Influence of Martensite Deformation on Cu Precipitation Strengthening

Abstract

1. Introduction

2. Materials and Methods

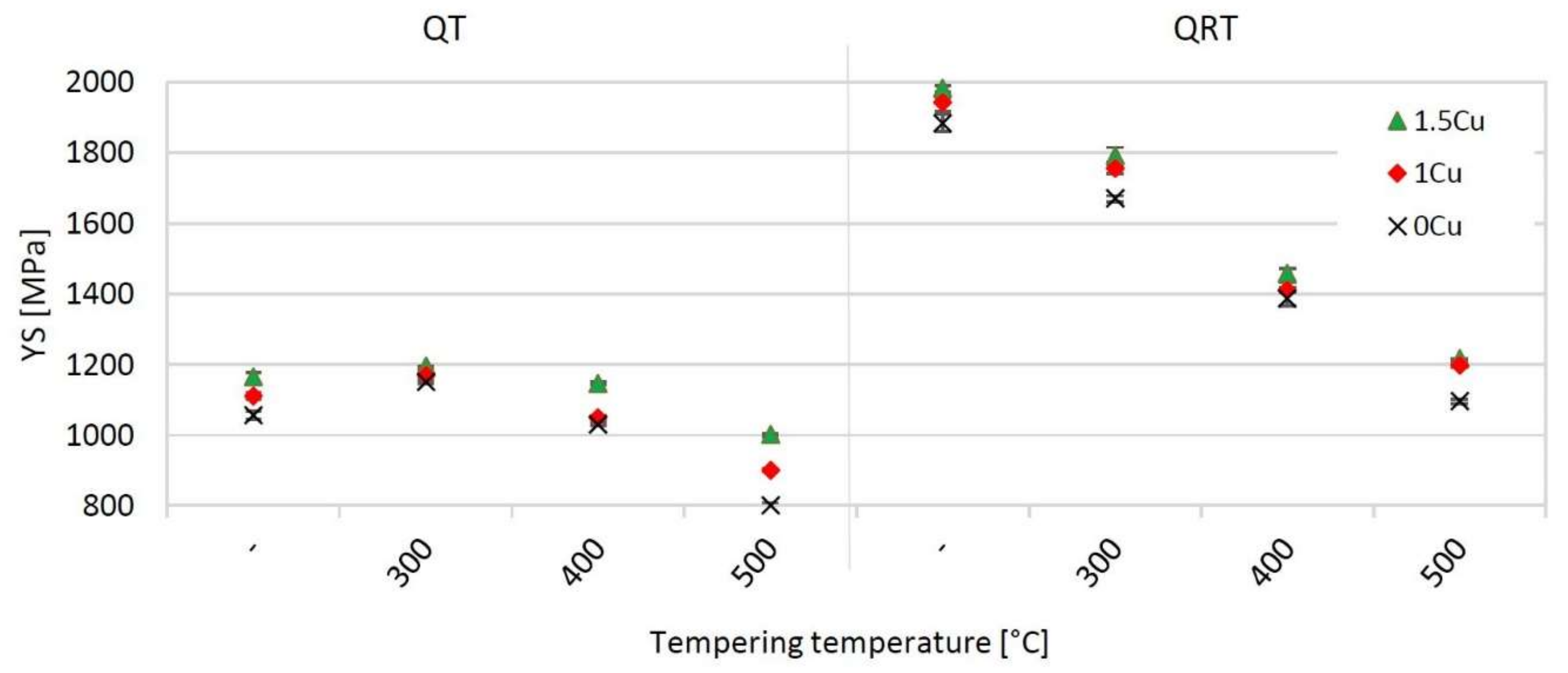

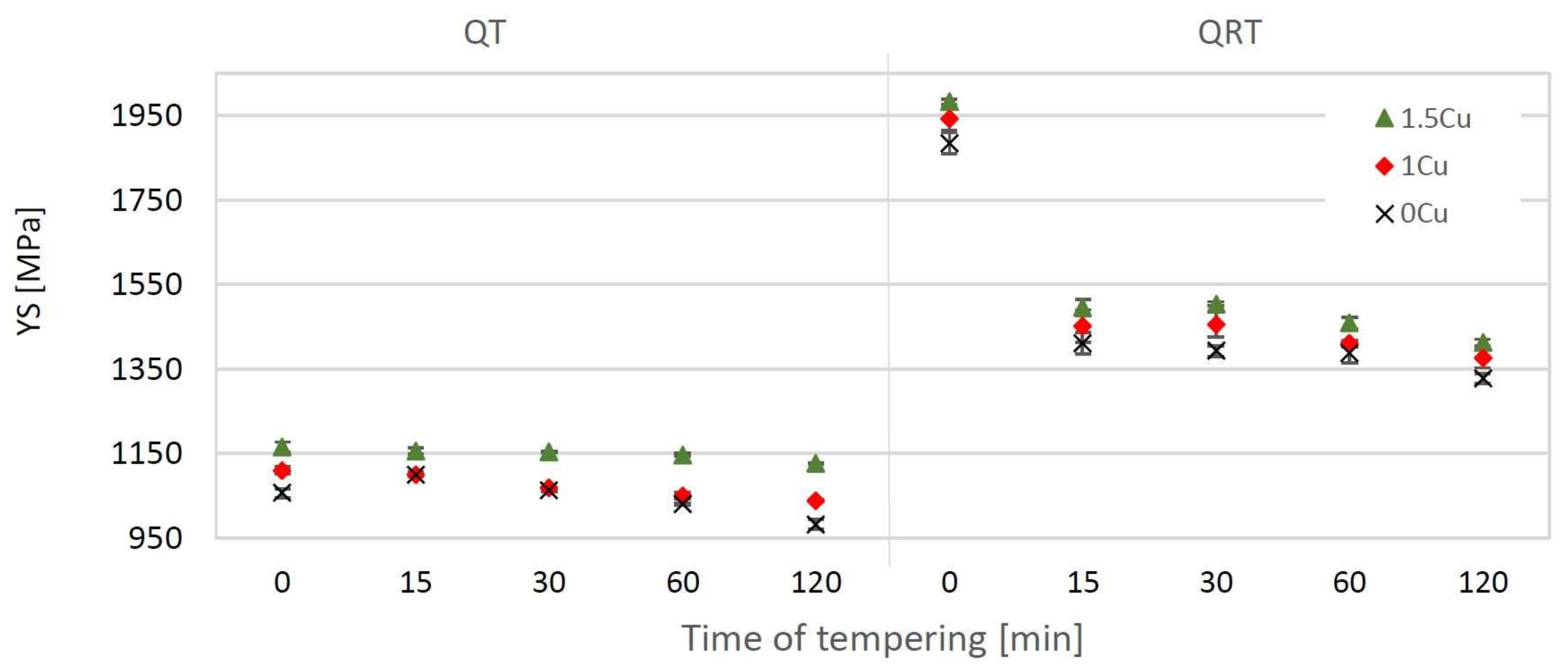

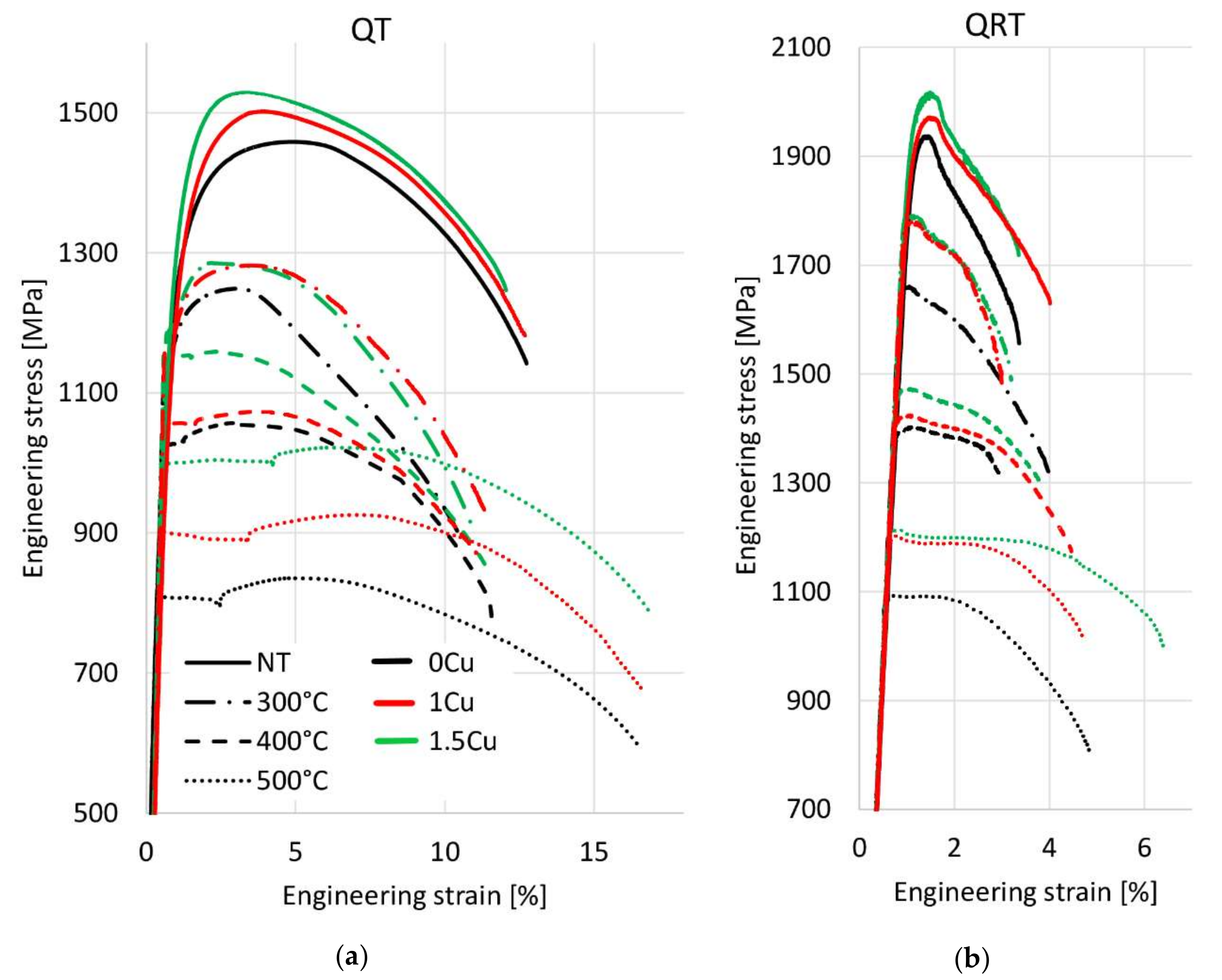

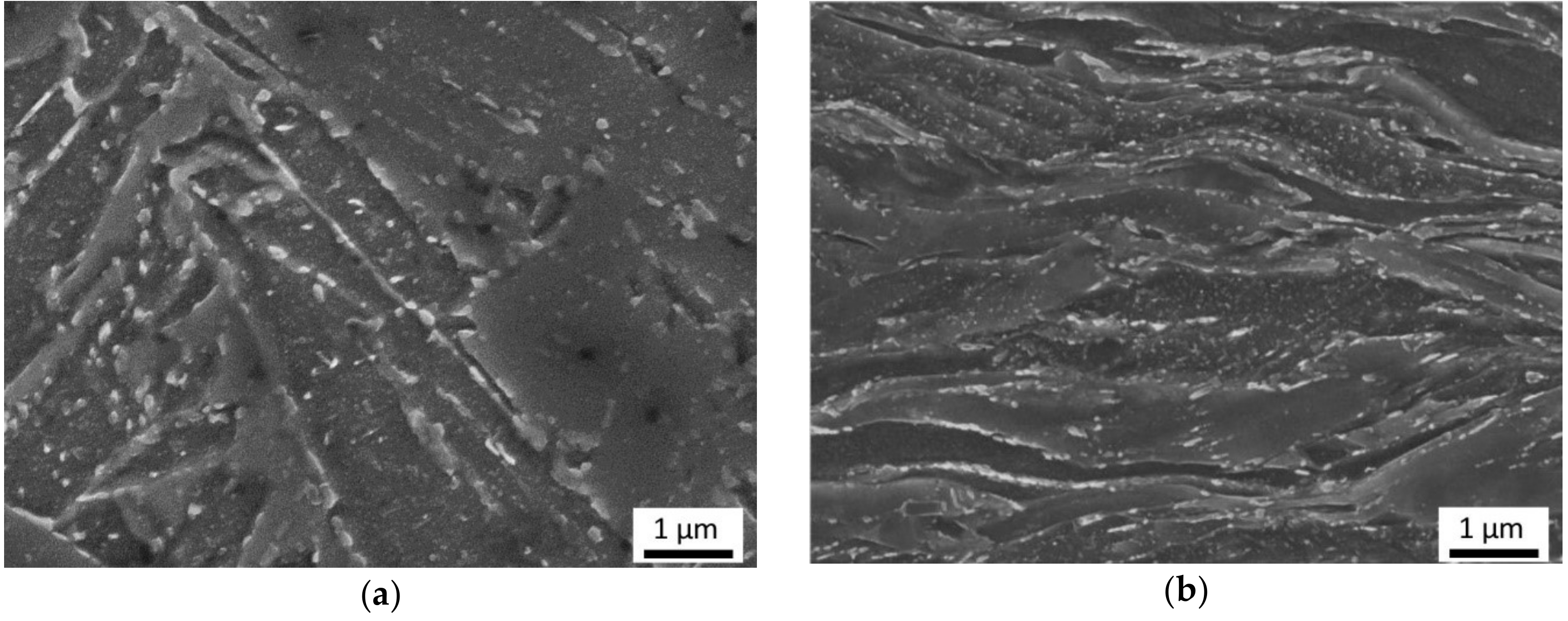

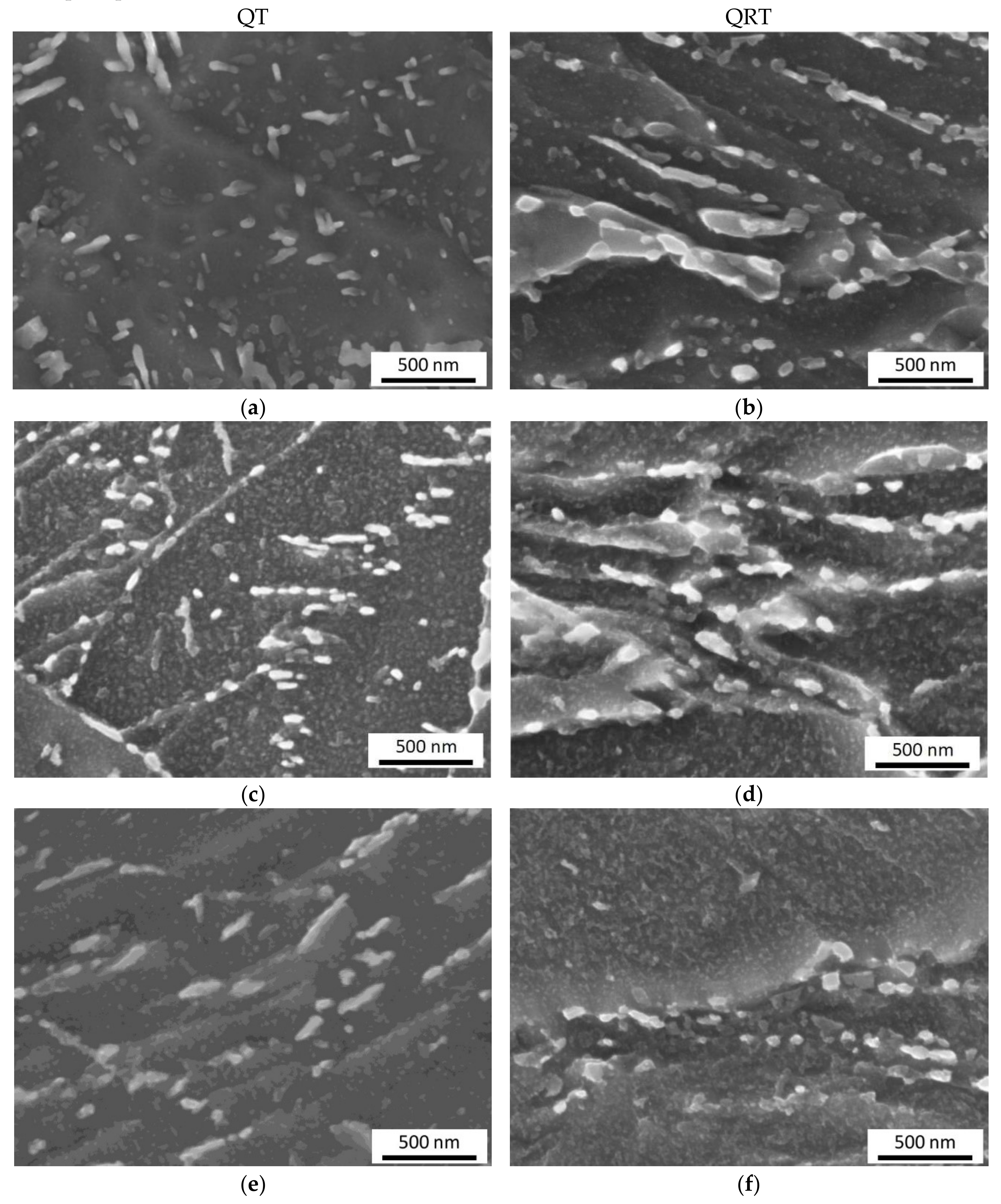

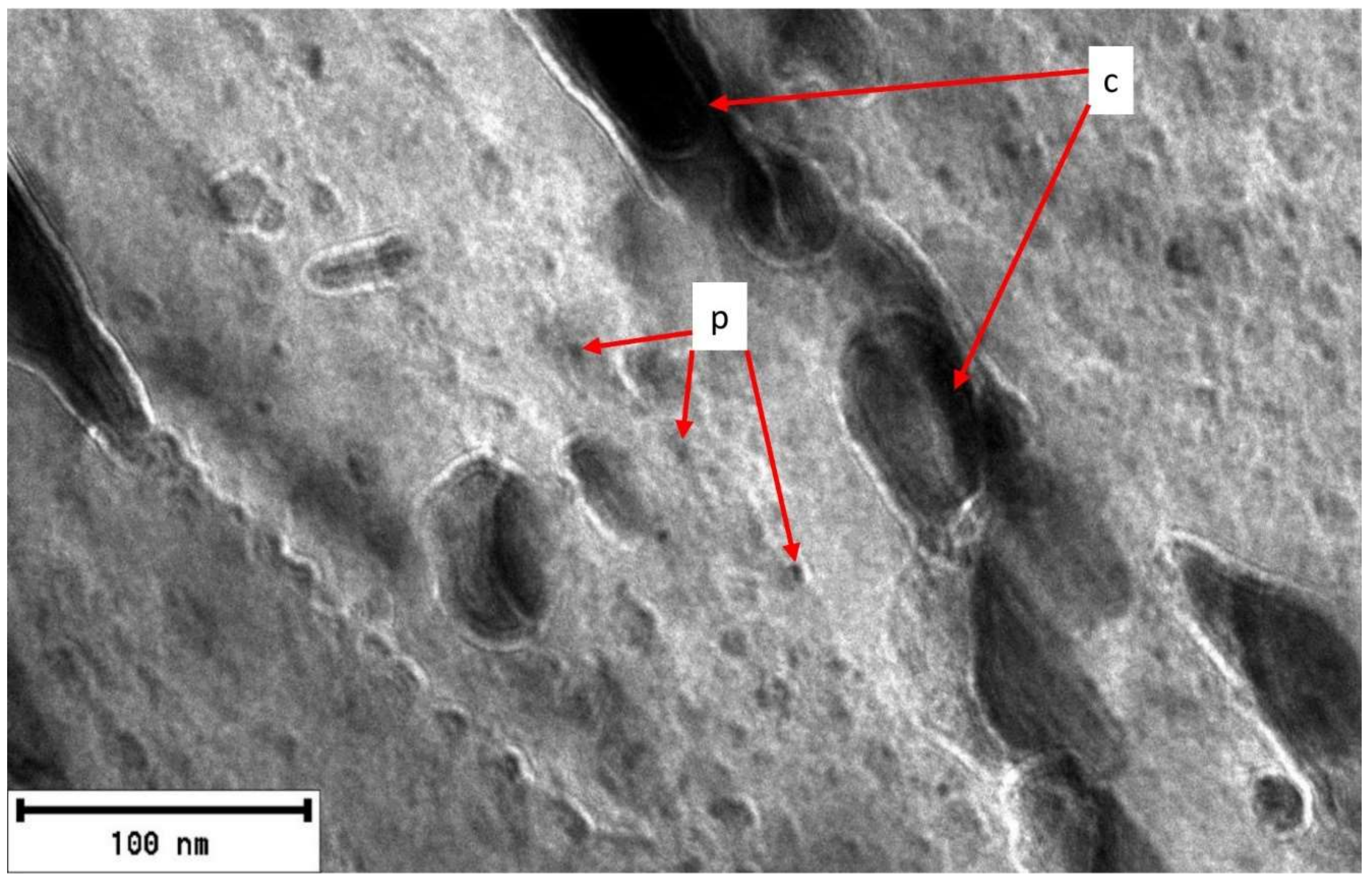

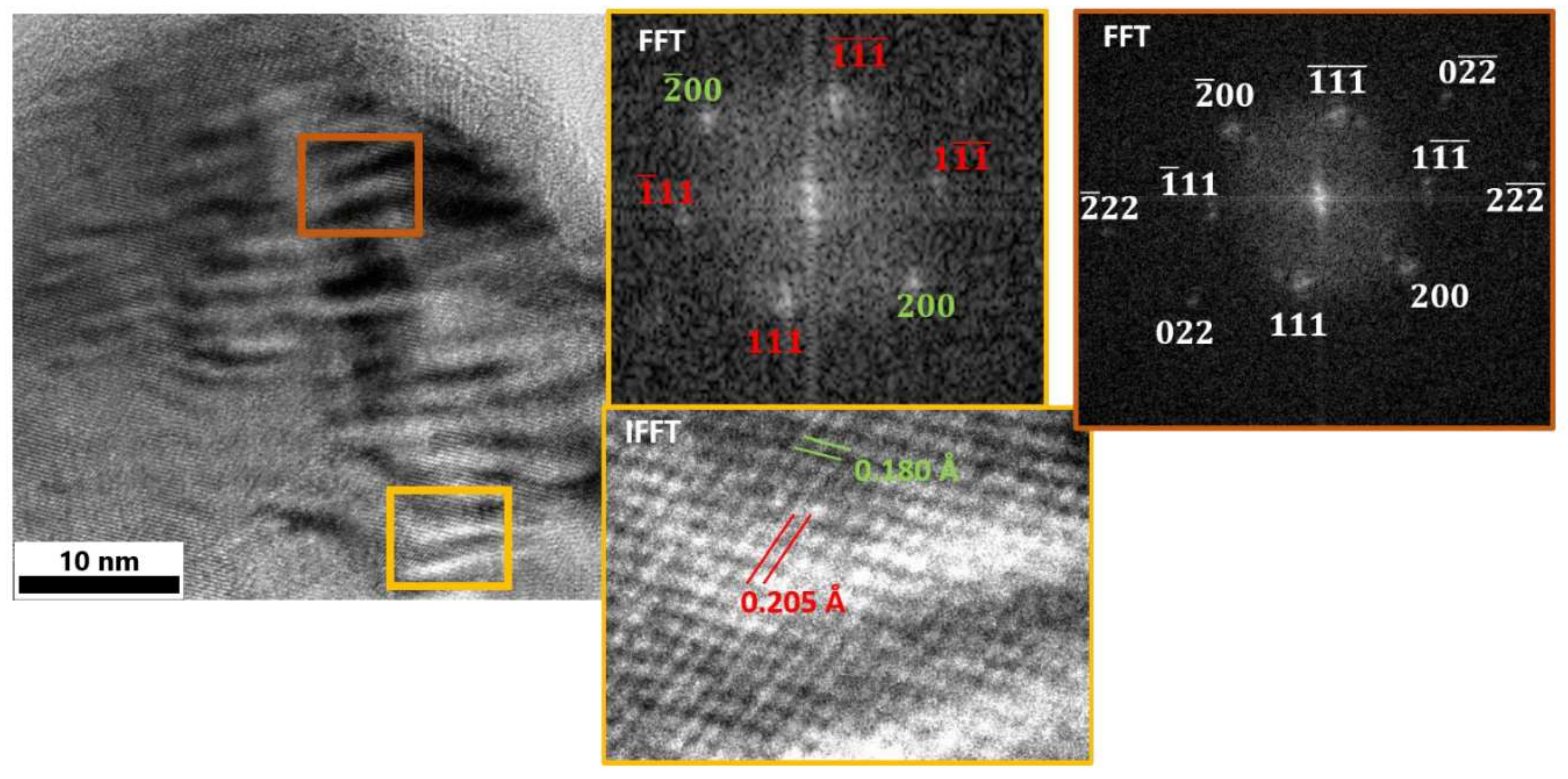

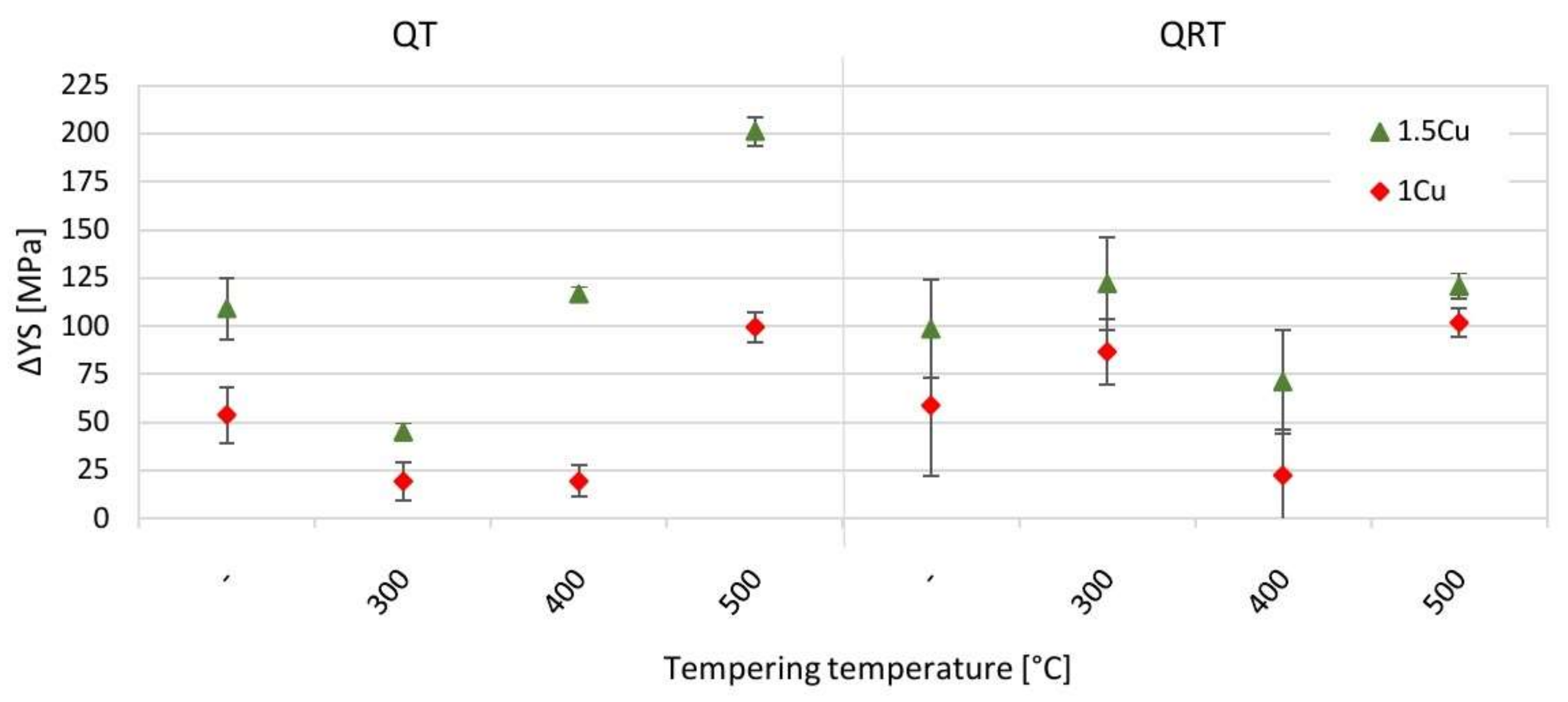

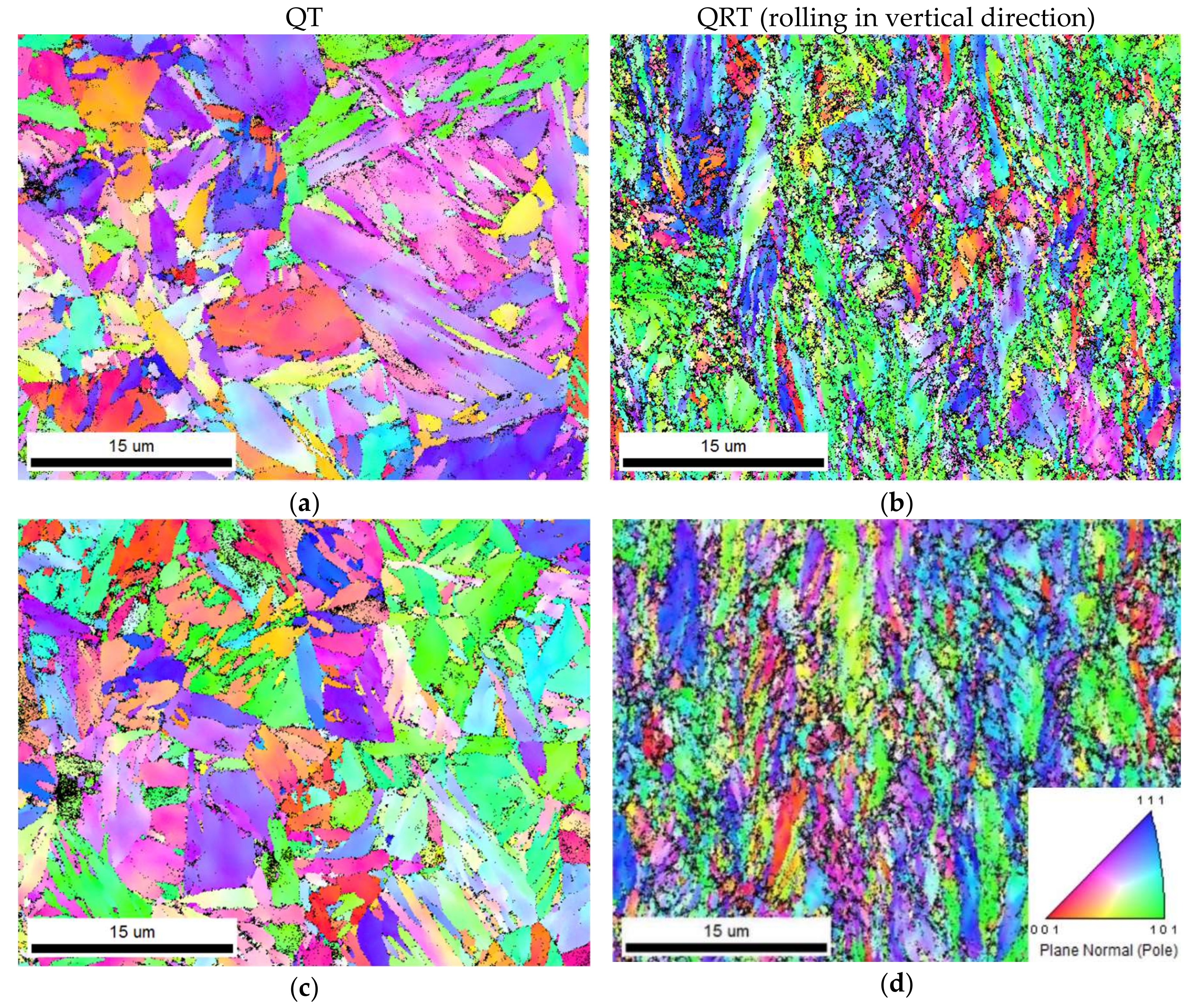

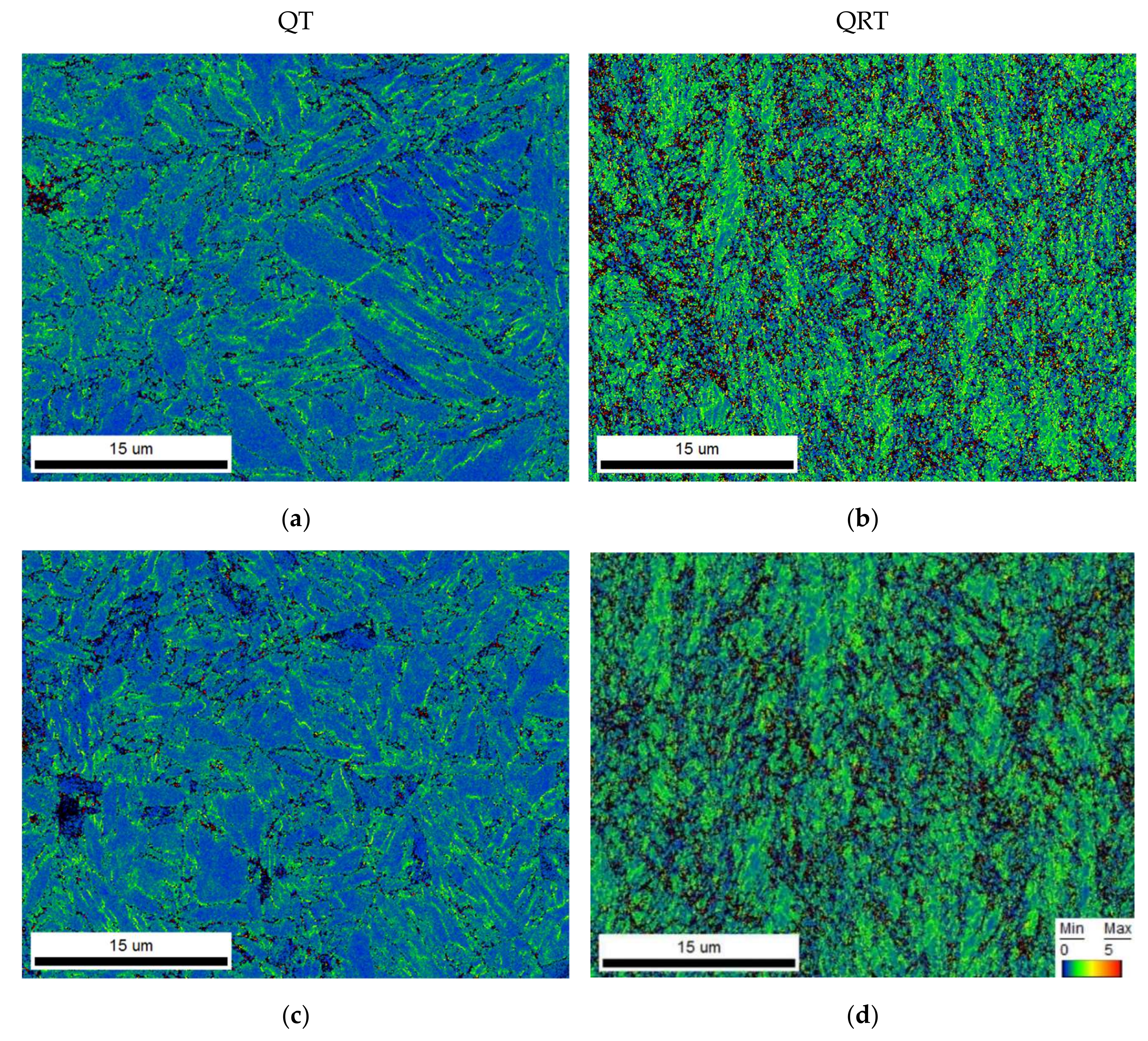

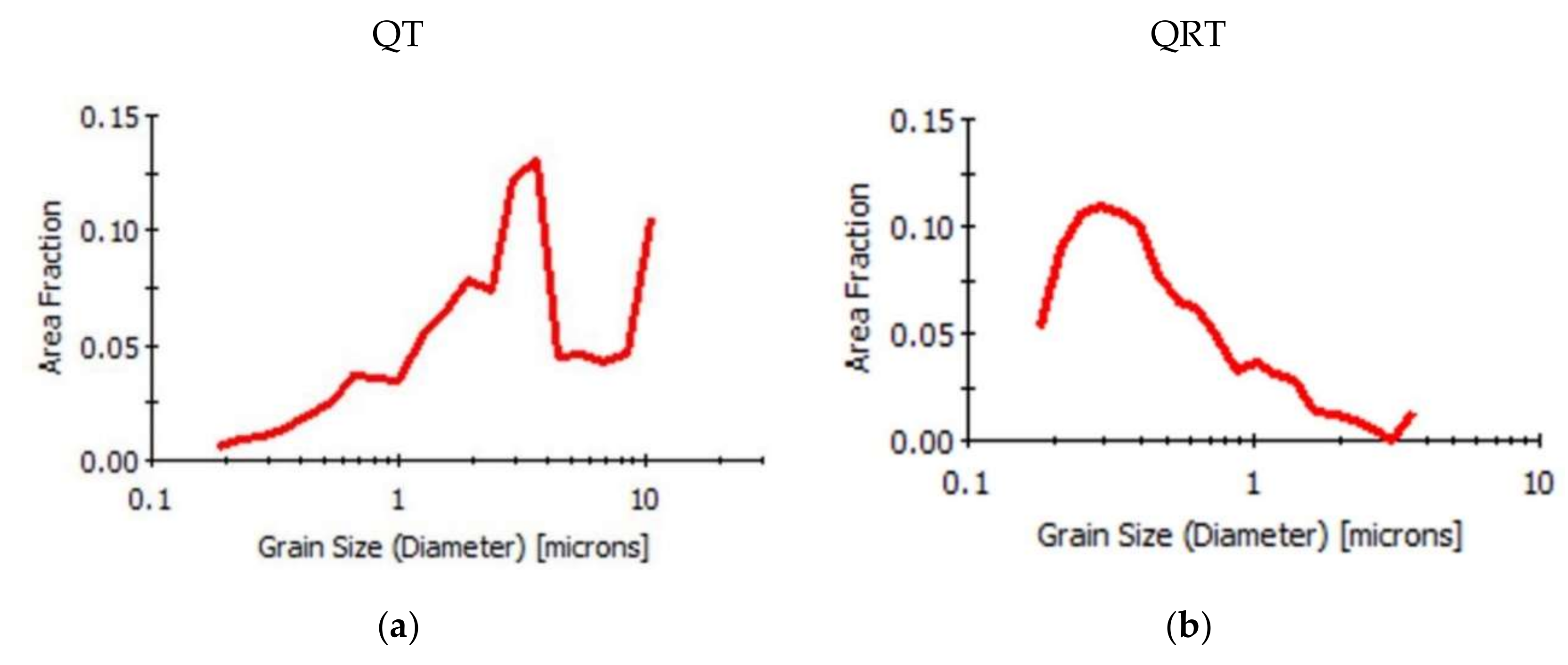

3. Results

4. Discussion

4.1. QT Samples–Yield Stress

4.2. QRT Samples—Yield Stress

4.3. Subgrain Structure

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Regime | Material | Tempering Time [min] | YS [MPa] | UTS [MPa] | Ag [%] | A5 [%] | Z [%] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| QT | 0Cu | 0 | 1057 | ± | 11 | 1447 | ± | 11 | 3.6 | ± | 0.1 | 13.9 | ± | 0.2 | 43.7 | ± | 0.1 |

| QT | 0Cu | 15 | 1062 | ± | 4 | 1101 | ± | 2 | 2.6 | ± | 0.3 | 12.6 | ± | 0.2 | 56.2 | ± | 0.8 |

| QT | 0Cu | 30 | 1030 | ± | 2 | 1051 | ± | 6 | 1.6 | ± | 0.7 | 11.9 | ± | 1.0 | 56.3 | ± | 1.2 |

| QT | 0Cu | 60 | 982 | ± | 12 | 1010 | ± | 19 | 2.8 | ± | 0.6 | 12.0 | ± | 0.1 | 57.0 | ± | 2.7 |

| QT | 0Cu | 120 | 1100 | ± | 2 | 1156 | ± | 8 | 2.2 | ± | 0.5 | 11.1 | ± | 2.0 | 52.2 | ± | 2.3 |

| QT | 1Cu | 0 | 1105 | ± | 3 | 1495 | ± | 11 | 3.1 | ± | 0.3 | 11.2 | ± | 0.5 | 46.8 | ± | 1.0 |

| QT | 1Cu | 15 | 1097 | ± | 1 | 1137 | ± | 7 | 2.6 | ± | 0.3 | 10.2 | ± | 0.7 | 54.3 | ± | 1.8 |

| QT | 1Cu | 30 | 1071 | ± | 8 | 1091 | ± | 1 | 2.1 | ± | 0.6 | 10.4 | ± | 0.8 | 55.4 | ± | 1.8 |

| QT | 1Cu | 60 | 1043 | ± | 3 | 1059 | ± | 11 | 2.2 | ± | 0.9 | 11.4 | ± | 0.4 | 51.5 | ± | 1.1 |

| QT | 1Cu | 120 | 1038 | ± | 5 | 1050 | ± | 6 | 2.5 | ± | 0.1 | 12.6 | ± | 0.3 | 51.5 | ± | 1.7 |

| QT | 1.5Cu | 0 | 1166 | ± | 4 | 1520 | ± | 5 | 1.9 | ± | 0.2 | 12.9 | ± | 1.5 | 48.6 | ± | 0.8 |

| QT | 1.5Cu | 15 | 1156 | ± | 7 | 1203 | ± | 5 | 3.1 | ± | 0.1 | 11.2 | ± | 0.8 | 54.6 | ± | 0.0 |

| QT | 1.5Cu | 30 | 1153 | ± | 2 | 1183 | ± | 1 | 3.4 | ± | 0.1 | 12.0 | ± | 0.7 | 51.4 | ± | 0.5 |

| QT | 1.5Cu | 60 | 1147 | ± | 3 | 1157 | ± | 2 | 1.7 | ± | 0.1 | 11.7 | ± | 0.6 | 54.2 | ± | 0.4 |

| QT | 1.5Cu | 120 | 1128 | ± | 2 | 1142 | ± | 3 | 3.9 | ± | 0.6 | 15.4 | ± | 0.7 | 51.5 | ± | 1.0 |

| QRT | 0Cu | 0 | 1884 | ± | 25 | 1911 | ± | 24 | 0.4 | ± | 0.1 | 4.5 | ± | 1.0 | 29.8 | ± | 14.9 |

| QRT | 0Cu | 15 | 1411 | ± | 25 | 1419 | ± | 22 | 0.3 | ± | 0.1 | 4.5 | ± | 0.4 | 18.9 | ± | 8.7 |

| QRT | 0Cu | 30 | 1393 | ± | 12 | 1402 | ± | 11 | 0.3 | ± | 0.1 | 4.8 | ± | 1.2 | 16.9 | ± | 8.1 |

| QRT | 0Cu | 60 | 1388 | ± | 23 | 1396 | ± | 26 | 0.3 | ± | 0.1 | 3.8 | ± | 0.5 | 9.0 | ± | 0.8 |

| QRT | 0Cu | 120 | 1328 | ± | 12 | 1334 | ± | 12 | 0.4 | ± | 0.1 | 6.4 | ± | 0.5 | 16.0 | ± | 9.5 |

| QRT | 1Cu | 0 | 1943 | ± | 27 | 1976 | ± | 22 | 0.4 | ± | 0.1 | 4.4 | ± | 0.7 | 30.1 | ± | 4.0 |

| QRT | 1Cu | 15 | 1451 | ± | 39 | 1456 | ± | 36 | 0.4 | ± | 0.1 | 6.4 | ± | 1.0 | 12.2 | ± | 9.0 |

| QRT | 1Cu | 30 | 1456 | ± | 29 | 1458 | ± | 25 | 0.3 | ± | 0.1 | 6.1 | ± | 0.7 | 24.1 | ± | 4.2 |

| QRT | 1Cu | 60 | 1410 | ± | 7 | 1412 | ± | 11 | 0.3 | ± | 0.1 | 5.1 | ± | 0.4 | 17.3 | ± | 3.8 |

| QRT | 1Cu | 120 | 1376 | ± | 23 | 1380 | ± | 22 | 0.3 | ± | 0.1 | 6.6 | ± | 0.5 | 13.2 | ± | 1.7 |

| QRT | 1.5Cu | 0 | 1983 | ± | 7 | 2006 | ± | 10 | 0.4 | ± | 0.1 | 4.3 | ± | 0.4 | 22.8 | ± | 3.7 |

| QRT | 1.5Cu | 15 | 1496 | ± | 19 | 1500 | ± | 18 | 0.3 | ± | 0.1 | 5.6 | ± | 0.2 | 15.4 | ± | 0.7 |

| QRT | 1.5Cu | 30 | 1505 | ± | 5 | 1506 | ± | 5 | 0.3 | ± | 0.1 | 4.8 | ± | 0.1 | 12.0 | ± | 0.9 |

| QRT | 1.5Cu | 60 | 1459 | ± | 14 | 1462 | ± | 14 | 0.3 | ± | 0.1 | 4.7 | ± | 0.9 | 16.3 | ± | 2.9 |

| QRT | 1.5Cu | 120 | 1413 | ± | 7 | 1415 | ± | 7 | 0.2 | ± | 0.1 | 6.0 | ± | 0.4 | 8.8 | ± | 4.2 |

| Regime | Material | Tempering Temperature [°C] | YS [MPa] | UTS [MPa] | Ag [%] | A5 [%] | Z [%] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| QT | 0Cu | - | 1057 | ± | 11 | 1447 | ± | 11 | 3.6 | ± | 0.1 | 13.9 | ± | 0.2 | 43.7 | ± | 0.1 |

| QT | 0Cu | 300 | 1151 | ± | 4 | 1252 | ± | 3 | 2.5 | ± | 0.1 | 12.6 | ± | 0.2 | 54.7 | ± | 1.8 |

| QT | 0Cu | 400 | 1030 | ± | 2 | 1051 | ± | 6 | 1.6 | ± | 0.7 | 11.9 | ± | 1.0 | 56.3 | ± | 1.2 |

| QT | 0Cu | 500 | 802 | ± | 7 | 832 | ± | 3 | 4.1 | ± | 0.2 | 16.7 | ± | 0.2 | 61.1 | ± | 0.8 |

| QT | 1Cu | - | 1110 | ± | 9 | 1495 | ± | 11 | 3.1 | ± | 0.4 | 11.2 | ± | 0.9 | 46.8 | ± | 2.3 |

| QT | 1Cu | 300 | 1170 | ± | 9 | 1284 | ± | 11 | 2.7 | ± | 0.2 | 10.5 | ± | 1.0 | 51.2 | ± | 1.2 |

| QT | 1Cu | 400 | 1049 | ± | 8 | 1059 | ± | 11 | 2.2 | ± | 0.6 | 11.4 | ± | 0.8 | 51.5 | ± | 1.8 |

| QT | 1Cu | 500 | 901 | ± | 4 | 937 | ± | 3 | 7.1 | ± | 0.9 | 16.8 | ± | 0.7 | 56.4 | ± | 1.5 |

| QT | 1.5Cu | - | 1166 | ± | 12 | 1520 | ± | 14 | 1.9 | ± | 0.1 | 12.9 | ± | 0.6 | 48.6 | ± | 1.5 |

| QT | 1.5Cu | 300 | 1196 | ± | 9 | 1292 | ± | 7 | 1.5 | ± | 0.1 | 12.0 | ± | 0.6 | 52.4 | ± | 3.2 |

| QT | 1.5Cu | 400 | 1147 | ± | 3 | 1157 | ± | 2 | 1.7 | ± | 0.1 | 11.7 | ± | 0.6 | 54.2 | ± | 0.4 |

| QT | 1.5Cu | 500 | 1003 | ± | 4 | 1024 | ± | 2 | 5.7 | ± | 0.1 | 16.7 | ± | 0.4 | 54.1 | ± | 0.5 |

| QRT | 0Cu | - | 1884 | ± | 25 | 1911 | ± | 24 | 0.4 | ± | 0.1 | 4.5 | ± | 1.0 | 29.8 | ± | 14.9 |

| QRT | 0Cu | 300 | 1670 | ± | 9 | 1671 | ± | 8 | 0.2 | ± | 0.1 | 6.0 | ± | 0.8 | 12.6 | ± | 7.0 |

| QRT | 0Cu | 400 | 1388 | ± | 23 | 1396 | ± | 26 | 0.3 | ± | 0.1 | 3.8 | ± | 0.5 | 9.0 | ± | 0.8 |

| QRT | 0Cu | 500 | 1095 | ± | 7 | 1101 | ± | 4 | 0.2 | ± | 0.1 | 7.8 | ± | 1.0 | 20.0 | ± | 6.1 |

| QRT | 1Cu | - | 1943 | ± | 27 | 1976 | ± | 22 | 0.4 | ± | 0.1 | 4.4 | ± | 0.7 | 30.1 | ± | 4.0 |

| QRT | 1Cu | 300 | 1757 | ± | 15 | 1761 | ± | 15 | 0.2 | ± | 0.1 | 5.0 | ± | 0.9 | 8.7 | ± | 1.4 |

| QRT | 1Cu | 400 | 1410 | ± | 7 | 1412 | ± | 11 | 0.3 | ± | 0.1 | 5.1 | ± | 0.4 | 17.3 | ± | 3.8 |

| QRT | 1Cu | 500 | 1197 | ± | 4 | 1201 | ± | 5 | 0.2 | ± | 0.1 | 8.6 | ± | 1.1 | 21.2 | ± | 2.7 |

| QRT | 1.5Cu | - | 1983 | ± | 7 | 2006 | ± | 10 | 0.4 | ± | 0.1 | 4.3 | ± | 0.4 | 22.8 | ± | 3.7 |

| QRT | 1.5Cu | 300 | 1792 | ± | 23 | 1796 | ± | 25 | 0.1 | ± | 0.1 | 4.1 | ± | 0.3 | 10.4 | ± | 3.4 |

| QRT | 1.5Cu | 400 | 1459 | ± | 14 | 1462 | ± | 14 | 0.3 | ± | 0.1 | 4.7 | ± | 0.9 | 16.3 | ± | 2.9 |

| QRT | 1.5Cu | 500 | 1216 | ± | 1 | 1221 | ± | 3 | 0.1 | ± | 0.1 | 8.8 | ± | 1.0 | 24.0 | ± | 6.2 |

References

- Isheim, D.; Kolli, R.P.; Morris, E.F.; Seidman, D.N. An atom-probe tomographic study of the temporal evolution of the nanostructure of Fe–Cu based high-strength low-carbon steels. Scr. Mater. 2006, 55, 35–40. [Google Scholar] [CrossRef]

- Takaki, S.; Fujioka, M.; Aihara, S.; Nagataki, Y.; Yamashita, T.; Sano, N.; Adachi, Y.; Nomura, M.; Yaguchi, H. Effect of Copper on Tensile Properties and Grain-Refinement of Steel and its Relation to Precipitation Behavior. Mater. Trans. 2004, 45, 2239–2294. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Haldar, A.; Chattopadhyay, P.P. Effect of ageing on the mechanical properties of directly quenched copper bearing microalloyed steels. Mater. Chem. Phys. 2010, 119, 436–441. [Google Scholar] [CrossRef]

- Rana, R.; Bleck, W.; Singh, S.B.; Mohanty, O.N. Development of high strength interstitial free steel by copper precipitation hardening. Mater. Lett. 2007, 61, 2919–2922. [Google Scholar] [CrossRef]

- Von Goldbeck, O.K. Iron—Copper Fe—Cu. In IRON—Binary Phase Diagrams; Springer: Berlin, Germany, 1982. [Google Scholar] [CrossRef]

- Sun, M.; Zhang, W.; Liu, Z.; Wang, G. Direct observations on the crystal structure evolution of nano Cu-precipitates in an extremely low carbon steel. Mater. Lett. 2017, 187, 49–52. [Google Scholar] [CrossRef]

- Hu, L.; Zhao, S.J.; Liu, Q. The effect of size of Cu precipitation on the mechanical properties of microalloyed steel. Mater. Sci. Eng. A 2012, 556, 140–146. [Google Scholar] [CrossRef]

- Holzer, I.; Kozeschnik, E. Computer simulation of the yield strength evolution in Cu-precipitation strengthened ferritic steel. Mater. Sci. Eng. A 2010, 527, 546–3551. [Google Scholar] [CrossRef]

- Takahashi, J.; Kawakami, K.; Kobayashi, Y. Consideration of particle-strengthening mechanism of copper-precipitation-strengthened steels by atom probe tomography analysis. Mater. Sci. Eng. A 2012, 535, 144–152. [Google Scholar] [CrossRef]

- Guo, H.; Cheng, J.; Yang, S.; He, X. Influence of combined Cu and Nb addition on the quenched microstructure and precipitation during tempering in ultra-low carbon steels. J. Alloys Compd. 2013, 557, S619–S625. [Google Scholar] [CrossRef]

- Dlouhy, J.; Podany, P.; Dzugan, J. Strengthening from Cu Addition in 0.2C-(1–2)Mn Steels during Tempering. Materials 2019, 12, 247. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, S.K.; Bhowmik, N.; Haldar, A.; Chattopadhyay, P.P. Effects of Cu addition on the synergistic effects of Ti–B in thermomechanically processed low carbon steels. Mater. Sci. Eng. A 2010, 527, 1082–1088. [Google Scholar] [CrossRef]

- Kapoor, M.; Isheim, D.; Ghosh, G.; Vaynman, S.; Fine, M.E.; Chung, Y.W. Aging characteristics and mechanical properties of 1600 MPa body-centered cubic Cu and B2-NiAl precipitation-strengthened ferritic steel. Acta Mater. 2014, 73, 56–74. [Google Scholar] [CrossRef]

- Podany, P.; Martinek, P. Thermomechanical processing of micro-alloyed steel. Mater. Tehnol. 2014, 48, 855–859. [Google Scholar]

- Podany, P.; Martinek, P.; Balcar, M. Mechanical properties of steel with various microalloying addition after particular thermomechanical processing. In Proceedings of the METAL 2011—20th International Conference on Metallurgy and Materials, Brno, Czech Republic, 18–20 May 2011; pp. 646–649. [Google Scholar]

- Ghosh, S.K.; Haldar, A.; Chattopadhyay, P.P. On the Cu precipitation behavior in thermomechanically processed low carbon microalloyed steels. Mater. Sci. Eng. A 2009, 519, 88–93. [Google Scholar] [CrossRef]

- International Standard EN ISO 6892-1. Metallic Materials—Tensile Testing—Part1: Method of Test at Room Temperature; International Organization for Standardization: Geneva, Switzerland, 2016. [Google Scholar]

- Lefebvre, S.; Devincre, B.; Hoc, T. Yield stress strengthening in ultrafine-grained metals: A two-dimensional simulation of dislocation dynamics. J. Mech. Phys. Solids 2007, 55, 788–802. [Google Scholar] [CrossRef]

- Wang, Y.M.; Ma, E. Strain hardening, strain rate sensitivity, and ductility of nanostructured metals. Mater. Sci. Eng. A 2004, 375, 46–52. [Google Scholar] [CrossRef]

- Pascuet, M.I.; Monnet, G.; Bonny, G.; Martinez, E.; Lim, J.J.H.; Burke, M.G.; Malerba, L. Solute precipitation on a screw dislocation and its effects on dislocation mobility in bcc Fe. J. Nucl. Mater. 2019, 519, 265–273. [Google Scholar] [CrossRef]

- Xu, S.S.; Zhao, Y.; Tong, X.; Guo, H.; Chen, L.; Sun, L.W.; Sun, G.A. Independence of work hardening and precipitation strengthening in ananocluster strengthened steel. J. Alloys Compd. 2017, 712, 573–578. [Google Scholar] [CrossRef]

| Material | C | Cu | Mn | Si | Ti | B | N |

|---|---|---|---|---|---|---|---|

| 0Cu | 0.22 | 0.12 | 0.98 | 0.07 | 0.022 | 0.0014 | 0.0056 |

| 1Cu | 0.21 | 1.08 | 0.98 | 0.08 | 0.025 | 0.0013 | 0.0063 |

| 1.5Cu | 0.21 | 1.49 | 0.99 | 0.10 | 0.022 | 0.0013 | 0.0054 |

| Regime | 15 min | 30 min | 60 min | 120 min |

|---|---|---|---|---|

| 300 °C | X | |||

| 400 °C | X | X | X | X |

| 500 °C | X |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dlouhy, J.; Podany, P.; Džugan, J. Influence of Martensite Deformation on Cu Precipitation Strengthening. Metals 2020, 10, 282. https://doi.org/10.3390/met10020282

Dlouhy J, Podany P, Džugan J. Influence of Martensite Deformation on Cu Precipitation Strengthening. Metals. 2020; 10(2):282. https://doi.org/10.3390/met10020282

Chicago/Turabian StyleDlouhy, Jaromir, Pavel Podany, and Ján Džugan. 2020. "Influence of Martensite Deformation on Cu Precipitation Strengthening" Metals 10, no. 2: 282. https://doi.org/10.3390/met10020282

APA StyleDlouhy, J., Podany, P., & Džugan, J. (2020). Influence of Martensite Deformation on Cu Precipitation Strengthening. Metals, 10(2), 282. https://doi.org/10.3390/met10020282