Effect of Thermal Ageing at 400 °C on the Microstructure of Ferrite-Austenite Interface of Nickel-Base Alloy Narrow-Gap Dissimilar Metal Weld

Abstract

1. Introduction

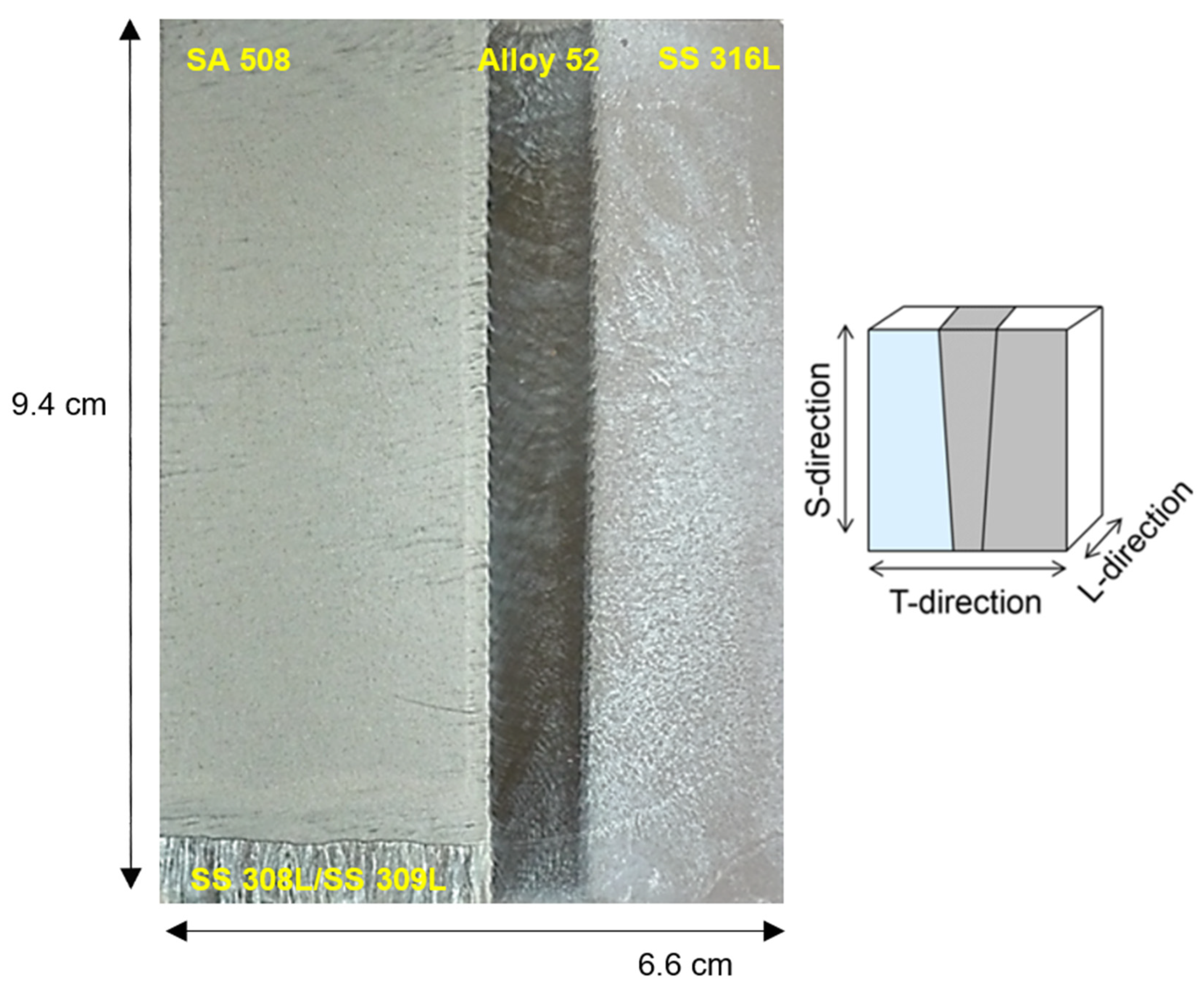

2. Experimental Methods and Materials

3. Results

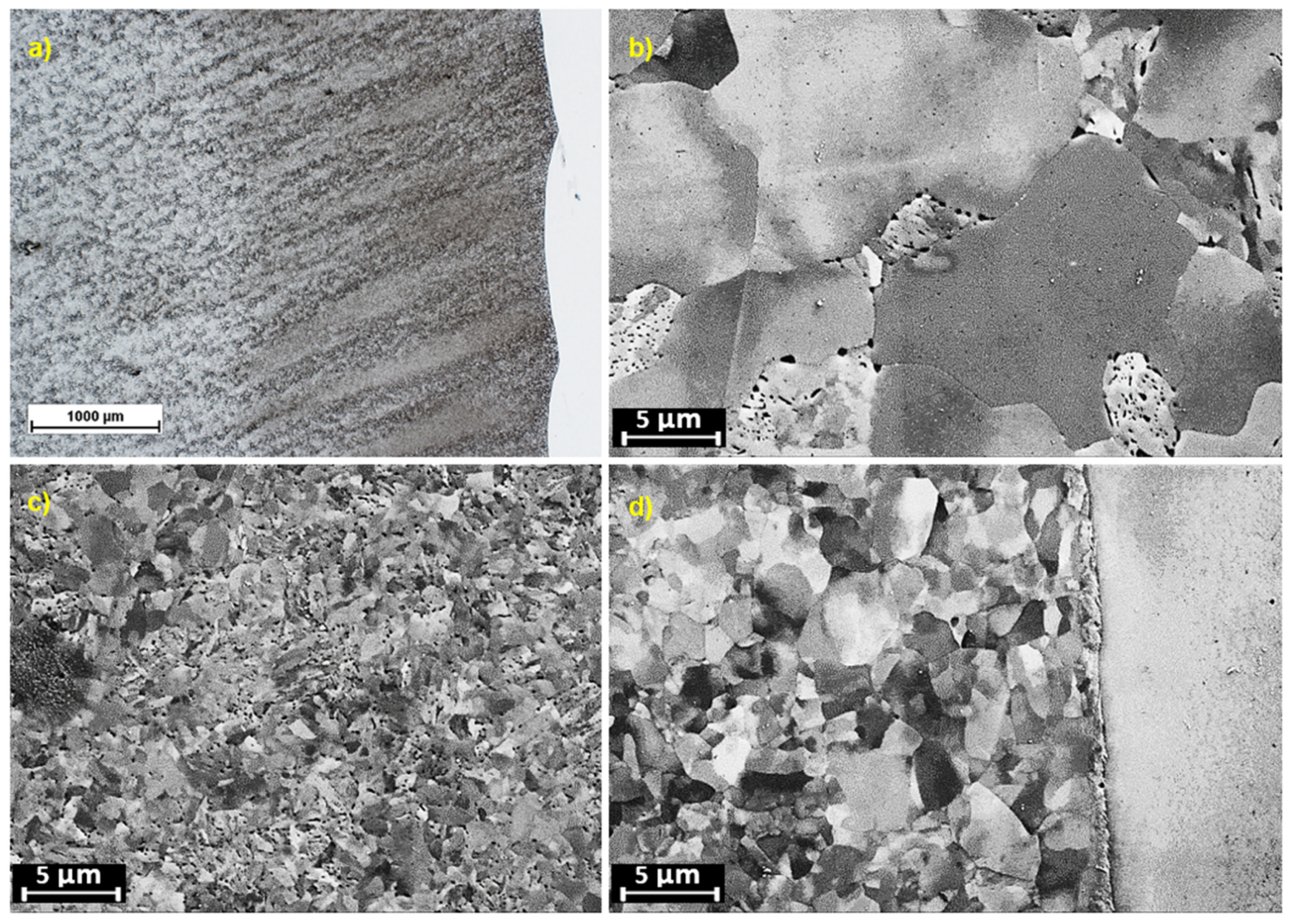

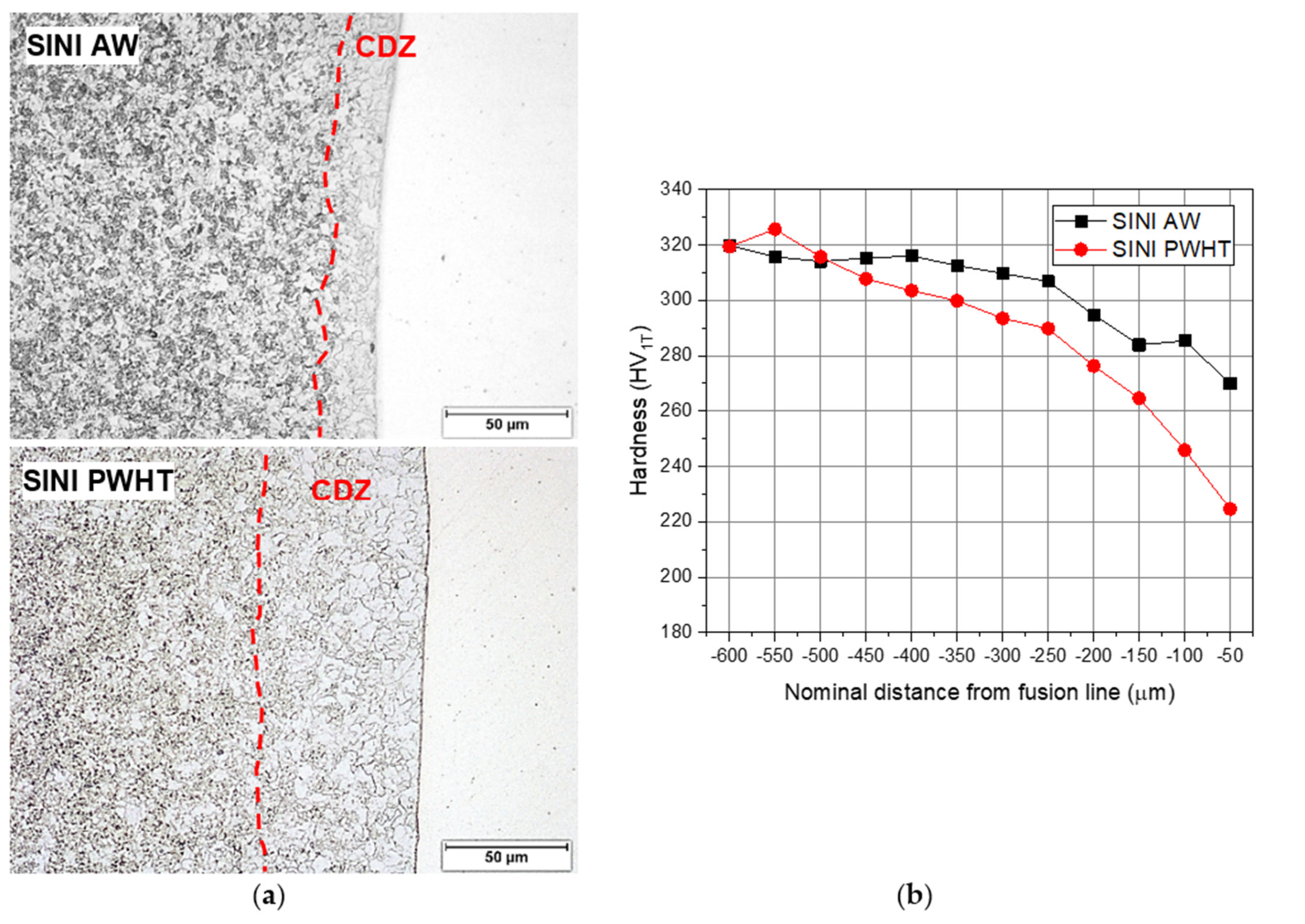

3.1. Heat-Affected Zone of the LAS

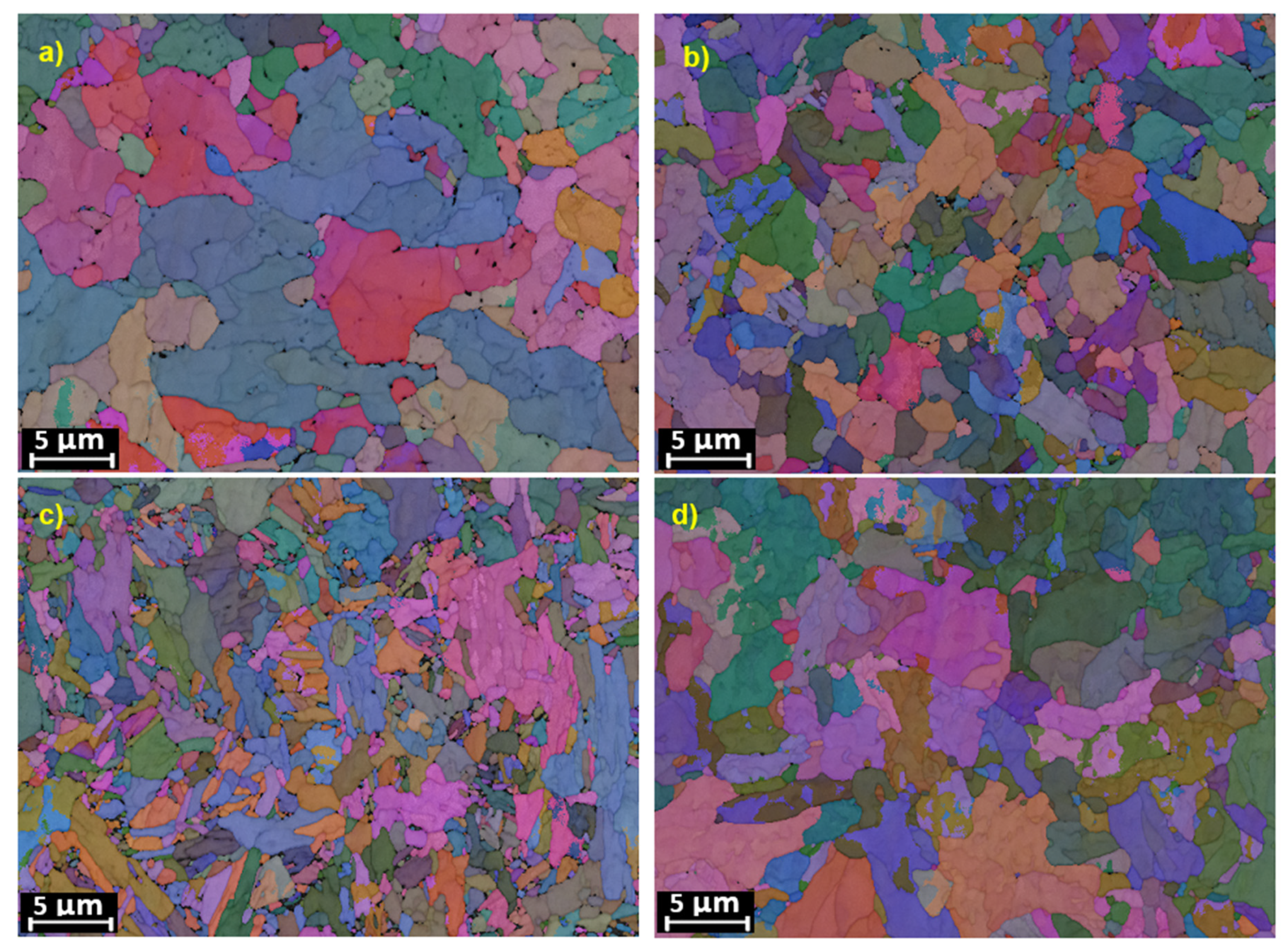

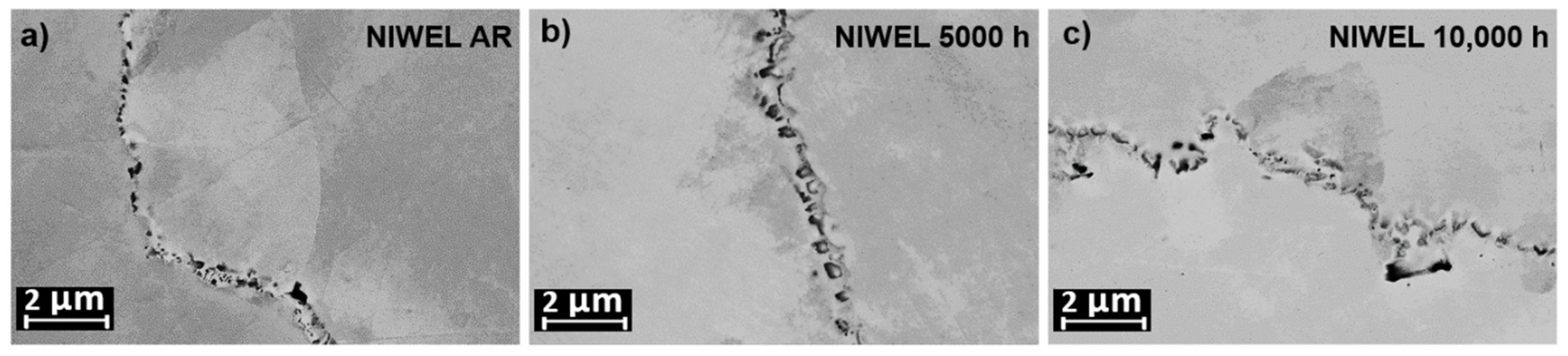

3.2. Alloy 52 Weld Metal

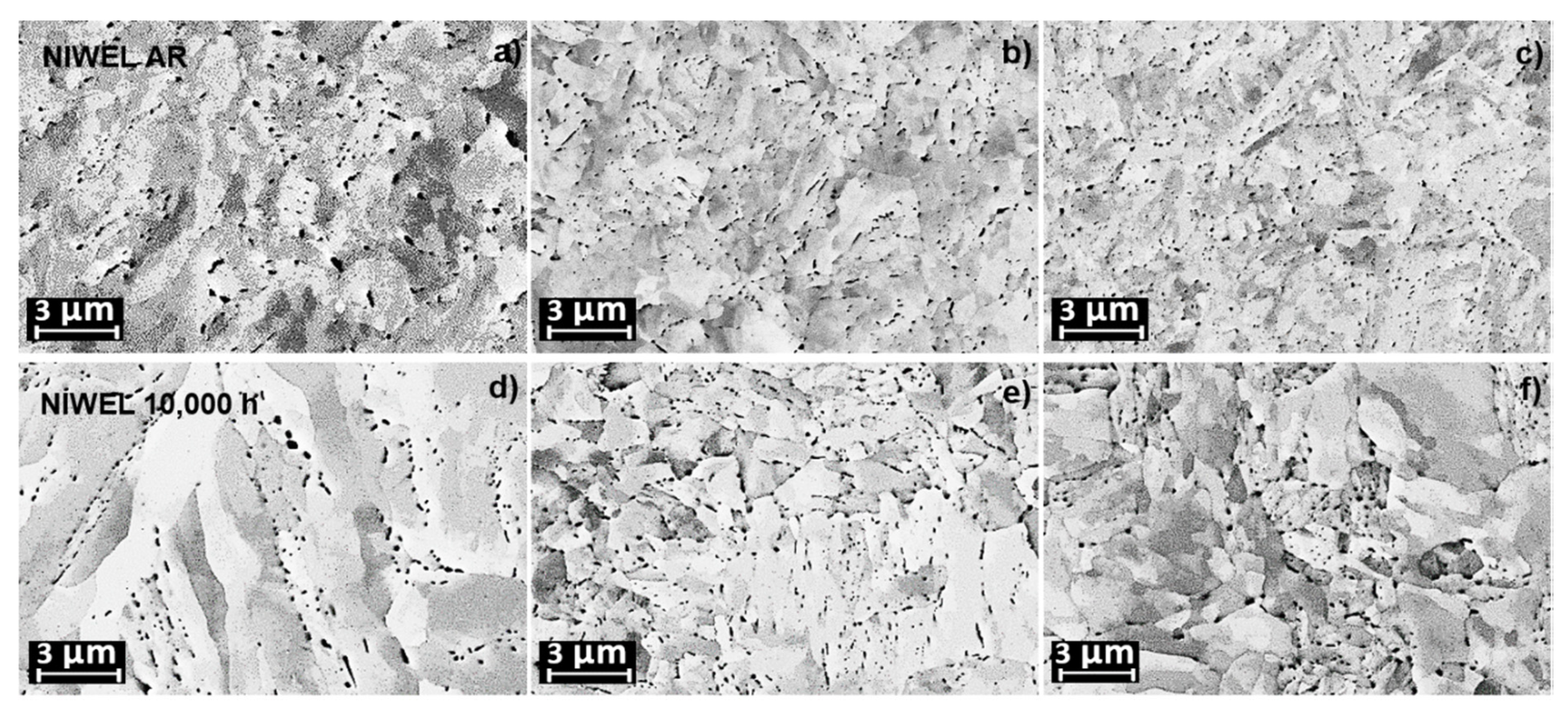

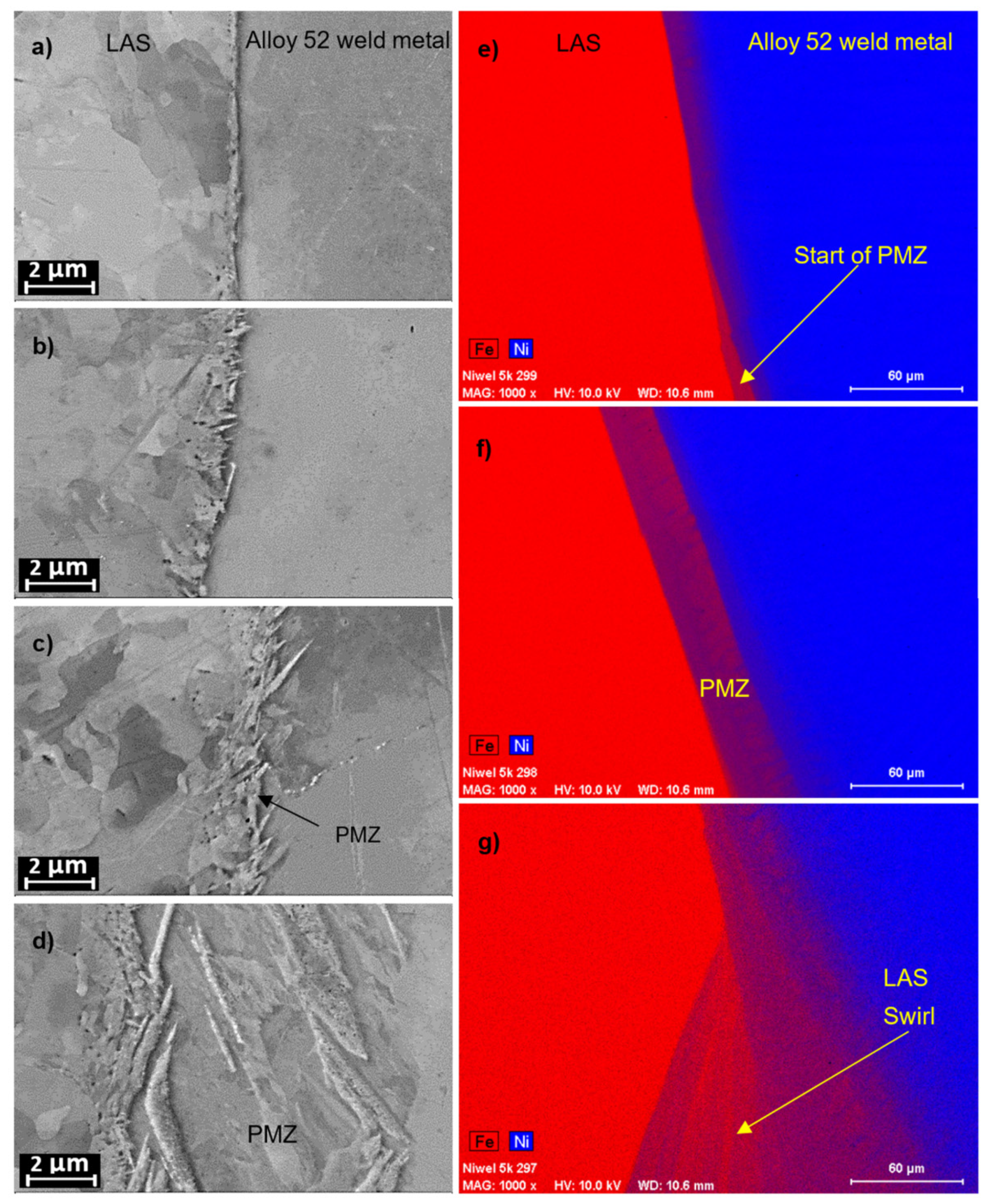

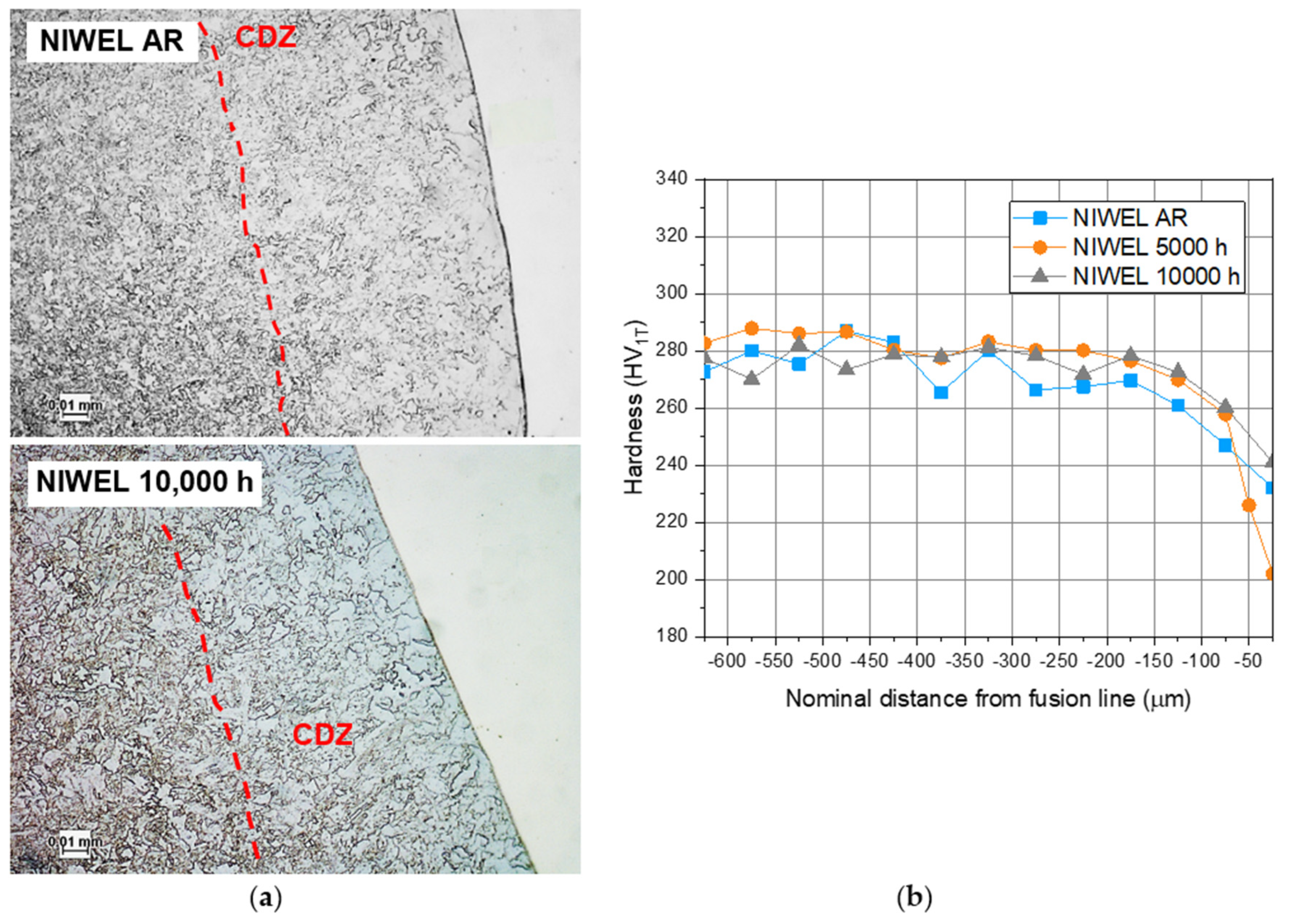

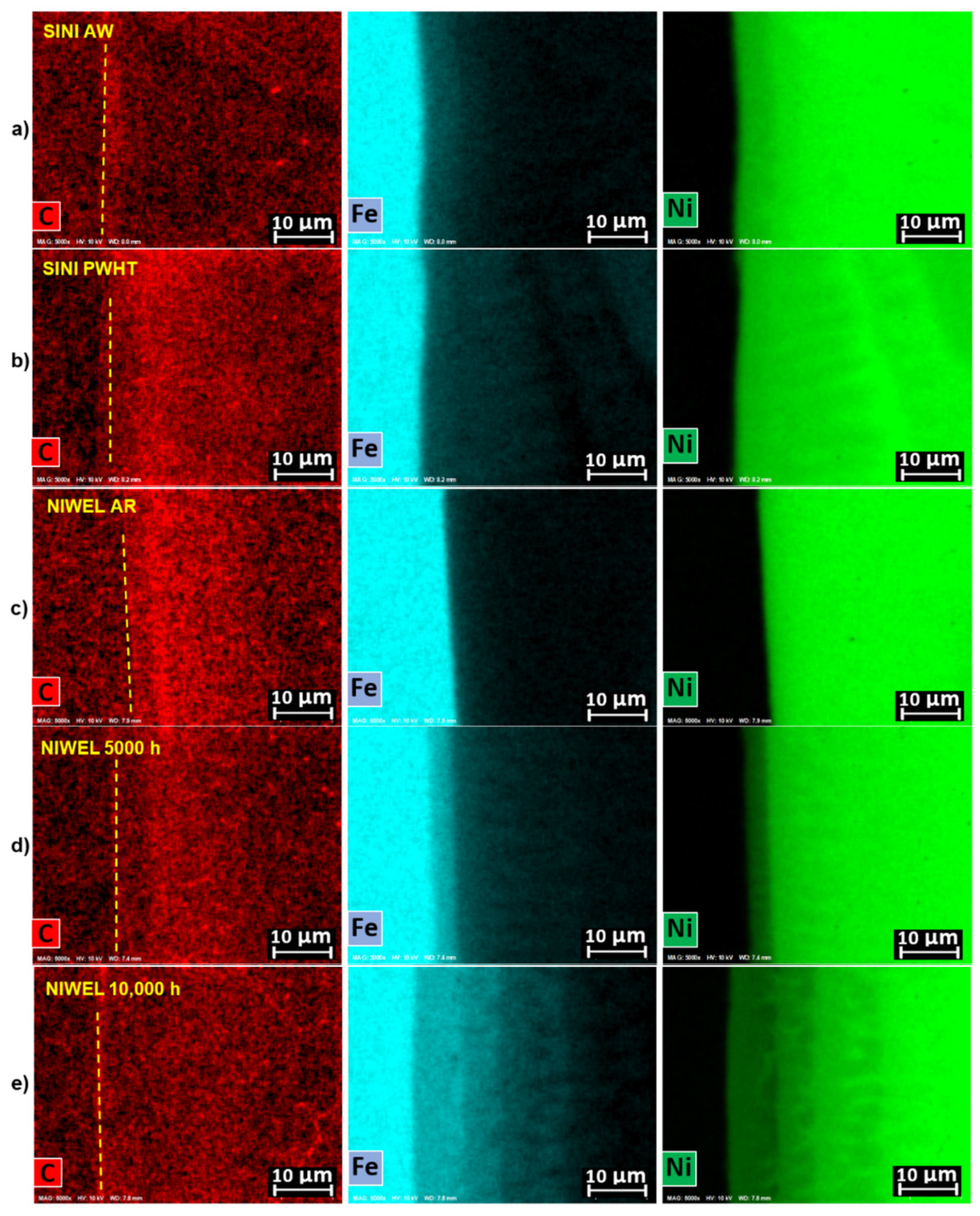

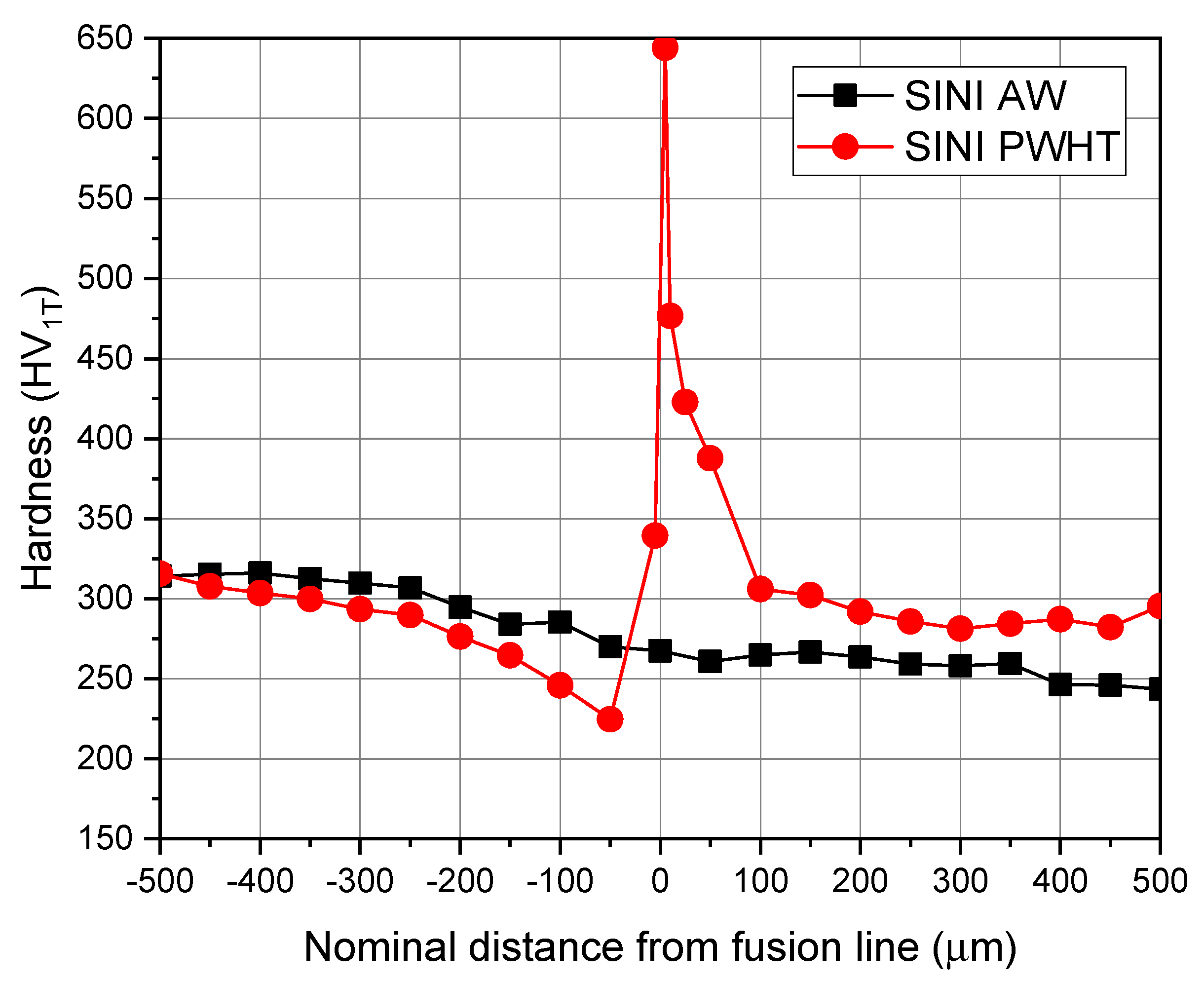

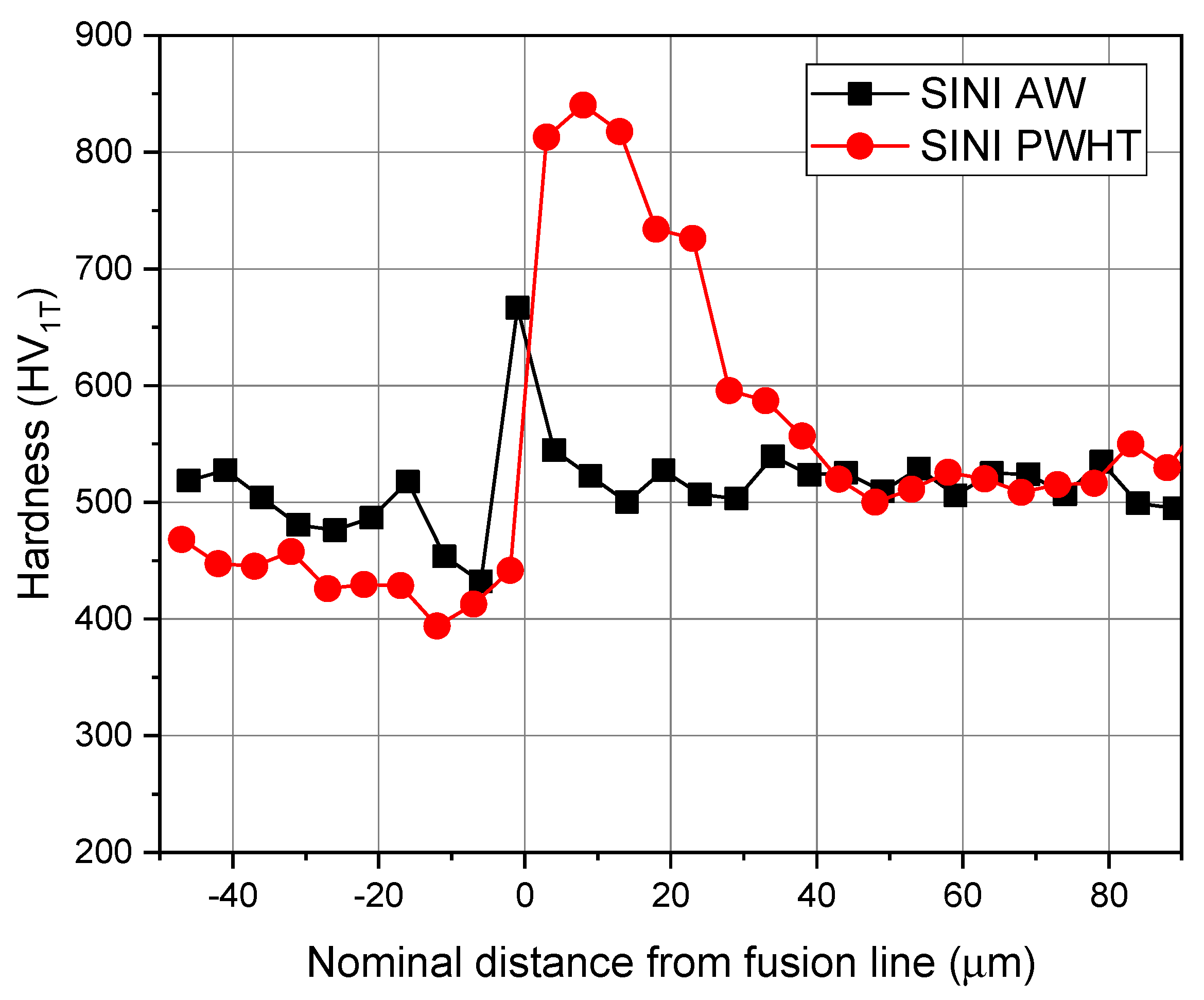

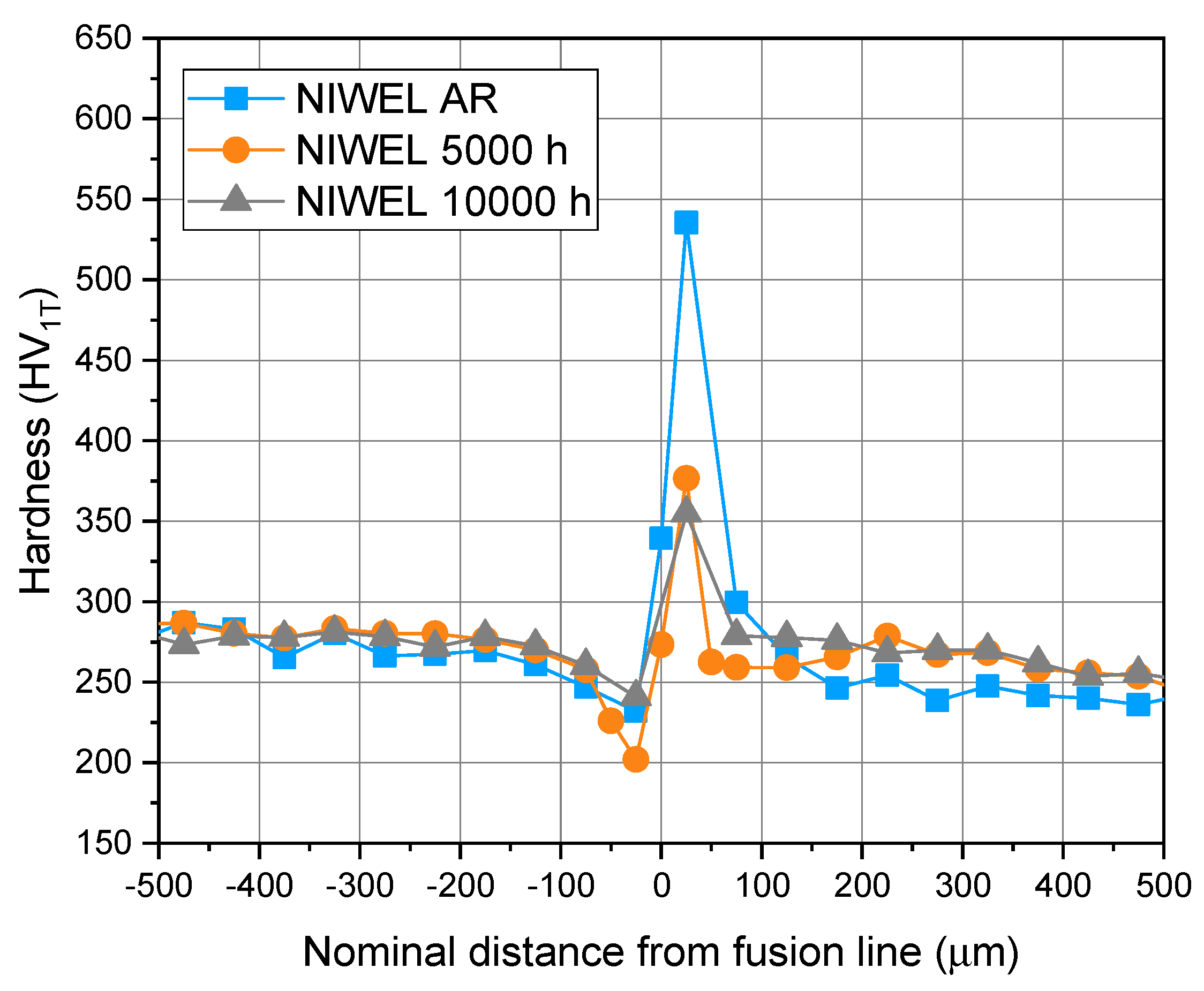

3.3. Ferrite/Austenite Interface

4. Discussion

5. Conclusions

- Thermal ageing of Alloy 52 at 400 °C for up to 10,000 h does not cause any remarkable changes in the microstructure of the weld metal or in the hardness level from the weld crown (lower hardness) to the weld root (higher hardness).

- Thermal ageing of the low-alloy steel (LAS) base material and heat-affected zone (HAZ) at 400 °C for up to 10,000 h does not lead to noticeable changes. The microstructure of the LAS HAZ is determined by the grain-refined, grain-coarsened, and carbon-depleted zone related to the welding process. A clear correlation was revealed between grain size and hardness variation in the LAS HAZ.

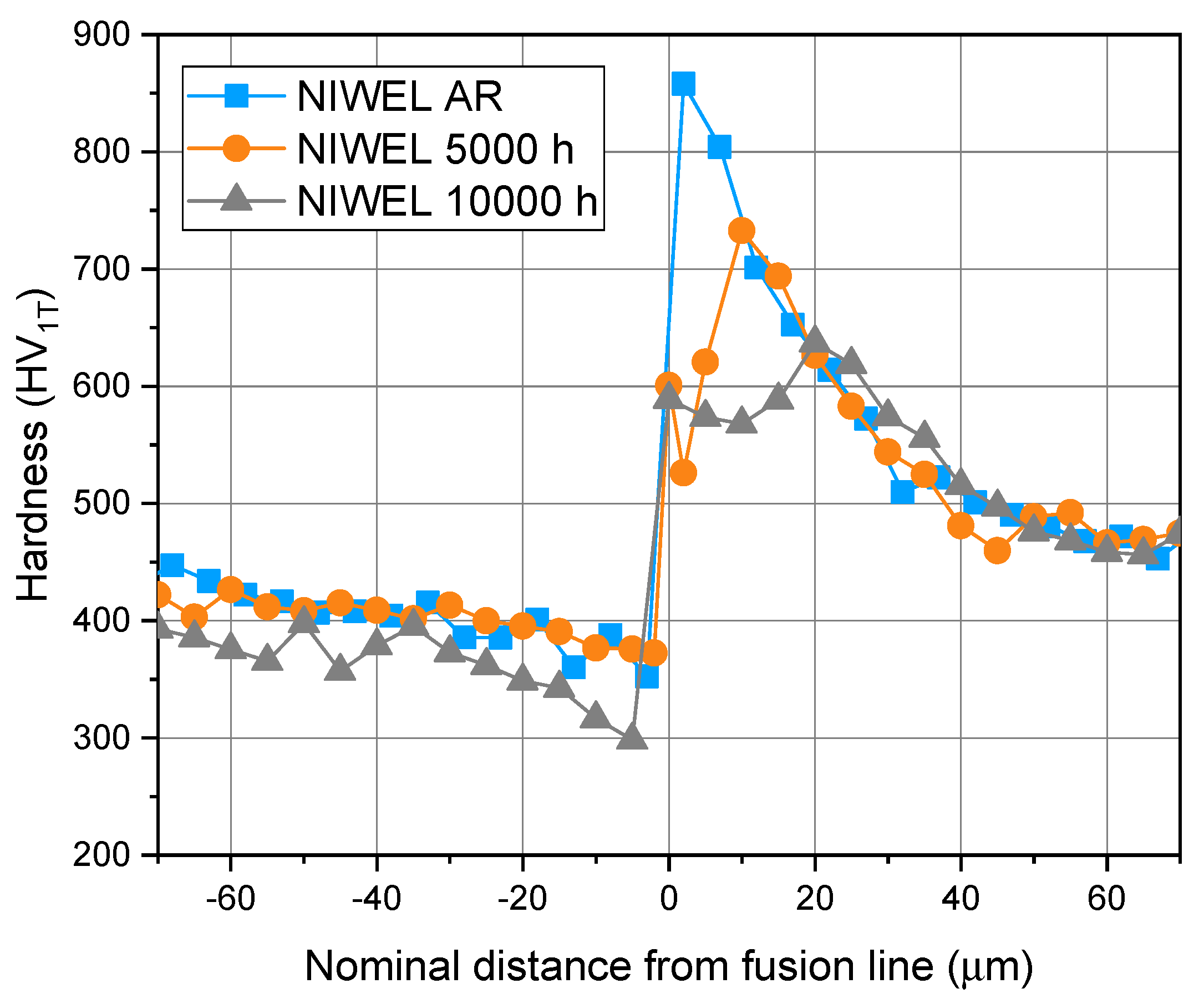

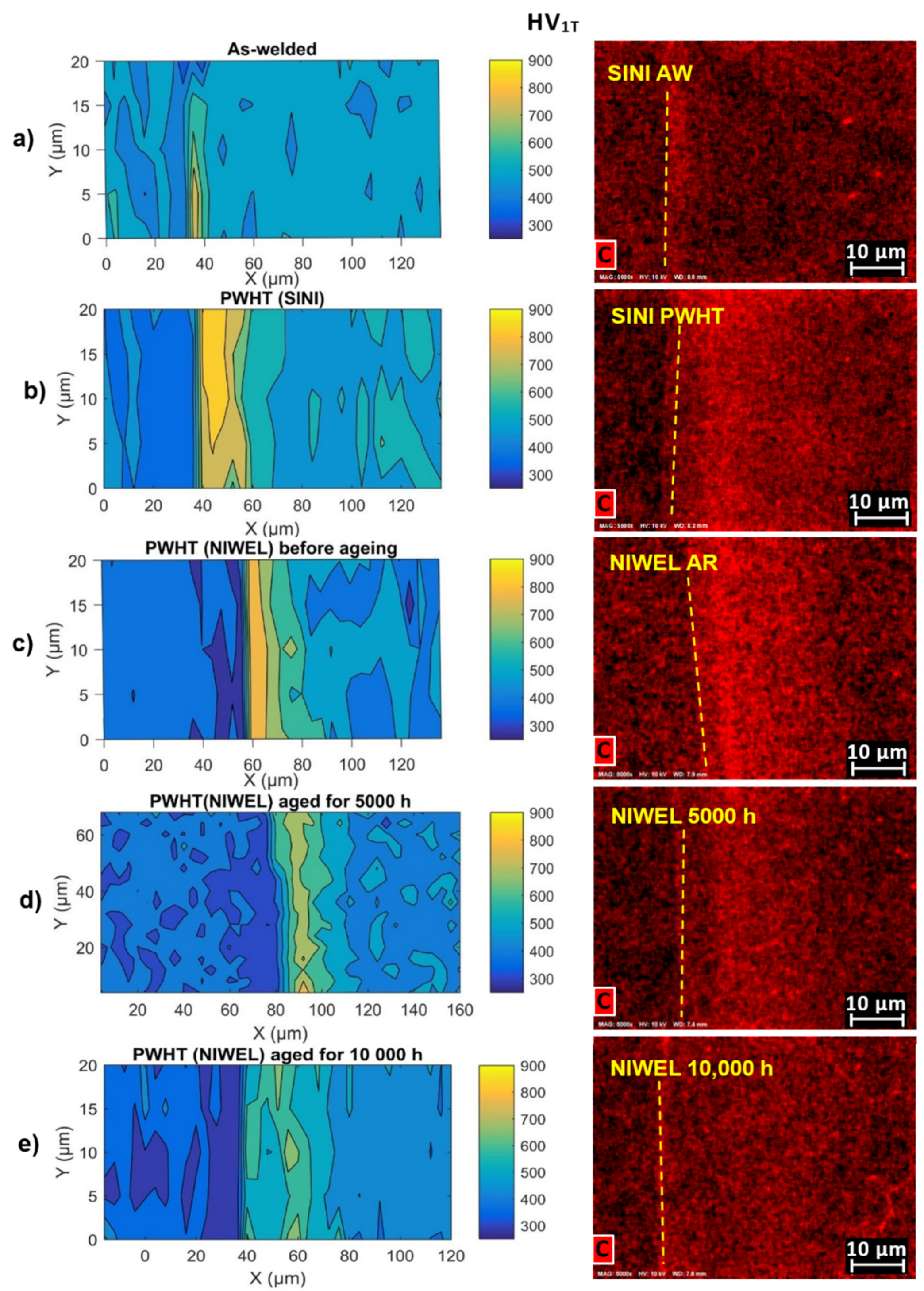

- The LAS/Alloy 52 weld metal interface was found to be affected by thermal ageing. The local hardness mismatch caused by the carbon migration from the LAS to the weld metal upon PWHT, with carbon pile-up next to the interface leading to a significant hardness peak in the weld metal, was reduced markedly upon thermal ageing. The hardness peak in the weld metal decreased and moved further away from the fusion boundary in association with a shift and attenuation of the carbon-rich layer in the weld metal near the fusion boundary after PWHT.

Author Contributions

Funding

Conflicts of Interest

References

- Féron, D. Overview of Nuclear Materials and Nuclear Corrosion Science and Engineering. In Nuclear Corrosion Science and Engineering; Woodhead Publishing: Cambridge, UK, 2012; pp. 31–56. [Google Scholar]

- MacDonald, D.D.; Cragnolino, G.A. Corrosion of Steam Cycle Materials. In ASME Handbook on Water Technology for Thermal Power Systems; Cohen, P., Ed.; ASME: New York, NY, USA, 1989; pp. 659–1031. [Google Scholar]

- Aaltonen, P.; Hänninen, H. Water Chemistry and Behavior of Materials in PWRs and BWRs; IAEA-TECDOC-965; IAEA: Vienna, Austria, 1997; pp. 205–222. [Google Scholar]

- Ehrnstén, U. Corrosion and Stress Corrosion Cracking of Austenitic Stainless Steels. In Comprehensive Nuclear Materials; Allen, T.R., Stoller, R.E., Yamanaka, S., Eds.; Elsevier Ltd.: Amsterdam, The Netherlands, 2012; Volume 5, pp. 93–104. [Google Scholar]

- Scott, P.M. Environment Assisted Cracking in Austenitic Components. Int. J. Press. Vessel. Pip. 1996, 65, 255–264. [Google Scholar] [CrossRef]

- Lu, Z.; Chen, J.; Shoji, T.; Takeda, Y.; Yamazaki, S. Characterization of Microstructure, Local Deformation and Microchemistry in Alloy 690 Heat-Affected Zone and Stress Corrosion Cracking in High Temperature Water. J. Nucl. Mater. 2015, 465, 471–481. [Google Scholar] [CrossRef]

- Payne, B.E. Nickel-base Welding Consumables for Dissimilar Metal Welding Applications. Met. Constr. 1969, 1, 79–87. [Google Scholar]

- Fyfitch, S. Corrosion and Stress Corrosion Cracking of Ni-Base Alloys; Elsevier Ltd.: Amsterdam, The Netherlands, 2019; Volume 5, pp. 69–92. [Google Scholar]

- Scenini, F.; Newman, R.C.; Cottis, R.A.; Jacko, R.J. Alloy Oxidation Studies Related to PWSCC. In Proceedings of the 12th International Conference on Environmental Degradation of Materials in Nuclear Power Systems-Water Reactors, Salt Lake City, Utah, 14–18 August 2005; pp. 891–902. [Google Scholar]

- Andresen, P.L.; Hickling, J.; Ahluwalia, K.S.; Wilson, J.A. Effects of PWR Primary Water Chemistry on PWSCC of Ni Alloys. In Proceedings of the 13th International Conference on Environmental Degradation of Materials in Nuclear Power Systems-Water Reactors, Whistler, BC, Canada, 19–23 April 2007; pp. 1–21. [Google Scholar]

- Vaillant, F.; Boursier, J.-M.; Legras, L.; Yrieix, B.; Lemaire, C.; Amzallag, C. A Review of Weldability and SCC Behaviours of Ni-base Weld Metals in Laboratory PWR Environment. In Proceedings of the 13th International Conference on Environmental Degradation of Materials in Nuclear Power Systems-Water Reactors, Whistler, BC, Canada, 19–23 April 2007; pp. 450–464. [Google Scholar]

- Seifert HPRitter, S.; Shoji, T.; Peng, Q.J.; Takeda, Y.; Lu, Z.P. Environmentally-Assisted Cracking Behaviour in the Transition Region of an Alloy182/SA 508 Cl.2 Dissimilar Metal Weld Joint in Simulated Boiling Water Reactor Normal Water Chemistry Environment. J. Nucl. Mater. 2008, 378, 197–210. [Google Scholar]

- Cattant, F. Materials Ageing in Light Water Reactors—Handbook of Destructive Assays; Materials Ageing Institute: Paris, France, 2014; 1166p. [Google Scholar]

- Chung, W.-C.; Huang, J.-Y.; Tsay, L.-W.; Chen, C. Microstructure and Stress Corrosion Cracking Behavior of the Weld Metal in Alloy 52-A508 Dissimilar Welds. Mater. Trans. 2011, 52, 12–19. [Google Scholar] [CrossRef]

- Lippold, J.C. Welding Metallurgy Principles. In Welding Metallurgy and Weldability; John Wiley & Sons: New Jersey, NJ, USA, 2015; 424p. [Google Scholar]

- Andresen, P.L.; Morra, M.M.; Ahluwalia, K. SCC of Alloy 690 and its Weld Metals. In Corrosion 2012, Paper C2012-0001187; NACE International: Houston, TX, USA, 2012. [Google Scholar]

- Sarikka, T.; Mouginot, R.; Ahonen, M.; Lindqvist, S.; Ehrnstén, U.; Nevasmaa, P.; Hänninen, H. Microstructural Characterization of Alloy 52 Narrow-Gap Dissimilar Metal Weld after Aging. In Proceedings of the 18th International Conference on Environmental Degradation of Materials in Nuclear Power Systems-Water Reactors, Portland, Oregon, 13–17 August 2017; pp. 763–778. [Google Scholar]

- Toloczko, M.; Olszta MOverman, N.; Bruemmer, S. Alloy 152/52-LAS Dilution Zone and Interface/Fusion Line PWSCC Testing. EPRI 690/152/52 PWSCC Research Collaboration Meeting, Tampa, FL, USA, November 29–1 December 2016. [Google Scholar]

- Laukkanen, A.; Nevasmaa, P.; Ehrnstén, U.; Rintamaa, R. Characteristics Relevant to Ductile Failure of Bimetallic Welds and Evaluation of Transferability of Fracture Properties. Nucl. Eng. Des. 2007, 237, 1–15. [Google Scholar] [CrossRef]

- Sarikka, T.; Ahonen, M.; Mouginot, R.; Nevasmaa, P.; Karjalainen-Roikonen, P.; Ehrnstén, U.; Hänninen, H. Microstructural, Mechanical, and Fracture Mechanical Characterization of SA 508-Alloy 182 Dissimilar Metal Weld in View of Mismatch State. Int. J. Press. Vessel. Pip. 2016, 145, 13–22. [Google Scholar] [CrossRef]

- Sarikka, T. Effect of Strength Mismatch on Fracture Behavior of Ferrite-Austenite Interface in Ni-Base Alloy Dissimilar Metal Welds. Ph.D. Thesis, Aalto University Espoo, Esborg, Finland, 2016; 135p. [Google Scholar]

- Peng, Q.; Shoji, T.; Ritter, S.; Seifert, H.-P. SCC Behavior in the Transition Region of an Alloy 182-SA 508 Cl.2 Dissimilar Weld Joint under Simulated BWR-NWC Conditions. In Proceedings of the 12th International Conference on Environmental Degradation of Materials in Nuclear Power Systems-Water Reactors, Salt Lake City, Utah, 14–18 August 2005; pp. 589–599. [Google Scholar]

- Rajeev, R.; Samajdar, I.; Raman, R.; Harendranath, C.S.; Kale, G.B. Origin of Hard and Soft Zone Formation During Cladding of Austenitic/Duplex Stainless Steel on Plain Carbon Steel. Mater. Sci. Technol. 2001, 17, 1005–1011. [Google Scholar] [CrossRef]

- Lundin, C.D. Dissimilar Metal Welds—Transition Joints Literature Review. Weld. J. 1982, 61, 58–63. [Google Scholar]

- Sudha, C.; Terrance, A.; Albert, S.; Vijayalakshmi, M. Systematic Study of Formation of Soft and Hard Zones in the Dissimilar Weldments of Cr–Mo Steels. J. Nucl. Mater. 2002, 302, 193–205. [Google Scholar] [CrossRef]

- Nelson, T.W.; Lippold, J.C.; Mills, M.J. Investigation of Boundaries and Structures in Dissimilar Metal Welds. Sci. Technol. Weld. Join. 1998, 3, 249–255. [Google Scholar] [CrossRef]

- Alexandrov, B.T.; Lippold, J.C.; Sowards, J.W.; Hope AT Saltzmann, D.R. Fusion Boundary Microstructure Evolution Associated with Embrittlement of Ni-Base Alloy Overlays Applied to Carbon Steel. Weld. World 2013, 57, 39–53. [Google Scholar] [CrossRef]

- Nelson, T.W.; Lippold, J.C.; Mills, M.J. Nature and Evolution of the Fusion Boundary in Ferritic-Austenitic Dissimilar Metal Welds—Part 2: On-Cooling Transformations. Weld. J. 2000, 10, 267–277. [Google Scholar]

- DuPont, J.N.; Lippold, J.C.; Kiser, S.D. Welding Metallurgy and Weldability of Nickel-Base Alloys; John Wiley and Sons: New Jersey, NJ, USA, 2009; 440p. [Google Scholar]

- Sui, G.; Titchmarsh, J.M.; Heys, G.B.; Congleton, J. Stress Corrosion Cracking of Alloy 600 and Alloy 690 in Hydrogen/Steam at 380 °C. Corros. Sci. 1997, 39, 565–587. [Google Scholar] [CrossRef]

- Young, G.A.; Tucker, J.D.; Eno, D.R. The Kinetics of Long Range Ordering in Ni-Cr and Ni-Cr-Fe Alloys. In Proceedings of the 16th International Conference on the Environmental Degradation of Materials in Nuclear Power Systems-Water Reactors, Asheville, NC, USA, 11–15 August 2013; pp. 1–22. [Google Scholar]

- Lee, H.T.; Wu, J.L. Intergranular Corrosion Resistance of Nickel-Based Alloy 690 Weldments. Corros. Sci. 2010, 52, 1545–1550. [Google Scholar] [CrossRef]

- Electric Power Research Institute. Materials Reliability Program: Resistance of Alloys 690, 152, and 52 to Primary Water Stress Corrosion Cracking (MRP-258); EPRI: Palo Alto, CA, USA, 2009. [Google Scholar]

- Joly, P.; Yescas, M.; Keim, E. Fracture toughness in the ductile-brittle transition and thermal ageing behavior of decarburized heat affected zone of Alloy 52 dissimilar metal welds of nuclear components. In Proceedings of the ASME-2014 Pressure Vessel and Piping Conference, Anaheim, CA, USA, 20–24 July 2014. [Google Scholar]

- Mouginot, R.; Sarikka, T.; Brederholm, A.; Saukkonen, T.; Hänninen, H. Characterization of a Ni-Base NG-DMW of Modern PWR. International Symposium Fontevraud 8 on Contribution of Materials Investigations and Operating Experience to LWRs’ Safety, Performance and Reliability, Avignon, France, 15–18 September 2014; 14p. [Google Scholar]

- Hänninen, H.; Brederholm, A.; Sarikka, T.; Mouginot, R.; Holmström, P.; Saukkonen, A.; Toivonen, A.; Karjalainen-Roikonen, P.; Nevasmaa, P.; Keinänen, H.; et al. Structural Integrity of Ni-base Alloy Welds; VTT Technology 175; VTT: Espoo, Finland, 2014; 257p. [Google Scholar]

- Sarikka, T.; Ahonen, M.; Mouginot, R.; Nevasmaa, P.; Karjalainen-Roikonen, P.; Ehrnstén, U.; Hänninen, H. Effect of Mechanical Mismatch on the Fracture Mechanical Behavior of SA 508-Alloy 52 Narrow Gap Dissimilar Metal Weld. Int. J. Press. Vessel. Pip. 2017, 157, 30–42. [Google Scholar] [CrossRef]

- Lindqvist, S.; Sarikka, T.; Ahonen, M.; Hänninen, H. The effect of crack path on tearing resistance of a narrow-gap Alloy 52 dissimilar metal weld. Eng. Fract. Mech. 2018, 201, 130–143. [Google Scholar] [CrossRef]

- Lindqvist, S.; Ahonen, M.; Lydman, J.; Arffman, P.; Hänninen, H. A crack-location correction for T0 analysis of an Alloy 52 dissimilar metal weld. Eng. Fract. Mech. 2019, 214, 320–334. [Google Scholar] [CrossRef]

- Ahonen, M.; Lindqvist, S.; Sarikka, T.; Mouginot, R.; Leskelä, E.; Lydman, J.; Ehrnstén, U.; Nevasmaa, P.; Seppänen, T.; Arffman, P.; et al. Thermal Ageing and Mechanical Performance of Narrow-Gap Dissimilar Metal Welds; VTT Technology 333; VTT: Espoo, Finland, 2018; ISBN 2242-122X. [Google Scholar]

| Element | SA508 Gr.2 Cl.1 | AISI 316L | AISI 308L | Alloy 52 (Plate) | Alloy 52 (Pipe) |

|---|---|---|---|---|---|

| C | 0.21 | 0.023 | 0.007 | 0.03 | 0.023 |

| Si | 0.17 | 0.53 | 0.37 | 0.13 | 0.15 |

| Mn | 0.78 | 1.29 | 1.9 | 0.24 | 0.26 |

| P | 0.002 | 0.031 | 0.013 | <0.001 | <0.005 |

| S | 0.009 | 0.002 | 0.001 | <0.001 | 0.0007 |

| Cr | 0.45 | 17 | 20.3 | 29.2 | 29.93 |

| Ni | 0.85 | 10.1 | 10.3 | 59.28 | 58.86 |

| Mo | 0.62 | 2.04 | 0.1 | 0.03 | <0.01 |

| Nb | - | - | - | <0.02 | <0.01 |

| N | 0.014 | 0.04 | 0.04 | - | 0.021 |

| Ti | 0.002 | - | - | 0.51 | 0.54 |

| Fe | Bal. | Bal. | Bal. | 9.8 | 10.43 |

| Al | 0.016 | - | - | 0.72 | 0.66 |

| Co | <0.003 | - | - | 0.009 | <0.01 |

| Cu | 0.06 | - | 0.05 | 0.04 | <0.01 |

| NIWEL | Crown | Centre | Root | |||

|---|---|---|---|---|---|---|

| Mean HVIT | SD | Mean HVIT | SD | Mean HVIT | SD | |

| As-received | 232 | 8 | 247 | 14 | 268 | 10 |

| 5000 h | 243 | 13 | 249 | 8 | 270 | 15 |

| 10,000 h | 239 | 15 | 245 | 17 | 257 | 12 |

| SINI | HVIT (1.5 mN) | Location | Distance of Peak Hardness from Fusion Line (µm) |

|---|---|---|---|

| As-welded | 667 | PMZ | 0 |

| PWHT | 840 | Weld metal | 0–5 |

| NIWEL | HVIT (1.5 mN) | Location | Distance of Peak Hardness from Fusion Line (µm) |

|---|---|---|---|

| As-received | 858 | Weld metal | 0–2 |

| 5000 h | 733 | Weld metal | 10 |

| 10,000 h | 637 | Weld metal | 20 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahonen, M.; Mouginot, R.; Sarikka, T.; Lindqvist, S.; Que, Z.; Ehrnstén, U.; Virkkunen, I.; Hänninen, H. Effect of Thermal Ageing at 400 °C on the Microstructure of Ferrite-Austenite Interface of Nickel-Base Alloy Narrow-Gap Dissimilar Metal Weld. Metals 2020, 10, 421. https://doi.org/10.3390/met10030421

Ahonen M, Mouginot R, Sarikka T, Lindqvist S, Que Z, Ehrnstén U, Virkkunen I, Hänninen H. Effect of Thermal Ageing at 400 °C on the Microstructure of Ferrite-Austenite Interface of Nickel-Base Alloy Narrow-Gap Dissimilar Metal Weld. Metals. 2020; 10(3):421. https://doi.org/10.3390/met10030421

Chicago/Turabian StyleAhonen, Matias, Roman Mouginot, Teemu Sarikka, Sebastian Lindqvist, Zaiqing Que, Ulla Ehrnstén, Iikka Virkkunen, and Hannu Hänninen. 2020. "Effect of Thermal Ageing at 400 °C on the Microstructure of Ferrite-Austenite Interface of Nickel-Base Alloy Narrow-Gap Dissimilar Metal Weld" Metals 10, no. 3: 421. https://doi.org/10.3390/met10030421

APA StyleAhonen, M., Mouginot, R., Sarikka, T., Lindqvist, S., Que, Z., Ehrnstén, U., Virkkunen, I., & Hänninen, H. (2020). Effect of Thermal Ageing at 400 °C on the Microstructure of Ferrite-Austenite Interface of Nickel-Base Alloy Narrow-Gap Dissimilar Metal Weld. Metals, 10(3), 421. https://doi.org/10.3390/met10030421