3.1. Microstructures and Mechanical Properties of the Rolled CRTMT and DRTMT Al Alloys after T6 Aging

Figure 2 shows the microstructure of 7055sq. It can be seen that the initial grains of 7055sq are coarse (grain size in length ≥400 μm, in transverse ≥200 μm. There still exist two kinds of second phase in the alloy matrix after solution treatment: coarse hollowed fishbone like particles (

Figure 2b) and coarse spherical particles (

Figure 2c). EDS results in

Figure 2d show that the hollowed fishbone like particles in

Figure 2b are Fe-rich phase while the coarse spherical particles in

Figure 2c are S (Al

2CuMg) phase. These particles cannot be dissolved back in the solution treatment. Dispersed MgZn

2 can hardly be observed in

Figure 2b,c, which indicates full redissolution into the matrix during two-stage solid solution treatment.

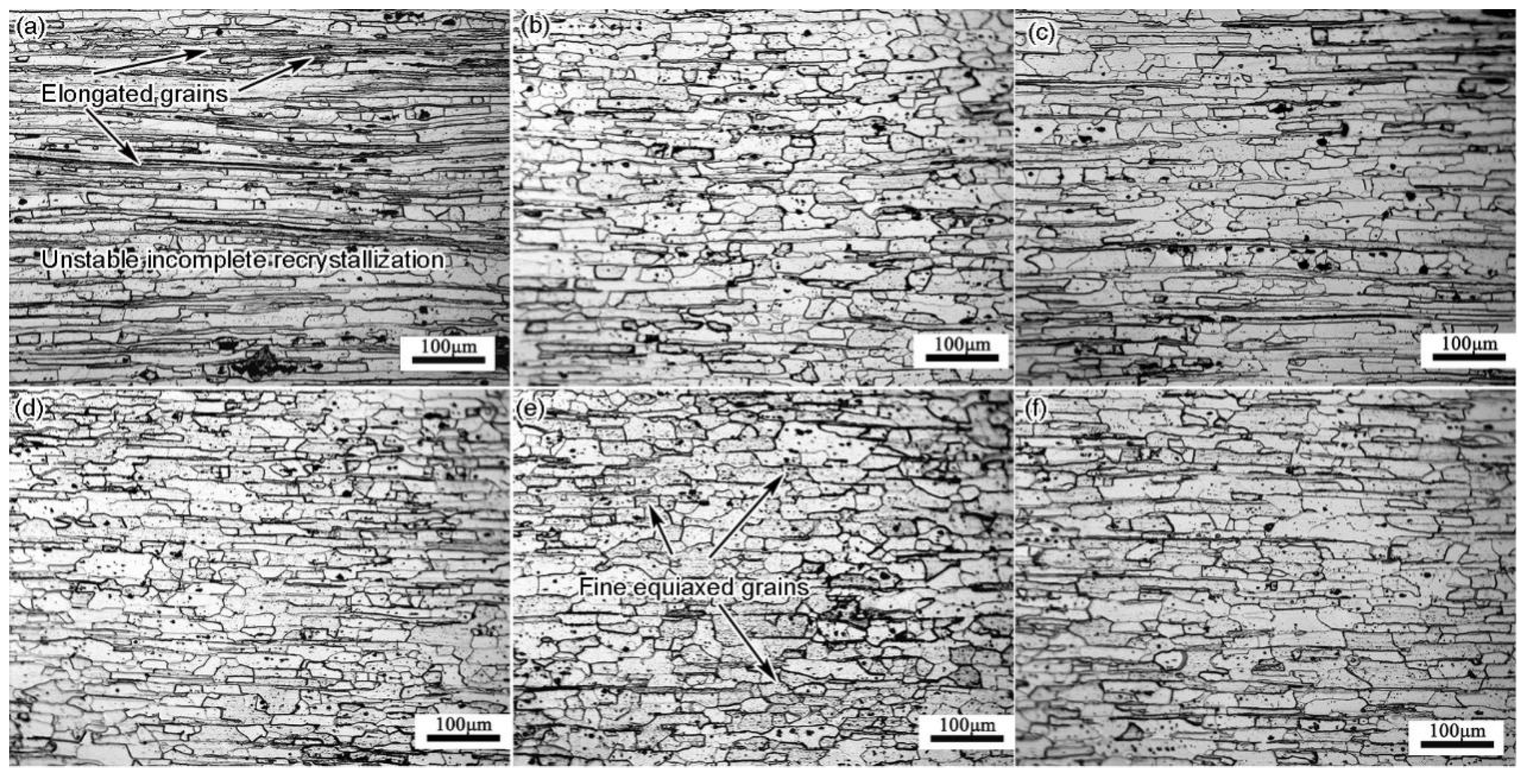

Figure 3 shows recrystallized microstructures of the CRTMT and DRTMT Al alloys. CRTMT shows elongated grains of unequal width and coarse equiaxed grains (

Figure 3a) while that of the latter (DRTMT

1~5) obtain grain refinement in various degrees. Grains in DRTMT Al alloy become wider in transverse and shorter in length compared to those in CRTMT Al alloy (>100 μm in length and 7 μm in transverse in

Figure 3a), tending to be more equiaxed.

The refinement of DRTMT is better, especially DRTMT

4 (

Figure 3d and

Figure 4a). The quantity of fine equiaxed grains of DRTMT samples is far more than CRTMT sample (

Figure 3).

Figure 3a–e and

Figure 4a reveal that grain sizes after recrystallization were reduced firstly and then increased with the increased second-stage deformation temperatures (DRTMT

1~DRTMT

5). The recrystallized grains are mainly affected by different TMT parameters.

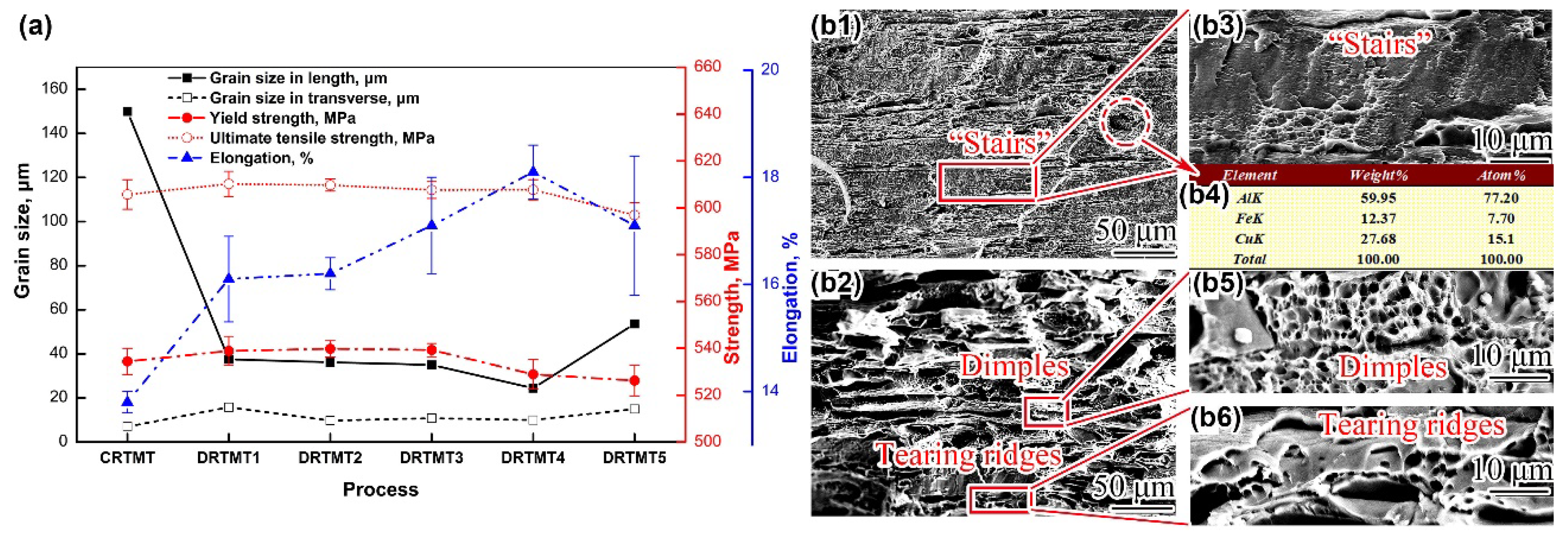

After solutionizing (475 °C for 0.5 h) and T6 aging treatment (120 °C for 24 h), mechanical properties (yield/tensile strength, elongation) of all processed alloys are presented in

Figure 4a. It shows that elongation of the DRTMT is higher, especially the DRTMT

4 sample (more than 18% in

Figure 4a), which may be attributed to grain refinement (

Figure 3e).

It is worth noting that the tensile/yield strengths of DRTMT alloy are similar to CRTMT alloy, but the former obtains higher elongation than the latter in T6 state (

Figure 4a). Here lies the explanation for different grain sizes exhibiting similar strengths. Precipitation hardening would be the main contribution in hardening response of heat-treatable Al alloys like 7xxx series and the refined grains slightly affect the tensile (yield) strengths of 7xxx series Al alloys. Hall and Petch found that the strength σ (MPa) is closely related to the average grain diameter

d (μm) [

21,

22]:

where σ

0 (Mpa) is the lattice frictional stress.

k (MPa·μm

1/2) is coefficient of grain boundary on strength. σ

0 and

k are constants. Grain refinement (reduced average grain diameter

d) should improve the yield strength σ. However, the yield strengths in

Figure 4a remain nearly the same with grain size ranging. Wert [

23] found that the coefficient

k in Hall-Petch equation for T6-treated 7075 Al was just 0.12. Ma et al. [

24] confirmed the high reliability of this value. But Di Russo et al. [

25] designed a new thermo-mechanical procedure to improve the ductility and toughness of Al-Zn-Mg-Cu alloys and found grain refinement plays a great role in improving the ductility. The influence of grain size on dislocation pile-ups and tensile fracture was investigated by Terlinde and Luetjering [

26] who found that longer total grain boundaries (fine grains) exhibit better coordination among grains during tensile tests. With fine-grained structures, the homogeneous dislocation slipping can occur and much more dislocations can be stored, making a higher strain hardening ability so as to delay fracture and contribute to the high ductility. This will increase the resistance of crack initiation and improve the ability of dislocation storage. Therefore, DRTMT treated alloys can get a significant increase of elongation under the same solution-aging treatment.

Figure 4b1–b6 shows the presence of tearing ridges, coarse intermetallic particles and dimples on the fractures of both alloys. The fracture of the CRTMT Al alloy appears to be a stair-step pattern (relatively flat in

Figure 4b1,b3) with a small amount of large and shallow dimples that contain some coarse particles (e.g., iron rich phase from EDS result in

Figure 4b4), which indicates that the fracture of CRTMT is brittle. However, on the fracture of DRTMT

4 Al alloy, the tearing ridges and large quantities of dispersed deep dimples appear throughout the fracture surface (

Figure 4b2,b4,b5), indicating a relatively ductile mode which would be attributed to grain refinement.

3.2. Microstructure Evolution during TMTs

Tian and Wang [

27] reported that plenty of second phase particles (e.g., coarse second phases (size: >0.6 μm), e.g., phases containing Fe, Si, and Cu elements), dispersed phases containing Cr/Mn/Zr (size: 0.02–0.6 μm), and fine precipitates (size: <0.5 μm) in Al alloys can play important roles during TMTs. Their interaction with the sub-structures during TMTs is one of the key issues to reveal the related grain refinement mechanism, especially the controllable precipitates. The coarse second particles and dispersed phases are hardly changed during the subsequent heat treatment and TMTs, but the precipitates can be precipitated or re-dissolved during the heat treatments/TMTs. These precipitates (e.g., MgZn

2 in 7055 Al alloy) were investigated with respect to their evolution and effects during the heat treatment and TMTs by Zuo [

28]. Cai [

29] studied the relationship between deformation and precipitation and revealed that the formation, spheroidization and refinement of precipitates can be enhanced by warm deformation which introduces defects (e.g., vacancies and dislocations) into alloys. Adequate energy/structural fluctuation and rapid diffusion paths of solute atoms can be afforded by these defects.

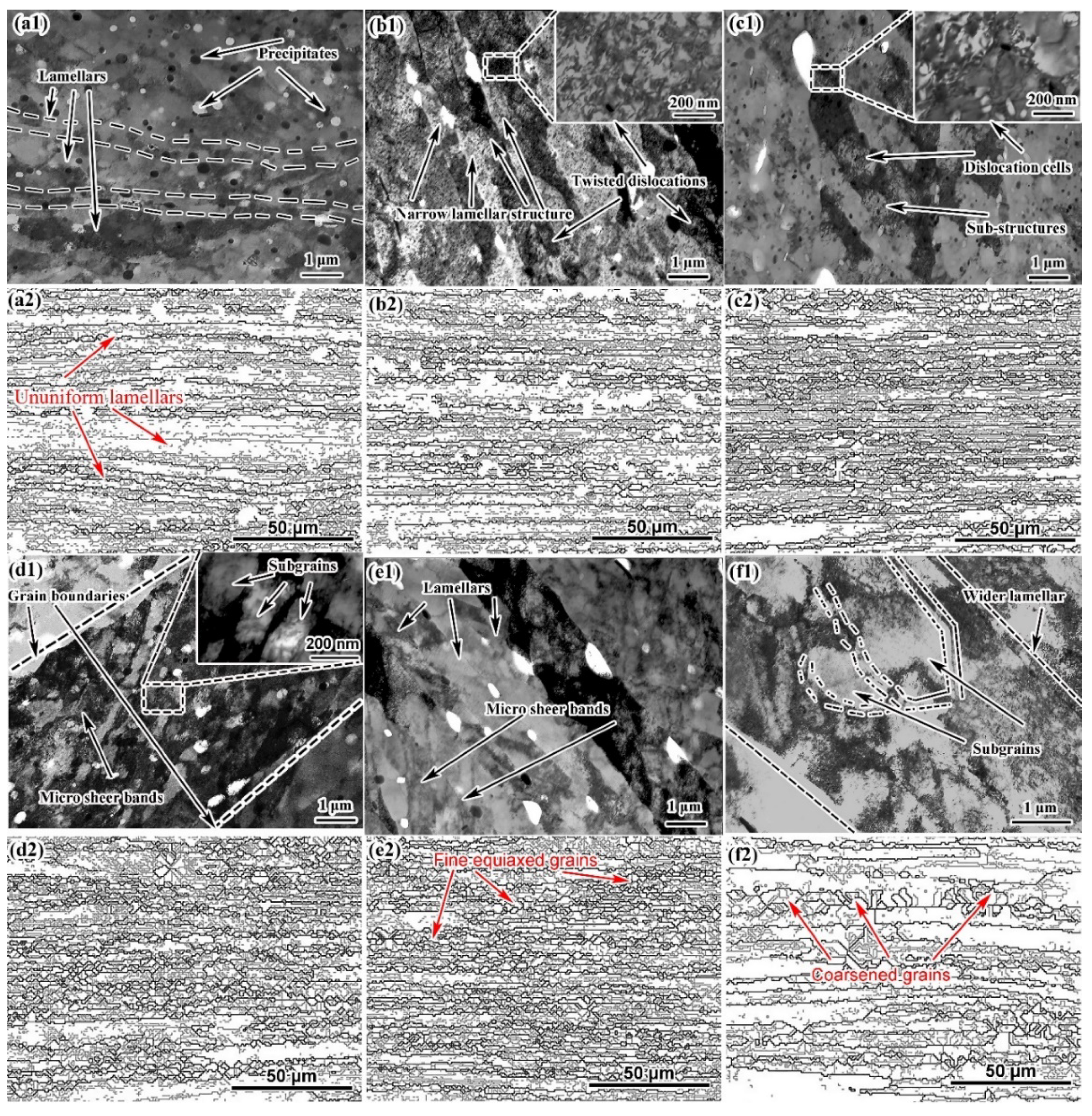

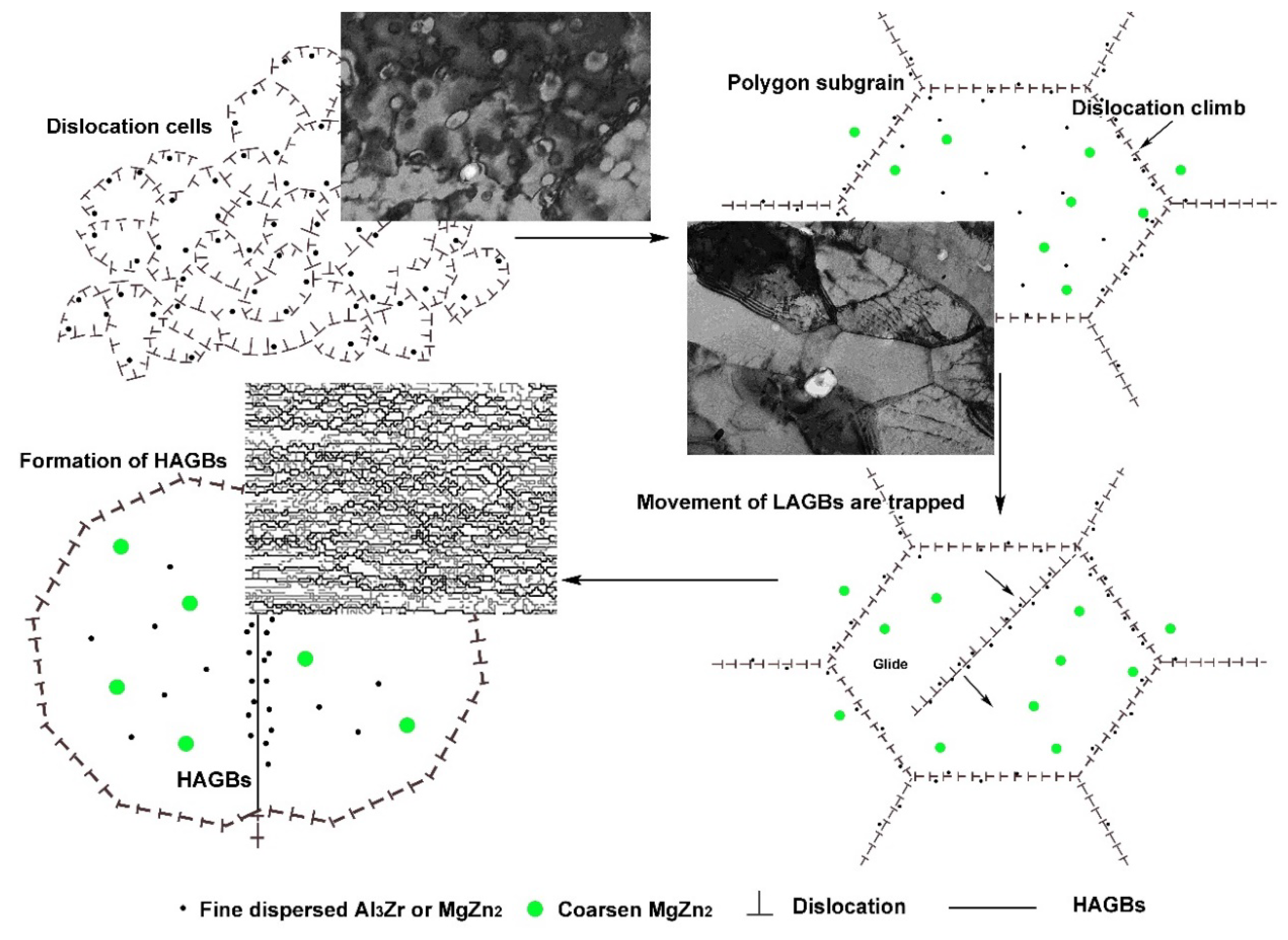

SEM with the embedded TEM images (the white spots are large particles that were etched away during twin-jet electro-polishing.) are shown in

Figure 5. After the first stage deformation (DRTMT-60%), spherical particles (~38 nm) wrapped by dislocation cells were precipitated (

Figure 5a). Dislocations were tangled together to form dislocation walls or cells of varying shape and size because of dynamic recovery. Dislocation slip was obstructed due to the drag force by precipitates. Thus, dislocations were piled up and formed dislocation-cells rather than polygonizing to form well-ordered sub-grains.

Commonly, the pinning force

PZ will be enhanced with smaller size and more area fraction of precipitates, which can be expressed as [

30]:

where

PZ denotes Zener drag force, N,

FV: area fraction of precipitates, %, γ

b a constant, N·μm, and

d the average particle diameter, μm.

It can be seen that the larger area fraction and the smaller size of precipitates result in higher drag force. Therefore, the migration of grain (sub-grain) boundaries or dislocations would be suppressed or even inhibited so that plenty of dislocation cells were formed during first stage deformation.

The precipitates sizes are not the same during precipitation process. Smaller particles dissolve and larger particles continue to grow, so the average particle size increases and that is called Ostwald coarsening [

31]. A similar phenomenon occurs after intermediate annealing process as shown in

Figure 5b (some precipitates grow while others are relatively smaller). At the same time, the dislocation cells that were originally entangled became clear sub grains after IA treatment. Precipitates follow the Ostwald coarsening mechanism, and some of them grow up or dissolve back into the matrix, so the pinning effect reduced. Therefore, clearly defined sub grains were formed due to the weakness of drag force and static recovery.

SEM/TEM images of precipitates after the second stage deformation are shown in

Figure 5c–g. For DRTMT

1, after the second stage deformation the average precipitate sizes were decreased and two different sizes (small: ~50 nm, large: ~300 nm) were formed (

Figure 5c). The coarse precipitates were generated by IA while the finer ones were precipitated during the second stage deformation at 300 °C. Also, two size precipitates appear in the DRTMT

2, both obey Ostwald ripening process (

Figure 5d). As shown in

Figure 5e, in DRTMT

3, uniformly distributed spherical precipitates and few rod-like particles (~80 nm in transverse and ~200 nm in length) appeared. After the second stage deformation of DRTMT

4, the fine spherical DEPs grew to larger sizes (

Figure 5f). Contrary to the increasement of particle sizes, the area fraction of the precipitates after second stage deformation decreased markedly compared to that after the first stage deformation. The solubility of (Mg and Zn) would be increased at higher temperature resulting in lower contents of undissolved Mg and Zn (atomic segregated to be MgZn

2). So, the equilibrium fraction of precipitates decreased. With increasing temperature, some particles were dissolved into Al matrix to promote others growing/coarsening (Ostwald ripening). So, the density of precipitates is also decreased after the second stage deformation at 430 °C. When the second stage deformation temperature rises to 450 °C (DRTMT

5), the solid solubility of MgZn

2 in Al matrix increases. And the atomic diffusion rate is increased, so plenty of MgZn

2 particles are re-dissolved into Al matrix, resulting in rapid coarsening of the remaining precipitates and sharp reduction of the area fraction (

Figure 5g). Compared with DRTMT, the precipitate sizes and distributions of CRTMT are more uniform, which may be related to the consistency of deformation temperature and process.

Figure 5i shows the EDS result and these precipitates in SEM images are proved to be MgZn

2 phase.

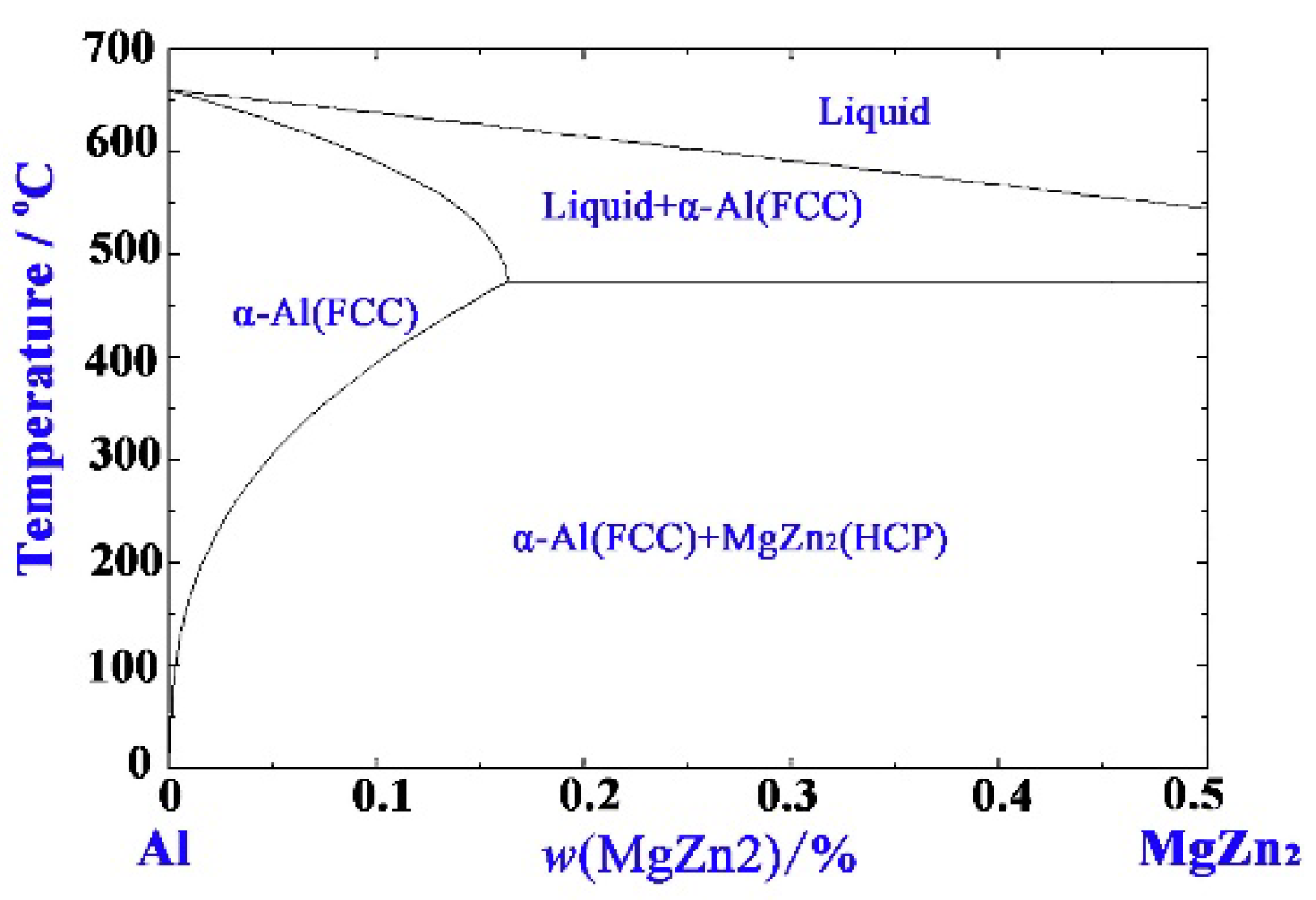

Figure 1 shows the Al-MgZn

2 pseudo-binary system, it can be seen that the solubility of MgZn

2 phase in Al matrix is increased slowly with raising temperature (<300 °C) but rapidly above 300 °C. Thus, the solubility of MgZn

2 in the Al matrix is lower under lower deformation temperature (

T < 300 °C), which means obvious precipitates appears. Furthermore, for the relatively slow atomic motion and diffusion under lower temperature, the precipitation would be insufficient in a short time (rolling time) from the perspective of dynamics. Moreover, at a relatively low deformation temperature, the higher deformation resistance maybe facilitated the sheet cracking. However, the solubility of MgZn

2 will be sharply increased at higher deformation temperature (

T > 300 °C) greatly weakening the pinning action (refer to formula (3)). Therefore, we set the pre-deformation temperature at 300 °C, which can not only obtain low deformation resistance but also rapid precipitation.

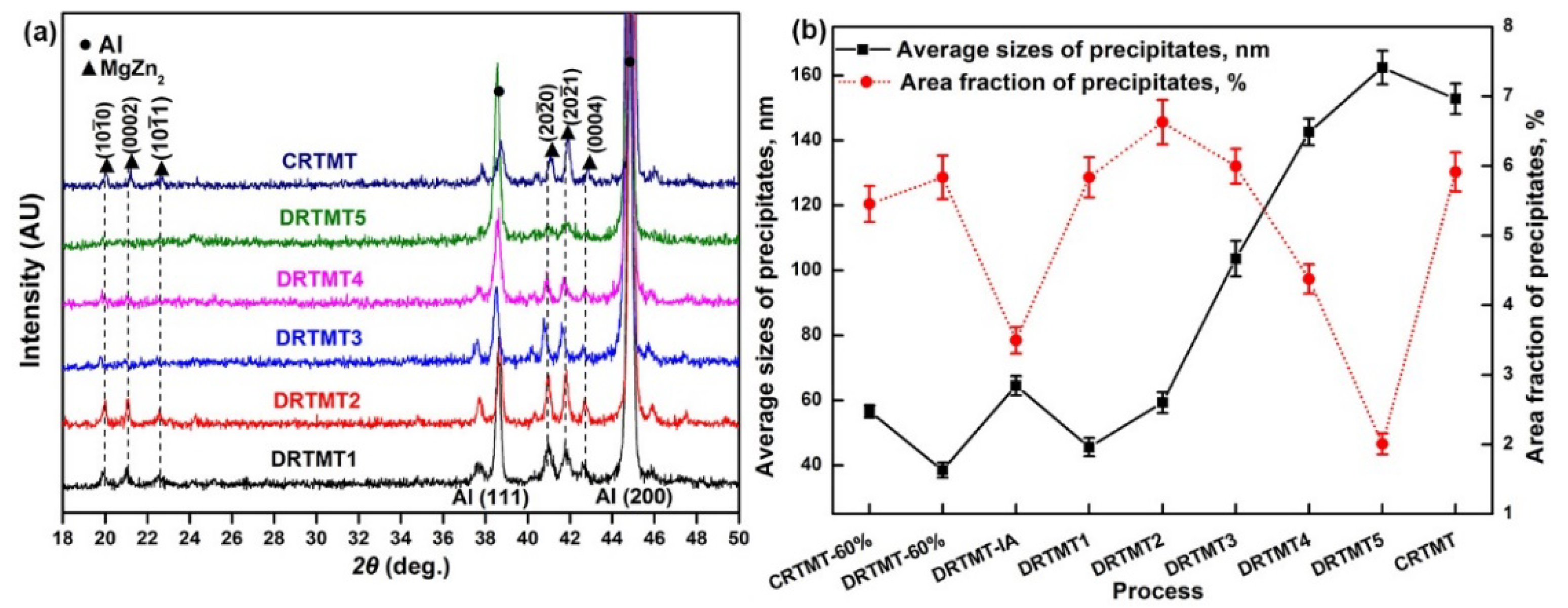

Figure 5i is the XRD spectrum after the first stage deformation. The height of the peak represents the intensity of precipitates (fraction). Kumar et al. [

32] and Buha et al. [

33] investigated the precipitation in 7xxx Al alloy and revealed that in typical 7xxx series Al alloys, the interval temperatures, 20–120 °C, 120–250 °C and 150–300 °C, correspond to the formation of GP zones, η’ and η phases, respectively, and the interval temperatures 50–150 °C, 200–250 °C, and 300–420 °C, correspond to their dissolution, which is consistent with the statistics of particle area fractions and XRD results (

Figure 5i). This confirms that these precipitates in

Figure 5 are mainly MgZn

2 particles according to the phase calibration. Which is consistent with the result by EDS in

Figure 5i. Simultaneously, few T-phase, Fe-rich phase, or S-phase may be formed during the hot rolling, but they cannot be detected by XRD tests for their relatively smaller area fraction.

After first stage deformation, MgZn

2 peak appeared which means hexagonal MgZn

2 particles were obtained during the first stage deformation at 300 °C (

Figure 5a,i). Then, the diffraction intensity of MgZn

2 peak decreased a lot indicating area fraction reduction during IA treatment (

Figure 5b,i). In other words, MgZn

2 particles were largely dissolved into Al matrix (consistent with the TEM/SEM results in

Figure 5, decrease of precipitate density and partial coarsening, partial smaller). MgZn

2 particles were largely dissolved into Al matrix for the high IA temperature (430 °C) closing to the solid solution temperature (475 °C). Therefore, drag force of precipitates after IA would be weaker than that after first stage deformation consisting with the trends in

Figure 5.

Similarly, after 60% hot deformation, the diffraction intensity of MgZn

2 peak also appeared in CRTMT alloy, as shown in the

Figure 5i. In addition, the peak intensity of CRTMT-60% alloy is between DRTMT-60% and DRTMT-IA, indicating the fraction of precipitates. As shown in

Figure 1, the solubility of MgZn

2 in Al matrix is greater at 430 °C than that at 400 °C, so more MgZn

2 particles is dissolved into Al matrix at 430 °C, resulting in less MgZn

2 precipitates. That is why the peak intensity of CRTMT-60% is higher than that of DRTMT-IA. In the same way, the solubility of MgZn

2 in Al matrix is lower (

Figure 1) and the precipitation tendency is greater when deformed at 300 °C, so the peak intensity of CRTMT-60% is lower than that of DRTMT-60%.

Figure 6a1,b1,c1 shows OM images of grain structures. After the first stage deformation (pre-deformation), all the grains are elongated. Black particles distributed along grain boundaries might be the etched traces of coarse second phases, e.g., Al

7Cu

2Fe, Al

2CuMg, which cannot be dissolved during the solution treatment. These undissolved, coarse second particles along the grain boundary were crushed during deformation, which might be good for mechanical properties. After 60% deformation, grain spacing becomes narrow (for weaker recovery) in the DRTMT sample (

Figure 6b1) with clear grain interior when compared to that of the CRTMT sample (

Figure 6a1). The lower pre-deformation temperature of DRTMT-60% (300 °C) as well as good pinning effect may contribute to weaker dynamic recovery and higher deformation storage energy than that of CRTMT-60%. After IA treatment, the static recrystallization apparently occurred and some fine equiaxed grains were formed (

Figure 6c1).

Figure 6a2–c2 shows that LAGBs are dominant in the first stage processed alloys, exhibiting a meta-stable micro-structure. The elongated grain boundaries are the HAGBs (in black). The LAGBs (in gray) have low misorientations and cross the elongated grain interiors (

Figure 6a2–c2). After 60% warm rolling at 300 °C, grains of DRTMT-60% are narrow (

Figure 6b2). At lower rolling temperature, the deformation storage energy obtained after DRTMT-60% would be higher than that after CRTMT-60%. However, these elongated grains are still stretched after DRTMT-IA with some fine equiaxed grains (

Figure 6c2). For the CRTMT Al alloys in

Figure 6a1,a2, elongated grains with straighter grain boundaries, larger grain spacing, and fewer gray LAGBs appeared, which indicates obvious dynamic recovery occurred during CRTMT-60%.

Figure 6c1–c3 shows the misorientation angle statistic of CRTMT-60%, DRTMT-60%, and DRTMT-IA. The percentage for LAGBs of CRTMT-60%, DRTMT-60%, and DRTMT-IA are 60.11 ± 1.3%, 64.78 ± 1.2%, and 65.95 ± 2.3% respectively. The deformation temperature of DRTMT-60% process is lower than that of CRTMT-60%, more defects (dislocations, etc.) can be accumulated under the same deformation amount, and more substructures (gray lines in

Figure 6a2,b2) can be formed by dynamic recovery, so LAGBs of DRTMT-60% are more than those of CRTMT-60% (

Figure 6a3,b3). After the short-time intermediate annealing, DRTMT-IA undergoes a static recovery process, forming a large number of sub-grains (

Figure 5b and

Figure 6c2), LAGBs slightly increases.

3.3. The Role of the 2nd-Stage Deformation Temperature in TMTs

After first stage treatment, followed by the second stage deformation. If the second stage deformation temperature is too low (<300 °C), the diffusion rate of atoms will slow down, resulting in insufficient activity for boundaries to transform/migrate. Furthermore, it is easy for the plate to crack when deformed seriously at low temperature. However, if the final hot rolling temperature is too high (>450 °C), according to Al-MgZn

2 system in

Figure 1, the solubility of MgZn

2 increase significantly and almost all the precipitates will be dissolved into Al matrix. It will greatly reduce the pinning effect of DEPs, and weaken grain refinement effect. What’s more, temperature of plates will be increased for the deformation heats that maybe causing over burning. Therefore, temperature among 300–450 °C are taken as the selected final hot rolling temperature and the corresponding evolution of precipitation and substructures are also investigated.

Figure 7 shows the TEM and EBSD results of all processed alloys after second stage deformation. Unremarkable dynamic recovery occurred under low second stage deformation temperature of DRTMT

1 leading relatively clear grain interior (with fewer gray LAGBs (

Figure 7b2)). The distance between elongated grains is short with tangled dislocations (

Figure 7b1). When the precipitates grow up to several tens of nanometer in the DRTMT

2 sample, they can still pin the movement of dislocations to form dislocation cells or walls while some coarse MgZn

2 particles (~300 nm) are precipitated on grain boundaries (

Figure 7c1). The energy fluctuation of grain boundary is high, so it is easy to be preferential nucleation site for precipitation. Then, raising second stage deformation to 400 °C (DRTMT

3), sub-grains with clear boundaries appeared. Some MSBs (micro sheer bands composed of fine sub-grains arranged according to certain rules, which is transformed from the deformation zone) can be observed after DRTMT

3 (

Figure 7d1). MSBs can refine sub-grains and perform as preferential nucleation sites in the subsequent recrystallization. At the same time, fine equiaxed grains appeared (

Figure 7d2) indicating the transformation of LAGBs to HAGBs (

Figure 7d). Sub-structures during the final hot rolling of DRTMT

3 (

Figure 5b) will be changed (the activity of boundaries increased gradually, but they are also pinned by DEPs, so the LAGBs are stabilized gradually and transformed into HAGBs) with accumulated larger deformation (80%) and higher temperature (400 °C). Thus, the LAGBs fraction gradually reduced (63 ± 0.9%). The specific grain refinement mechanism will be detailed below. After second stage deformation at 430 °C (DRTMT

4), the boundaries were increasingly aligned along RD with the rolling plane and lamellar structures developed (

Figure 7e2). Grains are markedly refined to less than 1 μm in transverse after second rolling, and MSBs can also be observed (

Figure 7e1). However, when the second stage deformation temperature rises too high (450 °C), most of the DEPs are dissolved into Al matrix and remain seriously coarse (

Figure 5g and

Figure 7f1), resulting in a sharply decreased area fraction (

Figure 8). According to Equation (3), the drag force of precipitates becomes weak. Then, the dislocations/boundaries will be more active. Meantime, a larger lamellar width among 20–65 μm (

Figure 7f1,f2) appears for serious dynamic recovery and a lack of pinning effect.

Meanwhile, with the increasing second stage deformation temperature, the proportion of LAGBs experienced a fluctuating process. Firstly, in the temperature range of 300–400 °C, the proportion of LAGBs increases (DRTT1: 54.9 ± 1.2%, DRTMT

2: 59.1 ± 1.7%, DRTMT

3: 64.5 ± 0.9%) with the increasing deformation temperature. In the temperature ranging from 300 °C to 400 °C, with the increasing deformation temperature, the dynamic recovery is intensified, so plenty of sub-grains (whose boundaries are composed of LAGBs) are formed. Thus, the proportion of LAGBs is increased; Then, in the temperature ranging from 400 °C to 430 °C, with increasing deformation temperature, the proportion of LAGBs decreases (DRTMT

4: 59.6 ± 1.1%). In this temperature range, due to the continuous accumulation of deformation at high temperature and the pinning effect of DEPs, some LAGBs gradually stabilized and transformed into HAGBs. Therefore, the proportion of LAGBs decreases with fine equiaxed grains (

Figure 7d2,e2). Finally, in the temperature ranging from 400 °C to 430 °C, with the increasing deformation temperature, the proportion of LAGBs increases (DRTMT

5: 64.8 ± 1.5%). When the deformation temperature is too high (>430 °C), precipitates are coarsening rapidly and their area fraction decreases sharply directly leading to the weakness of their pinning effect. Finally, with the increasing dynamic recovery and activity of boundaries, plenty of sub-grains were produced, so the proportion of LAGBs increased.

The EBSD/TEM results of CRTMT alloy are shown in

Figure 7a1,a2. All persistent boundaries, such as HAGBs, will undergo rigid body rotation during deformation at 400 °C, and will eventually be eventually aligned with the rolling plane forming uneven Lamellar microstructures. The widths of lamellar-like grains are quite ununiform ranging from 50 μm to hundreds of nanometers in CRTMT alloy.

Figure 8 shows the XRD spectrum and statistics of precipitates (size and area fraction of precipitates in SEM calculated by software “Image J”). The average size of the precipitates increases with the increasing second stage deformation temperature (

Figure 8b). Deschamps et al. found that the coarsening rate of MgZn

2 during deformation of 7xxx Al alloy can be expressed as [

34]:

where

Cv can be expressed as:

where

D is Diffusion coefficient of atom,

R is the radius of globular precipitates,

: the concentration of solute atoms in precipitated particles,

the concentration of solute atoms in matrix,

the concentration of solute atoms in the transition zone between matrix and precipitated particles,

the concentration of equilibrium vacancy,

Cv the current vacancy concentration, χ, constant, Ω, the atomic volume, constant,

Qf the vacancy formation energy, constant, σ the rheological stress during material deformation, approximate constant, and ε, strain. For 7055 Al alloy,

,

,

, and

can be approximated as constants. It can be seen that the growth rate of precipitates in the Al alloy is determined by the atomic diffusion coefficient

D when the strain ε is constant. The higher temperature the greater diffusion coefficient

D is and the faster growth rate of precipitates is. So, the average size of the precipitates increases with the increasing second stage deformation temperature. On the other hand, when the deformation temperature is stated, the growth rate of precipitates is determined by the strain ε. The larger ε is, the faster growth rate of precipitates, resulting in larger precipitates of CRTMT-80% than CRTMT-60% (

Figure 8b).

Different from the size evolution, With the increasing second stage deformation temperature, the area fraction of precipitates increases first and then decreases (

Figure 8b). This may be related to the solubility and precipitation rate of at different temperatures. The atomic activity is increased by raising temperature, leading to an increase of diffusion/precipitation rate. So, the area fraction of precipitates is increased. However, with the increasing temperature, the solubility of MgZn

2 in Al matrix increases, leading to plenty of atoms back dissolving and the amount of precipitates becomes low with the area fraction decreasing to a certain extent. The equilibrium point of the two factors is reached at 350 °C, so the area fraction of precipitates by DRTMT

2 is the highest, consistent with the variation tendency (the peak intensity on behalf of the MgZn

2 content) of XRD results (

Figure 8a) and the SEM/TEM results (

Figure 5).

In order to obtain fine-grained microstructures, the suitable second stage deformation temperature may be 430 °C, the lamellar structure could be refined to (0.5–1.2) μm in transverse with micro sheer bands (

Figure 7e1) and a large amount of equiaxed fine grains (

Figure 7e2). With lower deformation temperature, the slow dynamic recovery and low activity of boundaries make the transition from LAGBs to HAGBs difficult, and the final grain refinement is less significant. (

Figure 7b2–d2). However, if the deformation temperature is higher, precipitates are coarsened rapidly and their area fraction decreases sharply (

Figure 5g,

Figure 7f1,f2 and

Figure 8b). According to formula (3), drag force of precipitates becomes weaker. Due to the lack of the drag force, the transformation from LAGBs to HAGBs is difficult, and grains grow faster. Therefore, grain refinement is less obvious under high second stage deformation temperature. In conclusion, 430 °C may be the optimal balanced second stage deformation temperature to obtain effective grain refinement by dislocation rearrangement and LAGBs migration, in turn due to the pinning effects of DEPs.