Influence of Friction Stir Processing on Mechanical Behavior of 2507 SDSS

Abstract

1. Introduction

2. Material and Experimental Procedure

2.1. Material

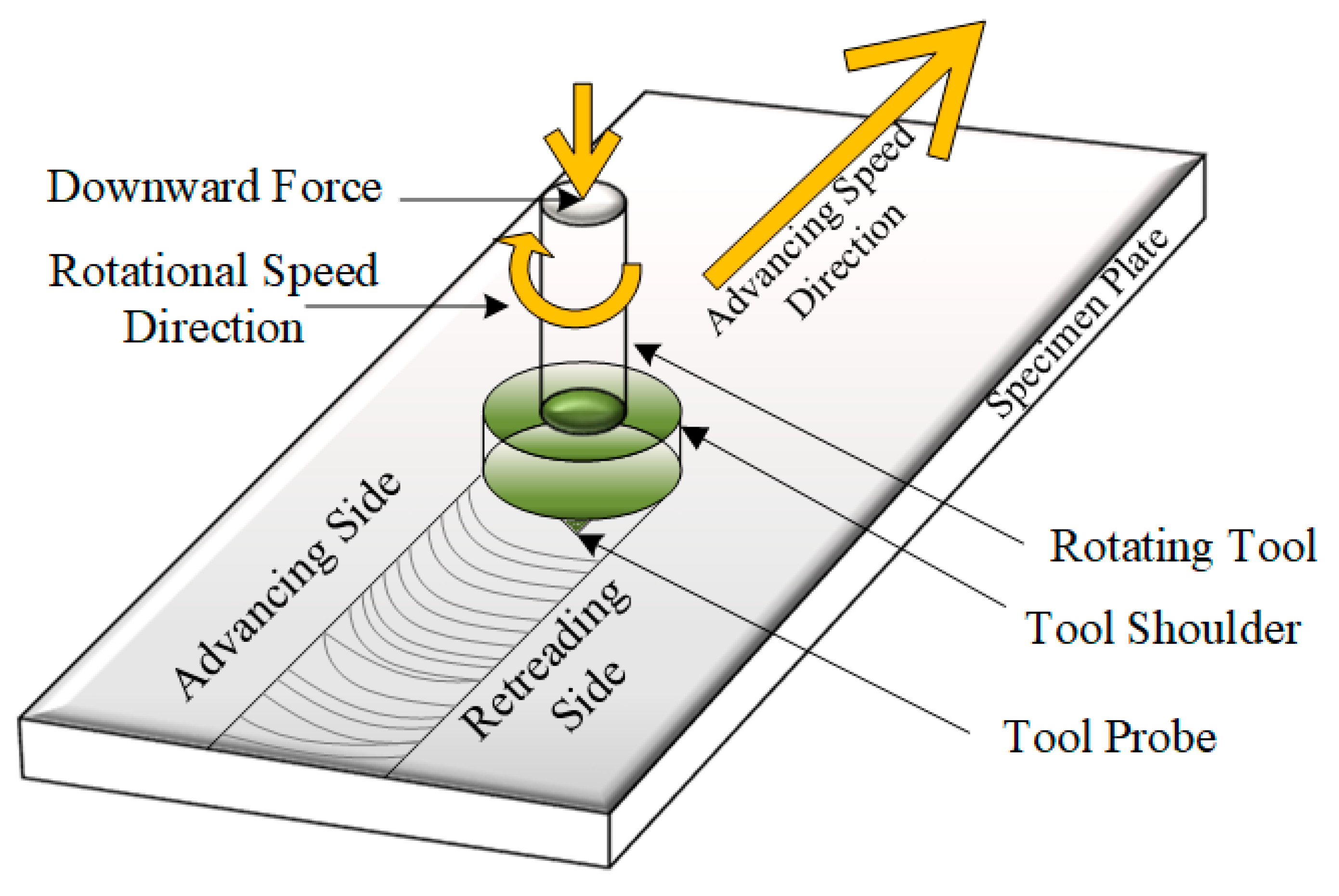

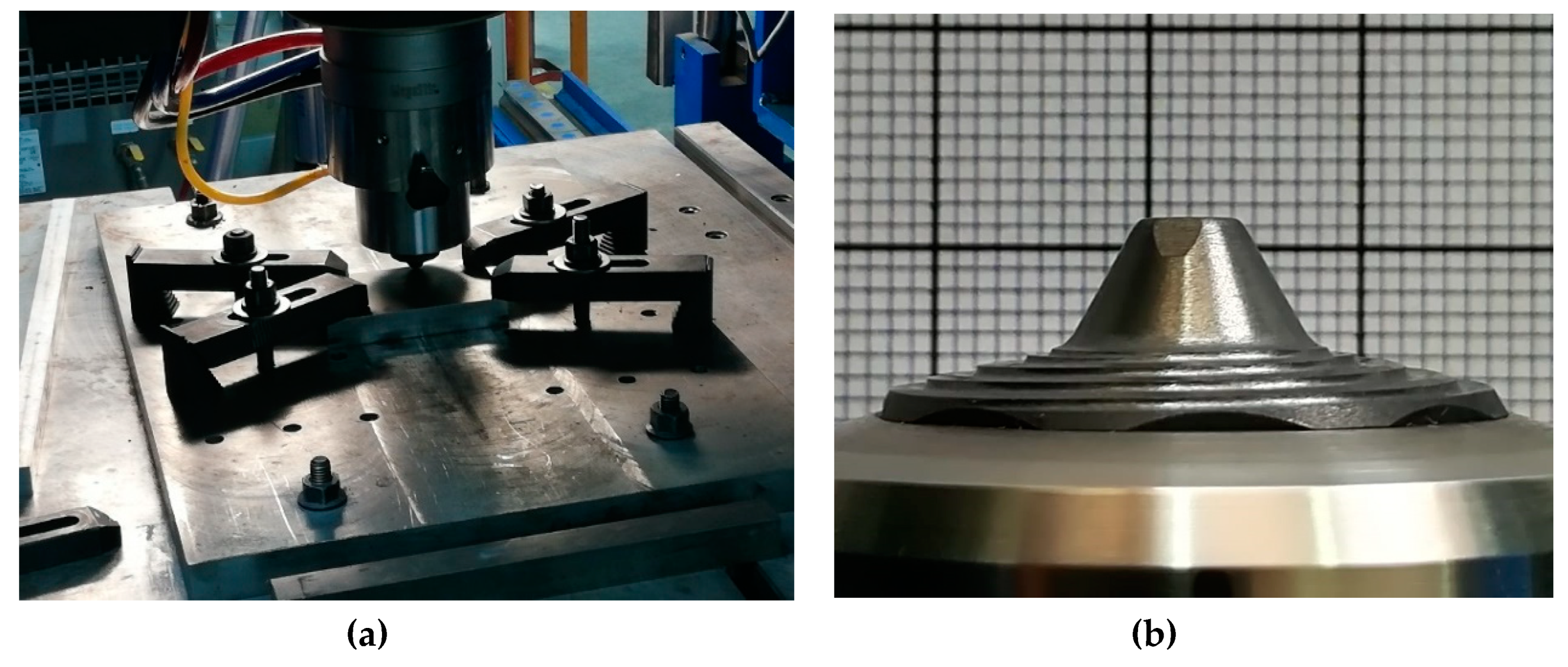

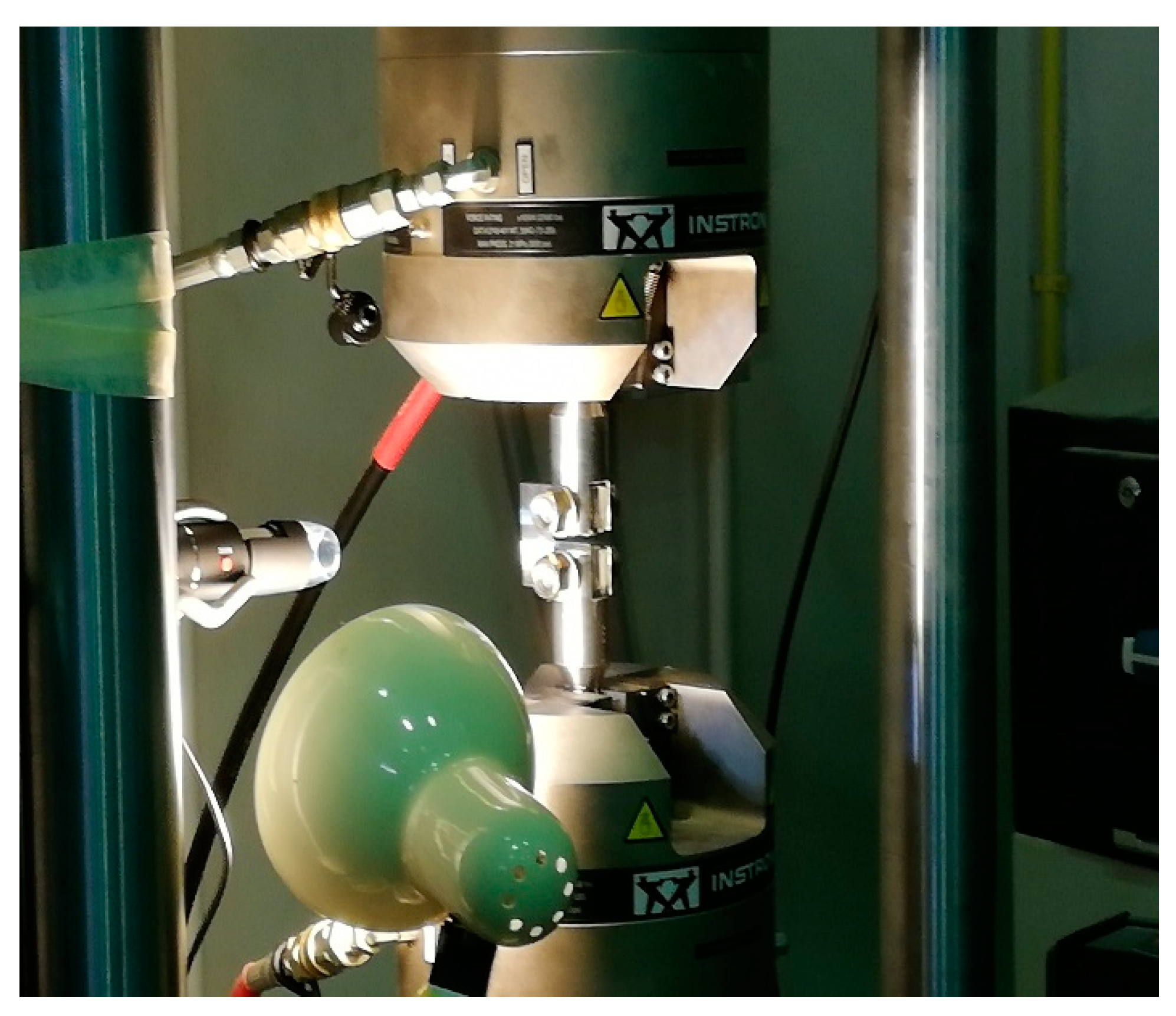

2.2. Friction Stir Processing

2.3. Microstructural Analysis

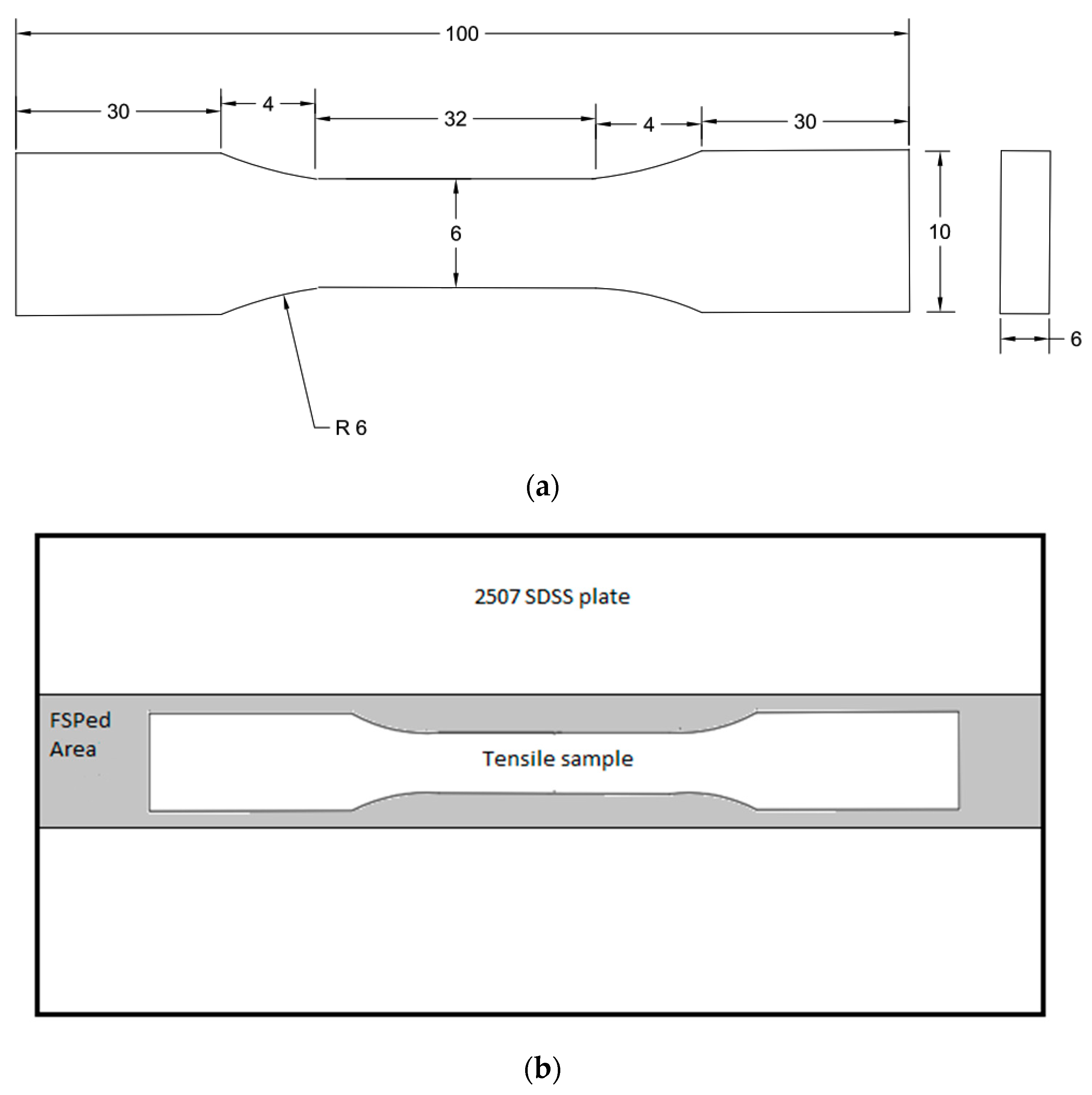

2.4. Tensile Testing

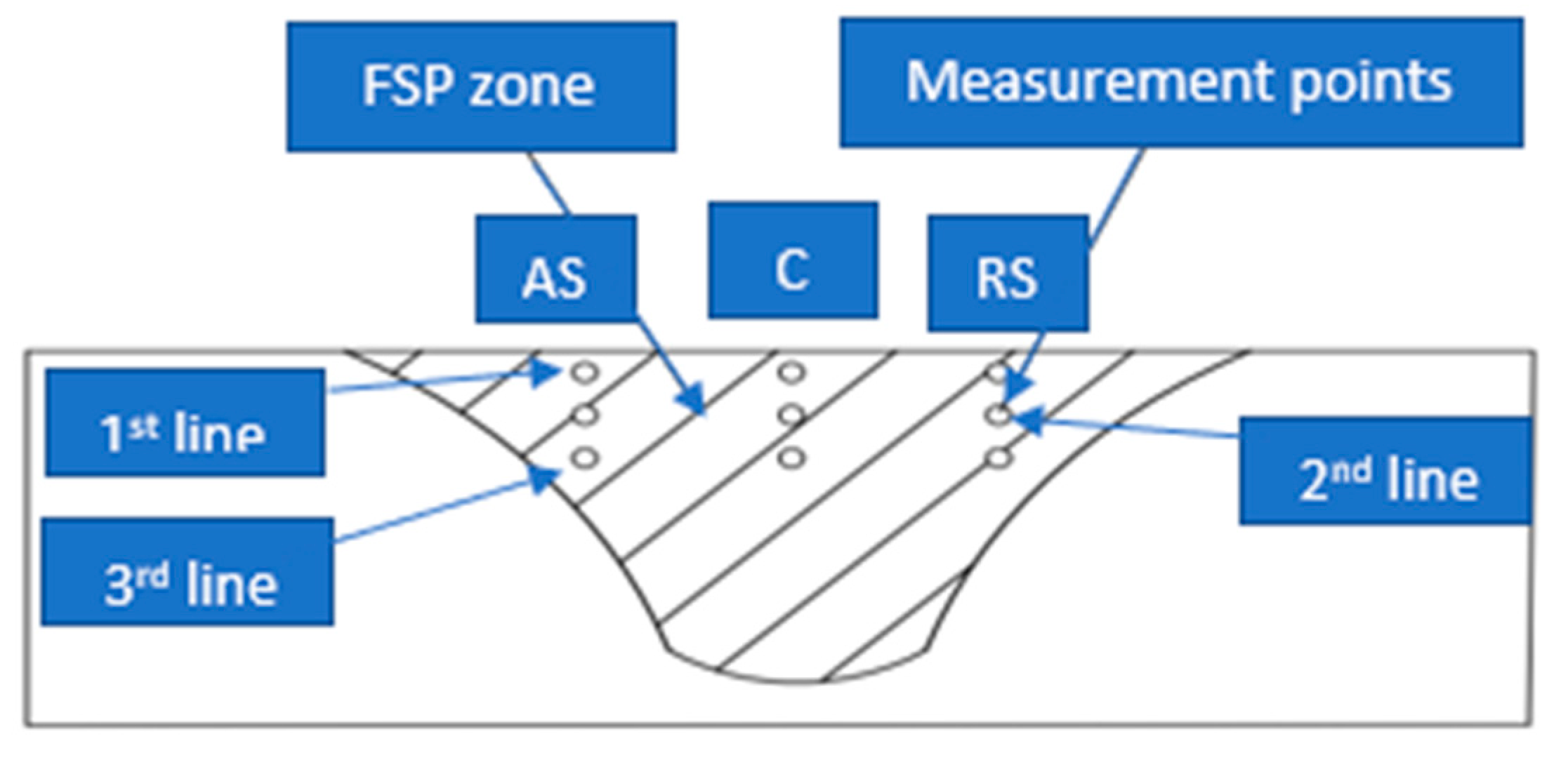

2.5. Microhardness Measurements

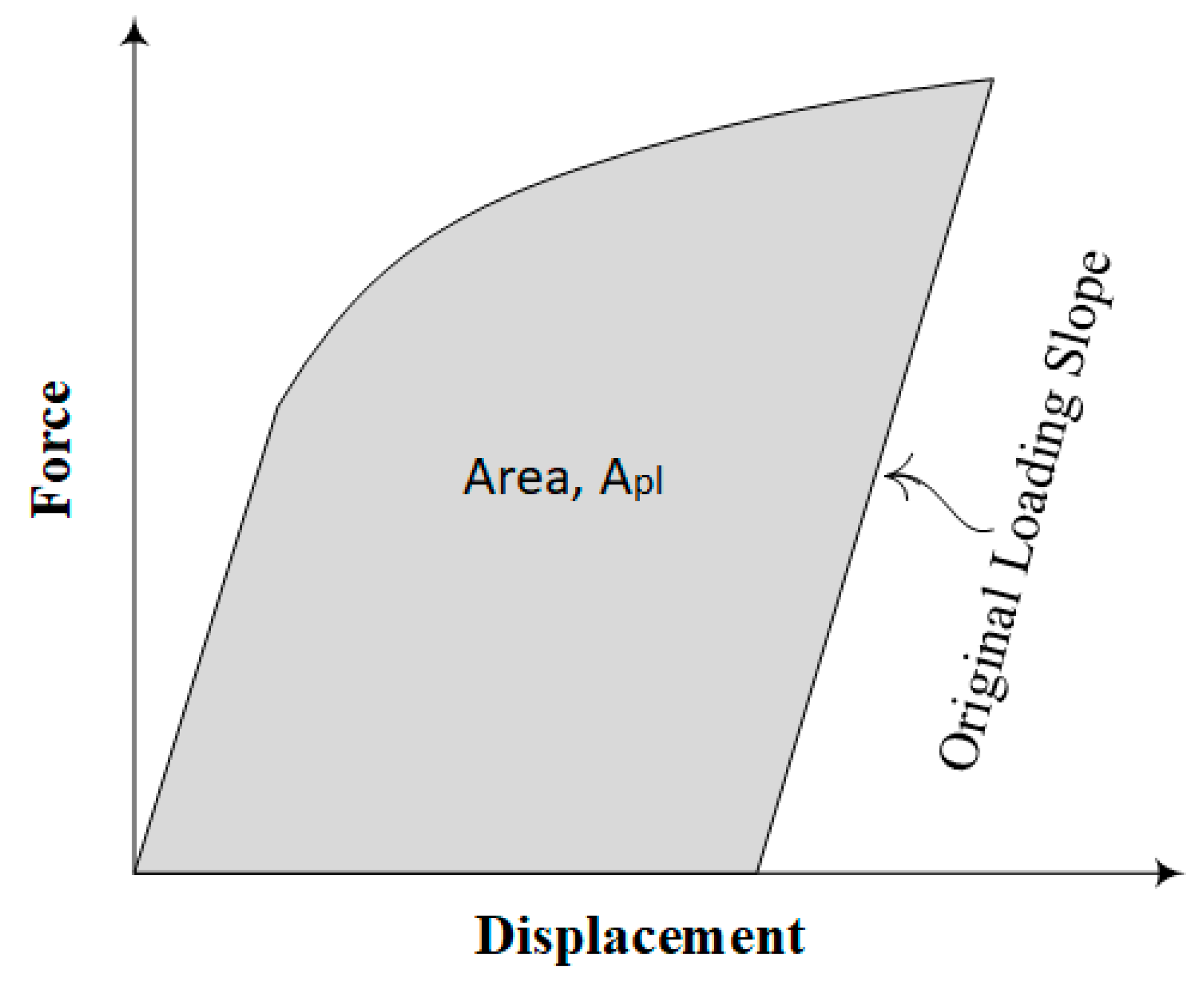

2.6. Fracture Toughness Testing

3. Results and Discussion

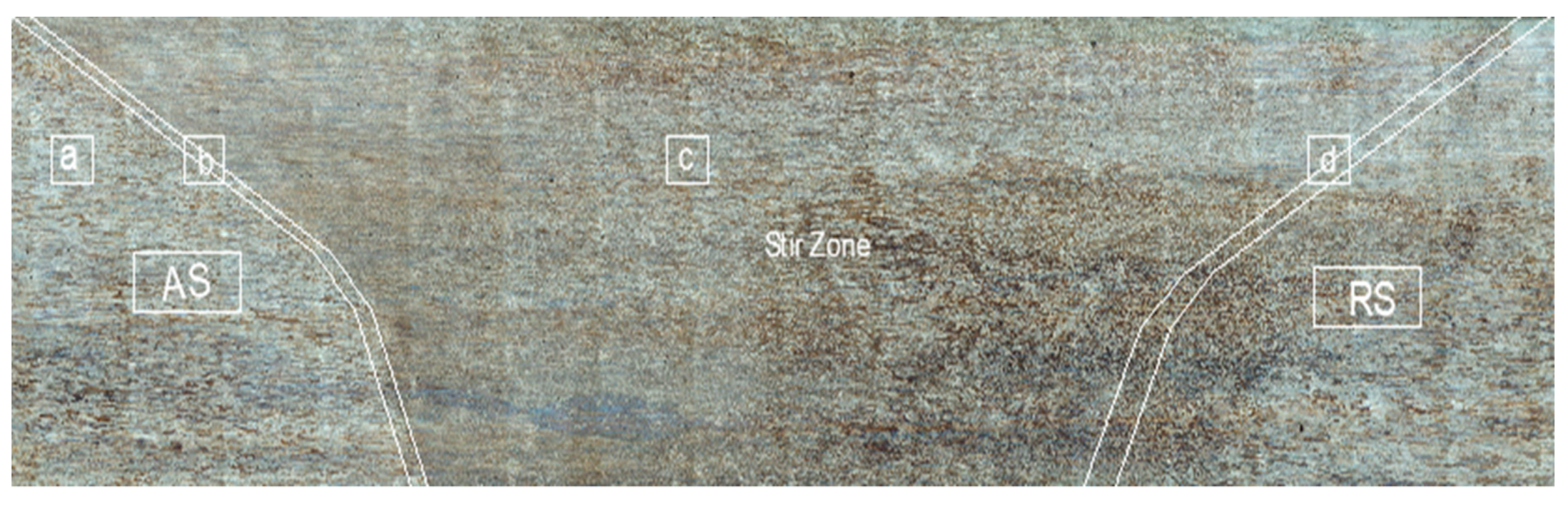

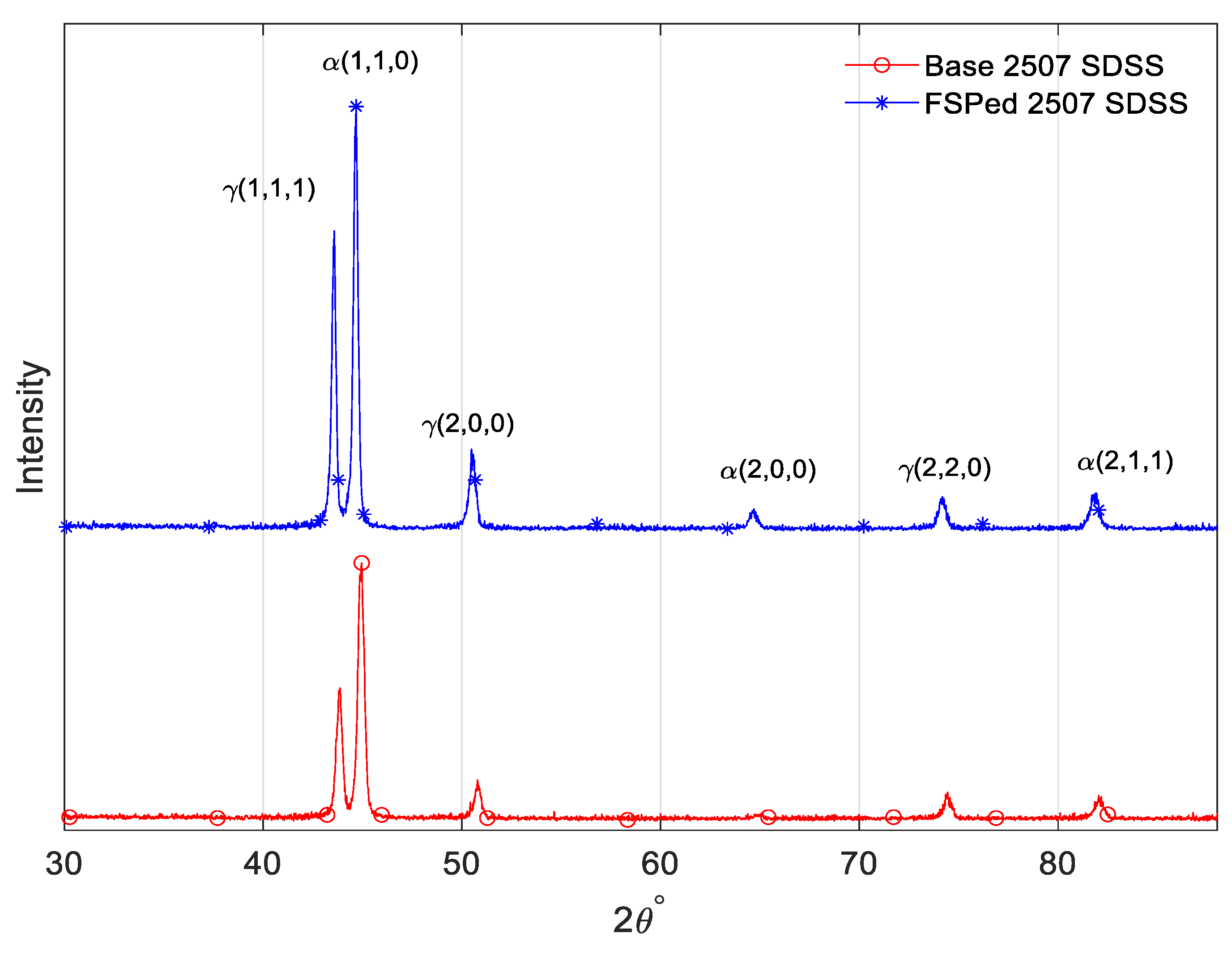

3.1. Microstructural Analysis

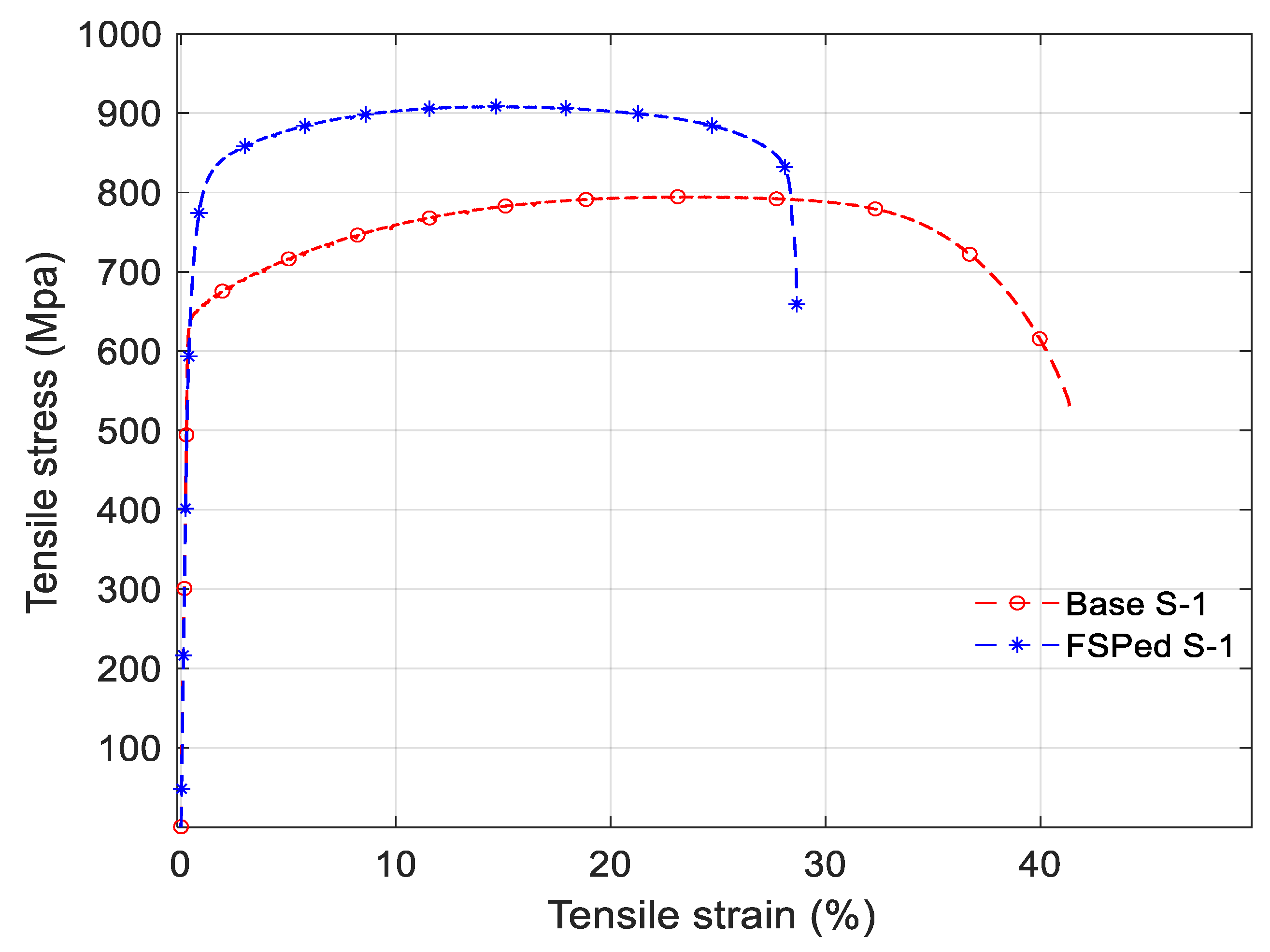

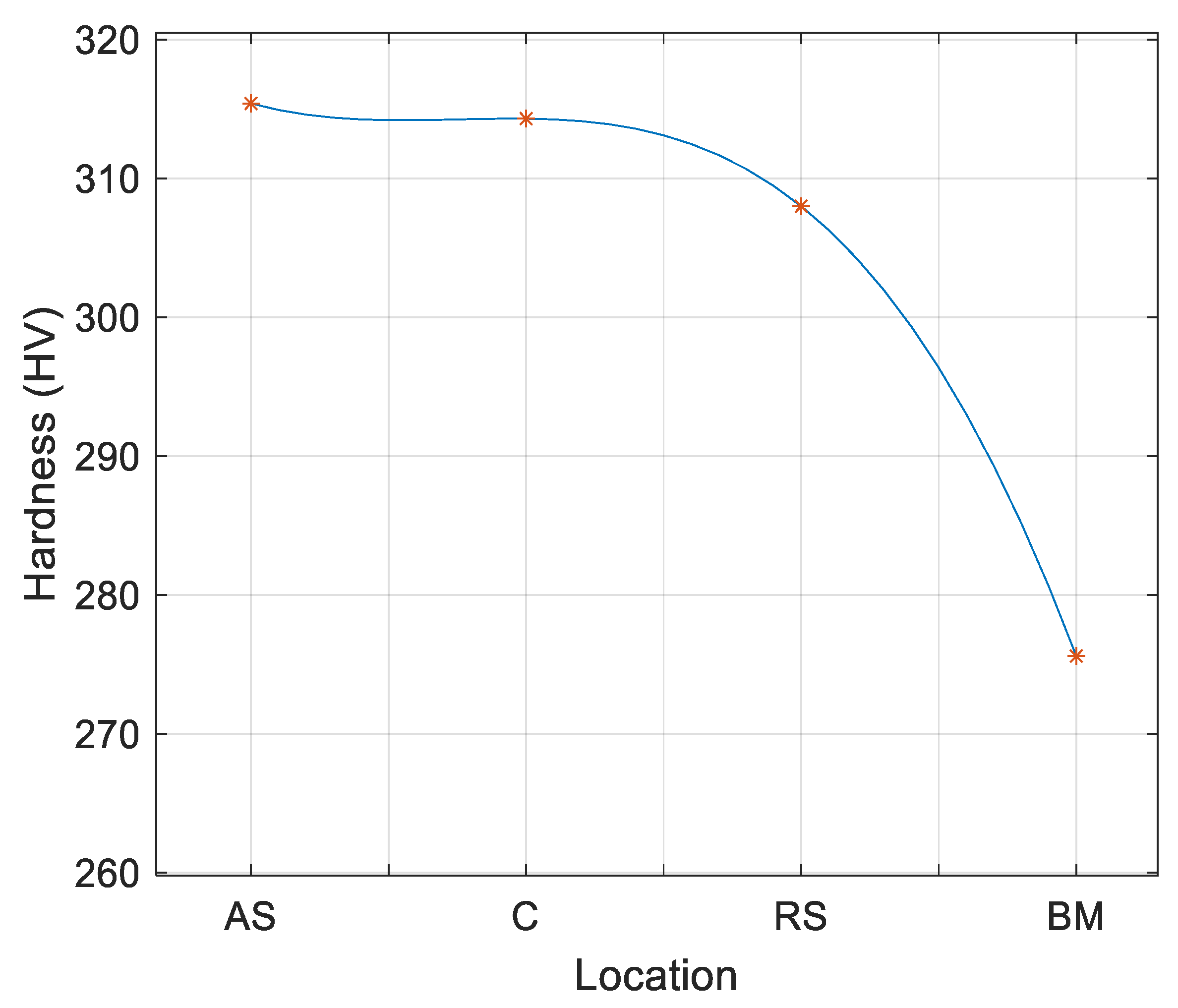

3.2. Effects of FSP on Tensile Properties and Microhardness

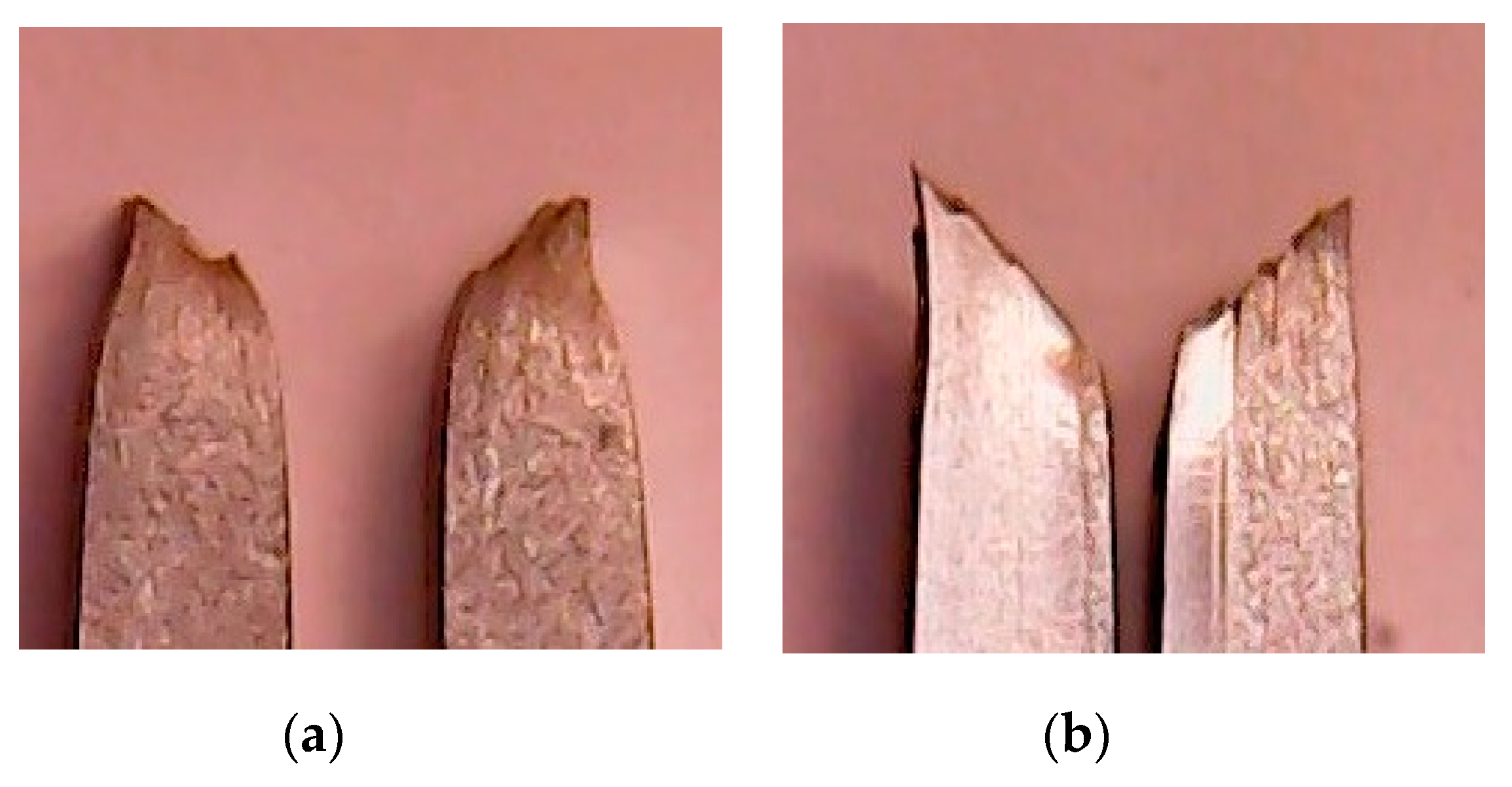

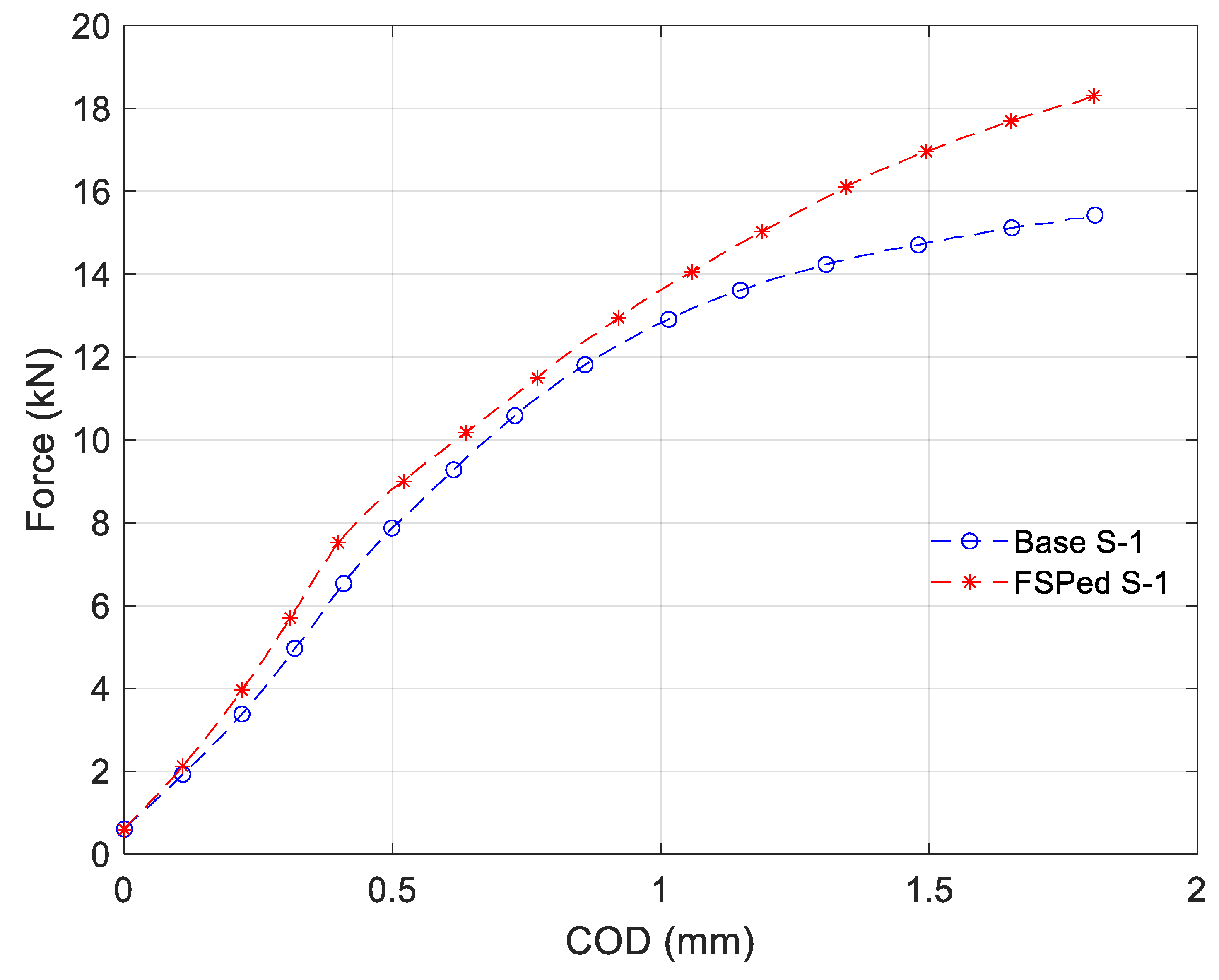

3.3. Influence of FSP on Fracture Toughness

4. Conclusions

- Microstructure refinement is asymmetric with respect to processed centerline;

- Grains are finer on the advancing side (AS) in the stir zone because grains on the AS experienced more plastic deformation/strain;

- FSP increased the yield strength, ultimate strength, and hardness of 2507 SDSS because of grain refinement;

- FSP increased the fracture toughness of 2507 SDSS because grain refinement increased the grain boundaries, which enhanced the resistance against the crack growth.

Author Contributions

Funding

Conflicts of Interest

References

- Nirosta, K. Practical Guidelines for the Fabrication of Duplex Stainless Steels. Available online: https://www.imoa.info/download_files/stainless-steel/Duplex_Stainless_Steel_3rd_Edition.pdf (accessed on 18 May 2019).

- Wallén, B. Corrosion of duplex stainless steels in seawater. In Avesta Corrosion Management and Application Engineering; Avesta Sheffield AB: Avesta, Sweden, 1998. [Google Scholar]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Sharma, V.; Prakash, U.; Kumar, B.V.M. Surface composites by friction stir processing: A review. J. Mater. Process. Technol. 2015, 224, 117–134. [Google Scholar] [CrossRef]

- Emami, S.; Saeid, T.; Khosroshahi, R.A. Microstructural evolution of friction stir welded SAF 2205 duplex stainless steel. J. Alloys Compd. 2018, 739, 678–689. [Google Scholar] [CrossRef]

- Emami, S.; Saeid, T.; Azari Khosroshahi, R. Microstructural refining during friction stir processing of SAF 2205 duplex stainless steel. J. Ultrafine Grained Nanostruct. Mater. 2018, 51, 20–25. [Google Scholar]

- Esmailzadeh, M.; Shamanian, M.; Kermanpur, A.; Saeid, T. Microstructure and mechanical properties of friction stir welded lean duplex stainless steel. Mater. Sci. Eng. A 2013, 561, 486–491. [Google Scholar] [CrossRef]

- Saeid, T.; Abdollah-Zadeh, A.; Assadi, H.; Ghaini, F.M. Effect of friction stir welding speed on the microstructure and mechanical properties of a duplex stainless steel. Mater. Sci. Eng. A 2008, 496, 262–268. [Google Scholar] [CrossRef]

- Saeid, T.; Abdollah-zadeh, A.; Shibayanagi, T.; Ikeuchi, K.; Assadi, H. On the formation of grain structure during friction stir welding of duplex stainless steel. Mater. Sci. Eng. A 2010, 527, 6484–6488. [Google Scholar] [CrossRef]

- Mishra, M.K.; Rao, A.G.; Balasundar, I.; Kashyap, B.P.; Prabhu, N. On the microstructure evolution in friction stir processed 2507 super duplex stainless steel and its effect on tensile behaviour at ambient and elevated temperatures. Mater. Sci. Eng. A 2018, 719, 82–92. [Google Scholar] [CrossRef]

- Sato, Y.S.; Nelson, T.W.; Sterling, C.J.; Steel, R.J.; Pettersson, C.O. Microstructure and mechanical properties of friction stir welded SAF 2507 super duplex stainless steel. Mater. Sci. Eng. A 2005, 397, 376–384. [Google Scholar] [CrossRef]

- Santos, T.F.d.A.; Torres, E.A.; Ramirez, A.J. Friction stir welding of duplex stainless steels. Weld. Int. 2018, 32, 103–111. [Google Scholar] [CrossRef]

- Meinhardt, C.P.; Scheid, A.; dos Santos, J.F.L.; Bergmann, A.; Favaro, M.B.; Kwietniewski, C.E.F. Hydrogen embrittlement under cathodic protection of friction stir welded UNS S32760 super duplex stainless steel. Mater. Sci. Eng. A 2017, 706, 48–56. [Google Scholar] [CrossRef]

- Fairchild, D.; Kumar, A.; Ford, S.; Nissley, N.; Ayer, R.; Jin, H.; Ozekcin, A. Research concerning the friction stir welding of linepipe steels. In Proceedings of the Trends in Welding Research, 8th International Conference, Pine Mountain, GA, USA, 1–6 June 2008; pp. 371–380. [Google Scholar]

- Santos, T.; Hermenegildo, T.; Afonso, C.; Marinho, R.; Paes, M.; Ramirez, A. Fracture toughness of ISO 3183 X80M (API 5L X80) steel friction stir welds. Eng. Fract. Mech. 2010, 77, 2937–2945. [Google Scholar] [CrossRef]

- Tribe, A.; Nelson, T.W. Study on the fracture toughness of friction stir welded API X80. Eng. Fract. Mech. 2015, 150, 58–69. [Google Scholar] [CrossRef]

- Avila, J.A.; Rodriguez, J.; Mei, P.R.; Ramirez, A.J. Microstructure and fracture toughness of multipass friction stir welded joints of API-5L-X80 steel plates. Mater. Sci. Eng. A 2016, 673, 257–265. [Google Scholar] [CrossRef]

- Sharma, S.; Mishra, R. Fatigue crack growth behavior of friction stir processed aluminum alloy. Scr. Mater. 2008, 59, 395–398. [Google Scholar] [CrossRef]

- ArcelorMittal: Steel Manufacturing. Available online: https://corporate.arcelormittal.com/ (accessed on 1 October 2019).

- E8/E8M-16a Standard Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- E1820-20 Standard Test Method for Measurement of Fracture Toughness; ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- Da Fonseca, E.B.; Santos, T.F.A.; Button, S.T.; Ramirez, A.J. Physical Simulation of a Duplex Stainless Steel Friction Stir Welding by the Numerical and Experimental Analysis of Hot Torsion Tests. Metall. Mater. Trans. A 2016, 47, 4543–4552. [Google Scholar] [CrossRef]

- Yuqing, M.; Liming, K.; Fencheng, L.; Yuhua, C.; Li, X. Investigations on temperature distribution, microstructure evolution, and property variations along thickness in friction stir welded joints for thick AA7075-T6 plates. Int. J. Adv. Manuf. Technol. 2016, 86, 141–154. [Google Scholar] [CrossRef]

- Seidel, T.; Reynolds, A.P. Visualization of the material flow in AA2195 friction-stir welds using a marker insert technique. Metall. Mater. Trans. A 2001, 32, 2879–2884. [Google Scholar] [CrossRef]

- Magnabosco, R. Kinetics of sigma phase formation in a duplex stainless steel. Mater. Res. 2009, 12, 321–327. [Google Scholar] [CrossRef]

- Tsai, M.-H.; Tsai, K.-Y.; Tsai, C.-W.; Lee, C.; Juan, C.-C.; Yeh, J.-W. Criterion for sigma phase formation in Cr-and V-containing high-entropy alloys. Mater. Res. Lett. 2013, 1, 207–212. [Google Scholar] [CrossRef]

- Li, J.; Liu, X.; Li, G.; Han, P.; Liang, W. Characterization of the microstructure, mechanical properties, and corrosion resistance of a friction-stir-welded joint of hyper duplex stainless steel. Metals 2017, 7, 138. [Google Scholar] [CrossRef]

- Sato, Y.S.; Kokawa, H. Preferential precipitation site of sigma phase in duplex stainless steel weld metal. Scr. Mater. 1999, 40, 659–663. [Google Scholar] [CrossRef]

- Elmer, J.W.; Palmer, T.A.; Specht, E.D. Direct Observations of Sigma Phase Formation in Duplex Stainless Steels Using In-Situ Synchrotron X-Ray Diffraction. Metall. Mater. Trans. A 2007, 38, 464–475. [Google Scholar] [CrossRef]

- Cui, L.; Fujii, H.; Tsuji, N.; Nakata, K.; Nogi, K.; Ikeda, R.; Matsushita, M. Transformation in stir zone of friction stir welded carbon steels with different carbon contents. ISIJ Int. 2007, 47, 299–306. [Google Scholar] [CrossRef]

- Morris Jr, J. The Influence of Grain Size on the Mechanical Properties of Steel; Technical Report for Lawrence Berkeley National Lab.: Berkeley, CA, USA, 1 May 2001. [Google Scholar] [CrossRef]

- Van Swygenhoven, H. Grain Boundaries and Dislocations. Science 2002, 296, 66–67. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, S.; Wan, F. Competition mechanism of brittle–ductile transition of metals under tensile condition. Mech. Mater. 2019, 137, 103138. [Google Scholar] [CrossRef]

- Whang, S.-H. Nanostructured Metals and Alloys: Processing, Microstructure, Mechanical properties and Applications; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Grain Size and Material Strength. Available online: https://materion.com/-/media/files/alloy/newsletters/technical-tidbits/issue-no-15---grain-size-and-material-strength.pdf (accessed on 10 November 2019).

- Sato, Y.S.; Urata, M.; Kokawa, H.; Ikeda, K. Hall–Petch relationship in friction stir welds of equal channel angular-pressed aluminium alloys. Mater. Sci. Eng. A 2003, 354, 298–305. [Google Scholar] [CrossRef]

- İriç, S.; Ayhan, A. Dependence of Fracture Toughness on Rolling Direction in Aluminium 7075 Alloys. Acta Phys. Pol. A 2017, 132, 892–895. [Google Scholar] [CrossRef]

- Broek, D. The crack tip plastic zone. In Elementary Engineering Fracture Mechanics; Springer: Dordrecht, The Netherlands, 1982; pp. 91–114. [Google Scholar]

- Lewinsohn, C. Mechanical Behavior of Materials by Norman E. Dowling. Mater. Manuf. Processes 2000, 15, 775–776. [Google Scholar] [CrossRef]

- Moghadam, D.G.; Farhangdoost, K. Influence of welding parameters on fracture toughness and fatigue crack growth rate in friction stir welded nugget of 2024-T351 aluminum alloy joints. Trans. Nonferrous Met. Soc. China 2016, 26, 2567–2585. [Google Scholar] [CrossRef]

- Rubio-González, C.; Ocaña, J.L.; Gomez-Rosas, G.; Molpeceres, C.; Paredes, M.; Banderas, A.P.; Morales, M. Effect of laser shock processing on fatigue crack growth and fracture toughness of 6061-T6 aluminum alloy. Mater. Sci. Eng. A 2004, 386, 291–295. [Google Scholar] [CrossRef]

| C | Mn | P | S | Si | Cu | Ni | Cr | Mo | N | Fe | PRE-N |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.026 | 0.847 | 0.027 | 0.0002 | 0.356 | 0.114 | 6.681 | 25.299 | 3.729 | 0.2758 | Bal. | 42 |

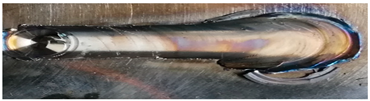

| FSP No. | Advancing Speed (mm/min) | Plunging Depth (mm) | Images |

|---|---|---|---|

| 1 | 50 | 5.2 |  |

| 2 | 100 | 5.8 |  |

| 3 | 150 | 6.2 |  |

| Sample No. | Yield Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|

| Base S-1 | 651.7 | 794.4 |

| Base S-2 | 665.0 | 784.3 |

| Base S-3 | 650.0 | 802.2 |

| Average | 655.6 | 793.6 |

| FSPed S-1 | 767.4 | 908.4 |

| FSPed S-2 | 769.9 | 904.0 |

| FSPed S-3 | 710.0 | 858.1 |

| Average | 749.1 | 890.2 |

| % Increase w.r.t* BM | 14.3 | 12.2 |

| Vickers Hardness (HV) | ||||

|---|---|---|---|---|

| Location | AS | C | RS | BM |

| 1st line | 327.6 | 310.4 | 326.9 | 276.0 |

| 2nd line | 313.3 | 313.3 | 309.3 | 279.0 |

| 3rd line | 305.4 | 319.1 | 287.7 | 271.8 |

| Average | 315.4 | 314.3 | 308.0 | 275.6 |

| Sample No. | (mm) | Peak Load (N) | (KJ/m2) | Avg. (KJ/m2) | ||

|---|---|---|---|---|---|---|

| Base S-1 | 20.4 | 15429.8 | 65.1 | 212.9 | 276.3 | 272.9 |

| Base S-2 | 20.5 | 14573.5 | 59.1 | 214.2 | 269.5 | |

| FSPed S-1 | 20.1 | 18312.9 | 86.9 | 220.2 | 306.9 | 304.7 |

| FSPed S-2 | 19.1 | 19646.3 | 86.2 | 216.5 | 302.5 | |

| Improvement | 11.7% | |||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abubaker, H.M.; Merah, N.; Al-Badour, F.A.; Albinmousa, J.; Sorour, A.A. Influence of Friction Stir Processing on Mechanical Behavior of 2507 SDSS. Metals 2020, 10, 369. https://doi.org/10.3390/met10030369

Abubaker HM, Merah N, Al-Badour FA, Albinmousa J, Sorour AA. Influence of Friction Stir Processing on Mechanical Behavior of 2507 SDSS. Metals. 2020; 10(3):369. https://doi.org/10.3390/met10030369

Chicago/Turabian StyleAbubaker, Hafiz M., Necar Merah, Fadi A. Al-Badour, Jafar Albinmousa, and Ahmad A. Sorour. 2020. "Influence of Friction Stir Processing on Mechanical Behavior of 2507 SDSS" Metals 10, no. 3: 369. https://doi.org/10.3390/met10030369

APA StyleAbubaker, H. M., Merah, N., Al-Badour, F. A., Albinmousa, J., & Sorour, A. A. (2020). Influence of Friction Stir Processing on Mechanical Behavior of 2507 SDSS. Metals, 10(3), 369. https://doi.org/10.3390/met10030369