Shear Band Formation in Amorphous Materials under Oscillatory Shear Deformation

Abstract

1. Introduction

2. Molecular Dynamics (MD) Simulations

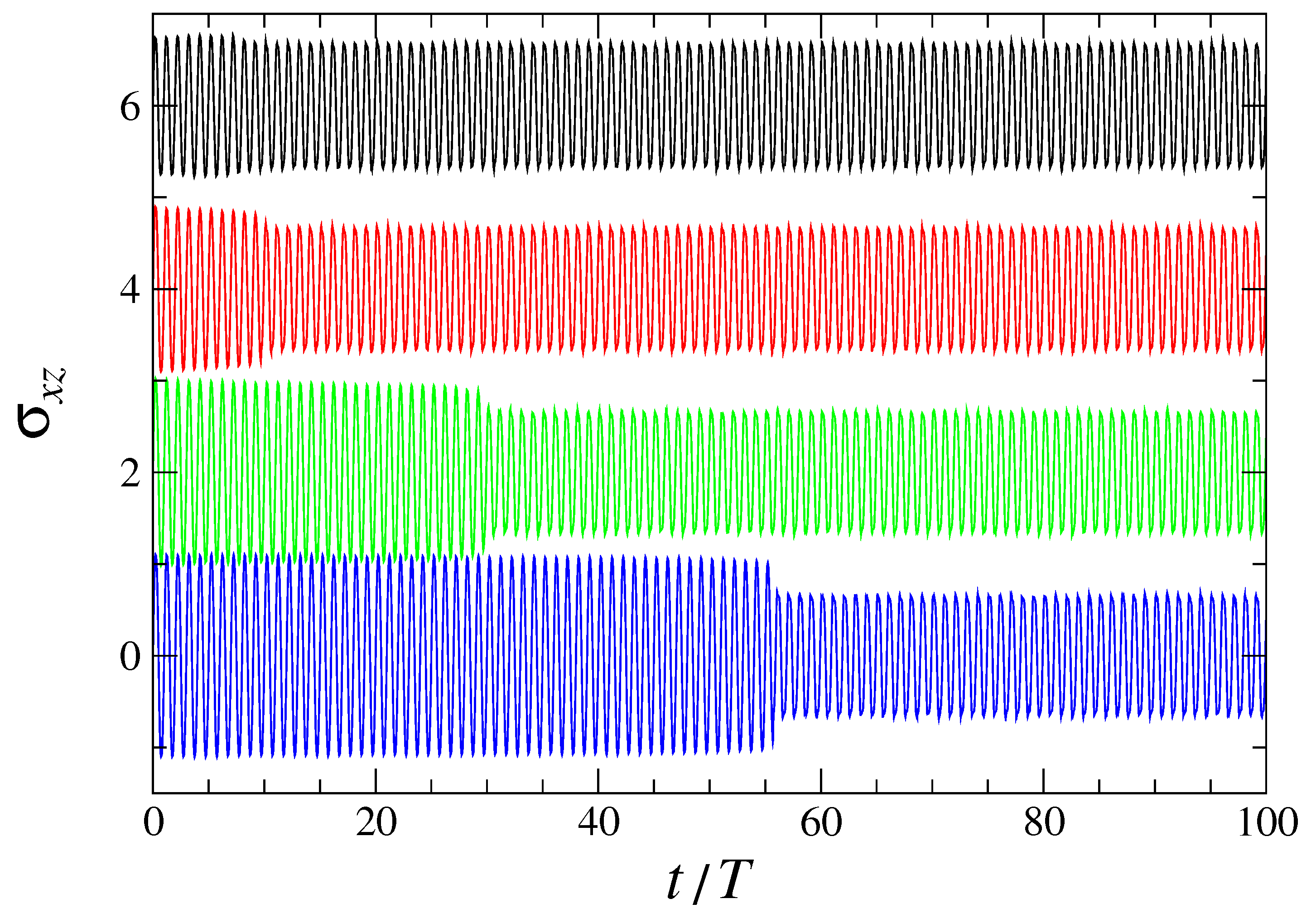

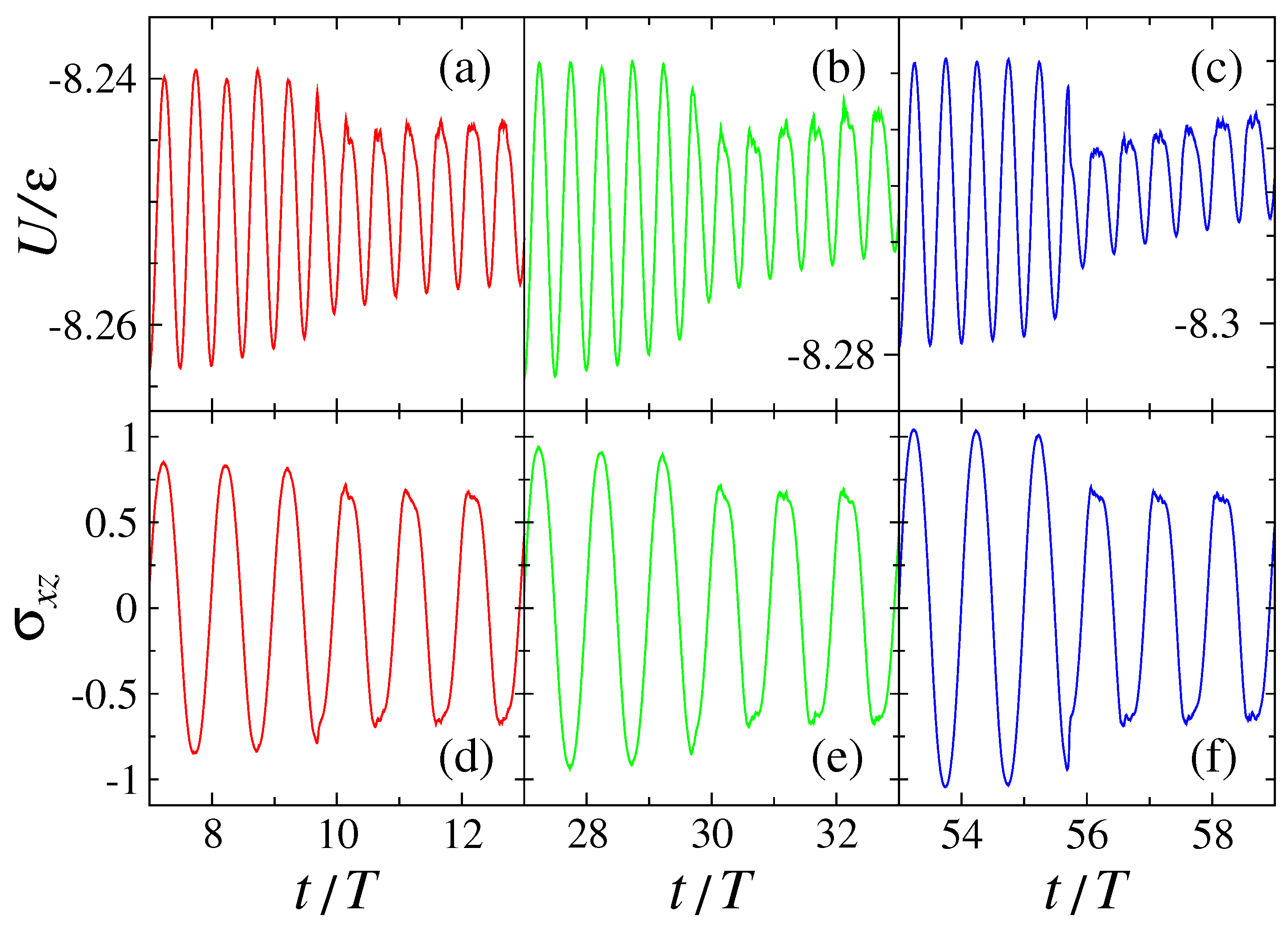

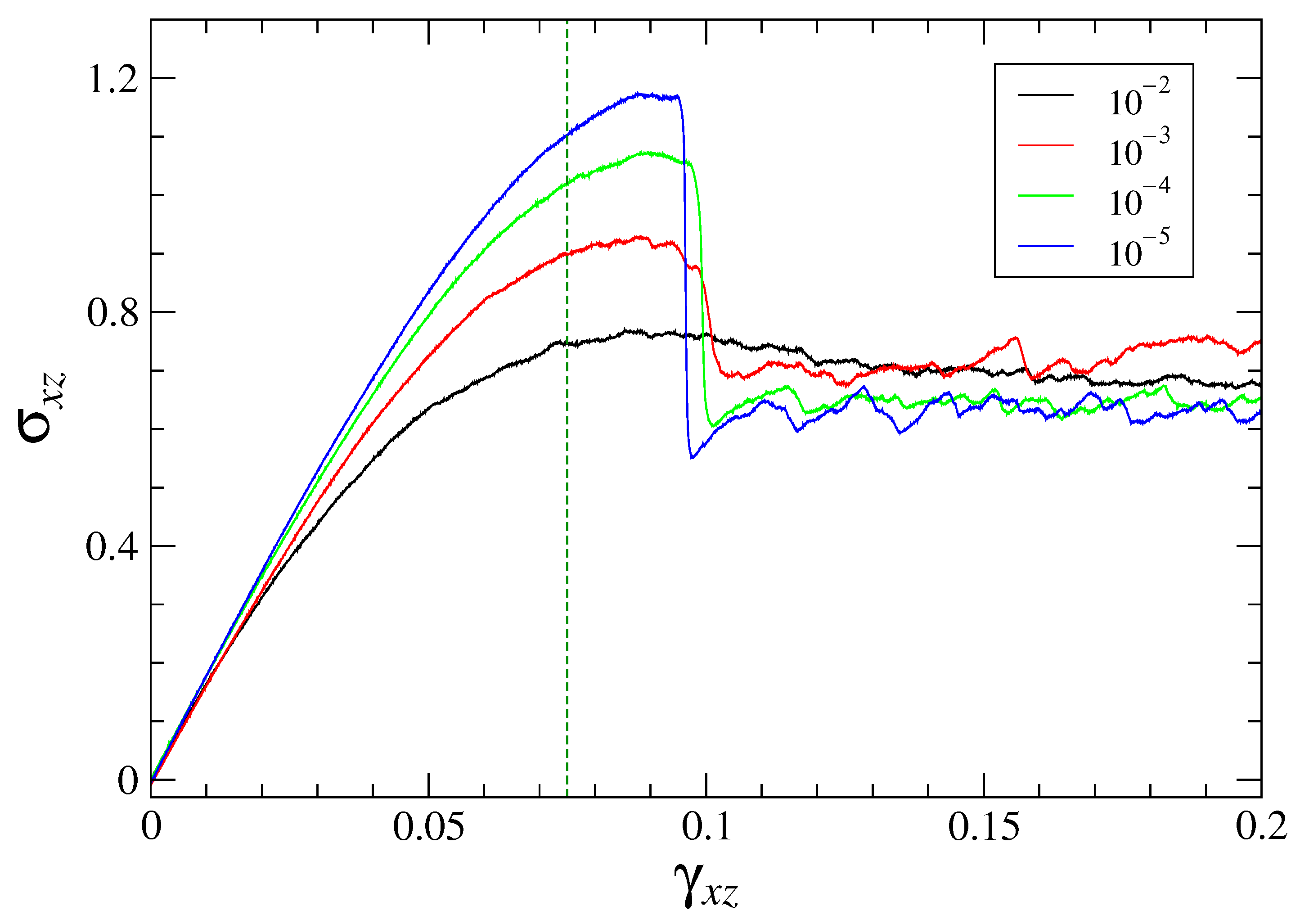

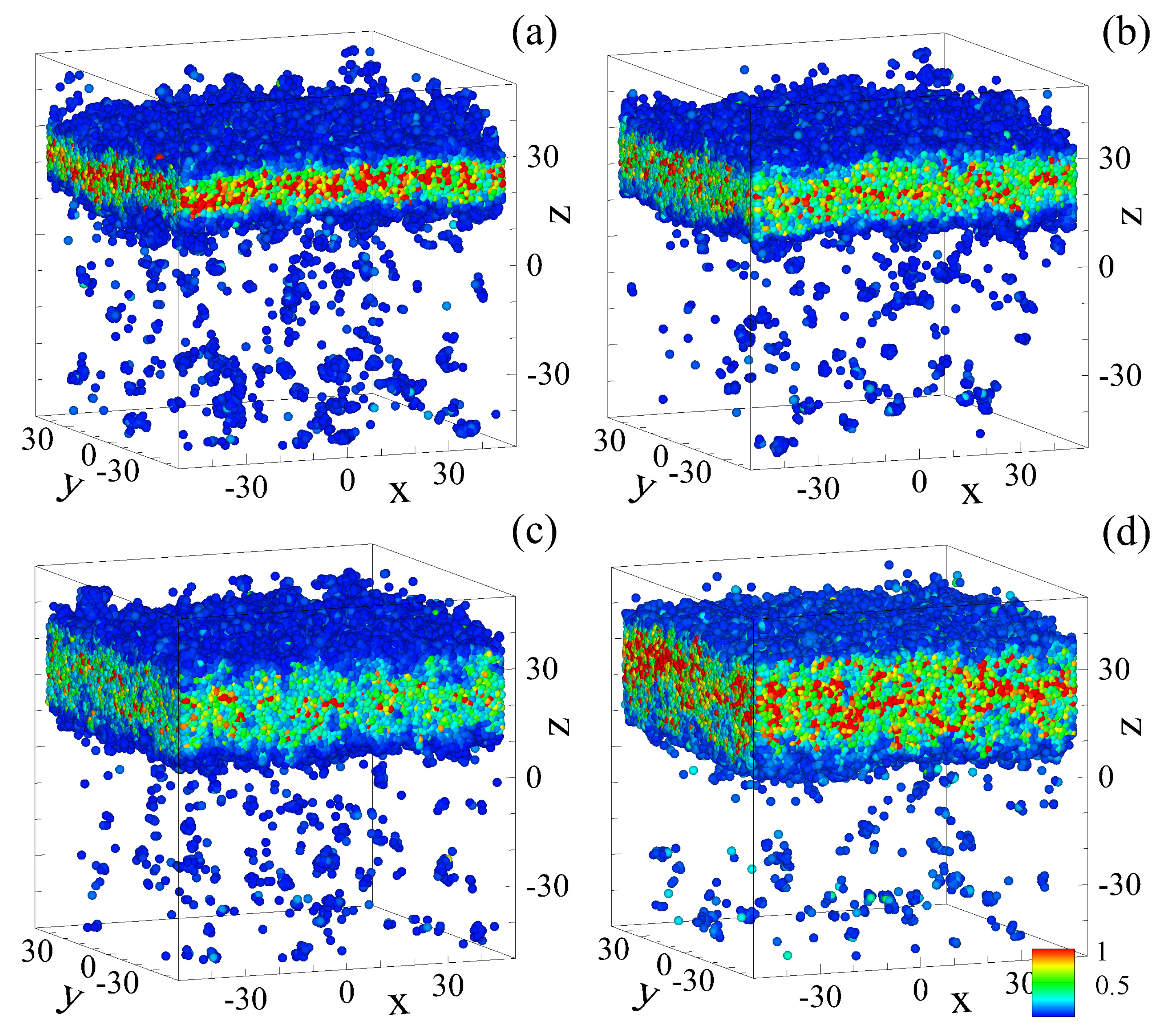

3. Results

4. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Hufnagel, T.C.; Schuh, C.A.; Falk, M.L. Deformation of metallic glasses: Recent developments in theory, simulations, and experiments. Acta Mater. 2016, 109, 375–393. [Google Scholar] [CrossRef]

- Li, H.F.; Zheng, Y.F. Recent advances in bulk metallic glasses for biomedical applications. Acta Biomater. 2016, 36, 1–20. [Google Scholar] [CrossRef]

- Parisi, G.; Procaccia, I.; Rainone, C.; Singh, M. Shear bands as manifestation of a criticality in yielding amorphous solids. Proc. Natl. Acad. Sci. USA 2017, 114, 5577–5582. [Google Scholar] [CrossRef] [PubMed]

- Wisitsorasak, A.; Wolynes, P.G. Dynamical theory of shear bands in structural glasses. Proc. Natl. Acad. Sci. USA 2017, 114, 1287–1292. [Google Scholar] [CrossRef] [PubMed]

- Spaepen, F. A microscopic mechanism for steady state inhomogeneous flow in metallic glasses. Acta Metall. 1977, 25, 407. [Google Scholar] [CrossRef]

- Argon, A.S. Plastic deformation in metallic glasses. Acta Metall. 1979, 27, 47–58. [Google Scholar] [CrossRef]

- Shi, Y.; Falk, M.L. Strain localization and percolation of stable structure in amorphous solids. Phys. Rev. Lett. 2005, 95, 095502. [Google Scholar] [CrossRef] [PubMed]

- Cao, A.J.; Cheng, Y.Q.; Ma, E. Structural processes that initiate shear localization in metallic glass. Acta Mater. 2009, 57, 5146–5155. [Google Scholar] [CrossRef]

- Ju, S.-P.; Huang, H.-H.; Wu, T.-Y. Investigation of the local structural rearrangement of Mg67Zn28Ca5 bulk metallic glasses during tensile deformation: A molecular dynamics study. Comput. Mater. Sci. 2015, 96, 56–62. [Google Scholar] [CrossRef]

- Tercini, M.; Veiga, R.G.d.; Zuniga, A. Local atomic environment and shear banding in metallic glasses. Comput. Mater. Sci. 2018, 155, 129–135. [Google Scholar] [CrossRef]

- Feng, S.-D.; Chan, K.K.C.; Zhao, L.; Wang, L.-M.; Liu, R.-P. Molecular dynamics simulation of structural signals of shear-band formation in Zr46Cu46Al8 metallic glasses. Materials 2018, 11, 2564. [Google Scholar] [CrossRef] [PubMed]

- Shrivastav, G.P.; Chaudhuri, P.; Horbach, J. Yielding of glass under shear: A directed percolation transition precedes shear-band formation. Phys. Rev. E 2016, 94, 042605. [Google Scholar] [CrossRef] [PubMed]

- Jana, R.; Pastewka, L. Correlations of non-affine displacements in metallic glasses through the yield transition. J. Phys. Mater. 2019, 2, 045006. [Google Scholar] [CrossRef]

- Priezjev, N.V. Spatiotemporal analysis of nonaffine displacements in disordered solids sheared across the yielding point. arXiv 2019, arXiv:1910.01543. [Google Scholar]

- Hieronymus-Schmidt, V.; Rosner, H.; Wilde, G.; Zaccone, A. Shear banding in metallic glasses described by alignments of Eshelby quadrupoles. Phys. Rev. B 2017, 95, 134111. [Google Scholar] [CrossRef]

- Hassani, M.; Lagogianni, A.E.; Varnik, F. Probing the degree of heterogeneity within a shear band of a model glass. Phys. Rev. Lett. 2019, 123, 195502. [Google Scholar] [CrossRef]

- Priezjev, N.V. Heterogeneous relaxation dynamics in amorphous materials under cyclic loading. Phys. Rev. E 2013, 87, 052302. [Google Scholar] [CrossRef]

- Fiocco, D.; Foffi, G.; Sastry, S. Oscillatory athermal quasistatic deformation of a model glass. Phys. Rev. E 2013, 88, 020301(R). [Google Scholar] [CrossRef]

- Regev, I.; Lookman, T.; Reichhardt, C. Onset of irreversibility and chaos in amorphous solids under periodic shear. Phys. Rev. E 2013, 88, 062401. [Google Scholar] [CrossRef]

- Priezjev, N.V. Dynamical heterogeneity in periodically deformed polymer glasses. Phys. Rev. E 2014, 89, 012601. [Google Scholar] [CrossRef]

- Priezjev, N.V. Reversible plastic events during oscillatory deformation of amorphous solids. Phys. Rev. E 2016, 93, 013001. [Google Scholar] [CrossRef] [PubMed]

- Kawasaki, T.; Berthier, L. Macroscopic yielding in jammed solids is accompanied by a non-equilibrium first-order transition in particle trajectories. Phys. Rev. E 2016, 94, 022615. [Google Scholar] [CrossRef] [PubMed]

- Priezjev, N.V. Nonaffine rearrangements of atoms in deformed and quiescent binary glasses. Phys. Rev. E 2016, 94, 023004. [Google Scholar] [CrossRef] [PubMed]

- Leishangthem, P.; Parmar, A.D.S.; Sastry, S. The yielding transition in amorphous solids under oscillatory shear deformation. Nat. Commun. 2017, 8, 14653. [Google Scholar] [CrossRef]

- Priezjev, N.V. Collective nonaffine displacements in amorphous materials during large-amplitude oscillatory shear. Phys. Rev. E 2017, 95, 023002. [Google Scholar] [CrossRef]

- Fan, M.; Wang, M.; Zhang, K.; Liu, Y.; Schroers, J.; Shattuck, M.D.; O’Hern, C.S. The effects of cooling rate on particle rearrangement statistics: Rapidly cooled glasses are more ductile and less reversible. Phys. Rev. E 2017, 95, 022611. [Google Scholar] [CrossRef]

- Sha, Z.; Wong, W.H.; Pei, Q.; Branicio, P.S.; Liu, Z.; Wang, T.; Guo, T.; Gao, H. Atomistic origin of size effects in fatigue behavior of metallic glasses. J. Mech. Phys. Solids 2017, 104, 84–95. [Google Scholar] [CrossRef]

- Priezjev, N.V. Molecular dynamics simulations of the mechanical annealing process in metallic glasses: Effects of strain amplitude and temperature. J. Non-Cryst. Solids 2018, 479, 42–48. [Google Scholar] [CrossRef]

- Priezjev, N.V. The yielding transition in periodically sheared binary glasses at finite temperature. Comput. Mater. Sci. 2018, 150, 162–168. [Google Scholar] [CrossRef]

- Priezjev, N.V. Slow relaxation dynamics in binary glasses during stress-controlled, tension-compression cyclic loading. Comput. Mater. Sci. 2018, 153, 235–240. [Google Scholar] [CrossRef]

- Priezjev, N.V.; Makeev, M.A. The influence of periodic shear on structural relaxation and pore redistribution in binary glasses. J. Non-Cryst. Solids 2019, 506, 14–20. [Google Scholar] [CrossRef]

- Priezjev, N.V.; Makeev, M.A. Structural transformations during periodic deformation of low-porosity amorphous materials. Model. Simul. Mater. Sci. Eng. 2019, 27, 025004. [Google Scholar] [CrossRef]

- Parmar, A.D.S.; Kumar, S.; Sastry, S. Strain localization above the yielding point in cyclically deformed glasses. Phys. Rev. X 2019, 9, 021018. [Google Scholar] [CrossRef]

- Priezjev, N.V. Accelerated relaxation in disordered solids under cyclic loading with alternating shear orientation. J. Non-Cryst. Solids 2019, 525, 119683. [Google Scholar] [CrossRef]

- Kob, W.; Andersen, H.C. Testing mode-coupling theory for a supercooled binary Lennard-Jones mixture: The van Hove correlation function. Phys. Rev. E 1995, 51, 4626. [Google Scholar] [CrossRef] [PubMed]

- Weber, T.A.; Stillinger, F.H. Local order and structural transitions in amorphous metal-metalloid alloys. Phys. Rev. B 1985, 31, 1954. [Google Scholar] [CrossRef] [PubMed]

- Plimpton, S.J. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1. [Google Scholar] [CrossRef]

- Morozov, I.V.; Kazennov, A.M.; Bystryi, R.G.; Norman, G.E.; Pisarev, V.V.; Stegailov, V.V. Molecular dynamics simulations of the relaxation processes in the condensed matter on GPUs. Comput. Phys. Commun. 2011, 182, 1974–1978. [Google Scholar] [CrossRef]

- Allen, M.P.; Tildesley, D.J. Computer Simulation of Liquids; Clarendon: Oxford, UK, 1987. [Google Scholar]

- Falk, M.L.; Langer, J.S. Dynamics of viscoplastic deformation in amorphous solids. Phys. Rev. E 1998, 57, 7192. [Google Scholar] [CrossRef]

- Priezjev, N.V. The effect of thermal history on the atomic structure and mechanical properties of amorphous alloys. Comput. Mater. Sci. 2020, 174, 109477. [Google Scholar] [CrossRef]

- Priezjev, N.V. The effect of cryogenic thermal cycling on aging, rejuvenation, and mechanical properties of metallic glasses. J. Non-Cryst. Solids 2019, 503, 131–138. [Google Scholar] [CrossRef]

- Liu, Q.-L.; Priezjev, N.V. The influence of complex thermal treatment on mechanical properties of amorphous materials. Comput. Mater. Sci. 2019, 161, 93–98. [Google Scholar] [CrossRef]

- Priezjev, N.V. Aging and rejuvenation during elastostatic loading of amorphous alloys: A molecular dynamics simulation study. Comput. Mater. Sci. 2019, 168, 125–130. [Google Scholar] [CrossRef]

- Chikkadi, V.; Schall, P. Nonaffine measures of particle displacements in sheared colloidal glasses. Phys. Rev. E 2012, 85, 031402. [Google Scholar] [CrossRef] [PubMed]

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Priezjev, N.V. Shear Band Formation in Amorphous Materials under Oscillatory Shear Deformation. Metals 2020, 10, 300. https://doi.org/10.3390/met10030300

Priezjev NV. Shear Band Formation in Amorphous Materials under Oscillatory Shear Deformation. Metals. 2020; 10(3):300. https://doi.org/10.3390/met10030300

Chicago/Turabian StylePriezjev, Nikolai V. 2020. "Shear Band Formation in Amorphous Materials under Oscillatory Shear Deformation" Metals 10, no. 3: 300. https://doi.org/10.3390/met10030300

APA StylePriezjev, N. V. (2020). Shear Band Formation in Amorphous Materials under Oscillatory Shear Deformation. Metals, 10(3), 300. https://doi.org/10.3390/met10030300