Effect of Roasting Temperature on Phase Transformation in Co-Reduction Roasting of Nickel Slag

Abstract

1. Introduction

2. Materials

3. Experimental Details

3.1. Experimental Procedure

3.2. Analysis and Characterization

4. Results and Discussion

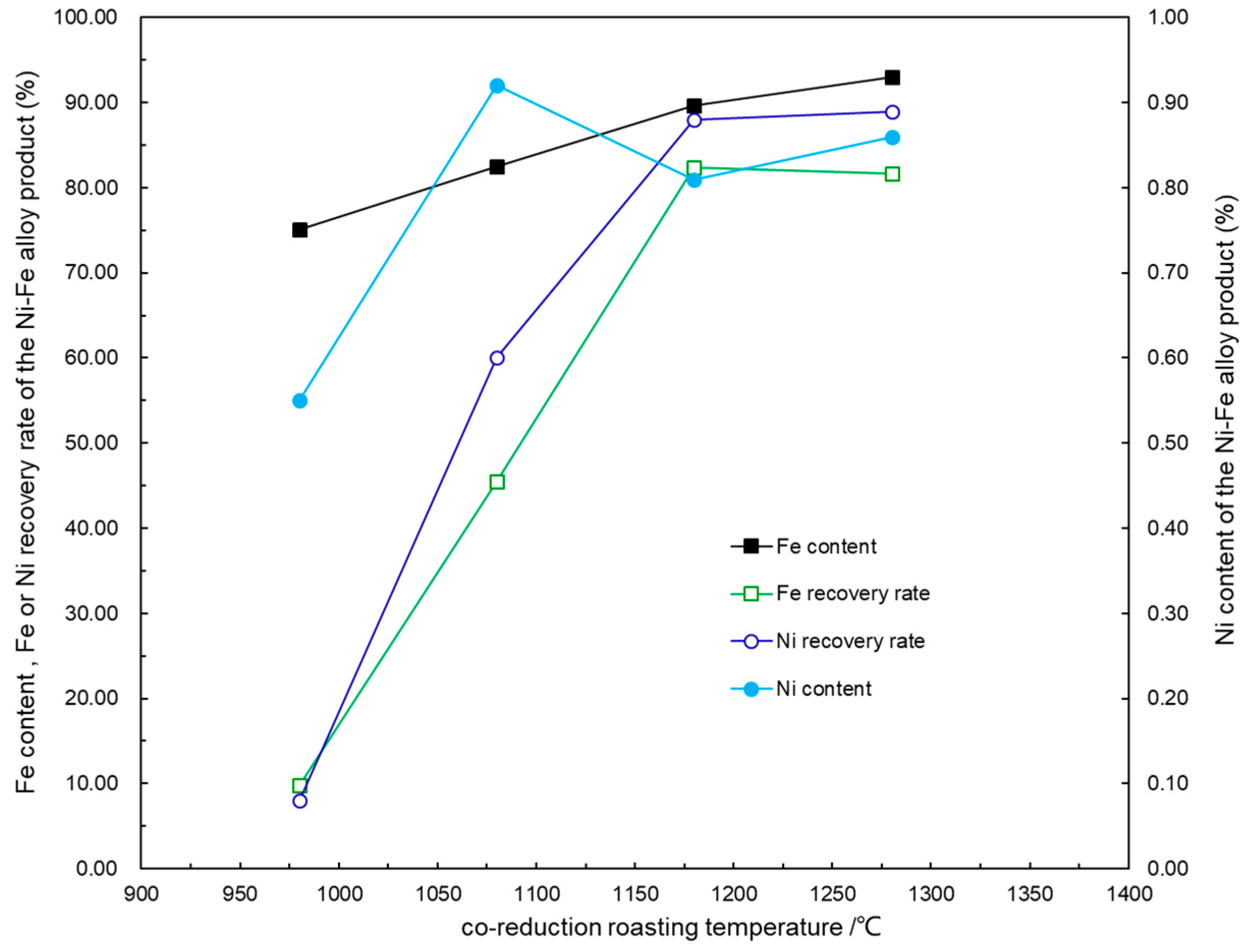

4.1. Effect of Roasting Temperature on the Co-Reduction Process

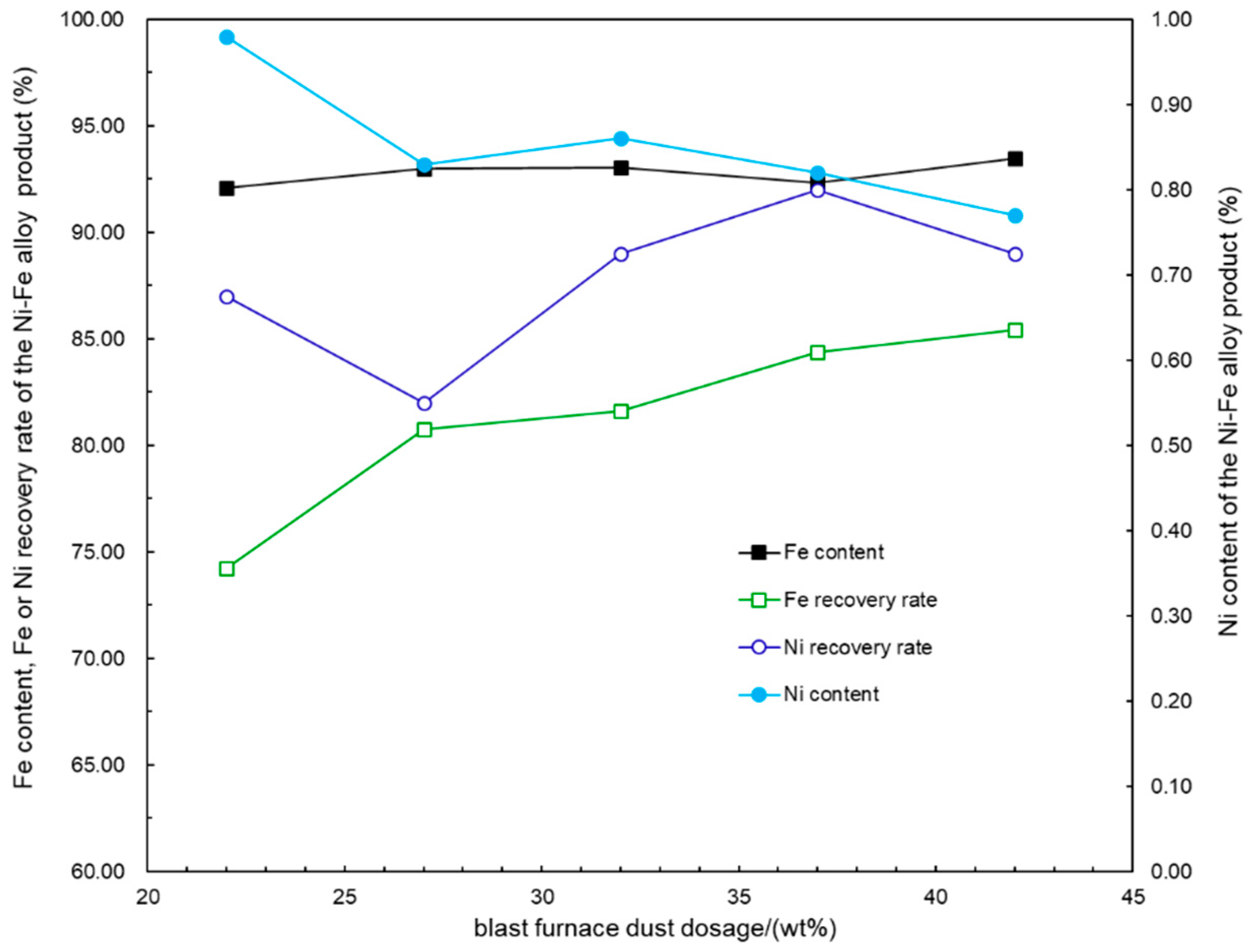

4.2. Effect of bfd Dosage on the Co-Reduction Process

4.3. Effect of Roasting Time on the Co-Reduction Process

5. Effect of Roasting Temperature on the Phase Transformation

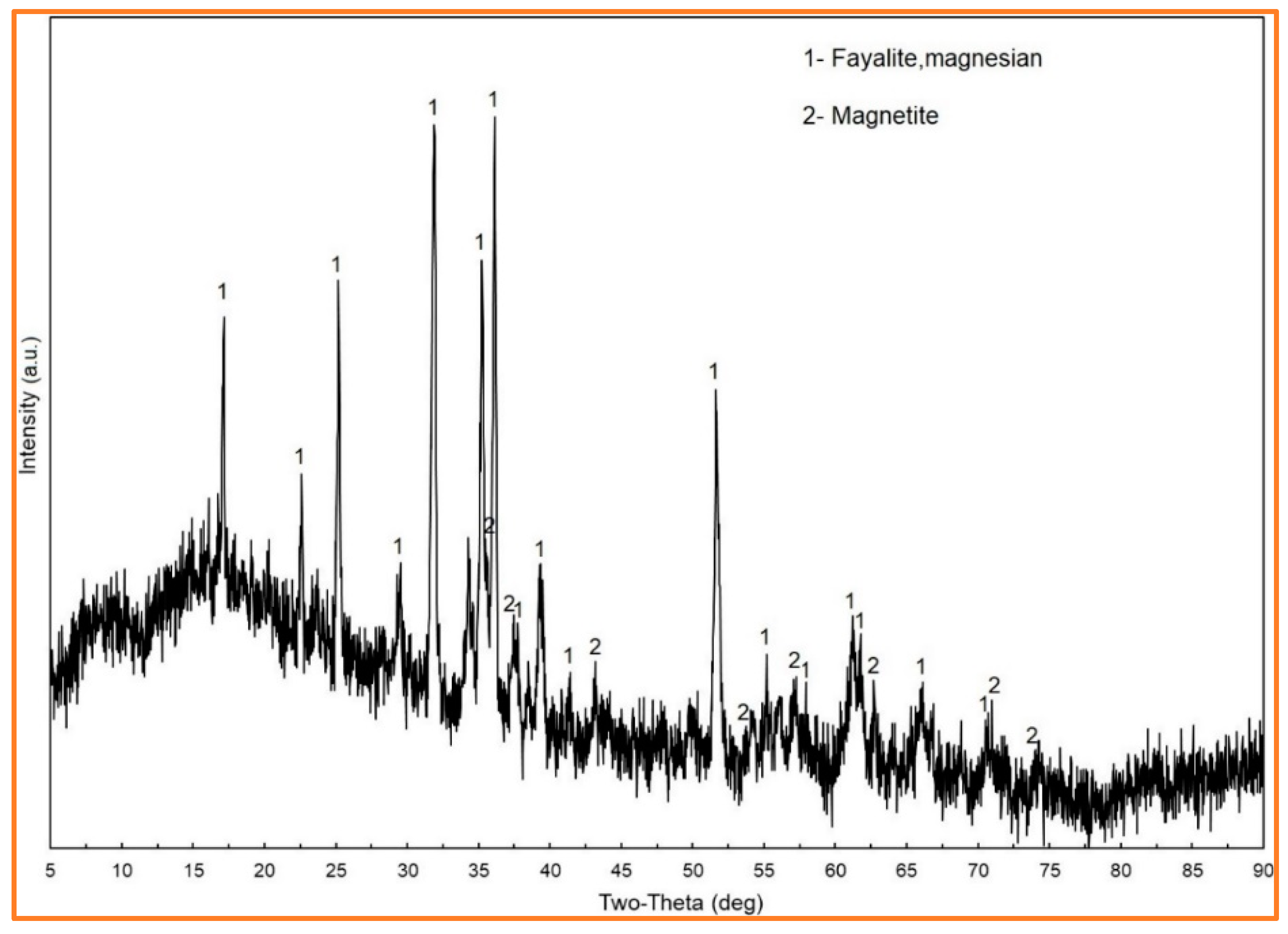

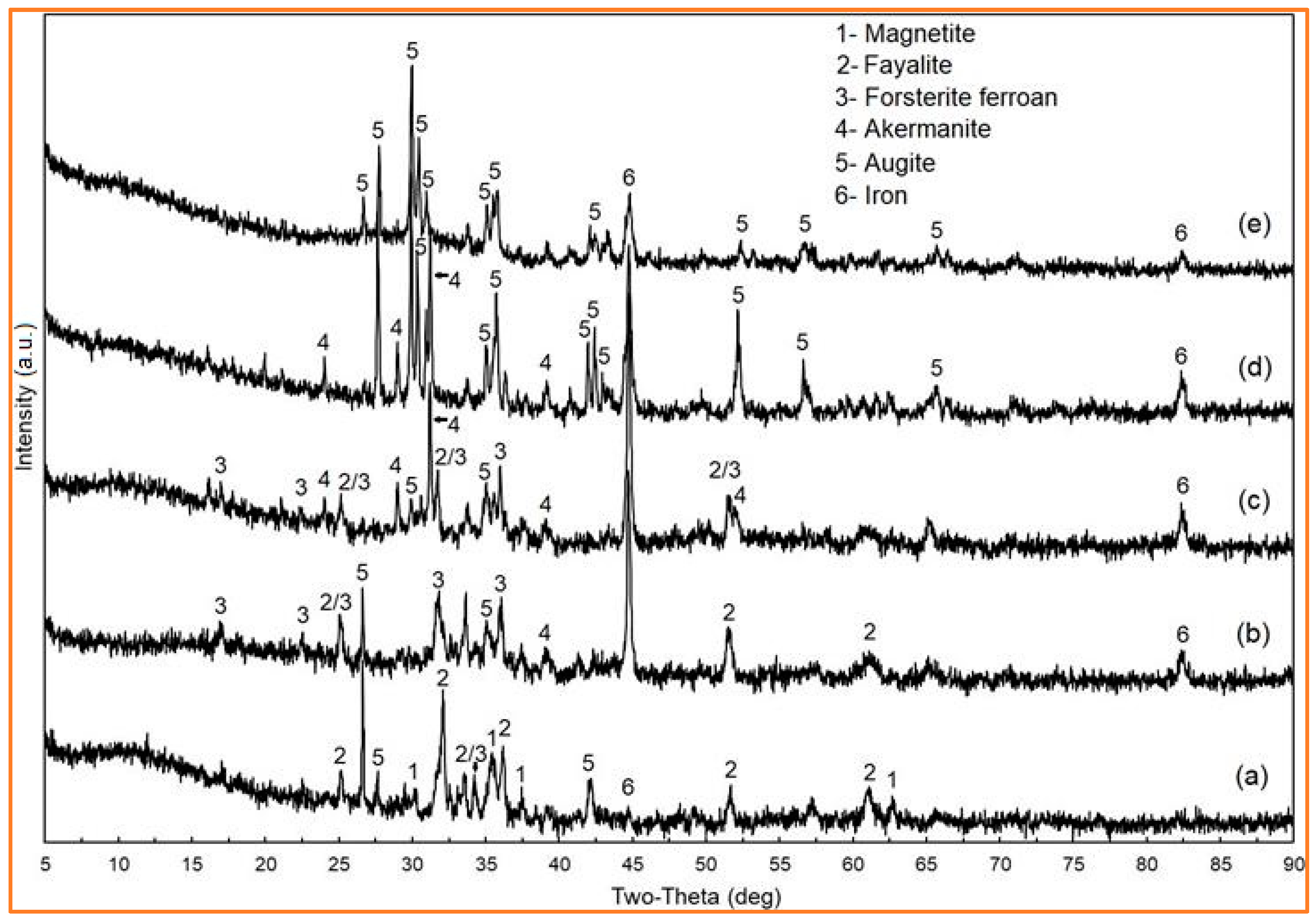

5.1. XRD Analysis

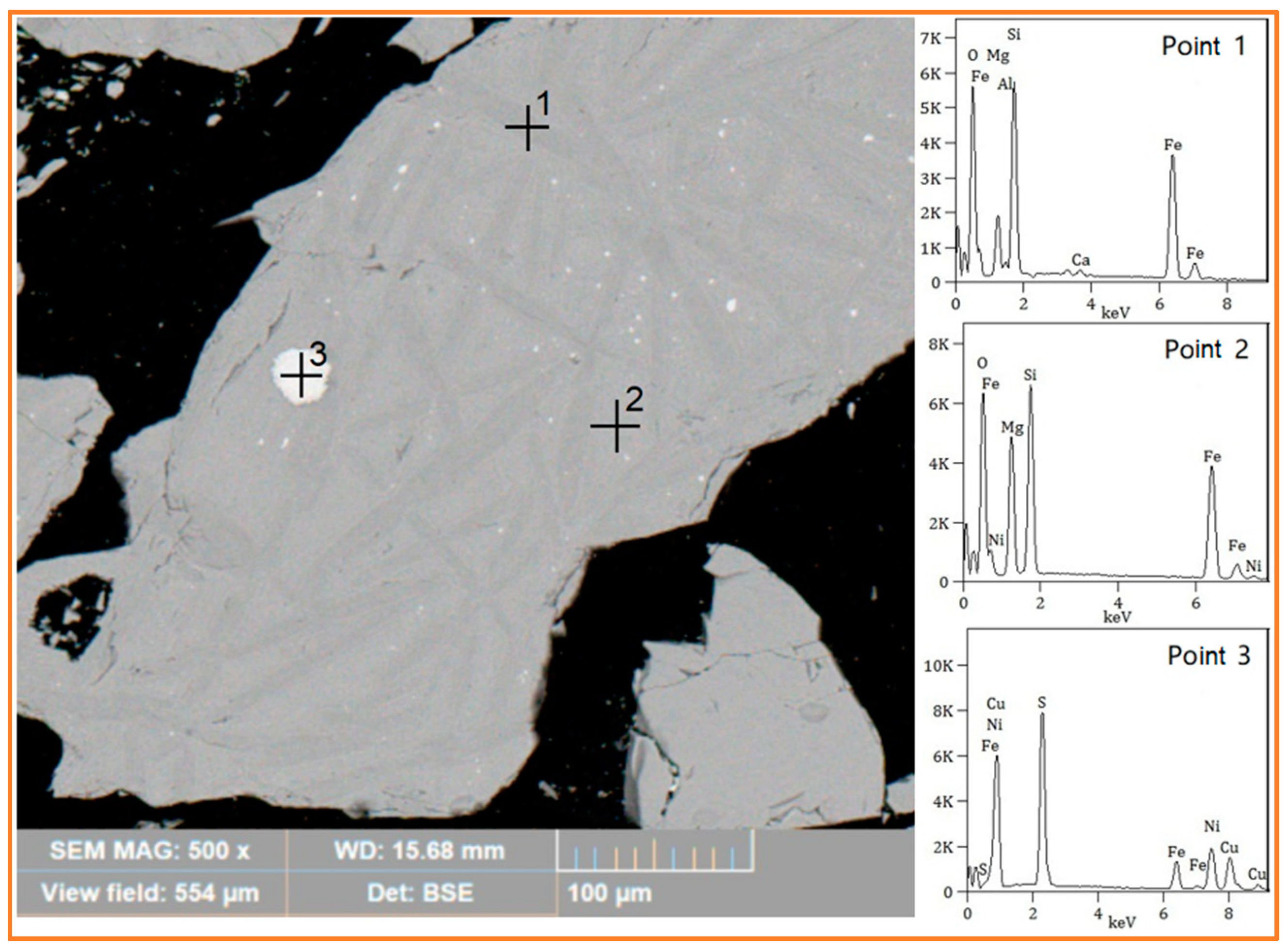

5.2. Analysis of the Microstructural Variation in the Roasted Products

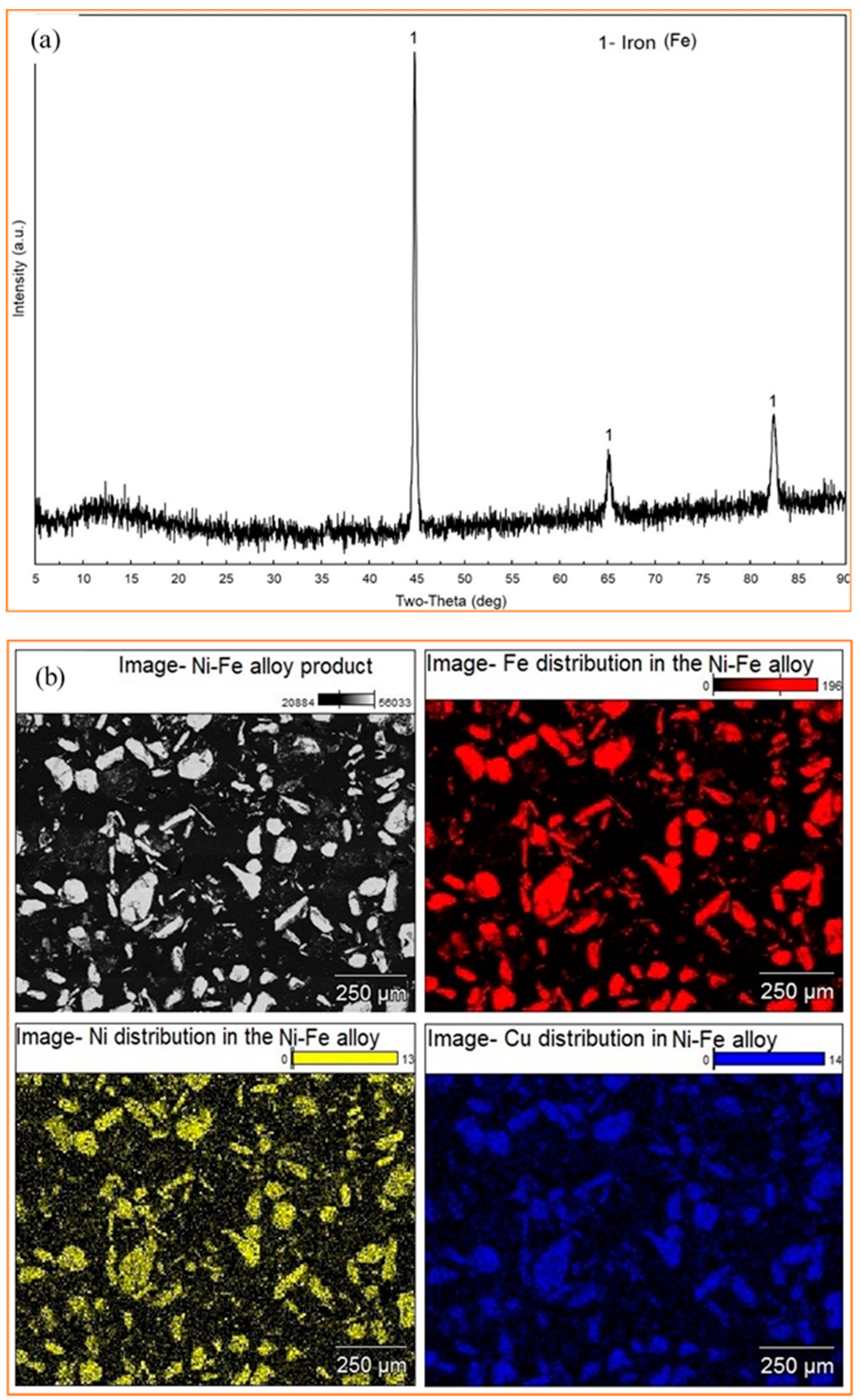

5.3. Analysis of the Ni-Fe Alloy Product

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- China Nonferrous Metals Industry Association. The Yearbook of Nonferrous Metals Industry of China 2018; China Nonferrous Metals Industry Association: Beijing, China, 2019. [Google Scholar]

- Zhang, Q.L.; Ji, T.; Yang, Z.X.; Wang, C.Q.; Wu, H.C. Influence of different activators on microstructure and strength of alkali-activated nickel slag cementitious materials. Constr. Build. Mater. 2020, 235, 117449. [Google Scholar] [CrossRef]

- Singh, J.; Singh, S.P. Geopolymerization of solid waste of non-ferrous metallurgy—A review. J. Environ. Manag. 2019, 251, 109571. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Yu, C.J.; Yang, J.M.; Chong, L.L.; Xu, X.C.; Xu, X.C.; Wu, Q.S. Influence of nickel slag powders on properties of magnesium potassium phosphate cement paste. Constr. Build. Mater. 2019, 205, 668–678. [Google Scholar] [CrossRef]

- Liu, X.M.; Gao, S.L.; Li, J.; Kou, J.; Sun, C.B. Process mineralogy of Jinchuan nickel slag in a settlement furnace. Chin. J. Eng. 2017, 39, 349–353. [Google Scholar]

- Huang, F.R.; Liao, Y.L.; Zhou, J.; Wang, Y.Y.; Li, H. Selective recovery of valuable metals from nickel converter slag at elevated temperature with sulfuric acid solution. Sep. Purif. Technol. 2015, 156, 572–581. [Google Scholar] [CrossRef]

- Wu, Q.S.; Wu, Y.; Tong, W.H.; Ma, H.G. Utilization of nickel slag as raw material in the production of Portland cement for road construction. Constr. Build. Mater. 2018, 193, 426–434. [Google Scholar] [CrossRef]

- Li, Y.J.; Papangelakis, V.G.; Perederiy, I. High pressure oxidative acid leaching of nickel smelter slag: Characterization of feed and residue. Hydrometallurgy 2009, 97, 185–193. [Google Scholar] [CrossRef]

- Xu, J.; Wang, N.; Zhou, Z.Y.; Chen, M.; Wang, P.F. Experimental and numerical studies of the gas-molten reduction behavior of blast furnace dust particles during in-flight process. Powder Technol. 2020, 361, 226–237. [Google Scholar] [CrossRef]

- Hu, W.T.; Xia, H.W.; Pan, D.L.; Wei, X.L.; Li, J.; Dai, X.J.; Yang, F.H.; Lu, X.; Wang, H.J. Difference of zinc volatility in diverse carrier minerals: The critical limit of blast furnace dust recycle. Miner. Eng. 2018, 116, 24–31. [Google Scholar] [CrossRef]

- Xu, J.; Wang, N.; Chen, M.; Zhou, Z.Y.; Wang, P.F. Evaluation of reduction behavior of blast furnace dust particles during in-flight process with experiment aided mathematical modeling. Appl. Math. Model. 2019, 75, 535–552. [Google Scholar] [CrossRef]

- Wu, Z.J.; Wang, L.C.; Gao, Z.F.; Liu, W.M.; Wu, X.R. Recycling blast furnace dust into metals (Al, Zn and Ti)-doped hematite with enhanced photocatalytic activity. J. Environ. Chem. Eng. 2016, 4, 341–345. [Google Scholar] [CrossRef]

- Zeng, G.W. Review on utilization technologies of blast-furnace gas sludge. Environ. Prot. Chem. Ind. 2015, 35, 279–283. [Google Scholar]

- Makkonen, H.T.; Heino, J.; Laitila, L.; Hiltunen, A.; Pöyliö, E.; Härkki, J. Optimisation of steel plant recycling in Finland: Dusts, scales and sludge. Resour. Conserv. Recy. 2002, 35, 77–84. [Google Scholar] [CrossRef]

- Hu, T.Y.; Sun, T.C.; Kou, J.; Geng, C.; Wang, X.P.; Chen, C. Recovering titanium and iron by co-reduction roasting of seaside titanomagnetite and blast furnace dust. Int. J. Miner. Process. 2017, 165, 28–33. [Google Scholar] [CrossRef]

- Sun, Y.S.; Zhou, W.T.; Han, Y.X.; Li, Y.J. Effect of different additives on reaction characteristics of fluorapatite during coal-based reduction of iron ore. Metals 2019, 9, 923. [Google Scholar] [CrossRef]

- Gao, P.; Li, G.F.; Han, Y.X.; Sun, Y.S. Reaction behavior of phosphorus in coal-based reduction of an oolitic hematite ore and pre-dephosphorization of reduced iron. Metals 2016, 6, 82. [Google Scholar] [CrossRef]

- Li, Y.L.; Sun, T.C.; Kou, J.; Guo, Q.; Xu, C.Y. Study on phosphorus removal of high-phosphorus oolitic hematite by coal-based direct reduction and magnetic separation. Miner. Process. Extr. Metall. Rev. 2014, 35, 66–73. [Google Scholar] [CrossRef]

- Wang, X.P.; Sun, T.C.; Chen, C.; Kou, J. Effects of Na2SO4 on iron and nickel reduction in a high-iron and low-nickel laterite ore. Int. J. Min. Met. Mater. 2018, 25, 383–390. [Google Scholar] [CrossRef]

- Geng, C.; Sun, T.C.; Ma, Y.W.; Xu, C.Y.; Yang, H.F. Effects of embedding direct reduction followed by magnetic separation on recovering titanium and iron of beach titanomagnetite concentrate. J. Iron Steel Res. Int. 2017, 24, 156–164. [Google Scholar] [CrossRef]

- Sun, Y.S.; Han, Y.X.; Li, Y.F.; Li, Y.J. Formation and characterization of metallic iron grains in coal-based reduction of oolitic iron ore. Int. J. Miner. Metall. Mater. 2017, 24, 123–129. [Google Scholar] [CrossRef]

- Li, X.M.; Wen, Z.Y.; Li, Y.; Yang, H.B.; Xing, X.D. Improvement of carbothermic reduction of nickel slag by addition of CaCO3. Trans. Nonferr. Met. Soc. China 2019, 29, 2658–2666. [Google Scholar] [CrossRef]

- Cao, Z.C.; Sun, T.C.; Xue, X.; Liu, Z.H. Iron recovery from discarded copper slag in a RHF direct reduction and subsequent grinding/magnetic separation process. Minerals 2016, 6, 119. [Google Scholar] [CrossRef]

| Reductant | Code | Mad (wt%) | Aad (wt%) | Vad (wt%) | FCad (wt%) |

|---|---|---|---|---|---|

| blast furnace dust | bfd | 2.62 | 68.04 | 8.79 | 20.55 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, Y.; Xu, C.; Tian, Y.; Hou, Y. Effect of Roasting Temperature on Phase Transformation in Co-Reduction Roasting of Nickel Slag. Metals 2020, 10, 550. https://doi.org/10.3390/met10040550

Cao Y, Xu C, Tian Y, Hou Y. Effect of Roasting Temperature on Phase Transformation in Co-Reduction Roasting of Nickel Slag. Metals. 2020; 10(4):550. https://doi.org/10.3390/met10040550

Chicago/Turabian StyleCao, Yunye, Chengyan Xu, Yuechao Tian, and Yanqing Hou. 2020. "Effect of Roasting Temperature on Phase Transformation in Co-Reduction Roasting of Nickel Slag" Metals 10, no. 4: 550. https://doi.org/10.3390/met10040550

APA StyleCao, Y., Xu, C., Tian, Y., & Hou, Y. (2020). Effect of Roasting Temperature on Phase Transformation in Co-Reduction Roasting of Nickel Slag. Metals, 10(4), 550. https://doi.org/10.3390/met10040550