Deep Contact Strength of Surface Hardened Gears

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Lebedev-Pisarenko Criterion

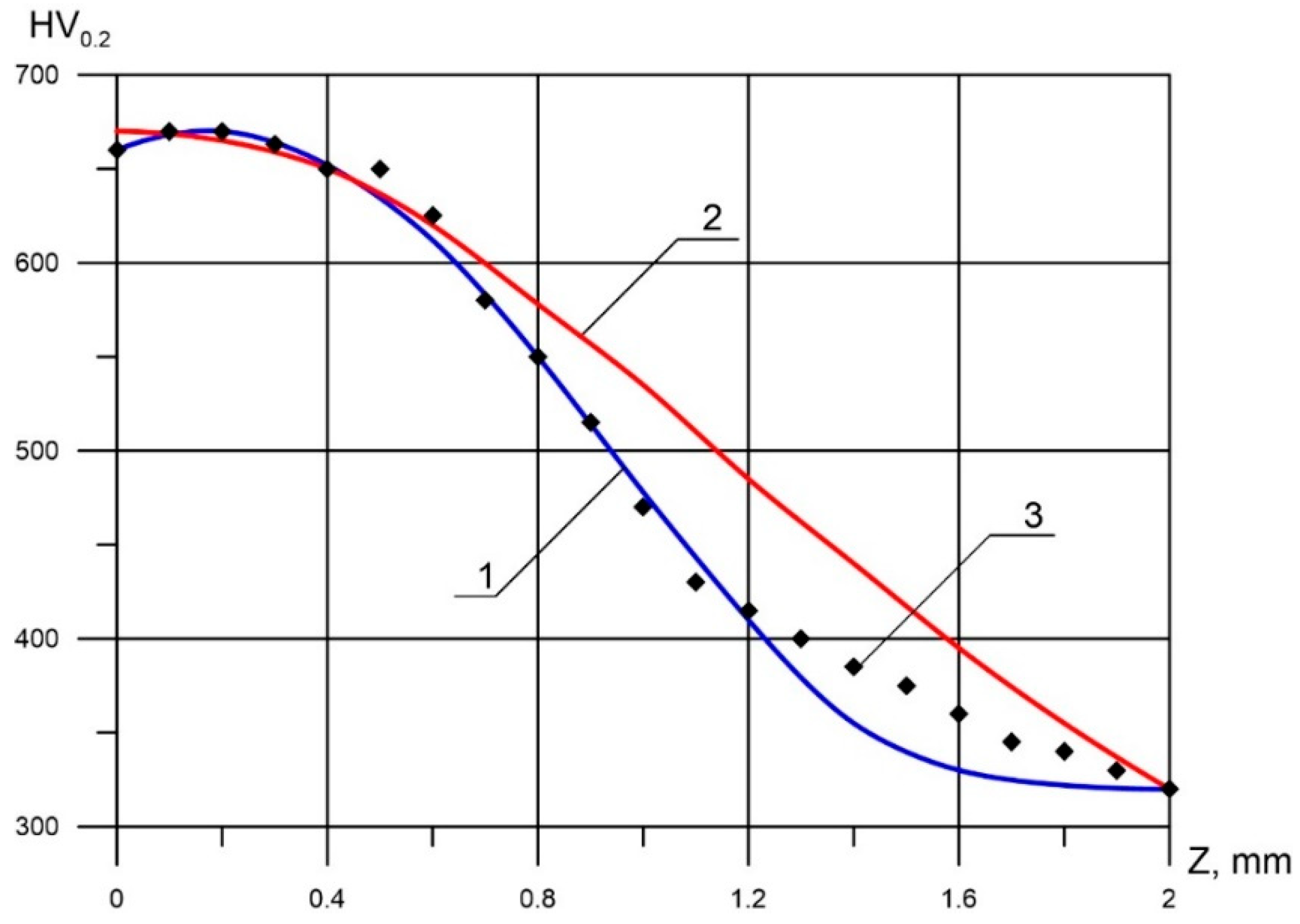

3.2. Hardness Distribution over the Thickness of the Hardened Layer

3.3. Gear Life Ratio

3.4. Effect of the Number of Potentially Dangerous Areas

3.5. Effect of the Approximation Error of Real Surfaces by Second-Order Surfaces

3.6. The Influence of Material Quality and the Dispersion of the Mechanical Properties of the Material in the Hardened Layer

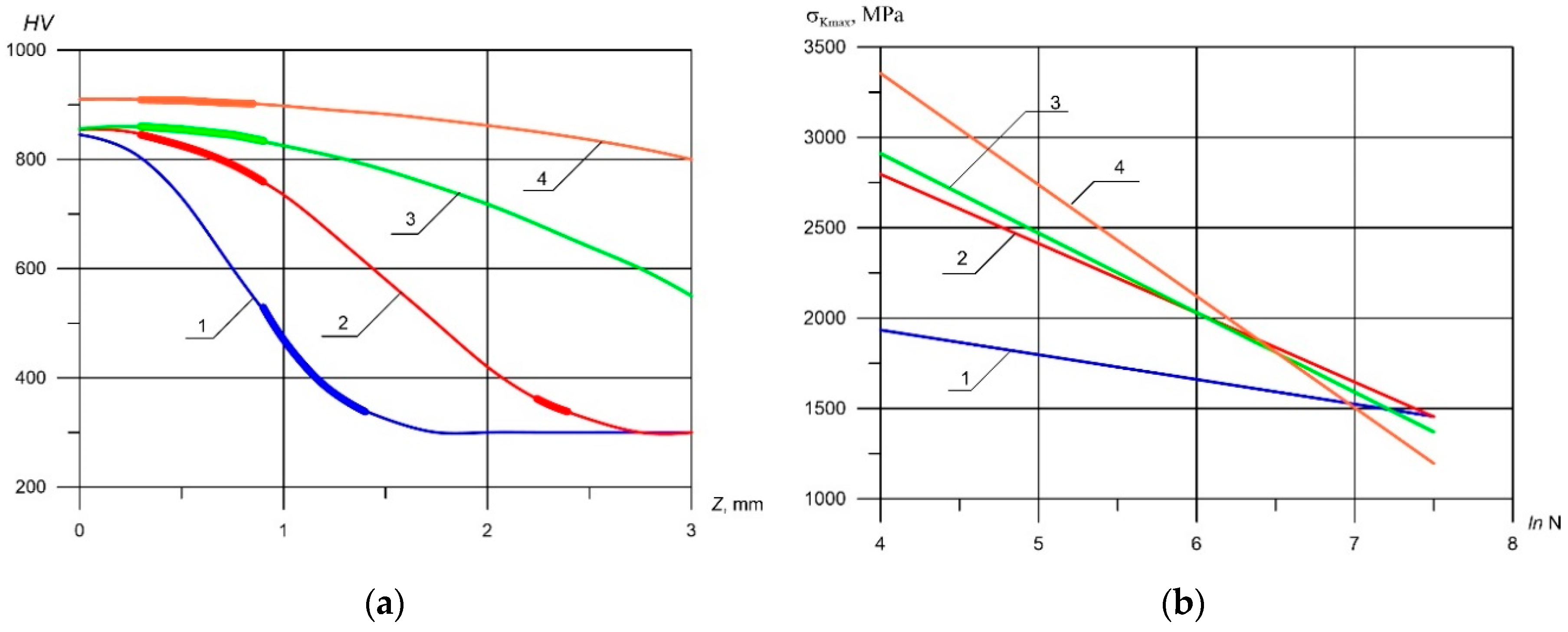

4. Model Analysis

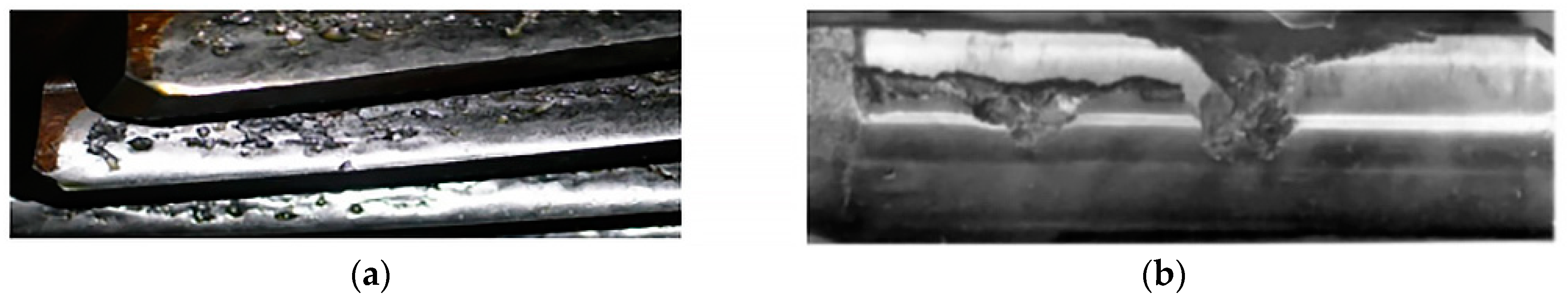

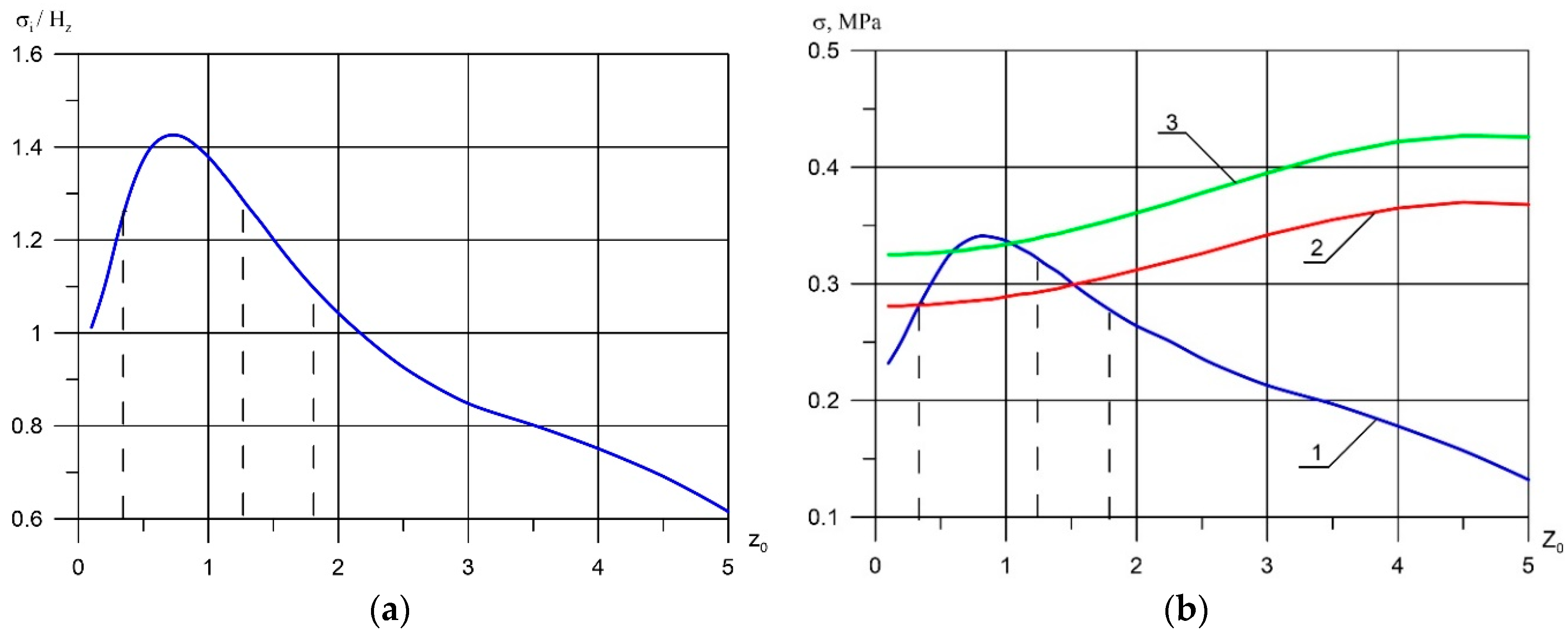

4.1. Sample CD-30

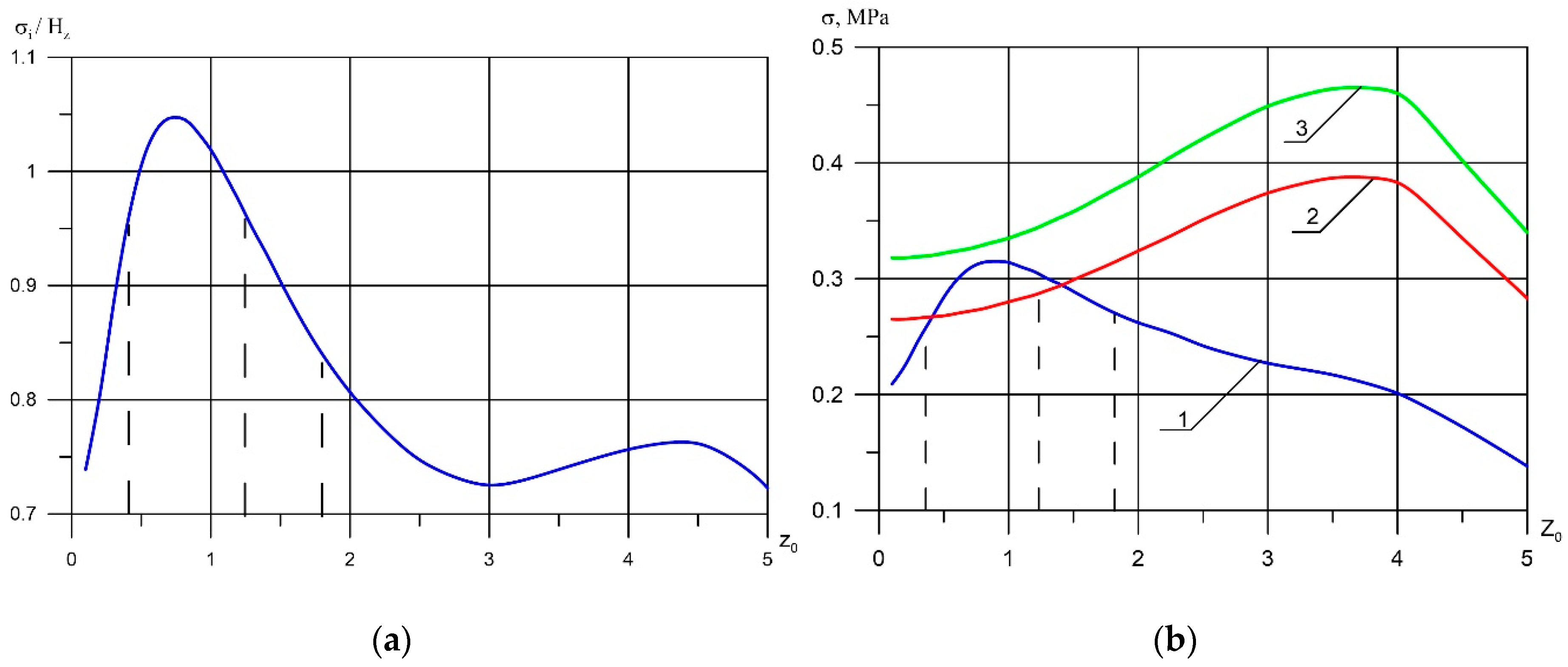

4.2. Sample CB-60

- (1)

- For CD-30 samples, the depth of the crack initiating DCS of this sample is about 0.15 mm (Figure 6). The fracture zone is in the area of maximum material strength; the load capacity of the part is limited by the strength of the diffusion layer itself. The deep contact strength of the samples is not provided. It is necessary to introduce a safety factor according to the DCS criterion ≥ 1.2.

- (2)

- The local maximum of the ratio is in good agreement with the average depth of contact fractures CD-30 samples. The presence of only one local maximum makes it possible to focus on the largest value of the coefficient .

- (3)

- The actual fracture area of the CD-30 samples corresponds to the predicted calculated depth interval.

- (4)

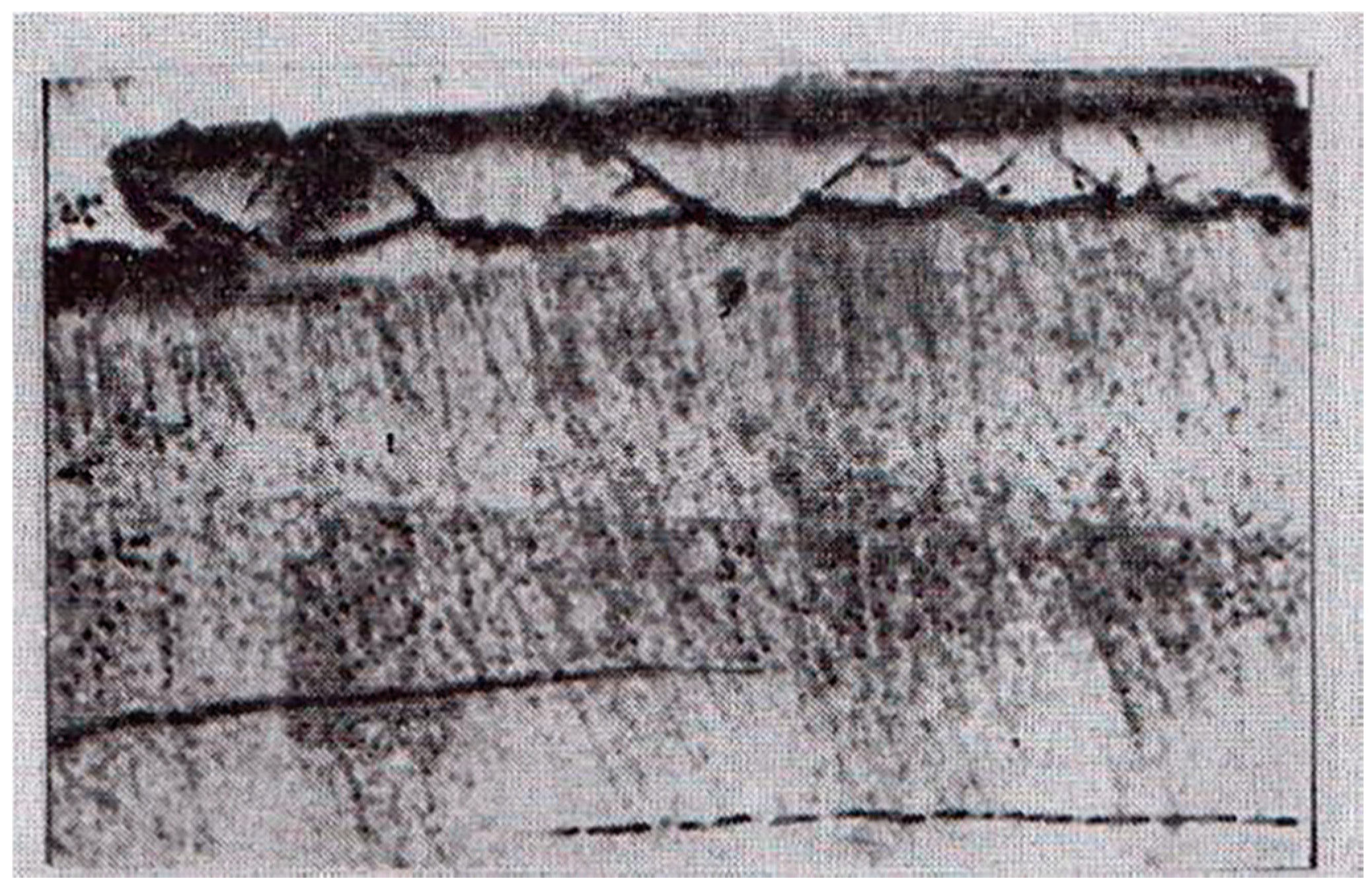

- In the photograph of the microsection (Figure 7), the fracture depth in the effective zone reaches 0.45–0.50 mm, which is rather close to the predicted calculated one. But in the sublayer (in the depth interval z = 1.7–2.1 mm), the main cracks were discovered in the stages coming before the branching. When testing the same samples at stress from 1668 MPa and above, fracturing in the sublayer became faster.

- (5)

- The graph of the ratio indicates the presence of two potentially dangerous areas: in the effective zone and in the sublayer. Outstripping were the destruction in the effective zone.

- (6)

- The deep contact strength of the samples is not provided. It is necessary to introduce a safety factor by the DCS criterion ≥ 1.32.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gupta, K.; Jain, N.; Laubscher, R. Advanced Gear Manufacturing and Finishing; Academic Press: Cambridge, MA, USA, 2017; 240p. [Google Scholar] [CrossRef]

- Fujita, K.; Yoshida, A. Surface failure of soft and surface-hardened steel rollers in rolling contact. Wear 1979, 55, 27–39. [Google Scholar] [CrossRef]

- Tobie, T.; Hippenstiel, F.; Mohrbacher, H. Optimizing Gear Performance by Alloy Modification of Carburizing Steels. Metals 2017, 7, 415. [Google Scholar] [CrossRef]

- Beskopylny, A.; Onishkov, N.; Korotkin, V. Assessment of the Fatigue Durability of the Rolling Contact. In International Scientific Conference Energy Management of Municipal Transportation Facilities and Transport EMMFT 2017; Advances in Intelligent Systems and Computing; Murgul, V., Popovic, Z., Eds.; Springer: Cham, Switzerland, 2018; Volume 692, pp. 184–191. [Google Scholar] [CrossRef]

- Leng, X.; Chen, Q.; Shao, E. Initiation and propagation of case crushing cracks in rolling contact fatigue. Wear 1988, 122, 33–43. [Google Scholar] [CrossRef]

- Tsushima, N.; Maeda, K.; Nakashima, N. Rolling contact fatigue life of various kinds of high-hardness steels and influence of material factors on rolling contact fatigue life. In Effect of Steel Manufacturing Processes on the Quality of Bearing Steels; Hoo, J., Ed.; ASTM International: West Conshohocken, PA, USA, 1988; pp. 132–148. [Google Scholar] [CrossRef]

- GOST 21354-87. Cylindrical Evolvent Gears of External Engagement. Strength Calculation; Publishing House of Standards: Moscow, Russia, 1988; 125p, Available online: http://docs.cntd.ru/document/1200011855 (accessed on 2 April 2020).

- Biserova-Tahchieva, A.; Cabrera, J.; Llorca-Isern, N. Study of the Thermochemical Surface Treatment Effect on the Phase Precipitation and Degradation Behaviour of DSS and SDSS. Materials 2020, 13, 165. [Google Scholar] [CrossRef]

- Amanov, A.; Darisuren, S.; Pyun, Y. Bearings Downsizing by Strength Enhancement and Service Life Extension. Materials 2018, 11, 1662. [Google Scholar] [CrossRef]

- Sugimoto, K.; Hojo, T.; Mizuno, Y. Effects of Vacuum-Carburizing Conditions on Surface-Hardened Layer Properties of Transformation-Induced Plasticity-Aided Martensitic Steel. Metals 2017, 7, 301. [Google Scholar] [CrossRef]

- Li, B.; Li, C.; Wang, Y.; Jin, X. Effect of Cryogenic Treatment on Microstructure and Wear Resistance of Carburized 20CrNi2MoV Steel. Metals 2018, 8, 808. [Google Scholar] [CrossRef]

- Li, G.; Li, C.; Xing, Z.; Wang, H.; Huang, Y.; Guo, W.; Liu, H. Study of the Catalytic Strengthening of a Vacuum Carburized Layer on Alloy Steel by Rare Earth Pre-Implantation. Materials 2019, 12, 3420. [Google Scholar] [CrossRef]

- Liu, C.-P.; Zhao, X.-J.; Liu, P.-T.; Pan, J.-Z.; Ren, R.-M. Influence of Contact Stress on Surface Microstructure and Wear Property of D2/U71Mn Wheel-Rail Material. Materials 2019, 12, 3268. [Google Scholar] [CrossRef]

- Kvryan, A.; Efaw, C.; Higginbotham, K.; Maryon, O.; Davis, P.; Graugnard, E.; Trivedi, H.; Hurley, M. Corrosion Initiation and Propagation on Carburized Martensitic Stainless Steel Surfaces Studied via Advanced Scanning Probe Microscopy. Materials 2019, 12, 940. [Google Scholar] [CrossRef]

- Borgioli, F. From Austenitic Stainless Steel to Expanded Austenite-S Phase: Formation, Characteristics and Properties of an Elusive Metastable Phase. Metals 2020, 10, 187. [Google Scholar] [CrossRef]

- Li, Z.; Illing, C.; Heuer, A.; Ernst, F. Low-Temperature Carburization of AL-6XN Enabled by Provisional Passivation. Metals 2018, 8, 997. [Google Scholar] [CrossRef]

- Adachi, S.; Ueda, N. Wear and Corrosion Properties of Cold-Sprayed AISI 316L Coatings Treated by Combined Plasma Carburizing and Nitriding at Low Temperature. Coatings 2018, 8, 456. [Google Scholar] [CrossRef]

- Chapurkin, V.V.; Tesker, E.I.; Aseev, N.; Tesker, S.Y. Laser treatment of polymer-coated steel components. In Proceedings of the SPIE 2713, Fifth International Conference on Industrial Lasers and Laser Applications ’95, Shatura, Moscow Region, Russia, 24–26 June 1995. [Google Scholar] [CrossRef]

- Tesker, E.I. Improvement of Methods of Design and Analysis of Load-Carrying Capacity of Case-Hardened Cageless Bearing Units for Power Drives of Mobile Machines. In New Approaches to Gear Design and Production. Mechanisms and Machine Science; Goldfarb, V., Trubachev, E., Barmina, N., Eds.; Springer: Cham, Switzerland, 2020; Volume 81, pp. 461–471. [Google Scholar] [CrossRef]

- Tesker, E.; Tesker, S. Modern Methods of Calculation and Increasing the Load-Carrying Capacity of Surface-Hardened Gears of Transmissions and Drives. In Theory and Practice of Gearing and Transmissions. Mechanisms and Machine Science; Goldfarb, V., Barmina, N., Eds.; Springer: Cham, Switzerland, 2016; Volume 34, pp. 233–261. [Google Scholar] [CrossRef]

- Korotkin, V.; Onishkov, N.; Gol’tsev, A. Estimating the deep contact strength of evolvent gear transmission with surface-hardened teeth. Russ. Eng. Res. 2008, 28, 407–413. [Google Scholar] [CrossRef]

- Galper, R. Deep contact strength of the surface hardened working surface. In Increasing the Bearing Capacity of a Mechanical Drive; Kudryavtsev, V.N., Ed.; Mechanical Engineering: Moscow, Russia, 1973; pp. 82–88. [Google Scholar]

- Rudenko, S.; Val’ko, A. Contact Fatigue of Transmission Gears of Energy-Intensive Machines; Belaruskaya Navuka: Minsk, Belarus, 2014; 126p. (In Russian) [Google Scholar]

- Rudenko, S.; Val’ko, A. Contact Fatigue Resistance of Carburized Gears from Chromium-Nickel Steels. Met. Sci. Heat Treat. 2017, 59, 60–64. [Google Scholar] [CrossRef]

- Wolkenstein, R. Die Hartentiefe an Zahnradern. Teil 1. Zahnflanke-Prinzip des Verfahrens. Maschinenwelt-Electrotechn. 1979, 5, 116–122. [Google Scholar]

- Elkholy, A. Case depth requirements in carburized gears. Wear 1983, 88, 233–244. [Google Scholar] [CrossRef]

- Korotkin, V.I.; Onishkov, N.P. Novikov gearing: Achievements and ways to further development. Russ. Eng. Res. 2007, 27, 217–219. [Google Scholar] [CrossRef]

- Beskopylny, A.; Meskhi, B.; Onishkov, N.; Korotkin, V. Strength Characteristics Analysis of Structurally Inhomogeneous Steel Gears. In VIII International Scientific Siberian Transport Forum. TransSiberia 2019; Advances in Intelligent Systems and Computing; Popovic, Z., Manakov, A., Breskich, V., Eds.; Springer: Cham, Switzerland, 2020; Volume 1115, pp. 894–903. [Google Scholar] [CrossRef]

- Beskopylny, A.; Meskhi, B.; Onishkov, N.; Korotkin, V. Limit-State Criteria and Their Use in Conditions of the Significant Structural Heterogeneity of the Gear Steel. In VIII International Scientific Siberian Transport Forum. TransSiberia 2019; Advances in Intelligent Systems and Computing; Popovic, Z., Manakov, A., Breskich, V., Eds.; Springer: Cham, Switzerland, 2020; Volume 1115, pp. 904–912. [Google Scholar] [CrossRef]

- Zinchenko, V.M. Surface engineering: A way to provide maximum properties in articles. Met. Sci. Heat Treat. 1999, 41, 292–300. [Google Scholar] [CrossRef]

- Voskamp, A.P. Material Response to Rolling Contact Loading. J. Tribol. 1985, 107, 359. [Google Scholar] [CrossRef]

- Broszeit, E.; Zwirlein, O. Internal Stresses and Their Influence on Material Stresses in Hertzian Contacts. Calculations with Different Stress Hypotheses. J. Tribol. 1986, 108, 387–393. [Google Scholar] [CrossRef]

- Pisarenko, G.S.; Lebedev, A.A. Deformation and Strength of Materials under Complex Stress Conditions; Naukova Dumka: Kiev, Ukraine, 1976. (In Russian) [Google Scholar]

- Pisarenko, G.S.; Koval’chuk, B.I.; Lebedev, A.A. Principles of deformation of carbon steel with complex loading under normal conditions and at low temperatures. Strength Mater. 1972, 4, 134–139. [Google Scholar] [CrossRef]

- Shapochkin, V.I.; Zaitseva, I.D.; Burenkóva, O.S. Resistance to contact fatigue of heavy-duty gear wheels made of steel 20KhN3A and hardened by thermochemical treatment. Met. Sci. Heat Treat. 1987, 29, 333–339. [Google Scholar] [CrossRef]

- Yatsenko, V.K.; Kostenko, N.A. Criteria for evaluating the surface strain-hardening of machine parts. Strength Mater. 1985, 17, 325–328. [Google Scholar] [CrossRef]

- Grum, J. How to Select Induction Surface Hardening and Finished Grinding Conditions in Order to Ensure High Compressive Residual Stresses on Machine Parts Surface. Mater. Sci. Forum 2003, 426–432, 2599–2604. [Google Scholar] [CrossRef]

- Yoshida, A.; Fujita, K.; Kanehara, T.; Ota, K. Effect of Case Depth on Fatigue Strength of Case-Hardened Gear. Bull. JSME 1986, 29, 228–234. [Google Scholar] [CrossRef]

| No. | Estimated Effective Stress | Ultimate Effective Stress | Formula | Reference |

|---|---|---|---|---|

| 1 | where maximum normal contact stress at the center of contact ellipse | , | [22] | |

| 2 | [22] | |||

| 3 | , | [19] | ||

| 4 | , —Figure 4.1 and 4.2 reference [23] | [23,24] | ||

| 5 | , where principal stresses | - | [25] | |

| 6 | - | [26] | ||

| 7 | , , | [19,20] | ||

| 8 | , , , where —half-width of the linear contact pad. | [7] | ||

| 9 | - | - | [2,5] |

| , HV | 795 |

| , HV | 260 |

| , HV | 550 |

| , mm | 0.00 |

| , mm | 1.08 |

| , mm | 3.20 |

| , mm | 0.2690 |

| , MPa | 2011 |

| 2.0400 | |

| 2.3600 |

| No. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.10 | 0.03 | 795/622 | 1.0120 | 0.649 | 0.232 | 0.281/0.325 | 1.21/1.40 | 1.33 |

| 2 | 0.20 | 0.05 | 794/622 | 1.0987 | 0.649 | 0.251 | 0.281/0.325 | 1.12/1.30 | 1.23 |

| 3 | 0.30 | 0.08 | 794 | 1.2088 | 0.650 | 0.274 | 0.282/0.326 | 1.03/1.19 | - |

| 4 | 0.40 | 0.11 | 792/620 | 1.3044 | 0.651 | 0.295 | 0.282/0.326 | 0.96/1.11 | 1.15 |

| 5 | 0.50 | 0.13 | 791 | 1.3729 | 0.652 | 0.314 | 0.283/0.327 | 0.90/1.04 | - |

| 6 | 0.60 | 0.16 | 789/619 | 1.4116 | 0.654 | 0.329 | 0.284/0.328 | 0.86/1.00 | 1.03 |

| 7 | 0.70 | 0.19 | 787 | 1.4257 | 0.655 | 0.337 | 0.285/0.329 | 0.84/0.98 | - |

| 8 | 0.80 | 0.22 | 785/618 | 1.4224 | 0.658 | 0.341 | 0.286/0.331 | 0.84/0.97 | 0.99 |

| 9 | 0.90 | 0.24 | 782 | 1.4044 | 0.660 | 0.340 | 0.287/0.332 | 0.85/0.98 | - |

| 10 | 1.00 | 0.27 | 779/615 | 1.3790 | 0.663 | 0.337 | 0.289/0.334 | 0.86/0.99 | 1.03 |

| 11 | 1.10 | 0.30 | 775 | 1.3463 | 0.666 | 0.331 | 0.291/0.336 | 0.88/1.01 | - |

| 12 | 1.20 | 0.32 | 771/611 | 1.3112 | 0.669 | 0.325 | 0.292/0.338 | 0.90/1.04 | 1.07 |

| 13 | 1.30 | 0.35 | 767 | 1.2738 | 0.673 | 0.317 | 0.294/0.341 | 0.93/1.07 | - |

| 14 | 1.40 | 0.38 | 763 | 1.2391 | 0.677 | 0.310 | 0.296/0.343 | 0.96/1.11 | - |

| 15 | 1.50 | 0.40 | 758/608 | 1.2018 | 0.681 | 0.301 | 0.299/0.345 | 0.99/1.15 | 1.17 |

| 16 | 1.75 | 0.47 | 745/600 | 1.1155 | 0.693 | 0.281 | 0.305/0.353 | 1.08/1.25 | 1.26 |

| 17 | 2.00 | 0.54 | 729 | 1.0427 | 0.707 | 0.264 | 0.312/0.361 | 1.18/1.37 | - |

| 18 | 2.25 | 0.61 | 712/582 | 0.9805 | 0.723 | 0.251 | 0.319/0.369 | 1.27/1.47 | 1.46 |

| 19 | 2.50 | 0.67 | 693 | 0.9263 | 0.740 | 0.236 | 0.326/0.378 | 1.38/1.60 | - |

| 20 | 3.00 | 0.81 | 650 | 0.8481 | 0.778 | 0.213 | 0.342/0.395 | 1.60/1.85 | - |

| , HV | 850 |

| , HV | 260 |

| , HV | 550 |

| , mm | 0.00 |

| , mm | 1.37 |

| , mm | 2.60 |

| , mm | 0.420 |

| , MPa | 1570 |

| 1.670 | |

| 2.003 |

| No. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.40 | 0.17 | 846/644 | 0.9540 | 0.603 | 0.265 | 0.267/0.320 | 1.01/1.21 | 1.55 |

| 2 | 0.50 | 0.21 | 844/644 | 1.0051 | 0.605 | 0.284 | 0.268/0.322 | 0.94/1.13 | 1.47 |

| 3 | 0.60 | 0.25 | 840 | 1.0347 | 0.608 | 0.299 | 0.270/0.324 | 0.90/1.08 | - |

| 4 | 0.70 | 0.29 | 837/640 | 1.0466 | 0.611 | 0.309 | 0.272/0.326 | 0.88/1.06 | 1.34 |

| 5 | 0.80 | 0.34 | 830 | 1.0461 | 0.616 | 0.314 | 0.274/0.329 | 0.87/1.05 | - |

| 6 | 0.90 | 0.38 | 826/635 | 1.0350 | 0.62 | 0.314 | 0.277/0.332 | 0.88/1.05 | 1.34 |

| 7 | 1.00 | 0.42 | 823 | 1.0188 | 0.624 | 0.314 | 0.280/0.335 | 0.89/1.07 | - |

| 8 | 1.10 | 0.46 | 817/632 | 0.9973 | 0.629 | 0.31 | 0.283/0.339 | 0.91/1.09 | 1.36 |

| 9 | 1.20 | 0.50 | 808 | 0.9744 | 0.635 | 0.306 | 0.287/0.343 | 0.94/1.12 | - |

| 10 | 1.50 | 0.63 | 786/615 | 0.9036 | 0.655 | 0.289 | 0.299/0.358 | 1.03/1.24 | 1.52 |

| 11 | 2.00 | 0.84 | 736 | 0.8066 | 0.701 | 0.262 | 0.324/0.388 | 1.24/1.48 | - |

| 12 | 2.50 | 1.05 | 670/562 | 0.7473 | 0.76 | 0.242 | 0.351/0.421 | 1.45/1.74 | 1.72 |

| 13 | 3.00 | 1.26 | 593 | 0.7252 | 0.828 | 0.227 | 0.374/0.449 | 1.65/1.98 | - |

| 14 | 3.50 | 1.47 | 510 | 0.7389 | 0.902 | 0.217 | 0.387/0.464 | 1.75/2.10 | - |

| 15 | 4.00 | 1.68 | 428/398 | 0.7565 | 0.975 | 0.201 | 0.383/0.460 | 1.90/2.22 | 1.68 |

| 16 | 4.50 | 1.89 | 355/350 | 0.7616 | 1 | 0.172 | 0.335/0.402 | 1.94/2.32 | 1.76 |

| 17 | 5.00 | 2.10 | 300 | 0.7226 | 1 | 0.138 | 0.283/0.341 | 2.05/2.44 | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beskopylny, A.; Meskhi, B.; Onishkov, N.; Kotelnitskaya, L.; Ananova, O. Deep Contact Strength of Surface Hardened Gears. Metals 2020, 10, 600. https://doi.org/10.3390/met10050600

Beskopylny A, Meskhi B, Onishkov N, Kotelnitskaya L, Ananova O. Deep Contact Strength of Surface Hardened Gears. Metals. 2020; 10(5):600. https://doi.org/10.3390/met10050600

Chicago/Turabian StyleBeskopylny, Alexey, Besarion Meskhi, Nikolay Onishkov, Lubov Kotelnitskaya, and Oxana Ananova. 2020. "Deep Contact Strength of Surface Hardened Gears" Metals 10, no. 5: 600. https://doi.org/10.3390/met10050600

APA StyleBeskopylny, A., Meskhi, B., Onishkov, N., Kotelnitskaya, L., & Ananova, O. (2020). Deep Contact Strength of Surface Hardened Gears. Metals, 10(5), 600. https://doi.org/10.3390/met10050600