrease | 0.2 | 99.8 | 0.0 | |

| 5 | Decrease | 0.4 | 99.6 | 0.0 | |

| 6 | Decrease | 0.8 | 99.2 | 0.0 | |

| 7 | Decrease | 1.4 | 98.6 | 0.0 | |

| Day | Evidence | Results of “Heat_State” (%) | |||||

|---|---|---|---|---|---|---|---|

| Superheat | Often_AE | Temp_Change | Block | Low | Normal | High | |

| 1 | Normal | No | No | 0.1 | 99.3 | 0.6 | |

| 2 | Normal | No | No | 0.1 | 99.3 | 0.6 | |

| 3 | No | Stable | No | 0.1 | 99.1 | 0.8 | |

| 4 | Medium | Decrease | Yes | 3.9 | 96.1 | 0.0 | |

| 5 | Medium | Decrease | Yes | 54.9 | 45.1 | 0.0 | |

| 6 | Medium | Decrease | Yes | 97.7 | 2.3 | 0.0 | |

| 7 | Medium | Decrease | Yes | 99.9 | 0.1 | 0.0 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, J.; Li, J. Diagnosis Method for the Heat Balance State of an Aluminum Reduction Cell Based on Bayesian Network. Metals 2020, 10, 604. https://doi.org/10.3390/met10050604

Zhu J, Li J. Diagnosis Method for the Heat Balance State of an Aluminum Reduction Cell Based on Bayesian Network. Metals. 2020; 10(5):604. https://doi.org/10.3390/met10050604

Chicago/Turabian StyleZhu, Jiaming, and Jie Li. 2020. "Diagnosis Method for the Heat Balance State of an Aluminum Reduction Cell Based on Bayesian Network" Metals 10, no. 5: 604. https://doi.org/10.3390/met10050604

APA StyleZhu, J., & Li, J. (2020). Diagnosis Method for the Heat Balance State of an Aluminum Reduction Cell Based on Bayesian Network. Metals, 10(5), 604. https://doi.org/10.3390/met10050604